Total Tank Management

World leader in tank management technology.

VALUE BY THE TANKFUL Emerson is the world leader in tank

management technology, providing Fisher

®

brand products, engineering,

installation, and service that successful tank management requires.

The Fisher Type ACE95 is a pilot-operated valve used for accurate

pressure control on low-setpoint blanketing systems.

• All Stainless Steel Construction

• In-line or Angled Body Connections

• Fully Balanced Plug

• Best in Class Accuracy

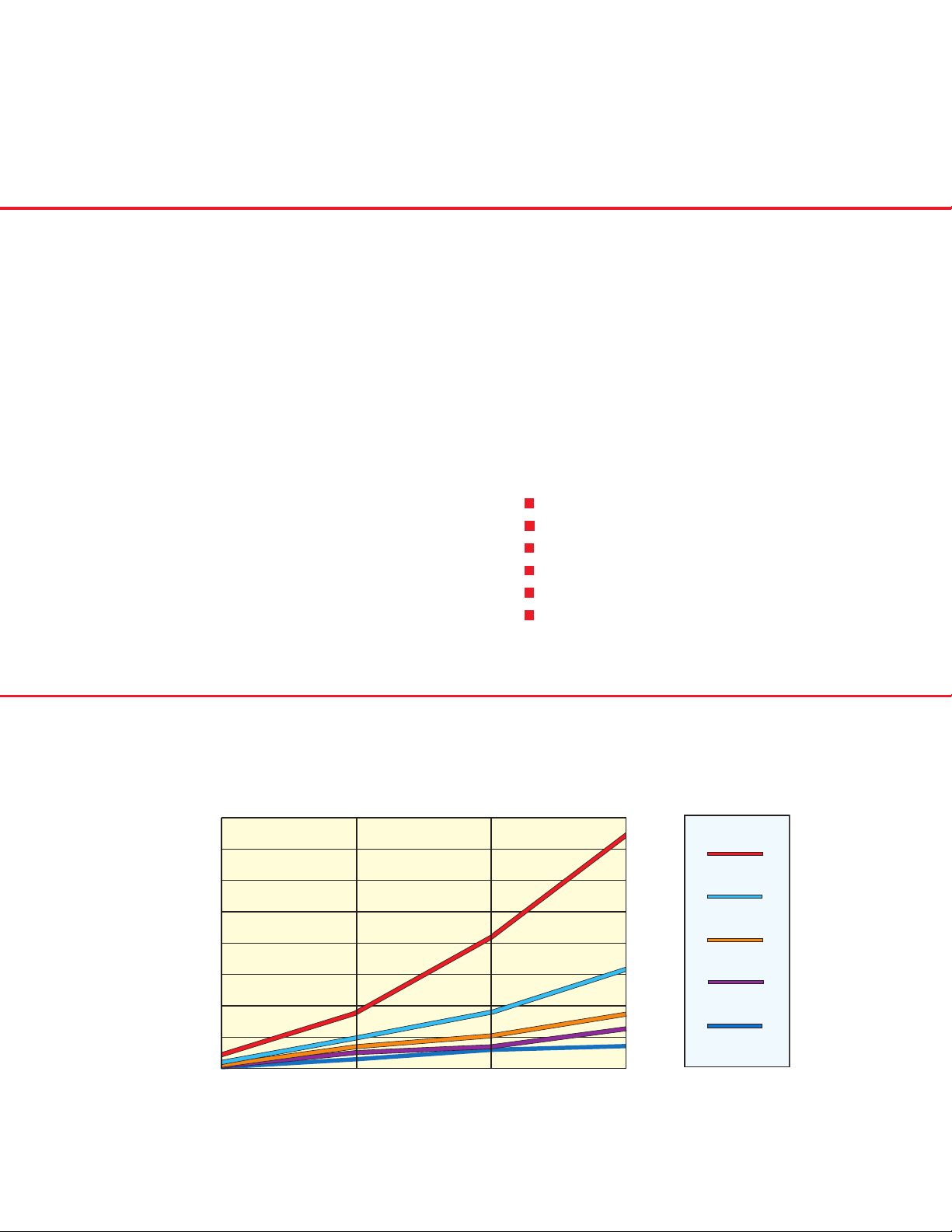

Nitrogen Cost Per Tank Per Year

Savings

Emerson’s Fisher® Brand Tank Blanketing

regulators save installation and operational costs.

Tank blanketing is needed when a stored liquid

product is ammable or deteriorates when exposed

to air or moisture. Tank management systems

provide vessel blanketing and vapor recovery

capabilities for both “pump out” and “pump in”

operations with high sensitivity to small changes

in vessel pressure. Lower internal tank blanketing

pressure is important for reduced fugitive emissions

and reduced gas costs, since less gas is lost through

the system.

Low-setpoint technology reduces gas blanketing expense.

Nitrogen Cost vs. Leak Diameter

$40,000

$35,000

$30,000

$25,000

Fisher tank management products and integrated

services help tank farm managers and single tank

operators lower gas blanketing costs by:

Providing efcient product blanketing

Preventing product contamination

Minimizing product evaporation

Reducing blanketing gas losses

Avoiding product spoilage or deterioration

Assuring compliance with clean

air regulations

Blanketing Setpoint

7-inches w.c.

17,5 mbar

2-inches w.c.

5 mbar

$20,000

$15,000

$10,000

$ 5,000

$ 0

1/4-inch

6,4 mm

1/2-inch

12,7 mm

Nitrogen Escape Path Ð Effective Leak Diameter

3/4-inch

19,1 mm

1-inch

25,4 mm

1-inch w.c.

2,5 mbar

3/4-inch

1,9 mbar

1/2-inch

1,2 mbar

1

The Fisher® Type ACE97 make-up and vent is used for very

accurate pressure control on low-pressure blanketing systems.

• All Stainless Steel Construction

• Fully Balanced Plug

• Single Tank Nozzle Connection

2

Solutions

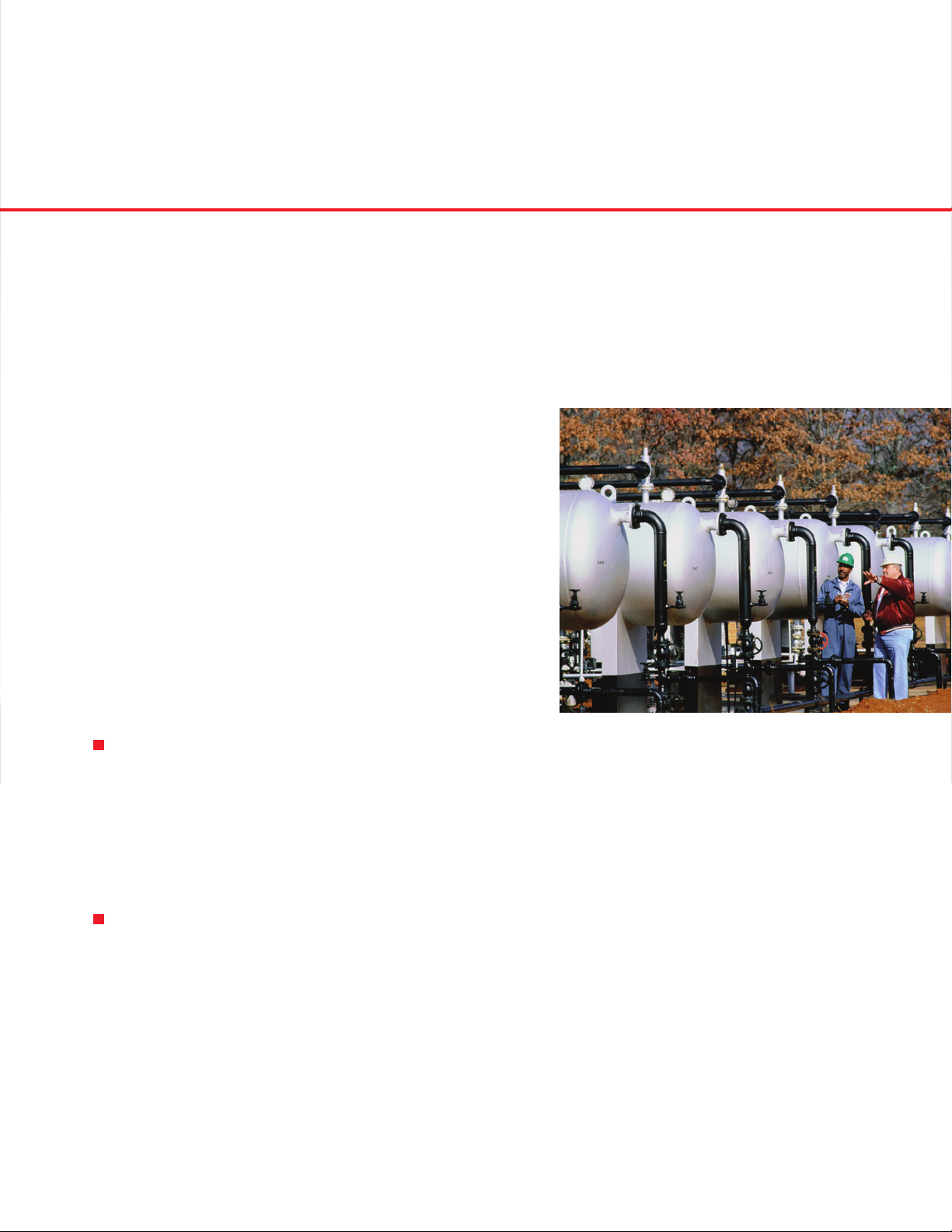

Emerson: a full-solutions provider of all tank

management needs, engineering, and installation.

Emerson is the industry,s leading manufacturer of Fisher

brand pressure regulators, consistently incorporating the

latest in engineering technology into its products, and tank

management products are no exception. Designed to satisfy

a wide variety of applications, Fisher brand tank management

products provide protection for liquids stored in small,

medium, and large vessels. As a complete solutions provider,

Emerson offers consulting, engineering and start-up services.

Emerson Performance Solutions group—with its own

application, consulting, design, and integration services—

is available for total tank management applications. Key

operational components include Industry Centers of Excellence

and Performance Services.

Industry Centers of Excellence is a network of

Emerson business segments and divisions providing

process and industrial customers broad access to

collaborative support. These areas of specialization

include oil and gas, hydrocarbon, pharmaceutical,

food and beverage, chemical, power, pulp, and

paper industries.

®

The Performance Services unit provides remedial,

periodic, preventive and predictive plant, and

facility maintenance. They also offer warranty,

parts, and repair.

3

The Fisher® Single Array Manifold (S.A.M.) provides tank

sensing connection and gas delivery/exhaust connection

through a single tank nozzle.

• All Stainless Steel Construction

• Any Nozzle Connection

4

Global

Emerson’s engineering and product

support span the world.

Equipped with the most complete line of tank management

products in the industry, Emerson’s worldwide distribution

network includes an experienced sales and support team.

More than 2,000 technical experts are available from nearly

200 offices throughout the world. Count on Emerson to help

meet even the most difficult tank management challenges.

Technical support unmatched in the industry

Knowledgeable local representatives

Same-day/next-day delivery

Products suitable for a variety of applications

Emerson’s global sales and factory support is just a phone

call or a few computer keystrokes away. Through the

website, customers and representatives alike have access to

all documentation needed for reference, maintenance,

and installation.

5

TotalTankManagement

Fisher® Tank Blanketing Regulator

Fisher Single Array Manifold (S.A.M.)

Fisher Displacement Level,

Interface or Density Measurement

Fisher Globe Style Control Valve

Micro Motion®

Coriolis Flowmeter

Rosemount® Pressure/

Level Measurement

Fisher Steam Pressure Regulator

6

Fisher® Vapor Recovery Regulator

Rosemount TankRadar®

Level Measurement

Fisher High Performance

Butterfly Valve

DeltaVTM Digital Automation System

7

Tank Management Products

1190

Fisher

ACE97

Fisher

ACE95Jr

Fisher

TANK BLANKETING VALVES

ACE95

Fisher

ACE95Jr

Fisher

ACE95Sr

Fisher

1190

Y690A

Fisher

Fisher

®

Description

High accuracy/medium

flow rate/pilot operated

blanketing valve.

High accuracy/low flow/direct

operated blanketing valve.

High accuracy/high flow rate/

pilot operated blanketing valve.

High accuracy/high flow rate/

pilot operated blanketing valve

Medium accuracy/low

flow rate/direct operated

blanketing valve.

Specifications

Maximum Inlet Pressure: 200 psig / 13,8 bar

Set Pressure Range: -5-inch w.c. to 5 psig /

-12 mbar to 0,35 bar

Temperature Capability: -20° to 212° F / -29° to 100° C

Maximum Inlet Pressure: 200 psig / 13,8 bar

Set Pressure Range: -5-inch w.c. to 1.5 psig /

-12 mbar to 0,35 bar

Temperature Capability: -20° to 212° F / -29° to 100° C

Maximum Inlet Pressure: 200 psig / 13,8 bar

Set Pressure Range: -5-inch w.c. to 1.5 psig /

-12 mbar to 0,35 bar

Temperature Capability: -20° to 212°F / -29° to 100°C

Maximum Inlet Pressure: 300 psig / 20,7 bar

Set Pressure Range: 0.25-inch w.c. to 7 psig /

0,6 mbar to 0,48 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Maximum Inlet Pressure: 150 psig / 10,3 bar

Set Pressure Range: 1-inch w.c. to 7 psig /

2,5 mbar to 0,48 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Connections

3/4, 1 NPT;

NPS 1, 1 x 2 CL150 RF, CL300 RF;

DN 25, 25 x 50 PN 16/25/40;

NPS 1 Sanitary flange

1/2, 1/2 x 1 , or 1 NPT;

NPS 1/2, 1/2 x 1, or 1 CL150 RF;

NPS 1 Sanitary flange;

DN 15, 15 x 25, or 25 PN 10/16

2 NPT;

NPS 2 CL150 RF nipple and flange,

or CL300 RF nipple and flange

1, 2 NPT; NPS 1, 2 SWE; NPS 1

through 6 BWE; NPS 1 through

8 x 6 CL125 FF, CL150 RF, CL250R F,

CL300 RF, CL600 RF; DN 25

through 150 PN 16/25/40

3/4, 1 NPT; NPS 3/4, 1 SWE,

CL150 RF, CL300 RF; DN 20, 25

PN 16/25/40

Special Features

Stainless steel construction.

Diagnostic port. In-line or

angled body connections.

Vacuum settings.

Balanced plug.

Stainless steel construction.

Vacuum settings.

Balanced plug.

Stainless steel construction.

Diagnostic port.

Balanced plug.

Stainless steel, cast iron,

or carbon steel construction.

Travel Indicator.

Stainless steel, ductile iron,

®

or Hastelloy

Outlet Pressure Rating

equals Inlet Pressure Rating

C construction.

Fisher

Y692

Medium accuracy/medium

flow rate/ direct operated

blanketing valve

VAPOR RECOVERY VALVES

1290

Fisher

Y696

Fisher

Y695A

Fisher

High accuracy/high flow

rate/pilot operated vapor

recovery valve.

Medium accuracy/medium

flow rate/direct operated vapor

recovery valve.

Medium accuracy/low flow

rate/direct operated vapor

recovery valve.

TANK BLANKETING/VAPOR RECOVERY

ACE97

Fisher

High accuracy blanketing

and vapor recovery valves

combined into a single unit.

Maximum Inlet Pressure: 150 psig / 10,3 bar

Set Pressure Range: 1-inch w.c. to 10 psig /

2,5 mbar to 0,69 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Maximum Inlet Pressure: 12.5 psig

Set Pressure Range: 0.5-inch w.c. to 7 psig /

1,2 mbar to 0,48 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Maximum Inlet Pressure: 15 psig / 1 bar

Set Pressure Range: 2-inch w.c. to 7 psig /

5 mbar to 0,48 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Maximum Inlet Pressure: 150 psig / 10,3 bar

Set Pressure Range: 2-inch w.c. to 7 psig /

5 mbar to 0,48 bar

Temperature Capability: -20° to 300°F / -29° to 149°C

Maximum Inlet Pressure: 200 psig

Set Pressure Range: 0.5-inch w.c. to 2.2 psig /

1,2 mbar to 0,29 bar

Temperature Capability: -20° to 212°F / -29° to 100°C

1-1/2, 2 NPT; NPS 1-1/2, 2 SWE,

CL125 FF, CL150 RF, CL300 RF;

DN 40, 50 PN 16/25/40

1, 2 NPT; NPS 1, 2 SWE; NPS 1

through 6 BWE; NPS 1 through

8 x 6 CL125 FF, CL150 RF, CL250 RF

CL300 RF, CL600 RF; DN 25

through 200 x 150 PN 16/25/40

1-1/2, 2 NPT; NPS 1-1/2, 2 SWE,

CL150 RF, CL300 RF; DN 40, 50

PN 16/25/40

3/4, 1 NPT; NPS 3/4, 1 SWE,

CL150 RF, CL300 RF; DN 20, 25

PN 16/25/40

1, 1-1/2, 2, 3, 4 NPT;

NPS 1, 1-1/2, 2, 3, 4

CL150 RF

Stainless steel, cast iron, or

Hastelloy C construction.

Stainless steel, cast iron,

or carbon steel construction.

Stainless steel, steel,

cast iron, or Hastelloy C

construction.

Stainless steel, ductile iron,

or Hastelloy C construction.

Stainless steel construction.

May be used with Single

Array Manifold

(SAM). Single tank

nozzle connection

8

SELF-POWERED STEAM VALVES

ACE SAM

Fisher

Description

Specifications

Connections

Special Features

92B

Fisher

®

SINGLE ARRAY

MANIFOLD (SAM)

Fisher

ACE SAM

CONTROL VALVES

Fisher easy-e

Emerson Process

Management

Fisher edisc

Emerson Process

Management

®

LEVEL AND FLOW MEASUREMENT

3051S

Rosemou nt

TankRadar

®

Rex

Rosemount Tank

Gauging

Fisher FIELDVUE

®

DLC3000-249

Emerson Process

Management

®

Elite

Flow Meters

Micro Motion

CONTROL SYSTEM

High accuracy/pilot operated

steam tracing pressure control.

Provides tank sensing connection

and gas delivery/exhaust

connection through a single tank

nozzle — saving installation cost.

Cage guided globe style control

valve with piston or diaphragm

actuator and FIELDVUE

®

digital

valve controller. Cavitation and

noise control trim options.

High performance butterfly

control valve with diaphragm

actuator and FIELDVUE

®

digital

valve controller.

Pressure, level, and

flow measurement.

High accuracy radar

level measurement.

Displacement level, interface or

specific gravity measurement

with FIELDVUE

®

digital

level controller.

Coriolis mass flow measurement.

Maximum Inlet Pressure: up to 300 psig / 20,7 bar

Set Pressure Range: 2 to 250 psig / 0,14 bar to 10,3bar

Temperature Capability: up to 600°F

Single flanged connection to tank.

NPT (external )connection to blanketing and

vapor recovery valve.

Max Inlet Pressure: up to 1440 psig / 99,3 bar

Temperature Capability: up to 800°F / 427°C

Input: 4- 20 mA, HART or FOUNDATION

Fieldbus Protocol

Max Inlet Pressure: up to 1440 psig / 99,3 bar

Temperature Capability: up to 450°F / 232°C

Input: 4- 20 mA, HART or FOUNDATION

Fieldbus Protocol

Liquid Level Measurement Range: 2.5 to 8320-inches w.c. /

0,62 to 2068 kPa

Total Performance: +/- 0.1% of span

Accuracy: +/- 0.025% of span

10 year stability: 0.2% of URL

Output: 4-20 mA with HART or Foundation fieldbus Protocol

Ambient Temperature Capability:

-40° to 185°F / -40° to 85°C

Liquid Level Measurement Range: 0 to 165 feet /

0 to 50 meters

Accuracy: +/- 0.02-inches / 0,5 mm

Output: 4-20 mA with HART or Modbus Protocol

Ambient Temperature Capability:

-40° to 158°F / -40° to 70°C

Liquid Level Measurement Range: 0 to 100% of displacer

length – standard 14 or 32-inches / 36 or 81 cm

Instrument Accuracy: less than 0.25% of full scale

Output: 4-20 mA with HART Protocol

Ambient Temperature Capability:

-40° to 176°F / -40° to 80°C

Flow Measurement Range: 0 to 2400 gallons /

0 to 9085 liters per minute

Accuracy: +/- 0.1% of rate

Output: 4-20 mA with HART Protocol or frequency pulse

or FOUNDATION Fieldbus Protocol

Ambient Temperature Capability:

-40° to 140°F / -40° to 60°C

1, 1-1/2, 2 NPT; NPS 1 through

4 CL125 FF, CL150 RF, CL250 RF,

CL300 RF; DN 25 through 100

PN 16/25/40

Tank Connection: 1, 1-1/2, 2,

or 4 NPT (internal); NPS 1, 1-1/2,

2, or 4 flanged

Inlet Connection: 1/2, 1,

1-1/2, 2 NPT (external)

1/2 through 24 NPT;

NPS 1/2 through 24 CL150 RF,

CL300 RF, CL600 RF; DN 15

through 600 PN 10 through 100

NPS 2 through 24 CL150 RF,

CL300 RF, CL600 RF; DN 50

through 600 PN 10 through 100

1/4 or 1/2 NPT for Coplanar/

Traditional flanges, NPS 2 or 3

ANSI level flange, NPS 2, 3, or 4

ANSI liquid level flange

Flanged connection options to fit

the application

1-1/2 or 2 NPT;

NPS 1-1/2 or 2 CL150 RF,

CL300 RF, CL600 RF.

NPS 1, 2, 3, 4, or 6 CL150 RF,

CL300 RF, CL600 RF;

DN 25, 50, 80, 100, or 150

PN 40, 100

Stainless steel, steel, or cast

iron construction. Hardened

trim for long service life.

Stainless steel construction.

Valve and instrument

diagnostics.

Valve and instrument

diagnostics.

Transmitter and advanced

diagnostics, Local LCD

display, Scalable

output variable.

Local LCD display.

Process and

instrument diagnostics.

Temperature compensation.

Simple re-ranging.

Meter and process

diagnostics. Simple

start-up.

DeltaV™

Digital Automation

System

Delivering embedded advanced

control, easy enterprise

integration and optimization, and

predictive maintenance —easy.

DeltaV hardware is built to:

Class 1, Division 2 hazardous areas

CENELEC Zone 2 hazardous areas

ISA-S71.04-1985 Airborne Contaminants Class G-3

DIN rail field junction box

High density cabinet mount.

DIN rail wall mount.

Skid mount

Ethernet-based hardware

communications and

supports major digital buses:

FOUNDATION Fieldbus, AS-I

bus, DeviceNet, Profibus DP.

9

10

Fisher® Type 1190 is a pilot-operated valve used for

very accurate pressure control on low-pressure

blanketing systems.

• Robust

• Travel Indicator

• Setpoints as low as 0.25-inches w.c. (0,6 mbar)

EveryApplication

Emerson has tank management solutions

for every tank blanketing application.

Emerson’s worldwide tank management experience enables

tank farm managers and single tank operators to choose the

right type of equipment and materials for each application.

Types of fluids that often need blanketing include:

Solvents

Water for injection

Juices

Fragrances

Sealants

Inks

Deionized water

Vegetable oils

Flavors

Adhesives

Industrial coatings

Any stored product that is flammable, oxygen-sensitive,

moisture-sensitive, environmentally hazardous,

contaminated, or degraded by atmospheric air is eligible for

blanketing. Emerson provides a broad selection of preferred

materials of construction for optimum compatibility with

the fluid blanketed.

11

WorldWebAccess

For around-the-clock access to total

tank management information:

TOTALtankmanagement.com

TOTALtankmanagement.com is a

24-hour, 7-day-a-week online source

of tank management information.

Connect with the Emerson line-up

of tank management resources

including: tank blanketing valves,

control valves, temperature

regulators, level control

instrumentation and more.

12

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Regulator Technologies, Inc.

Emerson Process Management

Regulator Technologies, Inc.

Americas

Worldwide Headquarters

310 East University Drive

McKinney, Texas 75069-1872 USA

T: +1 800 558 5853

Europe

Natural Gas : T: +39 051 4190611

Industrial: T: +39 051 4190606

LP-Gas: T: +420 2 710 35 607

TESCOM: T: +49 (0) 38823 31 0

T: +1 972 548 3574

F: +1 972 542 6433

TESCOM Corporation

12616 Industrial Boulevard

Elk River, Minnesota 55330-2445 USA

T: +1 800 447 1250

T: +1 763 241 3238

F: +1 763 241 3224

For further information visit www.emersonprocess.com/regulators

D350364X012 © 2011 Emerson Process Management Regulator Technologies, Inc. All rights reserved. Printed in the U.S.A. 10/11.

Fisher, Emerson Process Management, and the Emerson Process Management design are marks of one of the Emerson Process

Management group of companies. All other marks are the property of their respective owners.

Asia Pacific

T: +65 6770 8337

Middle East

T: +971 4811 8100

Loading...

Loading...