Page 1

AC8

SITE MONITORING AND SERVICES

USER MANUAL

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Methods of Viewing and Configuring the AC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Data Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Transformer Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Available Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.5 Outside Enclosure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Typical Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Controller Board Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.8 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.9 Typical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 INSTALLATION

2.1 Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Unpacking and Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Surface-Mounting the AC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Mounting the Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Flush-Mounting the AC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 Mounting the Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Connect Power to the AC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.1 Termination and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.2 Connecting the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4.3 Turning On the AC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.0 WIRING AND CONNECTIONS

3.1 Wiring Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Connecting Digital Inputs and Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Connecting Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 Connecting Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 Setting the Digital Output Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

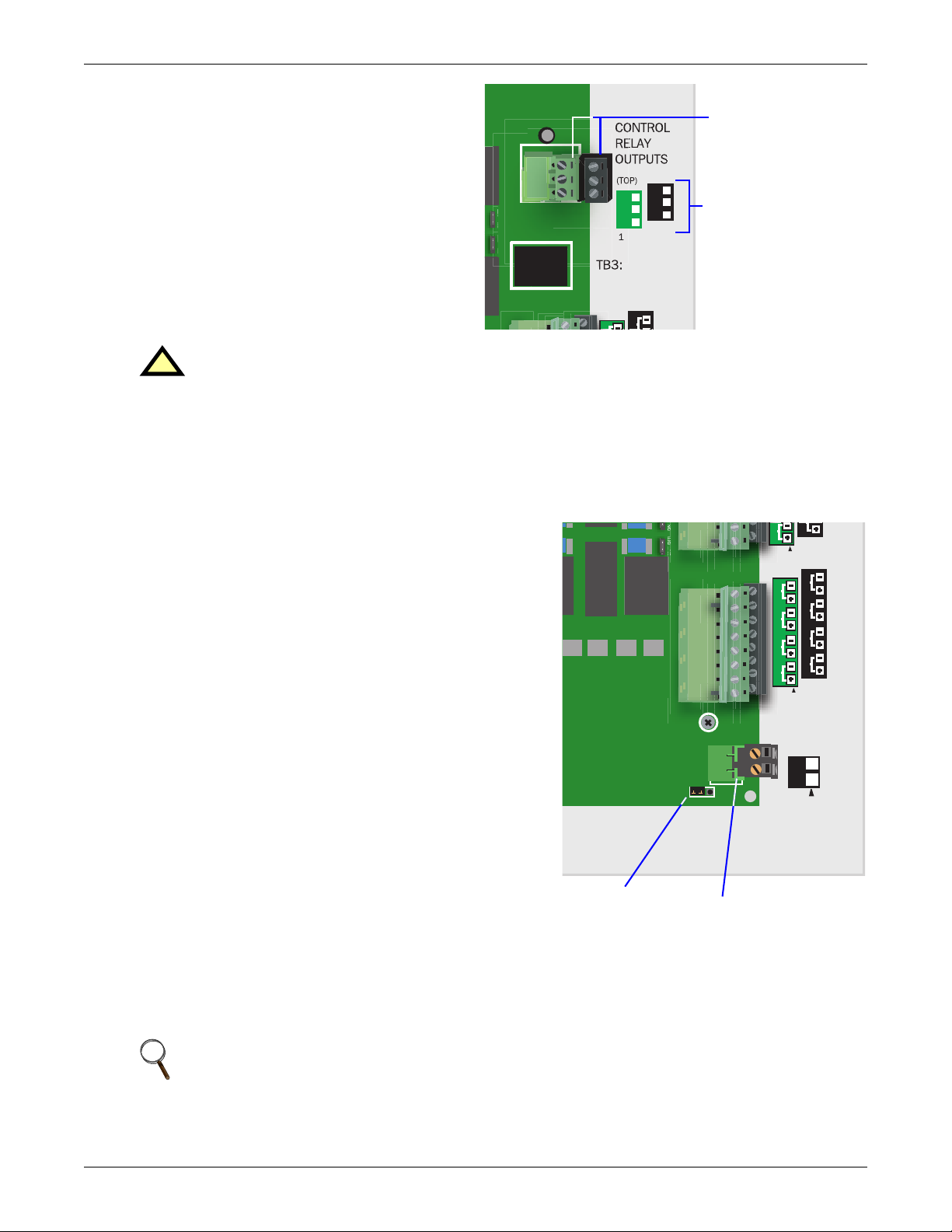

3.2.4 Connecting Control Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.5 Connecting the Emergency Power Operation (EPOP) Input . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.6 Setting the EPOP Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

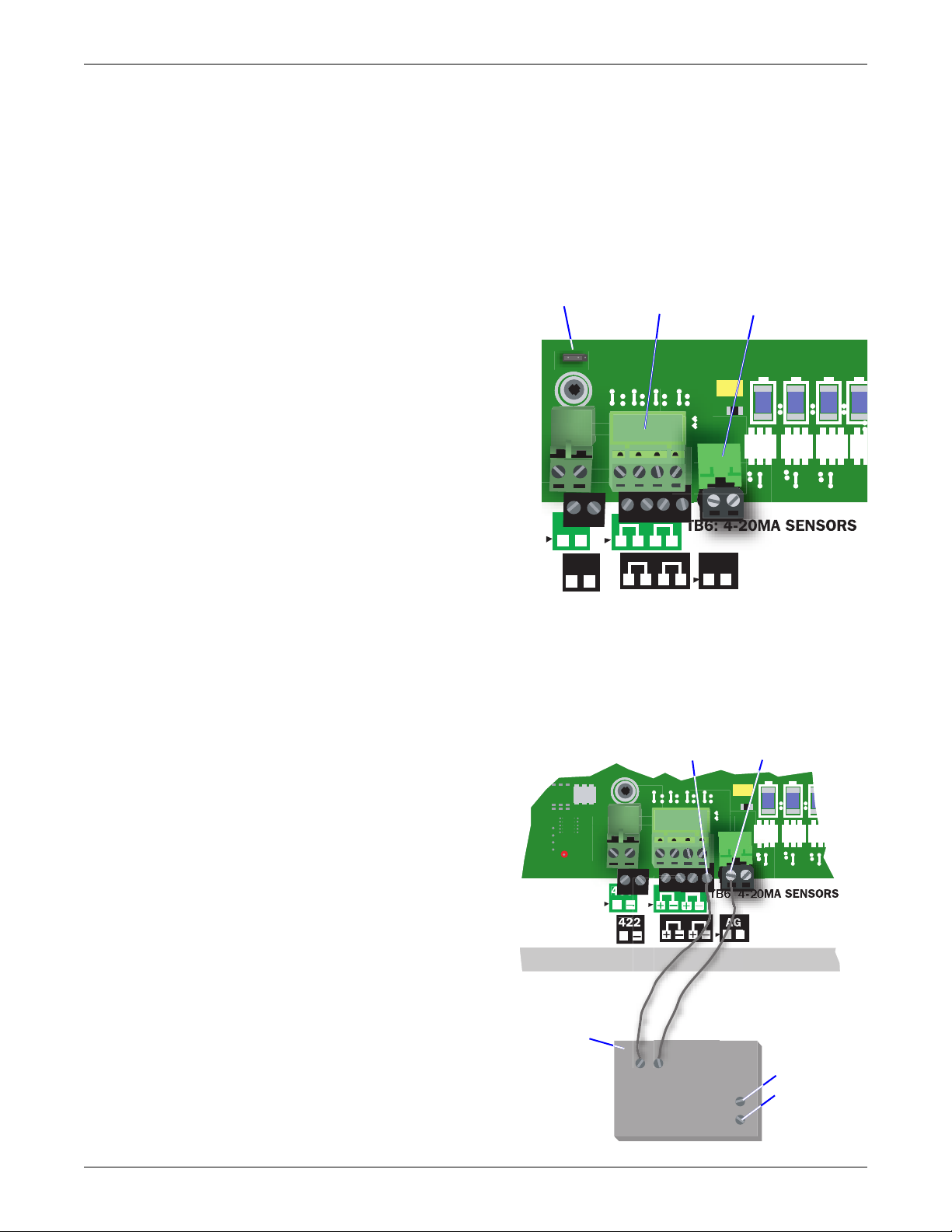

3.3 Connecting Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Setting the 12VDC/24VDC Analog Power Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Connecting the Analog Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

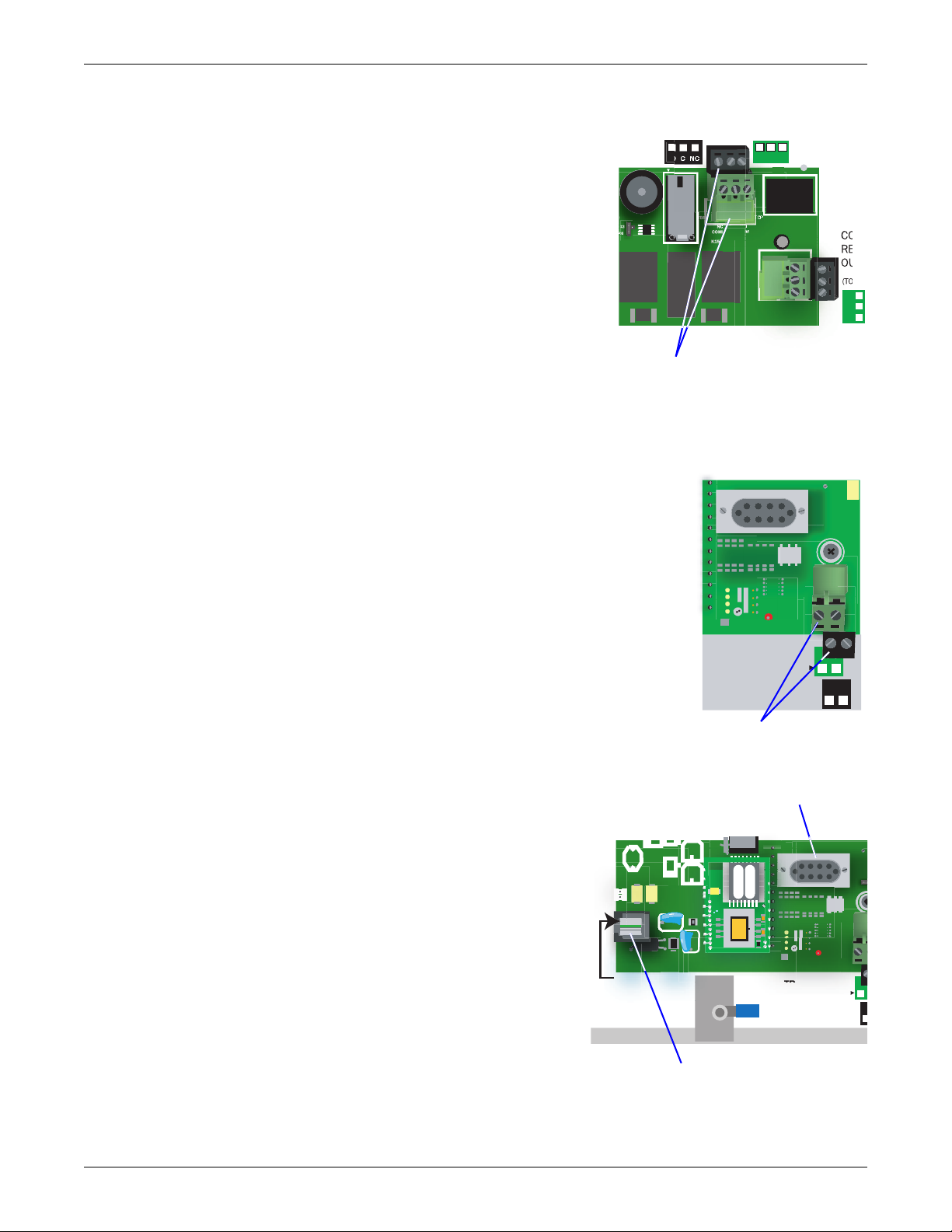

3.4 Connecting Common Alarm Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 EIA422 SiteScan Web Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Communications Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6.1 RS232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6.2 Phone Line Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.0 OVERVIEW OF MENUS

4.1 Opening Screen Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Main Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 LCD Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

i

Page 4

5.0 VIEW STATUS OPTIONS

5.1 View Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.1 Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 View Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.1 Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2.2 Backing Up the Alarm Log (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 View Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 Backing Up the Event Log (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 View Trend Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.1 Select a Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.2 View a Trend Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.3 Backing Up the Trend Log (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 View Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5.1 Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 View Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.6.1 Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.7 View Pager Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.1 Select a Pager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.2 View a Pager Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.3 View a Pager PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8 View Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.8.1 Select a Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.8.2 View Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.9 View Control Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.9.1 Control Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.0 SILENCE ALARM & BACKUP LOG FILES (SERVICE TERMINAL INTERFACE)

6.1 Silence Alarm (Service Terminal Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Back Up Log Files (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.0 SYSTEM AND CONTROL OPTIONS

7.1 Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2 Setup System - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Setup System - Setup Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3.1 Change Label (Name of Input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.2 Define Input as Normally Open or Normally Closed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.3 Define Input as Alarmable or Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.4 Set Up Alarmable Inputs in Latched or Unlatched Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3.5 Set Up Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4 Setup System - Setup Common Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5 Setup System - Setup Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5.1 Identify the Sensor as Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.5.2 Change Sensor Label (Name) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.5.3 Change Units Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.5.4 Change 4 mA Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.5.5 Change 20 mA Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.5.6 Change Offset Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.5.7 Define Sensor as Alarmable or Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.5.8 Set Up Alarmable Sensors in Latched or Unlatched Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.5.9 Change Low Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.5.10 Change High Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.5.11 Set Up Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ii

Page 5

7.6 Setup System - Setup Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.6.1 Set Up a Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.7 Setup System - Setup Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.7.1 Define Output as Normally Open or Normally Closed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.7.2 Define Operating or Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.7.3 Enable or Disable an Output Device in Alarm Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.7.4 Enable or Disable a Device during Emergency Power Operation . . . . . . . . . . . . . . . . . . . . . . 48

7.7.5 Configure Output for Loss of Power (“Fail-Safe”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.8 Setup System - Setup Modem & Pagers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.8.1 Modem Setup - Initialization String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.8.2 Modem Setup - Additional Features (Service Terminal Interface only) . . . . . . . . . . . . . . . . . 51

7.8.3 Pager Setup - Pager Number and PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.8.4 Pager Setup - Communications Check (Service Terminal Interface only). . . . . . . . . . . . . . . . 55

7.9 Setup System - Setup System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.9.1 Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.9.2 Change Date & Time/Automatic Daylight Saving Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.9.3 Setup Site ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.9.4 Connect Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.9.5 Backup and Upload Configuration File (Service Terminal Interface only) . . . . . . . . . . . . . . . 60

7.9.6 Setup Serv Ph Num - Enter Phone Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.9.7 Setup Serv Ph Num - Communications Check (Service Terminal Interface only) . . . . . . . . . 64

7.9.8 Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.9.9 Perform Firmware Update (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.9.10 Initiate Remote Alarm Test (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . 67

7.10 Setup Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.10.1 Turn Automatic Sequencing On or Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.10.2 Turn Standby Testing On or Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.10.3 Specify Failed Standby Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.10.4 Specify Hold Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.10.5 Specify Restart Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.10.6 Specify Staging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.11 Setup System - Setup I/O Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.11.1 Set Up Mapping for a Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.11.2 Set Up Mapping for an Analog Sensor Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.12 Override Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.13 Clear Alarms & Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.13.1 Clear Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.13.2 Clear the Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.13.3 Clear the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.13.4 Clear the Trend Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

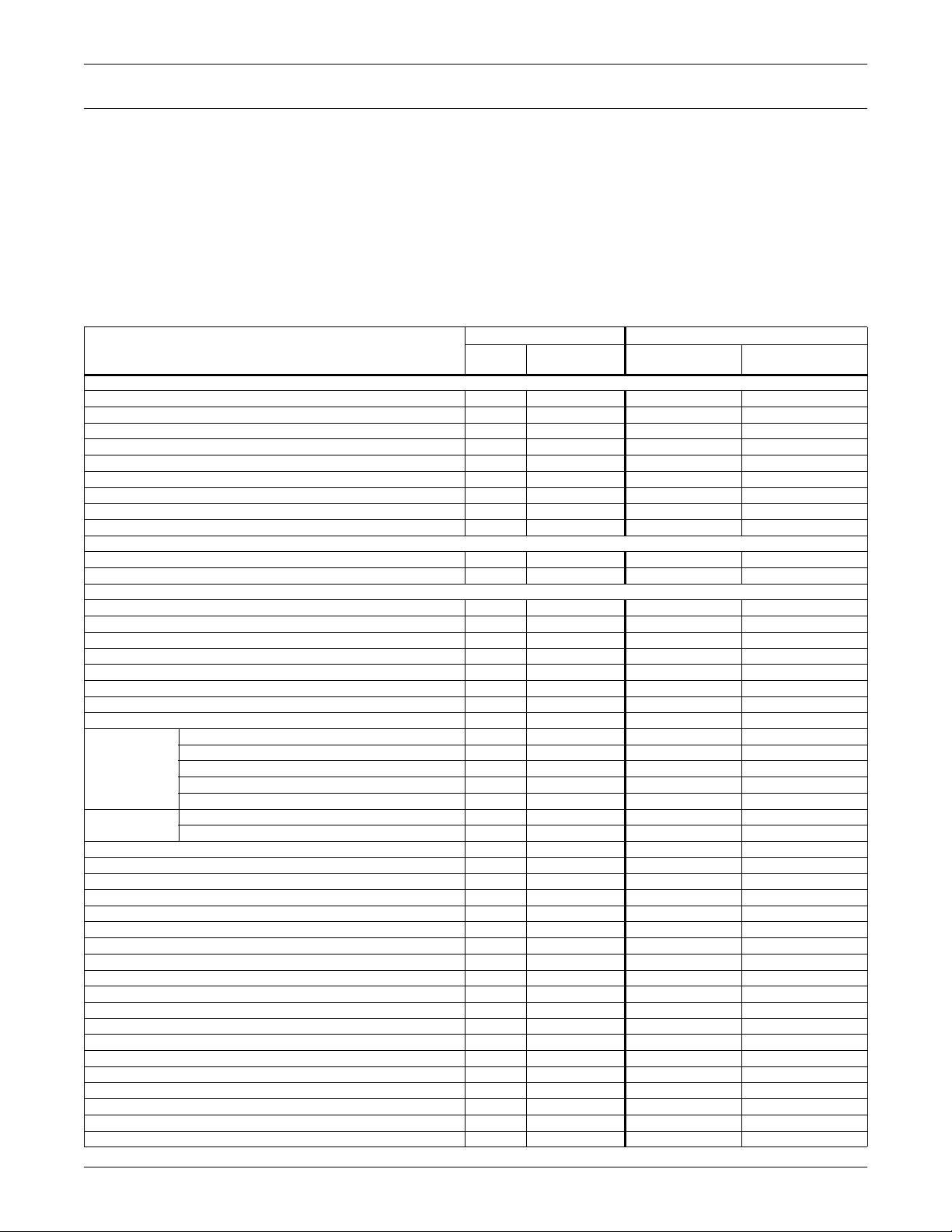

8.0 SPECIFICATIONS

8.1 AC8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

iii

Page 6

APPENDIX A-SERVICE TERMINAL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

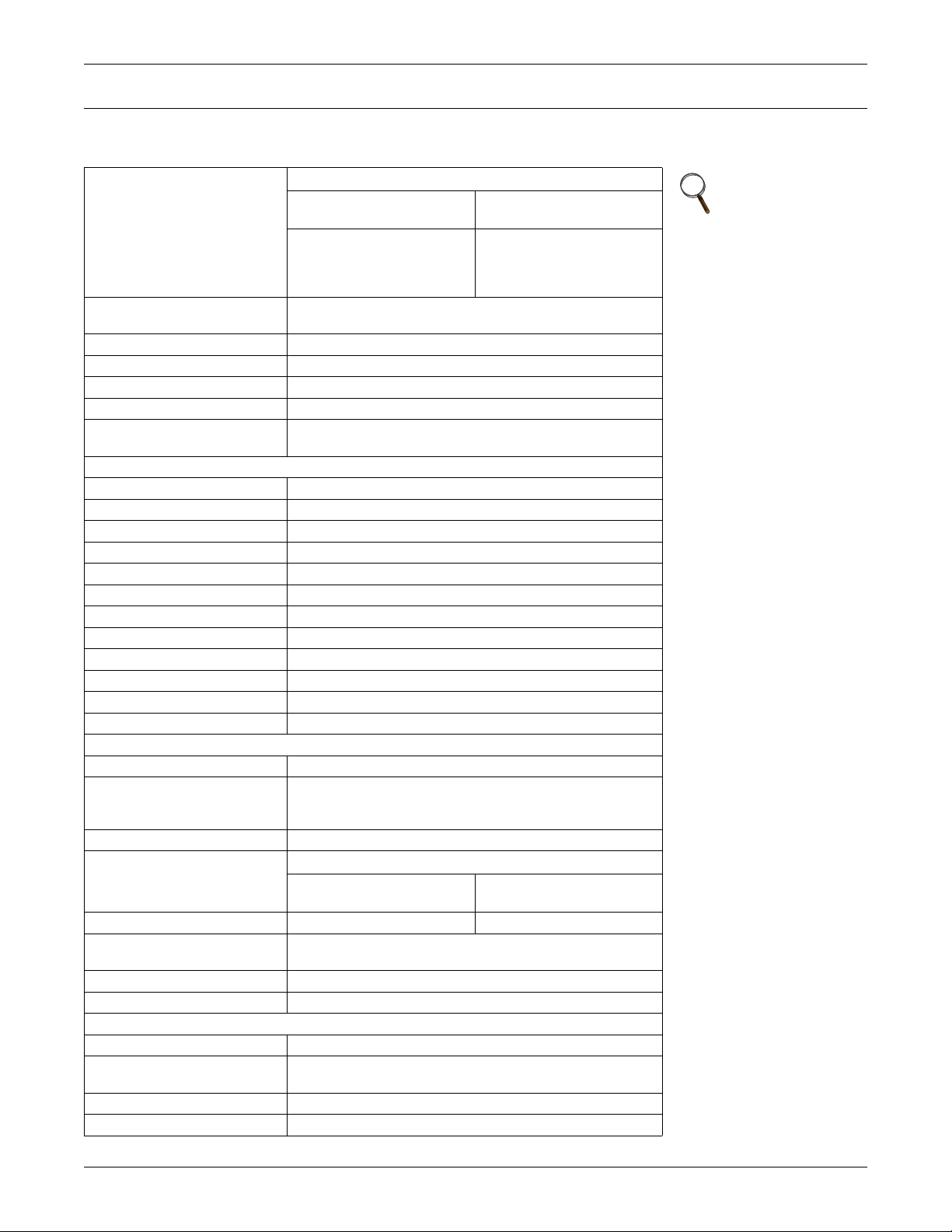

A.1 Comparison of Functions: LCD and Service Terminal Interface. . . . . . . . . . . . . . . . . . . . . . 79

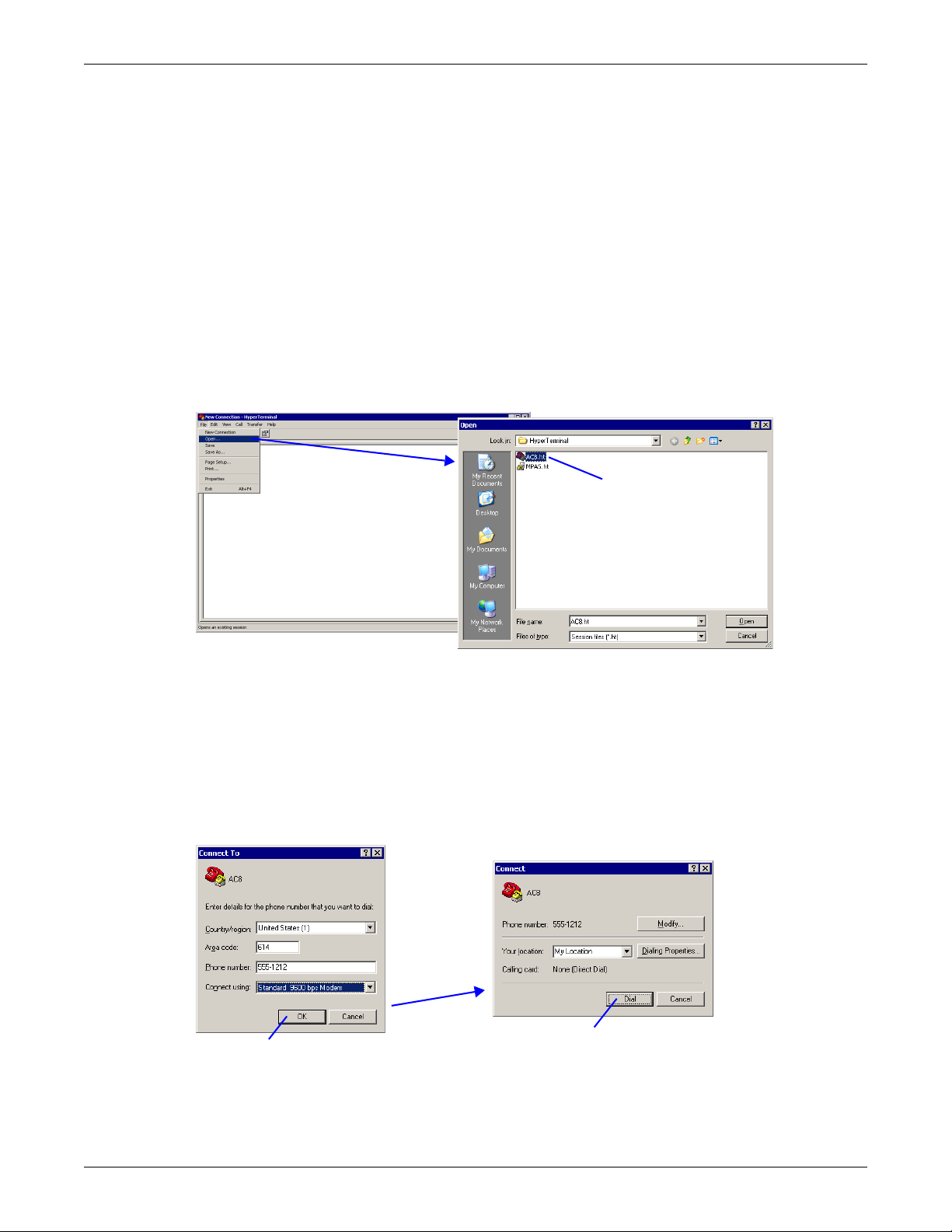

A.2 Connecting to the Service Terminal Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.2.1 Connection Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.2.2 Create a Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.2.3 Set Up the COM1 Port - Direct Connection Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.2.4 Set Up the Connection’s Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.2.5 Connect to the Service Terminal Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3 Overview of Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.1 View Status Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.2 Silence Alarm and Backup Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.3 Setup Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.4 View Status Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.1 View Active Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.2 View Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

A.4.3 View Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

A.4.4 View Trend Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

A.4.5 View Input Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

A.4.6 View Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

A.4.7 View Pager Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A.4.8 View Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A.4.9 View Control Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A.5 Silence Alarm & Back Up Log Files (Service Terminal Interface only). . . . . . . . . . . . . . . . . 92

A.5.1 Silence Alarm (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

A.5.2 Back Up Log Files (Service Terminal Interface only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A.6 Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

A.6.1 Setup Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

A.6.2 Setup Common Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

A.6.3 Setup Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A.6.4 Setup Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.6.5 Setup Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.6.6 Setup Modem & Pagers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

A.6.7 Setup System Info. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

A.6.8 Setup Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

A.6.9 Override Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A.6.10 Clear Alarms & Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A.6.11 Setup I/O Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

APPENDIX B-DEFAULT SETTINGS QUICK REFERENCE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . 117

iv

Page 7

FIGURES

Figure 1 AC8 enclosure—external features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 2 AC8 enclosure—internal features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3 Typical Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 4 Example of typical sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5 Mounting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6 Power wiring to TM115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7 Power wiring to TM230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

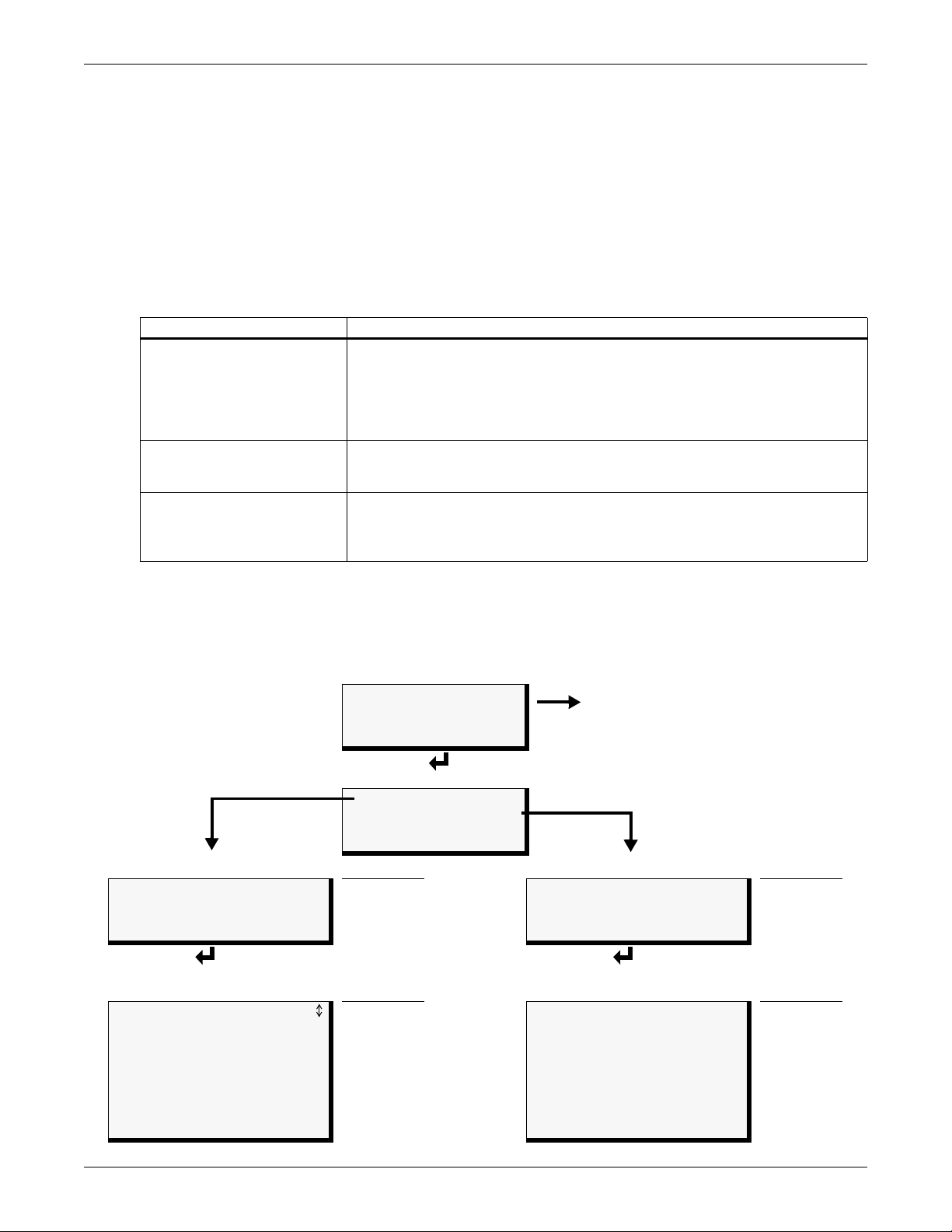

Figure 8 LCD Menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9 Menu overview - View Status menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10 Menu overview - System and Control menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

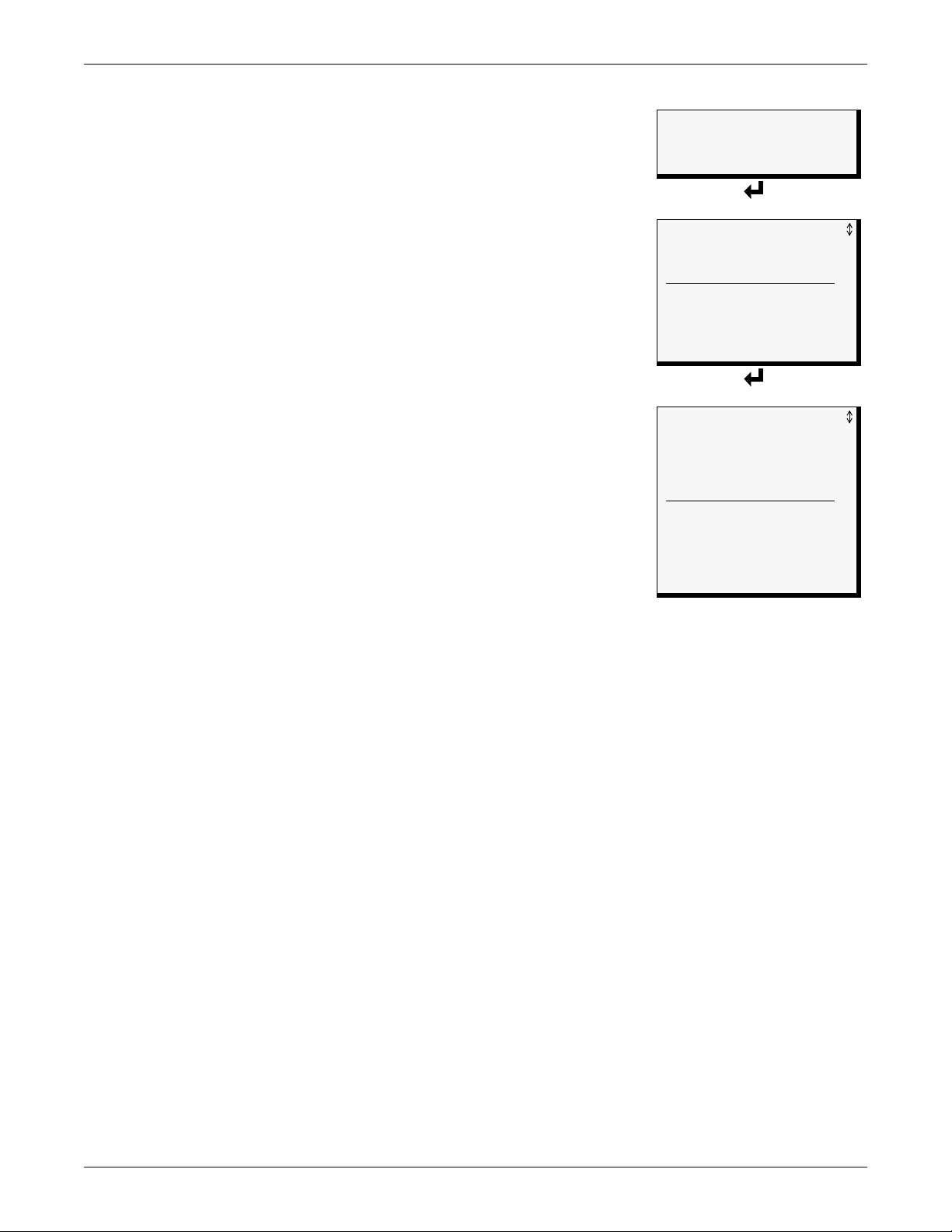

Figure 11 Menu overview - Setup System Info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 12 Menu overview - Setup Operation menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

TABLES

Table 1 Controller board components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2 LED indicators summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3 Packing manifest. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4 Wiring specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 5 Digital output jumper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 6 Guide to AC8 functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 7 Primary functions overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 8 Alarm log conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 9 Event log conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 10 Trend log conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 11 Analog input states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 12 Digital input states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 13 Digital output states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 14 Valid characters for data entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 15 Default settings - digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 16 Input and output labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 17 Default settings - analog sensor inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 18 Default zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 19 Default settings - digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

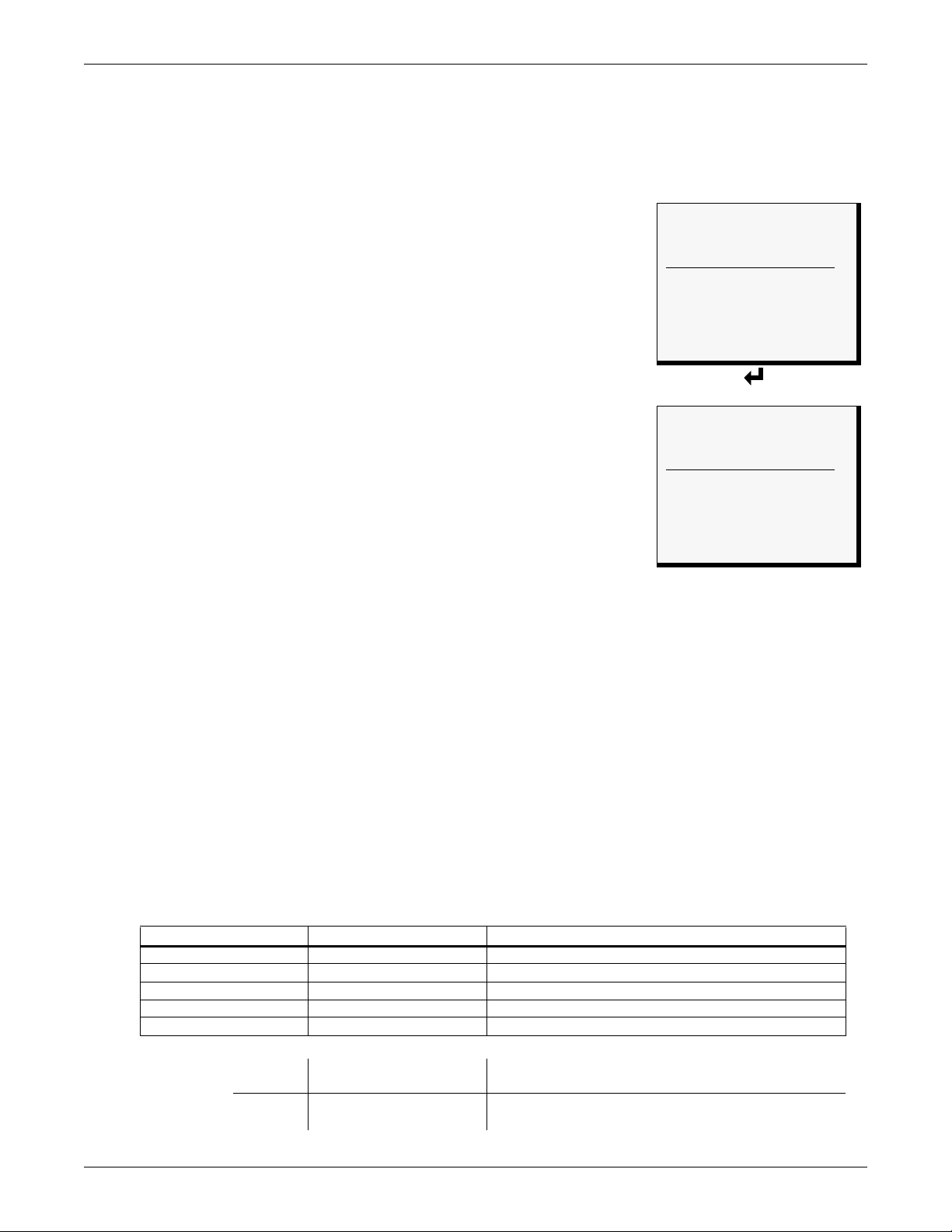

Table 20 Supported modem settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 21 Default settings - modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 22 Country codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

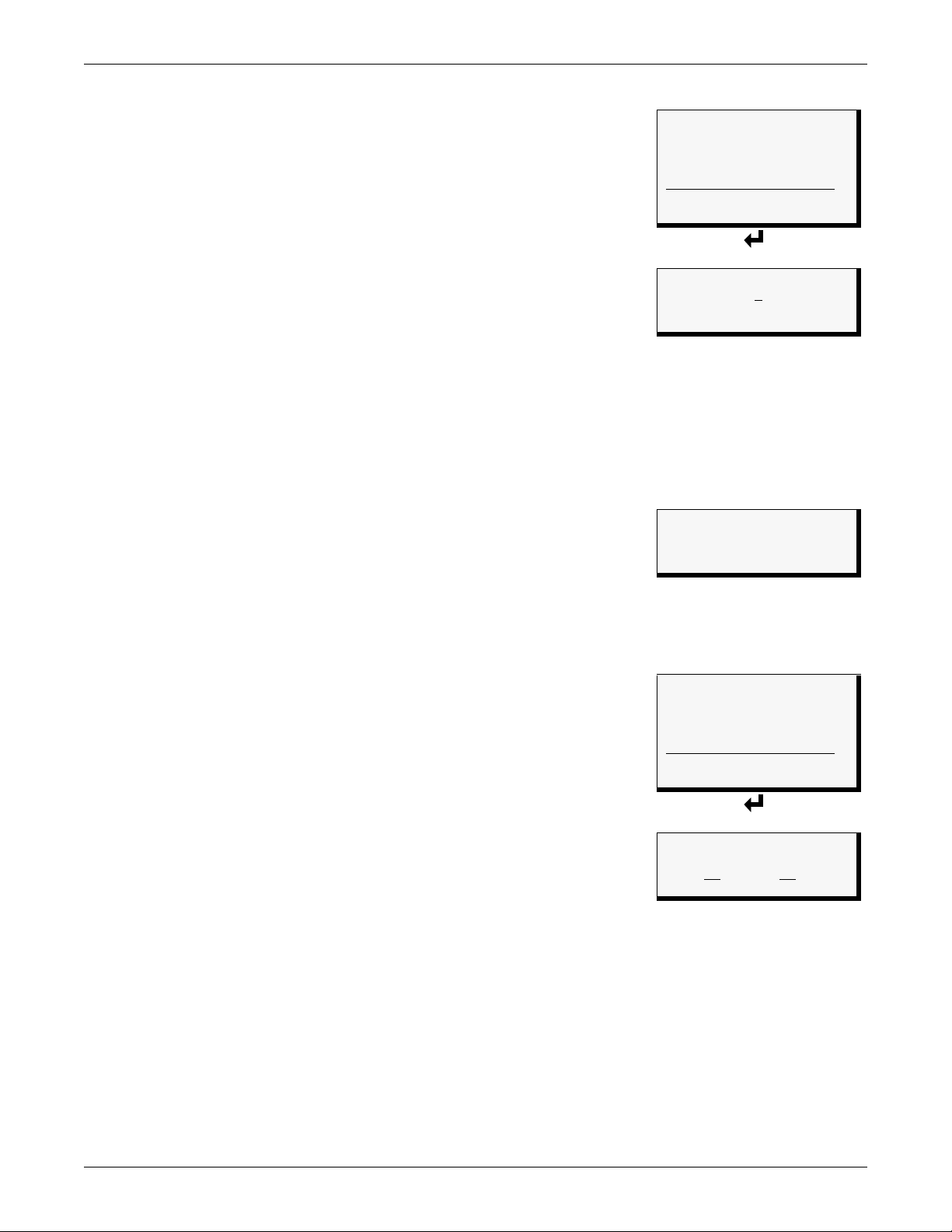

Table 23 Pager dialing results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 24 Guidelines for dialing pagers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 25 Battery alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 26 Service phone number dialing results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 27 Guidelines for dialing service phone number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 28 Default settings - operation features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 29 Failed Standby response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 30 Default mapping of digital inputs to relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 31 Default mapping of analog inputs to relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 32 Automatic / manual control - output points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 33 Guide to AC8 functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 34 Steps to set up a direct or remote connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 35 AC8 - default settings for inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 36 AC8 - other default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

v

Page 8

vi

Page 9

1.0 INTRODUCTION

The Liebert AC8 is ideal for coordinated control of systems with redundant equipment, such as

multiple environmental units or pumps. When the AC8 controller detects an alarm in an operating

device, the AC8 enables a standby device and controls the device in alarm as configured, either

leaving that device operating or disabling it.

The AC8 controller can also balance usage of devices by rotating units through Operating and

Standby modes according to a user-defined schedule. This helps keep redundant equipment operating

efficiently and only when needed. The AC8 can perform routine testing of standby devices and alert

personnel if a standby device fails an operating test and requires attention.

The staging feature permits standby devices to be turned on or off when a sensor detects specified

levels. For example, the AC8 might be configured to turn on a fan when the temperature reaches

75°F, then turn on a second fan at 80°F. When the temperature falls below 80°F, the second fan is

turned off; when it drops below 75°F, the first fan is turned off.

Another capability of the AC8 is monitoring the status of connected devices and keeping personnel

apprised through local alarming. The AC8 employs local alarming and remote paging services to keep

personnel on-site and at remote locations apprised of the status of equipment.

The AC8 controller can interface with anything that closes an electrical contact. To improve process

efficiency and troubleshooting, the controller tracks data in three types of logs: alarm, event and trend.

The AC8 has a local LCD interface and a remote dial-up interface.

When an alarm condition arises, the AC8 displays alarm information, sounds an audible alarm,

changes the state of the common alarm relay and turns connected devices on or off according to user

configuration. If configured, the controller also sends pager notifications. See 1.6 - Typical Configu-

ration for a more detailed example.

Introduction

1.1 Methods of Viewing and Configuring the AC8

The AC8 features access through two interfaces that allow users to configure the unit, silence alarms,

back up logs, and perform many other functions to keep a large or small operation running smoothly

and safely.

• LCD—liquid crystal display on the front of the panel

• Service Terminal Interface—accessible via computer connected directly through an RS232

port or remotely through the AC8’s onboard modem

These interfaces permit easy access and configuration of the AC8, allowing users to view data, silence

alarms and have full access to information stored in the controller, including logs of alarms and events.

One more interface—Liebert’s SiteScan Web enterprise monitoring system—is primarily for monitoring, though SiteScan also provides some configuration functions.

1.2 Data Logs

The three types of data logs—alarm history, event history and trend data of analog sensor readings—

can be viewed on the LCD on the front of the AC8 and downloaded through onboard communications

ports.

1.3 Transformer Module

A Transformer Module converts 115VAC or 230VAC to 24VAC.

1.4 Available Alarms

The alarms available with the AC8 are:

• Discrete input alarm

(for each digital input)

•High setpoint

• Low setpoint

• Loss of power

• Low battery

• Check battery

• Battery unplugged

• Internal modem fault

• No standby available

• Standby device

failed

1

• No restart available

• Emergency power

alarm

Page 10

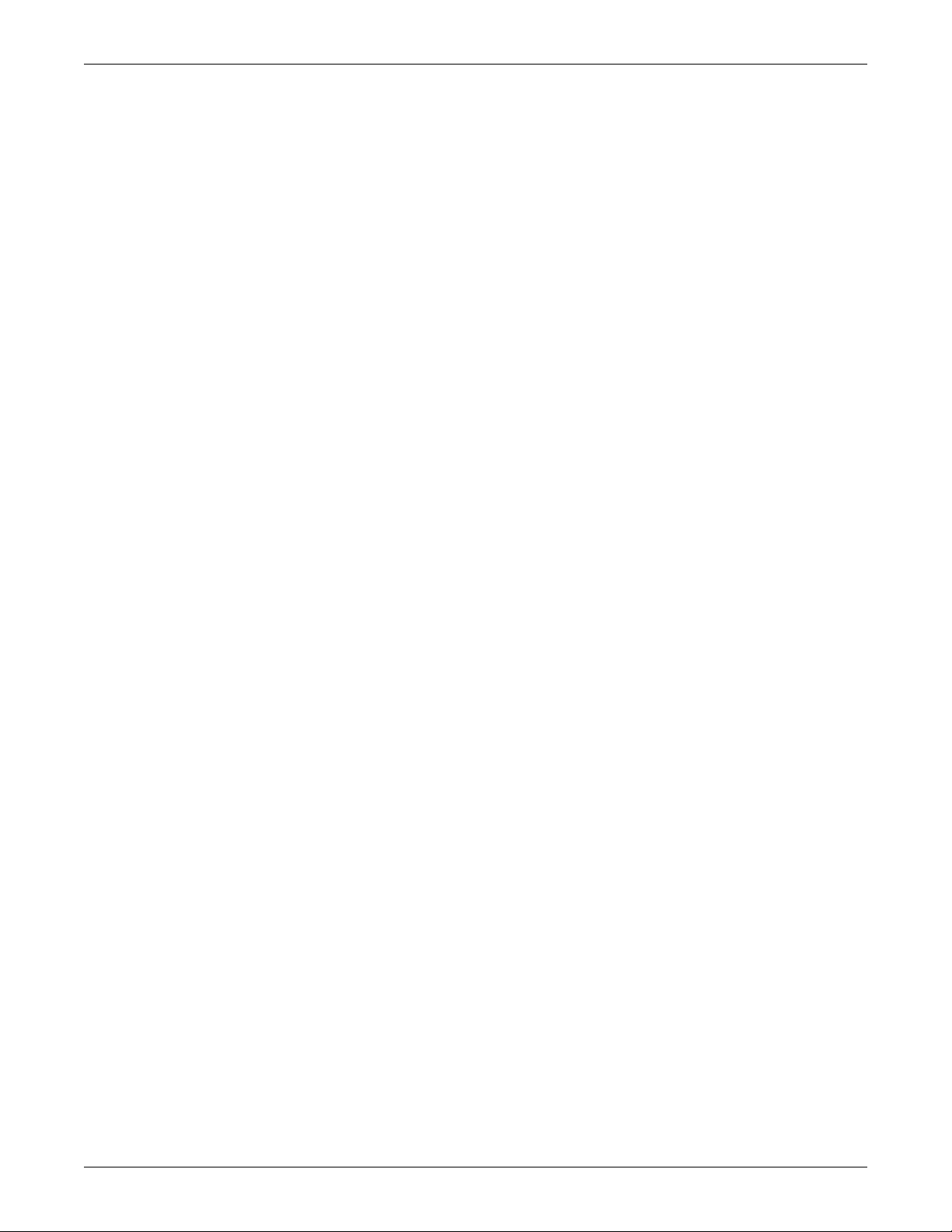

1.5 Outside Enclosure Overview

BAR CODE

NO

SENS

The AC8’s controller board comes in an enclosure that is 2-3/4" deep and has a built-in liquid crystal

display (LCD) and a key lock, as shown in Figure 1. The enclosure is made of metal to accommodate

secure conduit fittings and protect components against environmental debris.

Figure 1 AC8 enclosure—external features

The enclosure

has knockouts

and access slots

on top and

bottom for

cables and wires.

Introduction

LCD for configuration

and operation

Key lock

The enclosure houses the controller board and Transformer Module, as shown in Figure 2.

The enclosure must be secured to a wall, either flush-mounted or recessed in the wall, as described in

2.0 - Installation. Knockouts and access slots on the top and bottom allow easy connection of wires

and cables (see 3.0 - Wiring and Connections) with either mounting type.

Figure 2 AC8 enclosure—internal features

Transformer Module

Back of LCD

On/Off switch

for Transformer

Module

Ground wire

for LCD

Power receptacle

(115VAC model only)

TB5: COMMON ALARM

(TERMINAL BLOCKS ROTATED IN VIEW)

NO C NC NO C NC

(BOTTOM)

(TOP)

LS1

TB7:

START

BAR CODE

LIEBERT

MODEM

J11: PHONE

PIN 3-TIP

ON

PIN 4-RI"N"G

+

ENABLE

P11

AUDIBLE

R402

ALARM

R26

Q11

TOP

TB3:

RELAY

OUTPUTS

(BOTTOM)

(BOTTOM)

(TOP)

8

4

7

3

6

2

5

1

(BOTTOM)

(BOTTOM)

(TOP)

8

4

7

3

6

2

5

1

TB2:

CONTACT

ASS REV

TB9: ANALOG

GROUND

ALL CIRCUITS;

CLASS 2

INPUTS

1-2 TOP

3-4 BOTTOM

(TOP)

—

——

+

+ +

485

—

+—+

(BOTTOM)

—

+

Controller Board

Knockouts and

access slots

(top and bottom)

2

Page 11

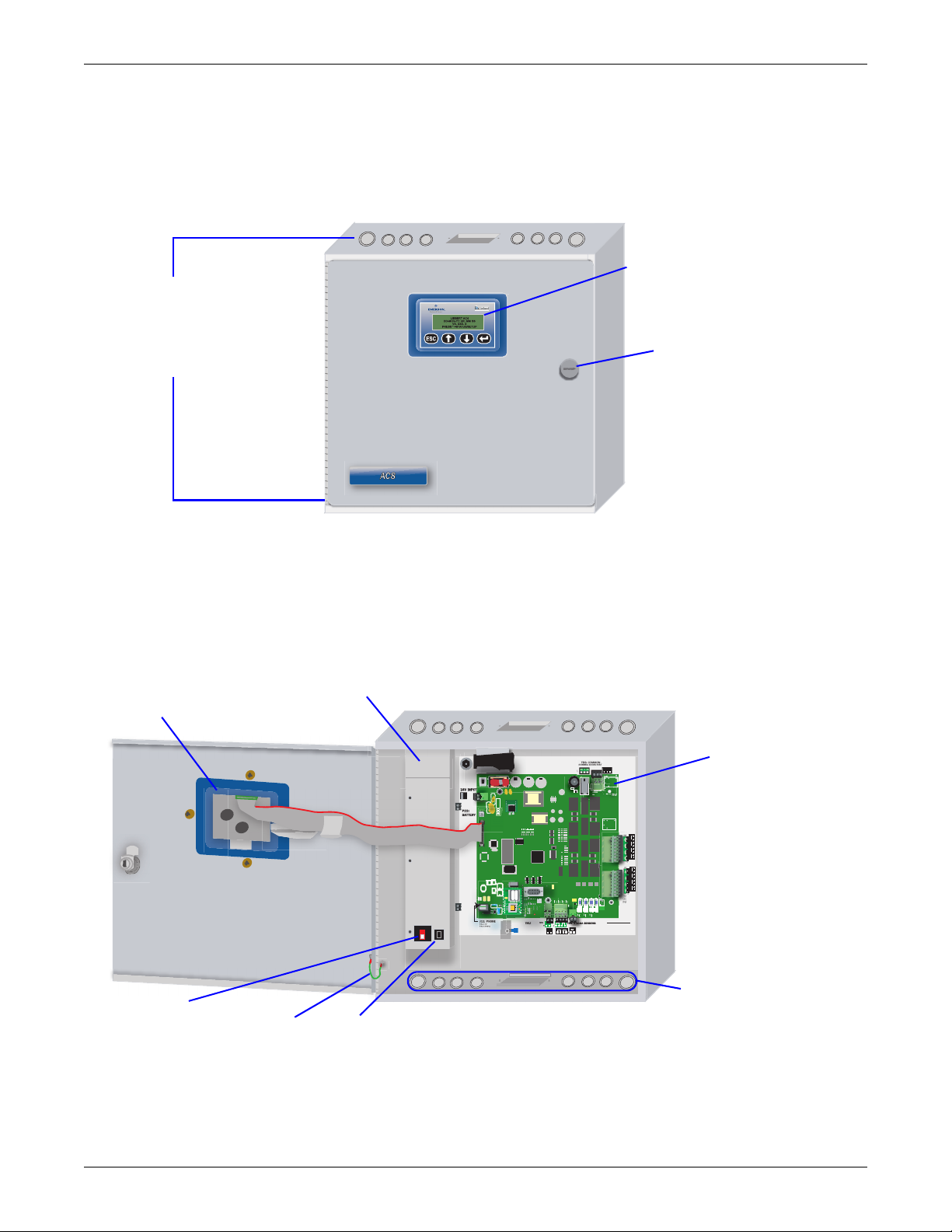

1.6 Typical Configuration

BAR CODE

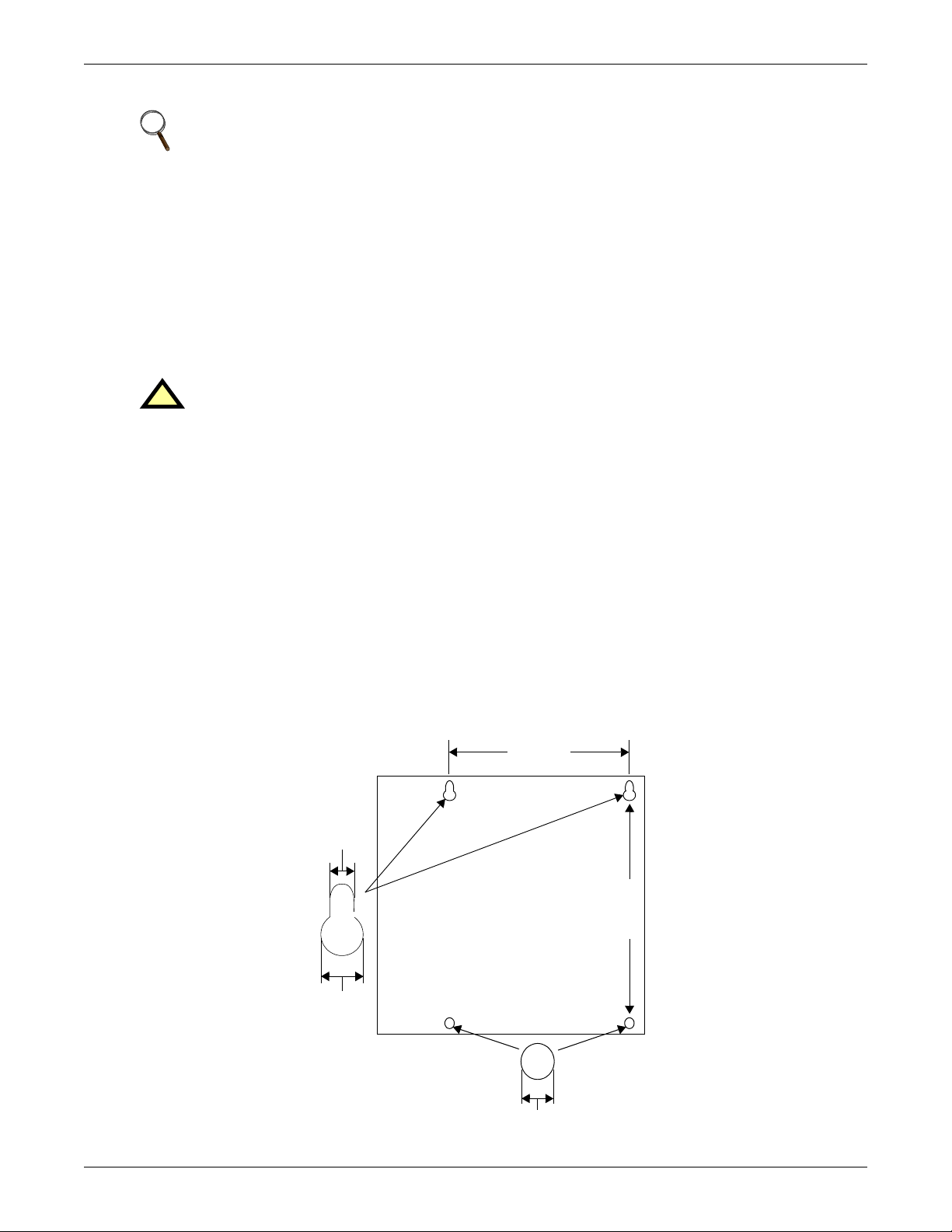

Figure 3 shows an example of external devices connected to the AC8’s controller board. Up to eight

devices may be connected to the eight digital inputs and eight digital outputs. There may be up to four

analog sensors connected to the analog inputs, and up to two devices connected to the control relay

outputs. The EPOP connection allows for one device, possibly a UPS or generator input actuated

during a power failure.

Remote access is available via SiteScan Web and through the modem, which enables pager notifications and use of the Service Terminal Interface. A computer may be connected to the RS232 port, providing access to the features of the Service Terminal Interface.

Figure 3 Typical Configuration

TB7:

START

24V INPUT

BATTERY

RS232

ON

Phone

line

P23:

BATTERY

VBATT

J11: PHONE

PIN 3-TIP

PIN 4-RING

LCD

CONTRAST

BAR CODE

LIEBERT

Introduction

Contact relay

TB5: COMMON ALARM

RELAY OUTPUTS

NO C NC

LS1

+

ENABLE

P11

AUDIBLE

Q11

TP1

GND

ON

ON

DIP

S2

1

2345678

OFF

MODEM

MODEM

OUTPUT1

DS56

OUTPUT2

DS54

OUTPUT3

DS63

OUTPUT4

DS61

OUTPUT5

DS60

OUTPUT6

DS62

OUTPUT7

DS55

OUTPUT8

DS57

CTRLLOCK

DS59

DS83

SENLOCK

DS58

CAN TX

CMN ALR

DS84

DS53

CAN RX

MOP

F PROG

574 TX

574 RX

485 RX

485 TX

INPUT1

INPUT2

INPUT3

INPUT4

DS70

INPUT5

DS67

INPUT6

DS66

INPUT7

DS65

INPUT8

DS64

R334

C71

1-2 TOP

3-4 BOTTOM

485

(TOP)

—

——

+

+ +

AG

422

TB9: ANALOG

—

+—+

(BOTTOM)

GROUND

—

+

(TOP)

NO C NC

BOTTOM

TOP

PFM5 PFM2

TB1

EPOP INPUT

EPOP

P19

EPOP

DIS EN

TB1, TB2 INPUTS:

DRY CONTACTS ONLY.

TB3, TB4, TB5

OUTPUT RELAY

RATINGS: 24V, 3A

CLASS 2 ONLY.

RELAY

OUTPUTS

(TOP)

4

3

2

1

(TOP)

REV

4

3

2

1

TB2:

CONTACT

ASS

INPUTS

TB1: EPOP

CONTACT

INPUT

TB4:

(BOTTOM)

NC

NC

C

C

NO

NO

2

(BOTTOM)

8

7

6

5

(BOTTOM)

8

7

6

5

Input 1 &Output 1

output

Humidity

lockout

DEVICES CONNECTED TO

DIGITAL INPUTS & OUTPUTS

ZONE 1 DEVICES

Device 1

connected to

Device 2

connected to

Input 2 & Output 2

SiteScan Web

Analog inputs

EPOP contact

input

Generator

3

Liebert

Challenger

3000

ZONE 2 DEVICES

Device 3

connected to

Input 3 &Output 3

Liebert

Himod

Liebert

Challenger

3000

Device 4

connected to

Input 4 & Output 4

Liebert

Himod

Page 12

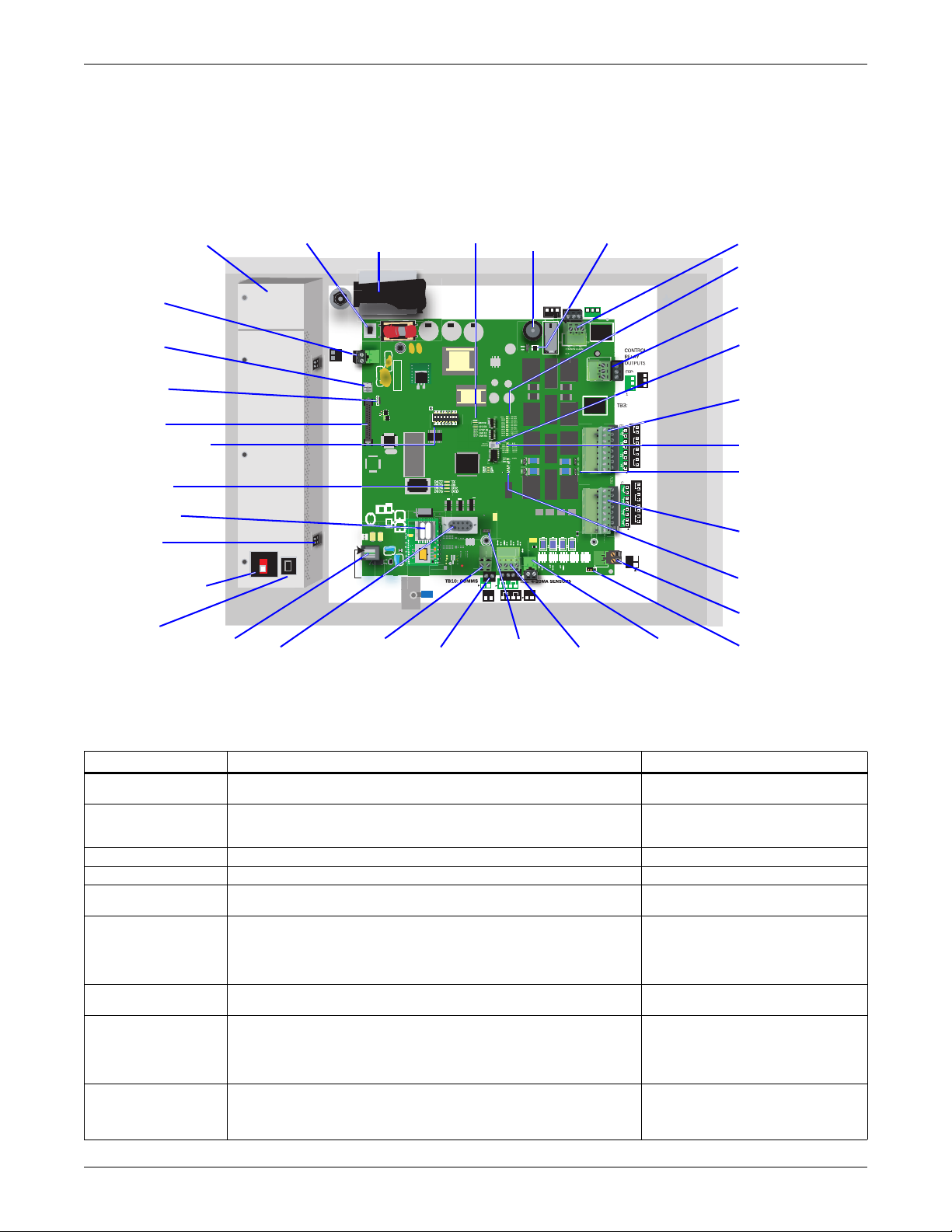

1.7 Controller Board Overview

BAR CODE

The AC8’s controller board has connectors for eight digital inputs, four analog inputs, eight digital

outputs, two control relay outputs and an EPOP contact input, as shown below. The board comes complete with light emitting diodes (LEDs) to display the status of connected devices, a battery pack for

short-term backup, communications ports, power connections and other features necessary to control

your operation.

HH - Transformer

Module

GG - 24VAC power

connector

FF - Battery pack

connector

EE - LCD contrast

adjustment

DD - LCD

connector

CC - DIP switch 1

BB - Modem

status LEDs

AA - Modem

Z - 24VAC

connector

Y - Power On/Off

switch

X - Power

receptacle

W - Phone

line

connector

A - Power

On/Off switch

ON

V - Serial

interface

connector

(RS232/EIA574)

B - Battery

pack

TB7:

24V INPUT

P23:

BATTERY

U - EIA485

connector

START

BAR CODE

LIEBERT

BATTERY

LCD

CONTRAST

VBATT

J11: PHONE

PIN 3-TIP

PIN 4-RING

T - SiteScan

Web

connector

(EIA422)

C - EIA422

LEDs

TP1

GND

ON

ON

S2

1

2345678

OFF

MODEM

MODEM

DIP

(TOP)

(BOTTOM)

OUTPUT1

DS56

OUTPUT2

DS54

OUTPUT3

DS63

OUTPUT4

DS61

OUTPUT5

DS60

OUTPUT6

DS62

OUTPUT7

DS55

OUTPUT8

DS57

CTRLLOCK

DS59

DS83

SENLOCK

DS58

CAN TX

CMN ALR

DS84

DS53

CAN RX

DS70

DS67

DS66

DS65

DS64

R334

C71

485

—

——

+

+ +

422

+—+

—

+

S - 12VDC/

24VDC analog

input jumper

D - Audible

horn

TB5: COMMON ALARM

RELAY OUTPUTS

NO C NC

LS1

+

ENABLE

P11

AUDIBLE

Q11

MOP

F PROG

574 TX

574 RX

485 RX

485 TX

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

INPUT6

INPUT7

INPUT8

1-2 TOP

3-4 BOTTOM

AG

TB9: ANALOG

—

GROUND

E - Audible horn

jumper

(TOP)

NO C NC

TB3, TB4, TB5

OUTPUT RELAY

BOTTOM

RATINGS: 24V, 3A

CLASS 2 ONLY.

TOP

TB4:

(BOTTOM)

NC

NC

C

C

NO

NO

2

RELAY

OUTPUTS

(BOTTOM)

(TOP)

8

4

7

3

6

2

5

1

PFM5 PFM2

REV

TB2:

CONTACT

ASS

INPUTS

TB1

EPOP INPUT

EPOP

P19

EPOP

DIS EN

TB1: EPOP

CONTACT

INPUT

TB1, TB2 INPUTS:

DRY CONTACTS ONLY.

(BOTTOM)

(TOP)

8

4

7

3

6

2

5

1

R - Analog

input

connectors

Q - Analog

ground

connector

Introduction

F - Common

Alarm

connectors

G - Digital output

status LEDs

H - Control relay

outputs

I - Manual

Override Switch

(outputs)

J - Digital output connectors

K - Status LEDs

L - Digital output

loss-of-power

jumper

M - Digital input

connectors

N - Digital input

status LEDs

O - EPOP

contact input

P - EPOP

jumper

Table 1 Controller board components

Item Description For more information, see:

A - Power On/Off

switch

B - Battery pack

C - EIA422 LEDs Indicates the connection status between the AC8 and SiteScan Web. 1.8: LED Indicators

D - Audible horn Provides audible notification when an alarm occurs. N/A

E - Audible horn

jumper

F - Common Alarm

connectors

G - Digital output

status LEDs

H - Control relay

outputs

I - Manual Override

Switch (outputs)

Power switch for the controller board. When switched off, the battery

pack is disabled.

Provides battery backup during a power loss to maintain normal

operation of the panel for a minimum of 10 minutes. The analog inputs

will not be functional during a power loss (P/N 133455P1).

2.4: Connect Power to the AC8

2.4.2: Connecting the Battery Pack

7.9.4: Connect Battery

Jumper to disable the audible horn (factory default is enabled). N/A

The two common alarm connections are used to connect to a secondary

warning device such as a horn, light or Building Management System

(BMS). When an alarm is present, the contacts close and the external

warning device is activated/notified. The common alarm contacts may

be configured to be reset with the Silence button/command.

Each output has an LED to indicate its status: ON/OFF (energized/deenergized).

Each of the two output connections is a two-state point: ON/OFF

(energized/de-energized). Digital and analog inputs may be mapped to

either or both relays to trigger change in state.

An example of a control relay output point is a humidity lock-out.

Placing the switch in the ON position will turn ON, or energize, all eight

outputs simultaneously. This switch removes all automatic output control

from the AC8.

3.0: Wiring and Connections

3.4: Connecting Common Alarm

7.4: Setup System - Setup Common

1.8: LED Indicators

3.0: Wiring and Connections

3.2.4: Connecting Control Relay

5.9: View Control Status

7.11: Setup System - Setup I/O Matrix

7.12: Override Output

The factory default is OFF (outputs controlled by programming).

4

Outputs

Alarm

Outputs

Page 13

Table 1 Controller board components (continued)

Item Description For more information, see:

J - Digital output

connectors

K - Status LEDs Indicates the operational status of the controller board. 1.8: LED Indicators

L - Digital output

loss-of-power

jumper

M - Digital input

connectors

N - Digital input

status LEDs

O - EPOP contact

input

P - EPOP jumper

Q - Analog ground

connector

R - Analog input

connectors

S - 12VDC/24VDC

analog input jumper

T - SiteScan Web

connector (EIA422)

U - EIA485 connector Not presently used N/A

V - Serial interface

connector (RS232/

EIA574)

W - Phone line

connector

X - Power receptacle

(Transformer Module)

Y - Power On/Off

switch (Transformer

Module)

Z - 24VAC connector

(Transformer Module)

AA - Modem On-board modem with 9600 baud rate.

BB - Modem status

LEDs

CC - DIP switch 1 DIP switch used for resetting password to default. 7.9.1: Change Password

DD - LCD connector Connection for the LCD on the enclosure door. N/A

EE - LCD contrast

adjustment

FF - Battery pack

connector

GG - 24VAC power

connector

HH - Transformer

Module

Each of the eight output connections is a two-state point: ON/OFF

(energized/de-energized).

An example of a field digital output point is an air unit On/Off control

circuit.

One of eight output jumpers. Each digital output has a jumper to set the

fail-safe position of the output point when power fails. The OFF position

makes the contact Normally Open (factory default). The ON position

makes the contact Normally Closed.

Note: The jumper position has no effect on the contact when the AC8

has power.

Each of the eight input connections is a two-state point: ON/OFF

(energized/de-energized).

An example of a field digital input point is a common alarm contact on an

air unit.

Each input has an LED to indicate its status: ON/OFF (energized/deenergized).

The emergency power operation (EPOP) input connection is a two-state

point: ON/OFF (energized/de-energized).

An example of an EPOP input point is a UPS or a generator.

Jumper to enable or disable emergency power operation (EPOP). Factory

default is disabled.

Connection for an externally powered analog sensor that needs a

reference to ground.

Each of the four input connections accepts a 4/20 mA signal.

An example of a field analog input point is a temperature sensor.

Jumper to select voltage supplied for two-wire analog sensors. The

jumper supplies all four analog input connectors with the same voltage.

Factory default is 24VDC.

Connection to monitor AC8 from Liebert’s SiteScan Web graphical

monitoring package.

Connection for laptop or video terminal. Used for configuration and

monitoring using the Service Terminal Interface. Requires a null modem

cable for connectivity

(P/N 201258P1).

Connection for phone line. Used for pager notifications, service phone

number, and configuration and monitoring using the Service Terminal

Interface. Requires an RJ11 connector.

115VAC power receptacle to power laptop during configuration and

diagnostics. Receptacle not available on 230VAC Transformer Module.

Power switch to turn power On/Off to both Transformer Module 24VAC

connectors and power receptacle.

One of the two 24VAC connectors for power (the second is also on the

right side of the Transformer Module near the top). Each connector is

rated for 40VA.

Indicates the operational status of the modem. 1.8: LED Indicators

Adjustment contrast for the LCD on the enclosure door. N/A

Connection for battery pack lead. 2.4.2: Connecting the Battery Pack

Power connection for the controller. Requires 24VAC. 2.4: Connect Power to the AC8

Transformer Module used to convert 115VAC or 230VAC to 24VAC. 2.4.1: Termination and Mounting

3.0: Wiring and Connections

3.2.2: Connecting Digital Outputs

5.6: View Output Status

7.7: Setup System - Setup Outputs

3.2.3: Setting the Digital Output

Jumpers

7.7.5: Configure Output for Loss of

Power (“Fail-Safe”)

3.0: Wiring and Connections

3.2.1: Connecting Digital Inputs

5.5: View Input Status

7.3: Setup System - Setup Inputs

1.8: LED Indicators

3.0: Wiring and Connections

3.2.5: Connecting the Emergency

Power Operation (EPOP) Input

3.2.6: Setting the EPOP Jumper

3.3.2: Connecting the Analog Ground

3.0: Wiring and Connections

3.3: Connecting Analog Inputs

5.5: View Input Status

7.5: Setup System - Setup Sensor

3.3.1: Setting the 12VDC/24VDC

Analog Power Jumper

3.0: Wiring and Connections

3.5: EIA422 SiteScan Web

Connector

3.6.1: RS232 Connector

A.2: Connecting to the Service

Terminal Interface

3.6.2: Phone Line Connector

7.8: Setup System - Setup Modem &

Pagers

7.9.6: Setup Serv Ph Num - Enter

Phone Number

A.2: Connecting to the Service

Terminal Interface

2.4.1: Termination and Mounting

3.0: Wiring and Connections

2.4.1: Termination and Mounting

3.0: Wiring and Connections

2.4.1: Termination and Mounting

3.0: Wiring and Connections

7.8: Setup System - Setup Modem &

Pagers

Introduction

5

Page 14

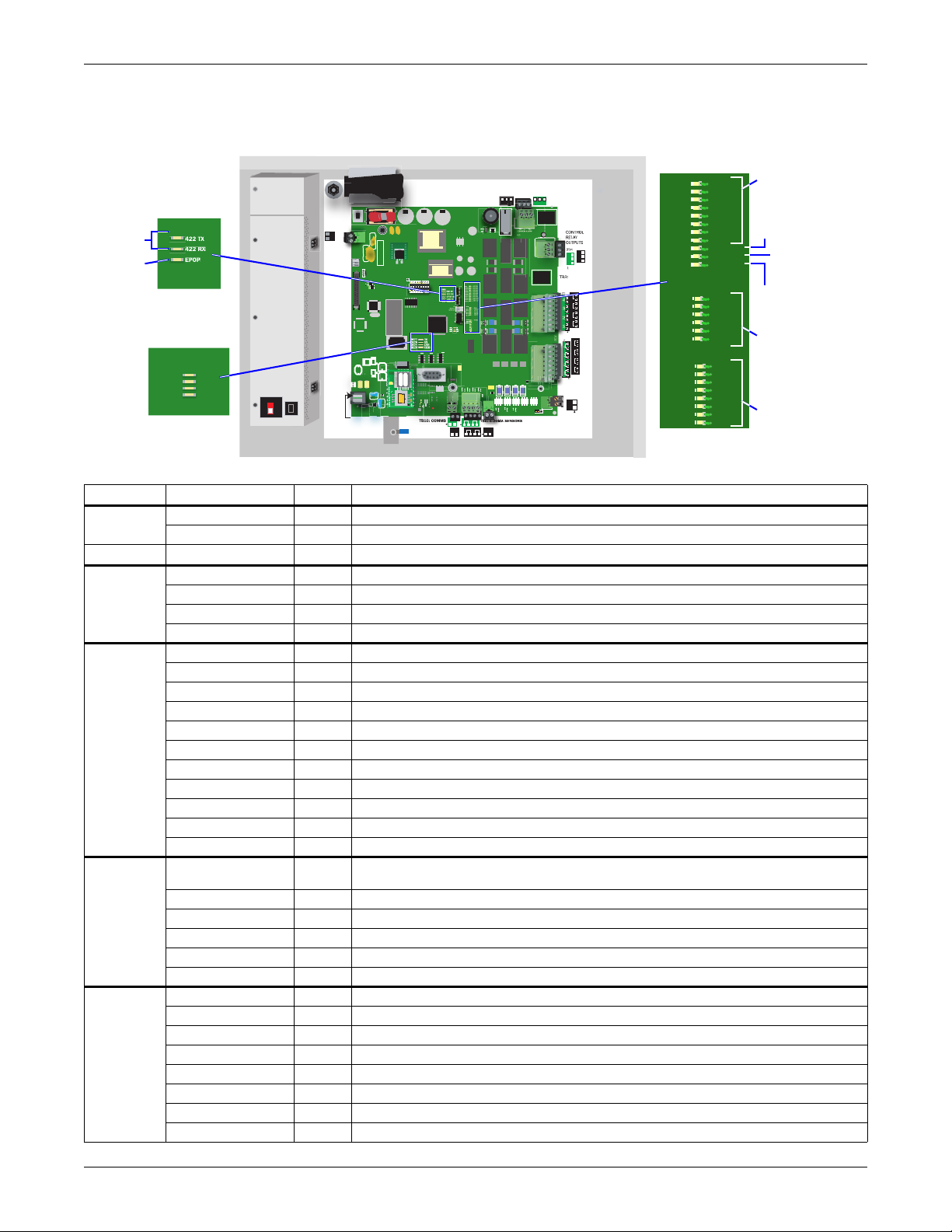

1.8 LED Indicators

BAR CODE

The AC8’s controller board has LED indicators that show the status of inputs, outputs and the common alarm, as well as the modem, SiteScan Web and EPOP connections.

Introduction

EIA422

EIA422

SS Web

EPOP

SiteScan Web

& EPOP

LEDs

DS50

DS49

DS68

Modem LEDs

MODEM

DS77 TX

DS76 RX

DS74 DTR

DS75 DCD

TB7:

START

24V INPUT

P23:

BATTERY

ON

BATTERY

LCD

CONTRAST

VBATT

J11: PHONE

PIN 3-TIP

PIN 4-RING

BAR CODE

LIEBERT

TP1

GND

ON

ON

DIP

S2

1

2345678

OFF

DS83

CAN TX

DS84

CAN RX

MODEM

MODEM

485

(TOP)

—

+

422

(BOTTOM)

—

+

TB5: COMMON ALARM

RELAY OUTPUTS

(TOP)

NO C NC

NO C NC

LS1

+

ENABLE

P11

AUDIBLE

Q11

OUTPUT1

DS56

OUTPUT2

DS54

OUTPUT3

DS63

OUTPUT4

DS61

OUTPUT5

DS60

OUTPUT6

DS62

OUTPUT7

DS55

OUTPUT8

DS57

CTRLLOCK

DS59

SENLOCK

DS58

CMN ALR

DS53

MOP

F PROG

574 TX

574 RX

485 RX

485 TX

INPUT1

INPUT2

INPUT3

INPUT4

DS70

INPUT5

DS67

INPUT6

DS66

INPUT7

DS65

INPUT8

DS64

R334

C71

1-2 TOP

3-4 BOTTOM

——

+ +

AG

TB9: ANALOG

—

+—+

GROUND

BOTTOM

TOP

PFM5 PFM2

TB1

EPOP INPUT

EPOP

P19

EPOP

DIS EN

TB1, TB2 INPUTS:

DRY CONTACTS ONLY.

TB3, TB4, TB5

OUTPUT RELAY

RATINGS: 24V, 3A

CLASS 2 ONLY.

RELAY

OUTPUTS

(TOP)

4

3

2

1

(TOP)

REV

4

3

2

1

TB2:

CONTACT

ASS

INPUTS

TB1: EPOP

CONTACT

INPUT

TB4:

(BOTTOM)

NC

NC

C

C

NO

NO

2

(BOTTOM)

8

7

6

5

(BOTTOM)

8

7

6

5

Table 2 LED indicators summary

LED Type LED Color Description

EIA422

LEDs

EPOP LED

Modem

LEDs

Output

LEDs

Status

LEDs

Input

LEDs

422 TX Green AC8 is transmitting information over the EIA422 port

422 RX Green AC8 is receiving information over the EIA422 port

EPOP IN Red Indicates Emergency Power Operation is open or in alarm

TX Green AC8 is transmitting information via the modem

RX Green AC8 is receiving information via the modem

DTR Green Indicates data terminal is ready (DTR)—lights up when modem is dialing

DCD Green Indicates data carrier is detected (DCD)—lights up when modem has connection

OUTPUT1 Green Indicates output is ON or energized

OUTPUT2 Green Indicates output is ON or energized

OUTPUT3 Green Indicates output is ON or energized

OUTPUT4 Green Indicates output is ON or energized

OUTPUT5 Green Indicates output is ON or energized

OUTPUT6 Green Indicates output is ON or energized

OUTPUT7 Green Indicates output is ON or energized

OUTPUT8 Green Indicates output is ON or energized

CTRLLOCK Green Indicates Control Relay 2 is ON or energized

SENLOCK Green Indicates Control Relay 1 is ON or energized

CMN ALR Green Indicates Common Alarm Relay is ON or energized

MOP Green

Indicates the microprocessor is operating properly (MOP)—must be on before AC8

will function

FPROG Green Indicates firmware is being upgraded—lights up during upgrade process

574 TX or 232 TX Green AC8 is transmitting information via the RS232 port

574 RX or 232 RX Green AC8 is receiving information via the RS232 port

485 RX Green Not used

485 TX Green Not used

INPUT1 Red Indicates input is ON or energized

INPUT2 Red Indicates input is ON or energized

INPUT3 Red Indicates input is ON or energized

INPUT4 Red Indicates input is ON or energized

INPUT5 Red Indicates input is ON or energized

INPUT6 Red Indicates input is ON or energized

INPUT7 Red Indicates input is ON or energized

INPUT8 Red Indicates input is ON or energized

DS56

DS54

DS63

DS61

DS60

DS62

DS55

DS57

DS59

DS58

DS53

DS51

DS48

DS47

DS78

DS52

DS79

DS69

DS71

DS72

DS70

DS67

DS66

DS65

DS64

OUTPUT1

OUTPUT2

OUTPUT3

OUTPUT4

OUTPUT5

OUTPUT6

OUTPUT7

OUTPUT8

CTRLLOCK

SENLOCK

CMN ALR

MOP

F PROG

574 TX

574 RX

485 RX

485 TX

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

INPUT6

INPUT7

INPUT8

Output LEDs

CTRLLOCK

Control Relay 2

SENLOCK

Control Relay 1

CMN ALR

Common Alarm

Status

LEDs

Input LEDs

6

Page 15

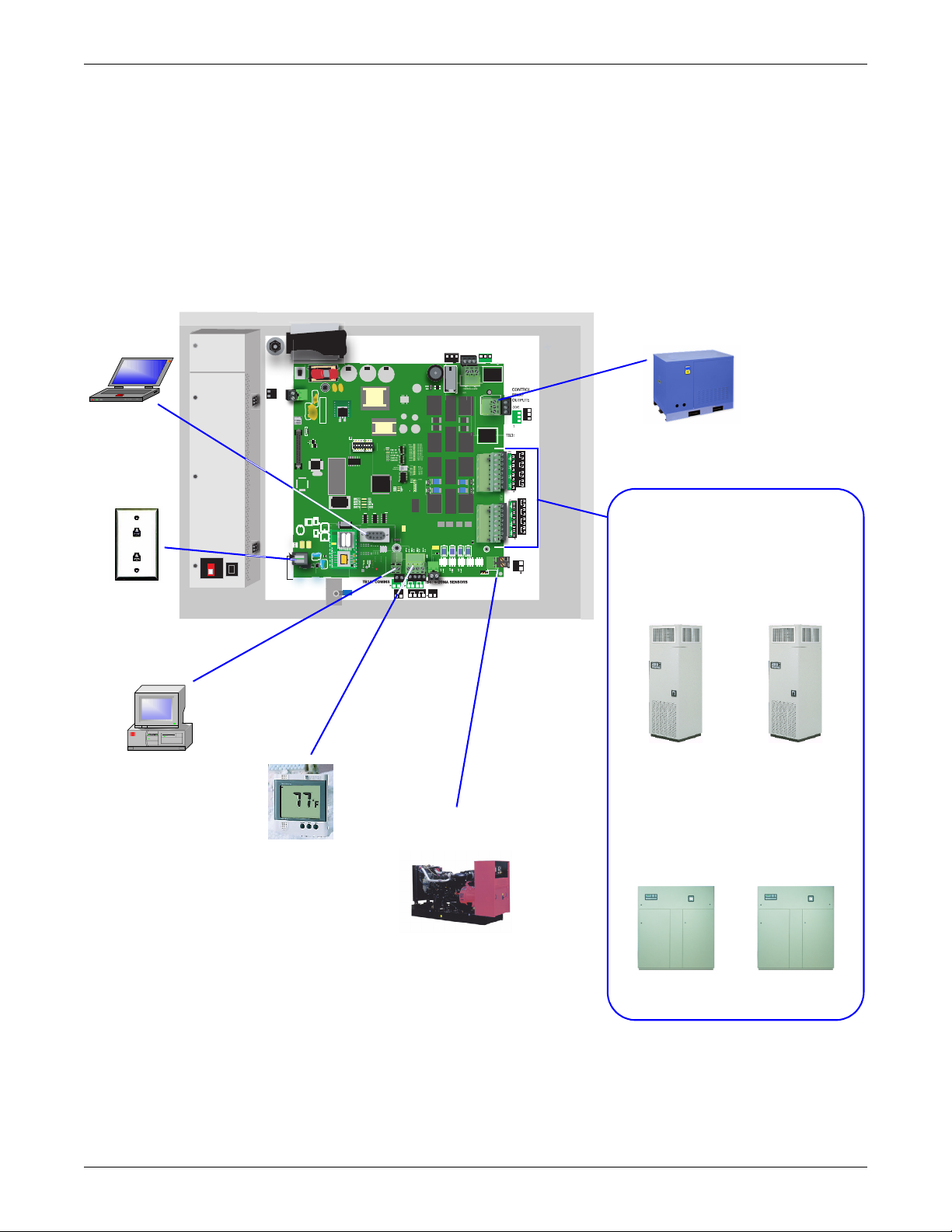

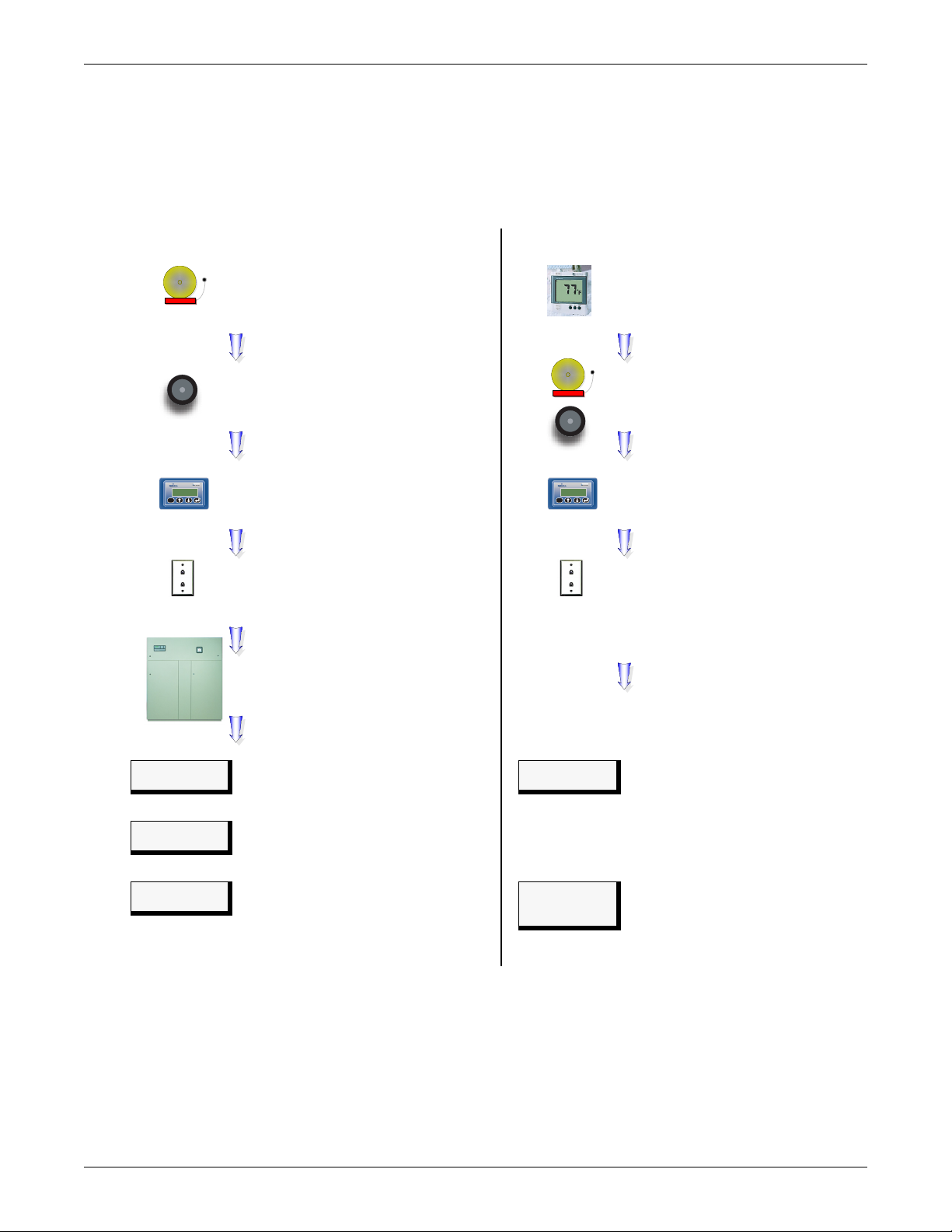

1.9 Typical Sequence

ESC

ESC

Figure 4 shows a typical sequence of how the AC8 functions after detecting a change in a monitored

device. Many responses depend on configuration settings. This example shows what happens when a

digital input changes state—assuming the input is defined as alarmable—and when the condition

returns to normal.

Figure 4 Example of typical sequence

RESPONSES TO AN ALARM RETURN-TO-NORMAL SEQUENCE

Introduction

ALARM CONDITION DETECTED

A device connected to the AC8

changes state.

RETURN TO NORMAL

The device that triggered the alarm

returns to its normal state.

The alarm is cleared

The horn sounds (audible horn on

the controller board—silence horn by

pressing any key on the LCD keypad)

(automatically if Unlatched; must be

cleared manually if Latched)

The horn stops sounding

(if user hasn’t silenced it)

UNIVERSAL MONITOR

05-SEP-02 14:04:13

V5.100.0

PRESS =STATUS/SETUP

ESC

The LCD flashes

(except during setup)

UNIVERSAL MONITOR

05-SEP-02 14:04:13

V5.100.0

PRESS =STATUS/SETUP

ESC

Pager numbers are dialed

(up to four configured pagers)

Service number is dialed

The LCD stops flashing

Pager numbers & service

number are dialed

Return-to-normal message sent

(if configured)

User setup determines output

control (for example, the device

in alarm might be disabled and a

standby device set to operate)

DEVICE_1 ALARM

CONTACT CLOSED

30-SEP-04 16:23:04

DEVICE_1 ALARM

CONTACT CLOSED

DEVICE_4 STARTED

30-SEP-04 16:23:10

Entry in Alarm Log

Condition (

& state (

ALARM)

CONTACT CLOSED)

Entry in Active Alarm Log

Condition (

& state (

ALARM)

CONTACT CLOSED)

Entry in Event Log

Status change

(DEVICE_4 STARTED)

ALARMS CLEARED

30-SEP-04 16:24:04

DEVICE_1 STARTED

DEVICE_2 STARTED

DEVICE_3 STARTED

DEVICE_4 OFF

30-SEP-04 16:24:06

Entry in Alarm Log

ALARMS CLEARED)

(

Entry in Event Log

Actions in response to event

(DEVICE_1 STARTED,

DEVICE_4 OFF

)

7

Page 16

2.0 INSTALLATION

This section provides instructions for installing, mounting and connecting power to the AC8.

2.1 Installation Considerations

The AC8 must be installed indoors and may be mounted on the surface of a wall or flush-mounted,

depending on the user’s application, the location of equipment and sensors to be monitored and the

type of wall the unit will be mounted on.

The AC8 should be mounted where it can be easily accessed. On-site personnel would access the unit

through the LCD on its front cover, service terminal connected to the RS232 port or through SiteScan.

For off-site monitoring, the AC8 should be placed near communications means such as a telephone

line connection that would permit remote access.

In addition to the communications connections, the site also must have electrical service and must

permit connecting the unit’s eight digital inputs, eight digital outputs and four analog inputs.

The wall material must be capable of supporting the weight of the AC8: see 8.0 - Specifications.

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Installation

2.1.1 Unpacking and Preliminary Inspection

• Before unpacking the AC8, inspect the shipping carton for damage or signs of mishandling, such

as gashes or holes in the carton or severely flattened corners.

• Open the shipping crates carefully. Use care to avoid puncturing the container with sharp objects

that might damage the contents.

• Inspect the AC8 and all included components for damage.

• If any damage from shipping or mishandling is observed, immediately file a damage claim with

the shipping agency and forward a copy to:

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Packing Contents

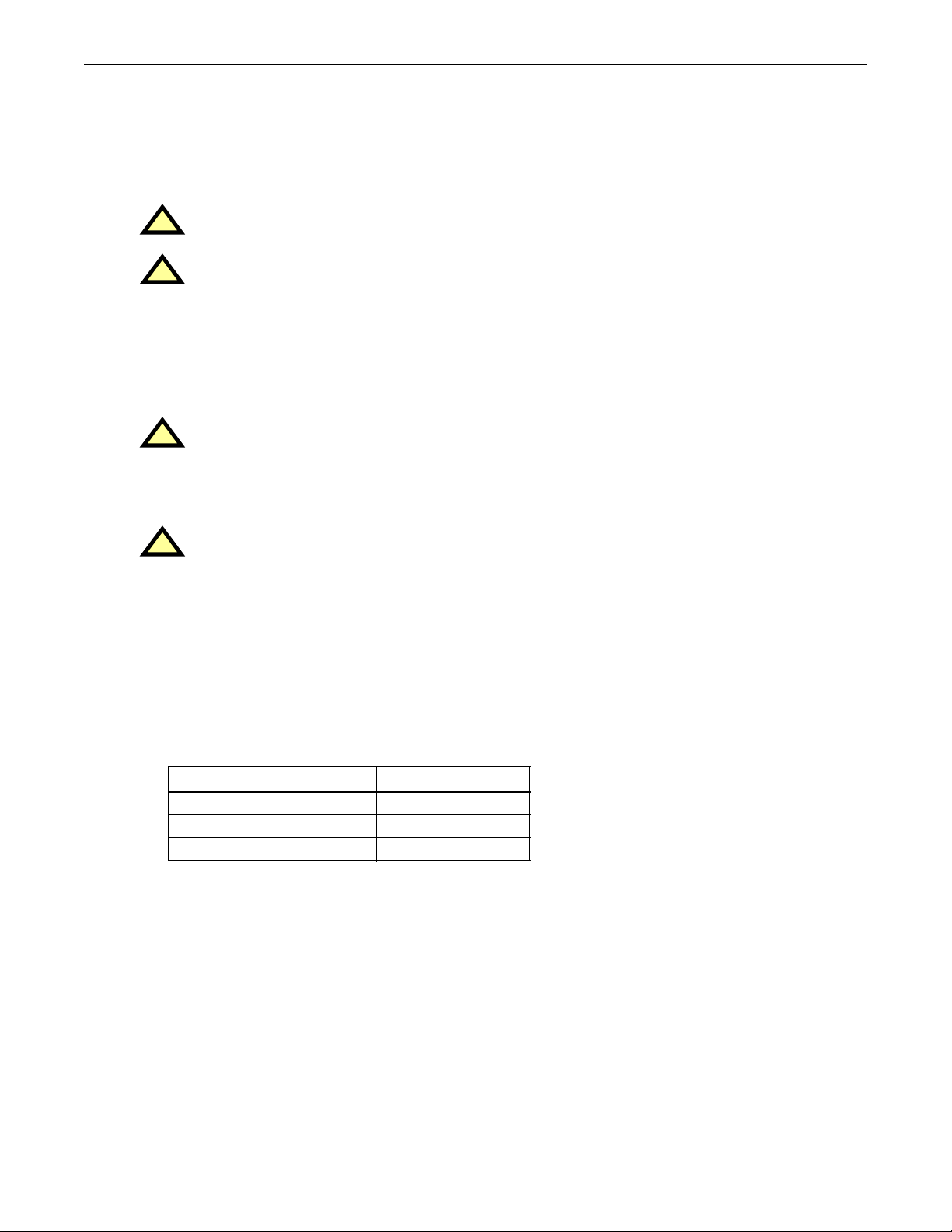

Table 3 Packing manifest

Standard Components

• AC8 controller board in enclosure

• User Manual

• Keys (2) to panel door lock

• Backup Battery - installed in unit (not connected or charged)

• RS232 Configuration Cable

8

Page 17

2.2 Surface-Mounting the AC8

NOTE

Removing the conduit knockouts before mounting the AC8 on the wall will ease installation

and prevent strain on the mounting hardware and wall. It is imperative to remove the

knockouts if the unit is to be flush-mounted.

After determining where to place the unit, check to ensure that you have all the hardware required to

install the panel on the surface of a wall. Obtain the needed tools and material.

Required tools

• Electric drill (if surface is too hard to drive screws without pilot holes)

• Screwdriver

• Marker to denote layout of holes

• Four screws, each #10

2.2.1 Mounting the Panel

CAUTION

!

Check building plans and other relevant documents to determine whether mounting the AC8

at the selected location might cause cutting or otherwise damaging electrical or

communication wiring or pipes.

1. Mark the wall for mounting holes, using the back of the unit as a template (see Figure 5).

2. Drill holes, if required, to install the four #10 screws that will secure the AC8 to the wall. Clean

up the debris.

3. If the wall material is not strong enough to hold the screws securely, use wall anchors.

4. Install the top two screws—the screw heads must be small enough to slip through the larger,

bottom portion of the pear-shaped mounting slot in the AC8 (see inset in Figure 5). The screws

must also be large enough to extend over the edges of the top of the mounting slot.

5. Hang the AC8 on the screws, letting the panel slip down until the screws are in the smaller, upper

portion of the slot.

6. Tighten the screws until they are snug.

7. Insert the remaining two screws in the bottom holes on the back of the panel and tighten.

Installation

Figure 5 Mounting dimensions

Mounting Slot

ENCLOSURE

12"

(304.8mm)

0.213"

(5.4mm)

16"

(406.4mm)

AC8

back plate

0.375"

(9.6mm)

0.213" (5.4mm)

Bottom hole diameter

9

Page 18

2.3 Flush-Mounting the AC8

NOTE

Removing the conduit knockouts before mounting the AC8 on the wall will ease installation

and prevent strain on the mounting hardware and wall. It is imperative to remove the

knockouts if the unit is to be flush-mounted.

The rectangular access doors on the top and bottom of the AC8 must be reversed so they slide

the opposite direction. Leaving the doors as shipped from the factory prevents them from being

opened when the panel is flush mounted in a wall.

The AC8 may be flush-mounted according to company practices—either with screws through the sides

of the panel into wall supports or with hanging hardware that attaches to the back of the panel. After

determining how and where to place the unit, check to ensure that you have all the hardware

required to install the panel in the wall. Obtain the needed tools.

Required tools

•Saw

• Electric drill

• Screwdriver

• Marker to denote layout of the hole to accommodate the AC8

• Mounting hardware

2.3.1 Mounting the Panel

Installation

CAUTION

!

Check building plans and other relevant documents to determine whether mounting the AC8

at the selected location might cause cutting or otherwise damaging electrical or

communication wiring or pipes.

1. Mark the wall for the cutout to accommodate the panel, using the back of the unit as a template.

2. Drill a pilot hole for the saw blade, if required.

3. Use the saw to cut out the marked section of the wall (if not new construction).

4. Rest the AC8 in the wall and mark where mounting screws will be inserted into the wall studs or

other support member.

5. Remove the panel and drill the holes for the mounting screws or wall anchors. Clean up the

debris.

6. Reverse the slide direction of the rectangular access doors on the top and bottom of the AC8.

Leaving the doors as shipped from the factory prevents them from being opened when the panel is

flush mounted in a wall.

7. Attach any field-supplied mounting hardware.

8. Reinsert the assembly into the wall.

9. Insert and tighten the screws or wall anchors.

10

Page 19

2.4 Connect Power to the AC8

The AC8 must be supplied with 115VAC or 230VAC; the power supplied must match the rating of the

unit’s Transformer Module. For information, consult your local dealer, Liebert representative or the

Liebert Worldwide Support Group.

The AC8 must be installed on a branch circuit protected by a certified 15A overcurrent device.

WARNING

!

Check that power is removed from wires prior to installation.

CAUTION

!

The AC8 is designed for use on properly grounded (earthed) 115VAC or 230VAC power, 60Hz

or 50Hz. The ground wire for the power lead must be wired to the earth ground terminal (stud

located next to the 24VAC terminal block).

This equipment is intended to be installed by a qualified and certified electrician who must

review and approve customer supplied wiring and circuit breakers, verify correct input and

grounded (earthed) connections to ensure compliance with technical standards and national

and local electrical codes.

WARNING

!

Be sure that the Power On/Off switch is set to OFF before installing any wiring to this unit.

The switch is in the top left corner of the unit, just below the battery pack.

2.4.1 Termination and Mounting

Installation

WARNING

!

Be sure that the Power On/Off switch is set to OFF before installing any wiring to this unit.

The switch is at the bottom of the unit.

Input Power Connections

To connect electrical power to the Transformer Module:

1. Install electrical wiring from utility power to the Transformer Module.

2. Use copper wires only; proper wiring to use for power is 14/2 AWG copper wire with ground.

3. For the TM230 only: strip wires 3/8" (9.6mm).

Note: For the TM115, wires are pre-stripped 0.4" (10.2mm) at the factory.

4. Connect the wiring as follows:

TM115 TM230 Connection Type

White wire Neutral (L2) Neutral

Black wire Line (L1) Power (Line)

Green wire Ground lead Ground

5. Secure the incoming electrical service wires to the TM115 input wires with wire nuts as shown in

Figure 6 or to the TM230 connectors as shown in Figure 7.

11

Page 20

Installation

24 VAC Output Power Connections

To connect to the 24VAC outputs:

1. Install electrical wiring from device requiring 24VAC power to the Transformer Module.

2. Use copper wire only; proper wiring to use for power is 18, 20 or 22 AWG copper wire. Strip

wire 1/4".

3. There are two 24 VAC output connectors (TB1 and TB2). Terminate wires to the connector as

shown in Figures 6 and 7. TB1 and TB2 are NOT polarity sensitive.

4. Secure the wires to the connector.

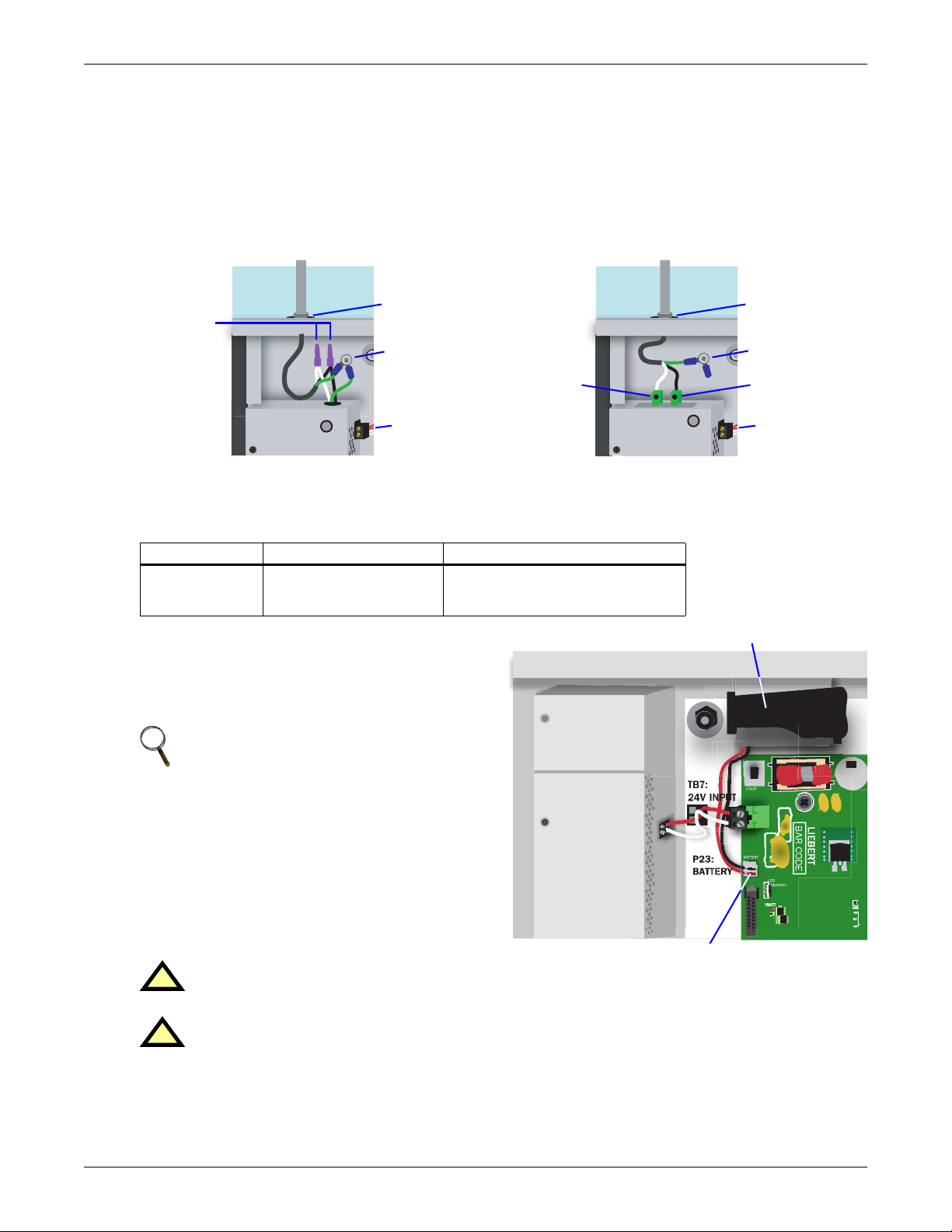

Figure 6 Power wiring to TM115 Figure 7 Power wiring to TM230

TM115

Wire nuts

connecting

electrical

wiring

Troubleshooting - Transformer Module

A common problem and possible solution are shown in the table below. For further information or if

you have other problems with the unit, consult your local dealer, Liebert representative or the Liebert

Worldwide Support Group.

Problem Possible Solution Replacement Fuse Part Numbers

24VAC power

not available

from TB1 or TB2

Check fuse for respective

output (TB1 or TB2).

2.4.2 Connecting the Battery Pack

Before connecting input power to the AC8, connect

the panel’s backup battery (factory-supplied) to the

jumpers so it will begin charging when electrical

power to the AC8 is switched on.

Knockout for

external wiring

Ground

24VAC output

(TB1)

• LITTLEFUSE 218002

or

• BUSSMANN GDC-2A

TM230

Neutral

(L2)

Knockout for

external wiring

Ground

Line (L1)

24VAC output

(TB1)

Battery pack

NOTE

If the battery is not hooked up BEFORE the

AC8 is switched on, it will trigger an alarm.

To connect the battery pack, insert the battery

leads into the jumpers as shown at right.

(To disconnect the battery pack, remove the

battery leads from the jumpers.)

Obtaining a Replacement Battery Pack

To obtain a replacement battery pack, contact your

local dealer or Liebert representative. The Liebert

part number is 133455P1.

WARNING

!

To prevent the risk of fire or explosion, replace only with 7.2 V rechargeable NiCad battery pack.

CAUTION

!

Dispose of the battery properly by sending it back to Liebert Corporation or an approved

battery recycling facility.

2.4.3 Turning On the AC8

After connecting the backup battery, turn on the power On/Off switches to the AC8 and the Transformer Module (see 1.7 - Controller Board Overview for location of switches).

Battery pack connector

12

Page 21

Wiring and Connections

3.0 WIRING AND CONNECTIONS

CAUTION

!

Switch OFF electric power to the AC8 before installing any wiring to the unit or changing

input or output connections. The Power On/Off switch is in the top left corner of the unit, just

below the battery pack.

3.1 Wiring Specifications

Input and output connections to the AC8 may be made in any order—it is not necessary, for example,

to make all input connections before making any output connections. Use copper conductors only for

all wiring.

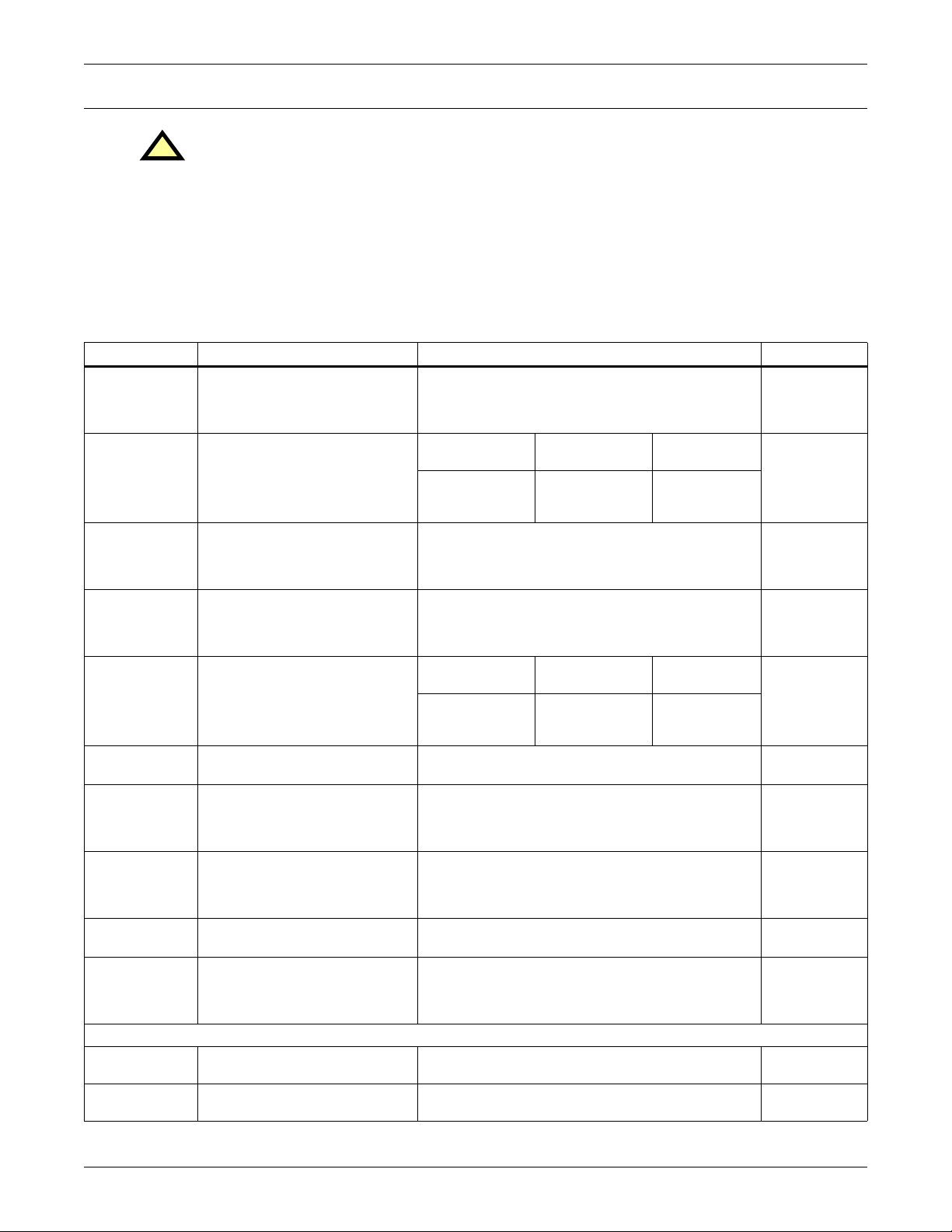

Table 4 Wiring specifications

Connection Supported Wire Type Maximum Wire Length Rating

Digital

Input/

EPOP

Digital

Output/

Control

Relay

Analog Input

2-Wire

Transducer

Analog Input

4-Wire

Transducer

Common

Alarm

Output

Communication

RS232

Communication

EIA422

SiteScan

Communication

EIA485

Phone/Modem

Line

24VAC Power

Connection

(TB7)

Power Connections (Transformer Module)

115VAC

230VAC

* Recommended

18-22 AWG Stranded & Unshielded

18 AWG* (recommended)

Non Plenum - Belden 9740

Plenum - Belden 89740

18-22 AWG Stranded & Unshielded

18 AWG* (recommended)

Non Plenum - Belden 9740

Plenum - Belden 89740

18-22 AWG Stranded & Unshielded

18 AWG* (recommended)

Non Plenum - Belden 9740

Plenum - Belden 89740

18-22 AWG Stranded & Unshielded

18 AWG* (recommended)

Non Plenum - Belden 8489

Plenum - Belden 88489

18-22 AWG Stranded & Unshielded

18 AWG* (recommended)

Non Plenum - Belden 9740

Plenum - Belden 89740

Null Modem Cable 50 ft. (15m) N/A

18-22 AWG Stranded & Shielded

22 AWG* (recommended)

Non Plenum - Belden 9461

Plenum - Belden 88761

18-22 AWG Stranded & Shielded

22 AWG* (recommended)

Non Plenum - Belden 9461

Plenum - Belden 88761

4 Wire (Pins 3 & 4)

RJ11 Connector

18-22 AWG Stranded & Shielded

18 AWG* (recommended)

Non Plenum - Belden 8770

Plenum - Belden 88770

14 AWG Stranded & Unshielded

Non Plenum - Belden 5101UE

14 AWG Stranded & Unshielded

Non Plenum - Belden 5101UE

18 AWG*

(recommended)

@3A 50 ft. (15m)

@2A 100 ft. (30m)

@1A 200 ft. (60m)

18 AWG*

(recommended)

@3A 50 ft. (15m)

@2A 100 ft. (30m)

@1A 200 ft. (60m)

750 ft. (225m)

20 AWG 22 AWG

@3A 40 ft. (12m)

@2A 60 ft. (18m)

@1A 100 ft. (30m)

750 ft. (225m)

750 ft. (225m)

20 AWG 22 AWG

@3A 40 ft. (12m)

@2A 60 ft. (18m)

@1A 100 ft. (30m)

1000 ft. (300m) N/A

3000 ft. (900m) N/A

N/A N/A

150 ft. (45m)

150 ft. (45m)

150 ft. (45m)

@3A 25 ft. (7m)

@2A 35 ft. (10m)

@1A 75 ft. (23m)

@3A 25 ft. (7m)

@2A 35 ft. (10m)

@1A 75 ft. (23m)

Dry Contact

24VAC@3A

4-20 mA Signal

Input Selectable

Power Source

(12/24VDC)

4-20 mA Signal

Input Selectable

Power Source

(12/24VDC)

(24VDC,

10 mA)

24VAC

@3A

24VAC

@1.3A

115VAC

@4A

230VAC

@0.5A

13

Page 22

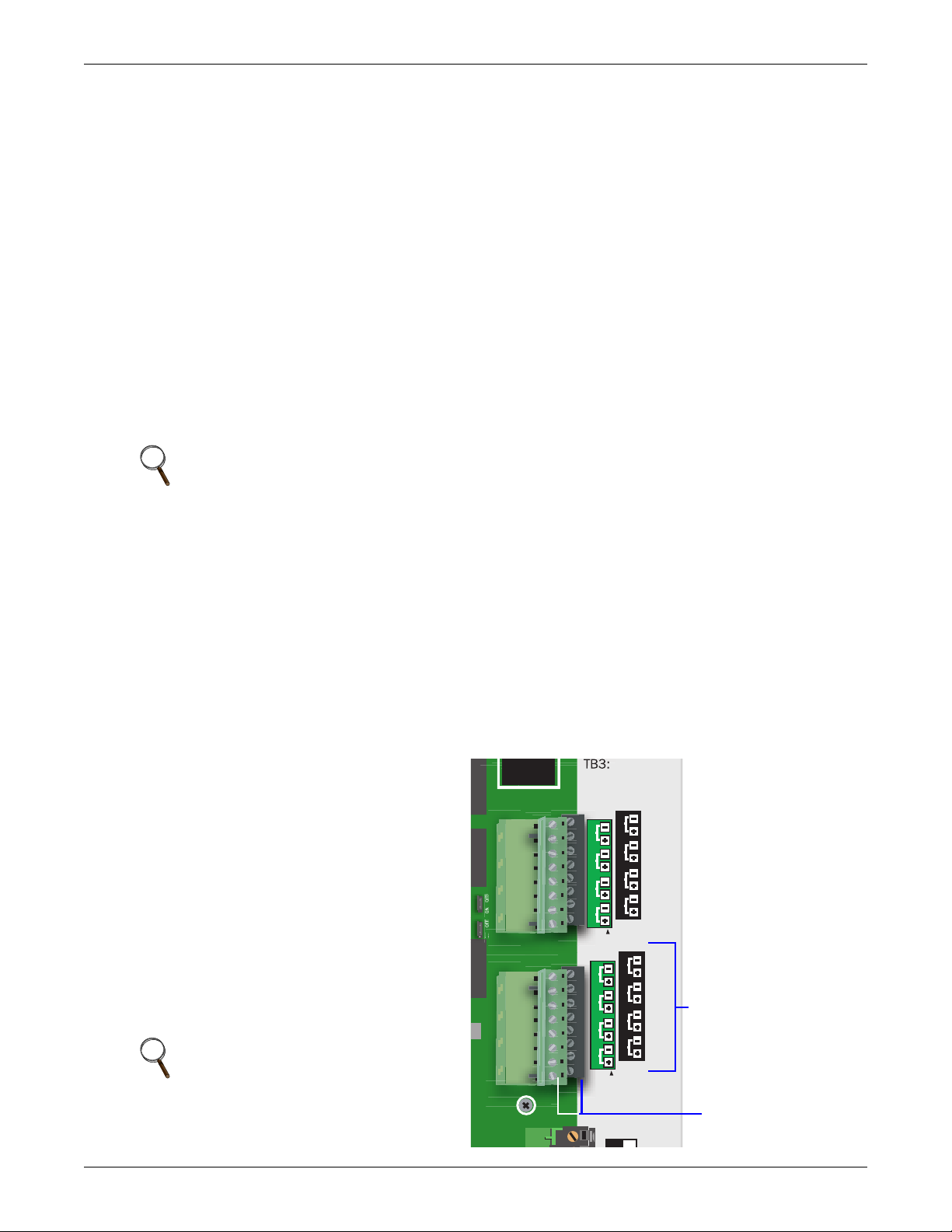

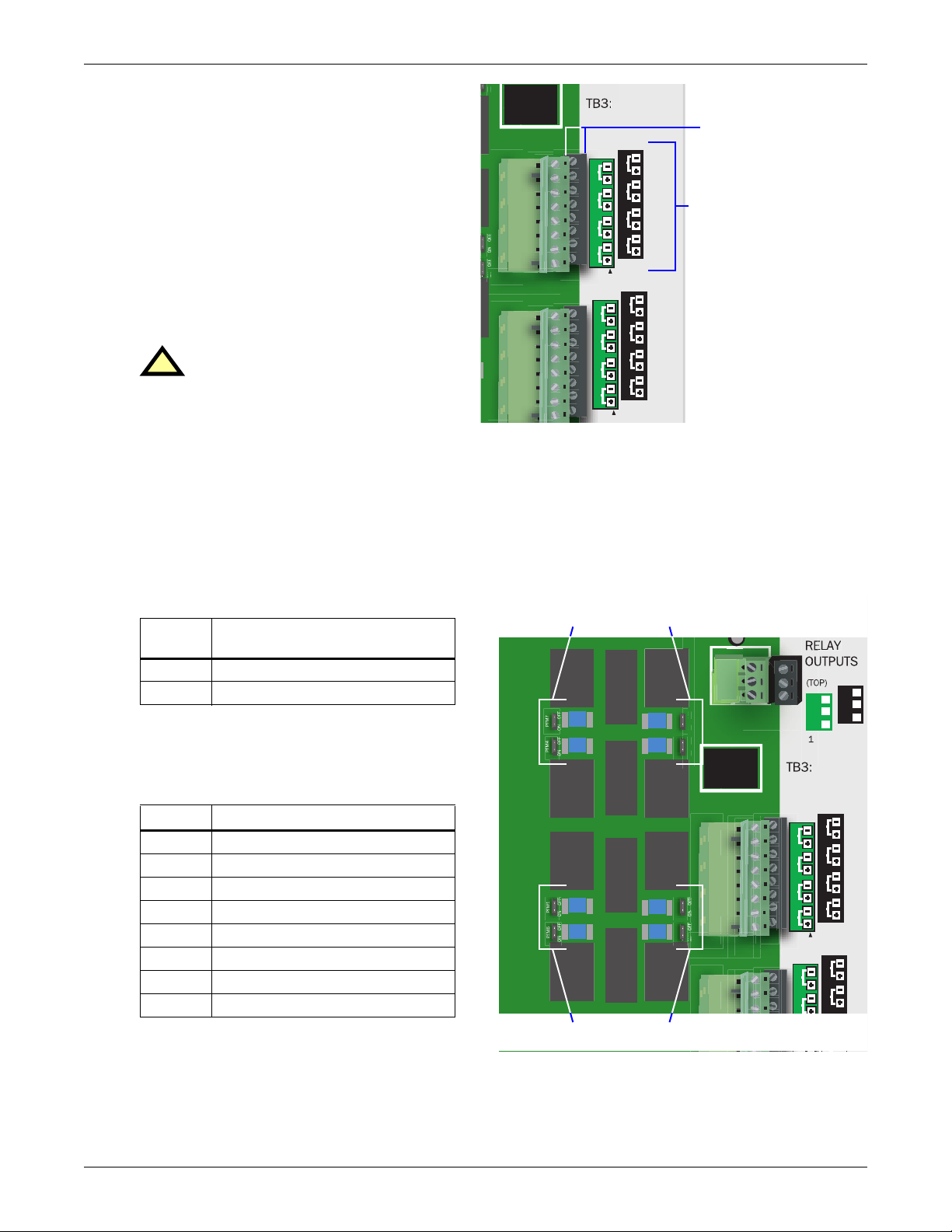

3.2 Connecting Digital Inputs and Digital Outputs

The digital inputs, digital outputs and control relay outputs are found on the right side of the AC8’s

printed wiring assembly board. Each set has two terminal blocks—one green, the other black:

• Digital inputs: two terminal blocks, with four inputs per block (8 inputs total)

• Digital outputs: two terminal blocks, with four outputs per block (8 outputs total)

• Control relay outputs: two terminal blocks, with one output per block (2 outputs total)

Each input is tied to an output with the same number:

• Input 1 is tied to Output 1 (default name: Device_1)

• Input 2 is tied to Output 2 (default name: Device_2)

• Input 3 is tied to Output 3 (default name: Device_3)

.

.

.

• Input 8 is tied to Output 8 (default name: Device_8)

Up to eight devices may be connected to the AC8. Each device must be connected to an input and an

output with the same number.

To determine the proper wire size, see Table 4 - Wiring specifications.

NOTE

Each terminal block is a removable, two-part assembly to permit easier connection of more

than one input at a time. If making multiple connections, grasp the upper portion of a block

and pull firmly to the right until the assembly pulls apart.

After making the connections, push the removed piece back into the portion attached to the

printed wiring assembly until the terminal block pieces lock together.

Wiring and Connections

Connecting Liebert Environmental Units

For Liebert environmental units, follow these steps (be sure to connect the same device to inputs and

outputs with the same number—one device to Input 1 and Output 1, another to Input 2 and Output 2,

and so on):

• Connect a digital input from the AC8 to the Common Alarm Relay of the environmental unit:

terminals 75/76 or TB1-6, TB1-7.

• Connect a digital output (numbered the same as the input) from the AC8 to the Remote Shutdown

(Power Control) of the environmental unit: terminal 37/38 or TB1-4, TB1-5.

3.2.1 Connecting Digital Inputs

To connect a digital input:

1. Turn OFF electrical power to the AC8.

2. If necessary, remove a conduit knockout

to permit wire entry into the AC8

enclosure.

3. Bring the wire(s) into the AC8 enclosure

through a conduit knockout or access slot.

4. Loosen the appropriate screw and slip the

stripped end of the wire into the terminal

block.

5. Tighten the screw until it holds the wire

snugly.

NOTE

Connect digital inputs to

nonpowered (dry) contacts only.

PFM2

PFM5

TB1

EPOP INPUT

EPOP

RELAY

OUTPUTS

(TOP)

4

3

2

1

(TOP)

REV

4

3

2

1

TB2:

CONTACT

ASS

INPUTS

(BOTTOM)

8

7

6

5

(BOTTOM)

8

7

6

5

NUMBERING KEYS Note numbering begins

with 1 at the bottom and