Page 1

SPEC. NO.

MODEL

581127000

710NPBA

NetSure™ +24V DC Power System

Installation Instructions

IM581127000 (Issue AB, March 22, 2012)

Page 2

Business-Critical Continuity™, Emerson Network Power, and the Emerson Network

Power logo are trademarks and service marks of Emerson Electric Co.

NetSure™, NetSpan™, NetReach™, NetXtend™, and NetPerform™

are trademarks of Emerson Network Power, Energy Systems, North America, Inc.

All other trademarks are the property of their respective owners.

The products covered by this instruction manual are manufactured and/or

sold by Emerson Network Power, Energy Systems, North America, Inc.

The information contained in this document is subject to change without notice and may not be

suitable for all applications. While every precaution has been taken to ensure the accuracy and

completeness of this document, Emerson Network Power, Energy Systems, North America, Inc.

assumes no responsibility and disclaims all liability for damages resulting from use of this information

or for any errors or omissions. Refer to other local practices or building codes as applicable for the correct

methods, tools, and materials to be used in performing procedures not specifically described in this document.

This document is the property of Emerson Network Power, Energy Systems, North America, Inc.

and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use or disclosure of it without the written permission

of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Copyright © 2012, Emerson Network Power, Energy Systems, North America, Inc.

All rights reserved throughout the world.

Page 3

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

TABLE OF CONTENTS

CONTENTS PAGE

IMPORTANT SAFETY INSTRUCTIONS .................................................................................. iv

General Safety .................................................................................................................................................... iv

Voltages .............................................................................................................................................................. iv

Battery ................................................................................................................................................................. iv

Circuit Card Handling ........................................................................................................................................... v

STATIC WARNING ................................................................................................................... vi

CHAPTER 1. GENERAL INFORMATION AND INSTALLATION CHECKLIST ........................ 1

Customer Documentation Package ..................................................................................................................... 1

Installation Acceptance Checklist ........................................................................................................................ 1

CHAPTER 2. INSTALLING THE SYSTEM ................................................................................ 3

General Requirements ......................................................................................................................................... 3

Securing the Relay Rack to the Floor .................................................................................................................. 3

Ventilation Requirements .............................................................................................................................. 3

Relay Rack Floor Mounting Dimensions ....................................................................................................... 4

Mounting System Components in an Equipment Rack ....................................................................................... 7

Mounting the Distribution Cabinet with Module Mounting Assembly ............................................................ 7

Installing a List 93 Battery Tray ................................................................................................................... 10

Installing Optional Lug Adapter Busbar Kits, Part Nos. 534449 and 514714 .................................................... 14

Installing Circuit Breakers and Fuses ................................................................................................................ 16

Installing Bullet Nose Type Fuseholders and TPS/TLS Fuses ................................................................... 16

Installing Bullet Nose Type Circuit Breakers ............................................................................................... 18

Installing an Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block ...................................... 19

Installing TPH Fuses ................................................................................................................................... 21

Installing TPL-B Fuses ................................................................................................................................ 22

Installing GJ/218 Circuit Breakers ............................................................................................................... 23

CHAPTER 3. SETTING JUMPERS AND SWITCH OPTIONS ................................................. 28

Circuit Card Locations ........................................................................................................................................ 28

Jumpers on System Interface Circuit Card ........................................................................................................ 29

Controller Power Option .............................................................................................................................. 29

Internal/External Battery Monitoring ............................................................................................................ 29

Switch Settings on IB2 Interface Board ............................................................................................................. 31

Switch Setting on Optional EIB Interface Board ................................................................................................ 31

Switch Setting on SM-DU+ ................................................................................................................................ 34

CHAPTER 4. MAKING ELECTRICAL CONNECTIONS .......................................................... 36

Important Safety Instructions ............................................................................................................................. 36

Wiring Considerations ........................................................................................................................................ 36

Relay Rack Grounding Connection (Frame Ground) ......................................................................................... 37

AC Input and AC Input Equipment Grounding Connections .............................................................................. 38

Connections to Factory Installed Module Mounting Shelves ...................................................................... 38

Table of Contents Page i

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 4

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Connections to Field Expansion Module Mounting Assembly .................................................................... 47

External Alarm, Reference, Monitoring, and Control Connections .................................................................... 49

Circuit Card Locations ................................................................................................................................. 49

System Interface Circuit Card ...................................................................................................................... 50

IB2 (ACU+ Controller Interface Board) ........................................................................................................ 52

Optional EIB (ACU+ Controller Extended Interface Board) ......................................................................... 55

Optional SM-DU+ and Shunt Interface Board ............................................................................................. 59

Optional SM-Temp Module .......................................................................................................................... 59

Ethernet Connection .......................................................................................................................................... 61

Control Bus Connections between Controller and Module Mounting Shelves .................................................. 62

Connecting List 60 Converter Output Jumpers .................................................................................................. 64

Load Connections .............................................................................................................................................. 66

Recommended Torques .............................................................................................................................. 66

Load Connections to Single Voltage Distribution Panels ............................................................................ 67

Load Connections to Dual Voltage Distribution Panels ............................................................................... 71

Load Connections to Return Bar ................................................................................................................. 73

Load Connections to GMT Distribution Fuse Block ..................................................................................... 73

Battery Connections ........................................................................................................................................... 74

Important Safety Instructions ....................................................................................................................... 74

Recommended Torques .............................................................................................................................. 74

Battery Connections to Optional Battery Disconnect Distribution Panels ................................................... 74

Battery Connections to Distribution Cabinet Battery Busbars ..................................................................... 78

Battery Connections to Optional Battery Landing Busbar Kit P/N 541371 ................................................. 79

Battery Connections to Optional Battery Landing Busbar Kit P/N 550265 ................................................. 80

Installing and Connecting Batteries in List 93 Battery Tray (if furnished) .......................................................... 81

Important Safety Instructions ....................................................................................................................... 81

Battery Manufacturer Information ................................................................................................................ 81

Installing Battery Landing Busbar Kit P/N 541371 (List 21) or 550265 (List 22, 23, or 24) ........................ 82

Wiring to the Battery Tray ............................................................................................................................ 85

Installing and Connecting Batteries ............................................................................................................. 88

CHAPTER 5. INSTALLING THE MODULES AND INITIALLY STARTING THE SYSTEM ..... 90

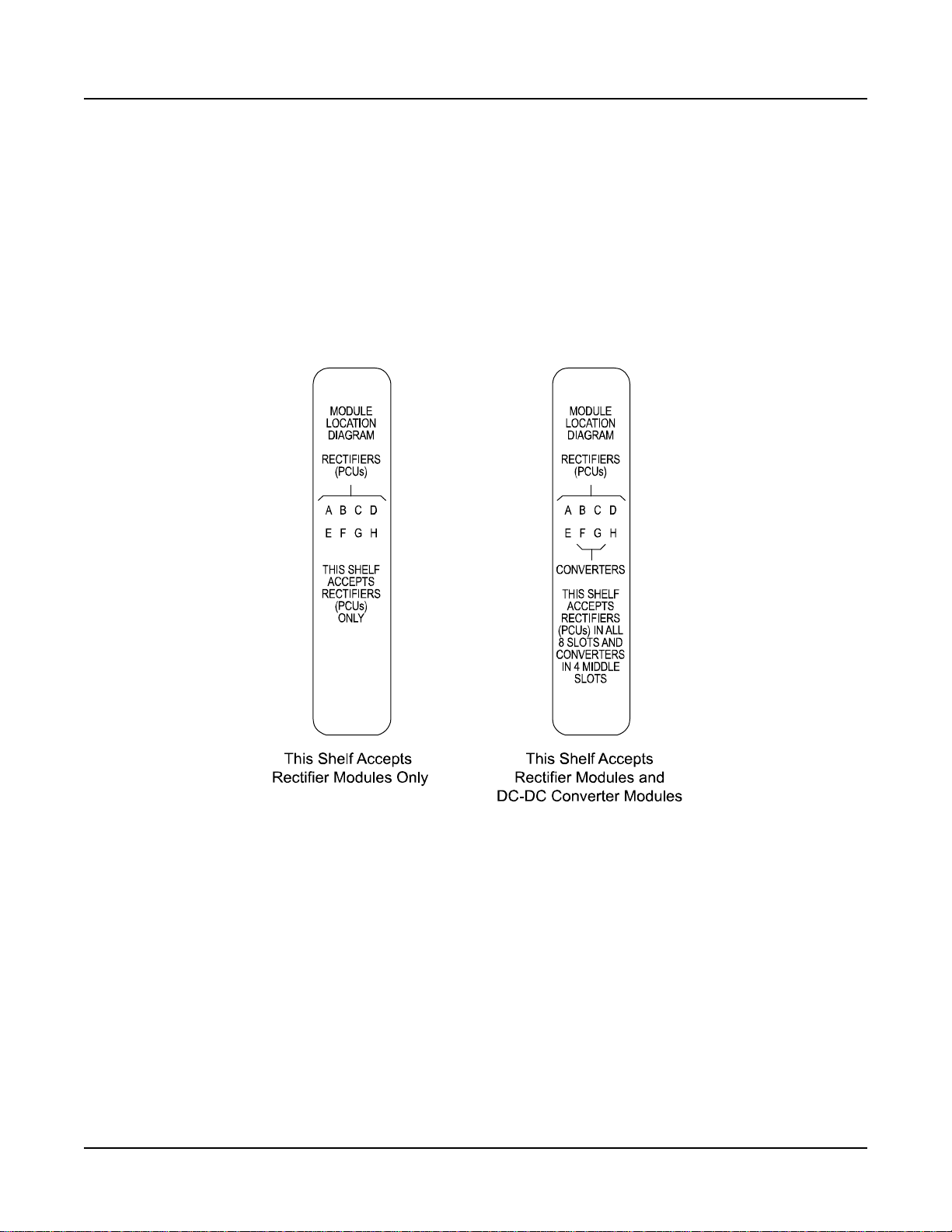

Installing the Rectifier and DC-DC Converter Modules ..................................................................................... 90

Initially Starting, Configuring, and Checking System Operation ........................................................................ 92

Important Safety Instructions ....................................................................................................................... 92

Initial Startup Preparation ............................................................................................................................ 92

Initially Starting the System ......................................................................................................................... 92

ACU+ Controller Initialization....................................................................................................................... 93

Verifying the Configuration File ................................................................................................................... 95

Checking Basic System Settings ................................................................................................................. 95

Checking System Status ............................................................................................................................. 97

Changing Battery Capacity Rating in the ACU+ .......................................................................................... 98

Configuring the ACU+ Identification of Rectifiers and Assigning which Input Phase is Connected

to the Rectifiers ............................................................................................................................................ 98

Configuring the ACU+ Identification of Converter Modules ......................................................................... 99

Page ii Table of Contents

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 5

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

ACU+ Alarm Relay Check ......................................................................................................................... 100

Final Steps ................................................................................................................................................. 108

REVISION RECORD .............................................................................................................. 110

Table of Contents Page iii

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 6

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

IMPORTANT SAFETY INSTRUCTIONS

GENERAL SAFETY

Danger: YOU MUST FOLLOW APPROVED SAFETY PROCEDURES.

Performing the following procedures may expose you to hazards. These

procedures should be performed by qualified technicians familiar with the

hazards associated with this type of equipment. These hazards may

include shock, energy, and/or burns. To avoid these hazards:

a) The tasks should be performed in the order indicated.

b) Remove watches, rings, and other metal objects.

c) Prior to contacting any uninsulated surface or termination, use a

voltmeter to verify that no voltage or the expected voltage is present.

d) Wear eye protection, and use recommended tools.

e) Use double insulated tools appropriately rated for the work to be

performed.

Caution: Performing maintenance and/or troubleshooting procedures may

interrupt power to the loads, if battery reserve is not sufficient.

VOLTAGES

AC Input Voltages

Danger: This system operates from AC voltage capable of producing fatal

DC Input/Output Voltages

Danger: This system produces DC Power and may require battery to be connected

BATTERY

Danger: Correct polarity must be observed when connecting battery leads.

Danger: Special safety precautions are required for procedures involving

electrical shock. AC input power must be completely disconnected from

the branch circuits wiring used to provide power to the system before any

AC electrical connections are made. DO NOT apply AC power to the

system until all electrical connections have been completed and checked.

to it. Although the DC voltage is not hazardously high, the rectifiers

and/or battery can deliver large amounts of current. Exercise extreme

caution not to inadvertently contact or have any tool inadvertently contact

a battery terminal or exposed wire connected to a battery terminal.

NEVER allow a metal object, such as a tool, to contact more than one

termination or battery terminal at a time, or to simultaneously contact a

termination or battery terminal and a grounded object. Even a momentary

short circuit can cause sparking, explosion, and injury.

handling, installing, and servicing batteries. Observe all battery safety

precautions in this manual and in the battery instruction manual. These

precautions should be followed implicitly at all times. Remove watches,

rings, and other metal objects before connecting battery leads.

Page iv Important Safety Instructions

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 7

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

CIRCUIT CARD HANDLING

Warning: Installation or removal of the circuit cards requires careful handling.

Before handling any circuit card, read and follow the instructions

contained on the Static Warning Page.

Important Safety Instructions Page v

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 8

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

STATIC WARNING

The printed circuit cards used in this equipment contain static sensitive components. The warnings listed below

must be observed to prevent damage to these components. Disregarding any of these warnings may result in

personal injury or damage to the equipment.

1. Strictly adhere to the procedures provided in this document.

2. Before touching any static sensitive component or printed circuit card containing such a component,

discharge all static electricity from yourself by wearing a wrist strap grounded through a one megohm

resistor. Some wrist straps, such as Emerson Network Power Part Number 631810600, have a built-in

one megohm resistor; no external resistor is necessary. Read and follow wrist strap manufacturer’s

instructions outlining use of a specific wrist strap.

3. Do not touch the traces or components on a printed circuit card containing static sensitive components.

Handle the printed circuit card only by the edges that do not have connector pads.

4. After removing a printed circuit card containing a static sensitive component, place the printed circuit card

only on conductive or anti-static material such as conductive foam, conductive plastic, or aluminum foil.

Do not use ordinary Styrofoam or ordinary plastic.

5. Store and ship static sensitive devices or printed circuit cards containing such components only in static

shielding containers.

6. If necessary to repair a printed circuit card containing a static sensitive component, wear an appropriately

grounded wrist strap, work on a conductive surface, use a grounded soldering iron, and use grounded

test equipment.

Page vi Static Warning

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 9

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

CHAPTER 1. GENERAL INFORMATION AND INSTALLATION CHECKLIST

CUSTOMER DOCUMENTATION PACKAGE

This document (IM581127000) provides Installation Instructions for NetSure™ Power

System Model 710NPBA, Spec. No. 581127000.

The complete Customer Documentation Package consists of…

Bound System Installation Manual

Power System Installation Instructions: IM581127000

Power System Quick Start Guide: QS581127000

Bound ACU+ Controller User Manual

ACU+ Controller User Instructions: UM1M820BNA

(includes instructions

for 1M820DNA Controller)

USB Drive with All Customer Documentation

Power System Installation Instructions: IM581127000

Power System Quick Start Guide: QS581127000

Power System User Instructions: UM581127000

Power System “System Application Guide”: SAG581127000

Power Data Sheet: PD588705200

(PD588705201, PD588705202,

PD588705203, PD588705204)

Rectifier Instructions: UM1R243000

Converter Instructions: UM1C24481500

Engineering Drawings

Also provided on the USB drive is an ACU+ configuration drawing and the ACU+

configuration files loaded into the ACU+ as shipped.

INSTALLATION ACCEPTANCE CHECKLIST

Provided below is an Installation Acceptance Checklist. This checklist helps ensure

proper installation and initial operation of the system. As the procedures presented in

Chapters 2 through 5 of this document are completed, check the appropriate box on this

list. If the procedure is not required to be performed for your installation site, also check

the box in this list to indicate that the procedure was read. When installation is done,

ensure that each block in this list has been checked. Some of these procedures may

have been factory performed for you.

Note: The system is not powered up until the end of this checklist.

Note: Some of these procedures may have been performed at the factory for you.

Chapter 1. General Information and Installation Checklist Page 1

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 10

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Chapter 2. Installing the System

Relay Rack Secured to Floor

System Components Mounted in Relay Rack (if required)

Optional Lug Adapter Busbar Kits Installed

Circuit Breakers Installed

Fuses Installed

Chapter 3. Setting Jumper and Switch Options

Jumpers on System Interface Circuit Card Set

Switch Setting on IB2 Interface Board Set

Switch Setting on Optional EIB Interface Board Set

Switch Setting on Optional SM-DU+ Set

Chapter 4. Making Electrical Connections

Relay Rack Grounding Connection (Frame Ground) Made

AC Input and AC Input Equipment Grounding Connections Made

External Alarm, Reference, Monitoring, and Control Connections Made

Ethernet Connection Made (if required)

Load Connections Made

Battery Connections Made

Batteries Installed and Connected in an optional Battery Tray (if furnished)

Optional Battery Tray Front Battery Covers Installed (if furnished)

Optional Battery Tray Circuit Breaker Guards Installed (if furnished)

Chapter 5. Installing the Modules and Initially Starting the System

Rectifier and Converter Modules Installed

System Started, Configured, and Checked

Page 2 Chapter 1. General Information and Installation Checklist

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 11

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

CHAPTER 2. INSTALLING THE SYSTEM

GENERAL REQUIREMENTS

This product is intended only for installation in a Restricted Access Location on or

above a non-combustible surface.

This product must be located in a Controlled Environment with access to Crafts

persons only.

This product is intended for installation in Network Telecommunication Facilities (CO,

vault, hut, or other environmentally controlled electronic equipment enclosure).

This product is intended for connection to the common bonding network in a Network

Telecommunication Facility (CO, vault, hut, or other environmentally controlled

electronic equipment enclosure).

The installer should be familiar with the installation requirements and techniques to

be used in securing the relay rack to the floor.

Clearance requirements are:

a) Recommended minimum aisle space clearance for the front of the relay rack is

2' 6".

b) Recommended minimum aisle space clearance for the rear of the relay rack is

2’ 0” for any of the following conditions:

1) Addition of a Module Mounting Assembly in the field.

2) Making AC input connections to the field expansion Module Mounting

Assembly.

For all other conditions, recommended minimum aisle space clearance for the rear of

the relay rack is that which is specified for proper module mounting assembly

ventilation. Refer to Module Mounting Assembly Power Data Sheet PD588705200

(PD588705201, PD588705202, PD588705203, PD588705204) for ventilation

spacing requirements.

Note: Minimum spacing specified for ventilation may not permit replacement of

certain components such as module mounting shelves.

SECURING THE RELAY RACK TO THE FLOOR

All equipment cabinets are factory mounted to the relay rack or shipping brackets

specified when ordered.

Secure the relay rack to the floor per site requirements. Refer to the General

Requirements section at the beginning of this chapter.

Ventilation Requirements

Refer to the General Requirements section at the beginning of this chapter.

Chapter 2. Installing the System Page 3

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 12

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

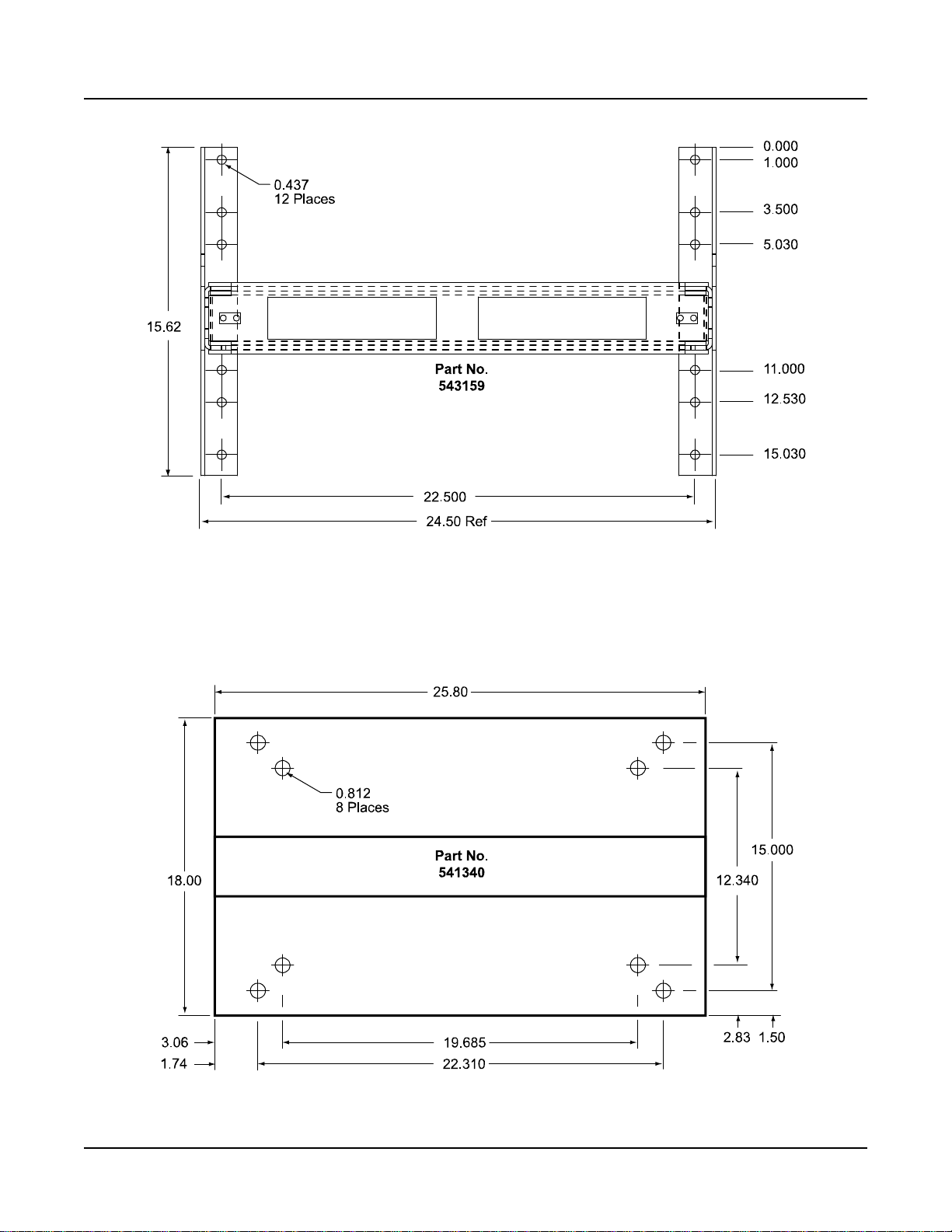

Relay Rack Floor Mounting Dimensions

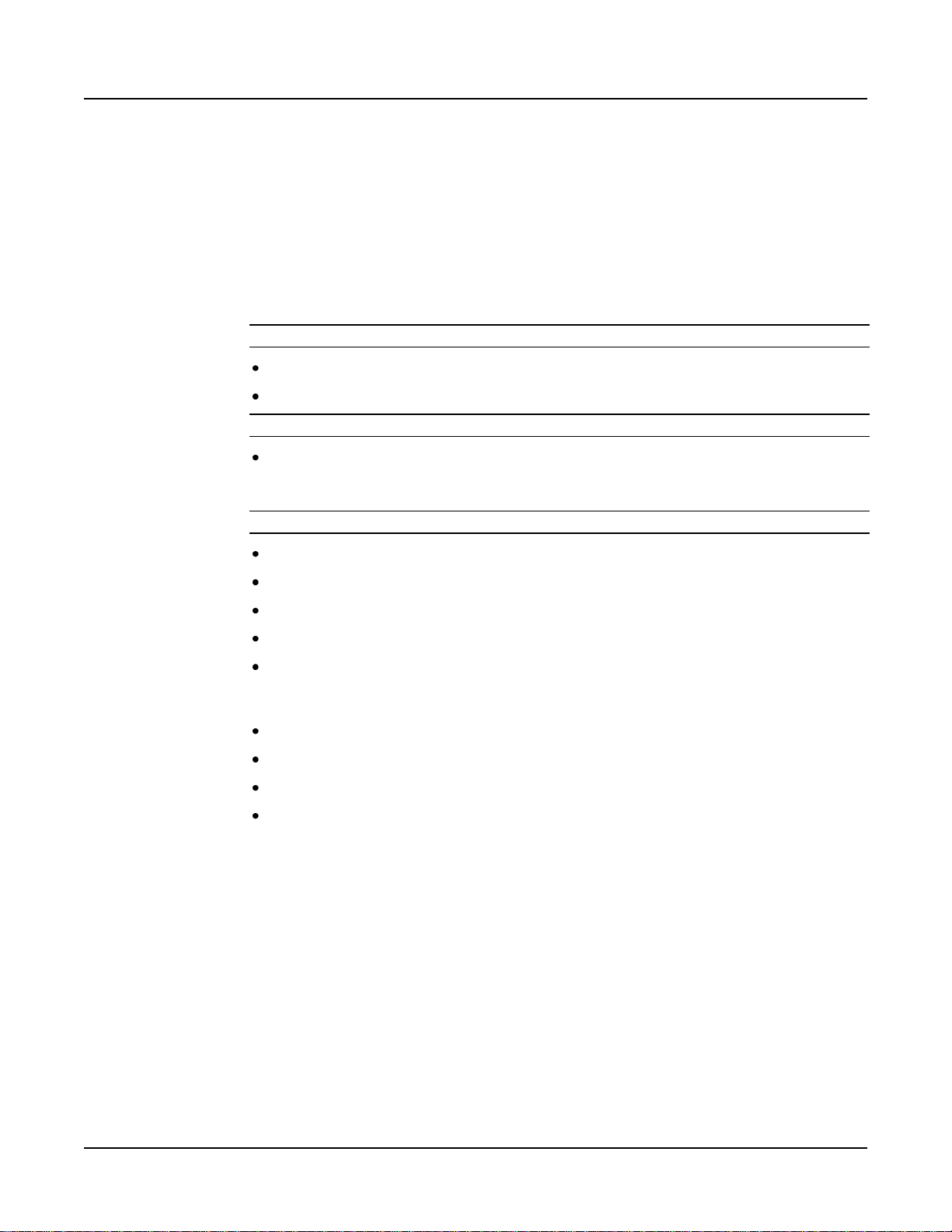

Refer to Figure 2-1 for relay rack floor mounting dimensions.

Figure 2-1 (cont’d on next page)

Relay Rack Floor Mounting Dimensions

Page 4 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 13

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Figure 2-1 (cont’d from previous page, cont’d on next page)

Relay Rack Floor Mounting Dimensions

Chapter 2. Installing the System Page 5

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 14

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

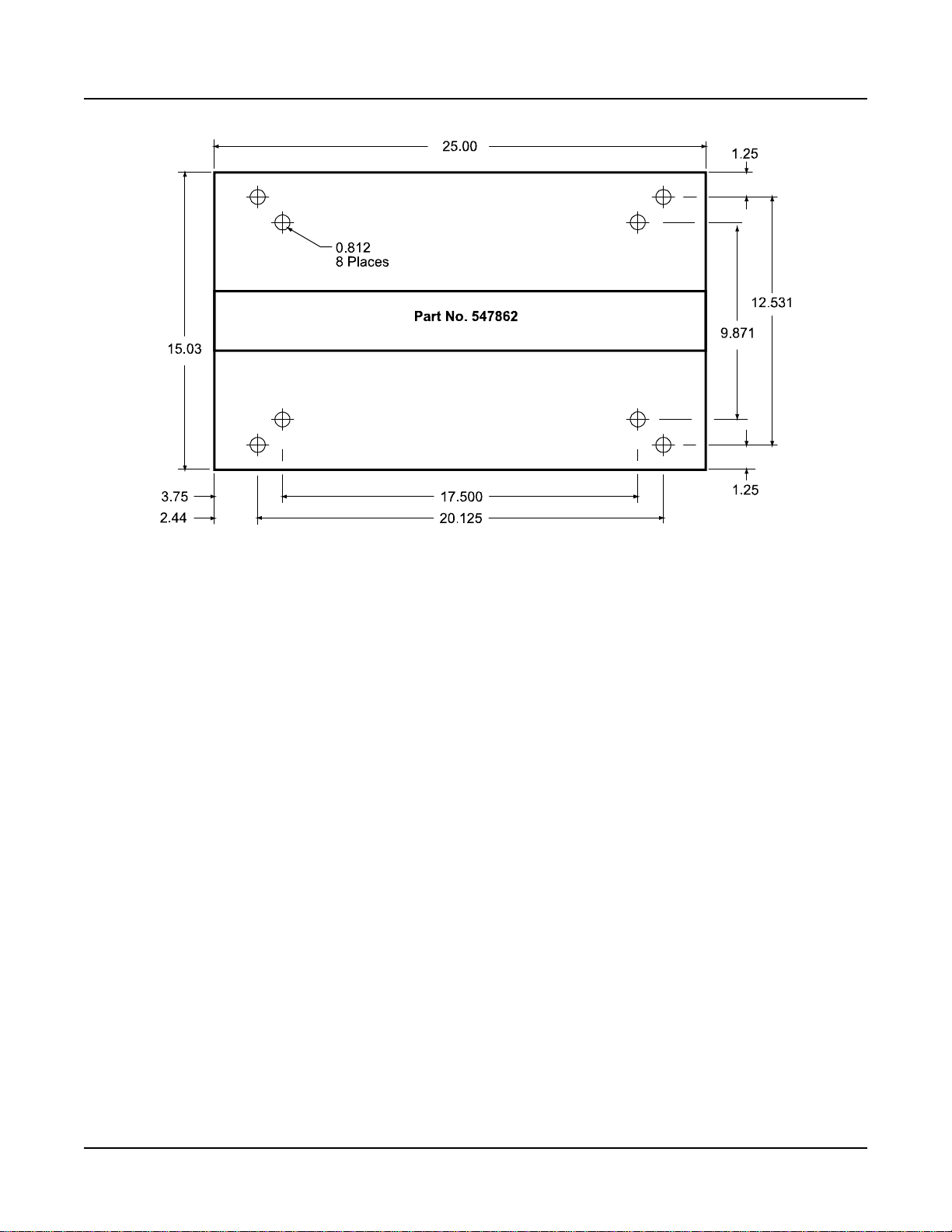

Figure 2-1 (cont’d from previous page)

Relay Rack Floor Mounting Dimensions

Page 6 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 15

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

MOUNTING SYSTEM COMPONENTS IN AN EQUIPMENT RACK

Note: If the power system was ordered in a relay rack, these procedures have been

performed at the factory.

This power system is designed to mount in a standard 23” relay rack having 1” or 1-3/4”

multiple drillings. Refer to System Application Guide SAG581127000 for overall

dimensions and a list of available relay racks.

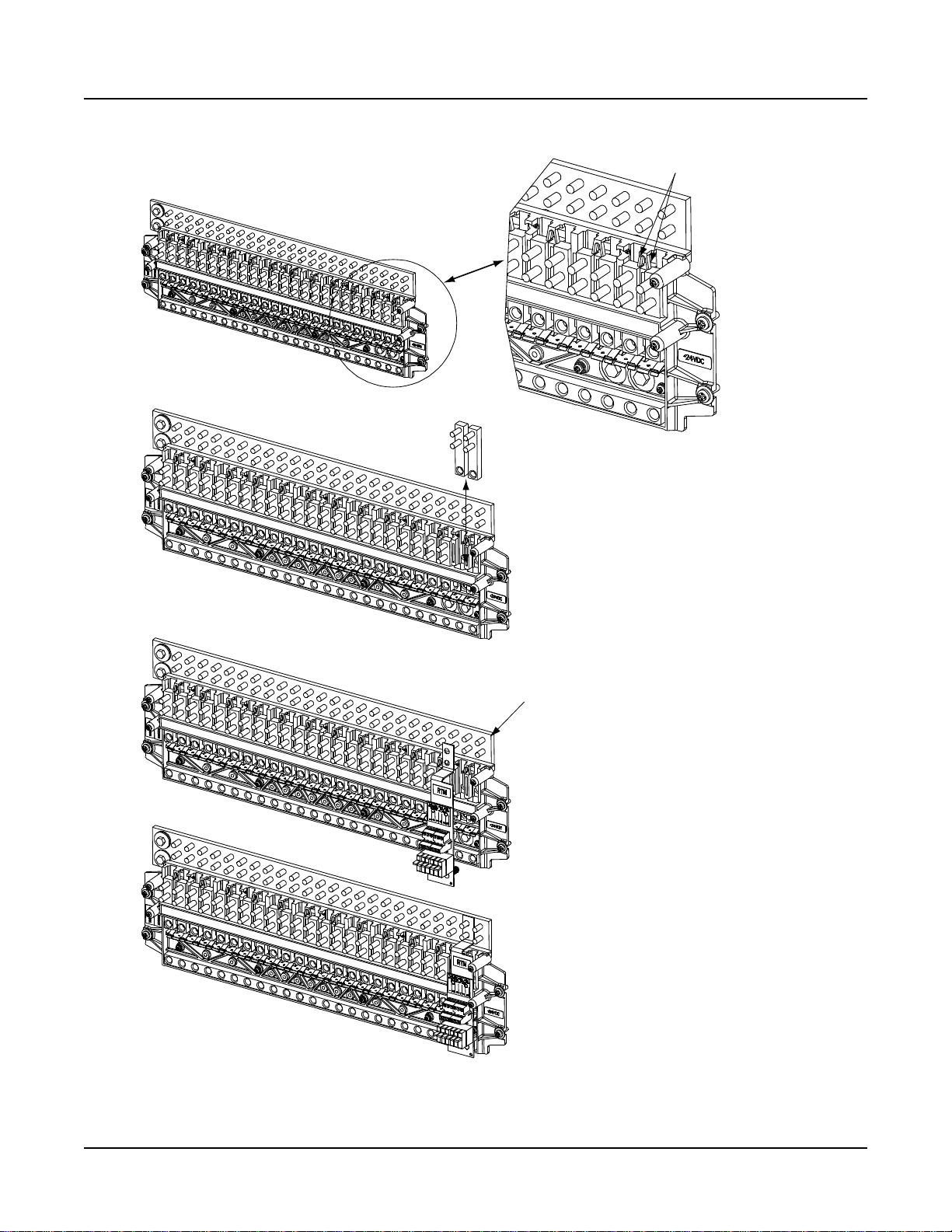

Mounting the Distribution Cabinet with Module Mounting Assembly

Note: The distribution cabinet is factory connected to the module mounting assembly.

The distribution cabinet with module mounting assembly is mounted as a

complete assembly.

The distribution cabinet with module mounting assembly must be the top-most

component in the rack. Perform the following steps to mount the distribution cabinet with

module mounting assembly.

Danger: The relay rack must be securely anchored to the floor before the

distribution cabinet with module mounting assembly is installed.

The distribution cabinet with module mounting assembly is heavy. Use a

hoist, battery lift, or other appropriate lifting device to raise and support

the assembly during the installation. Take appropriate precautions to

avoid injury.

Procedure

1) Remove the distribution cabinet with module mounting assembly from its

shipping brackets. Position the assembly in the equipment rack. Note that part

of the AC wireways will have to be temporarily removed from the distribution

cabinet to access the mounting hardware.

Note: Install the ground washers so the teeth dig into the paint on the mounting

angles. Torque all screws to 65 in-lbs.

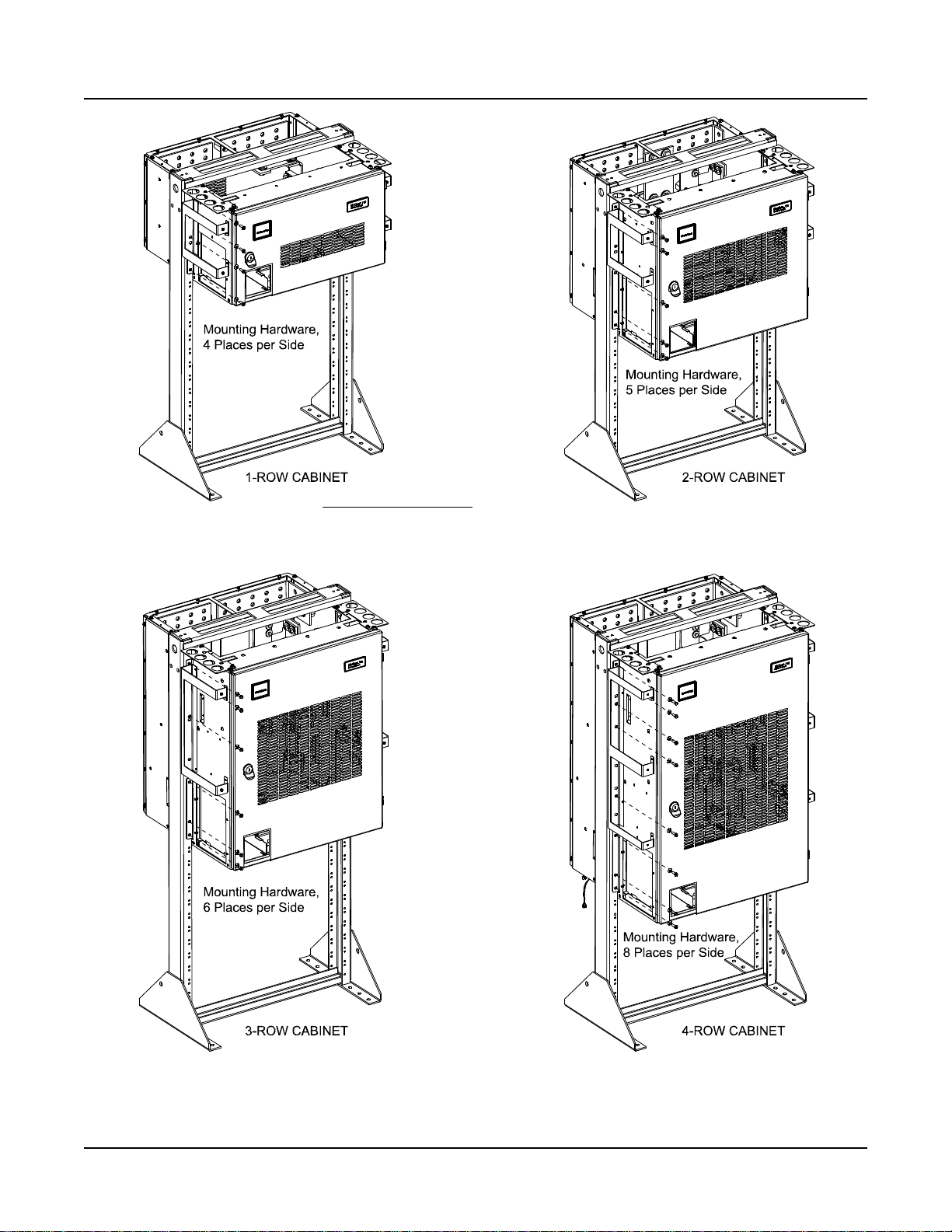

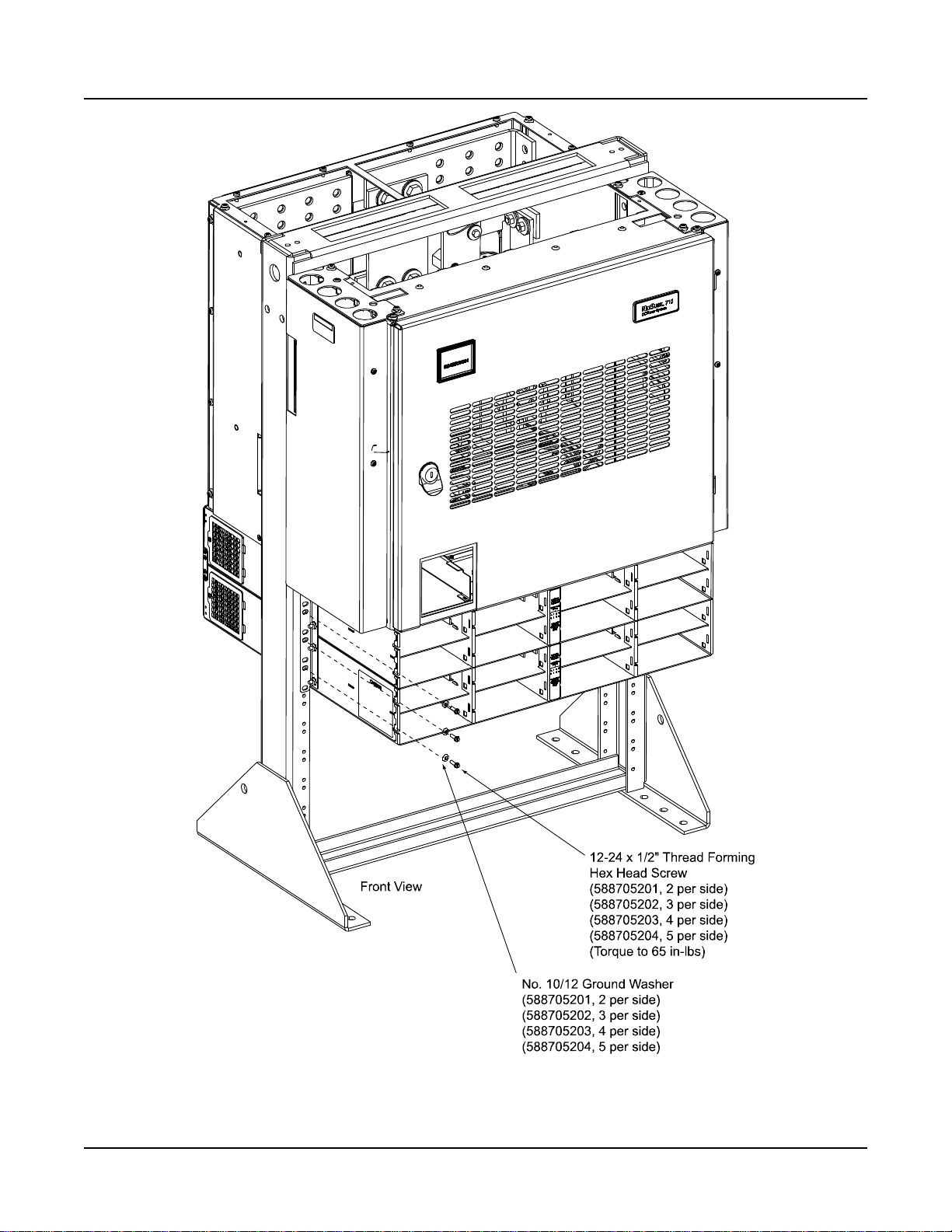

2) Mount the distribution cabinet to the relay rack using the following hardware.

Refer to Figure 2-2.

a) 1-Row Cabinet: Install (8) 12-24 x 1/2" hex head thread-forming screws

(P/N 218710500) and (8) No. 12 ground washers (P/N 215640600).

b) 2-Row Cabinet: Install (10) 12-24 x 1/2" hex head thread-forming screws

(P/N 218710500) and (8) No. 12 ground washers (P/N 215640600).

c) 3-Row Cabinet: Install (12) 12-24 x 1/2" hex head thread-forming screws

(P/N 218710500) and (14) No. 12 ground washers (P/N 215640600).

d) 4-Row Cabinet: Install (16) 12-24 x 1/2" hex head thread-forming screws

(P/N 218710500) and (16) No. 12 ground washers (P/N 215640600).

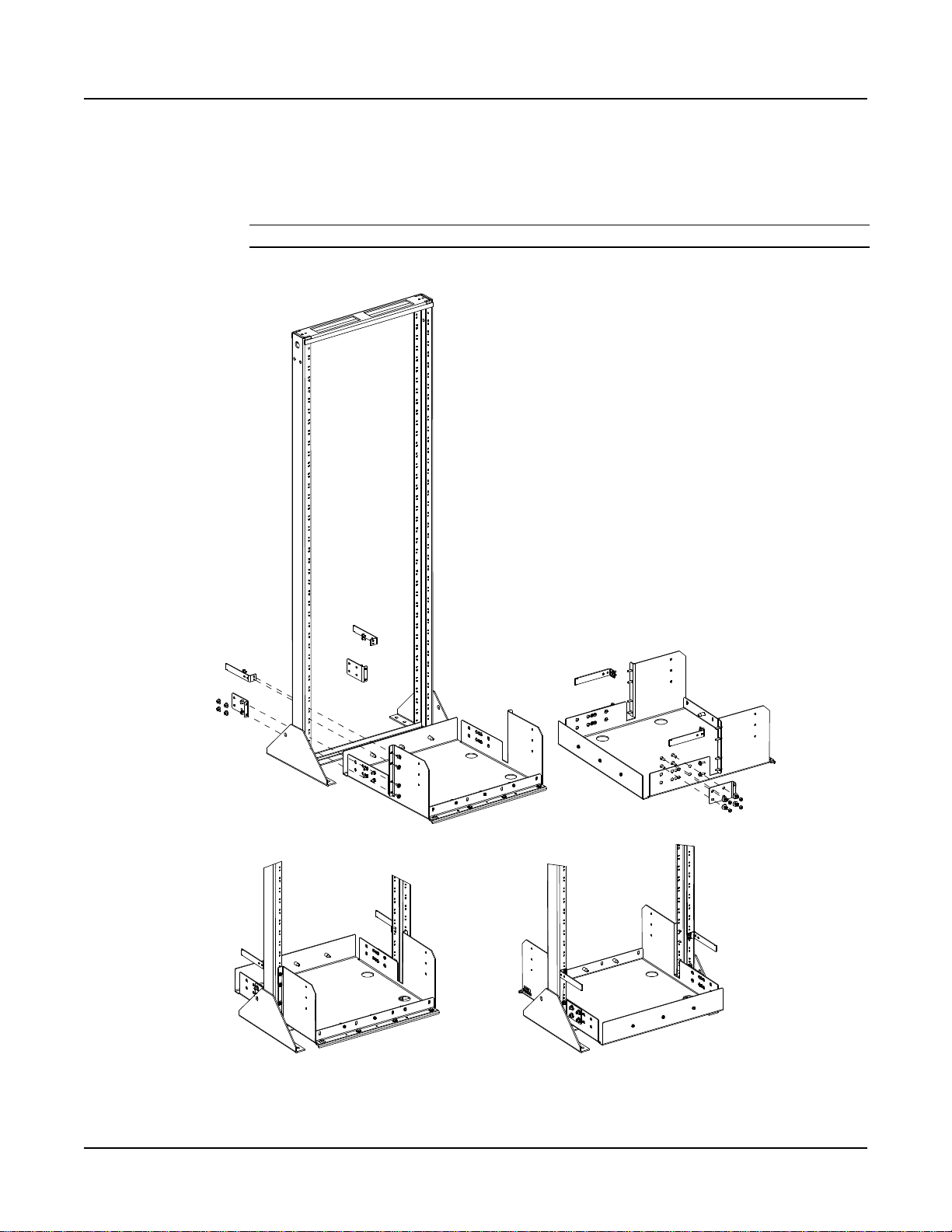

3) Mount the module mounting assembly to the relay rack using hardware as shown

Figure 2-3.

Chapter 2. Installing the System Page 7

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 16

IM581127000 Installation Instructions

MOUNTING HARDWARE

12-24 X1/2" THREAD FORMING HEX HEAD SCREW

NO. 12 GROUND WASHER

Module Mounting ShelfAssembly not shown for clarity only.

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Figure 2-2

Distribution Cabinet Mounting Hardware View

Page 8 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 17

Installation Instructions IM581127000

Secure the Module Mounting

Shelf to therelay rack.

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Figure 2-3

Module Mounting Assembly Mounting Hardware View

Chapter 2. Installing the System Page 9

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 18

IM581127000 Installation Instructions

Battery Tray

Rear

Angle

Bracket

Rear Angle Bracket

Cabling

Bracket

Front Rear

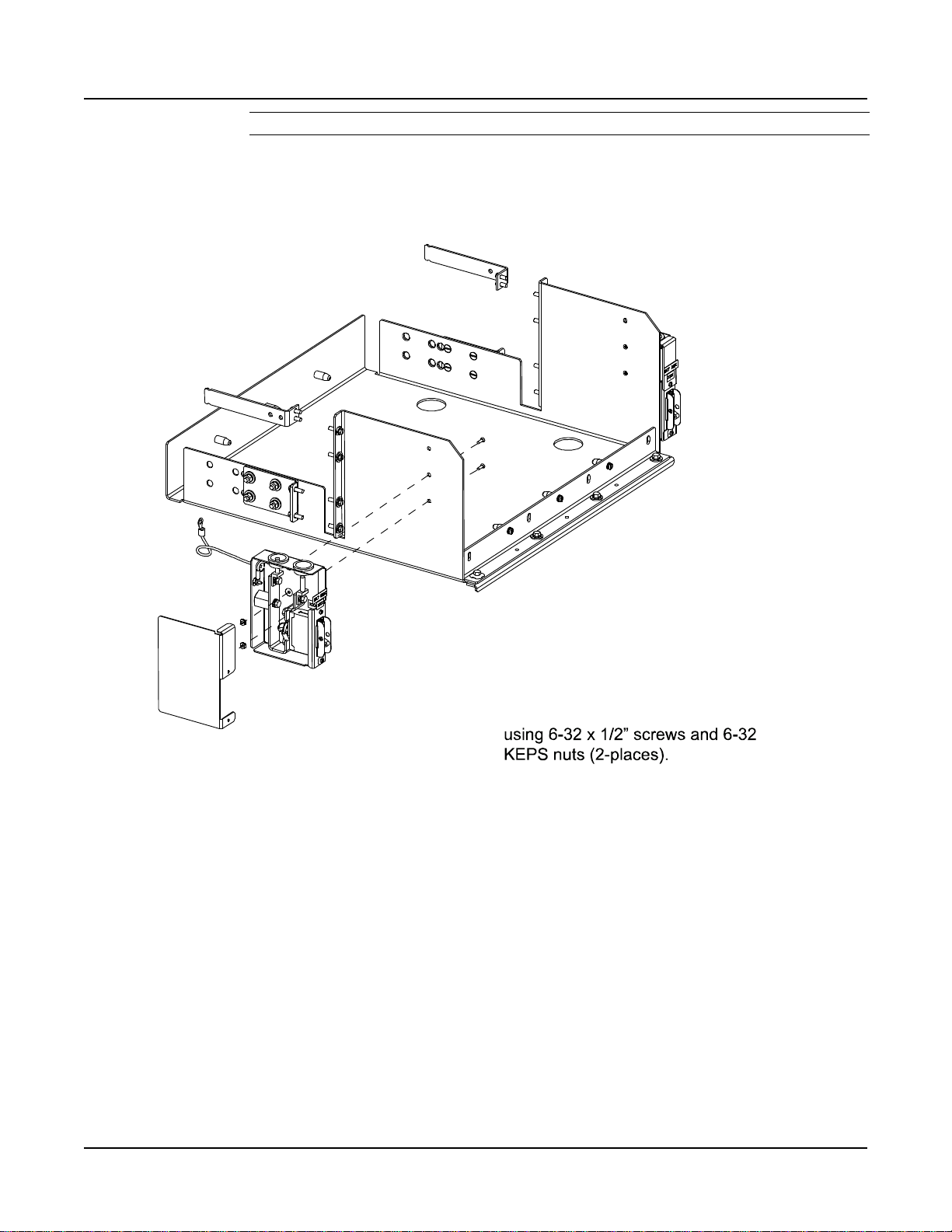

1. Slide battery tray into relay rack and

secure to relay rack with12-24 x 3/4"

thread forming hexhead screws and

#10/12 ground washers(1 place per

side) or #12flat washers (3 places per

side). (Torque to 70 in-lbs).

2. Secure rear angle brackets (both sides)

to battery traywith 1/4-20 x 3/4” bolts,

1/4” flat washers, 1/4” lockwashers, and

1/4” nuts. (Torque to 84 in-lbs).

3. Secure rear angle brackets (both sides)

to relay rackwith 12-24x 3/4" thread

forming hex head screws and #10/12

ground washers (1 place per bracket)

or #12 flat washers (1 place per bracket).

(Torque to70 in-lbs).

4. Secure cabling brackets (both sides) to

relay rack with 12-24 x1/2" thread forming

hex head screws.(Torque to 70 in-lbs).

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Installing a List 93 Battery Tray

Perform the following procedures to install a List 93 Battery Tray.

Danger: The relay rack must be securely anchored to the floor before a battery

tray is installed.

Installing a Battery Tray Procedure

1) To install a List 93 Battery Tray, perform the procedure in Figure 2-4.

Figure 2-4

Installing a List 93 Battery Tray

Page 10 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 19

Installation Instructions IM581127000

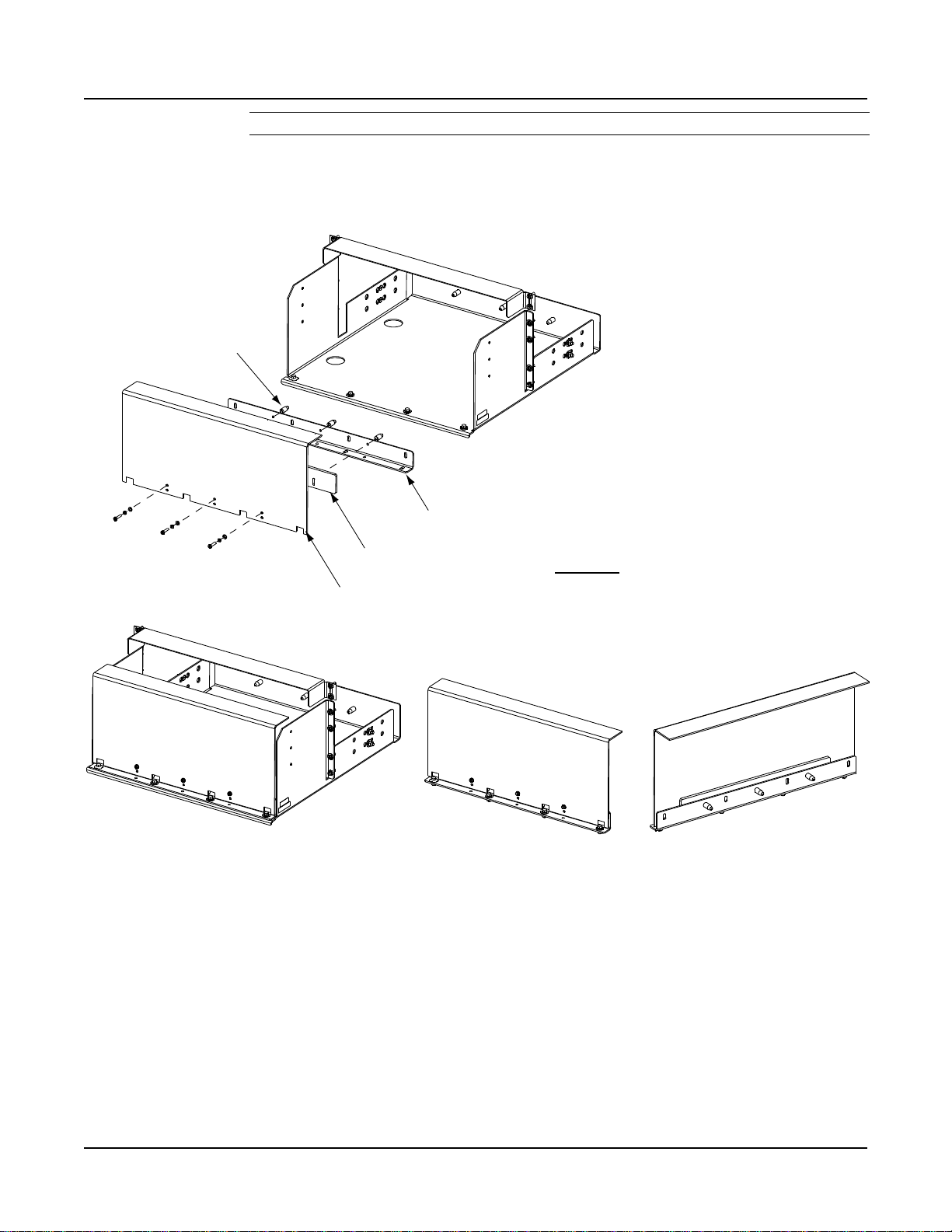

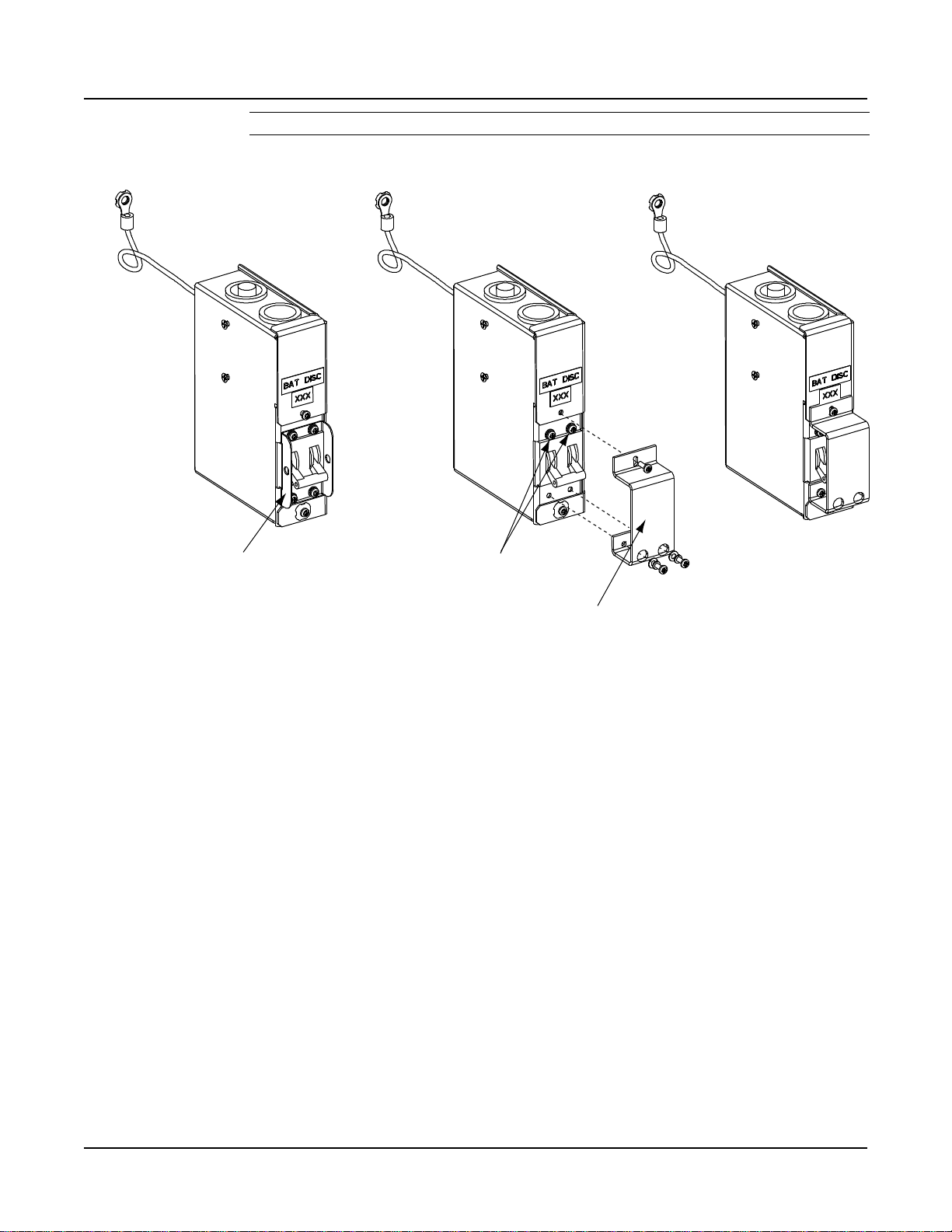

Battery Disconnect

Circuit Breaker Assembly

1. Remove the cover from the battery

disconnect circuit breaker assembly.

2. Secure the battery disconnect circuit

breaker assembly to the battery tray

3. Secure the ground lead under a battery

tray relay rack mounting bolt.

4. After wiring to the battery disconnect

circuit breaker, replace the cover.

5. Repeat for the other side of the battery

tray.

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Installing Optional Battery Disconnect Circuit Breakers Procedure

1) To install optional battery disconnect circuit breakers onto the List 93 Battery

Tray, perform the procedure in Figure 2-5.

2) Battery tray wiring is shown in “Installing and Connecting Batteries in List 93

Battery Tray” in Chapter 4. Making Electrical Connections.

Installing Optional Battery Disconnect Circuit Breakers onto a List 93 Battery Tray

Figure 2-5

Chapter 2. Installing the System Page 11

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 20

IM581127000 Installation Instructions

Assembled View

Kit Battery Cover

Assembled to Existing

Front Battery Bracket

Rear View

Kit Battery Cover

Assembled to Existing

Front Battery Bracket

Front View

Use kit supplied hardware.

Procedure

1. Install batteries.

2. Install kit battery cover to

existing front battery bracket.

3. Install kit battery cover with existing

front battery bracket to battery shelf.

Kit supplied cover.

Kit supplied spacer bar.

Existing front battery bracket.

Use existing

battery spacers.

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Installing Optional Front Battery Cover Procedure

1) To install an optional front battery cover onto a List 93 Battery Tray, perform the

procedure in Figure 2-6. Note that batteries must be installed first, as described

in “Installing and Connecting Batteries in List 93 Battery Tray” in Chapter 4.

Making Electrical Connections.

Installing Optional Front Battery Cover onto a List 93 Battery Tray

Figure 2-6

Page 12 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 21

Installation Instructions IM581127000

1. Remove this bracket. 2. Replace this hardware after

removing existing bracket.

3. Install Circuit Breaker

Guard Bracket using

existing hardware.

Installed View

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Installing Optional Circuit Breaker Guard Procedure

1) To install an optional circuit breaker guard onto a battery disconnect circuit

breaker, perform the procedure in Figure 2-7.

Figure 2-7

Installing Optional Circuit Breaker Guard

Chapter 2. Installing the System Page 13

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 22

IM581127000 Installation Instructions

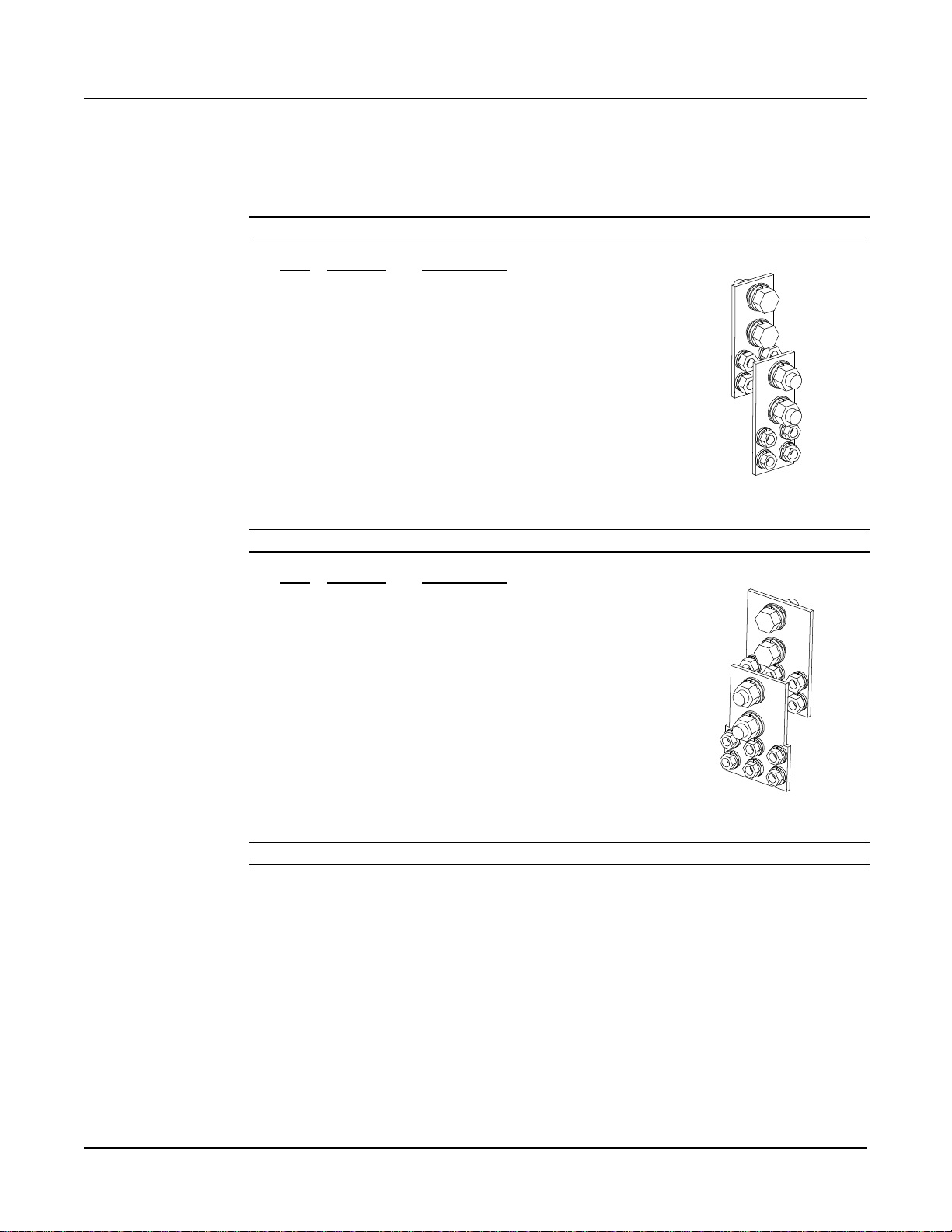

Qty.

Part No.

Description

1

534447

Busbar

1

534448

Busbar

8

214110100

Flat Washer, 1/4”

4

214112100

Flat Washer, 3/8”

8

215111100

Lock Washer, 1/4”

4

215111300

Lock Washer, 3/8”

4

227640400

Hex Head Bolt, 1/4-20 x 3/4”

(not used)

2

227646600

Hex Head Bolt, 3/8-16 x 1”

8

228557100

Nut, 1/4-20

2

228567100

Nut, 3/8-16

Qty.

Part No.

Description

1

514676

Busbar

1

514678

Busbar

12

214110100

Flat Washer, 1/4”

4

214112100

Flat Washer, 3/8”

12

215111100

Lock Washer, 1/4”

4

215111300

Lock Washer, 3/8”

6

227640400

Hex Head Bolt, 1/4-20 x 3/4”

(not used)

2

227646600

Hex Head Bolt, 3/8-16 x 1”

12

228557100

Nut, 1/4-20

2

228567100

Nut, 3/8-16

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

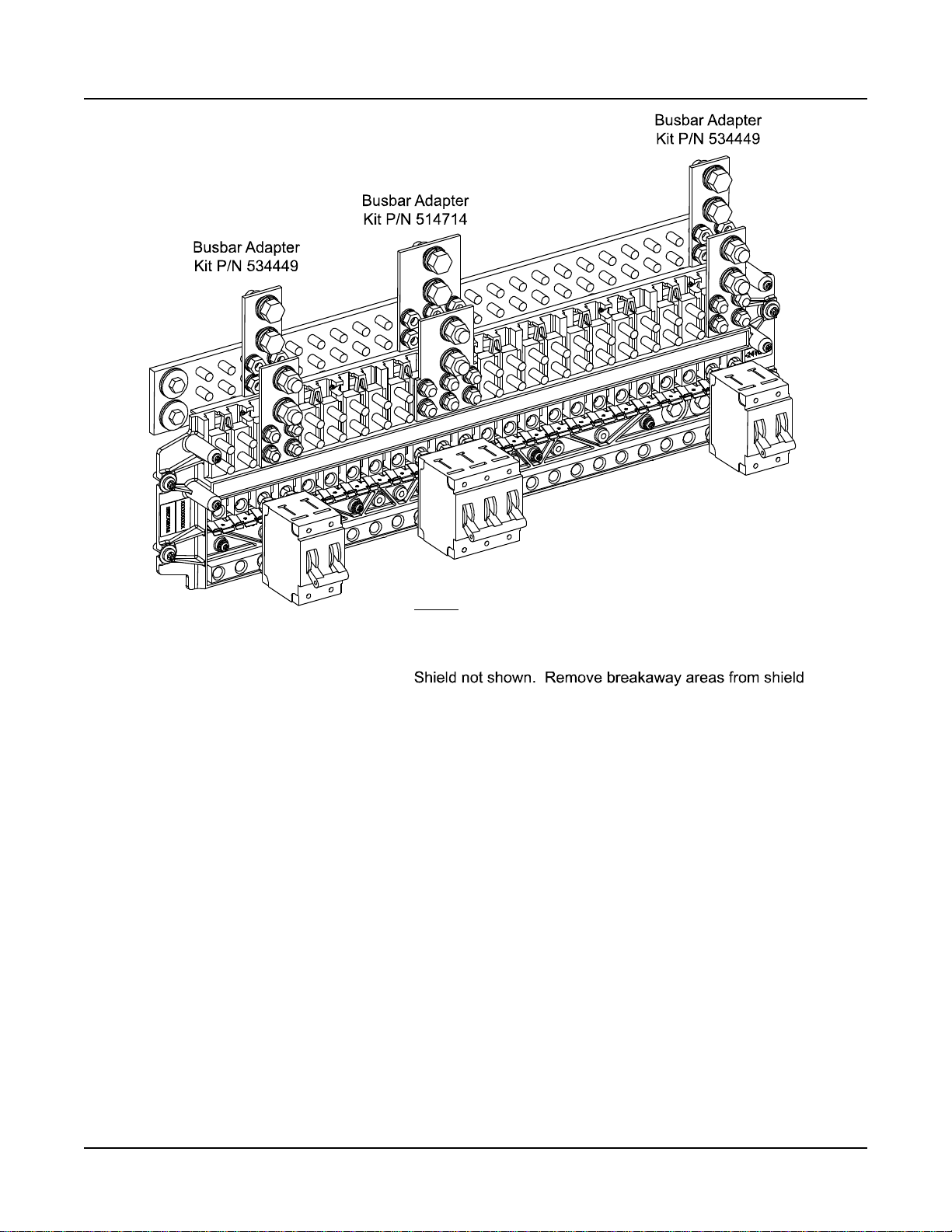

INSTALLING OPTIONAL LUG ADAPTER BUSBAR KITS, PART NOS. 534449 AND 514714

These kits provide lug adapter busbars plus hardware for use with 2-pole and 3-pole

circuit breakers.

Contents of Kit P/N 534449 (for 2-pole circuit breakers)

Contents of Kit P/N 514714 (for 3-pole circuit breakers)

Procedure

Perform the following steps to install the lug adapter busbars. Refer to Figure 2-8 as the

procedure is performed. Note also the restrictions on location in Figure 2-8.

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Install the lug adapter busbars as shown in Figure 2-8. Apply anti-oxidizing

compound to busbar mating surfaces before assembling. Recommended torque

is 72 in-lbs using the supplied 1/4” bolts and hardware.

Page 14 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

3) Orient the load lug hardware as shown in Figure 2-8. Recommended torque is

300 in-lbs using the supplied 3/8” bolts and hardware.

4) Close the distribution cabinet’s front door. Turn the latch clockwise to secure the

door.

Page 23

Installation Instructions IM581127000

Notes:

Orient busbars as shown.

as required. Breakaways are only provided forpositions

1-8, 9-12, and 23-24. This restricts 2 and 3-pole breaker

adapter kits to be located in thesepositions only.

Circuit breaker locations for reference only.

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Figure 2-8

Installing Lug Adapter Busbar Kits

Chapter 2. Installing the System Page 15

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 24

IM581127000 Installation Instructions

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

INSTALLING CIRCUIT BREAKERS AND FUSES

Circuit breakers and/or fuses may have been factory installed for you.

If so, verify their positions and sizes.

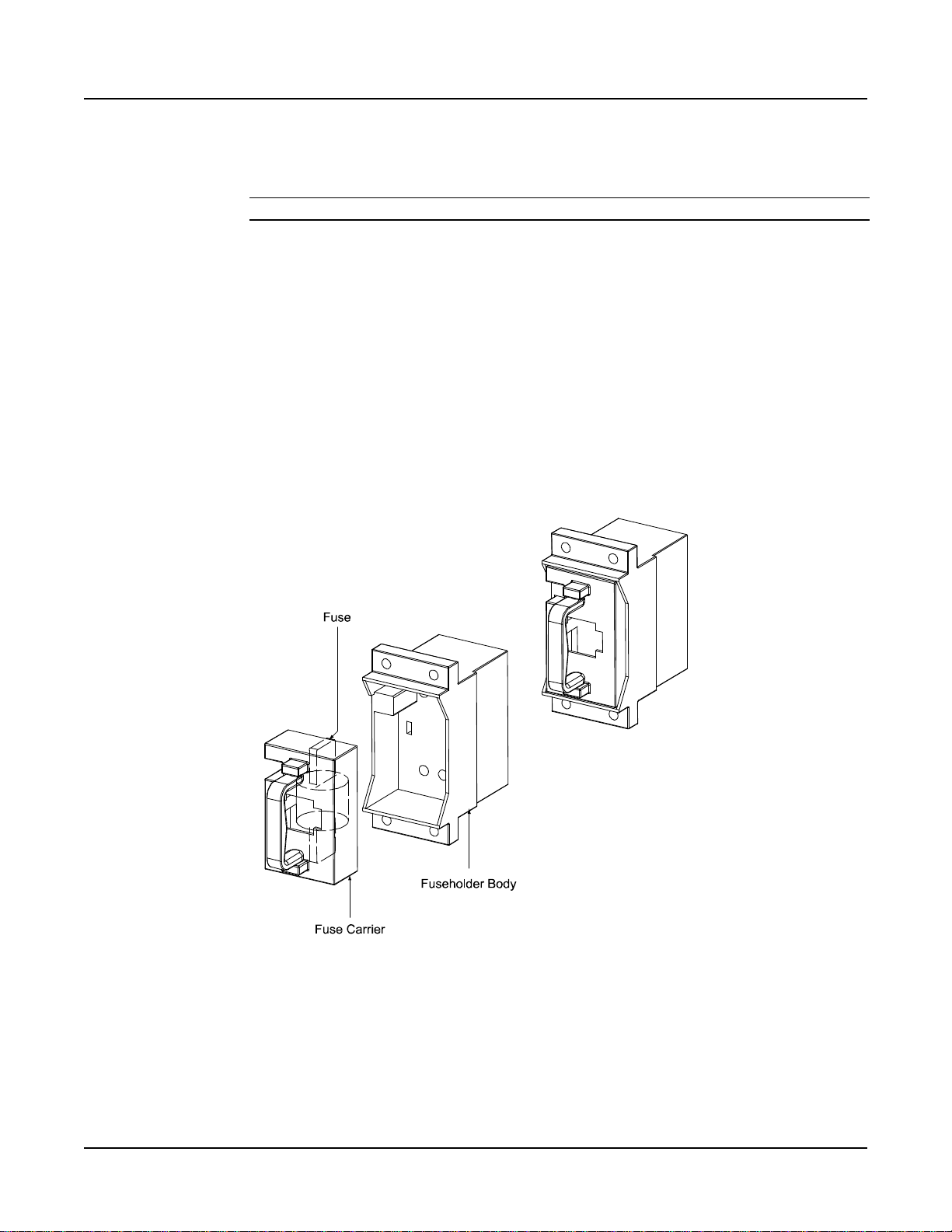

Installing Bullet Nose Type Fuseholders and TPS/TLS Fuses

Caution: A circuit breaker or fuse with a rating of 100A or greater SHALL HAVE an

empty mounting position between it and any other overcurrent protective

device.

Refer to the following procedure and install bullet nose type fuseholders and

appropriately sized TPS/TLS fuses into the proper mounting positions in the distribution

cabinet.

Procedure

Note: Refer to Figure 2-9 as this procedure is performed.

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Orient the fuseholder as shown in Figure 2-9. Insert the terminals on the rear of

the fuseholder into their corresponding sockets on the distribution panel. Ensure

the alarm contact on the back of the fuseholder makes contact with the alarm

terminal on the mounting circuit card. Push fuseholder in firmly until fully seated

in the distribution panel.

3) When all fuseholders are installed, install an appropriately sized TPS/TLS fuse in

each. To do this, remove the fuse carrier from the mounted fuseholder body by

pulling it straight out. Slide the fuse in place between the contacts of the fuse

carrier. When done, push the fuse carrier back into the fuseholder body. Note

that a polarizing key on the bottom of the carrier prevents the carrier from being

inserted upside down.

4) Verify that an 18/100 ampere alarm fuse is present in each fuseholder and that a

plastic safety cover is installed on this fuse.

5) Record all fuse sizes on the label provided on the shield.

6) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Page 16 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 25

Installation Instructions IM581127000

Fuseholder Assembly

Longer Side

to the Bottom

Shorter Side

to the Top

Fuse Carrier

Fuseholder Body

TPS/TLS Fuse

Polarizing Keyway

Matches Key on

Bottom of Fuse Carrier

Fuseholder Assembly

Exploded View

Fuseholder Assembly (P/N 117201)includes

body &carrier,alarm fuse,and alarmfuse safety cover.

Insert these terminals

into corresponding sockets

on distribution panel.

GMT-X

Safety Fuse Cover

(Replacement

P/N 248898700)

GMT-18/100A

Alarm Fuse

(Replacement

P/N 248610301)

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Chapter 2. Installing the System Page 17

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Installing a Bullet Nose Type Fuseholder and TPS/TLS Fuse

Figure 2-9

Page 26

IM581127000 Installation Instructions

Insert these terminals

into corresponding sockets

on distribution panel.

Longer Side

to the Bottom

Shorter Side

to the Top

Lettering on

handle must be

right side up.

Turn off

before installing.

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Installing Bullet Nose Type Circuit Breakers

Caution: A circuit breaker or fuse with a rating of 100A or greater SHALL HAVE an

empty mounting position between it and any other overcurrent protective

device.

Refer to the following procedure and install appropriately sized bullet nose type circuit

breakers into the proper mounting positions in the distribution cabinet.

Procedure

Note: Refer to Figure 2-10 as this procedure is performed.

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Ensure that the circuit breaker is in the OFF position and is of the correct rating.

Orient the circuit breaker as shown in Figure 2-10. Insert the terminals on the

rear of the circuit breaker into their corresponding sockets on the distribution

panel. Ensure the alarm contact on the back of the circuit breaker makes contact

with the alarm terminal on the mounting circuit card. Push distribution device in

firmly until fully seated in the distribution panel.

3) Record all circuit breaker sizes on the label provided on the shield.

4) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Page 18 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-10

Installing a Bullet Nose Type Circuit Breaker

Page 27

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Installing an Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block

Note: Refer to Figure 2-11 as this procedure is performed.

Procedure

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Follow the steps in Figure 2-11.

3) Install an appropriately sized GMT fuse in each fuse mounting position on the

GMT Distribution Fuse Block as required. If dummy fuses are installed, first

remove the dummy fuse.

a) Verify that dummy fuses are installed in all unused fuse positions on the

GMT distribution fuse block.

b) Verify that a plastic safety cover is installed on all GMT fuses on the GMT

distribution fuse block.

4) Record all fuse sizes (installed on the GMT distribution fuse block) on the label

provided on the shield.

5) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Chapter 2. Installing the System Page 19

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 28

IM581127000 Installation Instructions

Press in tabs to release

lug terminalbusbars for

positions to be occupied

by GMTFuse Block.

Remove twolug terminal busbars

for positions to be occupied

by GMTFuse Block.

Plug inGMT Fuse Block and secure

at twolocations on the RTN bar.

Torque to 72 in-lbs.

RTN Bar

GMT Fuse Block InstalledView

1.

2.

3.

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Figure 2-11

Installing an Optional Bullet Nose Type 6-Position GMT Distribution Fuse Block

Page 20 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 29

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Installing TPH Fuses

Refer to the following procedure and install appropriately sized TPH fuses into the proper

fuseholders in the distribution cabinet.

Procedure

Note: Refer to Figure 2-12 as this procedure is performed.

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Remove the TPH fuse carrier from the mounted fuseholder body by grasping its

handle and firmly pulling it straight out. Install the TPH fuse into the fuse carrier.

When done, push the fuse carrier securely back into the mounted fuseholder

body.

3) Verify that a 1/4 ampere alarm fuse is installed in the GMT-type fuseholder

located adjacent to the TPH fuseholder and that a plastic safety cover is install

on this fuse.

4) Record all fuse sizes on the cards provided within the fuseholders.

5) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Figure 2-12

Installing a TPH Fuse

Chapter 2. Installing the System Page 21

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 30

IM581127000 Installation Instructions

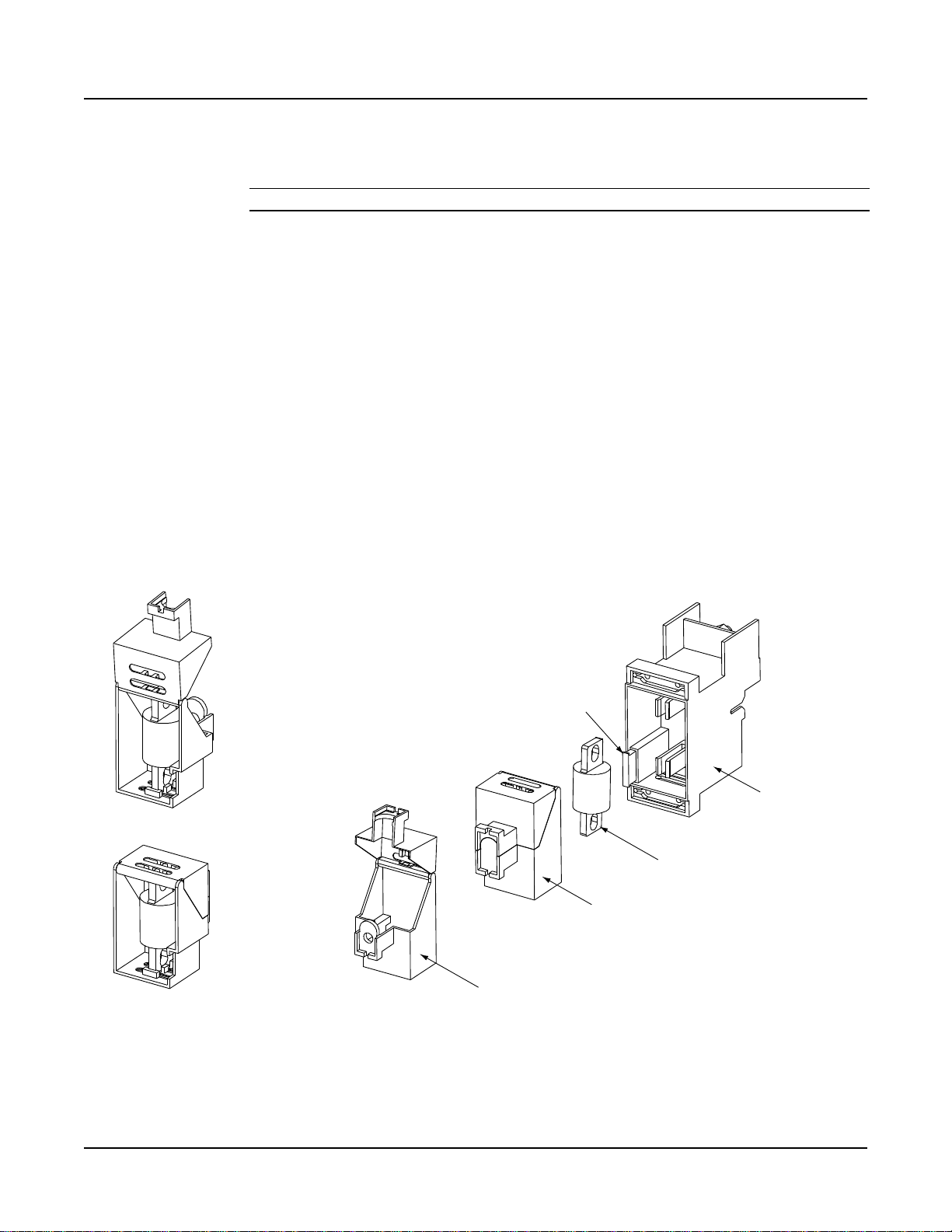

Fuse Case

Open FuseCase View

TPL Fuse

Fuse Installedin

Open FuseCase

(rear view)

Fuse Installedin

Closed Fuse Case

(rear view)

Fuseblock

(P/N 516241)

GMT-18/100AAlarm Fuse

(P/N 248610301) and

GMT-X Safety Fuse Cover

(P/N 248898700)

(Both are provided

w/ fuseblock)

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Installing TPL-B Fuses

Refer to the following procedure and install appropriately sized TPL-B fuses into the

proper fuseholders in the distribution cabinet.

Procedure

Note: Refer to Figure 2-13 as this procedure is performed.

1) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

2) Remove the fuse case from the mounted fuse block by grasping its handle and

pulling it straight out.

3) Verify that an 18/100 ampere alarm fuse is present in the GMT-type fuseholder

located on the fuse block and that a plastic safety cover is installed on this fuse.

4) Open the fuse case.

5) Install the TPL fuse into the fuse case.

6) Close the fuse case.

7) Firmly plug the fuse and fuse case into the fuse block.

8) Record all fuse sizes on the cards provided within the fuseholders.

9) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Page 22 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-13

Installing TPL-B Fuses

Page 31

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

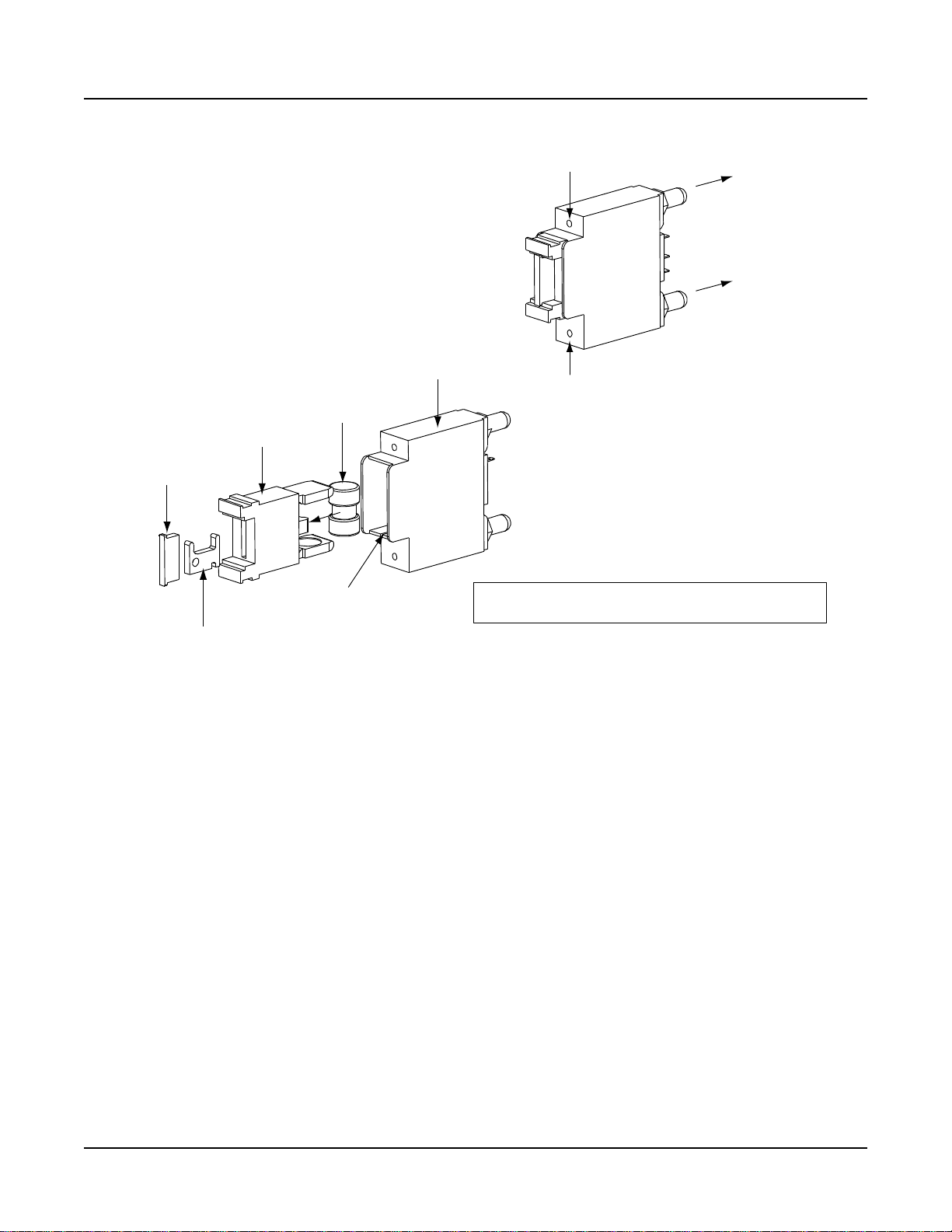

Installing GJ/218 Circuit Breakers

Refer to the following procedure and install appropriately sized GJ/218 circuit breakers

into the proper mounting positions in the distribution cabinet.

Procedure

Note: Refer to Figure 2-14 as this procedure is performed.

1) Locate the appropriate circuit breaker mounting kit ordered with the circuit

breaker. The circuit breaker mounting kit contains installation hardware, an

alarm jumper, a shunt jumper (if applicable), a busbar (for 2- and 3-pole circuit

breakers), and a circuit breaker guard. Refer to SAG581127000 for part

numbers of the circuit breaker mounting kits.

2) Open the distribution cabinet’s front door by turning the latch in the

counterclockwise position.

3) Ensure that the circuit breaker is in the OFF position, and is of the correct rating

and type (electrical trip/mechanical trip or electrical trip only). Apply antioxidizing compound to busbar mating surfaces on the distribution panel and the

circuit breaker. Orient the circuit breaker over its mounting location.

a) Attach the alarm jumper connectors to the back of the circuit breaker, then

plug the other end of the alarm jumper into its corresponding connector.

Wiring diagrams are provided in Figure 2-14 and at the end of this procedure.

b) Shunted Breakers Only: Attach the shunt jumper connectors to the back of

the circuit breaker, then route the jumper through the hole in the distribution

panel. Wiring diagrams are provided in Figure 2-14, Figure 2-15, and Figure

2-16.

Danger: The bolts being installed in the following step may be at system

potential. Use insulated tools.

4) Install the circuit breaker into its mounting position and secure with the provided

hardware. Torque to 60 in-lbs.

5) Install the circuit breaker guard and label (refer to Figure 2-14).

6) 2-Pole and 3-Pole Circuit Breakers Only: Install the mounting kit supplied

busbar as shown in Figure 2-14. Torque to 180 in-lbs.

7) Shunted Breakers Only: Route and connect shunt leads to the SM-DU+ and

Shunt Interface Assembly.

8) Record all circuit breaker sizes on the label provided on the shield.

9) Close the distribution cabinet's front door. Turn the latch clockwise to secure the

door.

Chapter 2. Installing the System Page 23

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 32

IM581127000 Installation Instructions

1/4" Hardened

Flat Washer

1/4" Belleville

Lock Washer

1/4-20 x 3/4” Bolt

(2 places)

Torque to 60 in-lbs.

OFF

ON

Apply anti-oxidizing compound to busbar mating

surfaces before mounting circuit breakers.

INSTALLING CIRCUITBREAKER GUARD

INSTALLING CIRCUITBREAKER

Alarm jumper connector.

Holes toroute shunt jumper through (if applicable).

ALARM WIRING(BREAKERS W/OUT SHUNTS)

ALARM WIRING (BREAKERS WITH SHUNTS)

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Page 24 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-14 (cont’d on next page)

Installing a GJ/218 Circuit Breaker (1-Pole)

Page 33

Installation Instructions IM581127000

1/4" Hardened

Flat Washer

1/4" Belleville

Lock Washer

1/4-20 x3/4” Bolt

(4 places)

Torque to 60 in-lbs.

Apply anti-oxidizing compound to busbar mating

surfaces before mounting circuit breakers.

OFF

ON

INSTALLING CIRCUITBREAKER GUARD

INSTALLING CIRCUITBREAKER

Alarm jumper connectors.

Holes toroute shunt jumper through (if applicable).

ALARM WIRING(BREAKERS W/OUT SHUNTS)

ALARM WIRING (BREAKERS WITH SHUNTS)

Busbar

2-pole breaker shown.

3-pole and 4-pole breakers similar.

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Installing a GJ/218 Circuit Breaker (2-Pole, 3-Pole, 4-Pole)

Chapter 2. Installing the System Page 25

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 2-14 (cont’d from previous page)

Page 34

IM581127000 Installation Instructions

List AC Only

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Figure 2-15

GJ/218 Circuit Breaker Wiring Diagram (List AC and AD)

Page 26 Chapter 2. Installing the System

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 35

Installation Instructions IM581127000

List BC Only

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Figure 2-16

GJ/218 Circuit Breaker Wiring Diagram (List BC and BD)

Chapter 2. Installing the System Page 27

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

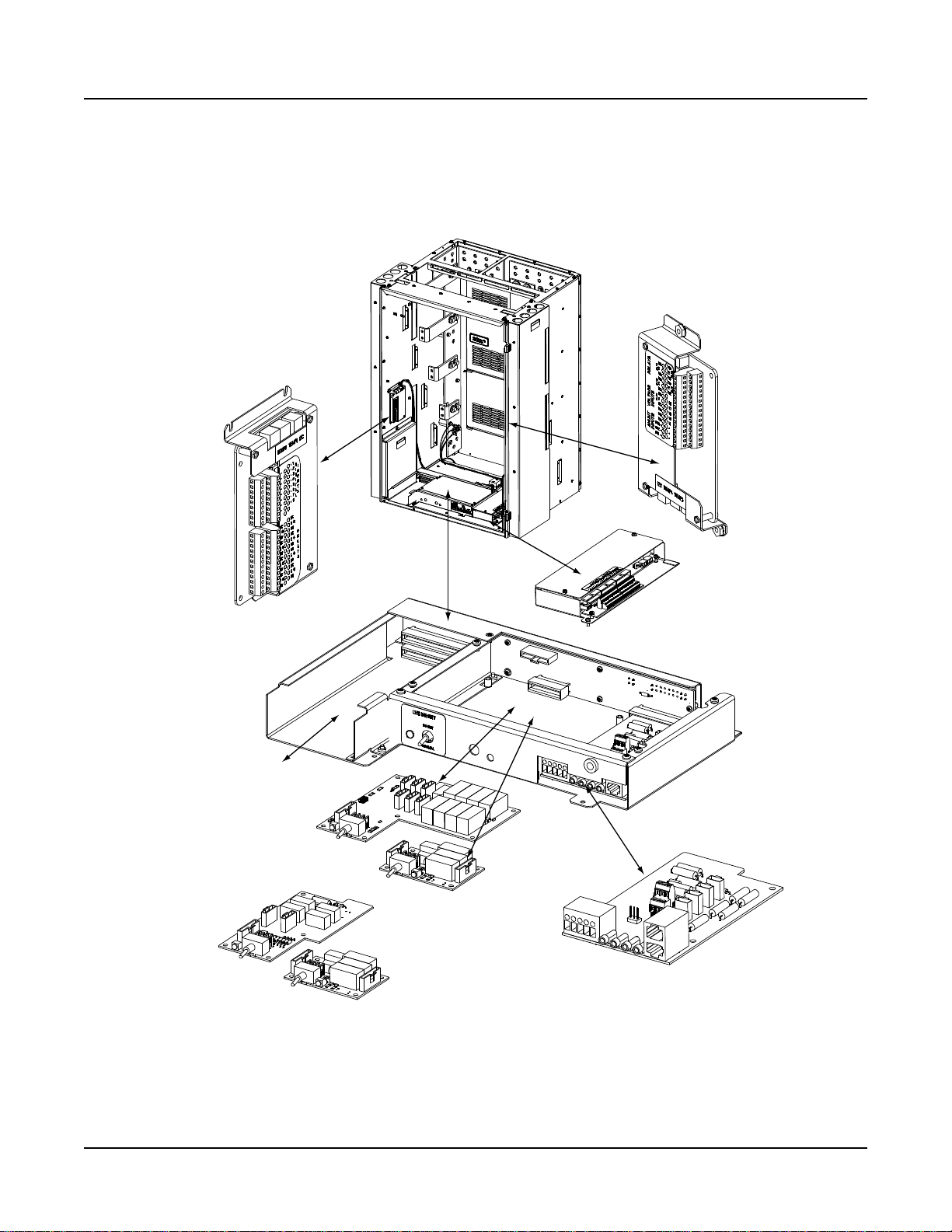

Page 36

IM581127000 Installation Instructions

IB2

(ACU+ Interface Board)

(located on inside sidepanel)

Optional EIB

(ACU+ Extended Interface Board)

(located on inside sidepanel)

Optional SM-DU+ and

Shunt Interface Board

4-Row Cabinet Shown,

Others Similar

(Front Door Removed in

Illustration for Clarity)

ACU+ Controller

Mounting Position

System Interface

Circuit Card

OR

Optional Manual Battery

Disconnect Circuit Card

Optional LVD

Driver Circuit Card

Optional LVD Driver

Lite Circuit Card

Optional Manual Battery

Disconnect Circuit Card

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

CHAPTER 3. SETTING JUMPERS AND SWITCH OPTIONS

CIRCUIT CARD LOCATIONS

Refer to Figure 3-1.

Figure 3-1

Page 28 Chapter 3. Setting Jumpers and Switch Options

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Circuit Card Locations

Page 37

Installation Instructions IM581127000

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

JUMPERS ON SYSTEM INTERFACE CIRCUIT CARD

Perform the following procedures to verify the factory settings and/or make the required

settings per your site requirements. These procedures can also be used to make

adjustments on a replacement circuit card.

Controller Power Option

The controller is always powered from the internal “system” bus. A jumper option allows

the controller to be also powered by battery. Battery power allows the controller to stay

running in the event rectifiers are off or battery LVD opens (if installed). Note that if

powering the controller from battery, the battery will drain if rectifiers are off or battery

LVD opens (if installed). The controller’s power consumption is 5W.

Procedure

1) Refer to Figure 3-2 and place the jumper on J8 in the “Battery Pwr” or “No

Battery Pwr” position.

Internal/External Battery Monitoring

Selects to monitor (and display via the controller) battery voltage from either an “internal”

or “external” source.

Procedure

1) Refer to Figure 3-2 and place the jumper on J10 in the “Internal” or “External”

position. If “External” is selected, connect sense leads to TB1-4 and TB1-5 (see

Figure 3-2).

Chapter 3. Setting Jumpers and Switch Options Page 29

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 38

IM581127000 Installation Instructions

J8

Selects to power Controller

from “Battery Power” or not.

Shorting Jumper

No

Battery

Pwr

Battery

Pwr

External Internal

J8

J10

1

2

3

7

8

9

3 2 1

J10

Battery Monitoring External /Internal

(see TB1-4 and TB1-5 for

external monitoring points)

1

1A 2A 3A

1B 2B 3B

5

Shorting Jumper

J1

J2

J3

J4

J8

TB2

TB1

TP1 TP2 TP3 TP4

J10

J5

TB1-4: External Battery Monitoring (-)

TB1-5: External Battery Monitoring (+)

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Page 30 Chapter 3. Setting Jumpers and Switch Options

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 3-2

System Interface Circuit Card Jumper Locations

Page 39

Installation Instructions IM581127000

Setting

DIP Switch SW1

1

2

IB2

OFF

OFF

Setting

DIP Switch SW1

1

2

EIB

ON

OFF

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

SWITCH SETTINGS ON IB2 INTERFACE BOARD

Dip Switch SW1 on the IB2 board is used to set the communications address for this

board. Refer to Table 3-1 for SW1 settings. Refer to Figure 3-3 for SW1 location.

Perform the following procedure to verify the factory settings. This procedure can also be

used to make adjustments on a replacement circuit card.

Procedure

1) Ensure SW1 is set per Table 3-1. Refer to Figure 3-3 for location.

Table 3-1

IB2 Interface Board Switch Settings

SWITCH SETTING ON OPTIONAL EIB INTERFACE BOARD

Dip Switch SW1 on the EIB board is used to set the communications address for this

board. Refer to Table 3-2 for SW1 settings. Refer to Figure 3-4 for SW1 location.

Perform the following procedure to verify the factory settings. This procedure can also be

used to make adjustments on a replacement circuit card.

Procedure

1) Ensure SW1 is set per Table 3-2. Refer to Figure 3-4 for location.

Table 3-2

Optional EIB Interface Board Switch Settings

Chapter 3. Setting Jumpers and Switch Options Page 31

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Page 40

IM581127000 Installation Instructions

J12

SW1

J2

J11

J9 J8 J7

J6

J5 J4 J3

IB2 Interface Board

(Top View)

Switch SW1 is located in

this corner of the IB2Board.

on

ON

off

OFF

1 2

1 2

SW1

In this system, switch settings

must be in positions shown.

SW1

Setting

DIP Switch SW1

1 2

IB2 OFF OFF

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

Page 32 Chapter 3. Setting Jumpers and Switch Options

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 3-3

IB2 Interface Board Switch Location and Settings

Page 41

Installation Instructions IM581127000

SW1

In this system, switch settings

must be in positions shown.

Optional EIB Interface Board

(Top View)

Switch SW1 is located in

this corner of the EIBBoard.

SW1

on

off

12

ON

OFF

12

SW1

Setting

DIP Switch SW1

2 1

EIB OFF ON

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Chapter 3. Setting Jumpers and Switch Options Page 33

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 3-4

Optional EIB Interface Board Switch Location and Settings

Page 42

IM581127000 Installation Instructions

SM-DU+ and

Shunt Interface Board

SM-DU+

Switches SW1 and SW2 arelocated

in this corner of theSM-DU+.

SW1 SW2

on

5 6 7 81 2 3 4

off

on

5 6 7 81 2 3 4

off

pow er

can RS485 RS4 85

SHUNT SHUNT FUSE

RS2 32

SW1 SW2

J1

J7 J8 J6

J3 J4 J4A

J5

ON

OFF

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

Red Indicator

Yellow Indicator

GreenIndicator

SW1 and SW2

In this system, switch settings

must be inthe positions shown.

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

SWITCH SETTING ON SM-DU+

SM-DU+ uses two (2) 8-bit switches for parameter setting (SW1 and SW2). Refer to

Table 3-3 for SW1 and SW2 settings. Refer to Figure 3-5 for SW1 and SW2 locations.

Perform the following procedure to verify the factory settings. This procedure can also be

used to make adjustments on a replacement circuit card.

Procedure

1) Ensure SW1 and SW2 are set per Table 3-3. Refer to Figure 3-5 for location.

Page 34 Chapter 3. Setting Jumpers and Switch Options

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Figure 3-5

Optional SM-DU+ Switch Location and Settings

Page 43

Installation Instructions IM581127000

DIP Switch SW1

Reserved

HW/

SW

Shunt

Voltage

Shunt

Current

Description

of Status

1 2 3 4 5 6 7

8

NA

OFF

NA

Shunt parameter is set through DIP switch.

ON

Shunt parameter is set through software (note 1).

NA

OFF

OFF

NA

Shunt Voltage: 25mV (note 1)

OFF

ON

Shunt Voltage: 50mV

ON

OFF

Shunt Voltage: 60mV

ON

ON

Shunt Voltage: 75mV

NA

OFF

OFF

OFF

Shunt Current: 500A (note 1)

OFF

OFF

ON

Shunt Current: 100A

OFF

ON

OFF

Shunt Current: 200A

OFF

ON

ON

Shunt Current: 300A

ON

OFF

OFF

Shunt Current: 400A

ON

OFF

ON

Shunt Current: 1000A

ON

ON

OFF

Shunt Current: 1500A

ON

ON

ON

Shunt Current: 2000A

DIP Switch SW2

Reserved

Communications

Address

Baud

Rate

Description

of Status

1 2 3 4 5 6 7

8

NA

OFF

OFF

OFF

NA

Address 1# (Setting for SM-DU+ in this system)

OFF

OFF

ON

Address 2#

OFF

ON

OFF

Address 3#

OFF

ON

ON

Address 4#

ON

OFF

OFF

Address 5#

ON

OFF

ON

Address 6#

ON

ON

OFF

Address 7#

ON

ON

ON

Address 8#

NA

OFF

19200 (note 1)

ON

9600

Spec. No. 581127000 (Model 710NPBA) Issue AB, March 22, 2012

Note 1: Setting for this system.

Optional SM-DU+ Board DIP Switch Settings

Chapter 3. Setting Jumpers and Switch Options Page 35

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Table 3-3

Page 44

IM581127000 Installation Instructions

Crimp Lug Part No.

Crimp Tool Required1, T&B Model

TBM12 or TBM15 Hydraulic Heads

Color Key

Die Index/

Code No.

Die Cat.

Number

245393500

Burndy: YA25L-4TCG1

PINK

42H

15508

245393600

Burndy: YA26L-4TCG1

BLACK

45

15526

245393700

Burndy: YA27L-4TCG1

ORANGE

50

15530

245393800

Burndy: YA28L-4TCG1

PURPLE

54H

15511

514872

T & B: 256-30695-1879

YELLOW

62

15510

Burndy: YA29L-4TCG1

514873

T & B: 256-30695-1880

RED

71

15514

Burndy: YA31L-4TCG1

Issue AB, March 22, 2012 Spec. No. 581127000 (Model 710NPBA)

CHAPTER 4. MAKING ELECTRICAL CONNECTIONS

IMPORTANT SAFETY INSTRUCTIONS

Danger: Adhere to the “Important Safety Instructions” presented at the front of

this document.

WIRING CONSIDERATIONS

All wiring and branch circuit protection should follow the current edition of the American

National Standards Institute (ANSI) approved National Fire Protection Association's

(NFPA) National Electrical Code (NEC), and applicable local codes. For operation in

countries where the NEC is not recognized, follow applicable codes.

For wire size, branch circuit protection, crimp lug, and general wiring recommendations;

refer to System Application Guide SAG581127000 and Power Data Sheet PD588705200

(PD588705201, PD58870520102, PD58870520103, PD58870520104).

Refer to drawing 031110100 for lug crimping information. Refer to drawings 031110200

and 031110300 for additional lug information.

Refer to Table 4-1 for supplemental lug crimping information when using the special

application crimp lug / strap combination.

1

The lugs should be crimped to the specifications given in the manufacturer’s

instructions furnished with the crimp tool or lug.

Page 36 Chapter 4. Making Electrical Connections

This document is property of Emerson Network Power, Energy Systems, North America, Inc. and contains confidential and proprietary information owned by Emerson Network Power, Energy

Systems, North America, Inc. Any copying, use, or disclosure of it without the written permission of Emerson Network Power, Energy Systems, North America, Inc. is strictly prohibited.

Table 4-1

Supplemental Lug Crimping Information when using the

Special Application Crimp Lug / Strap Combination

Page 45

Installation Instructions IM581127000

Frame Ground

Connection Point

(1/4” clearance holes on 5/8” centers)

Frame Ground

Connection Point

(1/4” clearance holeson 5/8” centers)

Top View