Page 1

Type 630 Regulator

Introduction

The Type 630 Big Joe™ regulators are directoperated, spring-loaded, pressure reducing regulators.

They are available in 1 and 2-inch / DN 25 and 50

body sizes, and they are designed for maximum inlet

pressures to 1500 psig / 103 bar and outlet pressures

from 3 to 500 psig / 0.21 to 34.5 bar. The Type 630

can be used with natural gas, air, or a variety of other

gasesforsuchapplicationsasrst-stagefarm-tap

regulators or high-pressure industrial regulators.

TheType630canbeconvertedintheeldtoa

relief valve or is available as the Type 630R relief

valve/backpressure regulator; refer to the separate

Type 630R Bulletin (71.4:630R) for information.

Bulletin 71.1:630

December 2012

Features

• High-Pressure Capabilities—Inlet pressures up

to 1500 psig / 103 bar and control pressures up to

500 psig / 34.5 bar.

• Rugged Construction—Compact, sturdy design

and solid metal construction provide a strong,

reliable, long-lasting regulator.

• Better Low-Pressure Control—The Type 630

is available in both high-pressure and low-pressure

constructions; the low-pressure units have a larger

diaphragm area to provide more accurate control of

low-pressure settings.

• Sour Gas Service Capability—Optional materials

are available for applications handling sour

gases. These constructions comply with

the recommendations of the NACE

International MR0175.

W1934

Figure 1. Type 630 Big Joe High-Pressure Regulator

The manufacturing processes and materials

used by Fisher® Controls assure that all products

speciedforsourgasservicecomplywiththe

chemical and physical requirements of NACE

International MR0175.

www.fisherregulators.com

D100121X012

Page 2

Bulletin 71.1:630

Specications

Body Sizes

1 and 2-inch / DN 25 and 50

End Connection Style

NPT, ASME CL150 RF, CL300 RF, or

CL600 RF

Maximum Inlet Pressure and Pressure Drops

(1)

Up to 1500 psig / 103 bar, See Table 1

Maximum Outlet Pressure

(1)

Up to 500 psig / 34.5 bar, See Table 2

Outlet Pressure Ranges

3 to 500 psig / 0.21 to 34.5 bar, See Table 2

Pressure Registration

Internal

Flow Capacities

See Tables 3 and 4

Orice Sizes and Wide-Open Flow Coefcients

for Relief Valve Sizing

ORIFICE SIZE

Inch mm

1/8

3/16

1/4

3/8

1/2

3.2

4.8

6.4

9.5

13

Temperature Capabilities

C

13.9

31.3

55.1

122.5

216.0

(1)

g

C

0.49

1.11

2.03

4.61

8.18

V

C

28.4

28.2

27.2

26.6

26.4

1

Nitrile (NBR), Nylon (PA), and Neoprene (CR):

-20 to 180°F / -29 to 82°C

Fluorocarbon (FKM) and

Polytetrauoroethylene (PTFE):

0 to 300°F / -18 to 149°C

Construction Materials

Body: Cast iron, or steel

Spring Case and Diaphragm Adaptor:

Cast iron or steel

Orice: Brass or stainless steel

Valve Disk: Nitrile (NBR), Nylon (PA),

Polytetrauoroethylene(PTFE),

or Fluorocarbon (FKM)

Valve Disk Holder: Brass or stainless steel

Valve Carrier: Brass or stainless steel

Diaphragm: Neoprene (CR) or

Fluorocarbon (FKM)

Inlet Body Gaskets: Copper with brass trim or

stainless steel with stainless steel trim

All Other Gaskets: Composition

Lever: Zinc-plated steel or Stainless steel

Diaphragm Connector: Aluminum with brass

trim or stainless steel with stainless steel trim

Pitot Tube: Stainless steel

Regulator Spring: Plated steel

Adjusting Screw: Steel

Diaphragm Plate: Zinc-plated steel

Upper Spring Seat: Zinc

Lower Spring Seat: Zinc-plated steel

(low pressure) or Zinc (high pressure)

Vent: Type Y602-9

Spring Case Vent

1/4 NPT

Options

PTFE diaphragm protector, wire-seal adjusting

screw, and NACE

Approximate Weight

1-inch End Connection: 25 pounds / 11.3 kg

2-inch End Connection: 30 pounds / 13.6 kg

1. The pressure/temperature limits in this Bulletin and any applicable standard or code limitation should not be exceeded.

Installation

These regulators may be installed in any position.

Some installations may require a remote vent line.

Protect all vent openings against the entrance of rain,

snow, debris, or any other foreign material that may

plug the opening.

Directionofowthroughtheregulatorbodymustbe

inthedirectionindicatedbytheowdirectionarrow

found on the regulator body.

Overpressure Protection

As is the case with most regulators, these regulators

have an outlet pressure rating that is lower than the

inlet pressure rating. Overpressure protection is

needed if the actual inlet pressure can exceed the

outlet pressure rating.

Regulatoroperationbelowthelimitsspeciedin

Tables 1 and 2 do not preclude the possibility of

damage from external sources or from debris in

the pipeline. The regulator should be inspected for

damage after any overpressure condition.

2

Page 3

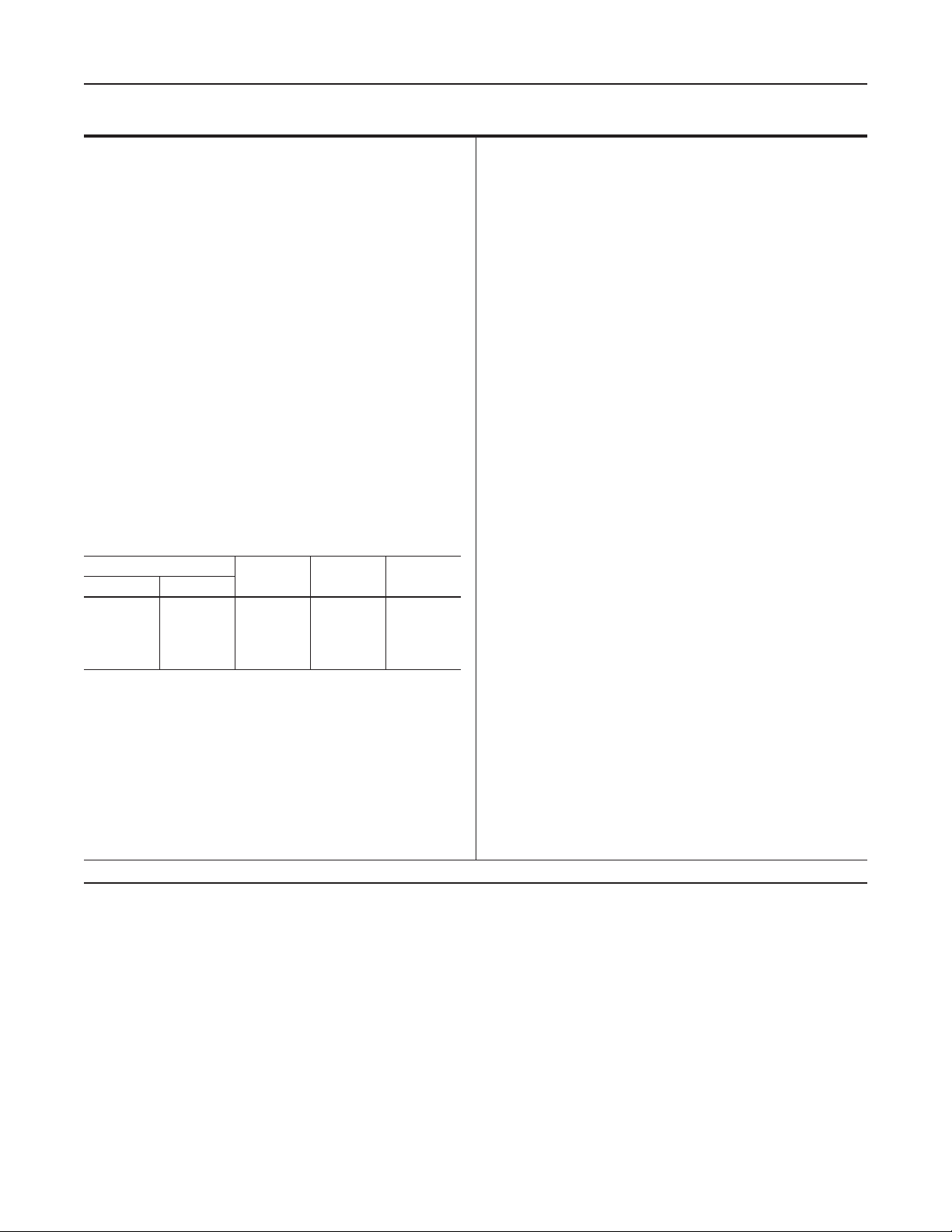

SPRING

CASE

Bulletin 71.1:630

DIAPHRAGM

DIAPHRAGM

CONNECTOR

DIAPHRAGM

ADAPTOR

W0428-3*

VALVE DISK

AND HOLDER

INLET ADAPTOR

FULL SECTION

LEVER

ORIFICE

PITOT TUBE

[1-INCH / DN 25 SIZE ONLY]

REGISTRATION HOLE

[2-INCH / DN 50 SIZE ONLY]

BODY

A6673

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 3. Type 630 Operational Schematic

Principle of Operations

Refer to Figure 2. In the regulator construction, outlet

pressure registers beneath the diaphragm. As long

as the outlet pressure is less than the set pressure,

spring force on the diaphragm causes the lever to hold

the valve open. When the outlet pressure exceeds the

set pressure, the diaphragm moves to compress the

spring and the lever closes the valve until the outlet

pressure returns to set pressure.

W0429-3*

BODY ONLY

(ROTATED 90°)

Figure 2. Type 630 Sectional Views

Capacity Data

Flow capacities are given in Tables 3 and 4 in standard

cubic feet per hour (SCFH) and normal cubic meters

per hour (Nm3/h)of0.6specicgravitynatural

gas.Todeterminetheequivalentowrateforother

gases, multiply the table value by the appropriate

factor: air—0.775; butane—0.547; nitrogen—0.789;

propane—0.627.

3

Page 4

Bulletin 71.1:630

Table 1. Maximum Inlet Pressure and Pressure Drops

MAXIMUM ALLOWABLE PRESSURE DROPS

ORIFICE SIZES

inches mm psig bar psig bar psig bar psig bar

1/8 and 3/16 3.2 and 4.8

1/4 6.4 1000 69

3/8 9.5 1000 69 500 34.5 500 34.5

1/2 13 750 51.7 250 17.2 250 17.2

1. Inlet pressure must not exceed the sum of the actual outlet pressure setting and the maximum allowable pressure drop. For example, with an outlet pressure setting of 200 psig / 13.8 bar

anda3/8-inch/9.5mmoricewithamaximumallowablepressuredropof500psid/34.5bard,themaximuminletpressureis700psig/48.3bar.

2. Nitrile (NBR) valve disks are normally furnished for pressure drops to 200 psi / 13.8 bar, differential. For better erosion resistance, Nylon (PA) valve disks are normally furnished for

higher

pressuredrops.Someerosionofvalvedisksoccursatallpressuredropsduetosolidparticlesintheowstream.Therateoferosionishigherwithlargeamountsofimpuritiesin

theowstreamandwithhighpressuredrops.Valvedisksandotherregulatorpartsmustbeinspectedperiodicallyforerosionanddamageandmustbereplacedasnecessary.

MAXIMUM ALLOWABLE

INLET PRESSURE

1500 103

(1)

Table 2. Outlet Pressure Ranges

REGULATOR

CONSTRUCTION

Low pressure

High pressure

1. Damage to internal parts of the regulator may occur if outlet pressure exceeds the actual pressure setting by amounts greater than those shown in this column.

2. For outlet pressure settings to 25 psig / 1.7 bar only. For pressure settings over 25 psig / 1.7 bar, outlet pressure is limited by maximum emergency outlet pressure of 45 psig / 3.1 bar.

3. For outlet pressure settings to 350 psig / 24.1 bar only. For pressure settings over 350 psig / 24.1 bar, outlet pressure is limited by maximum emergency outlet pressure of 550 psig / 37.9 bar.

4. Leakage or bursting of pressure-containing parts may occur if outlet pressure exceeds these values.

OUTLET PRESSURE

RANGE

psig bar inches mm inches mm psig bar psig bar

3 to 10 0.21 to 0.69 0W019227022 Red stripe 0.23 5.84

8 to 20 0.55 to 1.4 0W019127022 Olive green 0.28 7.11

17 to 30 1.2 to 2.1 0W019027022 Unpainted 0.34 8.64 20

27 to 40 1.9 to 2.8 0Y066427022 Green stripe 0.36 9.14

27 to 50 1.9 to 3.4 0W019227022 Red stripe 0.23 5.84

46 to 95 3.2 to 6.6 0W019127022 Olive green 0.28 7.11

90 to 150 6.2 to 10.3 0W019027022 Unpainted 0.34 8.64

150 to 200 10.3 to 13.8 0Y066427022 Green stripe 0.36 9.14

200 to 275 13.8 to 19.0 1J146927142 Blue stripe 0.38 9.65 6.1 155

275 to 500 19.0 to 34.5 1K370927082 Yellow stripe 0.44 11.2 6.2 157 200

SPRING

PART

NUMBER

Nylon (PA) and

Polytetrauoroethylene

(PTFE) Disk

1500 103

SPRING

COLOR

CODE

SPRING WIRE

DIAMETER

Fluorocarbon (FKM) Disk Nitrile (NBR) Disk

600 41.4

200 13.8

SPRING FREE

LENGTH

6.0 152

MAXIMUM

OUTLET

PRESSURE

OVER

SETPOINT

20 1.4

(2)

Limited by

Maximum

Emergency

Outlet Pressure

200 13.8

(1)

1.4

(3)

13.8

(2)

(3)

MAXIMUM

EMERGENCY

OUTLET

(CASING)

PRESSURE

66 4.6

550 37.9

(4)

To determine the wide-open capacity for relief sizing

withtheowcoefcients(Cg), use the appropriate

procedure below.

1. Ifowiscritical(absoluteoutletpressureis

equal to or less than one-half the absolute inlet

pressure), use the equation:

Flow = (Absolute Inlet Pressure) (Cg) (1.29)

4

TheowdeterminedwillbeinSCFH of 0.6

specicgravitynaturalgas.ToconvertSCFH to

Nm3/h multiply the SCFH result by 0.0268.

2. Ifowislessthancritical(absoluteoutlet

pressure is greater than one-half the absolute

inlet pressure), use Fisher®’s computerized sizing

programorcontactyourlocalSalesOfce.

Page 5

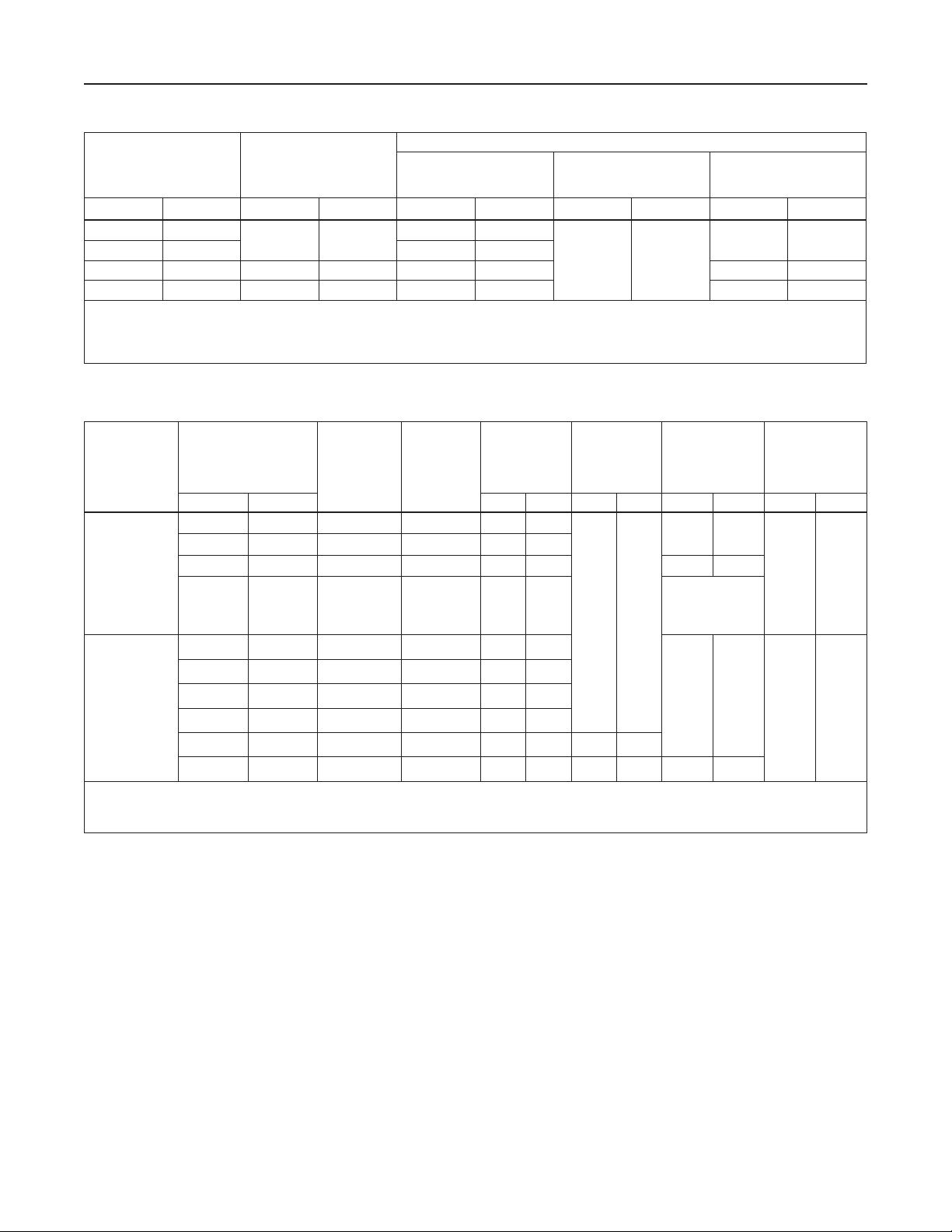

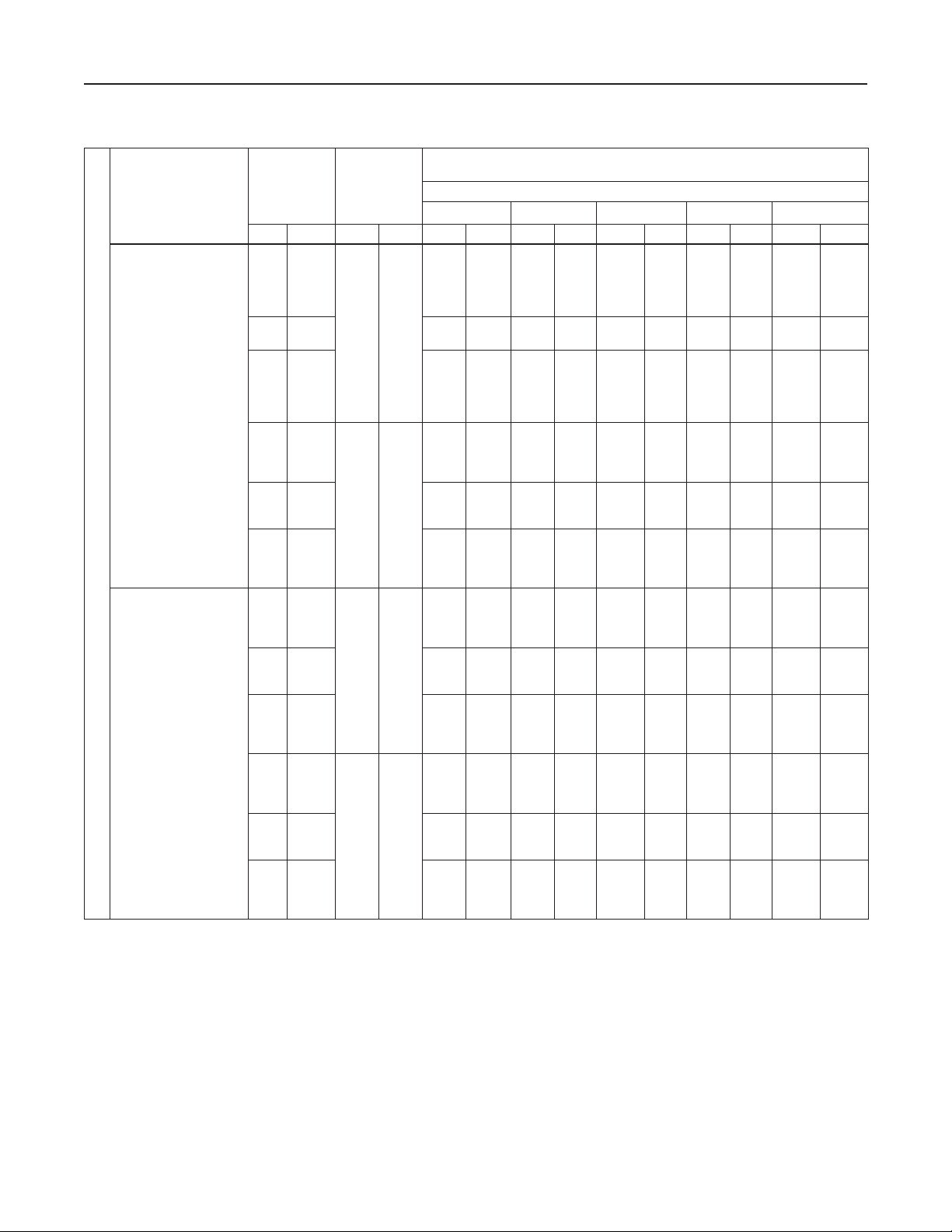

Table 3. 1-Inch / DN 25 Body Capacities (Based on 20% Droop)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

3 to 10 psig /

0.21 to 0.69 bar

0W019227022

Red Stripe

LOW PRESSURE

8 to 20 psig /

0.55 to 1.4 bar

0W019127022

Olive Drab

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

10

0.69

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

OUTLET

PRESSURE

5 0.34

10 0.69

10 0.69

15 1.0

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

200

400

600

950

1100

1700

30004680

3700

4100

4300

4600

5000

500

700

1000

1150

1600

3300

5400

6000

6500

7200

7400

500

700

900

1050

1600

3300

5400

6000

6500

7200

7400

470

600

1000

1150

1900

3600

7100

8300

8600

9600

10,000

Bulletin 71.1:630

1-INCH / DN 25 BODY CAPACITIES IN SCFH / Nm3/h

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

5

510

14

11

16

25

29

99

110

115

123

134

13

19

27

31

43

88

145

161

174

193

198

13

19

24

28

43

88

145

161

174

193

198

13

16

27

31

51

96

190

222

230

257

268

770

1100

1500

1750

2400

34006491

3900

4300

4600

4900

5400

1200

1400

2300

2700

3800

5800

6900

7100

7300

7700

8400

700

1300

1900

2300

3500

4800

6500

6900

7000

7700

8100

1000

1500

2300

2700

4300

7500

8700

8800

9600

10,000

11,000

21

29

40

47

105

115

123

131

145

32

38

62

72

102

155

185

190

196

206

225

19

35

51

62

94

129

174

185

188

206

217

27

40

62

72

115

201

233

236

257

268

295

990

1200

1500

2100

2400

2900

420078113

4500

4700

5000

5600

- - - -

1800

2800

4100

4200

5000

6900

7600

7900

8200

8400

- - - -

1400

2100

3200

3500

4600

6200

7600

7900

8200

8400

- - - -

1700

2500

3800

4300

6200

8500

10,000

10,500

10,800

11,000

- - - -

27

32

40

56

64

121

126

134

150

- - - -

48

75

110

113

134

185

204

212

220

225

- - - -

38

56

86

94

123

166

204

212

220

225

- - - -

46

67

102

115

166

228

268

281

289

295

- - - -

1700

2000

2200

2800

3000

4000

5100

6400

7400

- - - -

- - - -

- - - -

4200

4100

5100

5500

6400

7700

9000

9700

- - - -

- - - -

- - - -

2200

3100

4300

4700

5700

7500

8900

9400

- - - -

- - - -

- - - -

3300

4600

5500

6100

7600

9600

11,000

12,000

- - - -

- - - -

- - - -

46

54

59

75

80

107

137

172

198

- - - -

- - - -

- - - -

113

110

137

147

172

206

241

260

- - - -

- - - -

- - - -

59

83

115

126

153

201

239

252

- - - -

- - - -

- - - -

88

123

147

163

204

257

295

322

- - - -

- - - -

- - - -

2200

2700

3300

4200

4100

4900

6100

- - - -

- - - -

- - - -

- - - -

- - - -

4900

5300

6200

6500

7300

8200

- - - -

- - - -

- - - -

- - - -

- - - -

3600

4300

5400

5800

6900

8200

- - - -

- - - -

- - - -

- - - -

- - - -

4900

5200

5700

6800

9600

10,000

- - - -

- - - -

- - - -

- - - -

- - - -

59

72

88

113

110

131

163

- - - -

- - - -

- - - -

- - - -

- - - -

131

142

166

174

196

220

- - - -

- - - -

- - - -

- - - -

- - - -

96

115

145

155

185

220

- - - -

- - - -

- - - -

- - - -

- - - -

131

139

153

182

257

268

- - - -

- - - -

- - - -

- - - -

- - - -

- continued -

5

Page 6

Bulletin 71.1:630

Table 3. 1-Inch / DN 25 Body Capacities (Based on 20% Droop) (continued)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

8 to 20 psig /

0.55 to 1.4 bar

0W019127022

Olive Drab

17 to 30 psig /

1.17 to 2.1 bar

0W019027022

LOW PRESSURE

Silver

27 to 40 psig /

1.9 to 2.8 bar

0Y066427022

Green Stripe

1-INCH / DN 25 BODY CAPACITIES IN SCFH / Nm3/h

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

30

2.1

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

30

2.1

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

OUTLET

PRESSURE

20 1.4

20 1.4

30 2.1

30 2.1

40 2.8

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

600

800

1000

1150

1800

3600

7200

8500

10,000

11,000

12,000

1050

1700

3400

7000

8000

9600

10,000

12,000

1100

1700

3500

6900

8800

9700

15,500

16,400

1100

1700

3500

6900

8800

9700

15,600

16,400

1100

1800

3500

7100

8800

9800

16,800

20,000

193

228

268

295

322

590

790

900

188

214

257

268

322

820

900

185

236

260

415

440

800

900

185

236

260

418

440

950

190

236

263

450

536

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

16

1500

21

2000

27

2300

31

2700

48

4100

96

8000

10,000

10,800

12,000

12,300

13,000

16

21

1700

24

2200

28

2500

46

4000

91

6400

8700

9800

11,000

12,000

13,000

22

1700

24

2200

29

2600

46

4100

94

8000

13,000

14,000

15,000

17,800

18,500

21

1500

24

2000

29

2500

46

3900

94

7000

12,000

12,500

13,400

15,800

18,000

25

1800

29

2300

48

4100

94

7800

15,000

16,500

18,000

19,800

22,000

900

40

54

62

72

110

214

268

289

322

330

348

24

46

59

67

107

172

233

263

295

322

348

46

59

70

110

214

348

375

402

477

496

40

54

67

105

188

322

335

359

423

482

48

67

110

209

402

442

482

531

590

2500

3400

4200

4900

7400

10,000

13,000

13,400

13,800

15,000

- - - -

1700

2400

3600

4000

5500

9100

11,000

11,800

13,000

14,000

- - - -

2700

3600

4400

6800

11,000

15,000

15,600

16,000

17,900

- - - -

2400

3200

3900

6400

9400

15,000

15,600

16,000

17,900

- - - -

3200

4100

7000

12,000

18,000

18,700

21,000

22,800

- - - -

67

91

113

131

198

268

348

359

370

402

- - - -

46

64

96

107

147

244

295

316

348

375

- - - -

72

96

118

182

295

402

418

429

480

- - - -

64

86

105

172

252

402

418

429

480

- - - -

86

110

188

322

482

501

563

611

- - - -

4600

5700

6800

7500

9500

12,000

14,000

14,800

- - - -

- - - -

- - - -

3300

4000

4900

5500

7600

11,000

13,000

13,700

- - - -

- - - -

- - - -

5100

6400

7500

10,000

14,000

17,000

18,500

- - - -

- - - -

- - - -

4400

5600

6300

9400

14,000

17,000

17,800

- - - -

- - - -

- - - -

5500

7500

11,000

17,000

21,000

21,700

- - - -

- - - -

- - - -

123

153

182

201

255

322

375

397

- - - -

- - - -

- - - -

88

107

131

147

204

295

348

367

- - - -

- - - -

- - - -

137

172

201

268

375

456

496

- - - -

- - - -

- - - -

118

150

169

252

375

456

477

- - - -

- - - -

- - - -

147

201

295

456

563

582

- - - -

- - - -

- - - -

6800

8100

9000

9800

11,000

13,000

- - - -

- - - -

- - - -

- - - -

- - - -

4700

6100

6900

7400

9700

12,000

- - - -

- - - -

- - - -

- - - -

- - - -

7600

8700

9800

12,000

16,000

- - - -

- - - -

- - - -

- - - -

- - - -

6400

7700

8900

11,000

15,000

- - - -

- - - -

- - - -

- - - -

- - - -

8900

10,000

14,000

19,000

- - - -

- - - -

- - - -

- - - -

- - - -

182

217

241

263

295

348

- - - -

- - - -

- - - -

- - - -

- - - -

126

163

185

198

260

322

- - - -

- - - -

- - - -

- - - -

- - - -

204

233

263

322

429

- - - -

- - - -

- - - -

- - - -

- - - -

172

206

239

295

402

- - - -

- - - -

- - - -

- - - -

- - - -

239

268

375

509

- - - -

- - - -

- - - -

- - - -

- - - -

- continued -

6

Page 7

Table 3. 1-Inch / DN 25 Body Capacities (Based on 20% Droop) (continued)

Bulletin 71.1:630

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

27 to 50 psig /

1.9 to 3.4 bar

0W019227022

Red Stripe

46 to 95 psig /

3.2 to 6.6 bar

0W019127022

Olive Drab

HIGH PRESSURE

90 to 150 psig /

6.2 to 10.3 bar

0W019027022

Sliver

150 to 200 psig /

10.3 to 13.8 bar

0Y066427022

Green Stripe

1-INCH / DN 25 BODY CAPACITIES IN SCFH / Nm3/h

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

60

4.1

100

6.9

200

13.8

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

60

4.1

100

6.9

200

13.8

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

125

8.62

150

10.3

200

13.8

300

20.7

400

27.6

500

34.5

1000

69.0

1500

103

150

10.3

200

13.8

300

20.7

400

27.6

500

34.5

1000

69.0

1500

103

200

13.8

300

20.7

400

27.6

500

34.5

800

55.2

1000

69.0

1500

103

200

13.8

300

20.7

400

500

800

1000

1500

27.6

34.5

55.2

69.0

103

OUTLET

PRESSURE

50 3.4

50 3.4

75 5.17

100 6.9

125 8.62

150 10.3

150 10.3

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

900

1700

3500

5300

142

6900

185

8700

233

9800

800

1500

3400

5200

6800

8600

9800

1700

3500

7100

8600

9900

2000

2500

3600

5300

7000

8300

2400

3500

5200

7300

7900

3400

5300

7100

8000

3400

5300

7100

8000

263

434

509

139

182

230

263

362

482

190

230

265

448

616

142

188

222

469

670

139

196

212

429

697

142

190

214

348

456

697

142

190

214

348

448

697

16,200

19,000

13,500

18,000

16,700

23,000

17,500

25,000

16,000

26,000

13,000

17,000

26,000

13,000

16,700

26,000

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

24

46

94

21

40

91

46

94

54

67

96

64

94

91

91

2000

3500

7800

10,500

13,000

15,000

17,000

22,300

25,000

1500

3100

6800

8900

11,000

12,300

14,000

18,400

24,000

3200

7300

14,000

16,300

19,000

25,800

32,000

3600

4600

6600

9800

13,000

15,500

26,000

35,000

4600

6800

10,000

14,500

15,000

30,300

43,000

6800

10,000

14,000

18,800

29,000

34,000

47,000

6200

10,000

14,000

16,500

27,000

31,000

44,000

54

94

209

281

348

402

456

598

670

40

83

182

239

295

330

375

493

643

86

196

375

437

509

691

858

96

123

177

263

348

415

697

938

123

182

268

389

402

812

1152

182

268

375

504

777

911

1260

166

268

375

442

724

831

1179

3100

5700

11,000

14,000

17,000

19,000

21,000

26,300

- - - 2400

4200

9400

11,000

15,000

16,300

19,000

21,700

- - - 5000

10,000

19,000

21,300

25,000

31,000

- - - 5500

6800

9400

14,000

18,000

20,500

32,600

- - - -

6700

10,000

15,000

19,000

25,000

38,800

- - - -

10,000

15,000

22,000

26,300

38,000

44,300

- - - -

9300

15,000

21,000

26,300

37,000

43,900

- - - -

83

153

295

375

456

509

563

705

- - - 64

113

252

295

402

437

509

582

- - - 134

268

509

571

670

831

- - - 147

182

252

375

482

549

874

- - - 180

268

402

509

670

1040

- - - 268

402

590

705

1018

1187

- - - 249

402

563

705

992

1177

- - - -

5200

10,500

16,000

20,000

23,000

25,000

- - - -

- - - -

- - - -

4300

7500

14,000

16,000

20,000

22,000

- - - -

- - - -

- - - -

8000

16,000

27,000

28,700

- - - -

- - - -

- - - -

9200

11,000

13,000

21,000

27,000

31,000

- - - -

- - - -

11,000

15,000

25,000

29,000

36,000

- - - -

- - - -

16,000

24,000

34,000

39,300

- - - -

- - - -

- - - -

16,000

24,000

32,000

39,000

- - - -

- - - -

- - - -

139

281

429

536

616

670

- - - -

- - - -

- - - 115

201

375

429

536

590

- - - -

- - - -

- - - 214

429

724

769

- - - -

- - - -

- - - 247

295

348

563

724

831

- - - -

- - - 295

402

670

777

965

- - - -

- - - 429

643

911

1053

- - - -

- - - -

- - - 429

643

858

1045

- - - -

- - - -

- - - -

8100

13,000

19,000

23,000

- - - -

- - - -

- - - -

- - - -

- - - -

6400

10,000

17,000

20,000

- - - -

- - - -

- - - -

- - - -

- - - -

13,000

22,000

- - - -

- - - -

- - - -

- - - -

- - - -

13,000

16,000

22,000

30,000

- - - -

- - - -

- - - -

- - - -

17,000

23,000

34,000

- - - -

- - - -

- - - -

- - - -

26,000

35,000

42,000

- - - -

- - - -

- - - -

- - - -

26,000

30,000

38,000

- - - -

- - - -

- - - -

- - - -

217

348

509

616

- - - -

- - - -

- - - -

- - - -

- - - 172

268

456

536

- - - -

- - - -

- - - -

- - - -

- - - 348

590

- - - -

- - - -

- - - -

- - - -

- - - 348

429

590

804

- - - -

- - - -

- - - -

- - - 456

616

911

- - - -

- - - -

- - - -

- - - 697

938

1126

- - - -

- - - -

- - - -

- - - 697

804

1018

- - - -

- - - -

- - - -

- - - -

- continued -

7

Page 8

Bulletin 71.1:630

Table 3. 1-Inch / DN 25 Body Capacities (Based on 20% Droop) (continued)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

150 to 200 psig /

10.3 to 13.8 bar

0Y066427022

Green Stripe

200 to 275 psig /

13.8 to 19.0 bar

1J146927142

Blue Stripe

HIGH PRESSURE

275 to 500 psig /

19.0 to 34.5 bar

1K370927082

Yellow Stripe

1-INCH / DN 25 BODY CAPACITIES IN SCFH / Nm3/h

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

250

17.2

300

20.7

600

41.4

700

48.3

800

55.2

1000

69.0

1200

82.7

1500

103

250

17.2

300

20.7

600

41.4

700

48.3

800

55.2

1000

69.0

1200

82.7

1500

103

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

300

20.7

400

27.6

600

41.4

1000

69.0

1500

103

300

20.7

400

27.6

600

41.4

1000

69.0

1500

103

400

27.6

600

41.4

700

48.3

800

55.2

1000

69.0

1300

89.6

1500

103

500

34.5

600

41.4

800

55.2

900

62.1

1000

69.0

1200

82.7

1400

96.5

1500

103

550

37.9

600

41.4

900

62.1

1000

69.0

1500

103

OUTLET

PRESSURE

200 13.8

200 13.8

250 17.2

275 19.0

275 19.0

300 20.7

400 27.6

500 34.5

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

4200

5200

9500

11,000

13,000

16,000

20,000

26,000

4200

5200

9500

11,000

13,000

16,000

19,000

26,000

4900

7000

8500

9500

16,000

26,000

4700

6900

9300

16,000

26,000

4500

6600

9300

17,000

26,000

6600

9900

11,000

13,000

16,800

22,000

26,000

8300

9400

13,000

15,000

17,000

20,000

24,000

26,000

8700

9500

15,000

17,000

26,000

113

139

255

295

348

429

536

697

113

139

255

295

348

429

509

697

131

188

228

255

429

697

126

185

249

429

697

121

177

249

456

697

177

265

295

348

450

590

697

222

252

348

402

456

536

643

697

233

255

402

456

697

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

8300

222

10,000

22,000

25,000

30,000

37,000

41,000

53,000

8200

10,000

22,000

25,000

29,000

36,000

41,000

51,000

9000

14,000

18,000

22,000

39,000

59,000

9000

14,000

21,000

39,000

60,000

7500

12,000

18,400

32,000

46,000

11,000

19,000

23,000

26,000

32,500

43,000

49,000

16,000

21,300

30,000

34,000

38,000

46,000

55,000

60,000

16,000

19,000

34,000

39,000

59,000

268

590

670

804

992

1099

1420

220

268

590

670

777

965

1099

1367

241

375

482

590

1045

1581

241

375

563

1045

1608

201

322

493

858

1233

295

509

616

697

871

1152

1313

429

571

804

911

1018

1233

1474

1608

429

509

911

1045

1581

12,000

16,000

34,000

40,000

43,000

50,000

59,000

- - - -

11,000

14,500

31,000

35,000

42,000

50,000

55,000

- - - -

15,000

23,000

29,000

34,000

58,000

- - - -

15,000

25,000

39,800

67,000

- - - -

10,000

16,000

24,300

43,000

- - - -

16,000

26,000

30,000

35,000

43,800

58,000

- - - -

24,000

30,000

41,000

49,000

54,000

63,000

76,000

- - - -

26,000

36,800

52,000

60,000

72,000

322

429

911

1072

1152

1340

1581

- - - -

295

389

831

938

1126

1340

1474

- - - -

402

616

777

911

1554

- - - -

402

670

1067

1796

- - - -

268

429

651

1152

- - - -

429

697

804

938

1174

1554

- - - -

643

804

1099

1313

1447

1688

2037

- - - -

697

986

1394

1608

1930

20,000

25,000

55,000

61,500

- - - -

- - - -

- - - -

- - - -

20,000

25,000

51,000

55,000

- - - -

- - - -

- - - -

- - - -

28,000

40,000

51,000

59,000

- - - -

- - - -

28,000

40,000

76,100

- - - -

- - - -

20,000

31,000

43,800

- - - -

- - - -

31,000

48,000

54,000

61,000

- - - -

- - - -

- - - -

44,000

55,300

76,000

85,000

- - - -

- - - -

- - - -

- - - -

50,000

57,000

92,000

100,000

- - - -

536

670

1474

1648

- - - -

- - - -

- - - -

- - - -

536

670

1367

1474

- - - -

- - - -

- - - -

- - - -

750

1072

1367

1581

- - - -

- - - -

750

1072

2039

- - - -

- - - -

536

831

1174

- - - -

- - - -

831

1286

1447

1635

- - - -

- - - -

- - - -

1179

1482

2037

2278

- - - -

- - - -

- - - -

- - - -

1340

1528

2466

2680

- - - -

30,000

35,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

29,000

35,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

42,000

56,000

65,000

- - - -

- - - -

- - - -

39,000

54,000

- - - -

- - - -

- - - -

31,000

43,000

- - - -

- - - -

- - - -

42,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

62,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

77,000

- - - -

- - - -

- - - -

- - - -

804

938

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

777

938

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

1126

1501

1742

- - - -

- - - -

- - - -

1045

1447

- - - -

- - - -

- - - -

831

1152

- - - -

- - - -

- - - -

1126

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

1662

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

2064

- - - -

- - - -

- - - -

- - - -

8

Page 9

Table 4. 2-Inch / DN 50 Body Capacities (Based on 20% Droop)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

3 to 10 psig /

0.21 to 0.69 bar

0W019227022

Red Stripe

LOW PRESSURE

8 to 20 psig /

0.55 to 1.4 bar

0W019127022

Olive Drab

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

10

0.69

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

20

1.4

30

2.1

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

OUTLET

PRESSURE

5 0.34

10 0.69

10 0.69

15 1.0

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

290

500

760

1100

1250

1900

3700

7200

9100

10,000

18,000

22,000

560

770

1100

1250

1900

3700

7200

8900

10,000

18,000

27,000

550

760

1000

1200

1900

3600

7200

8800

10,000

18,000

27,000

520

740

1100

1250

1900

3700

7200

9200

11,000

18,000

27,000

Bulletin 71.1:630

2-INCH / DN 50 BODY CAPACITIES IN SCFH / Nm3/h

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

8

830

22

13

20

29

34

51

99

193

244

268

482

590

15

21

29

34

51

99

193

239

268

482

724

15

20

27

32

51

96

193

236

268

482

724

14

20

29

34

51

99

193

247

295

482

724

1200

1600

2200

2700

4300

8200

16,000

19,000

24,000

39,000

60,000

1300

1500

2400

2800

4400

8100

16,000

19,000

23,000

40,000

60,000

1200

1500

2300

2700

4300

8000

15,000

19,000

23,000

39,000

60,000

1100

1600

2400

2800

4400

8300

16,000

20,000

23,000

40,000

60,000

32

43

59

72

115

220

429

509

643

1045

1608

35

40

64

75

118

217

429

509

616

1072

1608

32

40

62

72

115

214

402

509

616

1045

1608

29

43

64

75

118

222

429

536

616

1072

1608

1300

2100

2700

3900

4500

7000

13,000

28,000

35,000

42,000

69,000

- - - -

2200

3000

4300

5000

7600

14,000

28,000

35,000

42,000

72,000

- - - -

1700

2500

3800

4500

7400

14,000

28,000

35,000

42,000

72,000

- - - -

1800

2800

4300

5000

7800

14,000

29,000

37,000

42,000

71,000

- - - -

35

56

72

105

121

188

348

750

938

1126

1849

- - - -

59

80

115

134

204

375

750

938

1126

1930

- - - -

46

67

102

121

198

375

750

938

1126

1930

- - - -

48

75

115

134

209

375

777

992

1126

1903

- - - -

3300

4800

7000

9800

11,100

17,000

32,000

64,000

79,000

- - - -

- - - -

- - - -

5100

7000

9800

11,100

17,000

33,000

62,000

76,000

- - - -

- - - -

- - - -

2500

4600

7800

9900

17,000

32,000

60,000

74,000

- - - -

- - - -

- - - -

3500

5900

9800

11,100

17,000

31,000

64,000

82,000

- - - -

- - - -

- - - -

88

129

188

263

297

456

858

1715

2117

- - - -

- - - -

- - - -

137

188

263

297

456

884

1662

2037

- - - -

- - - -

- - - -

67

123

209

265

456

858

1608

1983

- - - -

- - - -

- - - -

94

158

263

297

456

831

1715

2198

- - - -

- - - -

- - - -

5900

9100

11,000

17,000

19,500

30,000

57,000

- - - -

- - - -

- - - -

- - - -

- - - -

9000

11,000

17,000

19,500

30,000

57,000

- - - -

- - - -

- - - -

- - - -

- - - -

4900

8800

16,000

18,500

30,000

57,000

- - - -

- - - -

- - - -

- - - -

- - - -

5700

10,000

16,000

18,500

30,000

57,000

- - - -

- - - -

- - - -

- - - -

- - - -

158

244

295

456

523

804

1528

- - - -

- - - -

- - - -

- - - -

- - - -

241

295

456

523

804

1528

- - - -

- - - -

- - - -

- - - -

- - - -

131

236

429

496

804

1528

- - - -

- - - -

- - - -

- - - -

- - - -

153

268

429

496

804

1528

- - - -

- - - -

- - - -

- - - -

- - - -

- continued -

9

Page 10

Bulletin 71.1:630

Table 4. 2-Inch / DN 50 Body Capacities (Based on 20% Droop) (continued)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

8 to 20 psig /

0.55 to 1.4 bar

0W019127022

Olive Drab

17 to 30 psig /

1.17 to 2.1 bar

0W019027022

LOW PRESSURE

Silver

27 to 40 psig /

1.9 to 2.8 bar

0Y066427022

Green Stripe

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

30

2.1

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

30

2.1

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

40

2.8

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

50

3.4

60

4.1

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

OUTLET

PRESSURE

20 1.4

20 1.4

30 2.1

30 2.1

40 2.8

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

700

900

1100

1250

1900

3700

7300

9100

11,000

17,700

27,000

680

890

1000

1200

1900

3500

7100

8900

10,000

17,700

27,000

860

1000

1200

1800

3600

7000

8900

10,000

18,400

27,000

850

1000

1200

1800

3600

7000

8900

10,000

18,400

27,000

1000

1200

1900

3600

7200

8900

10,000

17,300

27,000

2-INCH / DN 50 BODY CAPACITIES IN SCFH / Nm3/h

19

24

29

34

51

99

196

16,000

244

19,300

295

24,000

474

39,200

724

60,000

18

24

27

32

51

94

190

15,000

239

19,200

268

24,000

474

39,200

724

60,000

23

27

32

48

96

188

16,000

239

19,100

268

23,000

493

39,800

724

61,000

23

27

32

48

96

188

15,000

239

18,800

268

23,000

493

39,700

724

61,000

27

32

51

96

193

16,000

239

19,600

268

23,000

464

39,400

724

61,000

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

1600

2100

2400

2800

4300

8200

1300

1800

2300

2700

4200

8000

1800

2300

2700

4200

8100

1600

2200

2600

4200

8100

2100

2600

4300

8200

43

56

64

75

115

220

429

517

643

1051

1608

35

48

62

72

113

214

402

515

643

1051

1608

48

62

72

113

217

429

512

616

1067

1635

43

59

70

113

217

402

504

616

1064

1635

56

70

115

220

429

525

616

1056

1635

2600

3500

4300

5100

7800

14,000

28,000

35,500

43,000

71,600

- - - -

2100

2800

3700

4300

6900

13,000

28,000

35,500

42,000

70,600

- - - -

2900

3800

4700

7800

14,000

28,000

34,900

42,000

70,900

- - - -

2600

3500

4200

6900

13,000

28,000

34,900

42,000

70,800

- - - -

3400

4300

7200

14,000

28,000

35,100

42,000

70,200

- - - -

70

94

115

137

209

375

750

951

1152

1919

- - - -

56

75

99

115

185

348

750

951

1126

1892

- - - -

78

102

126

209

375

750

935

1126

1900

- - - -

70

94

113

185

348

750

935

1126

1897

- - - -

91

115

193

375

750

941

1126

1881

- - - -

5200

7500

9400

11,000

17,000

32,000

63,000

78,800

- - - -

- - - -

- - - -

3500

5100

6200

7400

12,000

32,000

63,000

78,800

- - - -

- - - -

- - - -

5300

7300

8900

16,000

24,000

64,000

80,900

- - - -

- - - -

- - - -

4500

5900

7300

12,000

24,000

64,000

80,200

- - - -

- - - -

- - - -

5900

7900

13,000

30,000

63,000

79,400

- - - -

- - - -

- - - -

1688

1688

1715

2168

1715

2149

1688

2128

139

201

252

295

456

858

2112

- - - -

- - - -

- - - -

94

137

166

198

322

858

2112

- - - -

- - - -

- - - -

142

196

239

429

643

- - - -

- - - -

- - - -

121

158

196

322

643

- - - -

- - - -

- - - -

158

212

348

804

- - - -

- - - -

- - - -

9200

12,000

15,000

18,000

29,000

59,000

- - - -

- - - -

- - - -

- - - -

- - - -

6000

8200

10,000

12,500

24,000

56,000

- - - -

- - - -

- - - -

- - - -

- - - -

8500

11,000

14,000

28,000

58,000

- - - -

- - - -

- - - -

- - - -

- - - -

7200

9700

12,000

23,000

57,000

- - - -

- - - -

- - - -

- - - -

- - - -

9900

12,000

24,000

56,000

- - - -

- - - -

- - - -

- - - -

- - - -

247

322

402

482

777

1581

- - - -

- - - -

- - - -

- - - -

- - - -

161

220

268

335

643

1501

- - - -

- - - -

- - - -

- - - -

- - - -

228

295

375

750

1554

- - - -

- - - -

- - - -

- - - -

- - - -

193

260

322

616

1528

- - - -

- - - -

- - - -

- - - -

- - - -

265

322

643

1501

- - - -

- - - -

- - - -

- - - -

- - - -

10

- continued -

Page 11

Table 4. 2-Inch / DN 50 Body Capacities (Based on 20% Droop) (continued)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

27 to 50 psig /

1.9 to 3.4 bar

0W019227022

Red Stripe

46 to 95 psig /

3.2 to 6.6 bar

0W019127022

Olive Drab

HIGH PRESSURE

90 to 150 psig /

6.2 to 10.3 bar

0W019027022

Silver

150 to 200 psig /

10.3 to 13.8 bar

0Y066427022

Green Stripe

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

60

4.1

100

6.9

200

13.8

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

60

4.1

100

6.9

200

13.8

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

100

6.9

200

13.8

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

150

10.3

200

13.8

300

20.7

400

27.6

500

34.5

1000

69.0

1500

103

150

10.3

200

13.8

300

20.7

400

27.6

500

34.5

1000

69.0

1500

103

200

13.8

300

20.7

400

27.6

500

69.0

800

55.2

1000

69.0

1500

103

200

13.8

300

20.7

400

500

800

1000

1500

27.6

34.5

55.2

69.0

103

OUTLET

PRESSURE

50 3.4

50 3.4

75 5.17

100 6.9

125 8.62

150 10.3

150 10.3

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

1000

1800

3600

5500

7000

8800

10,000

18,000

27,000

900

1600

3500

5300

6900

8700

10,000

17,100

26,000

1800

3600

7200

8700

10,000

17,600

24,000

2600

3700

5400

7200

8600

17,200

27,000

2500

3600

5300

7000

8800

17,000

27,000

3500

5400

7200

8600

14,000

18,000

27,000

3500

5400

7200

8500

14,000

17,400

27,000

2-INCH / DN 50 BODY CAPACITIES IN SCFH / Nm3/h

27

2100

48

3600

96

7900

147

11,000

188

15,000

236

19,000

268

23,000

482

39,900

724

60,000

24

1600

43

3400

94

6700

142

10,000

185

13,000

233

16,300

268

20,000

458

38,700

697

59,000

48

3300

96

7400

193

15,000

233

19,000

268

23,000

472

39,000

643

60,000

70

4900

99

6900

145

10,000

193

14,000

230

17,500

461

38,600

724

59,000

67

5000

96

7400

142

11,000

188

15,000

236

19,000

456

39,000

724

60,000

94

7300

145

11,000

193

15,000

230

19,800

375

30,000

482

39,100

724

60,000

94

6900

145

11,000

193

15,000

228

18,300

375

30,000

466

38,600

724

60,000

Bulletin 71.1:630

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

56

96

212

295

402

509

616

1069

1608

43

91

180

268

348

437

536

1037

1581

88

198

402

509

616

1045

1608

131

185

268

375

469

1034

1581

134

198

295

402

509

1045

1608

196

295

402

531

804

1048

1608

185

295

402

490

804

1034

1608

3200

5800

12,000

19,000

27,000

34,300

42,000

70,400

- - - -

2500

4300

9600

14,000

21,000

26,300

35,000

68,800

- - - -

5200

11,000

24,000

31,400

39,000

69,300

- - - -

7400

10,000

16,000

21,000

27,500

66,000

- - - -

8100

11,000

17,000

24,000

30,000

69,300

- - - -

11,000

19,000

26,000

32,800

54,000

67,700

- - - -

10,000

17,000

24,000

30,250

51,000

66,400

- - - -

86

155

322

509

724

919

1126

1887

- - - 67

115

257

375

563

705

938

1844

- - - -

139

295

643

842

1045

1857

- - - 198

268

429

563

737

1769

- - - 217

295

456

643

804

1857

- - - 295

509

697

879

1447

1814

- - - 268

456

643

811

1367

1780

- - - -

5300

10,000

21,000

48,000

63,000

79,700

- - - -

- - - -

- - - -

4400

7600

16,000

27,000

46,000

73,300

- - - -

- - - -

- - - -

9000

19,000

- - - -

- - - -

- - - -

- - - -

- - - -

12,000

17,000

27,000

39,000

54,000

- - - -

- - - -

12,000

19,000

31,000

43,000

59,000

- - - -

- - - -

18,000

32,000

46,000

62,500

- - - -

- - - -

- - - -

17,000

28,000

40,000

53,000

- - - -

- - - -

- - - -

142

268

563

1286

1688

2136

- - - -

- - - -

- - - 118

204

429

724

1233

1964

- - - -

- - - -

- - - -

241

509

- - - -

- - - -

- - - -

- - - -

- - - -

322

456

724

1045

1447

- - - -

- - - -

322

509

831

1152

1581

- - - -

- - - -

482

858

1233

1675

- - - -

- - - -

- - - -

456

750

1072

1420

- - - -

- - - -

- - - -

12,000

21,000

55,000

83,000

- - - -

- - - -

- - - -

- - - -

- - - -

7300

12,000

27,000

51,000

- - - -

- - - -

- - - -

- - - -

- - - -

14,000

30,000

- - - -

- - - -

- - - -

- - - -

- - - -

18,000

27,000

44,000

- - - -

- - - -

- - - -

- - - -

20,000

30,000

48,000

65,000

- - - -

- - - -

- - - -

30,000

52,000

77,000

- - - -

- - - -

- - - -

- - - -

28,000

47,000

66,000

- - - -

- - - -

- - - -

- - - -

322

563

1474

2224

- - - -

- - - -

- - - -

- - - -

- - - 196

322

724

1367

- - - -

- - - -

- - - -

- - - -

- - - 375

804

- - - -

- - - -

- - - -

- - - -

- - - 482

724

1179

- - - -

- - - -

- - - -

- - - 536

804

1286

1742

- - - -

- - - -

- - - 804

1394

2064

- - - -

- - - -

- - - -

- - - 750

1260

1769

- - - -

- - - -

- - - -

- - - -

- continued -

11

Page 12

Bulletin 71.1:630

Table 4. 2-Inch / DN 50 Body Capacities (Based on 20% Droop) (continued)

OUTLET PRESSURE

RANGE, SPRING

PART NUMBER,

AND COLOR

150 to 200 psig /

10.3 to 13.8 bar

0Y066427022

Green Stripe

150 to 275 psig /

10.3 to 19.0 bar

1J146927142

Blue Stripe

HIGH PRESSURE

275 to 500 psig /

19.0 to 34.5 bar

1K370927082

Yellow Stripe

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

250

17.2

300

20.7

600

41.4

700

48.3

800

55.2

1000

69.0

1200

82.7

1500

103

250

17.2

300

20.7

600

41.4

700

48.3

800

55.2

1000

69.0

1200

82.7

1500

103

300

20.7

400

27.6

500

34.5

600

41.4

1000

69.0

1500

103

300

20.7

400

27.6

600

41.4

1000

69.0

1500

103

300

20.7

400

27.6

600

41.4

1000

69.0

1500

103

400

27.6

600

41.4

700

48.3

800

55.2

1000

69.0

1300

89.6

1500

103

500

34.5

600

41.4

800

55.2

900

62.1

1000

69.0

1200

82.7

1400

96.5

1500

103

550

37.9

600

41.4

900

62.1

1000

69.0

1500

103

OUTLET

PRESSURE

200 13.8

200 13.8

250 17.2

275 19.0

275 19.0

300 20.7

400 27.6

500 34.5

1/8 / 3.2 3/16 / 4.8 1/4 / 6.4 3/8 / 9.5 1/2 / 13

4300

5300

10,000

12,000

14,000

17,000

21,000

27,000

4300

5300

10,000

12,000

14,000

17,000

20,000

27,000

5000

7100

8600

10,000

17,000

27,000

4800

7000

10,000

17,000

26,000

4600

7000

10,000

18,000

27,000

7000

10,000

12,000

14,000

15,800

23,000

27,000

8800

10,300

14,000

16,000

18,000

21,000

25,000

27,000

9000

10,000

16,000

18,000

27,000

2-INCH / DN 50 BODY CAPACITIES IN SCFH / Nm3/h

115

142

11,000

268

23,000

322

27,000

375

31,000

456

39,000

563

48,000

724

60,000

115

142

11,000

268

23,000

322

27,000

375

31,000

456

39,000

536

46,000

724

60,000

134

10,000

190

15,000

230

19,000

268

23,000

456

40,000

724

60,000

129

10,000

188

15,000

268

23,000

456

40,000

697

61,000

123

188

13,000

268

23,000

482

37,000

724

57,000

188

13,000

268

21,000

322

26,000

375

29,000

423

33,200

616

50,000

724

58,000

236

17,000

276

22,300

375

31,000

429

36,000

482

40,000

563

48,000

670

57,000

724

61,000

241

18,000

268

20,800

429

35,000

482

40,000

724

60,000

OF 0.6 SPECIFIC GRAVITY OF NATURAL GAS

Orice Size, Inches / mm

9100

244

8900

8400

295

616

724

831

1045

1286

1608

239

295

616

724

831

1045

1233

1608

268

402

509

616

1072

1608

268

402

616

1072

1635

225

348

616

992

1528

348

563

697

777

890

1340

1554

456

598

831

965

1072

1286

1528

1635

482

557

938

1072

1608

13,000

18,000

40,000

47,000

54,000

69,000

83,000

12,000

18,000

38,000

45,000

52,000

68,000

83,000

17,000

25,000

34,000

41,000

68,000

17,000

26,000

40,800

68,000

13,000

20,000

40,800

57,000

21,000

34,000

40,000

47,000

53,600

80,000

28,000

36,000

51,000

58,000

66,000

80,000

96,000

30,000

34,500

60,000

67,000

82,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

348

482

1072

1260

1447

1849

2224

- - - -

322

482

1018

1206

1394

1822

2224

- - - -

456

670

911

1099

1822

- - - -

456

697

1093

1822

- - - -

348

536

1093

1528

- - - -

563

911

1072

1260

1436

2144

- - - -

750

965

1367

1554

1769

2144

2573

- - - -

804

925

1608

1796

2198

23,000

33,000

75,000

90,000

- - - -

- - - -

- - - -

- - - -

23,000

31,000

70,000

83,000

- - - -

- - - -

- - - -

- - - -

30,000

47,000

62,000

78,000

- - - -

- - - -

29,000

47,000

81,900

- - - -

- - - -

23,000

32,000

81,900

- - - -

- - - -

35,000

59,000

72,000

81,000

- - - -

- - - -

- - - -

49,000

66,300

95,000

110,000

- - - -

- - - -

- - - -

- - - -

53,000

62,300

113,000

130,000

- - - -

616

884

2010

2412

- - - -

- - - -

- - - -

- - - -

616

831

1876

2224

- - - -

- - - -

- - - -

- - - -

804

1260

1662

2090

- - - -

- - - -

777

1260

2195

- - - -

- - - -

616

858

2195

- - - -

- - - -

938

1581

1930

2171

- - - -

- - - -

- - - -

1313

1777

2546

2948

- - - -

- - - -

- - - -

- - - -

1420

1670

3028

3484

- - - -

42,000

52,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

35,000

46,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

52,000

76,000

103,000

- - - -

- - - -

- - - -

43,000

73,000

- - - -

- - - -

- - - -

37,000

53,000

- - - -

- - - -

- - - -

54,000

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

77,000

100,300

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

89,000

102,000

- - - -

- - - -

- - - -

1126

1394

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

938

1233

- -

- - - -

- - - -

- - - -

- - - -

- - - -

1394

2037

2760

- - - -

- - - -

- - - -

1152

1956

- - - -

- - - -

- - - -

992

1420

- - - -

- - - -

- - - -

1447

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

2064

2688

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

2385

2734

- - - -

- - - -

- - - -

12

Page 13

NPT OR

SWE

Bulletin 71.1:630

F (MAXIMUM)

B

A

Figure 4. NPT Dimensions

Table 5. NPT Dimensions

BODY SIZE

INCH DN

1

2

1

2

25

50

25

50

Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm

7.38

7.88

7.38

7.88

C

E

D

0X0541

AV1663

A5607

NPT DIMENSIONS

A B C D E F

Low-Pressure Regulator

187

200

3.69

3.94

94

100

7.19

7.19

183

183

10.31

10.94

262

278

1.38

2.00

35

51

15.88

16.38

High-Pressure Regulator

187

200

3.69

3.94

94

100

4.69

4.69

119

119

7.81

8.44

198

214

1.38

2.00

35

51

15.88

16.38

403

416

403

416

13

Page 14

Bulletin 71.1:630

L

A

B

E

G

F

A7049

Figure 5. Flanged Dimensions

Table 6. Flanged Dimensions

FLANGED DIMENSIONS

BODY SIZE

INCH DN Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm Inches mm

1

25 5017.9

2

1

25 5017.9

2

A B E

19.9

19.9

455

5058 9

455

5058 11.2

203

229

203

284

7.2

7.2

4.7

4.7

CL150

Low-Pressure Regulator

183

11.1

183

11.9

High-Pressure Regulator

119

8.6

119

9.4

F G

CL300

and CL600

282

11.4

290

302

218

239

12.2

8.9

9.7

310

226

246

2.1

3.0

2.1

3.0

CL150

53.3

76.2

53.3

76.2

CL300

and CL600

2.4

61.0

3.3

83.8

2.4

61.0

3.3

83.8

L

20.7

21.9

21.2

21.4

526

556

538

544

14

Page 15

Ordering Information

Bulletin 71.1:630

Then,carefullyrevieweachspecicationand

complete the Ordering Guide below. To ensure

orderingaccuracy,pleasecompletetheSpecications

Worksheet at the bottom of this page.

Ordering Guide

Body Size (Select One)

1-Inch / DN 25***