Page 1

Installation Manual

5100 Series, Catalog 5150

Connectivity Module

For use with Automatic Transfer Switches,

Power Manager, & Digital Power Meter

Section Page

Welcome............................................................................................................. ii

Overview, Specifications, Installation Overview, DIP Switch (RS485).............. iii

Outline and Mounting Drawing.......................................................................... iv

Interface Wiring Diagrams................................................................. v, vi, vii, viii

Status LEDs....................................................................................................... ix

1 Installation

Installation Overview, DIP switch (RS485)........................................................ iii

on Automatic Transfer Switches (7000, 4000, 300, 940/962)......................... 1-1

on stand-alone Power Manager, Test Communications.................................1-2

View & Change Configuration Pages, View Pages after

Installation..............1-3

2 7000 & 4000 Series ATS (with & without a Power Manager or Power Meter)

Configurator Screens................................................................................2-1, 2-2

Configuration Screen I/O Names for 7ATB with Power Manager .................. 2-3

Detail Screen...................................................................................................2-4

3 Series 300 ATS (with & without a Power Manager or Power Meter)

Configurator Screens................................................................................3-1, 3-2

Detail Screen...................................................................................................3-3

4 ASCO 940 / 962 ATS (with & without a Power Manager)

Configurator Screen ........................................................................................ 4-1

Detail Screen...................................................................................................4-2

5 Power Manager & Power Meter (stand-alone, generator, or circuit breaker)

Configurator Screen ........................................................................................ 5-1

Detail Screens..........................................................................................5-2, 5-3

Appendix

TCP/IP Installation & Configuration for Windows XP ® and Windows 7 ®.......A-1

Troubleshooting...............................................................................................A-3

Create & copy favorites folder, 3

Enabling SNMP Internet-standard protocol.....................................................A-5

Communication Address Forms..........................................................in the back

rd

Party Modbus ® device configuration........A-4

Index ................................................................................................................back page

381333-367 C

50 Hanover Rd, Florham Park, NJ 07932-1591 USA

call 1 800 800-2726 (ASC0) for sales or service www.ascopower.com

Page 2

ii Welcome Connectivity Module

Who Should Use this Installation Manual

This manual for the Connectivity Module should be used to assist individuals who will:

• install the Connectivity Module (mount and wire)

• configure the Connectivity Module

• enter in information about your Automatic Transfer Switches

(7000 & 4000 Series, Series 300, ASCO 940,962,436,434,447,448)

• use Ethernet access to monitor Connectivity Module (connected devices)

Prerequisites A working knowledge of Windows XP

®

and Windows Internet Explorer 6.0 or higher

(with Microsoft Virtual Machine or the latest version of the Java Runtime Environment

loaded) is necessary to configure the Connectivity Module.

Important information To properly set up the software, you will need the nameplate data and other

that you will need

7000 & 4000 Series ATS & Group 5 Controller 381333-126 & appropriate ATS manual

Series 300, ASCO 940, 962, 436, 434, 447, 448 ATS appropriate ATS manual

Power Manager Xp, Catalog 5220D, 5220T 381333-199

Digital Power Meter, Catalog 5210 381333-368

Serial Module, Catalog 5110 (Acc. 72A) 381333-240

ATS Remote Annunciator, Catalog 5310 (1 channel) 381333-316 & 381333-317

ATS Remote Annunciator, Catalog 5350 (8 channel) 381333-314 & 381333-315

ATS Remote Annunciator kits 8 channel K871966-004, 1 channel K871966-005

Kits include: ATS Remote Annunciat or (RA), Connectivity Module (CM ), power supply, mounting hardware, connecting cable

The CM can be configured to provide ATS data to ATS Remote Annunciators (RA) over Ethernet eit her on encryption disabled

or enabled mode. Details on how to configure all required parameters for the two modes are in the RA manuals listed above.

Encryption disabled mode is the default operation mode for both t he CM and the RA. In this m ode, the TCP port and protocol

assigned must be the same for both devices.

Encryption enabled mode is when both the CM and RA are configured for AES 128-bit encryption/decryption

communication. In this mode, the AES mode and AES port settings in the CM are enabled and assigned a value respectively.

Note that the AES port value must be different from the TCP port value (see screen on page 2-1).

Likewise, in the RA, encryption must be enabled and the TCP port is assigned with the same value as the AES port of the CM.

Note that the encryption works only on RAs with software version -003 or higher (refer to Confi gurati on, Annunciat or screen).

information from all your Automatic Transfer Switches including:

• ATS Name (your designation for the ATS)

• ATS Location (where the ATS is located in the building)

• Voltage Rating, Ampere Rating, and number of Poles for each ATS

• Catalog No. and Serial No. of each ATS

• Type of ATS (ATS or ATS/BP [ATS with bypass-isolation switch])

• Device Address (set in each ATS, Power Manager , or Digital Power Meter)

Product Manuals that you may need

Tip Ö Communication Address form is included at the back to help you fill in needed information on your

The Connectivity Module provides Ethernet-access that allows users to view data from ASCO automatic

transfer switches, Power Managers, and Digital Power Meters. All users must follow these precautions:

Connectivity Modules, ATSs, Power Managers, Digital Power Meters.

!

DANGER

To avoid possible shock, burns, or death, deenergize all electrical

NOTICE

sources to the ATS before installing the Connectivity Module.

Be sure that Users to whom you give access are those persons that you want to

view information about the electrical system.

Windows and Internet Explorer are registered trademarks of Microsoft Corporation.

Page 3

Connectivity Module Overview, Specifications, Installation Overview, DIP Switch iii

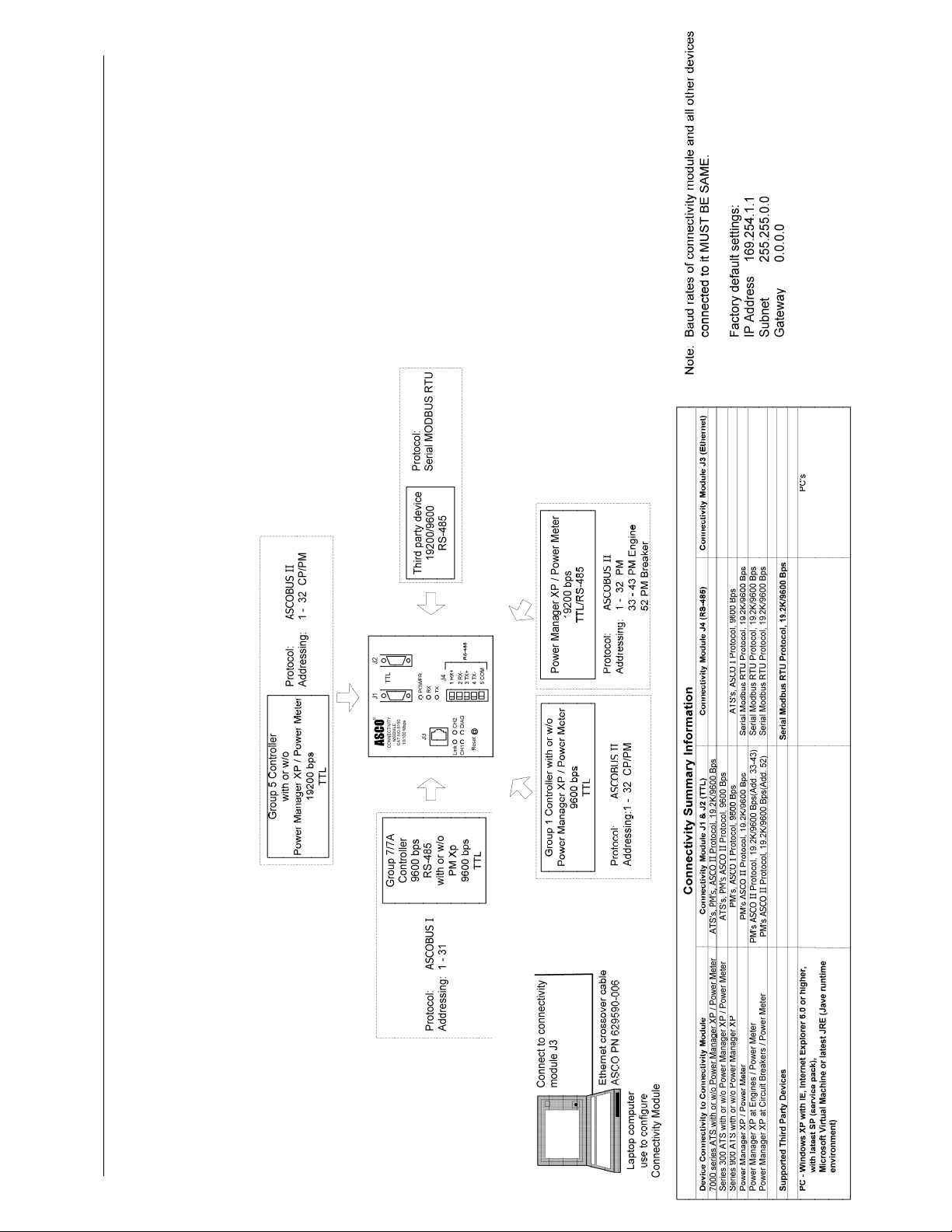

Overview

The Connectivity Module brings together several

different serial devices that communicate at different

baud rates and with different protocols to a common

Ethernet media. It can communicate with up to eight

clients, such as Web applications (web pages), Vpi, or

third-party Modbus

®

devices simultaneously over

Ethernet media.

Specifications

Power Requirements: 24 V dc nominal (8 – 28 V dc)

1.5 Watt, UL Class 2 power supply, if needed.

Mounting: 35 mm DIN rail

Dimensions: 3.5” H, 2.8” W, 2.9” D (8.9 cm, 7.1 cm, 7.4 cm)

Field Communication Cable Requirements:

Ethernet: Belden 7882A or equiv. UTP CAT 5 with

RJ45 connectors (untwisted pair or higher)

Serial: Belden 9842, 9829, 89729, 82729 or Apha

6202C, 6222C, 58902. UL Listed, stranded,

twisted pairs, over-all foil shield with stranded drain wire

J1, J2 TTL Port Connectors: Two built-in TTL ports

J3 Ethernet Port Connector :

One built-in 10 Base T (RJ45) 10 Mbps Ethernet port

J4 Serial RS-485 Port:

One 5-pin terminal block header with a socket block (J4)

designed to be daisy chained for up to 32 devices.

Terminal 1 – RX+ Terminal 4 – TXTerminal 2 – RX- Terminal 5 – Com

Ambient Temperature:

Configuration Parameters: The parameters that are required

Protocol Support: The following protocols are supported:

AES Encryption enable or disable

Terminal 3 – TX+

to make an Ethernet connection are:

IP Address 169.254.1.1

Subnet Mask 255.255.0.0

Gateway 0.0.0.0

TCP Port No. 10001

The TCP port is used for passing the data to the applications

and is configurable for user specific requirement.

Baud Rates 19200 (default) or 9600

Flow Control No Flow Control (default)

Interface Mode TTL/RS485 – 4 wires (default)

Reply Timeout 200 milliseconds (default)

Serial Protocol: ASCO I, II, and Modbus

Transport Protocol: TCP, UDP

Application Protocol: HTTP, Telnet, Modbus/TCP

(DB9 pin male) for ATS/PM connectivity

Operating 32 to 140° F (0 to 60° C)

Storage - -40 to 185° F (-40 to 85° C)

Installation Overview

1. Determine the kind of network to use to connect the

various devices to the Connectivity Module.

2. If a RS485 network will be used, do not install the

Connectivity Module until the DIP switches are

checked and set on the bottom of the unit. See below.

3. Refer to the outline & mounting drawing (page iv)

and wiring diagrams (pages v, vi).

4. Select the appropriate installation (pages 1-1, 1-2)

that corresponds to the product to be connected.

5. Establish and test communications (page 1-2).

Refer to Status LEDs (page vii).

6. View and change configuration pages (page 1-3).

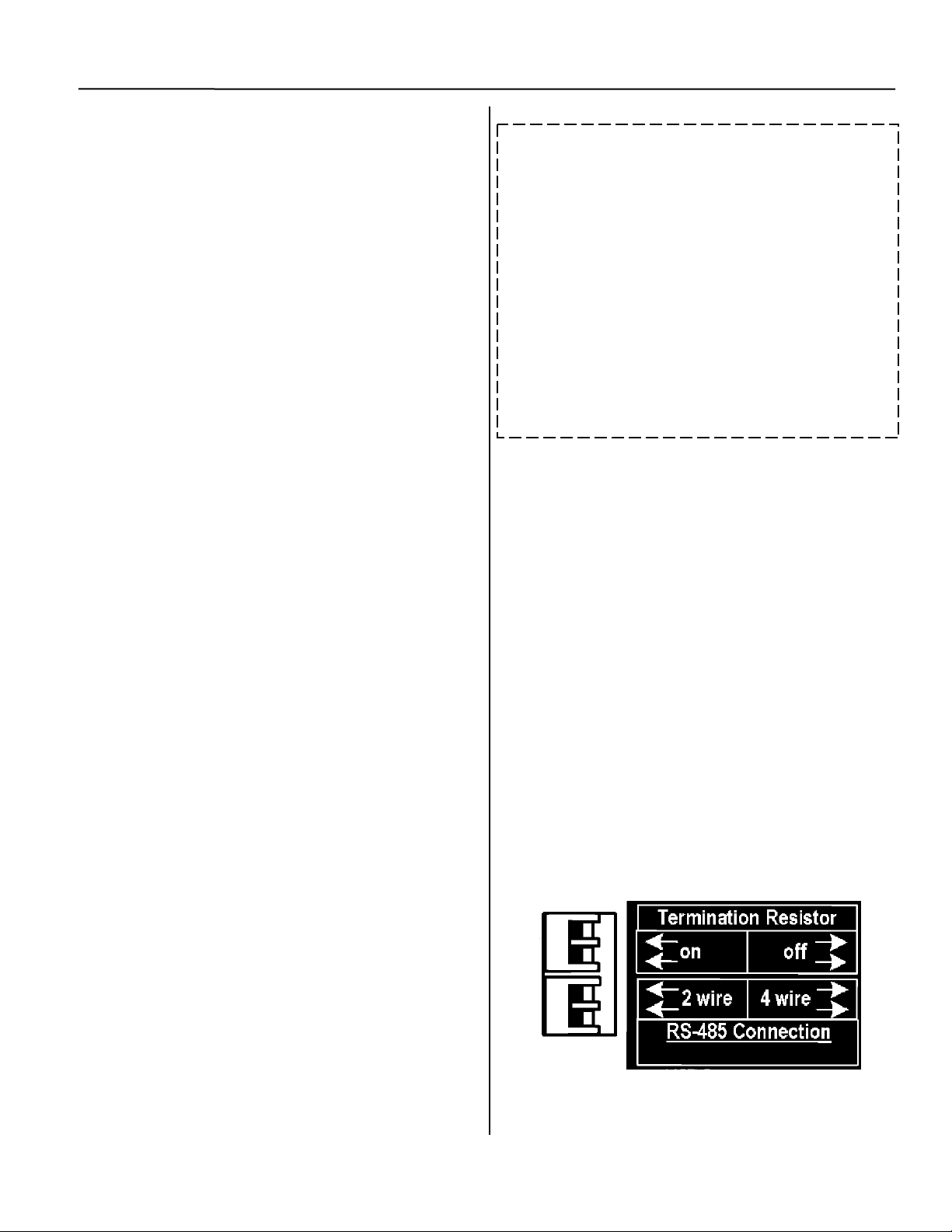

Check the DIP Switch Settings for RS485

For RS485 networks only, before installing the

Connectivity Module check the position of the DIP

switch actuators on the bottom of the unit. The upper two

actuators turn on a built-in termination resistor, if needed.

The lower two actuators select either a 2-wire or 4-wire

RS485 network. See the figure below.

Termination Resistor, upper two actuators

On a daisy chained RS485 network the Connectivity

Module termination resistor must be ON. Likewise only

the farthest device from the Connectivity Module must

have the termination resistor ON. All other devices must

be OFF. The DIP switch upper two actuators control the

built-in termination resistor:

ON – move to left. OFF – move to right.

2-Wire or 4-Wire network, lower two actuators

If a 2-wire RS485 network is to be attached to the

Connectivity Module, move the lower two actuators to

the left. If a 4-wire RS485 network is used, move these

actuators to the right.

DIP Switch on bottom of unit

Modbus is a registered trademark of Gould Inc.

Page 4

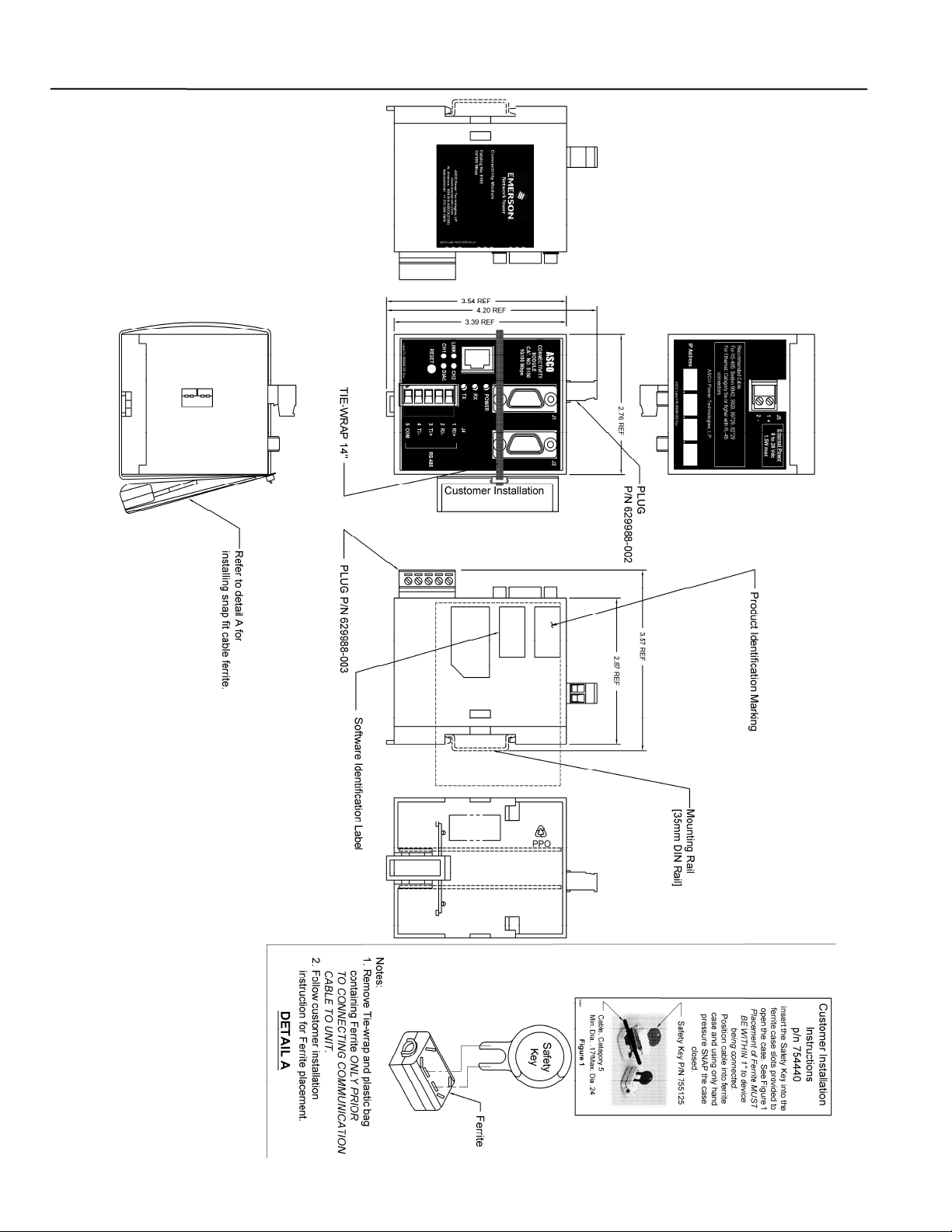

iv Outline and Mounting Drawing Connectivity Module

Page 5

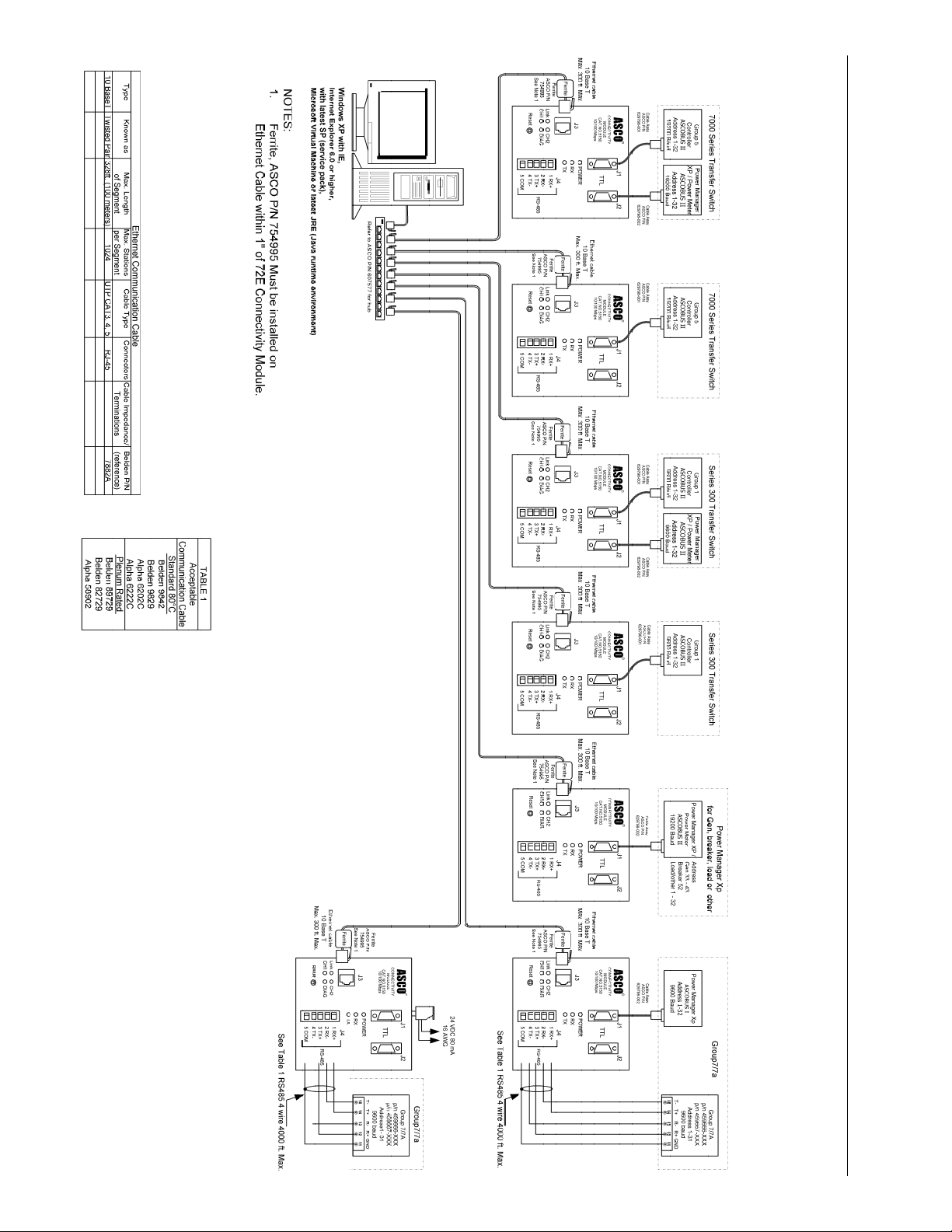

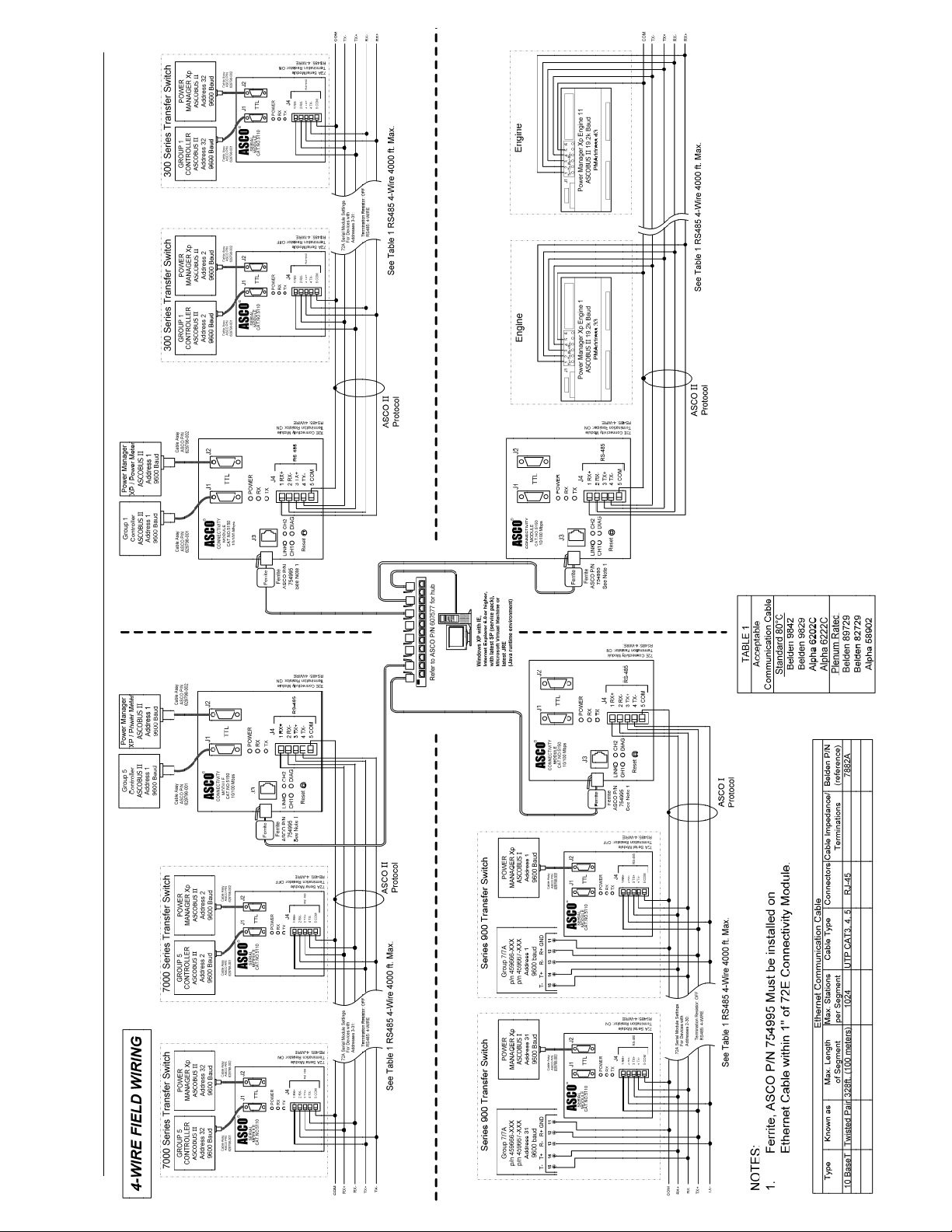

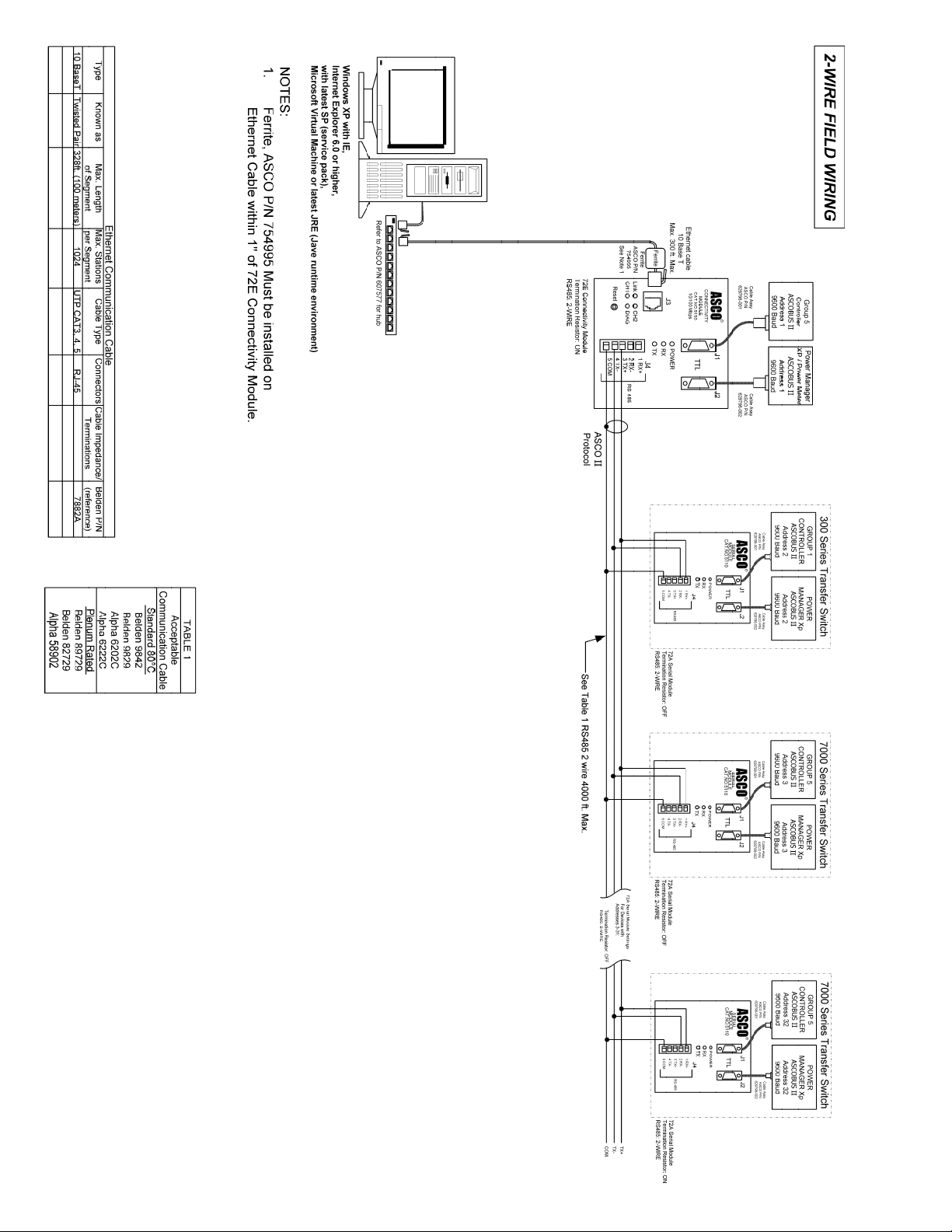

v Wiring Diagrams Connectivity Module

Page 6

Connectivity Module Wiring Diagrams vi

Page 7

vii Wiring Diagrams Connectivity Module

Page 8

Connectivity Module Wiring Diagrams viii

Page 9

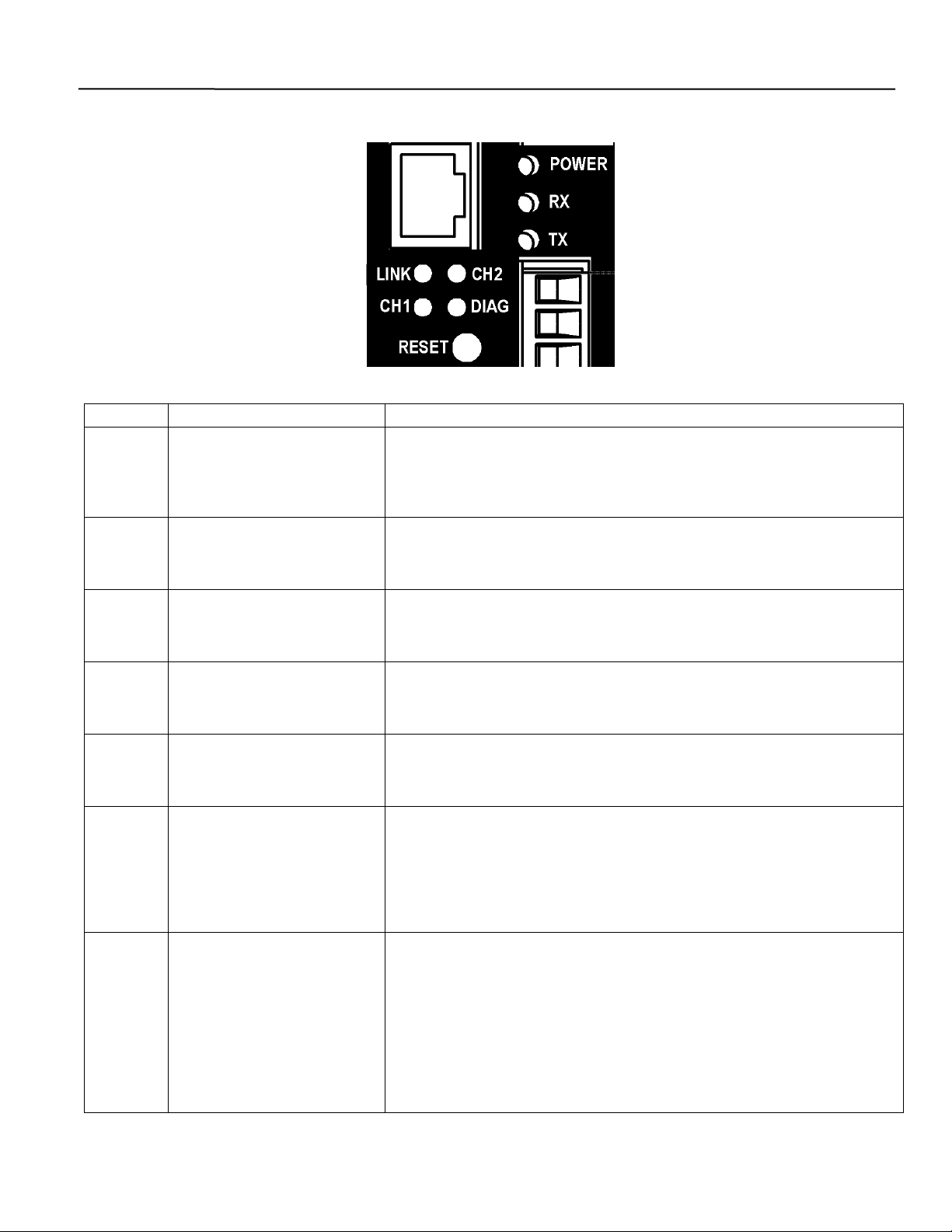

Connectivity Module Status LEDs ix

Status LEDs

LED LED Description LED Function / Mode of Operation

Solid GREEN – functioning as a Connectivity Module (Acc. 72E).

Solid AMBER – functioning as a Serial Module (Acc. 72A).

Blinking GREEN – indicates receiving data from a client.

Blinking GREEN – indicates transmitting data to a client.

Solid GREEN – indicates active Ethernet connection.

Blinking GREEN – indicates active Ethernet client connection.

Blinking YELLOW then off – indicates server disconnection because of

Ethernet client inactivity.

Solid YELLOW then off – indicates server disconnection due to Ethernet

client disconnection.

Off – indicates no error.

Short blinking RED then off – indicates active client/server write process.

Long blinking light then off – indicates server is receiving unrecognized

request packet from an Ethernet client.

Solid RED – indicates major error.

POWER

RX

TX

LINK

CH1

CH2

DIAG

Power indication status.

GREEN/AMBER

Data receiving status.

GREEN

Data transmit status.

GREEN

Link status.

GREEN

Client connection status.

GREEN

Additional Diagnostic LED.

YELLOW

Diagnostic.

RED

Page 10

1-1 Installation Connectivity Module

How to Install the Connectivity Module

on 7000 & 4000 Series and Series 300 ATSs

The Connectivity Module (CM) mounts on a DIN rail

under the ATS Controller (Group 5 & 1). A short serial

cable connects the CM to the Controller. If a Power

Manager (PM) or Digital Power Meter (DPM) is present,

a long serial cable connects the CM to the PM. Refer to

installation drawings provided and follow the steps below

to install the Connectivity Module.

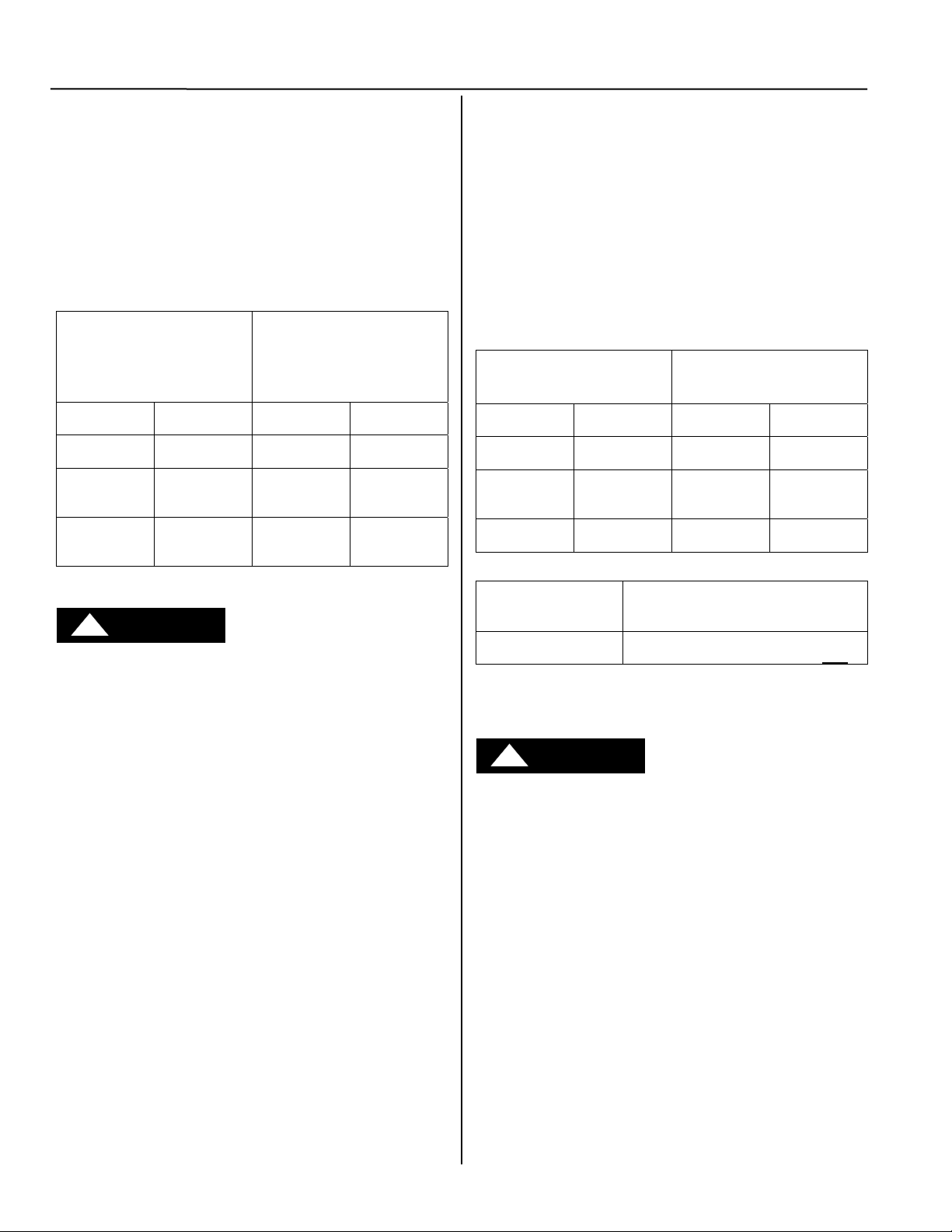

Connectivity Module Kit

K889950

for 7000 & 4000 Series

and Series 300 only

Connectivity

Module 5150

DIN Rail and

Hardware

10-in. Serial

Cable for

Controller

4-ft Serial

!

DANGER

To avoid possible shock, burns, or death, deenergize all

electrical sources to the ATS before installing the

Connectivity Module.

629800-004

754607

629798-001

1. De-energize both Normal and Emergency sources

that feed the ATS. Open enclosure door and check

with a non-contact AC voltage detector.

2. Mount the DIN rail (supplied in the kit) onto two

studs (on the door) below the Controller.

Connectivity Module will mount on the right side.

3. Install Connectivity Module onto DIN rail by

hooking the bottom of module on bottom of DIN rail

and rocking it upward unit it snaps in place.

4. Install the 10-inch serial cable between the Controller

receptacle (J7 on Group 5, J4 on Group 1) and the

Connectivity Module J1 receptacle.

5. If a PM (or DPM) is present, connect the 4-foot serial

cable between the PM J5 receptacle (or DPM J2

receptacle) and the Connectivity Module J2

receptacle.*

Now test communications (go to page 1-2).

Connectivity Module Kit

K889950-001 for

7000 & 4000 Series

and Series 300

with PM or DPM

Connectivity

Module 5150

DIN Rail and

Hardware

10-in. Serial

Cable for

Controller

Cable for

PM or DPM *

* A 9-foot serial cable (629798-004) is

required for G7ATB, G7ACTB, G7ADTB.

629800-004

754607

629798-001

629798-002

How to Install the Connectivity Module

on ASCO 940/962 ATSs

The Connectivity Module (CM) mounts on a DIN rail

near the ATS Control Panel. A separate power supply is

needed unless it is connected to a Power Manager (PM).

Group 6A/7A Control Panel must have a Serial

Communication Kit added. A single communication

cable (2 twisted pairs and overall shield connects the CM

to the Control Panel). Refer to installation drawings

provided and follow the steps below to install the

Connectivity Module.

Connectivity Module Kit

K889953

for ASCO 940/962 only

Connectivity

Module 5150

DIN Rail and

Hardware

Serial Com.

Kit for Group

6A/7A CP *

Serial Cable

** If a Power Manager (PM) is present, a power supply is not needed for

the Connectivity Module (CM). The serial cable from the PM provides

the power to the CM.

To avoid possible shock, burns, or death, deenergize all

electrical sources to the ATS before installing the

Connectivity Module.

1. De-energize both Normal and Emergency sources

* Serial communication & transient protection boards.

Required

Power Supply **

not supplied

24 Vdc, 80 mA ** use

16 AWG wire

!

DANGER

that feed the ATS. Open enclosure door and check

629800-004

754610

467508

Belden 9842, 9829, 89729, 82729 or

with a non-contact AC voltage detector.

2. Mount DIN rail (supplied in the kit) onto two studs

(on the door) below or adjacent to the Control Panel.

3. Install the Connectivity Module onto DIN rail.

4. Prepare and connect the specified communication

cable between the Control Panel terminals and the

Connectivity Module J4 terminals as listed below:

5. Prepare and connect the 24 Vdc power supply to the

Connectivity Module. Use 16 AWG wiring to J5

terminal plug (1 is + positive, 2 is – negative).

Now test communications (go to page 1-2).

Connectivity Module Kit

K889953-001

for ASCO 940/962 with PM

Connectivity

Module 5150

DIN Rail and

Hardware

Serial Com.

Kit for Group

6A/7A CP *

for PM

Communication Cable

(4 wires and an overall shield)

not supplied

Alpha 6202C, 6222C, 58902 only

629800-004

754610

467508

629798-002

Page 11

Connectivity Module Installation 1-2

How to Install the Connectivity Module for

a stand-alone Power Manager or Digital

Power Meter

The Connectivity Module (CM) mounts on a DIN rail

near the Power Manager (PM) or Digital Power Meter

(DPM). A long serial cable connects the Connectivity

Module to the PM or DPM. Refer to installation drawings

provided and follow the steps below to install the

Connectivity Module.

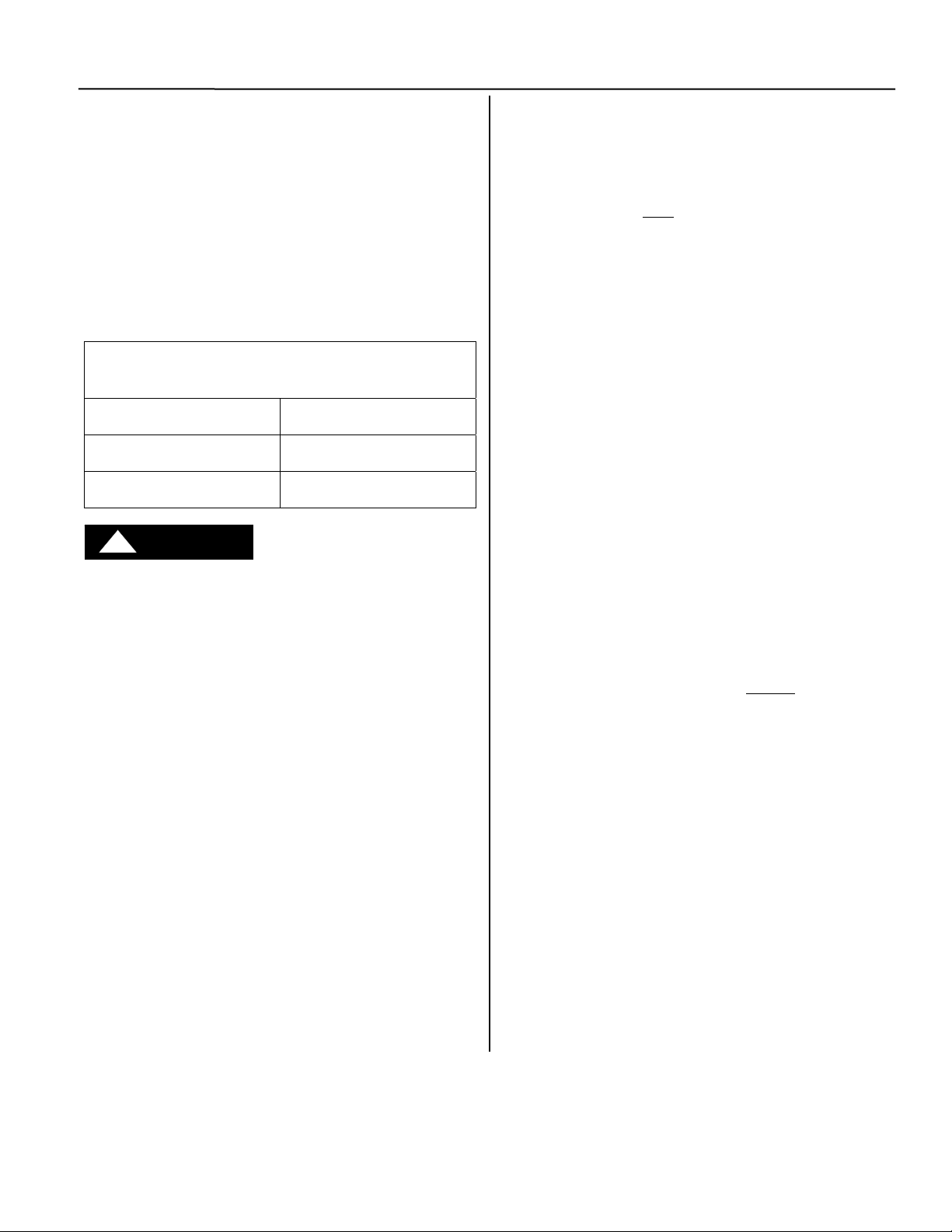

Connectivity Module Kit K889958

for a stand-alone Power Manager or Digital

Power Meter (not connected to an ATS)

Connectivity

Module 5150

DIN Rail and

Hardware

4 ft. Serial Cable

for PM or DPM

!

DANGER

To avoid possible shock, burns, or death, deenergize all

electrical sources to the ATS before installing the

Connectivity Module.

629800-004

754610

629798-002

1. De-energize the power source that feeds the PM (or

DPM). Open enclosure door and check with a

non-contact AC voltage detector.

2. Mount the DIN rail (supplied in the kit) onto two

studs (on the door) below or adjacent to the PM or

DPM.

3. Install Connectivity Module onto DIN rail by

hooking the bottom of module on bottom of DIN rail

and rocking it upward unit it snaps in place.

4. Install the 4-foot serial cable between the Power

Manager J5 receptacle (or Digital Power Meter J2

receptacle) and the Connectivity Module J2

receptacle.

Now test communications (go to next column).

How to Test Communication to the

Connectivity Module

You need the following settings from your network

administrator for each

connected to an Automatic Transfer Switch (ATS), Power

Manager (PM), or Digital Power Meter (DPM). Fill in the

form provided in the Appendix:

IP Address: ______________ (unique for each module)

Subnet mask __________ (usually same for all modules)

Gateway: ________________________ (usually blank)

Required items:

• Portable laptop computer with network card, running

Windows Xp and Windows Internet Explorer 6.0 +

installed.

• Ethernet crossover network cable (part no.

629590-006).

• Connectivity Module connected to the ATS, PM, or

DPM.

1. Directly connect the specified Ethernet crossover

cable between your laptop’s Ethernet jack and the

deenergized Connectivity Module jack J3.

2. For safety, close the ATS, PM, or DPM enclosure

door as far as possible (with the crossover cable

running to the laptop computer outside

Then energize ATS, PM, or DPM and the

Connectivity Module.

3. Refer to the Appendix and select the appropriate

TCP/IP Installation & Configuration instructions for

your laptop computer’s operating system. This

procedure sets up your laptop computer (if necessary)

for network connections and tests communications to

the Connectivity Module.

4. After you have confirmed communication with the

Connectivity Module, continue to the next page to

view and change the configuration of the

Connectivity Module and ATS, PM, or DPM.

Now view and change the configuration

Connectivity Module (CM)

the enclosure).

(go to page 1-3)

Page 12

1-3 Installation Connectivity Module

How to View & Change Configuration Pages

from a Connectivity Module

To view and change configuration pages on a client

computer, follow these steps:

1. Be sure that your computer is connected to the Internet.

2. Start Microsoft Internet Explorer browser on computer.

3. In the address bar, type in the address of the Connectivity

Module, add /config.htm, press Enter :

http://169.254.1.1/config.htm

How to View Pages from a Connectivity

Module after it is installed

installation, testing, and configuration is completed,

After

to view pages on a client computer, follow these steps:

1. Be sure that your computer is connected to the

Internet.

2. Start Microsoft Internet Explorer browser on the

computer.

3. In the address bar, type in the address of the

Connectivity Module:

http://169.254.1.1

Type the address of the Connectivity Module and add

/config.htm here.

On the Login screen there is

no password until you enter

one. If you click Login

without entering a password,

there is no protection. If you

want protection, click

Change Password; the

Change Password screen

appears. Then enter a

password (15 char. max.) in

New Password, enter it again

in Confirm New Password,

and click OK. You can set

only one password.

The Connectivity Module sends HTML files to the client

computer. Internet Explorer interprets these HTML files,

formats them, and displays the pages to the user.

Pages 2-1, 2-2, 3-1, 3-2, 4-1, 5-1 show Device Configurator

screens for ATSs and PMs or DPMs (go to the appropriate

section for the specific ATS, PM, or DPM).

Tip

You can add the address to your Favorites for convenient

access to multiple Connectivity Modules; follow these steps:

1. Click Favorites, then click Add to Favorites, click New

2. To rename the address, highlight it, and t ype the new name,

When you are finished viewing pages, close Internet Explorer.

PASSWORD

Folder, then type the Folder name (ATS Configuration,

for example), and click OK.

and click OK.

Type the address of the

Connectivity Module here

The Connectivity Module sends HTML files to the client

computer. Internet Explorer interprets these HTML files,

formats them, and displays the pages to the user.

Pages 2-3, 3-3, 4-2, 5-2, 5-3 show typical HTML pages

(Detail screens) for ATSs and PMs or DPMs (go to the

appropriate section for the specific ATS, PM, or DPM).

Tip

You can add the address to your Favorites for

convenient access to multiple Connectivity Modules;

follow these steps:

1. Click Favorites, then click Add to Favorites,

click New Folder, then type the Folder name

(ATSs, for example), and click OK.

2. To rename the address, highlight it, and type the

new name, and click OK.

3. When you are finished viewing pages, close

Internet Explorer.

Page 13

Connectivity Module 7000 & 4000 Series ATSs 2-1

A

A

d

Device Configurator Screen for 7000 & 4000 Series ATSs

The Device Configurator Screen for 7000 & 4000 Series ATSs shows the Group 5 controller configuration

settings (right side) and Connectivity Module (server) configuration settings (left side) for the selected ATS.

Group 5 Controller Configuration (right side)

Enter or change the ATS Name (8 char. max.)and the ATS Location (20 char. max.). Press the Update

button when finished to save the controller configuration changes.

Connectivity Module (server) Configuration (left side)

Several configuration settings must be set appropriately as described below. Press the Update Server button

when finished to save configuration changes.

Consult with your network

administrator for these 4 settings:

IP Address

Subnet Mask

Gateway Address

TCP Port Number

(Range of ports allowed is:

10024-65535, but do not

ports 14000-14009 or 30718)

use

TS Name

TS Location

Serial Port Speed 19200

Flow Control No flow control

Interface Mode RS485-4 or 2 Wire

Encyrption enable check box and

assign an AES port (same range as

TCP port but do not

port number used for TCP port.)

r

3

party device running own protocols

use the same

Press Update button when finished to

save the configuration changes. Do this

you press Update Server button.

before

After Controller has been updated,

press Update Server button to save

the configuration changes.

SNMP refer to Appendix A-5

When a Power Manager or Digital Power Meter is connected, additional buttons appear at the bottom of the

Connectivity Module Device Configuration screen.

Press to configure the Power

Manager or Digital Power Meter.

Press to configure the Group 5 Controller.

Device Configurator Screen for 7000 & 4000 Series ATSs

After Controller, PM, or DPM has

been updated, press Update Server

button to save the configuration

Additional Buttons on Device Configurator Screen for

7000 & 4000 Series ATSs with Power Manager or Digital Power Meter

Page 14

2-2 7000 & 4000 Series ATSs Connectivity Module

g

Device Configurator Screen for 7000 & 4000 Series ATSs with a PM or DPM

If a Power Manager (PM) or Digital Power Meter (DPM) is used with a 7000 & 4000 Series ATS, a button appears

on the lower left corner of the Connectivity Module Device Configurator screen. Press the Config PM button to

display the Power Manager or Power Meter Configuration screen (right side).

Power Manager or Power Meter Configuration

Enter or change the PM or DPM Name (8 char. max.) and Location (20 char. max.). Several configuration settings

must be set appropriately. Press the Update button when finished to save the PM or DPM configuration changes.

Input Name & Output Names (Power Manager only)

For a Power Manager, press the Config I/O Name button to display the Input Name and Output Name screen.

Enter or change the names (16 char. max.) of the inputs and outputs. Press the Update button when finished to save.

Press Config I/O Name button to

display Input & Output Names screen.

Power Manager

Input & Output Names (PM only) PM or DPM Configuration

Input names

Output names

Power Manager

name

Power Manager

location

Press Update button when

finished to save the configuration

Power Meter

Power Meter

name

Power Meter

location

Press Update button when

finished to save the configuration

Press To PM Config button to return to

Power Mana

er Configuration screen.

Press Update button when

finished to save the names.

For a 7ATB (automatic transfer &

bypass-isolation switch) with a

Power Manager, see page 2-3 for

the Power Manager IO Settings.

Update the PM, DPM, or Group 5

Controller first

the server. Do not close the browser

during the updating process. The

PM, DPM, or CP update request will

be discarded if the browser is closed.

NOTE

if you need to update

Page 15

Connectivity Module 7000 & 4000 Series ATSs 2-3

Configurator Screen Input and Output Names for a 7ATB with Power Manager

For 7ATB only (7000 Series Automatic Transfer & Bypass-Isolation Switch), the Power Manager selection

(Accessory 85 suffix letter designation) must be specified. The selection automatically assigns descriptive tags for

the associated inputs and outputs applicable to the chosen accessory. These fields will be pre-populated with their

known designations, but they are editable by the user. The user must press the Update button to save the

configuration selection and any changes.

Refer to the wiring diagram provided with the 7ATB. It shows the specific Accessory 85 suffix letter used. Set the

Power Manager IO Settings to the Accessory 85 specified on the wiring diagram.

Press Update button when

finished to save the configuration

The table below shows the descriptive tags assigned for each Accessory 85 selection, which are unique to 7ATBs.

The N/A selection does not provide any descriptive tags.

Accessory 85 Descriptive Tags Assigned

I/O

Input 1 Bypass on Normal Bypass on Normal Bypass on Normal Status Input 1

Input 2 Bypass on Emerg Bypass on Emerg Bypass on Emerg Status Input 2

Input 3 Closed Isolation Bypass on Auto Bypass on Auto Status Input 3

Input 4 Open Isolation Close Isolation Close Isolation Status Input 4

Input 5 Open Isolation Open Isolation Open Isolation Status Input 5

Input 6 Test Mode Emergency Accept Emergency Accept Status Input 6

Input 7 Normal Accept Normal Accept Status Input 7

Input 8 Engine Start Engine Start Status Input 8

Output 1 Trsfer To Emerg Trsfer To Emerg Status Output 1

Output 2 Status Output 2

Output 3 Status Output 3

Output 4 Status Output 4

85R 85S 85SB Other

Select the Accessory 85 specified on the 7ATB wiring diagram.

Example: Accessory 85S selected

Accessory

Page 16

2-4 7000 & 4000 Series ATSs Connectivity Module

A

p

)

A

A

Detail Screen for 7000 & 4000 Series ATSs

The Detail Screen for 7000 & 4000 Series ATSs shows the switch location, ratings, timer settings, actual

timer values, pickup and dropout settings, event logging, and other status indications.

ATS one-line icon shows position & source status (green or red circle

means source is acce

Status of

Emergency

Source

Active time delays

table, grey circle means source is not acceptable

ATS name

ATS type

ATS location

Status of Normal Source

Active time delays

Actual voltage

& frequency

readings from

ATS controller.

Voltage &

frequency

settings in ATS

controller.

ATS events

(date & time,

Description,

and cause)

Load connected to Normal or Emergency Source

Engine start signal (red means active)

Detail Screen for 7000 & 4000 Series ATSs with a Power Manager

Same as above and adds information from the Power Manager (voltage current, power, and rating).

Actual voltage

& frequency

readings from

ATS controller.

Voltage &

frequency

settings in ATS

controller.

TS ratings

TS events

on right

side of

screen

Detail Screen for 7000 & 4000 Series ATSs with a Digital Power Meter

Same as above and adds information from the Power Meter (voltage current, power, and rating).

TS events

on right

side of

screen

Page 17

Connectivity Module Series 300 ATSs 3-1

g

Device Configurator Screen for Series 300 ATSs

The Device Configurator Screen for Series 300 ATSs shows the Group 1 controller

configuration settings (right side) and the Connectivity Module (server) configuration

settings (left side) for the selected ATS.

Group 1 Controller Configuration (right side)

Enter or change the ATS Name (8 char. max.) and the ATS Location (20 char. max.). Press

the Update button when finished to save the Group 1 controller configuration changes.

Connectivity Module (server) Configuration (left side)

Several configuration settings must be set appropriately as described below. Press the Update

Server button when finished to save configuration changes.

Consult with your network

administrator for these 4 settings:

IP Address

Subnet Mask

Gateway Address

TCP Port Number

(Range of ports allowed is:

1024-65535, but do not

ports 14000-14009 or 30718)

use

ATS Name

ATS Location

Serial Port Speed 9600

Flow Control No flow control

Interface Mode RS485-4 or 2 Wire

Encyrption enable check box

and assign an AES port (same

range as TCP port but do not

the same port number used for

TCP port.)

SNMP refer to Appendix A-5

use

Device Configurator Screen for Series 300 ATSs

Press Update button when finished to

save the configuration changes. Do this

you press Update Server button.

before

After Controller or has been updated,

press Update Server button to save

the configuration changes.

When a Power Manager or Digital Power Meter is connected, additional buttons appear at the bottom of the

Connectivity Module Device Configuration screen.

Press to configure the Power

Manager or Digital Power Meter.

Press to configure the Group 1 Controller.

After Controller, PM, or DPM has been

updated, press Update Server button

to save the confi

uration changes.

Additional Buttons on Device Configurator Screen for

Series 300 ATSs with Power Manager or Digital Power Meter

Page 18

3-2 Series 300 ATSs Connectity Module

g

g

g

Device Configurator Screen for Series 300 ATSs with a PM or DPM

If a Power Manager (PM) or a Digital Power Meter (DPM) is used with a Series 300 ATS, a button appears on the

lower left corner of the Connectivity Module Device Configurator screen. Press the Config PM button to display

the Power Manager or Power Meter Configuration screen (right side).

Power Manager or Power Meter Configuration

Enter or change the PM or DPM Name (8 char. max.) and Location (20 char. max.). Several configuration settings

must be set appropriately. Press the Update button when finished to save the PM or DPM configuration changes.

Input Name & Output Names (Power Manager only)

For a Power Manager, press the Config I/O Name button to display the Input Name and Output Name screen.

Enter or change the names (16 char. max.) of the inputs and outputs. Press the Update button when finished to save.

Press Config I/O Name button to

display Input & Output Names screen.

Power Manager

Input & Output Names (PM only) PM or DPM Configuration

Input names

Output names

Power Manager

name

Power Manager

location

Press Update button when finished

to save the confi

Power Meter

Power Meter

name

Power Meter

location

uration changes.

Press To PM Config button to return to

Power Mana

er Configuration screen.

Press Update button when

finished to save the names.

Press Update button when finished

to save the confi

uration changes.

Update the PM, DPM, or Group 1

Controller first

the server. Do not close the browser

during the updating process. The PM,

DPM, or CP update request will be

discarded if the browser is closed.

NOTE

if you need to update

Page 19

Connectivity Module Series 300 ATSs 3-3

A

y

Detail Screen for Series 300 ATSs

The Detail Screen for Series 300 ATSs shows the switch location, ratings, timer

settings, actual timer values, pickup and dropout settings, and other status indications.

ATS one-line icon shows position & source status (green or red circle

means source is acceptable, grey circle means source is not acceptable)

Status of

Emergency Source

Actual voltage

& frequency

readings from

ATS controller.

ATS location

ATS type

Status of Normal SourceATS name

Actual voltage

reading from

TS controller.

Voltage &

frequency

settings in ATS

controller.

Engine start signal

(red means active)

Active

time dela

s

Load connected to Normal or Emergency Source

Detail Screen for Series 300 ATSs with a Power Manager

The Detail Screen for Series 300 ATSs with a Power Manager is the same as above

and adds information from the PM (voltage, current, power, and rating).

Detail Screen for Series 300 ATSs with a Digital Power Meter

The Detail Screen for Series 300 ATSs with a Digital Power Meter is the same as

above and adds information from the DPM (voltage, current, power, and rating).

Voltage &

frequency

settings in ATS

controller.

Active time delays

Page 20

Page 21

Connectivity Module ASCO 940/962 ATSs 4-1

A

Device Configurator Screen for ASCO 940/962 ATSs

The Device Configurator Screen for ASCO 940/962 ATSs shows the Group 7A controller configuration

settings (right side) and the Connectivity Module (server) configuration settings (left) for the selected ATS.

Group 7A Controller Configuration (right side)

Enter or change the ATS Name (18 char. max.) and ATS Nominal Voltage (must be entered to get correct

reading). Press the Update button when finished to save the Group 7A controller configuration changes.

Connectivity Module (server) Configuration (left side)

Several configuration settings must be set appropriately as described below. Press the Update Server button

when finished to save configuration changes.

Consult with your network

administrator for these 4 settings:

IP Address

Subnet Mask

Gateway Address

TCP Port Number

(Range of ports allowed is:

10024-65535, but do not

ports 1400-14009 or 30718)

use

xxx

Nom. VoltageATS Name

Serial Port Speed 9600

Flow Control No flow control

Interface Mode RS485-4 or 2 Wire

Encyrption enable check box and

assign an AES port (same range as

TCP port but do not

port number used for TCP port.)

use the same

Consult with your network

administrator for these 4 settings:

IP Address

Subnet Mask

Gateway Address

TCP Port Number

(Range of ports allowed is:

10024-65535, but do not

ports 1400-14009 or 30718)

Serial Port Speed 9600

Flow Control No flow control

Interface Mode RS422/485-4Wire

Encyrption enable check box and

assign an AES port (same range as

TCP port but do not

port number used for TCP port.)

use

use the same

Press Update Server button

when finished to save the

configuration changes.

Device Configurator Screen without Power Manager

TS Name

xxx

Press Update Server button

when finished to save the

configuration changes.

Device Configurator Screen with Power Manager

Press Update button

when finished to save

the configuration

Nom. Voltage

Press Update button

when finished to save

the configuration

Page 22

4-2 ASCO 940/962 ATSs Connectivity Module

A

A

A

p

Detail Screen for ASCO 940/962 ATSs

The Detail Screen for ASCO 940/962 ATSs shows the switch location,

ratings, timer settings, actual timer values, pickup and dropout settings, and

other status indications.

ATS one-line icon shows position & source status

(green or red circle means source is acceptable,

grey circle means source is not acceptable)

Status of

Emergency

Source

Status of Normal SourceATS name

Actual voltage

reading from

ATS controller.

Voltage &

frequency

settings in ATS

controller.

Time delay

settings in

ATS

controller.

TS ratings

Load connected to Normal or Emergency Source

Detail Screen for ASCO 940/962 ATSs with a Power Manager

The Detail Screen for ASCO 940/962 ATSs shows the switch location,

ratings, timer settings, actual timer values, pickup and dropout settings, and

other status indications.

ATS one-line icon shows position & source status (green or red circle

means source is acce

Status of

Emergency

Source

table, grey circle means source is not acceptable)

Status of Normal SourceATS name

Actual voltage

reading from

TS controller.

Voltage &

frequency

settings in ATS

controller.

Time delay

settings in

ATS

controller.

Actual voltage

reading from

ATS controller.

Voltage &

frequency

settings in ATS

controller.

Time delay

settings in

ATS

controller.

Load connected to Normal or Emergency Source

Actual voltage

reading from

TS controller.

Voltage &

frequency

settings in ATS

controller.

Time delay

settings in

ATS

controller.

Page 23

Connectivity Module Stand-Alone Power Managers & Digital Power Meters 5-1

g

Device Configurator Screen for Power Manager or Digital Power Meter

If a stand-alone Power Manager (PM) or Digital Power Meter (DPM) is used, a button appears on the lower left

corner of the Connectivity Module Device Configurator screen. Press the Config PM button to display the Power

Manager or Power Meter Configuration screen (right side).

Power Manager or Power Meter Configuration

Enter or change the PM or DPM Name (8 char. max.) and Location (18 char. max.) Several configuration settings

must be set appropriately. Press the Update button when finished to save the PM or DPM configuration changes.

Input Name & Output Names (Power Manager only)

For a Power Manager, press the Config I/O Name button to display the Input Name and Output Name screen.

Enter or change the names of the inputs and outputs. Press the Update button when finished to save theses names.

Power Manager

Press Config I/O Name button to

display Input & Output Names screen.

Input & Output Names (PM only) PM or DPM Configuration

Input names

Output names

Power

Manager name

Power Manager

location

Press Update button when

finished to save the configuration

Power Meter

Power Meter

name

Power Meter

location

Press Update button when

finished to save the configuration

Press To PM Config button to return to

Power Mana

er Configuration screen.

Press Update button when

finished to save the names.

Update the PM or DPM first

need to update the server. Do not

close the browser during the

updating process. The PM or DPM

update request will be discarded if

the browser is closed.

NOTE

if you

Page 24

5-2 Stand-Alone Power Managers & Digital Power Meters Connectivity Module

Detail Screen for Power Managers connected to a Load

The Detail Screen for Power Managers shows energy levels, power

measurements, settings, discrete I/O status, and other status information.

Energy

levels

Settings

PM name

PM location

Power

measurements

Actual voltage, current, and

power readings from the PM.

Discrete Input / Output

name & status information

Detail Screen for Digital Power Meters connected to a Load

The Detail Screen for Digital Power Meters shows energy levels, power

measurements, settings, discrete I/O status, and other status information.

Settings

Energy

levels

Power

measurements

DPM name

DPM location

Actual voltage, current, and

power readings from the DPM.

Discrete Input / Output

name & status information

Page 25

Connectivity Module Stand-Alone Power Managers & Digital Power Meters 5-3

Detail Screen for Power Managers connected to a Generator

The Detail Screen for Power Managers shows energy levels, power

Gen-set icon appears if

Power Manager

address is set to 33-43.

Energy

levels

Power

measurements

measurements, settings, discrete I/O status, and other status information.

Settings

PM name PM location

Actual voltage, current, and

power readings from the PM.

Discrete Input / Output

name & status information

Detail Screen for Digital Power Meters connected to a Generator

The Detail Screen for Digital Power Meters shows energy levels, power

Gen-set icon appears if

Digital Power Meter

address is set to 33-43.

measurements, settings, discrete I/O status, and other status information.

Settings

DPM name

DPM location

Energy

levels

Power

measurements

Actual voltage, current, and

power readings from the DPM.

Discrete Input / Output

name & status information

Page 26

5-4 Stand-Alone Power Managers & Digital Power Meters Connectivity Module

Detail Screen for Power Managers connected to a Circuit Breaker

CB icon appears if

Power Manager

address is set to 52.

Energy

levels

Power

measurements

Actual voltage, current, and

power readings from the PM.

The Detail Screen for Power Managers shows energy levels, power

measurements, settings, discrete I/O status, and other status information.

Settings

PM name

Discrete Input / Output

name & status information

Detail Screen for Digital Power Meters connected to a Circuit Breaker

CB icon appears if

Digital Power Meter

address is set to 52.

The Detail Screen for Digital Power Meters shows energy levels, power

measurements, settings, discrete I/O status, and other status information.

Settings

DPM name

DPM location

Energy

levels

Power

measurements

Actual voltage, current, and

power readings from the DPM.

Discrete Input / Output

name & status information

Page 27

Connectivity Module Ethernet TCP/IP Network Connections in Windows XP & 7 A-1

How to Create an Ethernet TCP/IP Network Connection in Windows XP & 7

1. Start Windows, then click the Start button.

Select Control Panel.

2. Select Network Connections (Windows XP) or

Network and Internet and/or Network and

Sharing Center (Windows 7).

3. Windows XP)

Double click Local Area Connection to display

the properties screen.

5. On Local Area Connection Properties screen:

Windows XP Scroll to verify that

; Internet Protocol (TCP/IP) is selected and

highlighted, then click the Properties button.

Windows 7

Select Local Area Connection then click the

Properties button.

4. On Local Area Connection Status screen click

the Properties button.

Windows 7 Scroll to verify that

Internet Protocol Version 6 (TCP/IPv6) is deselected

; Internet Protocol Version 4 (TCP/IPv4) is

selected and highlighted, then click the

Properties button.

Page 28

A-2 Ethernet TCP/IP Network Connections in Windows XP & 7 Connectivity Module

6. If the computer is on the company network

contact the facilities IT personnel for

appropriate settings.

If it is a stand-alone computer, enter the IP # for

this computer that is listed on the Interface

Diagram. For example:

IP address: 169.254.1.2 (last digit must

be different than the CM)

Subnet Mask: 255.255.0.0 (same as CM)

Gateway: 0.0.0.0 (same as CM)

Windows XP

7. Once the TCP/IP setup is complete at the

computer, restart the computer (click the Start

button, then click Shut Down).

8. Restart Windows, then click the Start button.

Windows XP

Select All Programs > Accessories >

Command Prompt.

Windows 7

In the Command Prompt window:

type cmd and press ENTER.

9. In the command prompt window type ipconfig

and press ENTER. The settings are displayed.

10. In the command prompt window type ping

169.254.1.1 and press ENTER. You should see:

Reply from 169.254.1.1

This reply confirms communication between the

computer and the CM. Close the command

prompt window. Proceed to the appropriate

section How to View & Change Configuration

Pages from a Connectivity Module.

Windows 7

Page 29

Connectivity Module Troubleshooting A-3

Troubleshooting the Connectivity Module Listed below are possible problems, their causes, possible solutions

Problem Cause Solution

DIAG red light blinks rapidly then stays

on when the CM is first powered up.

DIAG red light blinks slowly or stays on

after the CM is properly configured.

Message: Page not found. Wrong or improper IP address and subnet. Problem with

Message: No controller or power

manager has been found.

Message: 72E baud rate and at least

another device baud rate are

mismatched (or similar message).

Message: Communication error stays

on. (RX light is blinking & TX light is

off).

Message: Communication error

comes on then goes off by itself.

LINK light is off

4-wire / 2-wire Modbus

communication problem

Intermittent loss of

communication / connection

AES enable client getting incorrect

response or no response from the CM.

ATS = automatic transfer switch, CM = Connectivity Module, DPM = Digital Power Meter, PM = Power Manager

Duplicate IP address. The IP address of one or more CMs

on the same network is set as same.

Major software or communication failure.

connections between CM, ATS Controller, PM, and/or

DPM. Wrong configuration.

Problem with connections between CM Module, ATS

Controller, PM, and/or DPM.

Baud rates of CM, ATS Controller, PM, and/or DPM are

different.

Lost connections. Check connections

Busy network or lost connections Increase reply time out.

Invalid network Check if it is a proper IP address.

- ATS or PM are not configured for Modbus protocol

- ATS or PM are not configured with the same baud rate

as the CM

- ATS or PM are configured with the same serial address

- For 4-wire communication, ATS was not configured for

4-wire mode

- For 2-wire communication, ATS was not configured for

2-wire mode

- For 2-wire communication, CM 2-wire DIP switch was not

enabled

- For 2-wire communication, 2-wire mode was not enabled

at the CM configuration page

- Modbus master is not requesting the correct set of

holding registers

- Modbus master requesting more holding registers than

the CM can handle

- Modbus master reply timeout may be too short

- Modbus master using incorrect CM IP address or TCP

port

CM disconnects the client because client was inactive / idle

(stops sending requests longer than 10 seconds)

Incorrect CM configuration settings:

- AES is not enabled

- Incorrect AES port

Unplug the Ethernet cable from all CMs.

Follow the instructions from the

appropriate configuration section to

change to a proper IP address. Reconnect

this CM to the network. The red DIAG light

should blink then go off. Repeat this

procedure for all other CMs one by one.

Press Reset button on CM. If condition still

exists, call your local ASI representative.

Try to refresh the page again. If you get

the same results, verify the IP address and

wiring by pinging the device.

Check wiring then press Reset button on

CM.

If 7000 or 4000 Series ATS, set baud rate

of all the devices to 19200.

If Series 300 or ASCO 940/962, set baud

rate of all the devices to 9600.

Check the Ethernet cable and

connections.

- Make sure ATS and PM are configured

with: Modbus protocol

the same baud rate as CM

the correct serial I/F setting

(4-wire/2-wire)

unique serial addresss

- For 2-wire communication, make sure

to configure the CM serial I/F setting for

2-wire mode at the configuration page;

and to enable its 2-wire DIP switch

- Modbus master should refer to doc.

381339-221 for the ATS and PM

holding registers.

- Modbus master must use appropriate

relay timeout (usually starting with 1000

ms) and to consider using retries (3

recommended) before calling for

communication error.

- Modbus master must request a

maximum of 12 holding registers from

the ATS controller & 24 from the PM

- Modbus master connect to the same IP

address and TCP port assigned to CM

- Check serial wiring connection between

ATS/PM and the CM

When client connects to the CM, it should

never stop communicating (sending

request) at all times. When CM detects

inactivity from the connected client (from

its last request) longer than 10 seconds,

the CM will automatically disconnect it.

That client must then reconnect to resume

communication.

Provide correct CM AES configuration

settings

Page 30

A-4 Create Favorites folder, 3rd Party Modbus Configuration Connectivity Module

How to create a Favorites folder for ASCO

device pages and copy it to another

computer

To create a favorites folder and copy it to another user’s

computer, the administrator should follow these steps:

1. Open the first page and then pull down the Favorites

manual and select Add to Favorites … This window

will appear:

2. Click the New Folder button, type the new folder

name as asco, then click the OK button.

3. Click folder asco and click OK.

4. Open the other pages one by one and click Add to

Favorite, click folder asco, then click OK.

5. Once the administrator is done with saving all the

pages, the following steps describe how to copy the

asco folder from the administrator’s computer to

another user’s computer.

a. For Windows XP, find the asco folder from directory

‘c:documentd and settings\’user name’\favorites’.

b. Copy the asco folder into the corresponding path

above.

c. Open browser and select address or name from

favorite asco folder to view the device pages.

Third Party Modbus Device Configuration

The Connectivity Module supports the Modbus devices

with Modbus/TCP portocol. The transmit and receiving

data format are as follows:

:

Read

Requests:

Bytes 0, 1 Transaction ID.

Usually zero when making a request, the server

will copy them into the response.

Bytes 2, 3 Protocol number. It must be zero.

Byte 4 length (high byte) its always zero.

Byte 5 length (low byte) of the following total bytes

Byte 6 device address

Byte 7 function code

Bytes 8, 9 Modbus address of the starting transfer.

Bytes 10, 11 number of word to transfer

Response:

Bytes 0, 1 Transaction ID. Its faithfully copied from the

request

Bytes 2, 3 Protocol number. It always is zero.

Byte 4 length (high byte) its always zero

Byte 5 length (low byte) of the following total bytes

Byte 6 device address

Byte 7 function code

Bytes 8 byte count of Modbus data.

Bytes rest data values

Configure the Connectivity Module to properly

communicate with the other devices. The following

items should be ready before you start to configure it:

1. Ethernet crossover cable.

2. Laptop with proper Ethernet connect ability.

3. Start Internet browser and type ‘IP

address\config.htm’ on the browser address field.

4. This page should appear:

From this page,

configure all the

parameters except

reply timeout which

needs to configured

from client device.

xxx

Page 31

Connectivity Module SNMP Internet-standard Protocol A-5

How to set SNMP (Simple Network Management Protocol) Configuration

Firmware 869764-003 and higher

provides SNMP configuration.

1. On the Device Configuration screen (page 2-1

or 3-1) click the SNMP button at the bottom.

2. On the SNMP Configuration screen click the

check box ; SNMP Enabled (to enable it).

3. Assign the Community name for READ and

Community name for WRITE.

4. Assign the SNMP Manager IP Addresses.

Start with the 1 IP address and be sure the

addresses have 4 octets where each octet has

3 digits in it. Click the Close button.

xxx.xxx.xxx.xxx

5. Review all settings, then click Update Server

button to save the configuration settings.

SNMP TRAP messages

With SNMP enabled the CM can notify changes on

ATS status and power metering conditions by

sending TRAP messages. The changes listed below

are regarded as alarms and are strictly monitored

during runtime.

1. ATS transfer to emergency source

2. ATS retransfer to normal source

3. Engine running

4. Normal source unavailable

5. Emergency source unavailable

6. Power manager digital inputs 1 to 8 activation.

7. Power manager digital outputs 1 to 4 activation

Device Configuration Screen (see page 2-1 or 3-1)

SNMP Configuration Screen

RESET

button

RESET button on CM

Page 32

A-6 SNMP Internet-standard Protocol Connectivity Module

Recommended ASCO SNMP MIB file

A file containing 934904-xxx.mib can be downloaded from the location shown below.

http://www.emersonnetworkpower.com/

en-US/Products/PowerSwitchingandControls/MonitoringandControl/Pages/

ASCO5150ConnectivityModuleAcc72E.aspx

The 934904-xxx.mib file is written in the MIB module definition language based on the SMI specifications.

This protocol file contains a structure block of information pertaining to ATS status and analog data. When

SNMP is enabled, the CM polls for the information and shares it with requesting SNMP manager(s). The

SNMP manager must use the file as a reference in sending SNMP requests for ATS information.

Troubleshooting SNMP Configuration

Problem Cause Solution

SNMP Manager cannot communicate

with the Connectivity Module; do not

get trap message after alarms occur.

- Host running SNMP Manager is

not in the same network or

Connectivity Module

- SNMP is not enabled.

- Incorrect SNMP IP Manager IP

addresses

- Incorrect SNMP community

setting.

- Check SNMP configuration at

Connectivity Module

configuration page.

- Hook up a laptop to the same

network and ping the

Connectivity Module and SNMP

Manager(s).

Page 33

Address set

in PM or DPM**

in ATS

Controller*

Address set

ATS

Catalog No.

ATS

Serial No.

Gateway

mask

Subnet

Communication Address Form for Connectivity Module (CM)

IP Address

No.

Row

* For Group 7A Control Panel (ASCO 940, 962, 436, 434, 447, 448) refer to Accessory 72A Instructions 381339-172

** For Power Manager refer to Operator’s Manual 381333-199. For Digital Power Meter refer to Operator’s Manual 381333-368.

* For Group 1 Controller (Series 300) refer to Communication Interface Module Instructions 381339-189

Instructions: Fill in the information for each Connectivity Module (CM) with an ATS, Power Manager (PM), and/or Digital Power Meter (DPM).

* For Group 5 Controller (7000 & 4000 Series) refer to User’s Guide 381333-126

For Serial Module Catalog 5110 (Accessory 72A) refer to Installation Manual 381333-240.

Page 34

Instructions: Fill in the information for each Connectivity Module (CM) with an ATS, Power Manager (PM), and/or Digital Power Meter (DPM).

* For Group 5 Controller (7000 & 4000 Series) refer to User’s Guide 381333-126

Row

No.

For Serial Module Catalog 5110 (Accessory 72A) refer to Installation Manual 381333-240.

* For Group 1 Controller (Series 300) refer to Communication Interface Module Instructions 381339-189

* For Group 7A Control Panel (ASCO 940, 962, 436, 434, 447, 448) refer to Accessory 72A Instructions 381339-172

** For Power Manager refer to Operator’s Manual 381333-199. For Digital Power Meter refer to Operator’s Manual 381333-368.

IP Address

Subnet

mask

Gateway

Communication Address Form for Connectivity Module (CM)

Serial No.

ATS

Catalog No.

ATS

Address set

Controller*

in ATS

in PM or DPM**

Address set

Page 35

Address set

in PM or DPM**

in ATS

Controller*

Address set

ATS

Catalog No.

ATS

Serial No.

Gateway

mask

Subnet

Communication Address Form for Connectivity Module (CM)

IP Address

No.

Row

* For Group 7A Control Panel (ASCO 940, 962, 436, 434, 447, 448) refer to Accessory 72A Instructions 381339-172

** For Power Manager refer to Operator’s Manual 381333-199. For Digital Power Meter refer to Operator’s Manual 381333-368.

* For Group 1 Controller (Series 300) refer to Communication Interface Module Instructions 381339-189

Instructions: Fill in the information for each Connectivity Module (CM) with an ATS, Power Manager (PM), and/or Digital Power Meter (DPM).

* For Group 5 Controller (7000 & 4000 Series) refer to User’s Guide 381333-126

For Serial Module Catalog 5110 (Accessory 72A) refer to Installation Manual 381333-240.

Page 36

A

Access, NOTICE, ii

AES encryption, iii, 2-1, 3-1, 4-1

Annunciators, ATS Remote, ii

ASCOSNMP.MIB, A-5

ATS information needed, ii,

communication address form

ATS Remote Annunciators, ii

C

Cable, communication, iii

CH1, CH1 light, vii

Change Password, 1-3

Circuit breaker, 5-4

Communication error message, A-3

Configuration

7000 Series ATSs, 2-1, 2-2

7000 Series ATBs, 2-1, 2-2, 2-3

4000 Series ATSs, 2-1, 2-2

Series 300 ATSs, 3-1, 3-2

ASCO 940/962 ATSs, 4-1

Power Managers, 5-1

Power Meters, 5-1

Configuration parameters, iii

Copy Favorites folder, A-4

Create Favorites folder, 1-1, A-4

D

DANGER, ii

Detail Screens (View Pages)

7000 Series ATSs, 2-4

4000 Series ATSs, 2-4

Series 300 ATSs, 3-3

ASCO 940/962 ATSs, 4-2

Power Managers, 5-2

Power Meters, 5-2

DIAG red light, vii, A-3

DPM, see Power Meter

E

Encryption, iii, 2-1, 3-1, 4-1, A-3

Ethernet TCP/IP Network

Connection, how to create

Windows XP, A-1, A-2

Event log, 7000 Series ATSs, 2-4

F

Favorites folder, create, 1-3, A-4

Ferrite, snap-on split core, iv

Form, communication address,

back of manual

INDEX

G

Generator, 5-3

K

Kits

7000 Series ATSs, 1-1

4000 Series ATSs, 1-1

Series 300 ATSs, 1-1

ASCO 940/962 ATSs, 1-1

Power Managers, 1-1, 1-2

Power Meters, 1-1, 1-2

H

Help, troubleshooting, A-3

I

Input/Output Names for 7ATB, 2-3

Installation, 1-1

Interface Wiring Diagrams, v, vi

Internet-standard protocol, SNMP,

A-5

IP address, A-3

L

LEDs, Status, vii, A3

LINK light, vii, A-3

Load status, 2-1

7000 Series ATS, 2-4

4000 Series ATS, 2-4

Series 300 ATS, 3-3

ASCO 940/962 ATSs, 4-2

Login, password, 1-3

M

Manuals, ii

N

Network, Ethernet TCP/IP

Connection, how to create

Windows XP, A-1, A-2

No controller or power manager

has been found message, A-3

O

Outline and Mounting Drawing, iv

Overview, iii

P

Page not found message, A-3

Password, 1-1

PM, see Power Manager

Ports, iii

POWER light, vii

Power Manager (PM), ii

7000 Series ATSs, 2-1, 2-2, 2-4

7000 Series ATBs, 2-1 thru 2-4

4000 Series ATSs, 2-1, 2-2, 2-4

Series 300 ATSs, 3-1, 3-2, 3-3

ASCO 940/962 ATSs, 4-1, 4-2

Stand-alone, 5-1, 5-2, 5-3, 5-4

Power Meter, Digital (DPM), ii

7000 Series ATSs, 2-1, 2-2, 2-4

4000 Series ATSs, 2-1, 2-2, 2-4

Series 300 ATSs, 3-1, 3-2, 3-3

Stand-alone, 5-1, 5-2, 5-3, 5-4

Power requirements, iii, 3-1

Protocol support, iii

R

Remote Annunciators, ATS, ii

RESET button, A-3

RX light, vii, A-3

S

SNMP protocol, A-5, A-6

Specifications, iii

Status LEDs, vii

T

Test Communication, 1-2

Third party Modbus device

configuration, A-4

Troubleshooting, A-3

TX light, vii, A-3

V

View Pages (Detail Screens), iii, 1-3

7000 Series ATSs, 2-4

4000 Series ATSs, 2-4

Series 300 ATSs, 3-3

ASCO 940/962 ATSs, 4-2

Power Managers, 5-2, 5-3

W

Welcome, ii

Wiring Diagrams, v, vi

Printed in U.S.A. © ASCO Power Technologies, L.P. 2012 All Rights Reserved.

Loading...

Loading...