Page 1

500 Series

510 Surge Protective Device

Installation, Operation and Maintenance Manual

Page 2

Surge Pr

EMERSON NETWORK POWER SURGE

DE

VICE INSTALL

ATION

, OPER

MAINTENANCE MANUAL

TAB

LE OF CONTENTS

UNPACKING AND INSTALL

Unpacking and Prelimi

H

andling Cons

St

orage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCA

TION CONSIDERATIONS

En

vironm

A

udible Noi

Service Cle

Mounting . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

War

nings Defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL NUMBER CONFIGURATION

Model Number Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration & Voltage (Chart) . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

idera

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ent

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

se

. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

aran

ces

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATION

nar

y Inspection . . . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROTEC

ATI

ON AND

TIVE

. . . . . . . . . . . . . . . . . . . . . . . . . . .

otectiv

. . . . . . . . . . . . . . . . . . . . .

e Devi

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . .

ces

2

2

2

2

2

2

2

2

3

3

ELECTRICAL CONNECTIONS

Volt

age Ratings and Power Source Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Over Curren

NEC C

Volt

age Pr

Circuit Am

System Grounding and Bonding . . . . . . . . . . . . . . . . .

P

arallel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ne

utral Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INST

ALLATION INST

Product Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA 12 (Metal) Enclosure Option

NEMA 4X (Non-Metallic) Enclosure Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA 1 Panelboard Extension Enclosure Option . . . . . .. .

MO

NITORING FEA

Extern

A

udible A

Sum

mar

T

ransient Cou

ons

al

idera

otec

pacit

Statu

lar

y A

t Pr

otec

tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

tion Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

y Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . .

RUC

TUR

ES

s Indicator

m (Stan

larm Contac

nte

dard

r (

Optional

TIONS

. . . . . . . . . . . . . . . . . .

s (Stan

/Optional

t (Stan

dard)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

)

. . . . . . . . . . . .

dard

/Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

)

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . .

.

. . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

4

4

4

4

4

4

4

5

5

5

6

7

7

8

9

9

9

9

TR

OUBLESHO

T

roubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servic

ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrective Maintenance

Pr

eventative Maintenance

Installation,

OTI

NG/SERVICING/MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .

Opera

tion and Maintenance Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . .

1

IO-70103

Re

v 0, 1/2013

9

9

9

Page 3

UNPACKING AND INSTALL

Unpacking and Preliminary Inspection

1. Inspect the shipping crate(s) for

si

gns of mishandling before unpacking the unit.

2.

Remove

and inspect the unit for any obvious shipping

3. If

any dam

immediate

forward a copy to y

Surge Protection Sales Representative.

Handling Considerations

Larger

h

andling

wei

ght.

Stor

age

The unit should be stored in a

en

vironment. Storage temp

t

o +85ºC (+185ºF). Care should be

c

ondensation. All packing and shipping materi

be left i

the unit has been stored for an

unit sho

plac

ing int

any secur

age

as a re

ly file a

units are bolted

by forklift or p

Refer t

ntac

uld be

o service.

cl

o the cabinet dat

t until the unit is

cle

aned and carefully inspected

ing bands and cardb

sult

of

shipping is obs

aim with the

our local

to a

all

Emerson Network Power

shipping pall

et j

ack. Check the

a furnished with the unit.

era

ture range is -55ºC (-67ºF)

re

ady for final installation. If

exte

dam

shipping ag

et to fac

cle

an,

taken to avoid

nded period of time, the

ATION

age or

oard p

damages.

erved,

ency

ili

tate

size

and

dry

als should

bef

acking

and

ore

Surge Pr

LOCATI

F

or optimum transient surge pr

suppression should be applied at the

all other ele

CATV, etc.), at known surge g

building (

etc.), as well as at sensitive electronic loads (such as

c

ompu

etc.). For

da

ta

cabling), transi

applied

En

vironment

am

bient tempera

with a relative humidity o

The unit is pr

dust-ti

with

excessi

or explosive atmosph

A

udible Noise

than

40 dB

almost

Servi

with hinged doors on the front tha

opened. Thi

recommende

Mounting

installation inst

W

arnings Defined

ON CONSIDER

ctr

ical connections to the buildin

lar

ge motor

ter

s, electronic appliances, solid s

interc

to the interc

ovi

ght and d

ve du

at 5 feet,

an

y room if desire

ce Clearance

rty-

d.

s, arc welders, switched ca

onnected electronic

ent sur

ge suppression should also be

onnecting wiring (dat

Unit is d

tures of -40ºC (-40ºF) to +60ºC (+140ºF)

ded in an industrial use

rip-ti

st,

six in

Unit is i

ruc

tions for mounting dimensions and

esi

gned for op

f 0% to 95% (no

ght and should not be installed in areas

corrosive v

eres.

The audible noi

whi

ch

allows its

d.

s

Service cle

che

s (36 in/914 mm) minimum is

nte

nded to be wall mou

D

anger:

hazardou

avoided, will result in death or

seriou

wor

d is to be limited to the

mo

st extreme situations.

otectiv

ATI

ONS

otec

tion, coordinat

service en

enera

ting loads within the

lo

ads (su

apors, flammable materials

se of

placement

aran

t are capable of being

Indicate

s situation that, if not

s inj

ury

e Devi

trance and

g (

tele

pacitor

tat

e motor d

ch as by way of

a cables).

era

tion indoors in

n-c

ondensing).

enclo

sure, which is

the unit is les

ce is

needed for units

nted. Refer to

s an im

. This

ed surge

phone,

rive

within

wei

minently

sign

al

ces

s,

s,

s

ght.

Installation,

Opera

tion and Maintenance Manual

W

arning:

hazardou

avoided, could result in death or

seriou

C

aution:

hazardou

avoided, may result in minor or

mod

us

ed to alert against unsafe

practice

2

Indicate

s situation that, if not

s injury.

Indicate

s situation that, if not

erate injury. It may also be

s.

s a p

s a p

IO-70103

otenti

otenti

Re

v 0, 1/2013

ally

ally

Page 4

(11) Enclosure

Q

= High R

ated

(8) Modes of Protection

(1-3) Series

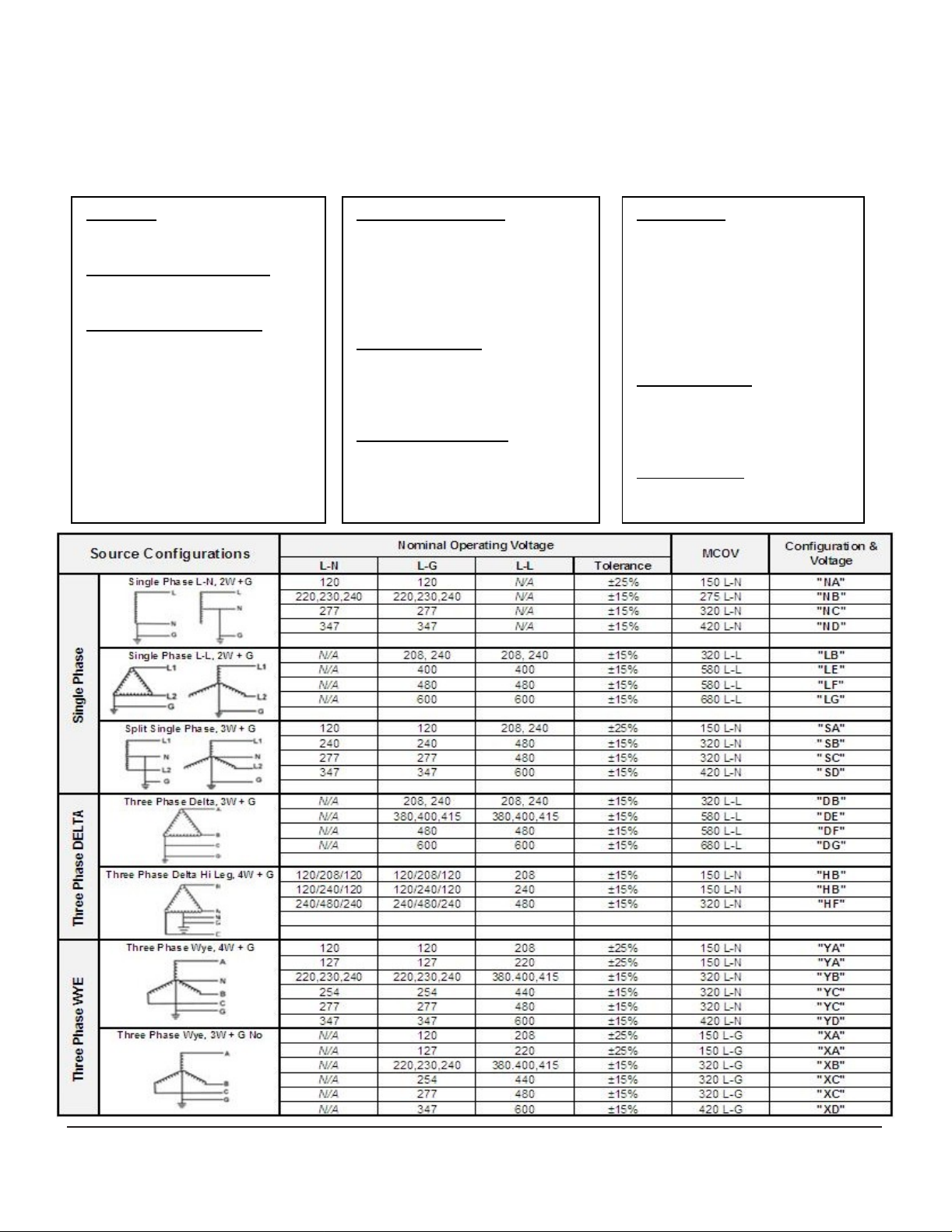

MODEL NUMBER CONFIGURATION

Model #: _ _ _ _ _ _ _ _ _ _ _ _ _

1 2 3 4 5 6 7 8 9 10 11 12 13

A

510

= Modular/Non-Modular MOV

(4-5) Configuration & Voltage

See Chart Below

(6-7) Surge Rating Per Mode

06

= 65kA

08

= 80kA

10

= 100kA

12

= 125kA

16 = 160kA

20

= 200kA

25

= 250kA

= All Modes of Protection

B

= L-N & N

E

= L

F

= L

G

= L

(9) Connection Type

N

= Wiring terminals/Lugs

R

= Rotary Disconnect Switch

W

= Wire

(10) Monitoring Options

R

= LED/Relay

A

= LED/Alarm/Relay

C

= LED/Alarm/Counter/Relay

-G

-L

-N

-G

Leads

R

G

H

J

L

F

S

0

1

2

(13) MOV Option

S

Surge Pr

= Type 3R (me

= Type 4 (metal)

= Type 4X (Stainless Steel)

= Type 4X (Non-Metallic)

= Type 12 (metal)

= Panelboard Flush (metal)

= Panelboard Surface (metal)

(12) UL 1449 Type

= No UL

= Type 1

= Type 2

= Standard

otectiv

tal)

e Devi

ces

Installation,

Opera

tion and Maintenance Manual

3

IO-70103

Re

v 0, 1/2013

Page 5

ELECTRICAL CONN

All ele

ctr

ical connections should be installed by a qualified

(li

cens

ed) ele

ctrici

an only. All wiring must comply with the

Na

tional Ele

codes.

DE-

ENE

Volt

age Ratings and

Bef

ore making connections to the unit,

model numb

appropriate for connection to the i

See the

with

typ

Wire Con

the wiring

circuit s ampacity

suppr

c

opper

to surge curren

ne

utral (if required), and ground condu

together

an

y s

Overc

practically no

c

onducts

NEC C

Ele

ctr

NEC 285.21 Con

NEC

accordance

(A) Installation. Type 1 SPD

f

oll

ows:

(1)

the

per

230.82(4) or

(B) At the service. Whe

grounding conductor of a Type 1 SPD shall be connected

t

o one of the followin

ctr

ical Code (NEC)

VERIFY THAT ALL POWER C

RGI

ZED AND LOCKED OUT BEFORE MAKING

ELECTRICAL CONNECTION

Pow

er

and nameplate voltage rating are

char

t on page

ical power s

nec

tions

to

the SPD unit is ind

ess

or connecting condu

or #12 aluminum.

ts, it is recommended t

and routed in the same raceway (conduit).

har

p bends in the condu

urrent Protec

curren

ver

y short duration transient surge

onsiderations

ic Code 2008 Edition.

285.23 Type

with 285.35(A) and (B).

Type 1 SPDs sh

supply

side of

mitted in

(2) Type

c

onnected in Type 2 locations as spec

1 SPDs sh

3 f

ource configurations.

With parallel connection, the size of

. NEC Article 285-21(B) requires surge

tion

t under normal op

-

The following is from the National

nec

tions

1 SPD s. Sh

all be

the

n installed at the

g:

and applicable local

IRCU

ITS ARE

S.

er Source Configurations

verif

nte

nded power s

or voltage rating applications

ependent of

ctors t

o be at least #14

To

redu

ce

the wiring impedan

hat

the phase

ctors

ctors.

The SPD unit conducts

era

tion

all be installed in

s shall be installed as

per

mitted

to be c

service disc

all be

per

onne

mitted

to be

service

y that the unit

ource.

the pr

otected

,

are twisted

Avoi

and only

curren

ts.

onnected to

ct as

ified in 285.24.

s, the

Surge Pr

ECTI

ONS

(1) Grounded

(2) Grounded electrode conductor

(3) Grounding electrode for

(4)Equipm

Volt

age Protec

pr

otec

tion ratings (VPR

L

aboratory

for Saf

ety

Third Edition

wire size listed for

the unit to your

c

ondu

ctors othe

differen

Circuit

these products

L

live circuits or components at system voltages and fault

curren

Saf

Third Edition

Syst

safety o

and bonding. Grounding is required for s

ce

impl

In

op

d

All ele

UNGROUNDED POWER SYSTEMS ARE INHERENTLY

UNSTABLE AND CAN

LINE-TO- GR

C

ELECTRICAL EQUIPMENT, INCLUDING AN SPD, MAY BE

SU

DESIG

PROVI

DE

ELECTRICAL EQUIPMENT ON AN UNGROUNDED

PO

UNGROUNDED APPLICATION

An insulated

met

F

be the same wire

c

t VPRs.

Ampacity Limitations

aboratorie

ts up to 200,000 AIC, as descr

ety

, Surge Pr

em Grounding and Bonding

f any SPD system is d

ementa

correc

t grounding can reduce or impede the

era

tion.

ctr

ical circuits to the SPD must include an equipm

ONDITIONS. DURING THESE

BJEC

TED TO

NED R

DED TO THE USER SO THAT AN

CISION CAN BE MADE BEFORE INSTALLING ANY

WER SYSTEM. CON

allic racew

or parall

ondu

el-c

ctors.

service c

ent

grounding

tion Ratings

, In

cor

por

, Surge Pr

, released (2009), mark

eac

fac

iliti

r than the wire

hav

s, In

cor

otectiv

, released (2009).

tion also

OUND

VOLTAGES W

ATINGS

grounding conductor is required in addition

ay,

whi

onnected SPDs, the grounding conductor should

size as

onductor

s), as obtained by Und

ated

, in accordanc

otectiv

e Dev

h product must be utilized to connect

es

power grid. C

e been investigat

porated to withstand, without exposing

e Dev

enhance

PRODUCE EXCESSIVE

VOLTAGES DURING CER

. THIS

TACT FACTORY F

ch may be used as a

otectiv

service

terminal in

T

o obtain the voltage

ice

s (

siz

e listed may result in

Repres

ice

s (

SPD

ependent

s equipment p

gro

unding conductor as

required by the NEC and local

codes.

FAULT C

HICH E

INF

ORMATION IS BEING

S.

the associated pow

e Devi

the

service

erwriter

e with the Standard

SPD

s), Standar

ed on this product, the

onnections made with

entative samples of

ed by Und

ibed in the Standar

s), Standar

The p

erwriter

erformanc

on proper grounding

afety. Correc

erformance

SPDs

ONDITIONS ANY

XCEED THEIR

INF

ORMED

OR

grounding condu

ces

equipm

LY HIGH

TAIN FAUL

er

ent

s

d 1449,

s

d for

d 1449,

e and

t

.

ent-

to an

ctor

T

y

.

Installation,

Opera

tion and Maintenance Manual

4

IO-70103

Re

v 0, 1/2013

Page 6

d

(with

Ground

Protected

Panel

T

ypical

out Internal

Neutral

Phases

Par

allel Con

Wire should be

less than 5

and straigh

as pos

sibl

Rotar

feet

t

e

nec

tions

y Discon

Ne

utra

l

Phase(s

)

T

ransient

Groun

d

S

afety

Groun

d

P

ARALLEL CONN

nect)

T

o

Protect

Lo

ads

Surge

Protectiv

e

Device

ed

Surge Pr

ECTI

ONS

T

ypical

(with Internal

Groun

Protected

Phases

Panel

Neutral

Par

allel Con

Wire shoul

less than 5 feet

and straigh

as possibl

Rotar

d be

t

e

otectiv

nec

y Discon

Rotary

Disconne

ct

e Devi

tions

nect)

Ne

utra

l

Pha

se(s

T

ransient

Groun

d

S

afety

Groun

d

ces

T

o

Protect

ed

Lo

ads

Surge

Protectiv

Device

e

)

Grounding condu

power c

met

mu

raceway

The

met

recommende

G

dischar

device

to c

In the case of lightning whose p

respec

t

o the grounding electrode (

mo

lo

without involving the grounding electrod

ondu

allic raceways are

st be maintai

termina

use o

allic conduit run is a p

rounding Electrode

ge all su

s can also di

omplete the ele

t to th

st transient su

ads, the SPD di

ctors mu

ctor

s in the same raceway (conduit). When

ned at all raceway connections,

tions to the ele

f isola

ting bushings or other means to i

d.

rges t

e

ear

rge

ver

st be routed with the associated

used

, adequate electr

ctr

ical

enclo

otenti

al s

afety hazar

Surge pr

o ground (

ver

t the surge

ctr

ical circuit.

th, the SPD di

ear

s that are d

ts the surge

otectiv

ear

th). Surge pr

curren

otenti

al is d

ver

th connection). H

eve

loped by switching

curren

ical

con

tinuity

particular

sures.

nterrup

d and is not

e devices do not

otectiv

e

t back to its source

eve

loped with

ts the surge

t back to its source

e.

owe

curren

ver, f

F

or proper SPD p

grounding electrode system must comply with the NEC by

ha

ving all available electrodes (building s

ly

pipe

, d

rive

n rods, concrete encased electrodes, etc.)

properly bonded togeth

syste

t a

t

or

m grounding.

The use of a

S

PD defeats the

hazard, ma

(refe

renc

e NEC 250-51 and 250-54), and is not

recommende

Neutr

al Con

C

ONNECTED

FAIL

URE TO PROVIDE A RELIABLE NEUTRAL

C

ONNECTION MAY R

erformance

er

and connected to the powe

separat

y cause equipment

d.

nec

e grounding electrode to ground the

effectiveness of

tion

TO THE NEU

TRAL OF THE

ESUL

T IN FAILURE!

, the

service en

tee

the

SPD, is a potential safety

damage

F

OR PROPER AND

OPERATION, THE

NEUTRAL, MUST BE

RELIAB

, is an NEC violation

LY

trance

l, metal

SOUR

wate

r

SAFE

SPDs

CE.

r

Installation,

Opera

tion and Maintenance Manual

5

IO-70103

Re

v 0, 1/2013

Page 7

v 0, 1/2013

INST

ALL

ATI

The Emerson Network Power

Device

s (SPDs) are high quality, high

di

ver

sion systems d

from

dam

aging transient voltage su

is required for maximum system p

The installer should p

qu

ality installation. The entire installation manual should be

re

ad before s

replace na

electr

system

1.

Insure that all powe

installation.

electr

2. The standard SPD is pr

NEMA12 (indoor) or NEMA 4X (outdoor)

suitable for use in indoor or outdoor installations. Verify

the SPD enclosure rating by referencing

Model Number Configuration tool on page 3.

tional or local ele

ical cod

should only be

A qu

ical connections.

esi

erfor

tar

ting installation. These inst

es to e

nsure complian

r is remov

alified li

510 Serie

gned to pr

m the following s

ctr

ical codes. Chec

perfor

med

ed before beginning

censed electrician sh

ovi

ded in a

s Surge Pr

ener

otect se

rge

s. Proper installation

erformance.

ce.

Installation

by qu

alified p

NEMA 1 (indoor),

otectiv

gy surge

nsitive equipment

teps to as

ruc

rated

position 11 in

curren

sure a

tions do not

k applicable

of

the SPD

ers

onnel.

all install all

enclo

sur

ON INST

e

t

es

the

Surge Pr

RUCTI

6. Apply power

when the

the fro

LED s are ex

to e

indication is present, remove power t

Em

ers

6169 or 1-607-721-8840

7.

Per

pr

otec

the RED LED is illuminated

Networ

6169 or

8.

The pr

replace

Pr

otec

ONS

. The surge pr

GR

EEN

LED s on

nt of

the

enclo

sure are illuminated

tinguished or a RED LED is illuminated, c

nsure tha

on N

iodically monitor the s

tion exists if the

tion for r

t power is

etwork Powe

k Power Surge Pr

1-

607-721-8840.

otec

tion modules in these

able,

contac

t Em

eplacement.

GREEN LED s are ex

otectiv

otect

or is fully op

the

modul

applied to the

r Surge Pr

.

. Pl

ers

on N

otec

tatus of the LED s. R

ease contac

otec

tion at

etwork Powe

e Devi

es

(when applicable),

. If the GREEN

SPD. If an

o the SPD and

tion at 1-800-288

SPD s may be

ces

era

educed

tinguished or

t Em

ers

1-

800-288

r Surge

tional

heck

abnormal

contac

on

-

and

-

t

3.

Deter

mine where the SPD is to be mou

f

or minimum length of wire b

power termin

proper hole size in the

knockout to be utilized in the

plastic enclosure units include a flexible conduit/nipple

accessory

mounting holes in wall at location picked for SPD next to

service panel us

t

able

below.

appropriate size & type mounting

4. Connect black wires (line or phas

L3/C, the white wire (neutral)

(grou

nd)

below. T

electr

ical distribution system,

a

s possible and avoi

5. Connection

with #18

are 5 amps at 250 VAC maximum with a power fact

1.0. For additional i

als of the

no punching/drilling required in SPD) Drill

ing mounting dimensions shown in the

Mou

nt surge

mark

ed G, of the SPD using the wire range listed

o yield the best p

d s

to the unit s summar

22

AWG.

nformation,

etwee

service pane

si

de of the SPD

service pane

suppr

ess

mark

erformance o

kee

har

p bends.

The

ra

tin

gs of

see Monitoring sec

n itself and the input

hardware.

p all condu

nted

, allowing

l. Punch or cut the

closest

l.

or to wall using

e)

mark

ed L1/A, L2/B or

ed N, and the green wire

f the SPD within the

y a

larm contac

the

Form C

t

o the

(NEMA 4X

ctors a

s short

ts shall be

contacts

or of

tion.

If

the SPD

and a Neutral con

contact factory.

model is

nec

a Wye c

tion is not available, please

onfi

gured unit (4W+G),

Installation,

Opera

tion and Maintenance Manual

6

IO-70103

Re

Page 8

v 0, 1/2013

Surge Rating

CircuitBreake

r

Siz

e

Allowable Range

Allowable Range: #14

NC

COM

NO

A

C

B

E

D

F

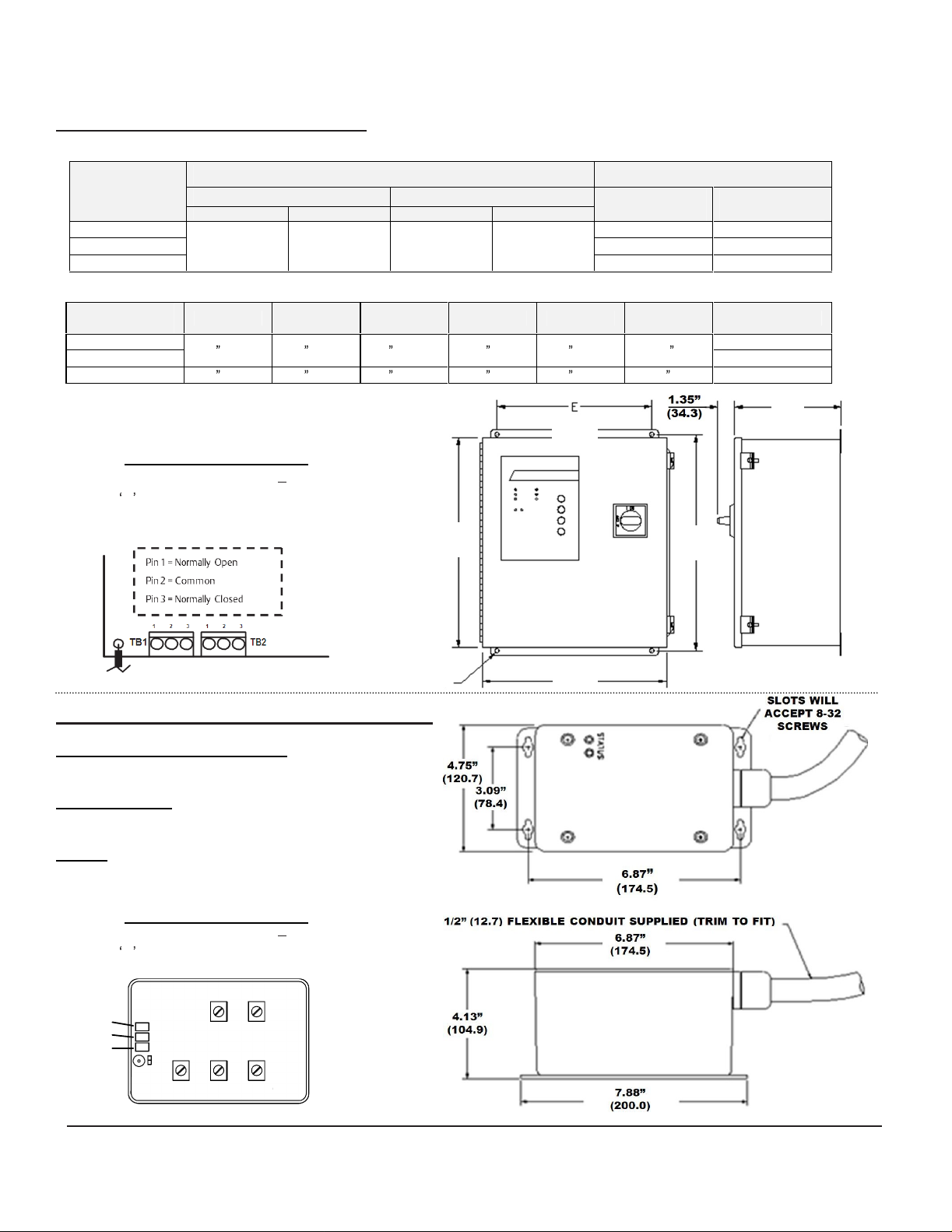

NEMA 12 (Metal) Enclosure Option

SUGGE

DIMENSIONAL INFORMATION

STED CIRCUIT

Surge Rating

Per Mode

60kA-80kA

100kA-160kA

200kA-250kA

Per Mode

60kA-80kA

100kA-160kA

200kA-250kA

C

onnection shall be with #18

Form C

250 VAC max.

20 (508) 16 (406) 9 (229) 21.3 (540) 10 (254) 0.44 (11)

Summary Alarm Contacts

contacts

BRE

With Disconne

40A-150A

A B C D E F

16 (406) 14 (356) 8 (203) 16.8 (426) 12 (305) 0.31

are rated

AKER AND WIRE SIZE

Allowable R

ct

Without Disconne

15A-100A

22

AWG.

5 amps at

ct

ange

Connec

With Disconne

#8-1/O

tion Wire Size

ct

Without Disconne

#14-#2

Surge Pr

Factory

Circuit Br

ct

Size

40 Amp

40 Amp

100 Amp

Sugg

eaker

(8)

otectiv

ested Size

Connec

32 lb. (14.5 kg)

41 lb. (18.6 kg)

56 lb. (25.4 kg)

e Devi

tion

Wire Size

#8 AWG

#8 AWG

#2 AWG

Weight

ces

(Located on PCB behind monitoring panel)

NEMA 4X (

Overcurrent Prot

Connection Wire

Weight:

6.5 lb. (3 kg)

C

onnection shall be with #18

Form C

250 VAC max.

Installation,

Non-Metallic

ection (Circuit Breaker)

: 15A - 30A

:

Summary Alarm Contacts

contacts

Shown with cover removed

Opera

tion and Maintenance Manual

-

#10

are rated

) Enclosure Option

:

Suggested Size: 30A

Suggested Size: #10

22

AWG.

5 amps at

7

IO-70103

Re

Page 9

v 0, 1/2013

Allowable Range

Allowable Range: #14

Surge

-

ard Extension

Customer Supplied

Panelboard

ACBED

F

(SURFACE)

G

(FLUSH)

NO

NEMA

SUGGE

1 Panelboard Extension Enclosure

STED CIRCUIT

Overcurrent Protection (Circuit Breaker)

: 15A - 100A Suggested Size: 30A

Connection Wire

Weight:

30 lb. (13.6 kg)

Summary Alarm Contacts

Co

nnection shall be with #18

Form C

250 VAC max.

:

contacts

BRE

- #2

are rated

AKER AND WIRE SIZE

Suggested Size: #10

5 amps at

:

22

AWG.

COM

NC

Surge Pr

Option

otectiv

e Devi

ces

Shown with

DIMENSIONAL INFORMATION

A B C D E F G

18

(457)

12

(305)

module

6

(152)

cover removed

11

(279)

15

(

381)

20.25

(514)

21.5

(546)

(

REMOVE COVER

FOR ACCESS

)

Installation,

Opera

tion and Maintenance Manual

8

510

Protective Device

Panelbo

IO-70103

Re

Page 10

v 0, 1/2013

MONITORI

Ext

ernal

Stat

us Indica

pr

ovide a

module. For normal conditions, the green

illuminat

surge SPD or

LED is turned off and the red

A

udible Alarm

module requires r

activat

required to r

audible a

syste

alarm switch and

the Test switc

Summa

two sets of

N.C.) are pr

SPD

m

aximum with

contacts is provi

the unit s cover.

Surge Counter (Optional

f

or transient voltage surge moni

line su

rese

sine wave. The

voltage. Other se

T

roubleshootin

If s

tatus f

have ch

deter

If the SPD

electrici

c

onnections are normal, the unit should be repaire

At

this poi

f

ollowing i

sum

mary of

ed and the red

module requires r

(St

andard

eplacemen

ed to draw

lar

m will automa

ry

modul

rge

s monitored since the last time the cou

t. The circuit counts all su

SERVICING/ MAINTENANCE

ailure indication oc

anged state

mine if the systems voltage and proper phasing exists.

rem

an is

nt c

nformatio

atten

est

ore the system to normal op

m disable is pr

tically rese

Service

h on the system monitor panel.

Alarm Con

sum

mar

y a

ovi

ded for

e. Contac

a power factor of

ded

factory se

ttings include 50%, 70%, and 100%.

TROUBLESHOOTIN

g

ains in an

sa

tisfied that

onsult the

n:

NG FEATUR

tor

s (Standard)

the

status of

Service

tion to the

tact (St

larm For

remote

ts are

via contact termin

tting is 30% ove

, a qualified ele

alarm c

factory, having

LED is

eplacemen

Service

/Optional

t, an audible a

fact that repair

ovi

ded to sil

t itself

LED can be test

andard

m C relay contac

indication

rated 5 amps at

1.0.

)

The surge cou

tor

ing. The cou

rge

s that deviate from the line

cur

s or sum

ctrici

ond

the ele

ctr

ES

These indicator

the surge SPD

OK LED is

ex

tinguishe

t, the green

LED illuminated.

)

If the surge SPD

larm may be

era

tion. An

enc

e the a

after repair.

ed by activating

/Optional

of

the failed surge

250

Access to

als located inside of

nter

nter total

r nominal line

G/

mar

y a

larm contac

an shall first

ition on

ical sys

avail

ce

tem

able the

d. If

the

OK

servic

e is

lar

m. The

The audible

)

One or

ts (N.O

. and

VAC

the

is provi

nter wa

the

and its

ded

ize

s

d.

Surge Pr

Servicing

s

The Emerson Network Power 5

ten year warrant

local Sales Representativ

Surge Pr

ONLY QUAL

MAINTENANCE ON THE SYSTE

HAZARDOUS

UNIT DURI

ELECTRICAL SAFETY

FOLLO

TO PRE

OFF AND LOCK OUT ALL POWER SOU

UN

C

orrective Maintenance - The

51

0 Series SPD is d

op

era

f

ail under abnormal conditions. Diagnostic indicator

pr

ovi

s

replacemen

f

ailed units should be repaired or r

convenient service

modules, other components should be inspected for

dam

troubleshooting procedur

problems oth

When r

c

omponents for

Pl

ease contact factory f

ts

Preventative Maintenance (Inspection and

Per

c

hecks are recommended to ensure r

performanc

It is

maintenance

Inspections for failed surge modules using available

di

agnostics should be done routinely (

y. For

servic

otec

tion at

800-288-6169 or 607-721-8840.

IFI

ED

PER

SONNEL SHOULD PERFORM

VOLTAGES ARE

NG NORMAL OPERATION

PRE-CA

WED WHEN SERVICING THIS U

VENT RISK OF ELECTRICAL SHOCK, TURN

IT BEFORE SERVICING U

esi

gned for

tion. H

owe

ver, eve

ded to indicate when the unit needs repair or

t. To ensure

age and r

iodic system inspections,

di

fficult

eplac

er than f

eplac

ing components, use

con

e and

to est

sin

ce c

n the most r

opportuni

ed if necessary. Standard electr

es

ailed surge

tinued proper op

or i

con

tinued surge transient pr

ablish

a sch

onditions

otectiv

10 Series comes

ing assistance,

e or Em

con

ers

on N

M.

PRE

SENT INSIDE THE

UTIONS MUST BE

NIT.

Emerson Net

years o

eli

able equipment may

tinuity of surge pr

eplac

ty. When replac

should be

nformation on r

cle

edule for pr

vary

used to isolate

curren

t di

iden

tically rated

era

aning, and connection

eli

from si

wee

S.

f trouble-free

ed at the

tion and s

able system

e Devi

etwork Power

NIT.

RCES T

verte

eplacement par

eventativ

te to site.

kly or monthly).

ces

with

contact y

O THE

work Power

s are

otec

tion,

earliest

ing surge

ical

r modules.

afety

Cle

aning)

otec

tion.

e

a

our

,

.

ts.

-

Unit

iden

tification numb

seri

al numbers detailed on the data labe

located on the front of the

Na

ture of problem

indicator

Installation,

s and a

Opera

tion and Maintenance Manual

(including s

lar

ms).

er

(refe

enclo

rs to

sure.)

tatus o

the

l and is

f all s

mod

tatu

el

and

s

9

IO-70103

Re

Page 11

v 0, 1/2013

Surge Pr

otectiv

e Devi

ces

Installation,

Opera

tion and Maintenance Manual

10

IO-70103

Re

Page 12

v 0, 1/2013

Surge Pr

otectiv

Emerson Network Power

100 Emerson Parkway

Binghamton, NY 1

800

288 6169 Phone (U.S. & Canada Only)

607 721 8840 (Outside U.S.)

607 722 8713 FAX

United States of America

Emerson Network Power

European Headquarters

Via Leonar

Zon

35028 Piove Di Sacco (PD)

It

aly

39 049 9719 111 Phone

39 049 5841 257 FAX

do Da Vinci 8

a Industriale Tog

3905

nana

e Devi

ces

Em

ers

on N

29/F,

F. Ortigas Jr. Road, Ortigas Center

Pasig City 1605

Philippines

+63 2 687 6615

+63 2 730 9572 FAX

Technical Support

800 288 6169 Tol

607 721 8840 Phone

6

07 722 8713 FAX

© 2012 Emerson Network Power.

the world. Specifications subject to change without noti

IO-70103

etwork Power

The Orient Square Building

l-F

Rev 0,

(1/2013

ree

)

Asia Pac

All rights r

ific

eserv

ed throughout

Printed in

ce.

USA

Installation,

Opera

tion and Maintenance Manual

11

IO-70103

Re

Loading...

Loading...