Page 1

50F06-843

!

Universal Furnace Electronic Fan

Timer Control Kit

INSTALLATION INSTRUCTIONS

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

PARTS INCLUDED

• 50F06-843 Electronic Fan Timer Control Board

• 2 - Main Harness Assemblies (ST9101, ST9141)

• 1 - Jumper Harness (ST9160)

• 2 - 7” Long Transformer Wiring Extensions (EXT)

• 2 - 3/16” QC crimp on terminals for

optional use with Wiring Extensions

• 4 - 1” Sheet Metal Mounting Screws

(for mounting tray corner locations)

DESCRIPTION

The 50F06-843 is an aftermarket universal replacement fan

timer control kit for single stage furnaces with PSC inducer

and blower motors.

• 2 - ½” Sheet Metal Mounting Screws

(for mounting tray center tabs)

• 2 - Wire Ties

• Troubleshooting Label

• Installation Instructions

TWINNING: 50F06-843 can be twinned. Both control

boards must be from the same manufacturer for proper

functionality.

SPECIFICATIONS

ELECTRICAL RATINGS:

Input Low Voltage: 25 VAC, 60 Hz

Input Line Voltage: 115/230VAC, 60 Hz, 1φ

Max Input Current: 800mA @ 25 VAC

Relay Contact Ratings:

Inducer Output: 1.5 FLA @ 115 VAC

.75A @ 230 VAC

Blower Output: 15 FLA @ 115 VAC

7.5A FLA @ 230VAC

Humidifier and EAC Load: .8A FLA @ 115 VAC

.4A FLA @ 230VAC

POST PURGE TIMING:

5 seconds

LOCKOUT AUTO RESET TIMING:

60 minutes

OPERATING TEMPERATURE RANGE:

-40° to 176°F (-40° to 80°C)

HUMIDITY RANGE:

5 to 95% relative humidity (non-condensing)

GASES APPROVED: Natural, Manufactured, Mixed,

Liquid Petroleum, and LP Gas Air Mixtures.

CAUTION

Risk of Electric Shock.

Disconnect electric power

to system until installation

is complete. Do not use on

circuit exceeding specified

voltage. Higher voltage will

damage control and could

cause shock or fire hazard

This control is not intended

for use in locations where

it may come in contact with

water.

May cause flame rollout.

Shut off main gas to

heating system until

installation is complete.

PART NO. 37-7803001

emerson.com/white-rodgers

View installation video

1931

Page 2

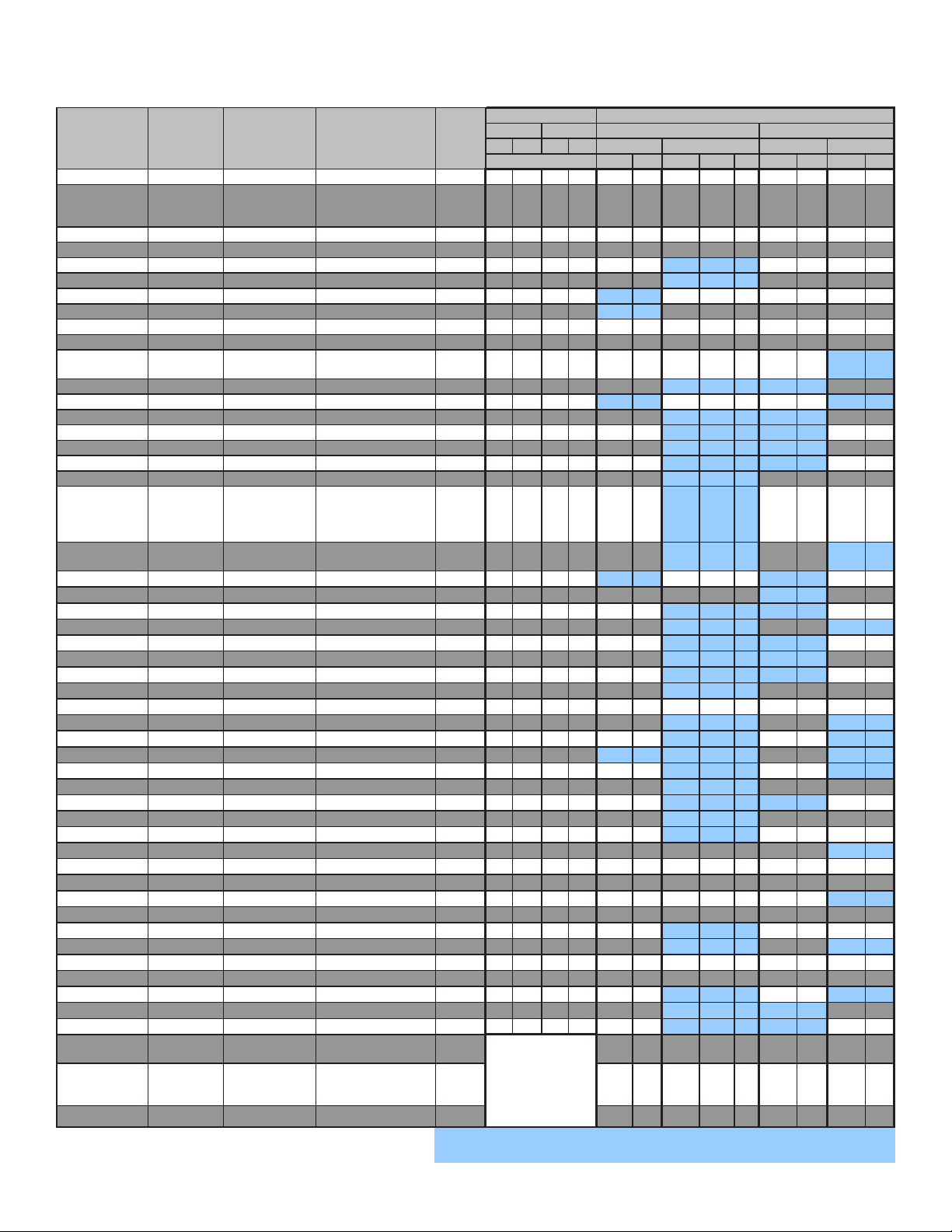

TABLE 1: CROSS REFERENCE, HARNESS SELECTION, DIPSWITCH SETTINGS

(Harness Part Numbers Match Control Model Being Replaced for Easy Identication)

Honeywell, ICM,

Robertshaw

Control Model

ST9101A1006 Rheem ST9101 30 100 4 0 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9101A1014 Rheem 47-22827-xx

ST9101A1022 Trade ST9101 30 100 4 0 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9120A1006 Armstrong N/A 30 100 4 0 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9120A2004 Armstrong 40403-001 N/A 30 140 4 0 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9120B1005 Ducane N/A 30 60 4 0 OFF 30 ON OFF 60 OFF 4 OFF 30

ST9120C1012 Snyder Gen N/A 60 100 4 0 ON 60 OFF OFF 120 OFF 4 OFF 30

ST9120C1020 Nordyne N/A 60 100 4 0 ON 60 OFF OFF 120 OFF 4 OFF 30

ST9120C2002 York 031-01237-000 031-02959-000 N/A 30 100 4 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9120C2010 Ducane 20054502 CAR20054502 N/A 30 100 4 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9120C2028 Armstrong 40403-001

ST9120C3000 ICP HQ1010031HW 1010031 N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120C3018 Bard N/A 60 100 4 60 ON 60 OFF OFF 120 OFF 4 ON 60

ST9120C4008 ICP N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120C4016 ICP HQ1009836HW 1009836 N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120C4040 ICP HQ1011179HW 1011179 N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120C4057 ICP HQ1011927HW 1011927 N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

*ST9120C5005 ICP HQ1084197HW 1084197 N/A 30 140 4 30 OFF 30 OFF ON 150 OFF 4 OFF 30

*ST9120C5013 ICP HQ1170063HW

*ST9120D3009 Goodman B18099-11(S)

ST9120G2008 ICP HQ1008773HW 1008773 N/A 60 100 30 0 ON 60 OFF OFF 120 ON 30 OFF 30

ST9120G2016 ICP N/A 30 100 30 30 OFF 30 OFF OFF 120 ON 30 OFF 30

ST9120G2024 Skymark N/A 30 60 30 30 OFF 30 ON OFF 60 ON 30 OFF 30

ST9120G2032 Skymark N/A 30 60 4 100 OFF 30 ON OFF 60 OFF 4 ON 60

ST9120G4004 ICP HQ1009838HW 1009838, HG1009838HW N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120G4012 ICP HQ1009836HW 1009836 N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120G4038 Trade N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9120U1003 Trade N/A 30 140 4 30 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9120U1011 N/A 30 120 4 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9141A1002 Consolidated 406650 Weil-McLain 4116000 ST9141 30 140 6 60 OFF 30 OFF ON 150 OFF 4 ON 60

ST9141A1028 Consolidated ST9141 30 140 6 60 OFF 30 OFF ON 150 OFF 4 ON 60

ST9141B1001 Consolidated ST9141 75 180 6 60 ON 60 ON ON 180 OFF 4 ON 60

ST9150A1003** Consolidated N/A 36 168 7 72 OFF 30 ON ON 180 OFF 4 ON 60

ST9150B2000** N/A 36 144 7 0 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9150B2018** ICP N/A 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9150B2026** Ducane N /A 36 144 7 36 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9150B2034** N/A 36 144 7 36 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9160A1002 Armstrong 45392-001 ST9160 30 90 6 60 OFF 30 OFF OFF 120 OFF 4 ON 60

ST9160B1001 ST9160 30 120 6 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9160B1019 ST9160 30 120 6 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9160B1027 ST9160 30 120 6 60 OFF 30 OFF OFF 120 OFF 4 ON 60

ST9160B1035 ST9160 30 120 6 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9160B1043 ICP ST9160 30 140 6 30 OFF 30 OFF ON 150 OFF 4 OFF 30

ST9160B1050 ICP HQ1012358HW 1012358 ST9160 30 140 6 60 OFF 30 OFF ON 150 OFF 4 ON 60

ST9160B1068 Armstrong 45692-001 ST9160 30 120 6 60 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9160B1076 Ducane 2043081 28M99(01) ST9160 30 120 6 30 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9160B1084 ICP 1014460 ST9160 30 140 6 90 OFF 30 OFF ON 150 OFF 4 ON 60

ST9160C1000 ST9160 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ST9160C1018 ST9160 30 140 30 30 OFF 30 OFF ON 150 ON 30 OFF 30

ICM270 Evcon 2702-300

ICM270 Rheem 47-22827-xx

695-003 Rheem 47-22828-xx (Robertshaw) ST9101 OFF 30 OFF OFF 120 OFF 4 OFF 30

* Heat Fan O Delay seng may need adjustment based on performance

** Replacement requires 60Hz power supply

Appliance

OEM

OEM Part Alt OEM Part(s)

47-22693-xx,

47-22828-xx,

47-22830-xx

40403-002, 40403-003,

025-32816-000, 87H88

1170063, 1008786,

1009837, 1011543,

1012106, 1150489,

1160192, 1138-200

CARB1809911,

CARL38267

2895-3001,

026-34030-000

47-22693-xx,

47-22828-xx,

47-22830-xx

Harness

Req'd

ST9101 30 100 4 0 OFF 30 OFF OFF 120 OFF 4 OFF 30

ST9101

ST9101 OFF 30 OFF OFF 120 OFF 4 OFF 30

Original Delay Timing 50F06-843 Suggested Delays

Heat Cool Heat Cool

ON OFF ON OFF ON OFF ON OFF

seconds sw1-1 sec sw1-2 sw1-3 sec sw1-4 sec sw2-1 sec

N/A 30 100 4 60 OFF 30 OFF OFF 120 OFF 4 ON 60

N/A 30 140 4 30 OFF 30 OFF ON 150 OFF 4 OFF 30

N/A 30 140 4 60 OFF 30 OFF ON 150 OFF 4 ON 60

OFF 30 OFF OFF 120 OFF 4 OFF 30

Check Unit

Documentaon or

Exisng Control

BLUE SHADING = A CHANGE FROM DEFAULT SELECTION IS REQURED

2

Page 3

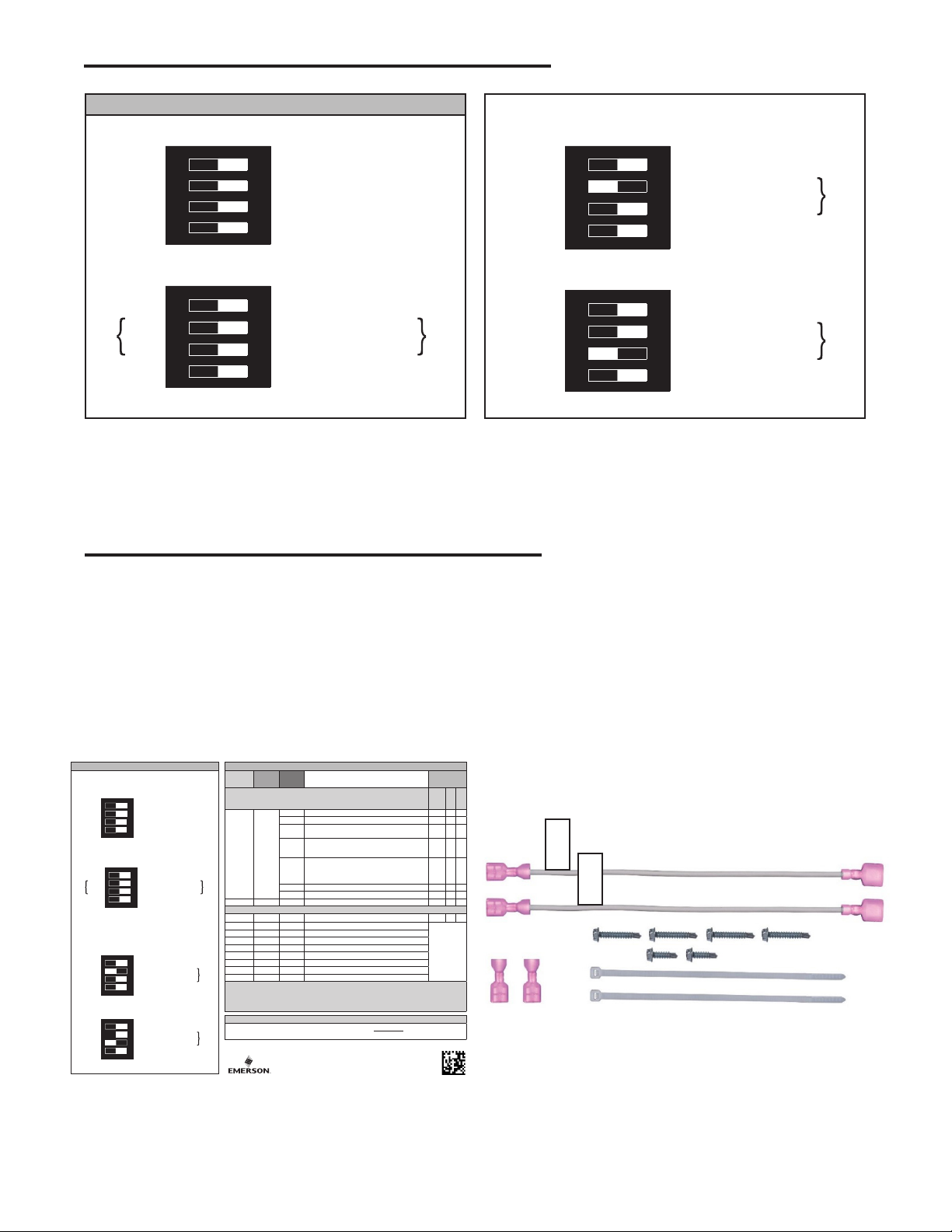

DIPSWITCH CONFIGURATION

TROUBLESHOOTING

GREEN

FLASH

AMBER

FLASH

RED

FLASH

1

Limit switch, burner limit switch, or fuse is open

X

X

2

Primary limit switch is open

X

Pressure switch improperly closed, or open

when inducer has been running >30 seconds

150 seconds.

>30VAC for more than 10 seconds. Not detected

seconds proper voltage.

9

Reversed 120VAC polarity / grounding

XXX

Other

Additional codes displayed on gas valve LED

X

Flash codes NOT stored in memory

Alternate

Alternate

Alternate

Self-test mode active

Rapid

Control power up

Solid

Standby

Continuous

Fan only call (G)

1

Call for cool (Y)

2

Call for heat (W)

6

Twinning error

DIPSWITCH SETTINGS

ONON

OFFOFF

ALTERNATE HEAT OFF DELAYS

ONON

OFFOFF

NOT USED

NOT USED

"G" FAN SPEED

COOL

60s

HEAT*

1 2 3 4

30s*

COOL OFF DELAY

SW2

30s

ON OFF

180s

4s*

COOL ON DELAY

HEAT OFF DELAY

120s*

ON OFF

HEAT ON DELAY

60s

30s*

1 2 3 4

SW1

*DEFAULT SETTING

150s

HEAT OFF DELAY

SW1

60s

HEAT OFF DELAY

1 2 3 4 1 2 3 4

SW1

Note: Cycle Power After Changes Are Made

ON

OFF

OFF

ON

Notes:

• To change settings break through yellow protective plastic film and make required adjustments

• See Table 1 for dipswitch setting recommendations by control board part number (any changes to be made from 50F06-843

defaults will be highlighted in BLUE)

• Cycle power after making any changes

INSTALLATION ACCESSORIES

• 7” long wiring extensions EXT can be used if existing transformer wires do not easily reach the new control board connections.

Extension wires have ¼” male x ¼” female spades

• 3/16” male crimp-on quick connects can be used to modify the EXT extension leads if they are needed for units having smaller

transformer connections

• Mounting screws can be used with the plastic tray CORNER HOLES (4x long) or MOUNTING TABS (2x short)

• Wire ties can be used to secure any wiring as needed

• Troubleshooting label can be placed on furnace access panel for referencing dipswitch setup and LED codes

DIPSWITCH SETTINGS

Note: Cycle power after changes are made

ON

OFF

NOT USED

1 2 3 4

OFF

1 2 3 4

OFF

1 2 3 4

HEAT *

30s *

SW2

1 2 3 4

150s

SW1

60s

SW1

OFF

4s *

120s *

30s *

SW1

NOT USED

“G” FAN SPEED

COOL OFF DELAY

COOL ON DELAY

HEAT OFF DELAY

HEAT ON DELAY

* DEFAULT SETTING

HEAT OFF DELAY

HEAT OFF DELAY

COOL

60s

ON

30s

ON

180s

ON

60s

ALTERNATE HEAT OFF DELAYS

ON

ON

LED

LED

LED

Up to 5 ash codes stored in memory (auto-erased after 14 days)

3

4

OFF

OFF

OFF OFF OFF Check power / internal control fault

ON

OFF

SELF-TEST - Power cycle control, press FAULT button 2x during rapid green ash

FAULT RECALL - In standby, hold FAULT button < 5 seconds

FAULT ERASE - In standby, hold FAULT button > 5 seconds but < 10 seconds

CONTROL LOCKOUT RESET - Remove 24VAC power > 10 Seconds

OFF

ON

7

8 Gas valve sensed energized when it should be off X

Solid ST9160 jumper missing, plug into connector J1 X

Place Jumper Harness ST9160 in connector J1 for ALL ST9160 replacements.

This Harness is NOT USED for any other replacements

ERROR / CONDITION

Overheated due to air not circulating (lockout).

Three consecutive primary limit open events >

Wrong 24VAC supply condition <18VAC or

with fault 9. Operation resumes with 120

JUMPER HARNESS

50F06-843

SYSTEM

TYPE

ST9101

ST9120

X

X

X X X

ALL

5002-0377

ST9141

ST9160

EXT

EXT

3

Page 4

ADAPTER HARNESSES, JUMPER PLUG, AND WIRING NOTES

(Harness Part Numbers Match Control Model Being Replaced for Easy Identication)

ST9101

Black to Control Board

L1/S/S1-S3 (E15 or E12

L1/S/S1-S3

Control Board E38

connector not used

(smallest 6-pin)

L2

Neutral

IND / DI

Furnace

9-pin

ST9101

L2

Neutral

Used with Honeywell ST9101, ICM270, and Robertshaw 695-003 Control Replacements

ST9141

ST9141

Furnace

9-pin

PRSW

Blue to Control Board

IND/DI (E2)

Control Board

6-pin J1

2 Whites to any Control

Board Neutrals (E1-E7)

Control Board E38

connector not used

(smallest 6-pin)

Control Board

6-pin J1

Brown to Control Board

PRSW (E30, remove

protective cap)

LIM

Used with Honeywell ST9141 Control Replacements

ST9120

These Control Replacements install without the use of a wiring harness.

Plug factory wiring into

For additional details please see WIRING DIAGRAM and original appliance schematic

4

Gray to Control

Board LIM (E24, remove

protective cap)

Control Board E38

connector not used

(smallest 6-pin)

Control Board

6-pin J1

Page 5

ADAPTER HARNESSES, JUMPER PLUG, AND WIRING NOTES

(Harness Part Numbers Match Control Model Being Replaced for Easy Identication)

ST9160

Plug factory wiring into

Control Board E38

(smallest 6-pin)

Jumper Harness required on all ST9160 Systems. Failure to install will

disable furnace operation and produce a Solid Amber LED code.

Jumper plugs into

Control Board

ST9160

6-pin J1

For additional details please see WIRING DIAGRAM and original appliance schematic

INSTALLATION

MOUNTING AND WIRING

NOTE: All wiring should be installed according to local and

national electrical codes and ordinances.

1. Disconnect electrical power and gas supply to unit, then

remove unit access panels.

2. Mark and disconnect all wires from the existing control,

then remove control. TIP: first take a picture or two for

reference.

3. 50F06-843 can be mounted in any orientation. Select a

location that will not damage, obstruct or place any stress

on the terminations or harnesses.

4. Mount 50F06-843 in the unit using one of the two

mounting tray options noted below. Be certain not to

damage any components such as transformers, wire

harness or blower wheels when drilling or installing

screws.

5. Refer to Table 1 and select the proper wire adapter(s)

or jumper needed to replace the existing control board

(if applicable).

6. Adjust Cool ON, Cool OFF, Heat ON, and Heat OFF

delay dipswitches if needed per Table 1 and “Dipswitch

Configuration” section.

7. Reconnect all wires to 50F06 control board referencing

“Adapter Harnesses, Jumper Plug, and Wiring Notes”,

“Wiring Diagram”, and “Blower, Accessory, and

System Operation” sections as needed.

8. Ensure all wires are secure to the control board and

unused blower speed wires are attached to the M1, M2,

M3 / Unused terminals. Apply wire ties as needed to

secure wiring.

9. Install provided Troubleshooting Label in a suitable

location for easy viewing.

10. Reinstall unit access panels and reconnect electric power

and gas supply to the unit.

11. Verify unit operation in Heat, Cool, and Fan modes.

Corner Holes will match many existing OEM locations with no drilling

required. Use 4 x 1” screws. Tray can also be used as template for

drilling new locations if needed.

Universal Tab Drill Holes. Use tray as template and 2 x ½” screws for

mounting.

5

Page 6

INDUCER

MOTOR

UNUSED MOTOR

LEADS

120VAC

HUMIDIFIER

HOT / L1NEUTRAL / L2

FUSE

115 / 230 VAC

INPUT

AIR CLEANER

2

120VAC

OPTIONAL CONTINUOUS (LOW)

1

BLOWER

MOTOR

115 / 230 VAC

24 VAC CLASS II

TRANSFORMER

24 VAC

3

1

4

5

2

3

6

3

WIRING DIAGRAM

1

4

2

5

3

6

3

ACC MAY BE CONNECTED IN ST9101 SYSTEMS HAVING

1

ONE FAN SPEED FOR BOTH HEAT AND COOL

FOR 230 VAC INSTALLATIONS THE VOLTAGE READING

2

BETWEEN L1 AND APPLIANCE CHASIS MUST BE 115 VAC

3

REMOVE PROTECTIVE CAP TO USE

OPTIONAL TERMINALS

THERMOSTAT

INPUTS

Additional Notes:

- ST9101 systems (also ICM270/RS 695) have INDUCER MOTOR, HOT / L1, and NEUTRAL / L2 connected through adapter harness

- ST9141 systems have Limit and Pressure Switch connected through adapter harness to E24 (LIM) and E30 (PRSW) terminals

- ST9160 systems have INDUCER MOTOR connected to Gas Valve control

6

Page 7

SELF-TEST

NOTE

50F06-843 is equipped with a self-test routine that checks the

functionality of the control, blower, and inducer to verify they

are in proper working order. Ensure thermostat is turned OFF

or thermostat wires are disconnected to enable.

ENTER SELF-TEST BY:

• Turn on power and/or manually close blower door switch

• Wait 1 second

• Slowly double-click “FAU LT ” button within ~3 seconds

SEQUENCE IS AS FOLLOWS:

• LED will flash in red the five last stored fault codes

• Afterward, the LED will slowly flash alternate colors (red,

amber, green) to indicate Self-Test is active and continue

until Self-Test is complete

• For ST9160 furnaces using E38 primary connector:

1. Blower operates HEAT speed for 10 seconds

Self-Test is available after power up and until a solid green

LED is present (5 seconds after power up). During this

time, the control will ignore all active calls. If a solid

green LED is present, disconnect power for 10 seconds

before starting Self-Test routine.

2. Blower operates COOL speed for 10 seconds

3. Blower shuts off and control goes to Standby

• For all ST9101, ST9120, and ST9141 Furnaces using J1

primary connector:

1. Inducer operates for 7 seconds

2. Blower operates HEAT speed for 10 seconds, inducer

continues to run

3. Blower operates COOL speed for 10 seconds, inducer

is off

4. Blower shuts off and control goes to Standby

BLOWER, ACCESSORY, AND SYSTEM OPERATION DETAILS

Action System & Control Response - All Models

"Y" call for cool from thermostat

"Y" call for cool removed

"G" call for fan from thermostat

"G" call for fan removed - Blower is de-energized without delay

CONT continuous blower fan - option

to connect blower low speed tap

EAC electronic air cleaner - optional

line voltage accessory

HUM humidifier - optional line voltage

accessory

ACC single speed blower

Action System & Control Response – ST9101 & ST9120 Models

"W" call for heat from thermostat

"W" call for heat removed

- Contactor is energized

- Cool ON delay timer, then blower energized at COOL speed

- Contactor is de-energized

- Cool OFF delay timer, then blower is de-energized

- Blower is energized without delay at HEAT speed (default) or at COOL speed

(optional - if selected by dipswitch)

- If a call for heat occurs, blower runs at HEAT speed

- If a call for cool occurs, blower runs at COOL speed

- Always energized with no call for HEAT "W", COOL "Y", or FAN "G"

- If blower operation is required for HEAT, COOL, or FAN then control switches to

appropriate speed

- EAC terminal is energized with blower HEAT or COOL output, EAC is not energized

when CONT blower terminal is energized

- HUM terminal is energized with inducer output

- ACC terminal is energized with "Y" or "W" and is a convenience terminal for ST9101

systems using the same blower speed for HEAT and COOL

- Inducer energized

- Pressure switch makes

- Ignition system energized

- Gas valve opens, main burner lights

- Heat ON delay timer, then blower energized at HEAT speed

- Ignition system de-energized, gas valve closes

- 5 second postpurge timer, then inducer is de-energized

- Heat OFF delay timer, then blower is de-energized

7

Page 8

BLOWER, ACCESSORY, AND SYSTEM OPERATION DETAILS

Action System & Control Response – ST9101 & ST9120 Models cont.

- Ignition system is de-energized

Limit switch string opens

Limit switch string remakes

Action System & Control Response - ST9141 Models

"W" call for heat from thermostat

"W" call for heat removed

Primary limit switch string opens

Primary limit switch string closes

Primary limit string open >150

seconds for 3 consecutive cycles

Burner limit switch string opens

Burner limit switch string remakes

- Gas valve closes

- Inducer energized, blower energized at HEAT speed

- Red fault LED flashes once

- Inducer energized for 5 second postpurge timer

- Blower remains energized for dipswitch selected HEAT off delay timer

- Normal operation resumes

- Pressure switch confirmed in no airflow position, otherwise Red fault LED flashes

three times

- Inducer energized

- Pressure switch makes. If pressure switch shows no airflow >30 seconds Red fault

LED flashes three times

- Ignition system energized

- Gas valve opens, main burner lights

- Heat ON delay timer, then blower energized at HEAT speed

- Ignition system de-energized

- Gas valve closes

- 5 second postpurge timer, then inducer is de-energized

- Heat OFF delay timer, then blower is de-energized

- Ignition system is de-energized

- Gas valve closes

- Inducer de-energized, blower energized at HEAT speed

- Red fault LED flashes twice

- Blower de-energized after HEAT off delay timer

- Normal operation resumes

- Inducer, blower, and ignition system de-energized. Control lockout until 24VAC reset

>10 seconds. Red fault LED flashes four times

- Ignition system de-energized

- Gas valve closes

- Inducer energized, blower energized at HEAT speed

- Red fault LED flashes once

- Inducer energized for 5 second postpurge timer

- Blower remains energized for dipswitch selected HEAT off delay timer

- Normal operation resumes

Action System & Control Response - ST9160 Models

"W" call for heat from thermostat

"W" call for heat removed

Limit switch opens at SVll system

control (gas valve)

Limit switch open condition removed

at SVll system control (gas valve)

8

- 50F06-843 control detects SVll system via data line at power up

- Request for HEAT passed to SVll system control (gas valve) on data line

- Main burner lights

- Heat ON delay timer, then blower energized at HEAT speed

- Request for HEAT removed from SVll system control (gas valve) on data line

- Heat OFF delay timer, then blower is de-energized

- Blower will remain energized at HEAT speed. Valve green LED flashes 4 times

- Blower remains energized for dipswitch selected HEAT off delay timer. Normal

operation resumes. Valve green LED displays bright/dim heartbeat

Page 9

TROUBLESHOOTING, FAULT AND STATUS CODES

The LED will indicate fault or status codes as shown in the table below:

TROUBLESHOOTING

GREEN

LED

FLASH

AMBER

LED

FLASH

RED

LED

FLASH

ERROR / CONDITION

Up to 5 ash codes stored in memory (auto-erased after 14 days)

1 Limit switch, burner limit switch, or fuse is open

2 Primary limit switch is open

SYSTEM

TYPE

ST9101

ST9120

X X

ST9141

X

ST9160

Pressure switch improperly closed, or open when inducer has been

3

running >30 seconds

Overheated due to air not circulating (lockout). Three consecutive

4

primary limit open events >150 seconds.

Wrong 24VAC supply condition <18VAC or >30VAC for more than

7

10 seconds. Not detected with fault 9. Operation resumes with 120

seconds proper voltage.

8 Gas valve sensed energized when it should be off

9 Reversed 120VAC polarity / grounding

Other Additional codes displayed on gas valve LED

Flash codes NOT stored in memory

Solid ST9160 jumper missing, plug into connector J1 X

OFF OFF OFF Check power / internal control fault

Alternate Alternate Alternate Self-test mode active

Rapid Control power up

Solid Standby

Continuous Fan only call (G)

1 Call for cool (Y)

2 Call for heat (W)

6 Twinning error

SELF-TEST - Power cycle control, press FAULT button 2x during rapid green ash

FAULT RECALL - In standby, hold FAULT button < 5 seconds

FAULT ERASE - In standby, hold FAULT button > 5 seconds but < 10 seconds

CONTROL LOCKOUT RESET - Remove 24VAC power > 10 seconds

X

X

X X X

X

X X X

X

ALL

FAULT RECALL

When the control is in Standby mode (no call for heat or cool),

press the fault button for approximately 2 to 5 seconds or until

the diagnostic LED turns off. Up to 5 fault codes are stored.

NOTE: While displaying the stored fault codes, the control will

ignore any new call for heat, cool or fan.

FAULT CODE ERASE & RESET

When the control is in Standby mode (no call for heat or

cool), press the fault button for 5 to 10 seconds or until the

diagnostic LED begins to rapid flash.

NOTE: If the button is pressed for over 10 seconds the rapid

flash will stop and the control will return to Standby.

CONTROL LOCKOUT RESET

Control automatically resets after 1 hour in lockout. Removing

24VAC power to the control for greater than 10 seconds will

reset the control.

TWINNING

• Connect Twin/Z1/Z2 terminal between two boards using

an 18ga wire. Boards must be from same manufacturer.

• Board with thermostat connected has full functionality

including LED and dipswitch settings. Twinned board

will operate blower only simultaneously (LED showing

Standby) unless “W” or “Y” are powered to it.

• Twinned unit can be wired for Heat by utilizing the “W”

terminal either with the 1st unit or as a 2nd stage.

9

Page 10

Emerson and White-Rodgers are

trademarks of Emerson Electric

Co. ©2019 Emerson Electric Co.

All rights reserved.

TECHNICAL SUPPORT: 1-888-725-9797

emerson.com/white-rodgers

Loading...

Loading...