Page 1

ACTURA Flex 48330 Power System

User Manual

Version: V1.0

Revision date: May 20, 2005

BOM: 31011084

Emerson Network Power provides customers with technical support.

Users may contact the nearest Emerson local sales office or service

center.

Copyright © 2005 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to

change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District

518057, Shenzhen China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Page 2

Safety Precautions

To avoid accident, read the safety precautions very carefully before operation.

The "Caution, Notice, Warning, Danger" in this manual do not represent all the

safety points to be observed. Therefore, the installation and operation

personnel must be strictly trained and master the correct operations and all the

safety points before actual operation.

When operating Emerson products, the safety rules in the industry, the general

safety precautions and special safety instructions must be strictly observed.

Electrical Safety

1. Hazardous voltage

Some components of the power system carry hazardous voltage in operation,

direct contact or indirect contact through moist objects with these components

will result in fatal injury.

Safety rules in the industry must be observed when installing the power

system. The installation personnel must be licensed to operate high voltage

and AC power.

In operation, be sure to remove conductive objects, such as watch, bracelet,

ring, and so on.

When water or moisture is found on the cabinet, turn off the power immediately.

In moist environment, take precautions to keep moisture out of the power

system.

"Prohibit" warning label must be attached to the switches and buttons which

are not permitted to be operated on during installation.

High voltage operation may cause fire and electric shock. The connection and

wiring of AC cables must be in compliance with the local codes and

regulations. Only those who are licensed to operate high voltage and AC

power can perform high voltage operations.

2. Tools

In high voltage and AC operation, special tools must be used. No common or

homemade tools should be used.

3. Thunderstorm

Never operate on high voltage, AC, iron tower or mast on a day with

thunderstorm.

Page 3

In thunderstorms, a strong electromagnetic field will be generated in the air.

Therefore the equipment should be well-earthed in time to avoid damage by

lightning strikes.

4. ESD

The static electricity generated by the human body will damage the static

sensitive elements on PCBs, such as large-scale ICs. Before touching any

plug-in board, PCB or IC chip, ESD wrist strap must be worn to prevent body

static from damaging the sensitive elements. The other end of the ESD wrist

strap must be well earthed.

5 Short-circuit

During operation, never short the positive and negative terminals of the MFU

of the system or the non-earthing terminal and the earth. The power system is

a constant voltage DC power equipment, short circuit will result in equipment

burning and endanger human safety.

Check carefully the polarity of the cable and connection terminal when

performing DC live operations.

Never wear a watch, bracelet, ring, or other conductive objects during

operation.

Insulated tools must be used.

Battery

Before any operation on battery, read very carefully the safety precautions for

battery transportation and the correct battery connection method.

Non-standard operation on the battery will cause danger. In operation,

precautions should be taken to prevent battery short circuit and overflow of

electrolyte. The overflow of electrolyte will pose potential threat to the

equipment, it will erode the metal objects and PCBs, thus causing equipment

damage and short circuit of PCBs.

Before any operation on battery, pay attention to the following points:

Remove the watch, bracelet, bangle, ring, and other metal objects on the wrist.

Use special insulated tools.

Wear an eye protection device, and take preventive measures.

Wear rubber gloves and apron to guard against electrolyte overflow.

In battery transportation, the electrode of the battery should always be kept

facing upward. Never put the battery upside down or slanted.

Page 4

Special Safe Requirements of This Equipment

The equipment has multi power inputs;

The equipment shall be installed on cement ground.

Others

1 Safety requirement

Please use the same model fuse to replace the fuse in the DC Power System.

2. Sharp object

When moving equipment by hand, wear protective gloves to avoid injury by

sharp object.

3. Cable connection

Please verify the compliance of the cable and cable label with the actual

installation prior to cable connection.

4. Binding the signal cables

The signal cables should be installed separately far away from heavy current

and high voltage cables, with distance at least 150mm.

Page 5

Contents

Chapter 1 System Description................................................................................................1

1.1 Abbreviation..............................................................................................................1

1.2 Introduction...............................................................................................................1

1.3 Features....................................................................................................................1

1.4 Sy

1.5 Components..............................................................................................................4

Chapter 2 Installation...........................................................................................................12

2.1 Installation Preparation ...........................................................................................12

2.2 Installation Procedures............................................................................................15

2.3 External Electrical Connection

2.4 Battery Installation And Cabling

2.5 Parallel Connection Of Cabinets.............................................................................29

stem Configuration................................................................................................2

1.5.1 Rectif

1.5.2 Rectif

1.5.3 SCU................................................................................................................7

1.5.4 Multi-Function Unit (MFU)...............................................................................9

1.5.5 Battery Connection Unit (BCU).....................................................................10

1.5.6 Sy

2.1.1 Env

2.1.2 Power Supply................................................................................................12

2.1.3 Si

2.1.4 Tools & Material............................................................................................13

2.1.5 Unpacking.....................................................................................................14

2.2.1 Cabinet Installati

2.3.1 Connection Of Inpu

2.3.2 Connection Of Load Cables..........................................................................20

2.3.3 Connection

2.3.4 Layout Of Connector Board S6415X2...........................................................22

2.3.5 Interface Definition Of Connector Board S6415X2........................................23

2.3.6 Connection

2.3.7 Connection With MODEM.............................................................................24

2.3.8 Connection

2.4.1 Battery Installation ........................................................................................25

2.4.2 Battery Cable Connection.............................................................................26

ier Shelf..................................................................................................4

ier...........................................................................................................6

stem Cabinet.............................................................................................11

ironmental Conditions.............................................................................12

te Survey

...................................................................................................13

on .......................................................................................15

Interface .................................................................17

t Cables..........................................................................17

Of Communication Cables.........................................................21

Of Temperature Sensor Cables.................................................24

With Dry Contacts......................................................................25

..............................................................................25

Chapter 3

3.1 Checki

3.2 Startup Process

3.3 Parameters Configuration.......................................................................................31

Startup.................................................................................................................30

ng Before Startup.........................................................................................30

......................................................................................................31

Page 6

Chapter 4 Testing.................................................................................................................32

4.1 Testing MFU ...........................................................................................................32

4.2 Testing Rectifier......................................................................................................32

4.3 Testing SCU............................................................................................................32

4.4 Battery

4.5 BCU Te

Breaker Test...............................................................................................33

st ................................................................................................................33

4.6 Load Breaker Test ..................................................................................................33

Chapter 5 Operating SC

U....................................................................................................34

5.1 Operation Panel......................................................................................................34

5.2 Operation Procedures.............................................................................................35

5.3 Query

5.3.1 First Page Of System Informatio

ing System Status .........................................................................................36

n.................................................................36

5.3.2 Other System Information Screen.................................................................37

5.4 Querying Rectifier Status........................................................................................39

5.5 Querying Alarms And Setting Alarm Plans

..............................................................40

5.5.1 Querying Active Alarm..................................................................................40

5.5.2 Query Alarm History

......................................................................................41

5.5.3 Alarm Type Table..........................................................................................43

5.5.4 Changing Audible/Visual Alarm And Alarm Call Back Pl

an...........................46

5.5.5 Changing Alarm Types Of Dry Contacts.......................................................46

5.5.6 Setting Alarm Type For Dry

Contacts ...........................................................46

5.5.7 Set the Alarm Names Through PLC Function...............................................48

5.6 Maintenance ...........................................................................................................51

5.7 Setting System Parameters ....................................................................................53

5.7.1 Parameter Setting

Method............................................................................53

5.7.2 Batt. Selection...............................................................................................55

5.7.3 LVD

Parameter Description..........................................................................56

5.7.4 Charging Management Parameters..............................................................57

5.7.5 Bat

tery Test Parameters...............................................................................60

5.7.6 Temperature Compensation Coefficient Parameters....................................62

5.7.7 AC Se

ttings...................................................................................................63

5.7.8 DC Setting ....................................................................................................64

5.7.9 Rect Settings ................................................................................................65

5.7.10 Sy

stem Settings..........................................................................................66

5.7.11 Alarm Settings.............................................................................................70

Chapter

6 Routine Maintenance...........................................................................................72

6.1 Mainte

nance Of Rectifier.........................................................................................72

6.2 Maintenance Of SCU..............................................................................................72

6.3 Mainte

nance Of MFU..............................................................................................72

6.4 Cover Plates ...........................................................................................................73

6.5 Battery Maint

6.5.1 Stora

enance...............................................................................................73

ge And Supplementary.........................................................................73

Page 7

6.5.2 Daily Inspection.............................................................................................73

6.5.3 Replacement.................................................................................................74

Chapter 7 Troubleshooting...................................................................................................75

7.1 Troubleshooting Rectifier........................................................................................75

7.2 Mains Failure ..........................................................................................................76

7.3 Disastrous Accidents ..............................................................................................76

Appendix 1 System Technical Parameters ..........................................................................77

Appendi

x 2 Engineering Design Diagram ............................................................................79

Appendi

x 2.1 Engineering Design Diagram For 2000mm%600mm%600mm Cabinet

Appendix 2.2 Engineering Design Diagram For 2000mm%600mm%400mm Cabinet

Appendix 2.3 Engineering Design Diagram For 700mm%600mm%400mm Cabinet....81

Appendi

x 2.4 System Input And Output Connecto

Appendix 3 System Circ

uit Diagram.....................................................................................82

r Specs............................................81

Appendix 3.1 System Electric Schematic Diagram.......................................................82

Appendix 3.2 System Wiring Diagram

..........................................................................83

Appendix 3.3 MFU Electric Wiring Diagram..................................................................84

Appendix 3.4 BCU Electric Wiring Diagram..................................................................85

Appendi

x 4 Glossary............................................................................................................86

..79

..80

Page 8

Table List

Table 1-1 Configurations of Actura Flex 48330 Power System..............................................3

Table 1-2 Dimensions of rectifier shelf...................................................................................5

1-3 Function of indicators.............................................................................................7

Table

Table 1-4 Authority and default password..............................................................................9

Table 1-5 Configuration of MFU...........................................................................................10

Table 1-6 BCU configuration................................................................................................11

2-1 Environmental conditions in power room .............................................................12

Table

Table 2-2 AC input modes ...................................................................................................17

Table 2-3 Configuration number of load MCBs and battery MCBs.......................................20

Table 2-4 Interface definition of connector board S6415X2.................................................23

3-1 System checklist before startup...........................................................................30

Table

Table 5-1 Functions of LED indicators.................................................................................34

Table 5-2 Functions of SCU keys.........................................................................................34

Table 5-3 Alarm type table

Table 5-4 Changing audible/visual alarm and alarm call back plan......................................46

Table 5-5 Optional alarm types............................................................................................47

Table 5-6 Logic matrix used for configuring 8 dry contacts..................................................49

Table 5-7 Example of PLC setting........................................................................................49

Table 5-8 PLC SN and Alarm...............................................................................................49

5-9 Password levels and authorities...........................................................................54

Table

Table 5-10

Table 5-11 Value description of the LVD parameters...........................................................57

Table

Table 5-13 Value description of the battery test parameters................................................61

Table 5-14 Value description of temperature compensation coefficient...............................62

Table 5-15 Value description of AC se

Table 5-16 Value description of DC se

Table 5-17 Value description of rectifier settings..................................................................65

Value description of the basic battery parameters .............................................56

5-12 Charging management parameter value description..........................................59

...................................................................................................43

ttings........................................................................63

ttings........................................................................64

Table 5-18 Value description of system settings

Table 5-19 Relationship between system model and system type.......................................70

Table 5-20 Value description of alarm settings ....................................................................71

Table 7-1 Troubleshooting ...................................................................................................75

..................................................................68

Page 9

Figure List

Figure 1-1 Outline .................................................................................................................. 2

Figure 1-2 Rectifier shelf outline.............................................................................................

Figure 1-3 Rectifier shelf with rectifiers and CU.....................................................................4

Figure 1-4 Dimensions...........................................................................................................6

Figure 1-5 Outline of SCU......................................................................................................7

Figure 1-6 Outline and components of MFU..........................................................................9

Figure 1-7

Figure 2-1 Installation dimensions of the cabinet base ........................................................15

Figure 2-2 Installing expansive pipe.....................................................................................16

Figure 2-3 Fixing cabinet with Tap.......................................................................................16

Figure

Figure 2-5 Connection of input terminals .............................................................................18

Figure 2-6 Top cover............................................................................................................18

Figure 2-7 Connection of 3-phase AC power input ..............................................................18

Figure 2-8

Figure 2-9 Connection of dual-phase AC power input..........................................................19

Figure 2-10 Connection of load cables.................................................................................20

Figure 2-11 Cable connection to MCB

Outline of battery connection unit (BCU).............................................................10

2-4 Cable mounted with H terminal...........................................................................17

Connection of single-phase AC power input.......................................................19

.................................................................................20

4

Figure 2-12 Connector board in rectifier shelf......................................................................21

Figure 2-13 Layout of connector board S6415X2.................................................................22

Figure 2-14 Input/output interfaces of TD-5648DC MODEM................................................24

Figure 2-15

Figure 2-16 Connection of battery cables. ...........................................................................27

Figure 2-17 Positive and negative battery cables in each level............................................27

Figure 2-18 Negative battery cables connection in BCU......................................................28

Figure 2-19 Parallel connection of DC power system cabinet with battery cabinet..............29

Figure

Figure

Figure 5-3 Schematic diagram of the test function...............................................................61

Figure

Cabinet with four battery strings ins

5-1 SCU Front Panel.................................................................................................34

5-2 BC/FC switchover diagram.................................................................................59

5-4 System model description...................................................................................69

talled .........................................................26

Page 10

Page 11

Chapter 1 System Description

1.1 Abbreviation

AC Alternate Current

DC Direct Current

SCU Standard Controller Unit

BCU Battery Connection Unit

CSU Central Supervision Unit

HVSD High Voltage Shutdown

MCB Miniature Circuit Breaker

Chapter 1 System Description 1

APFC Active Power Factor Correction

MFU Multi-Function Unit

1.2 Introduction

The ACTURA Flex 48330 Power system consists of 50A rectifiers, Control Unit,

Multi-Function Unit (MFU), rectifier shelf and BCU (optional).

The product is used in base station, small exchange station, satellite

communication, data communication, and so on, with a strong adaptability to power

network fluctuation.

This system is used as a power supply for telecom equipment with system nominal

voltage of -48V and positive terminal earthed.

1.3 Features

The DC power system is easy-to-operate, easy-to-install and easy-to-maintain. Its

main features are:

Rectifier uses APFC technology and therefore its PF is up to 0.99;

Wide AC input voltage range of 85~290V;

Rectifier efficiency is at least 90%;

Extra low EMI of rectifier and excellent EMC performance;

ACTURA Flex 48330 Power System User Manual

Page 12

2 Chapter 1 System Description

High power density of rectifier;

Rectifier has damage-free hot plugging/unplugging function, the replacement

time is less than 1min;

Rectifier has two kinds of over-voltage protection methods;

Perfect battery management with BLVD function;

Up to 200 PCS of historical alarms can be stored in SCU;

Provide RS232, Modem and dry contacts communication interfaces;

1.4 System Configuration

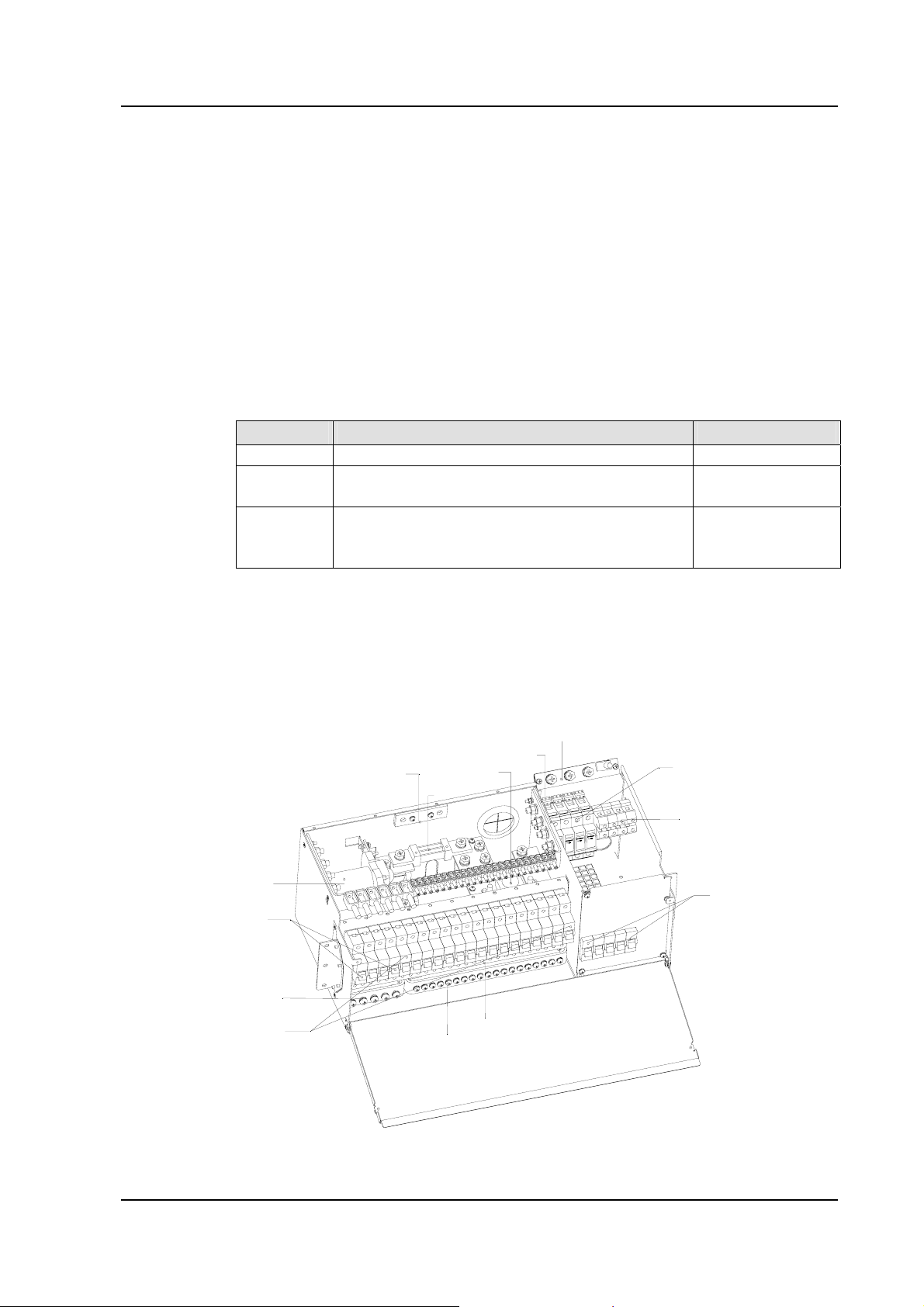

The outline of the DC Power System is illustrated in Figure 1-1:

Multi-function unit

Rectifier

Connector Board

Control unit

Rectifier shelf

Rectifier cover

Battery connection unit

Battery shelf

Door

Figure 1-1 Outline

There are three kinds of DC Power Systems, and their detail configurations are as

shown in Table 1-1:

ACTURA Flex 48330 Power System User Manual

Page 13

Chapter 1 System Description 3

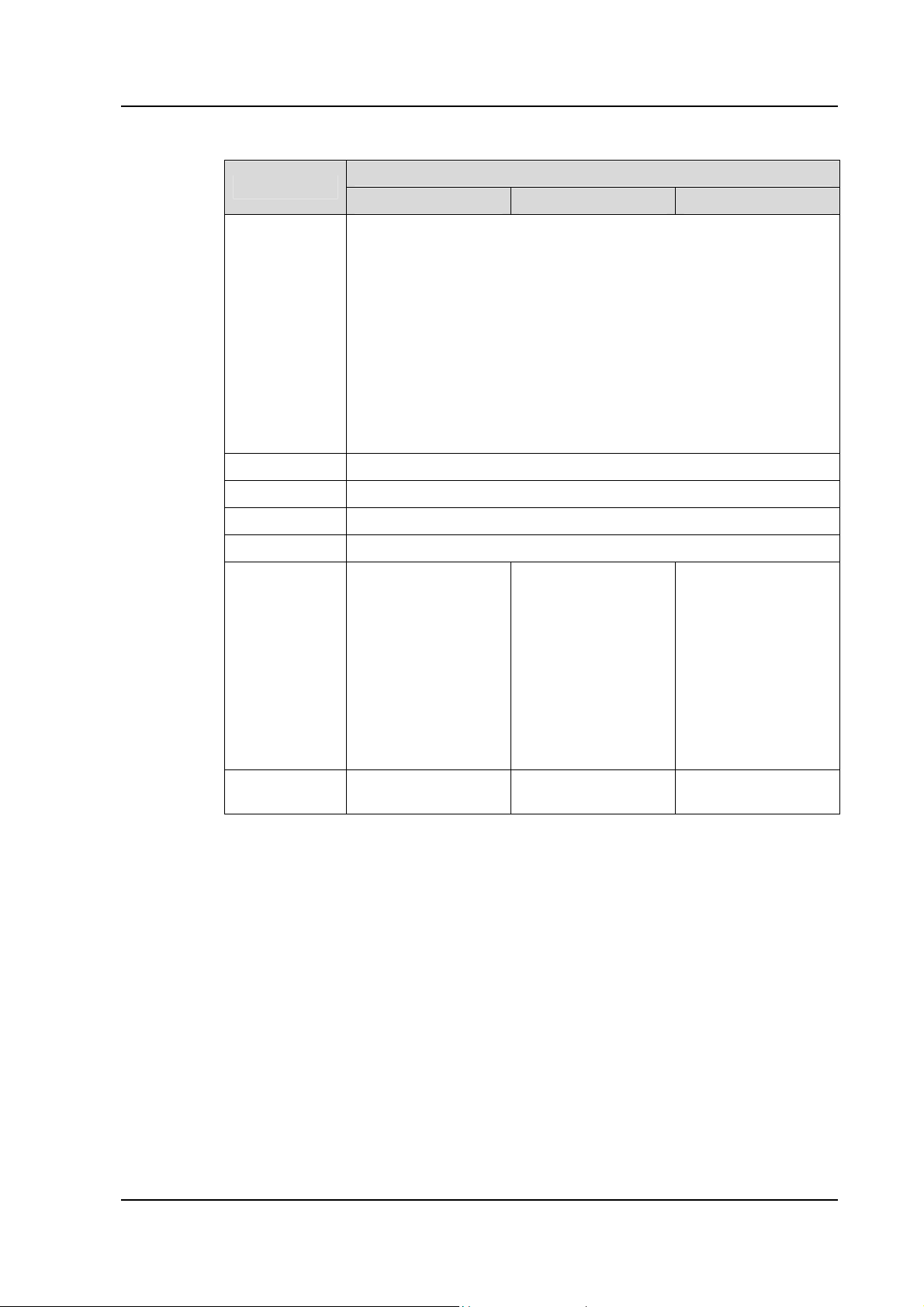

Table 1-1 Configurations of Actura Flex 48330 Power System

Configuration

Cabinet dimension

2.0 % 0.6 % 0.6 m3 2.0 % 0.6 % 0.4 m3 0.7 % 0.6 % 0.4 m3

3P+N/380V AC input with SPD

3P+N/380V AC input without SPD

1P+N/220V AC input with SPD

1P+N/220V AC input without SPD

AC distribution

DC distribution Up to 28 13mm-wide MCB, or 20 18mm-wide MCB

Rectifier Up to 5 rectifiers

Control unit 1 SCU

BCU 1 BCU with up to 5 battery circuit breakers

Battery

Dimensions

(H×W ×D) mm

L1+L2/220V AC input with SPD

L1+L2/220V AC input without SPD

3P/220V AC input with SPD

3P/220V AC input without SPD

5 2P AC input MCBs

Individual AC cables with just terminals

Telion 12V 165Ah FT:

16 Blocks

Hawker 12V 155Ah FT:

16 Blocks

Hawker 12V 105Ah FT:

20 Blocks

Hawker 12V 105Ah FT

and 6U space:

16 Blocks

2000×600×600 2000×600×400 700×600×400

Hawker 12V82F:

16 Blocks

Hawker SBSC11 and

3U space:

16 Blocks

EB4: 20 Blocks

Hawker 12V82F( no

BCU):

20 Blocks

No battery

ACTURA Flex 48330 Power System User Manual

Page 14

4 Chapter 1 System Description

1.5 Components

1.5.1 Rectifier Shelf

Outline

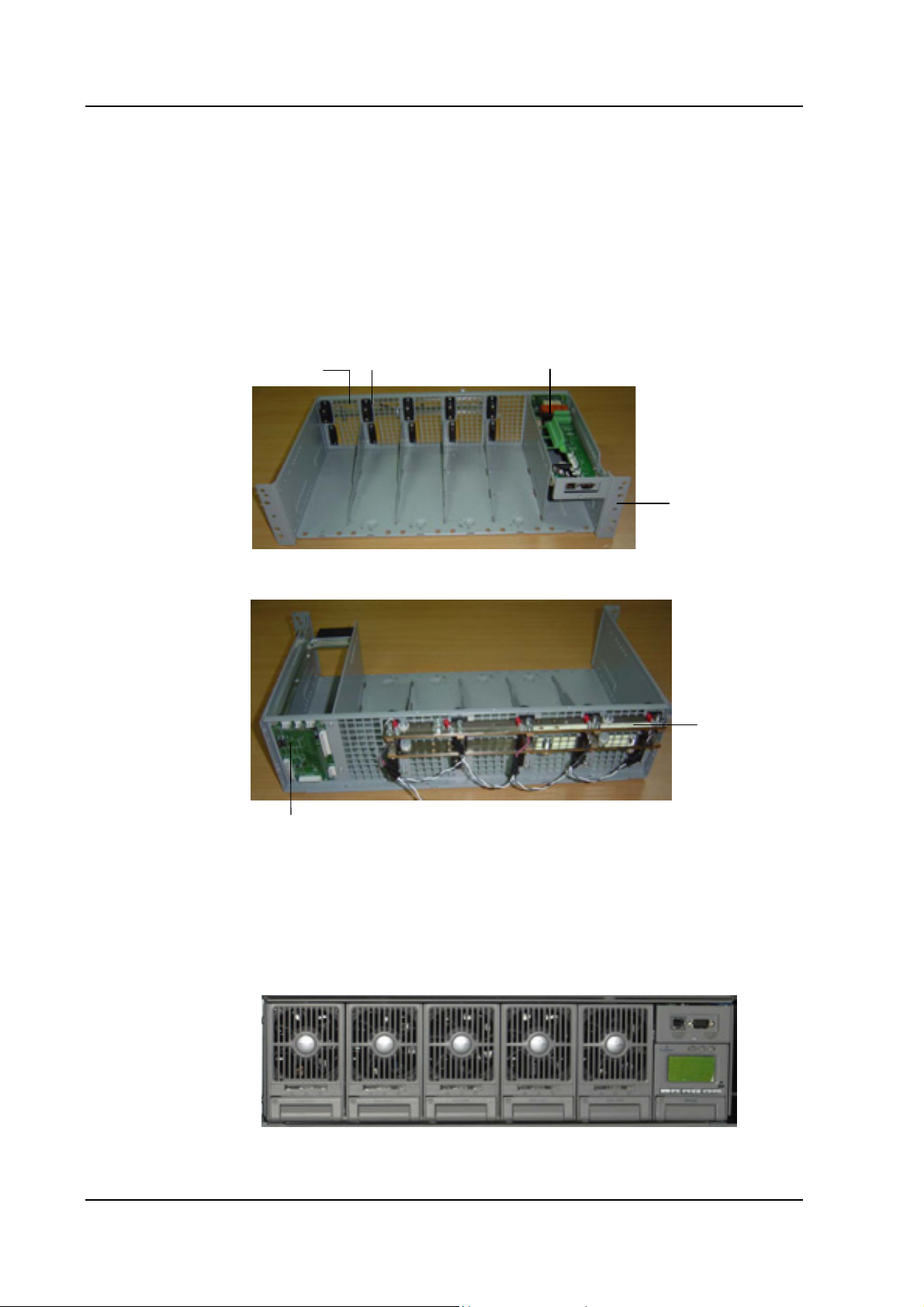

The outline of the Rectifier Shelf is illustrated in Figure 1-2:

Chassis

Terminal connecting

50A Rectifier

Connector Board

Ear Bracket

(a) Actual appearance (front view)

Bus Bar

Back Board

(b) Actual appearance (rear view)

Figure 1-2 Rectifier shelf outline

The shelf can accommodate 5 rectifiers and a control unit as shown in Figure 1-3.

The user can mount the rectifier shelf into cabinets with widths of 600mm and

depths of 400mm. The rectifier shelf has a height of 3U (132.5mm).

Figure 1-3 Rectifier shelf with rectifiers and CU

ACTURA Flex 48330 Power System User Manual

Page 15

Chapter 1 System Description 5

The Dimension of Rectifier Shelf are given in Table 1-2

Table 1-2 Dimensions of rectifier shelf

Manufacture type W(mm) ×D(mm) ×H(mm) Note

PSS485023/C 584.2×327×132.5 23’’ with controller

Backboard

The backboard has the functions below:

DC power source feed for controller and the connector board.

DC input filter and input fuse.

All the ingoing and outgoing signals of the controller

The backboard also contains system internal connectors below:

10 Distribution unit fuses alarm signal measurement input

4 battery fuse alarm signal measurement input

2 battery current shunt measurement inputs

1 load Current shunt measurement input

System bus-bar DC Voltage measurement input

Three-phase from two mains AC Voltage measurement inputs

CAN communication between rectifiers and controller

AC alarm module signals

System fault indicator drivers

LLVD & BLVD mono contactor driver outputs

The entire signal outgoing to the connector board

Connector board

Connector board is a user interface board and has the functions below:

8-channel relay outputs

8-channel digital inputs

One power source feed terminal (for digital inputs)

2-channel temperature sensor inputs

2-channel RS232 parallel connection outputs

LLVD & BLVD bistable contactor driver circuits and outputs

ACTURA Flex 48330 Power System User Manual

Page 16

6 Chapter 1 System Description

One Ethernet output

One RS485 output

One console output for ECU debug

The connector board can be hot plug and has enough space for

accommodating all the interface cables.

The connector board should space the hollow to the SCU convection for air

flowing

The connector board is mounted in the room 1U×2U at the top of the SCU.

The shelf has a 1U×2U panel for the connector board.

One RS232 and Ethernet ports are located at the front of the connector board.

The shelf has two rails for supporting the connector board

1.5.2 Rectifier

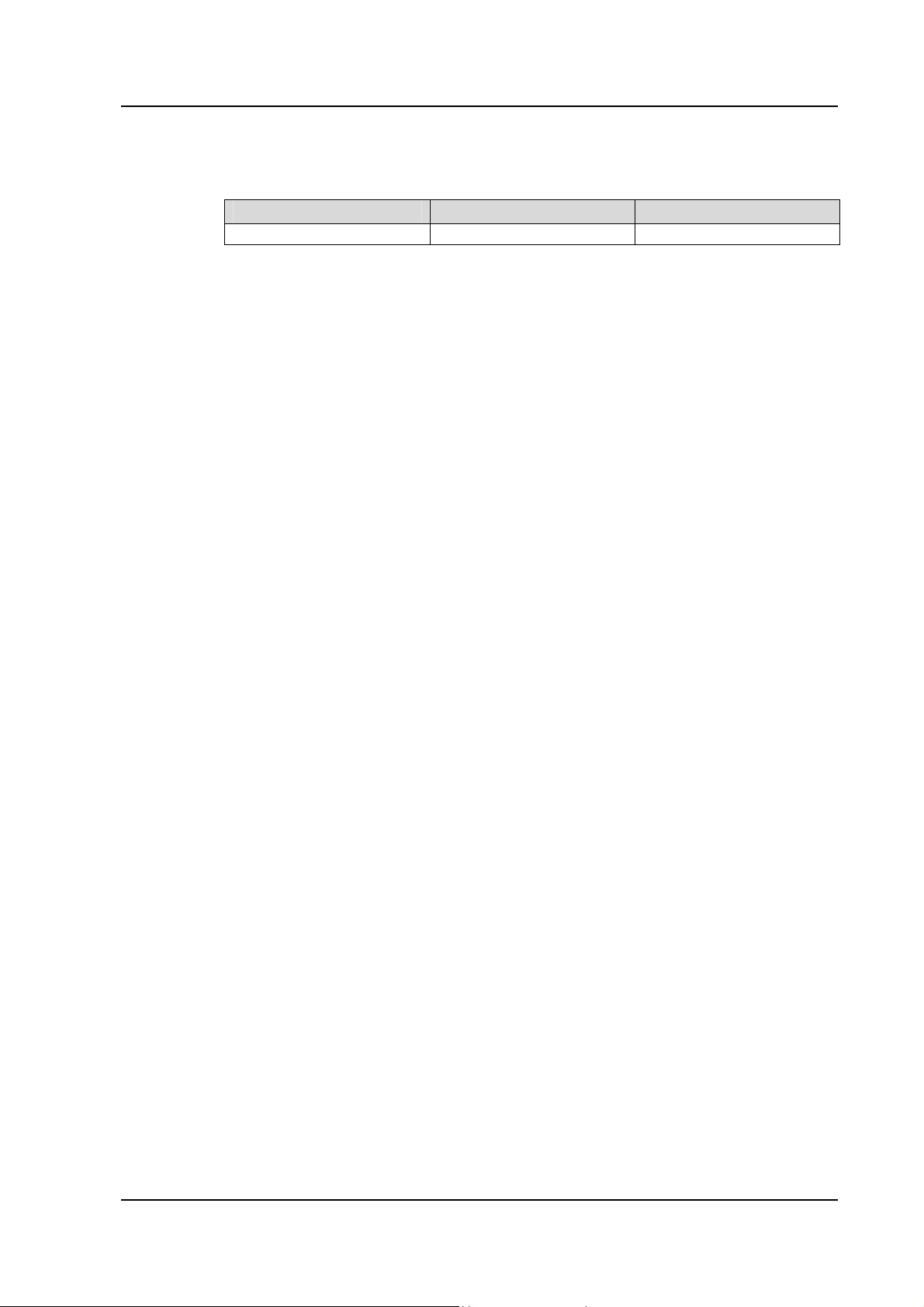

Outline

The appearance and dimensions (unit: mm) of the rectifier are illustrated in the

following figure.

Figure 1-4 Dimensions

Weight: ≤3.5kg

Dimensions (H × W % D): 124.3mm % 84mm % 287mm

The functions of the indicators in front panel are listed in Table 1-3.

ACTURA Flex 48330 Power System User Manual

Page 17

1.5.3 SCU

LED Normal Abnormal Cause of abnormality

Power indicator (green) ON

Protection indicator

(yellow)

Alarm indicator (red) OFF

OFF

Outline

Chapter 1 System Description 7

Table 1-3 Function of indicators

OFF No AC Mains Supply

Blinking Rectifier is under control by SCU

ON

Blinking Communication of rectifier with SCU failure

ON Output Over-voltage

Blinking Fan Failure

AC input over/under voltage, PFC

over/under voltage and over temperature

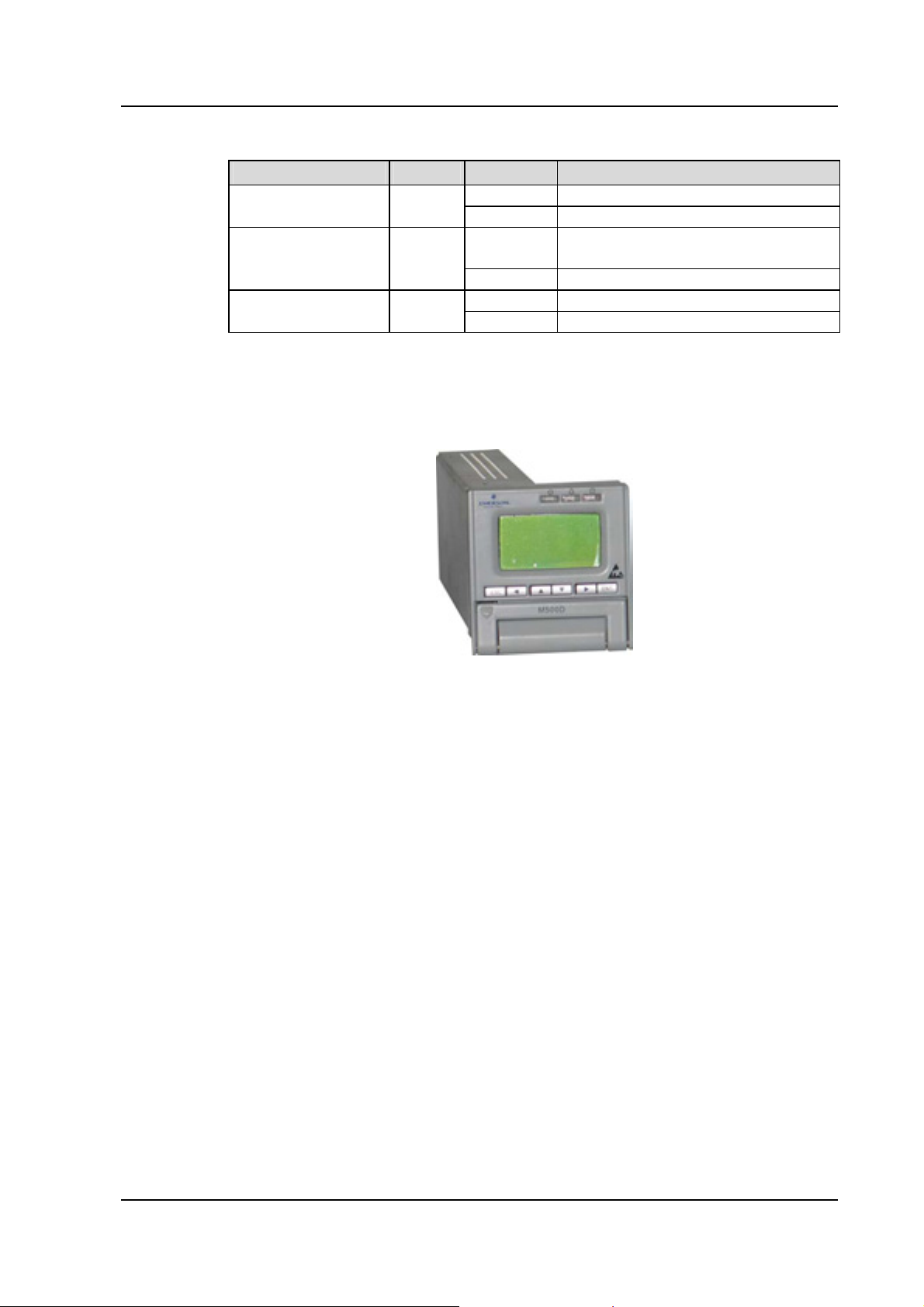

Figure 1-5 Outline of SCU

Dimension (H % W % D):132mm % 85mm % 287mm

Weight: 0.76kg

Multi-Communication mode

SCU communicates with MC (Main Computer) through the RS232/MODEM

communication port and 8 groups of alarm dry contacts on the Signal Junction

Board.

SCU supports both China Telecom Communication Protocol and EEM Protocol.

Make sure that the baud rates for receiving and transmitting are set to be

consistent when using SCU.

1. Communication through RS232

RS232 communication mode is mainly used for short-distance point-to-point

communication. The communication distance shall be less than 15m. If SCU

communicates with MC through RS232, just connect SCU RS232 port to the

RS232 port of MC.

2. Communication through MODEM or ES-MOD

ACTURA Flex 48330 Power System User Manual

Page 18

8 Chapter 1 System Description

When SCU communicates with MC through MODEM or ES-MOD, it uses PSTN to

realize long-distance monitoring. Power supply cables and communication cables

shall be prepared for the communication through MODEM.

3. Dry Contacts Output

SCU has 8 dry-contact outputs. Every dry-contact output has NC (normally closed)

and NO (normally-open) contacts. Every dry-contact output shall be configured

before the alarm event occurs. Different dry-contact output can trigger different

alarms. Once the alarm event occurs, the dry-contact will close or open to generate

the alarm.

If the user has other intelligent equipment to be monitored by SCU, the user can

connect the dry contacts to the interface of the intelligent equipment, and control

the intelligent equipment through these dry contacts.

Capacity of dry contacts: 2A@30Vdc; 05A@125Vac;

Maximum power dissipation: 60W

Functions fulfilled by SCU and MC

In RS232 and MODEM communication modes, the MC can fulfill the following

functions through SCU:

1. Remote acquisition of analog and digital values: MC can acquire the real-time

analog and digital values of DC Power System through SCU;

2. Remote control functions: MC can shut down the rectifiers, change the boost

charge status to float charge status (or in reverse), silence the alarm and stop/start

the battery test through SCU.

Alarm category settings for dry contact output

1. Through setting the parameter of “Relate Relay”, the user can configure the

alarm category for every dry-contact output. Every dry-contact output has been

configured to correspond to an alarm category before SCU is delivered to

customer.

2. SCU has PLC functions in the alarm management. The PLC is to realize simple

logic operation, i.e. the "And", "Or" and "Not" operations. The PLC inputs are all the

possible alarm signals, and the PLC outputs can be used to select one of the 8 dry

contacts. The alarm categories can be configured flexibly for every dry-contact

output through MC. The PLC settings for every dry-contact have three alarm inputs,

and two relation flag. The SN of three alarm categories and the mutual logic

relationships need to be configured.

PLC can be set to “Disabled”. If PLC functions and alarm co-relation are enabled at

the same time, the dry contact will act to activate an alarm when any alarm event

occurs.

ACTURA Flex 48330 Power System User Manual

Page 19

Chapter 1 System Description 9

Password protection for important operations

The users must input the correct password before they conduct “Maintenance” and

“Settings” operations. The password has 3 levels: user, operator or administrator.

The authorities of the 3 levels are the same while conducting “Maintenance”, but

different in conducting “Settings”. The operator can see 3 more pages than the user,

which are “resetting system”, “resetting password” and “modifying system type”.

The administrator can see 2 more pages than the operator, which are “modifying

password of all levels” and “controlling alarm sound volume”. In addition, the

administrator can browse the rectifier parameter serial No., software version and

the setting of internal switches. See the following table:

Table 1-4 Authority and default password

Level Authority Default password

User Configuration of general parameters 123456

Operator

Administrator

User’s authority, plus resetting system, resetting

password and modifying system type.

Operator’s authority, plus modifying password of all

levels, controling alarm sound volume, browsing system

parameters that can be set only through the host

654321

640275

1.5.4 Multi-Function Unit (MFU)

Outline and components

The outline and the components of the MFU are illustrated in the following figure.

Bypass bar

BLVD contactor

Battery MCB

Battery -48V bus

Load MCB

OV DC bus

LLVD contactor

Shunt

Prior load bus

PE bus

SPD

AC input terminals

Rectifier AC input MCB

Low prior load bus

Figure 1-6 Outline and components of MFU

ACTURA Flex 48330 Power System User Manual

Page 20

10 Chapter 1 System Description

Table 1-5 Configuration of MFU

No. Component Description

1 SPD

2 AC input terminals Rating Current 150A

3 Rectifier AC input MCB Rating Current 25A

4 BLVD contactor 200A or 400A optional

5 LLVD contacto r 200A or 400A optional

6 Shunt 300A/75mV

7 Battery MCB 100A MCB (up to 5 battery MCBs can be selected to configure)

8 Load MCB Selected according to user’s requirement

The user can mount the distribution unit into cabinets with widths of 600mm and

depths of 400mm and 600mm. It has a height of 4.5U (200mm).

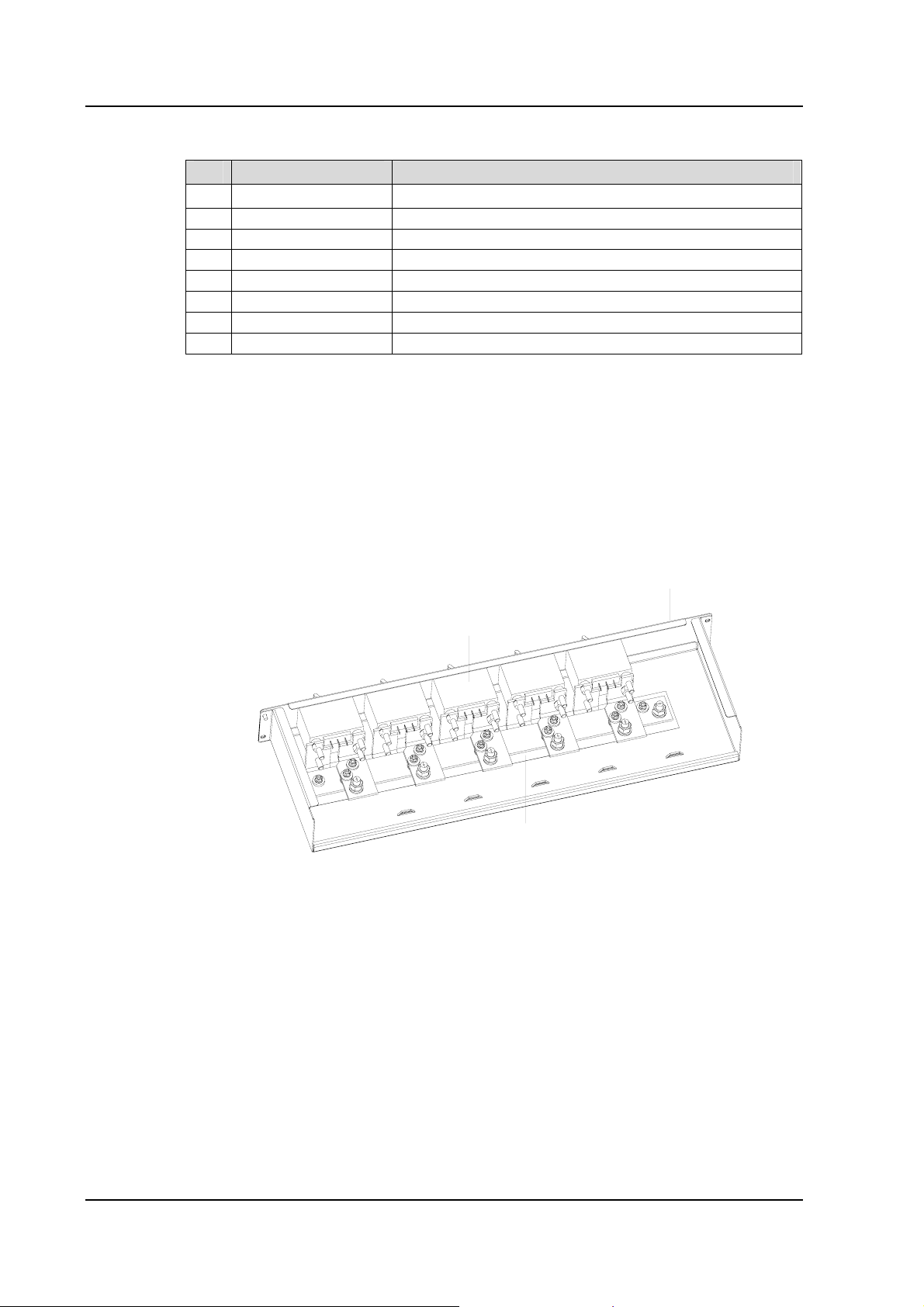

1.5.5 Battery Connection Unit (BCU)

Outline

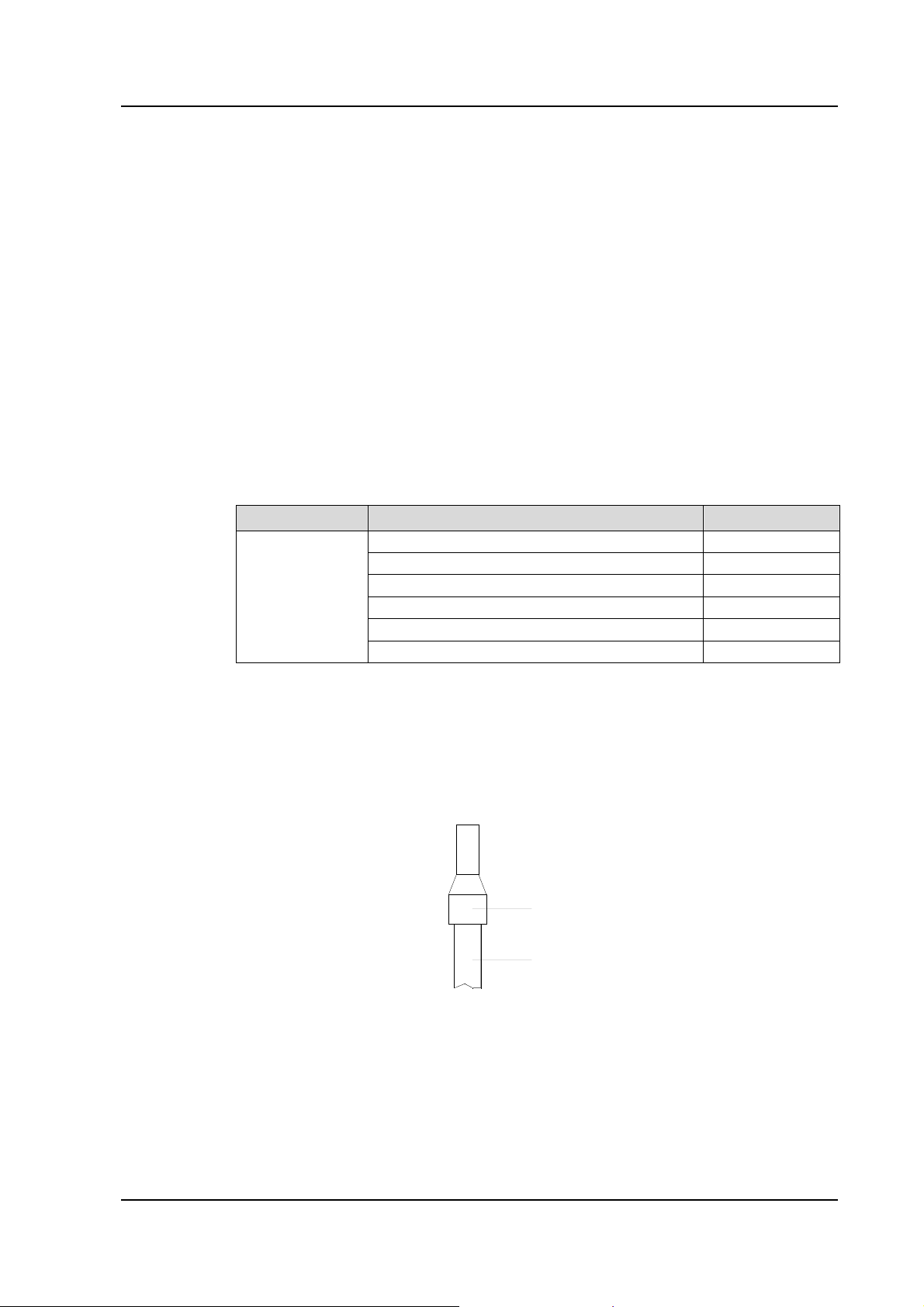

Norminal Dischage Current(8/20μS) 20kA; Ue=385V

The outline of the Battery Connection Unit (BCU) is illustrated in Figure1-7.

Enclosure

Battery MCB

-48V DC Bus

Figure 1-7 Outline of battery connection unit (BCU)

Physical size

Battery Connection Unit (BCU) can be installed in cabinets with widths of 600mm

and depths of 400mm and 600mm. BCU has a maximum height of 1.5U (67mm).

BCU contains 2 to 5 circuit breakers, each with ratings of 100A and 200A.

Alarm output

The BCU will generate an alarm if a battery circuit breaker is off. This alarm shall be

possible to connect to the connector board for display in the Controller. It shall be

possible to combine the alarms from 2 BCUs to generate a single alarm in the

controller. It shall also be possible to combine the alarm from the BCU with an

ACTURA Flex 48330 Power System User Manual

Page 21

alarm generated from battery circuit breakers that are switched off in the BCU (for

example when using a BCU in an extension battery cabinet and battery circuit

breakers in the BCU in a main cabinet).

BCU configuration

The BCU configuration is as shown in Table 1-6:

Item Function unit Amount

Battery connection unit

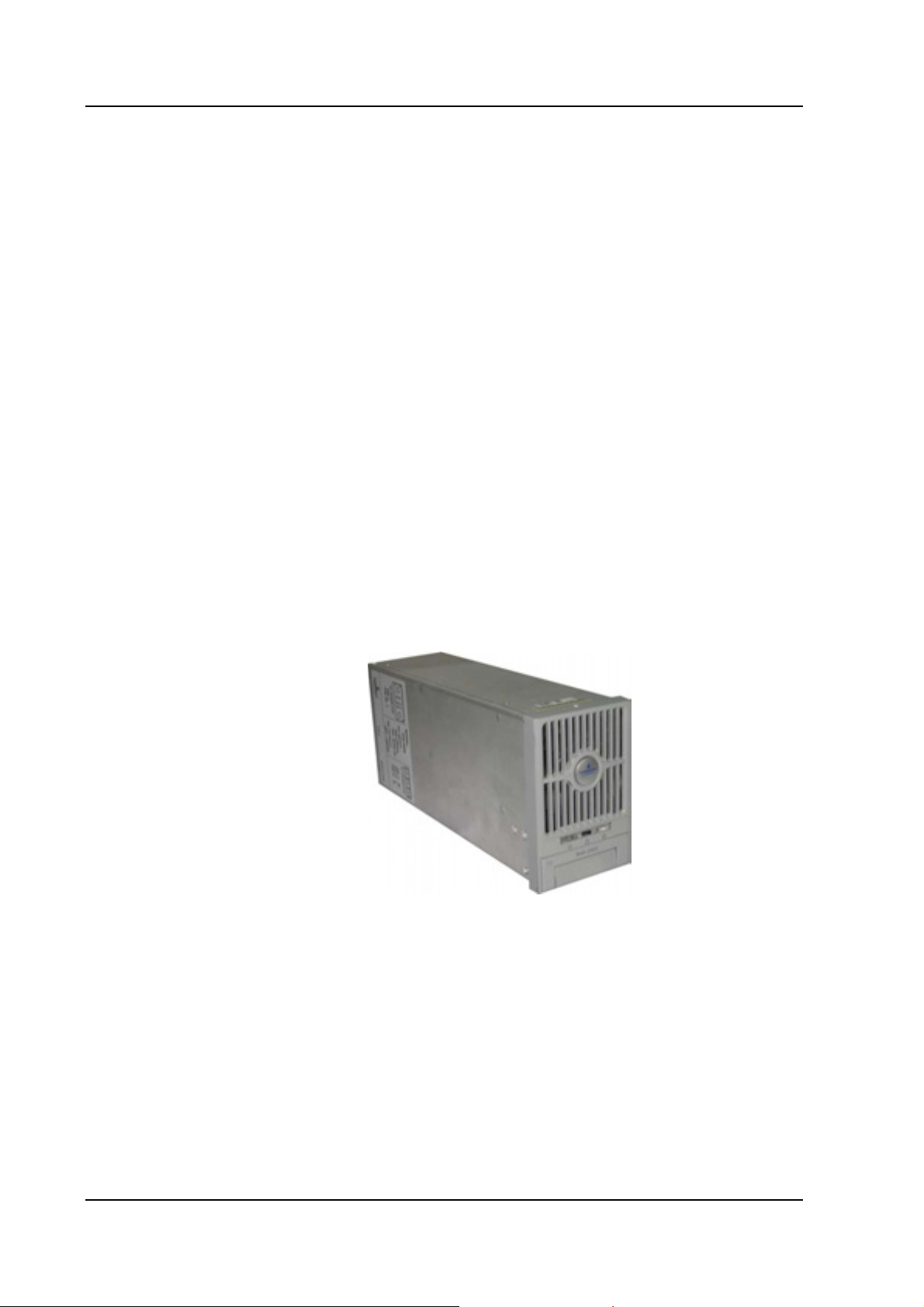

1.5.6 System Cabinet

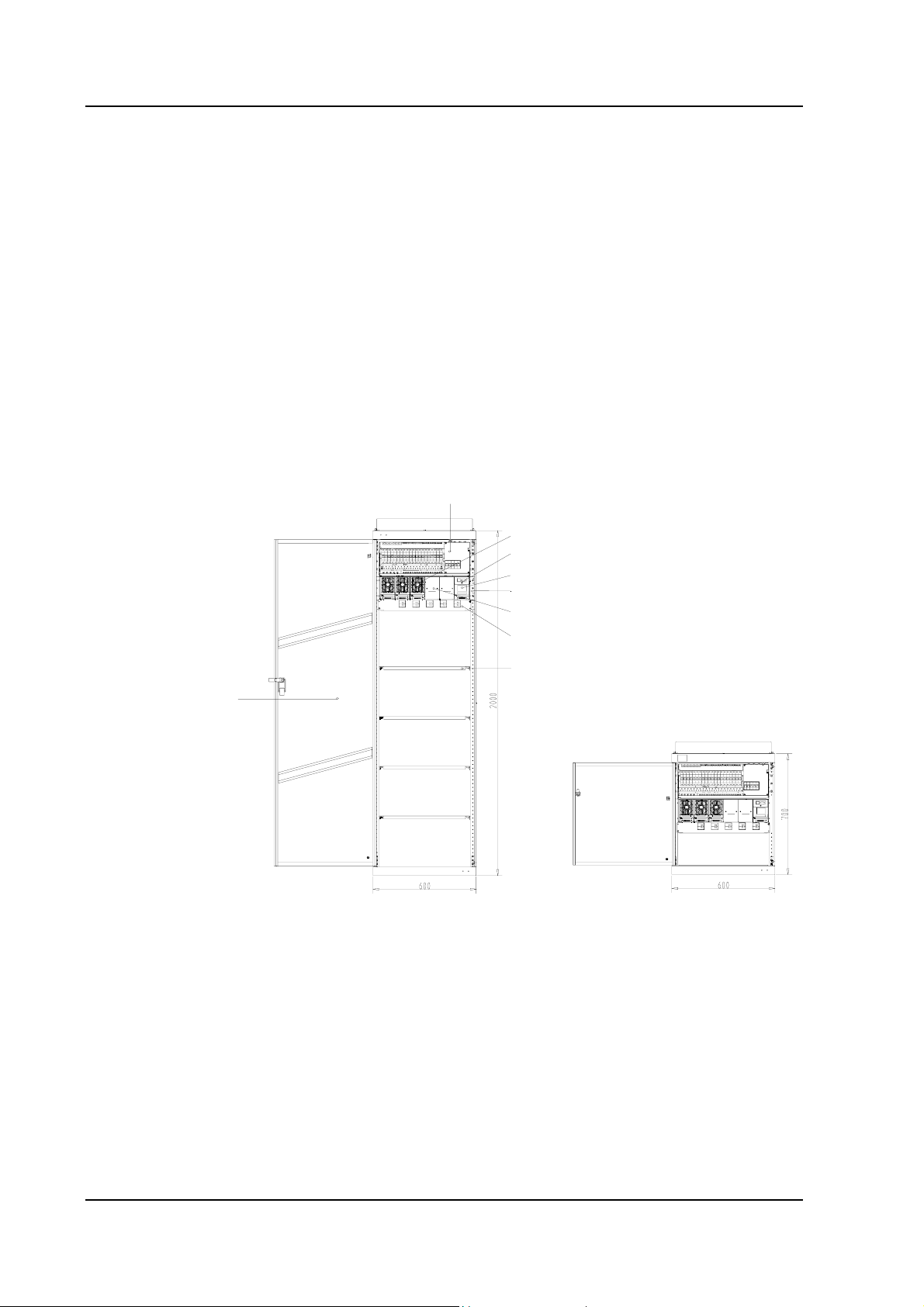

There are three kinds of cabinets. Their dimensions are 2.0m % 0.6m % 0.6m, 2.0m

% 0.6m % 0.4m and 0.7m % 0.6m % 0.4m respectively.

Chapter 1 System Description 11

Table 1-6 BCU configuration

100A CB for battery input 2/3/4/5

200A CB for battery input 2/3/4/5

2.0m % 0.6m % 0.6m cabinet

This cabinet is installed with 1 % MFU, 1 % Rectifier Sub-rack, 1 % BCU and the

following combination of units:

16 Blocks of Telion 12V 165Ah FT batteries or 16 % Hawker 12V 155Ah FT

batteries

20 Blocks of Hawker 12V 105Ah FT batteries

16 Blocks of Telion 12V 100Ah FT batteries (20 blocks is preferred, if possible)

16 Blocks of Hawker 12V 105Ah Ft batteries and 6U of unspecified equipment

(such as DC/DC converters or similar)

2.0m % 0.6m % 0.4m cabinet

This cabinet accommodates 1 % MFU,1 % Rectifier Sub-rack, 1 % BCU and the

following combination of units:

16 Blocks of Hawker 12V82F batteries or 16 Blocks of Hawker SBSC11 and

3U available for additional equipment such as DC/DC converters

20 Blocks of EB4 batteries

20 blocks of Hawker 12V82F batteries (20 blocks and BCU is preferred, if possible)

0.7m % 0.6m % 0.4m cabinet

This cabinet accommodates 1 % MFU, 1 % Rectifier Sub-racks and 1 % BCU.

There shall be 3U available for the mounting of additional equipment such as

DC/DC converters. The cabinet should not be installed any battery.

ACTURA Flex 48330 Power System User Manual

Page 22

12 Chapter 2 Installation

Chapter 2 Installation

2.1 Installation Preparation

2.1.1 Environmental Conditions

Make sure the following environmental conditions are satisfied when selecting the

installation site:

Table 2-1 Environmental conditions in power room

Environmental conditions Recommended range

Ambient temperature

Humidity ≤90%RH, non-condensing

Dust

Sunlight No direct sunlight

Corrosives No pollutants, such as salt, acid, and smoke, etc.

Shake

Insects, pests, and termites None

Mildew None

Moisture Water proof

Fire protection No flammable on the top/bottom of the cabient.

The DC Power system will be damaged if dust or sand accumulates in it. The

following measures are recommended for dusty environment:

-5~50°C (If ambient temperature > 45°C, for the cabinet with

400mm depth, it should demount the front door of cabinet to

ensure the normal operation of the system.)

3

≤1mg/m

≤1.5m/s

2

1.The system should be installed in an airtight and air-conditioned power room. The

air-conditioner filter should be well serviced without being obstructed. To reduce the

dust in the power room, un-attendance in the power room is recommended.

2.The air filter should be cleaned periodically.

3.The product should be installed on a cement ground.

2.1.2 Power Supply

AC power supply for communication uses AC mains as its main power source.

Backup batteries and generator should be configured according to the actual power

supply situation. The AC power supply system composed of AC mains and

generator should adopt centralized power supply mode to supply power, while low

ACTURA Flex 48330 Power System User Manual

Page 23

voltage AC power supply system should adopt three-phase five-line or single-phase

three-line modes.

The AC power cable should adopt copper core cable, and the cable section should

suit the load. It is recommended that the power cable outside the power room be

buried directly under the ground or by means of cable pipe. Power cable should be

wired separately from signal line.

The AC mains voltage shall be within the range of the voltage input range of

rectifiers.

The DC power system has a circuit breaker that can cut the AC mains power to it.

2.1.3 Site Survey

The power room must be surveyed prior to installation, which should be focused

on:

1. Checking the wiring device, including cable chute, wiring rack, floor, wiring holes.

Chapter 2 Installation 13

2. Checking the environmental conditions, including temperature, humidity, dust.

3. Checking the conditions for implementing the installation, including power supply

and lighting.

2.1.4 Tools & Material

1. Tools required for power equipment installation include electric drill, wire cutter,

wire presser, various wrenches, screwdriver, electrician knife, and steel saw. The

tools must be insulated and antistatic handled before they are used.

2. Power cables for electrical connection include AC cables, DC load cables,

battery cables, earth cables, earth bar and lighting connection cables. Their design

specifications should be in accordance with relevant specifications in the electrical

industry and the materials should be purchased according to the design material

list.

AC cables: this system uses 3-phase or single-phase AC power. Copper-core

flame-retardant PVC insulated cable and PVC sleeve soft cable, such as NH-BVR,

are recommended for the AC cables, whose sectional area should suit the load.

When the wiring distance is less than 30 meters, take 2.5A/mm

current density to calculate the sectional area of the AC cables.

2

of economical

The sectional area of the DC load cables and battery cables should be calculated

using the following formula:

A=ΣI×L/K△U

ACTURA Flex 48330 Power System User Manual

Page 24

14 Chapter 2 Installation

In this formula: A is the sectional area of the lead (mm2), ΣI is the total current (A)

flowing through the lead, L is the length (m) of the lead loop, △U is the permitted

voltage drop on the lead, while K is the conductivity. Kcopper=57. For safety, the

voltage drop on the cables connecting battery and load cannot exceed 3.2V.

The sectional area of the lightning protection earth cable should not be less than

2

6mm

, and that of the DC operation earth cable, usually between 35-50mm2, is

determined by user. Take the greatest sectional area among the above 3 earth

cables as that of the cable connecting the user earth bar.

3. Purchase materials according to the materials list and inspect the materials, for

example, check the heat durability, moisture resistance, flame resistance, and

voltage resistance of the cable.

4. The auxiliary materials for power supply installation include expansive bolts,

binding strips, and insulating tape.

2.1.5 Unpacking

To ensure smooth installation, the power equipment must be carefully inspected

when it is unpacked.

The equipment unpacking and inspection are allowed only after it arrives the

installation site. The inspection is co-accomplished by the user representative and

representative from Emerson Network Power Co., Ltd.

When inspecting the equipment, first open the packing case with packing list put in

it, take out the packing list, and conduct inspection against the packing label,

including the customer name, customer address, machine No., total amount, case

No., contract No., etc.

Unpacking and inspection: after opening the packing case, check the goods one by

one according to the goods list on the packing label. The checking should include:

1. The number and serial number marked on the packing cases according to the

actual number of the packing cases.

2. The correctness of the equipment packing according to the packing list.

3. The number and model of the accessories according to the accessory list.

4. The completeness of the equipment set according to the system configuration.

5. The condition of the goods through visual inspection. For example, check if the

cabinet is damaged, if the cabinet has regained moisture; shake gently the rectifiers

and monitoring module to see if the parts and connections have been loosened

during delivery.

ACTURA Flex 48330 Power System User Manual

Page 25

2.2 Installation Procedures

2.2.1 Cabinet Installation

Installation on the floor

Step 1: mark the position where the power system is to be installed.

Determine the installation position of the power supply cabinet in the power room

according to the installation chart. Based on the mechanical specifications (see Fig.

2-1) of the installation holes of the power supply cabinet, determine the accurate

position of the center points of the installation holes on the floor, and mark them

with a pencil or oil pen.

Chapter 2 Installation 15

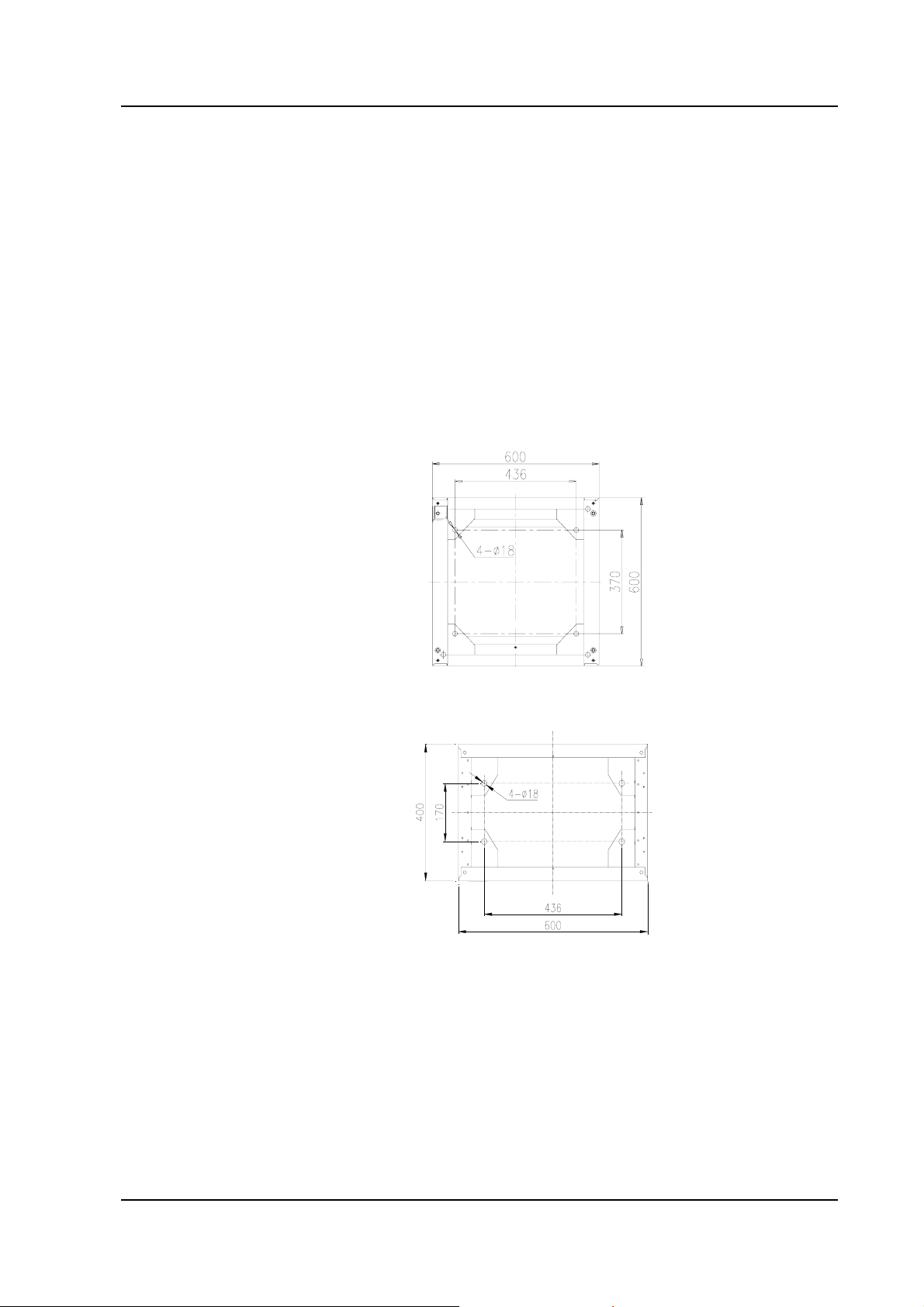

(Applicable to the cabinet with 600mm depth)

(Applicable to the cabinet with 600mm depth)

Figure 2-1 Installation dimensions of the cabinet base

Step 2: drill reserve holes.

The expansive pipes delivered with the power system are M10%55mm, therefore,

use electric drill with drill bit Φ12 and depth 70mm to drill holes at the center points

of the installation holes marked on the ground. To avoid being off-center, be careful

ACTURA Flex 48330 Power System User Manual

Page 26

16 Chapter 2 Installation

not to shake the drill, and try to keep as vertical as possible to the ground, as

shown in Figure 2-2.

Step 3: install expansive pipes.

Clean the dust, and insert the expansive pipe into the reserve hole, knock it down

gently using a hammer until the top of the expansive pipe is level with the ground,

as shown in Figure 2-2.

Power

cabinet

1) Drill vertically

Expansive

pipe

2) Clean the dust 4) Tighten the bolt

3) Knock it into place

Figure 2-2 Installing expansive pipe

Step 4: place cabinet in position

Move the cabinet to the installation position aligning the installation holes of the

cabinet to the expansive pipe on the ground.

Step 5: fix the cabinet

After the cabinet is in position, make some horizontal and vertical adjustments.

Insert some iron pieces under the lower edge and corner of the cabinet to adjust

the vertical obliquity of the cabinet within 5 degrees. Finally, screw down the tap

bolt with plain washer and spring washer into the expansive pipe, and tighten it with

wrench. The cabinet fixation is illustrated in Figure 2-3.

Tap bolt

Spring washer

Cabinet base

Ground

Expansive pipe

Figure 2-3 Fixing cabinet with Tap

ACTURA Flex 48330 Power System User Manual

Plain washer

Page 27

2.3 External Electrical Connection Interface

2.3.1 Connection Of Input Cables

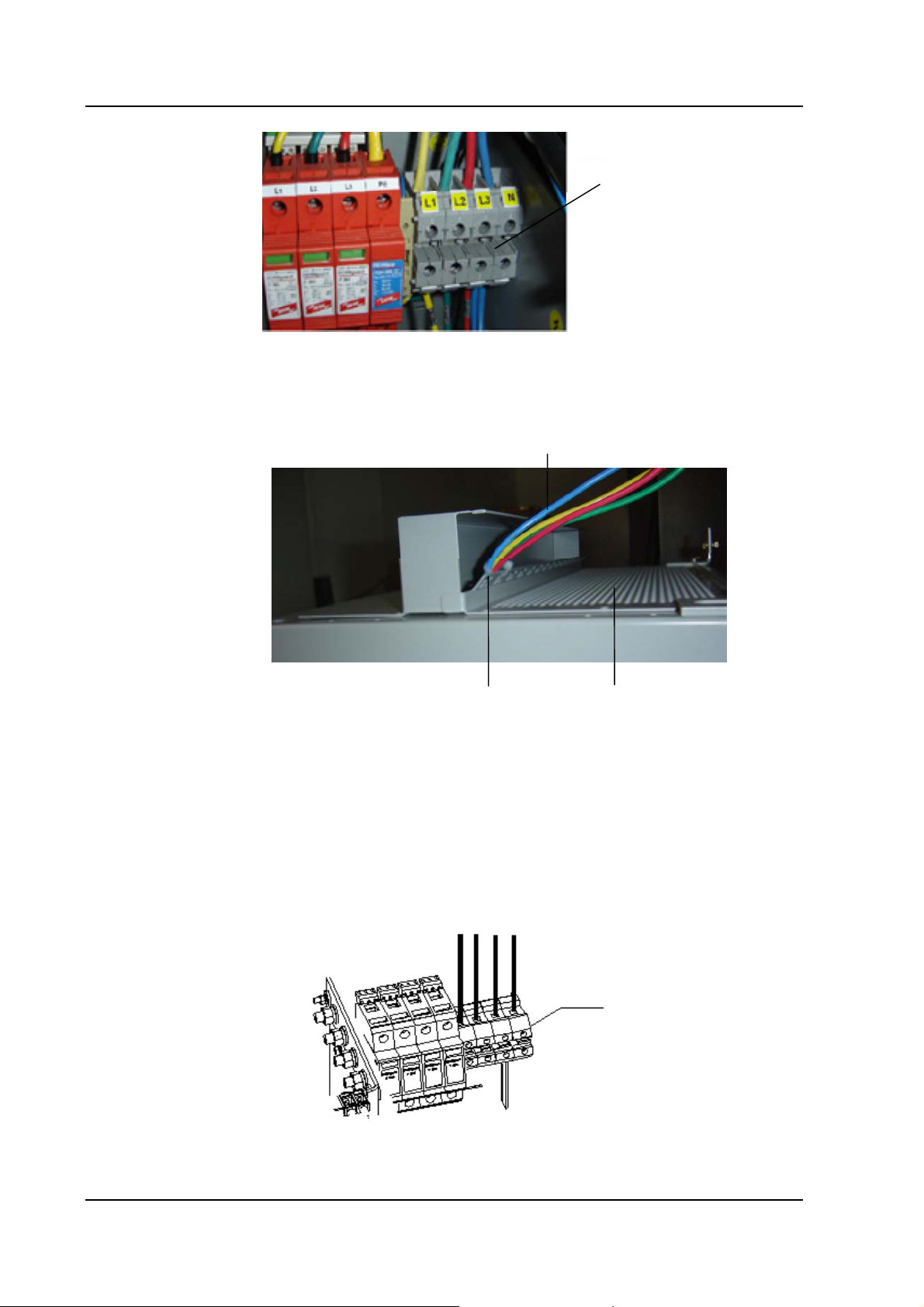

The AC input terminals, SPD, rectifier AC input switch, PE bus and PE terminals

are illustrated in Figure 1-6. SPD is just adjacent to the AC input terminals and has

been connected in before delivery. PE bus is at the top of the MFU and is

connected to the DC Power Cabinet through screws. PE bus is connected PE

terminal through a cable.

Connection requirements

The AC mains is connected to the AC input terminals directly. There are 6 AC input

modes as shown in Table 2-2:

Table 2-2 AC input modes

Item Function unit Amount

3P+N/380V AC input

1P+N /220V AC input

AC distribution

L1+L2/220V AC input

3P/220V AC input

Terminals only - for individual rectifier AC feeds

2P MCB only - for individual rectifier AC feeds

Chapter 2 Installation 17

Connection method

Strip the insulation layer of one end of the AC input cable, and then mounted the

cable end with an H terminal.

The cable mounted with an H terminal is shown in Figure 2-4.

H Terminal

AC Input Cable

Figure 2-4 Cable mounted with H terminal

After attaching the H terminal to the AC input cable, connect the AC input cable to

the AC input terminals as shown in Figure 2-5:

ACTURA Flex 48330 Power System User Manual

Page 28

18 Chapter 2 Installation

A

A

A

C input terminals

Figure 2-5 Connection of input terminals

The AC input cable is fed to the system through the top cover of the cabinet, as

shown in Figure 2-6:

C input cable

Cable bracket

Top cover

Figure 2-6 Top cover

There is a cable bracket on the top cover. The input cables are bound to the cable

bracket with a cable tie.

Different cable connection modes

There are 4 AC input terminals. For 3-phase AC power input, just connect the AC

input cables as shown in Figure 2-7:

L1 L2 L3 N

C input terminals

Figure 2-7 Connection of 3-phase AC power input

ACTURA Flex 48330 Power System User Manual

Page 29

Chapter 2 Installation 19

For single-phase AC power input, connect the AC input cables as in Figure 2-8:

L

N

AC Input Terminals

Figure 2-8 Connection of single-phase AC power input

If the AC input is single phase, the second and fourth terminals are not connected.

For dual-phase AC power input, connect the AC input cables as in Figure 2-9:

L1

L2

AC Input Terminals

Figure 2-9 Connection of dual-phase AC power input

If the AC input is dual-phase, the second and fourth terminals are not connected.

The yellow, green, red, and light blue AC cables correspond respectively to the AC

phase L1, L2, L3 and neutral lines. If the cables are the same color, they should be

identified with labels.

The AC cables should be laid separately from the DC cables.

No splice, damage, or scratch on the cables is permitted.

The rectifier AC input cables have already been connected in factory.

Note

1.To insure AC input cable has enough bearing current capability, the section area of the AC

input cable for 3-phase AC power input should not be less than 10mm

AC power input and dual-phase AC power, it should not be less than 25mm

area of input earth line should not be less than 35mm

2

.

2. The external AC input MCB of cabinet must be sure to disconnect all the AC input lines

(including live lines, zero line), but input earth line can not be disconnected by any breaking

device. It is recommended that the rated current of the AC input MCB is not less than 125A.

2

; and for single-phase

2

. The section

ACTURA Flex 48330 Power System User Manual

Page 30

20 Chapter 2 Installation

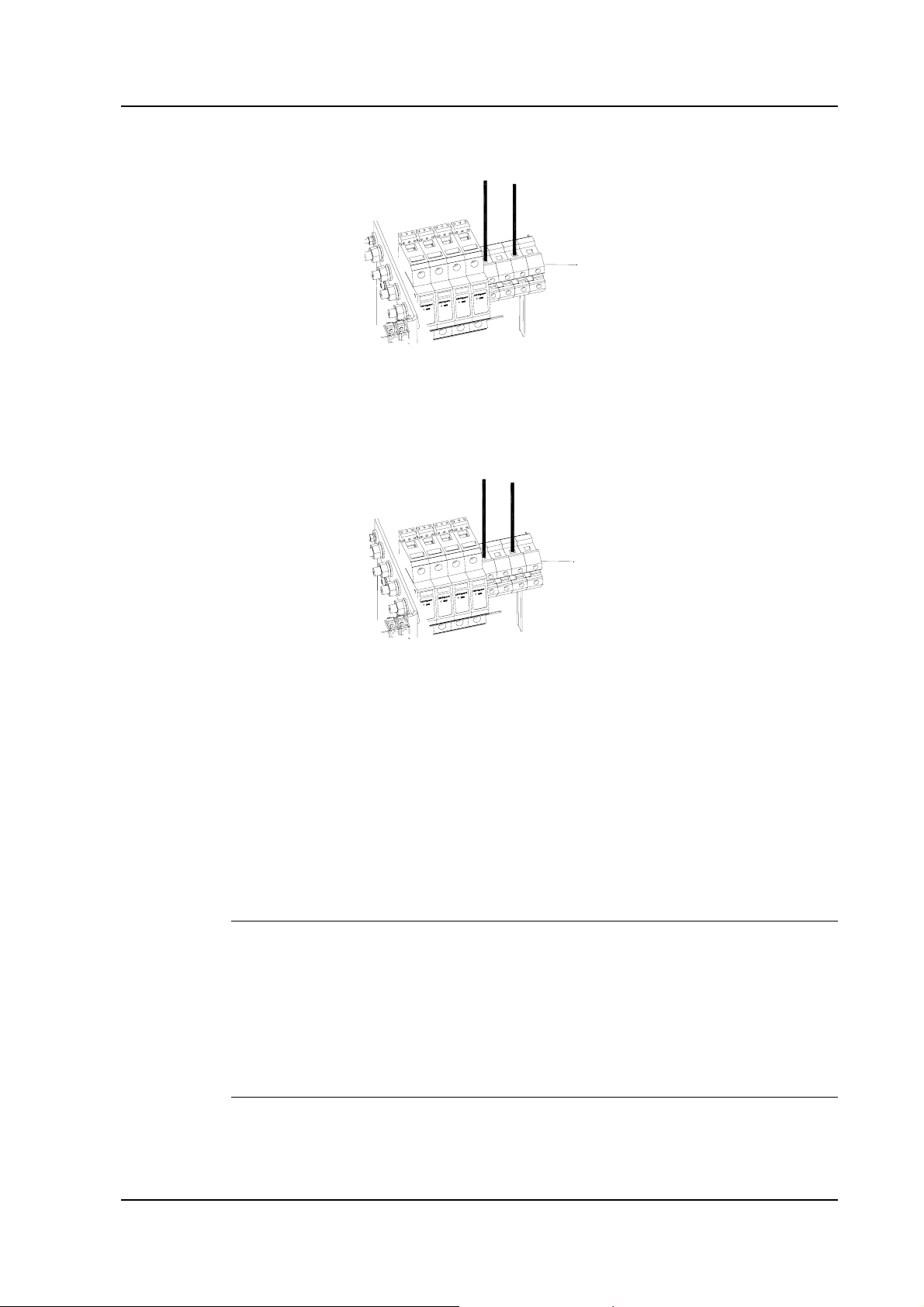

2.3.2 Connection Of Load Cables

Loads are connected to the MCB with suitable capacity to avoid their failure to

function in the case of overload. The capacity of the MCBs is recommended to be

about 1.5 times of the peak value of the load capacity. The load circuit breakers are

shown in Figure 1-7. The circuit breakers can be ABB or CBI circuit breakers.

We take the CBI circuit breakers of 13mm for example to illustrate the load cable

connection, as shown in the Figure 2-10.

connected with

low-priorit y loa d

busbar

Low-priority

load busbar

Battery –48V busbar

High-priority load busbar

connected with

high-priority load

busbar

Figure 2-10 Connection of load cables

Explanation: the load MCBs and battery MCBs can be configured flexible according

to the actual requirements. Their setting range is shown in the following table.

Table 2-3 Configuration number of load MCBs and battery MCBs

Busbar type Max. load number Note

Battery -48V busbar 0~5

High-priority load busbar 0~19

Low-priority load busbar 0~28

Total number of the load should not

exceed 20 with 18mm-width MCB or

not exceed 28 with 13mm-width MCB.

Cable connection to MCB: strip the power cable end, crimp-connect the copper

core to an H terminal, See Figure 2-4 for the cable mounted with a H terminal. After

attaching the H terminal to the cable, insert the cable into the wiring hole of the

MCB, then tighten the screw to fix the copper core, as shown in Figure 2-11:

Cable

H terminal

Figure 2-11 Cable connection to MCB

ACTURA Flex 48330 Power System User Manual

Page 31

Note

1. The cable should not be spliced. The load cable, signal cable and AC cables should be

wired separately as possible to avoid them affecting each other.

2. If the power supply system is in operation, switch off the DC output MCB before

connecting the cables.

3. The rated current of the output cable should be bigger than tha t of the correspo ndi ng

MCB connected with it.

DC output branch should match the load capacity. It is highly recommended to

connect priority load to BLVD branch, and normal load to LLVD branch.

2.3.3 Connection Of Communication Cables

There is a connector board in the rectifier shelf. The board is shown in Figure 2-12:

Chapter 2 Installation 21

J10

J11

Ethernet Port

Figure 2-12 Connector board in rectifier shelf

There is an Ethernet port and a DB9 RS232 port on the front panel. For the

connection of communication cables, first connect the Ethernet port to the

transmission equipment, and then connect the DB9 RS232 port to the Main

Computer.

ACTURA Flex 48330 Power System User Manual

Page 32

22 Chapter 2 Installation

2.3.4 Layout Of Connector Board S6415X2

Figure 2-13 Layout of connector board S6415X2

ACTURA Flex 48330 Power System User Manual

Page 33

2.3.5 Interface Definition Of Connector Board S6415X2

Table 2-4 Interface definition of connector board S6415X2

Connector Pin Signal name Mark number Logic relation

1 Relay output 1 normal cl ose DO1_NC

2 Relay output 2 normal cl ose DO2_NC

J3

J4

J5

J6

J10

J11

J12, J18

J13

3 Relay output 1 common DO1_COM

4 Relay output 2 common DO2_COM

5 Relay output 1 normal open DO1_NO

6 Relay output 2 normal open DO2_NO

1 Relay output 3 normal cl ose DO3_NC

2 Relay output 4 normal cl ose DO4_NC

3 Relay output 3 common DO3_COM

4 Relay output 4 common DO4_COM

5 Relay output 3 normal open DO3_NO

6 Relay output 4 normal open DO4_NO

1 Relay output 5 normal cl ose DO5_NC

2 Relay output 6 normal cl ose DO6_NC

3 Relay output 5 common DO5_COM

4 Relay output 6 common DO6_COM

5 Relay output 5 normal open DO5_NO

6 Relay output 6 normal open DO6_NO

1 Relay output 7 normal cl ose DO7_NC

2 Relay output 8 normal cl ose DO8_NC

3 Relay output 7 common DO7_COM

4 Relay output 8 common DO8_COM

5 Relay output 7 normal open DO7_NO

6 Relay output 8 normal open DO8_NO

1 Digital circuits power +5V

2 Temperature signal 1 input TEMP1 4~20mA

3 Analog ground GND

1 Digital circuits power +5V

2 Temperature signal 2 input TEMP2 4~20mA

3 Analog ground GND

1 Data Carrier Detect DCD232

2 Receive Data RXD232

3 Transmit Data TXD232

4 Data Terminal Ready DTR232

5 Data Communication ground DGND

6 Empty

7 Request To Send RTS232

8,9 Empty

1 Ethernet TX+ NETTX+

2 Ethernet TX- NETTX-

3 Ethernet TR+ NETTR+

4 Empty

5

6 Ethernet TR- NETTR-

7~12 Empty

Chapter 2 Installation 23

Empty

ACTURA Flex 48330 Power System User Manual

Page 34

24 Chapter 2 Installation

Connector Pin Signal name Mark number Logic relation

1 RS485 communication+ E485+

J14

J19

2 RS485 communication- E485-

3 Protection ground PGNG

1 48V+ POWER+

2 48V- POWER-

2.3.6 Connection Of Temperature Sensor Cables

There are two 3-pin terminals on the connector board in rectifier shelf. These two

terminals are J11 and J10 respectively. They are used to connect the temperature

sensors. The locations of J11 and J10 are as shown in Figure 2-12.

The user can connect the temperature sensor cables to J11 and J10.

2.3.7 Connection With MODEM

Take e-TEK TD-5648DC MODEM for example to illustrate the connection.

Power

Figure 2-14 Input/output interfaces of TD-5648DC MODEM

Conneting modem with M500D control unit

MODEM connects with M500D monitoring module through connector board

S6415X2:

1. Connect telephone line to the “LINE” port of MODEM.

2. Connect the 48V “POWER” terminal of MODEM with the J19 socket of connector

board S6415X2.

3. Connect “RS-232” (DB25 female) communication port of MODEM with the J12 or

J18 terminal (DB9 male) of connector board S6415X2 using a communication

cable.

Note

When the cabinet has a front door, before con nect in g the RS232 terminal, pull out the

S6415X2 board first, pass the RS232 terminal through the opening on the right side o f the

rectifier subrack and connect it with the J18 terminal on the S6415X2 board, then insert the

S6415X2 board.

ACTURA Flex 48330 Power System User Manual

Page 35

2.3.8 Connection With Dry Contacts

The M500D monitoring module provides 8 sets of alarm dry contacts through the

J3-J6 sockets on the connector board S6415X2. Each set has a normally open

contact and a normally closed contact. Once the corresponding alarm event occurs,

the dry contact will act to report alarms under the control of M500D monitoring

module. Through the dry contact networking, the system can realize the level

isolation transmission of fault signals.

When delivery, each set of dry contacts is corresponding to one default alarm type,

and users can reset it as other alarm types.

Connecting method

After peeling the signal cable terminal, insert it into the dry contact terminal, then

tighten the hold-down bolt to compress the signal cable.

2.4 Battery Installation And Cabling

Chapter 2 Installation 25

2.4.1 Battery Installation

The DC Power System with standard configuration has 4 battery strings. The DC

Power System with non-standard configuration can connect to up to 5 battery

strings. In the system cabinet, there are 5 levels and each battery string is installed

in one level. One battery string has four +12V battery blocks.

Procedures to install battery:

1. Install the batteries in the cabinet from low level to high level;

2. Place the battery on the level and push it inward until the battery is blocked;

3. Connect the positive and negative battery cable to the battery string.

The cabinet with four battery strings installed is shown in Figure 2-15:

ACTURA Flex 48330 Power System User Manual

Page 36

26 Chapter 2 Installation

Battery Connection Unit(BCU)

Battery(4 in a string)

Battery Shelf

Figure 2-15 Cabinet with four battery strings installed

Note

To satisfy the safety requirement of the whole equipment, the fire-retardant class of the

battery materials should not be lower than V-2.

Insure that the charge/discharge current of single battery group is not bigger than 100A, and

the total charge/discharge current of the all battery groups are not bigger than 200A.

2.4.2 Battery Cable Connection

The battery connection for the cabinet with standard configuration is different from

that of the cabinet with non-standard configuration.

Standard configuration

The DC Power System with standard configuration has no BCU. The system has

four battery strings. The negative battery cable is of blue color and the positive one

is of black color. There are two connection methods, one is for the cabinet of 600 %

400 % 700(mm), and another is for the cabinets of 600 % 400 % 2000(mm) and

600 % 600 % 2000(mm).

1) Batter Connection for Cabinet of 600 % 400 % 700(mm)

The four left-most circuit breakers in the MFU connect to the negative battery

cables (blue) respectively as shown in Figure 2-16. Another end of the negative

ACTURA Flex 48330 Power System User Manual

Page 37

Chapter 2 Installation 27

battery cable is connected to the negative terminals of the battery string in each

level as shown in Figure 2-16:

Negative Battery Cables

4 Battery Circuit Breakers

Figure 2-16 Connection of battery cables.

2) Batter Connection for Cabinets of 600 % 400 % 2000(mm) and 600 % 600 %

2000(mm)

The connection is show in Figure 2-17:

Negative battery

cable

Positive battery

cable

Figure 2-17 Positive and negative battery cables in each level

One end of positive battery cable is connected to the neutral bus of the DC power

cabinet. Another end of the positive battery cable is connected to the positive

terminal of the battery string in each level as shown in Figure 2-17.

ACTURA Flex 48330 Power System User Manual

Page 38

28 Chapter 2 Installation

Note

The actual number of battery circuit breakers in MFU may be 0~5 according to the user’s

need.

Non-standard configuration

The DC power system with non-standard configuration has a BCU. The connection

of positive cables is the same with that of the system with standard configuration.

The only difference is that there are five positive battery cables because the system

has five battery strings. One end of positive battery cable is connected to the

neutral bus of the DC power cabinet. Another end of the positive battery cable is

connected to the positive terminal of the battery string in each level as shown in

Figure 2-17.

One end of negative battery cable is connected to the negative terminal of the

battery string in each level as shown in Figure 2-17. Another end is connected to

the BCU as shown in Figure 2-18. The connection has already been done in

factory.

Negative Battery Cables(Blue)

Figure 2-18 Negative battery cables connection in BCU

Note

1. Before connecting the battery cables, the corresponding battery fuse or the battery switch

must be disconnected.

2. Be careful not to reverse connect the battery, otherwise, the battery and the power supply

system will be damaged!

Since the battery voltage decreases in discharge, hence the sectional area of the

cable connecting the battery and the MFU or BCU should be relatively big to keep

the voltage drop on the cable within 0.5V.

ACTURA Flex 48330 Power System User Manual

Page 39

2.5 Parallel Connection Of Cabinets

In order to prolong the backup time of battery, the battery capacity should be

increased. Another cabinet can be connected in parallel with the DC power system

cabinet. The expanded cabinet has no rectifier shelf and Multi-Function Unit. It is

only installed with battery strings and a BCU. So, it is actually the battery cabinet.

BCU in Extension Unit connects to Main Unit through cables. The parallel

connection of the DC power system cabinet with the battery cabinet is shown in

Figure 2-19:

Chapter 2 Installation 29

Main cabinet

BCU

Batteries

Extension cabinet

Figure 2-19 Parallel connection of DC power system cabinet with battery cabinet

DC/Parallel connections

The DC cables are connected to the output of the rectifier shelf in the MFU.

Up to two Battery Connection Units (BCUs) can be connected in the DC Power

System – up to one BCU in the main cabinet and up to one BCU in an extension

battery cabinet.

SCU can display the alarm signals from these two BCUs.

The user can connect the MFU to an additional extension MFU (only for additional

load circuit breakers) through suitably rated cables.

ACTURA Flex 48330 Power System User Manual

Page 40

30 Chapter 3 Startup

Chapter 3 Startup

3.1 Checking Before Startup

Check the DC Power System according to Table 3-1 before startup.

Table 3-1 System checklist before startup

Item Action Result

Check all the circuit breakers of the

1

shelf and BCU

Check the mains supply fuses/circuit

2

breakers.

Check with an ohmmeter between

3

the positive and negative terminals of

battery.

Check with an ohmmeter between

4

the battery terminals and shelf

chassis.

Check the battery block voltage and

5

total battery voltage.

6 Check the mains phase voltage.

7 Check the connection of cables.

They should be switched off.

They should be removed/switched off.

They must be no short circuit (>50ohms)

They must be no short circuit (>50ohms)

The voltages shall correspond to the

values given by battery manufacturer.

The voltage shall be within the rectifier

input voltage range (85Vac~290Vac).

The cables shall be connected to their

correct terminals firmly.

Comments (fill in

“Ok” or not)

ACTURA Flex 48330 Power System User Manual

Page 41

3.2 Startup Process

Chapter 3 Startup 31

Item Action Result

The LEDs on the rectifiers and the

controller will emit light.

Connect/switch on the mains supply

1

fuses/circuit breakers of the DC shelf.

The rectifier fans will start.

The LVD contactors will operate.

The green LEDs of the rectifiers and

the controller will flash for about 10 s.

and then emit steady light.

The voltage should be close to what

Check the DC voltage on the test outlet

2

marked U in the supervision unit.

has been set in the controller.

If temperature compensated charging

is activated, the difference may be

V from the set value.

If temperature compensated

charging is activated, warn the

3

sensor on the battery with your hand

and observe the system voltage.

The voltage should start to drop.

The battery voltage will increase and

reach the system voltage.

4

Switch on the battery circuit breakers.

(Might take hours, depending on the

charging state of the battery.)

5

Switch on the circuit breakers in MFU. The loads will get DC supply.

6

Check all the LEDs of the shelf.

Only the green LEDs are On should

emit light. No LED shall flash.

Comments (Fill

in “OK” or not)

±

3

3.3 Parameters Configuration

After start up the DC Power System, following parameters need to be configured:

Password, AC parameters, DC parameters, rectifier parameters, battery

parameters, time and communication parameters.

Refer to Chapter 5 on how to configure the parameters.

ACTURA Flex 48330 Power System User Manual

Page 42

32 Chapter 4 Testing

4.1 Testing MFU

Measure the L-N voltage at the input terminals with a multi-meter to check if it is

normal.

4.2 Testing Rectifier

1. Turn on one rectifier input MCB in the MFU to feed AC supply to the

corresponding rectifier, the rectifier should operate normally;

2. Turn off this MCB, and turn on the other rectifier input MCBs one by one to check

if all the other rectifiers operate normally.

Chapter 4 Testing

If all of the rectifiers can operate normally, switch them on. In case of rectifier

malfunction, take the rectifier out and inspect it.

4.3 Testing SCU

When the rectifiers are operating normally, switch on the SCU, the SCU should

start and display the start screen. If the system self-test is normal, seconds later,

SCU displays Initial Screen with System Information:

There are default system parameter settings in the SCU, including the AC voltage

alarm points, DC voltage alarm points, battery management parameters, which are

available on the parameter card delivered with the system. If the battery capacity or

charging parameters set by user are different from those on the parameter card, or

if user has different BLVD management requirements, please reset the system

parameters according to the actual situation, and record the new settings on the

parameter card.

2004-09-16

53.5V 300 A

System: Alarm

Auto /BC

ACTURA Flex 48330 Power System User Manual

Page 43

4.4 Battery Breaker Test

1. Before turning on the battery circuit breaker, confirm with a multi-meter that the

battery is not reverse-connected.

2. When connecting the battery, be careful not to short the two battery terminals.

3. When connecting two batteries, be careful to avoid battery mutual charging due

to unequal terminal voltages of the two batteries.

4.5 BCU Test

The BCU can connect to a single battery via suitably sized cables from the

Distribution Unit.

The BCU can connect to up to five battery strings via suitably sized cables.

The user can route the battery cables via the left hand side and via the right hand

side of the BCU. A maximum of 7 cables can be routed via the left hand side of the

BCU and a maximum of 5 cables via the right hand side of the BCU.

Chapter 4 Testing 33

The user can mount the BCU 15mm or more above a Front terminal battery. Care

shall be taken to connect the battery to the BCU via cables in this orientation.

The user can safely connect battery cables on a live system with only front access.

BCU can be partially slid out in order for this to be achieved.

The user can safely install or replace a battery circuit breaker on a live system with

only front access. BCU can be partially slid out in order for this to be achieved.

4.6 Load Breaker Test

Before connecting load to the system, check with a multi-meter if the connection

polarity of the load and the power system is correct and the voltage is

1. Close the load MCB, DC power should be fed to the load;

2. Adjust the system parameters through the SCU, and make sure that the

information viewing and output control functions are normal.

normal.

ACTURA Flex 48330 Power System User Manual

Page 44

34 Chapter 5 Operating SCU

运行指示灯

A

Chapter 5 Operating SCU

5.1 Operation Panel

SCU has a LCD with backlight, keys, LEDs and a latch, as shown in Figure 5-1:

Run indicator

告警指示灯

larm indicator

Critical alarm indicator

紧急告警指示灯

液晶显示屏

LCD

ESC

M500D

ENT

功能操作键

Functional key s

Figure 5-1 SCU Front Panel

Functions of LED indicators are illustrated in Table 5-1

Table 5-1 Functions of LED indicators

Indicator Normal state Fault state Fault cause

RUN (Green) On Off No operation power supply

Alarm (Yellow) Off On There are observation alarms

Critical alarm (Red) Off On There are major or critical alarms

SCU controller uses a 128×64 dot-matrix LCD unit. It has 6 functional keys. Its

interface is easy-to-use and supports multi-language display. The panel of the

controller is easy-to-remove. The functions of these 6 keys are shown in Table 5-2:

Table 5-2 Functions of SCU keys

Key Function

ESC Return to the upper level menu.

ENT

“” and

”

“

“” and

”

“

Enter the main menu or confirm the menu

operation

Shift among parallel menus or parameters.

Change values at a value setting interface.

At the first page of system information, use

these two keys to change LCD contrast.

Pressing ESC and ENT simultaneously

can reset the monitoring module

To change a character string whose

digits needs setting separately, use

““ and ““ to move the curso left or

right, or “

” and “” to set each digit.

ACTURA Flex 48330 Power System User Manual

Page 45

5.2 Operation Procedures

After the system is powered on for the first time, you should set the system type

according to the actual configuration. The monitoring module will restart after the

system type is changed. In that case, you should re-configure those parameters

whose default values are inconsistent with the actual situation. Only after that can

the monitoring module operate normally.

After configuring the system parameters, you can carry out various operations

directly without resetting the parameter values. As for those important parameters

related to battery management, such as BLVD, you should be fully aware of their

influence upon the system before you change their values.

Note

For the exact meanings of the abbreviations used in LCD displayer, see Appendix E

Glossary.

1. The LCD will prompt you to select a language once the monitoring module is

powered on.

Chapter 5 Operating SCU 35

英文

English

You can use “

”, “”, “” or “” to select the language you want, and press

“ENT” to confirm.

2. The monitoring module will prompt you to wait, and start initialization.

Waiting……..

3. The first system information page appears

2004-09-16

53.5V 125 A

System: No alarm

Auto /BC

The system information is shown in many pages. You can repeatedly press “

view other system information pages in a cycle.

” to

ACTURA Flex 48330 Power System User Manual

Page 46

36 Chapter 5 Operating SCU

4. At any system information page, press “ENT” to enter the “MAIN MENU” page,

which contains 3 sub-menus: “Status”, “Maintenance” and “Settings”.

You can press “

” or “” repeatedly to select a sub-menu, and press “ENT” to

enter the sub-menu. Press “ESC” to return to the menu of higher level.

1) Status

Including rectifier information, active alarm information and alarm history

information.

2) Maintenance

The maintenance operation can be conducted only when the battery management

mode is set to “Manual”. The maintenance includes battery FC, BC and test, load