Page 1

47D40-801

WARNING

!

Demand Defrost Control

INSTALLATION INSTRUCTIONS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

DESCRIPTION

The 47D40-801 control is a microprocessor-based demand

defrost controller intended for Rheem heat pump systems.

This controller uses basic differential temperature means to

detect degradation of system performance due to ice build-up

on the outdoor coil. The controller uses “self-calibrating” principles to calibrate to the heat pump system. The defrosting is

performed by reversing the refrigerant direction of flow.

The 47D40-801 is meant to replace the following controllers

in Rheem heat pump systems:

47-21517-16

47-21517-17

47-21517-18

47-21517-23

47-21517-24

47-21517-11

47-21517-14

47-21517-13

47-21517-82

47-21517-88

47-102685-01

47-102685-03

47-102684-01

47-102684-03

47-102684-83

DDL-013102-1RH

DDL-017002-2RH

DDL-017102-1RH

DDL-017702-1RH

DDL-117702-3RH

DDL-013002-0RH

DDL-013002-1RH

47D40-801

PRECAUTIONS

CAUTION

• This control is intended only for Rheem heat pump

systems.

• Replace 47D40-801 control as a unit - no user serviceable parts.

If in doubt about whether your wiring is millivolt, line or low

voltage, have it inspected by a qualified heating and air

conditioning contractor or licensed electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes

and ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could

cause the control to malfunction.

CONTENTS

Description ................................................................ 1

Precautions .............................................................. 1

Specifications ........................................................... 2

Operation .................................................................. 2

Installation ................................................................ 3

• To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

• This control is not intended for use in locations where

it may come in direct contact with water. Suitable

protections must be provided to shield the control from

exposure to water (dripping, spraying, rain, etc.)

• Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper or loss of

heat pump operation and/or shock hazard.

• Following installation or replacement, follow appliance

manufacturer’s recommended installation/service

instructions to insure proper operation.

• Do not use on circuits exceeding specied voltage.

Higher voltage will damage control and could cause

shock or re hazard.

!

white-rodgers.com

emersonclimate.com

PART NO. 37-7200B

Replaces 37-7200A

1536

Page 2

SPECIFICATIONS

Electrical Ratings [@ 77o F (25o C)]:

Rated Voltage ..................................... 24 VAC

Rated Voltage Range ............................... 18-30 VAC

Max. Power Consumption @ 24 VAC .................. 4.08 VA

Nominal Frequency................................. 50/60 Hz

Relay Load Ratings:

Compressor Contactor Relay ...................... 20 VA in rush, 6 VA holding

Fan Relay ...................................... 1/2 HP @ 240, 1/4 HP @ 120 VAC

Reversing Valve Relay (RV) ........................ 24 VA

Auxiliary Heat Relay (D)........................... 1 Amp. 0.6 P.F.

Operating Temperature Range ........................ -40o to 150o F (-40o to 65o C)

Humidity Range ................................... 5% to 95% relative humidity

(non-condensing)

Timing Specications @ 60Hz*

Nom Units

Defrost Lockout Time 34 Mins.

Maximum Defrost Time 14 Mins.

Transient Delay 2 Mins.

Maximum Frosting Time 6 Hrs.

Short Cycle Lockout Time 5 Mins.

Noise Abatement Time 5 Sec.

*50Hz Timings are 20% longer.

The control is recognized by UL as an incorporated

electronics control per UL 60730-1A. This control does

not perform any safety/protective functions. This device is

automatic, type 1 action, incorporated control.

OPERATION

Each controller has 24 VAC input and B, Y, and D terminals

for connection to a standard thermostat. The controller has

pins for connection of two temperature sensors to measure

ambient and coil temperature. Controlled outputs are outdoor

fan, reversing valve, and compressor contactor.

The controller has a LED to indicate system operation status.

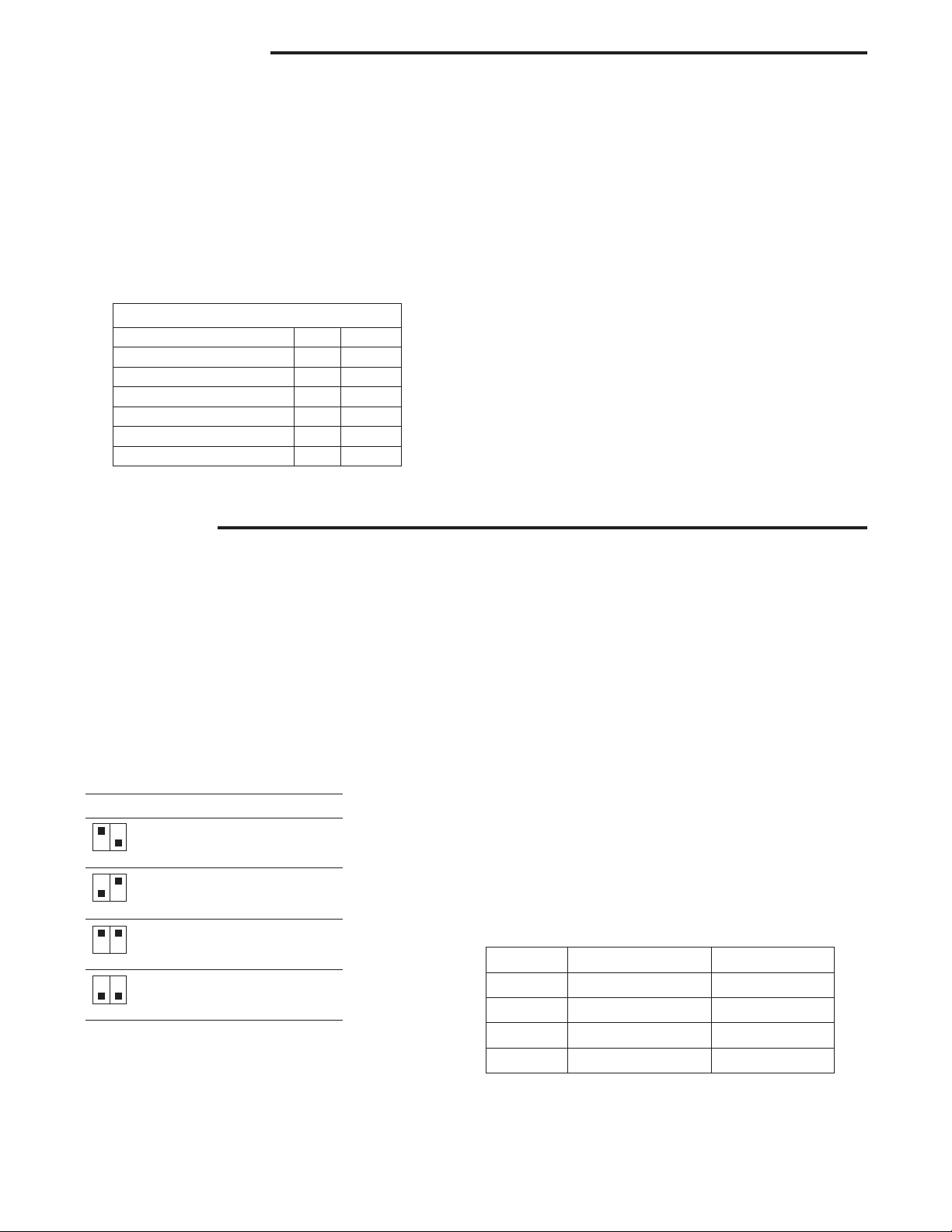

Option Switch

Switch labeled SW1 is used to select the defrost mode

termination temperature of outdoor coil. Defrost mode is

terminated when the coil temperature exceeds the selected

termination temperature. Temperature options for SW1 switch

settings are:

B A

On Off 50o F

B A

Off On 60o F

B A

On On 70o F (default)

B A

Off Off 80o F

B A

Test Pins

The connector labeled TEST can be used to change

operation mode in the field. Momentarily short the test pins

to force the system into the defrost mode. Momentarily short

the test pins again to terminate the defrost mode. To avoid

unnecessary system mode transition, do not use the test pins

frequently.

Short Cycle Protection

The control includes protection against short cycling the

compressor. At power-up, and each time the Y input is

interrupted, the control will enter a 5-minute short cycle

lockout period. During this lockout, the control will not

energize the compressor contactor, even if a call for heating

or cooling is received on the Y input. The control will resume

normal operation when the lockout period expires.

Noise Abatement

When the reversing valve is switched during an active call for

heating or cooling, such as when entering or leaving a defrost

cycle, the control will de-energize the compressor contactor

for 5 seconds in order to reduce compressor noise.

Diagnostic Features

The control continuously monitors system operation. If a fault

occurs, the red LED on the control will flash a diagnostic

code, if more than one fault occurs, only the code with the

higher priority will flash. The flash time is to be 0.5 seconds

on and 0.5 seconds off followed by 2 seconds off. The table

shows the diagnostic codes:

LED Fault Indication Display Priority

ON Normal 0

1 Flash Defrost mode 1

2 Flashes Coil sensor fault 3

3 Flashes Ambient sensor fault 2

2

Page 3

INSTALLATION

NOTE

COMPR

CONTACTO

FAN MOTOR

On some units, the Outdoor Ambient Temperature (OAT) and

Outdoor Coil Temperature (OCT) sensors may be attached

permanently to the controller. The 47D40-801 includes

replacement OAT and OCT sensors that plug onto the 2- and

3-pin connectors on the controller board.

Before removing the old controller, note the location of the

OCT sensor on the outdoor coil. The new sensor should

be attached to the coil in the same location, or as close as

possible. The OAT sensor is typically 24-48” long, although

some controllers have the sensor on the board. Placement of

the OAT sensor is not as critical as the OCT sensor, but both

sensors are required for the controller to operate.

Four metal standoffs are used to support and mount the

control into the unit.

Board size is 3.375 in. x 3.625 in. and requires 1 inch of

headroom (not including mounting).

Typical System Wiring Table

47D40

Terminal Type System Component Connection

C 0.25” QC Reversing valve common

RV 0.25” QC Reversing valve output

CC 0.25” QC Compressor contactor coil

Yout 0.25” QC Compressor call output

C (2) 0.25” QC Common, 24VAC return

D 0.25” QC Defrost output

Y 0.25” QC Compressor call input

B 0.25” QC Heating mode signal input

R (2) 0.25” QC 24VAC input

Fan (2) 0.25” QC Outdoor fan control

OAT 2-pin connector Outdoor ambient temperature sensor

OCT 3-pin connector Outdoor coil temperature sensor

All wiring should be installed according to local and national

electrical codes and ordinances.

The 47D40-801 control may be mounted on any convenient

surface using the four standoffs provided.

The control must be secured to an area that will experience

a minimum of vibration and remain below the maximum

ambient temperature rating of 150o F. The control is approved

for minimum ambient temperatures of -40o F.

Any orientation is acceptable.

Refer to the wiring diagram and wiring table when

connecting the 47D40-801 control to other components of

the system.

UL approved, 105o C rated 18 gauge min., stranded 2/64”

thick insulation wire is recommended for all low voltage safety

circuit connections.

UL approved, 105o C rated 16 gauge min., stranded 2/64”

thick insulation wire is recommended for all line voltage

connections.

Following installation or replacement, follow appliance

manufacturer’s recommended installation or service

instructions to insure proper operation.

Legend

COMPRESSOR

ESSOR

R

REVERSING

VALVE

Low Voltage

Line Voltage

Internal Control

Tracing

HERM FAN

RUN CAPACITOR

TO THERMOSTAT

Y

C

B

CC

RV

S

R

C

L1

L2

D

Yout

CC

RV

C

Demand Defrost Control

Fig 1. Typical System Wiring Diagram

C

OUTDOOR

R

S

C

R

FAN

FAN

OAT

OCT

3

Page 4

White-Rodgers is a business

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

white-rodgers.com

emersonclimate.com

Loading...

Loading...