Page 1

Infrastructure Management & Monitoring

For Business-Critical Continuity™

Liebert Liqui-tect® 460

Installation Manual - Zone Leak Detection Sensor

Page 2

Page 3

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

EXTERIOR DIMENSIONS AND MOUNTING DETAILS. . . . . . . . . . . 1

PLACEMENT ON SUBFLOOR UNDER COOLING SUPPORT

EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

WIRING TO AUXILIARY ALARM PANELS . . . . . . . . . . . . . . . . . . 4

CONFIGURATION SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . 5

Leak Detect Filter Delay(SS1) . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Latching or Non-Latching Alarms (SS2) . . . . . . . . . . . . . . . . . . 5

Alarm Retest Delay (SS3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LED OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION OF LEAK DETECTION SYSTEM CABLE . . . . . . . . 8

LEAK DETECTION KIT INSTALLATION SCENARIOS . . . . . . . . . 10

i

Page 4

ii

Page 5

Introduction

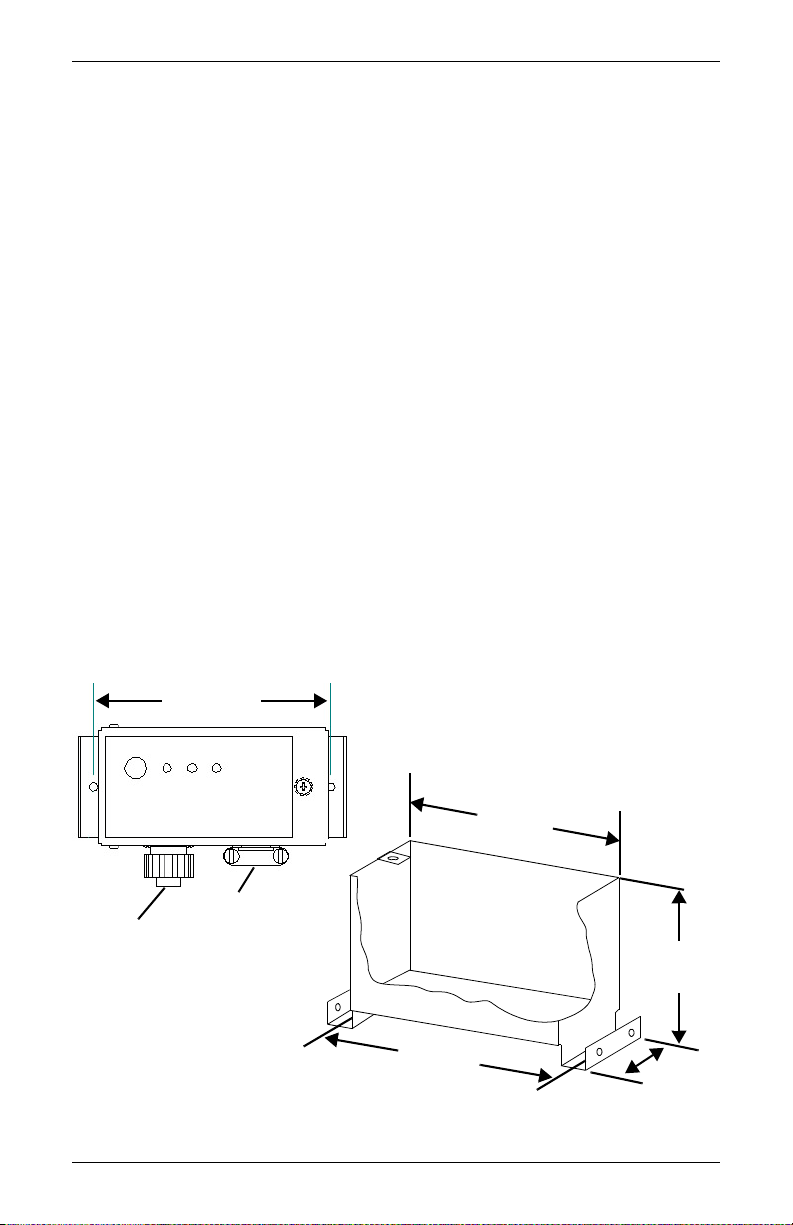

4.75"

(120.65mm)

4.25"

(108mm)

3.25"

(83mm)

4.75"

(121mm)

2"

(51mm)

Shipping weight: 2 Ibs (0.9 kg)

Mounting holes: #8 screws

TOP VIEW

Leak

detection

cable

connector

Form-C relay

outputs &

power wiring

connection

FRONT VIEW

Liebert Liqui-tect® Leak Detection Sensors install quickly and work

simply for reliable detection of conductive aqueous fluid leaks.

The Liqui-tect 460 Sensor provides zone protection using the easy-toinstall and quick-drying Liebert leak detection cable. LEDs located on

the top cover of the module provide visual indication. A reset button

provides optional manual acknowledgement of alarms.

The top cover is hinged, allowing easy access to the electronics housed

inside the steel enclosure. Terminal blocks allow easy interconnection

of power and alarm outputs.

Dual Form-C relay outputs can simultaneously signal the local alarm

panel and remote monitoring system. The Liqui-tect 460 Sensor features supervised operation through alarms for cable faults, circuit failure or loss of power, ensuring a completely self-monitored leak

detection system.

The LT460 is conveniently available in packaged kits with 20, 25, 30,

35 or 45 feet of leak detection cable and hold-down clips. Note that

additional cable cannot be added to packaged kits.

The LT460 sensor can also be purchased independently. The sensor

can accommodate up to 100 feet of leak detection cable if the sensor

and leak detection cables are purchased as independent components.

Exterior Dimensions and Mounting Details

1

Page 6

Placement on Subfloor Under Cooling Support

* Output connections to external alarm monitoring panels

such as the Liebert contact closure alarm panels

Leak detection

zone (directly

beneath unit)

Leak

detection

cable

To a Liebert

environmental

unit and

an optional*

monitoring

panel

To ext e r n a l

power

supply or

directly

from

unit

(see

Power Wiring

on page 3)

LT460

Equipment

(Other applications such as long perimeter walls can be monitored)

As shown above, the Liqui-tect 460 (LT460) may be placed on a subfloor, where it is connected to the leak detection cable that surrounds

the leak detection zone—the area directly beneath the unit being

protected or other areas such as the perimeter of a room.

Note: For a downflow unit, the leak detection cable must be

located six feet in front of the unit.

The LT460 requires a 24 VAC power supply either from the environmental unit or an external source. There are two sets of Form-C dry

contacts for connection to a Liebert environmental unit and an external monitoring panel.

For more information:

• See Installation of Leak Detection System Cable on page 8 for

instructions on installing the cable and proper placement of the

hold-down clips.

• See Leak Detection Kit Installation Scenarios on page 10 for

cable placement, distance from the unit, and part numbers.

2

Page 7

Power Wiring

Power Wiring

24V from Liebert Environmental Unit to LT460

Liebert Deluxe Sys/3,

Challenger, Himod or

MM2 (8 Ton)

TB1

T5

(24V)

G5

(Ground)

LT460

TB1

TB1-1

TB1-2

Liebert MM2 (1 to 5 Ton) LT460

TB1

TB1-1

TB1-2

4V transformer of

tions)

(24V)

(Ground)

From 24V

transformer*

TB1-2

TB1-1

TB1

Liebert Mini-Mate2 (1 to 5 ton) LT460

* Requires a 24V external transformer (there are

no designated terminal connections on the unit)

Challenger, Himod or

MM2 (8 Ton)

TB1

T5

(24V)

G5

(Ground)

LT460

TB1

TB1-1

TB1-2

Transformer

LT460

TB1

TB1-1

TB1-2

From 24V

transformer

24V from Transformer to LT460

Liebert MM2 (1 to 5 Ton) LT460

TB1

TB1-1

TB1-2

tions)

(24V)

(Ground)

T5 (24V)

TB1-2

TB1-1

G5 (Ground)

TB1TB1

Liebert DS, Deluxe System/3,

Challenger, Himod or Mini-Mate2 (8 ton) LT460

Location of

T5 (24V)

connection

on Liebert unit

Transformer

LT460

TB1

TB1-1

TB1-2

From 24V

transformer

From 24V

transformer

TB1-2

TB1-1

TB1

Transformer LT460

The LT460 is rated for 24 VAC, 50/60 Hz and 0.12 amp.

Figure 1 24V from Liebert environmental units to LT460

Figure 2 24V from transformer to LT460

3

Page 8

Wiring to Auxiliary Alarm Panels

Liebert Deluxe Sys/3,

Challenger, Himod or

MM2 (8 Ton)

24

(24V)

51

LT460

TB2

TB2-2

(C)

TB2-1

(N.O.)

TB2-3

(N.C.)

Env. Unit

Liebert MM2 (1 to 5 Ton)

TB1-1

(24V)

TB1-2

LT460

TB2

TB2-2

(C)

TB2-1

(N.O.)

TB2-3

(N.C.)

Env. Unit

OR

TB2

TB2-2

(C)

TB2-1

(N.O.)

TB2-3

(N.C.)

Env. Unit

TB1-1

(24V)

TB1-3

Liebert MM2 (1 to 5 Ton)LT460

TB2-3 (N.C.)

TB2

Liebert DSLT460

TB2-2 (C)

TB2-1 (N.O.)

Environmental

unit

24 (24V)

50, 51, 55 or 56

TB2-3 (N.C.)

TB2

Liebert Deluxe System/3,

Challenger, Himod or

Mini-Mate2 (8 ton)

LT460

TB2

Liebert Mini-Mate2

(1 to 5 ton)

LT460

TB2-2 (C)

TB2-1 (N.O.)

TB2-3 (N.C.)

TB2-2 (C)

TB2-1 (N.O.)

Environmental

unit

Environmental

unit

24 (24V)

51, 55 or 56

TB1-1 (24V)

TB1-2 or TB1-3

TB2

TB2-2

(C)

TB2-1

(N.O.)

TB2-3

(N.C.)

LT460

Liebert Contact

Monitor Panel

Input

Contact

(N.O.)

Alarm Pa nel

TB2-3 (N.C.)

TB2-2 (C)

TB2-1 (N.O.)

TB2

LT460

Alarm panel

Liebert contact

monitor panel

Input

contact

(N.O.)

The LT460 has two Form-C dry contact alarm output contacts (TB2 &

TB3). Each contact is rated for 24 VAC at 3 amp.

Figure 3 LT460 to Liebert environmental units

Figure 4 LT460 to Liebert contact monitor panel

4

Page 9

Configuration Switch Settings

Switch Settings OFF ON

S1

1. Leak Detect Filter 10sec 2min

2. Alarm Latch No Yes

3. Alarm Retest Delay No 1 hr

4. Not Used ——

Contacts

Rating:

24V,3A

CONNECT ENCLOSURE TO EARTH GROUND

TB3-3

TB3-2

TB3-1

TB2-3

TB2-2

TB2-1

TB1-2

TB1-1

Contacts

Rating:

24V,3A

24V

50/60Hz

0.12A

2

1

N.C.

C

N.O.

N.C.

C

N.O.

ALL CIRCUITS: CLASS 2

Contacts shown in POWERED, NON-ALARM state

A four-position DIP switch is used to

select two alarm (filter) delays and

three mutually exclusive alarm

modes. The switches are located

next to the wiring termination

blocks.

Leak Detect Filter Delay(SS1)

SS1 selects the leak detect filter

delay, the interval for which a leak

condition must be continuously

detected before an alarm is

triggered:

OFF = 10 seconds (default)

ON = 2 minutes

This feature is useful for eliminating nuisance alarms. SS1 works

independently of the settings of SS2

and SS3. While the alarm delay is selectable (factory default is

OFF=10 seconds), the cable fault delay is preset at approximately

2 seconds.

Latching or Non-Latching Alarms (SS2)

SS2 selects latching or non-latching alarms, the setting in which an

alarm will latch ON until manually reset:

OFF = Non-latching (default)

ON = Latching

The factory default is OFF=Non-latching. If the sensor is in latching

mode (ON=Latching) and the leak condition clears itself in the

interim, a manual reset is required. While the alarm is latched, the

sensor goes into a “sleep” mode and power to the leak detection cable

is discontinued. De-powering the cable prevents damage to the cable

should it be in contact with the conductive liquid for an extended

duration. After a manual reset, the sensor resumes its normal operation, continuously checking for leaks. If the leak condition has not yet

cleared but the sensor is manually reset, the sensor will re-alarm after

the appropriate leak detect filter delay. SS2 in the ON position will

disable the operation of SS3.

5

Page 10

Alarm Retest Delay (SS3)

SS3 selects the alarm retest delay, the setting in which an alarm is

latched and retested every hour.

OFF = Non-latching (default)

ON = Latching-retest each hour

The factory default is OFF=Non-latching. If SS3= ON and a leak is

detected, the alarm condition is latched, the sensor goes into a “sleep”

mode and power to the leak detection cable is discontinued. After one

hour, the sensor will automatically retest if the leak is still present. If

the leak has cleared itself, the sensor deactivates the alarm, resets

itself and resumes normal operation; if the leak is still present, the

alarm condition remains activated and the sensor goes to “sleep” and

retests in another hour. This procedure will repeat indefinitely until

the leak is cleared or until the alarm is manually reset.

A manual reset can be initiated at any time. If the leak condition has

not yet cleared, the sensor re-alarms after the selected leak detect filter delay; if the leak has cleared, the sensor deactivates the alarm and

resets itself. SS3 is disabled if SS2= ON.

The factory default settings of SS2=OFF and SS3 = OFF place the

sensor in a non-latching, continuous retest mode. The sensor does not

go to “sleep” after detecting a leak—instead, it continually checks to

determine whether the leak condition has cleared itself. Alarms automatically reset when the leak condition clears. Initiating a manual

reset will cause the sensor to trigger the alarm again after the selected

leak detect filter delay. The leak detect cable remains powered at all

times.

SS4 is not used.

SS1 SS2 SS3 SS4 MODE

OFF OFF OFF

ON OFF OFF

OFF ON —

ON ON —

OFF OFF ON

ON OFF ON

(not

used)

(not

used)

(not

used)

(not

used)

(not

used)

(not

used)

Non-latching, 10-second filter delay

(factory default)

Non-latching, 2-minute filter delay

Latching, 10-second filter delay

Latching, 2-minute filter delay

1-hour latch/retest, 10-second filter delay

1-hour latch/retest, 2-minute filter delay

6

Page 11

LED Operation

System

Normal

Alarm

Pending

Leak

Detected

Reset

Cable

Fault

Liqui-tect® Sensor

LT460

System Normal (Green):

• ON continuously when power is applied

to sensor.

Alarm Pending (Yellow):

• ON continuously during leak detect filter

delay and cable fault delay.

• FLASHING (with Leak Detected LED) to

indicate cable fault condition.

Leak Detected (Red):

• FLASHING to indicate leak detected

alarm.

• FLASHING (with Alarm Pending LED)

to indicate cable fault condition.

Notes

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of FCC rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to

correct the interference at his own expense.

In the event of a severe leak causing submersion or partial-submersion of the enclosure and/or the electronic circuitry inside the enclosure, the entire module should be returned to the factory for

inspection.

7

Page 12

Installation of Leak Detection System Cable

1. Attach the leak detection cable to the LT460 module.

2. Activate module and test detection cable. (Touch detection cable

with a clean moist cloth or paper towel.) Dry detection cable to

remove the alarm condition. (A hair dryer can be used to speed up

the drying.)

Note: Do not try to saturate the detection cable for testing! It only

requires a small amount of water to alarm. The detection cable will

have to dry for the alarm condition to clear.

DETECTION CABLE PLACEMENT PRECAUTIONS

• Do not use detection cable that is damaged or dirty—for

example, from plaster, spackle or construction debris.

• Detection cable should not be dragged through contaminants

(dirty or greasy areas). Floor must be clean for the detection

cable to function properly and for the hold-down clips to

adhere to the floor surface.

• Careful consideration should be taken to place detection cable

out of the direct discharge airflow path of environmental

equipment. This type of equipment can discharge moisture

into the airflow. Place cable six feet from discharge to avoid

nuisance alarms during humidification.

• Tools or heavy objects can do permanent damage when

dropped, rolled, or set on the detection cable. Avoid foot traffic

on the detection cable as well.

• Do not use any type of adhesive tapes to secure the detection

cable.

• Do not allow soldering or welding near the detection cable

without providing protection from heat or contaminants. (Also

avoid installing the detection cable in or near these type of

areas.)

• Mild dishwashing liquid can be used to clean the detection

cable of many contaminants.

3. Once the cable passes the test, lay it in the pattern desired.

8

Page 13

4. The installation of the hold-down clips should be in pairs according

Hold-down

clips every

6-8 ft.

Hold-down

clips every

3-4 ft.

Hold-down

clips at

beginning &

end of arc

to Figure 5 with the following considerations:

Figure 5 Installation of hold-down clips in pairs

a. One pair every 6 to 8 feet in straight patterns (see Figure 6).

b. One pair every 3 to 4 feet in circular patterns (see Figure 7).

c. One pair at the beginning and end of the arc when turning

90 degrees (see Figure 8).

d. One pair as needed to maintain consistent uniform contact

between the floor and detection cable.

Figure 6 Cable laid in

straight patterns

Figure 7 Cable laid in

circular patterns

Figure 8 90° turn in cable

5. Be certain the detection cable is protected from the adhesive installation for the hold-down clips. No adhesive should come in contact

with the detection cable.

6. Once adhesive is completely dry, snap the cable into each hold-down

clip.

7. Check that there are no gaps between the floor and detection cable.

(Add clips as required.)

8. Be certain there are no alarms present on the module.

9. Do final testing as per instruction in Step 2.

9

Page 14

Leak Detection Kit Installation Scenarios

2-ft clearance

in front

2-ft clearance

in front

6-ft clearance

in front

6-ft clearance

in front

Scenarios

Upflow

Unit

Detection

around

entire unit

Distance:

In back

On sides

In front

2 ft

2 ft

2 ft

Unit

(footprint-in.)

Challenger

(32.5 x 32.5) LT460-Z30 LT460-Z20 LT460-Z30 LT460-Z25

Himod

(69 x 35) LT460-Z35 LT460-Z20 LT460-Z35 LT460-Z25

Deluxe System/3

(50 x 35) LT460-Z30 LT460-Z20 LT460-Z35 LT460-Z25

(74 x 35) LT460-Z35 LT460-Z20 LT460-Z35 LT460-Z25

(99 x 35) LT460-Z45 LT460-Z25 LT460-Z45 LT460-Z30

(122 x 35) LT460-Z45 LT460-Z25 LT460-Z45 LT460-Z30

DS

(73 x 35) LT460-Z35 LT460-Z20 LT460-Z45 LT460-Z30

(86 x 35) LT460-Z35 LT460-Z20 LT460-Z45 LT460-Z30

(98 x 35) LT460-Z45 LT460-Z25 LT460-Z45 LT460-Z30

(109 x 35) LT460-Z45 LT460-Z25 LT460-Z45 LT460-Z30

(132 x 35) LT460-Z45 LT460-Z25 LT460-Z45 LT460-Z30

Upflow

Unit

Detection

on sides and

in front of unit

Distance from unit

No cable behind

2 ft

2 ft

Part number

Downflow

Unit

Detection

around

entire unit

1 ft

1 ft

6 ft

Downflow

Detection

on sides and

in front of unit

No cable behind

Unit

1 ft

6 ft

10

Page 15

Page 16

Ensuring The High Availability

Of Mission-Critical Data And Applications.

While every precaution has been taken to ensure the accuracy and completeness of this literature, Liebert Corporation assumes

no responsibility and disclaims all liability for damages resulting from use of this information or for any errors or omissions.

© 2010 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change without notice.

® Liebert is the registered trademark of Liebert Corporation.

All names referred to are trademarks or registered trademarks of their respective owners.

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

29/F, The Orient Square Building

F. Ortigas Jr. Road, Ortigas Center

Pasig City 1605

Philippines

+63 2 687 6615

Fax: +63 2 730 9572

The global leader in enabling Business-Critical Continuity

™

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are

trademarks and service marks of Emerson Electric Co. or one of its affiliated companies.

©2010 Emerson Electric Co.

AC Power

Connectivity

DC Power

Infrastructure Management & Monitoring

Embedded Computing

Embedded Power

Power Switching & Controls

Precision Cooling

Outside Plant

EmersonNetworkPower.com

Racks & Integrated Cabinets

Services

Surge Protection

Technical Support / Service

Web Si te

www.lieber t.com

Monitoring

liebert.monitoring@emerson.com

800-222-5877

Outside North America: +00800 1155 4499

Single-Phase UPS & Server Cabinets

lieber t.upstech@emer son.com

800-222-5877

Outside North America: +00800 1155 4499

Three-Phase UPS & Power Systems

800-543-2378

Outside North America: 614-841-6598

Environmental Systems

800-543-2778

Outside the United States: 614-888-0246

Emerson Network Power.

SL-31045_REV5_12-11

Loading...

Loading...