Page 1

Vilter 450 XL® Compressor

For Industrial Refrigeration

Page 2

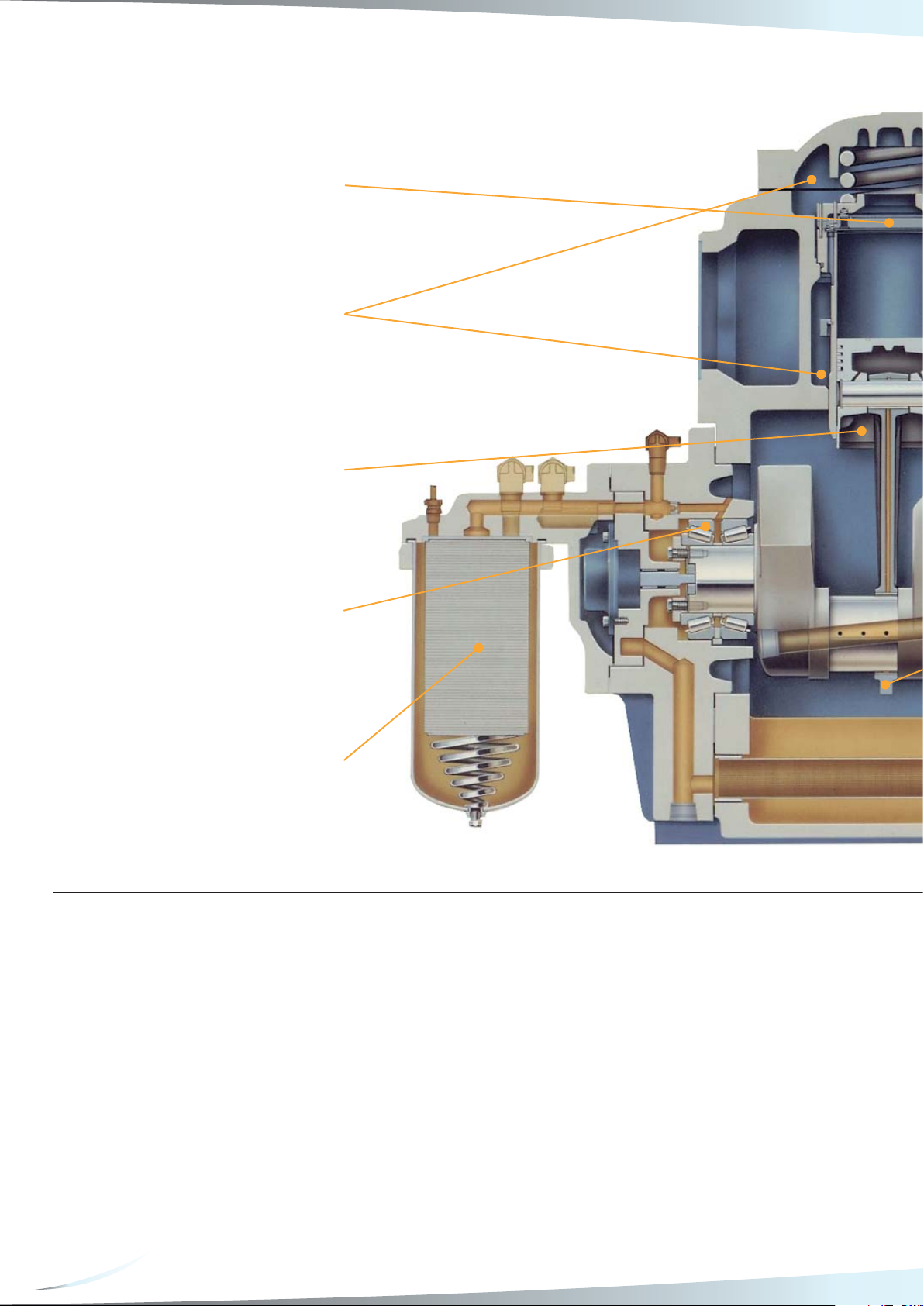

450XL Cross Section

Spring Loaded Safety Heads

Protect against liquid slugging by relieving internal

cylinder pressure if cylinders are subjected to an

incompressible fl uid.

Suction and Discharge Porting

Maximum suction and discharge porting through the

compressor achieves minimum pressure drop with

valve plates that are made to exacting Vilter material

and manufacturing requirements for long-term

service.

Piston and Connecting Rod

The unique design of the piston and connecting rod

assembly allows for movement only between the connecting rod bushing and piston pin, while providing

positive lubrication throughout the entire compression cycle.

Double Tapered Roller Bearings

Energy-effi cient roller bearings enable the compressor

to be used for high suction pressure applications as

well as high belt-drive horsepower requirements.

Tri-Micro® Oil Filter

Removes 95% of contaminants as small as 3 microns

in size. Allows full fl ow of oil at all times, resulting in

reduced wear on compressor components. Combines

extreme fi ltering capacity with the convenience of a

throw-away recharge element. Filter is enclosed in a

seamless drawn carbon steel shell with cast iron cover,

and is equipped with a means for determining pressure drop across the fi lter.

The versatile VMC 450XL is now even better!

While retaining all of the features that are exclusive to Vilter compressors, we’ve made several design improvements:

• Piston

• Connecting road and bearing insert

• Crankshaft

• Safety head

• Capacity reduction system

Even though we’ve made these specifi c changes, we’ve retained

all of the exclusive Vilter features, including provisions for fast and

easy servicing with components that are easy to access.

The 450XL can operate with ammonia, halocarbon and even some

hydrocarbon refrigerants. It works in extreme applications with up

to a 17,2 bar pressure differential. It can be belt-driven up to 224

kW or direct driven all the way up to 285 kW. And it can run at high

compression ratios all the way up to 12:1 with certain halocarbon

refrigerants.

2

Page 3

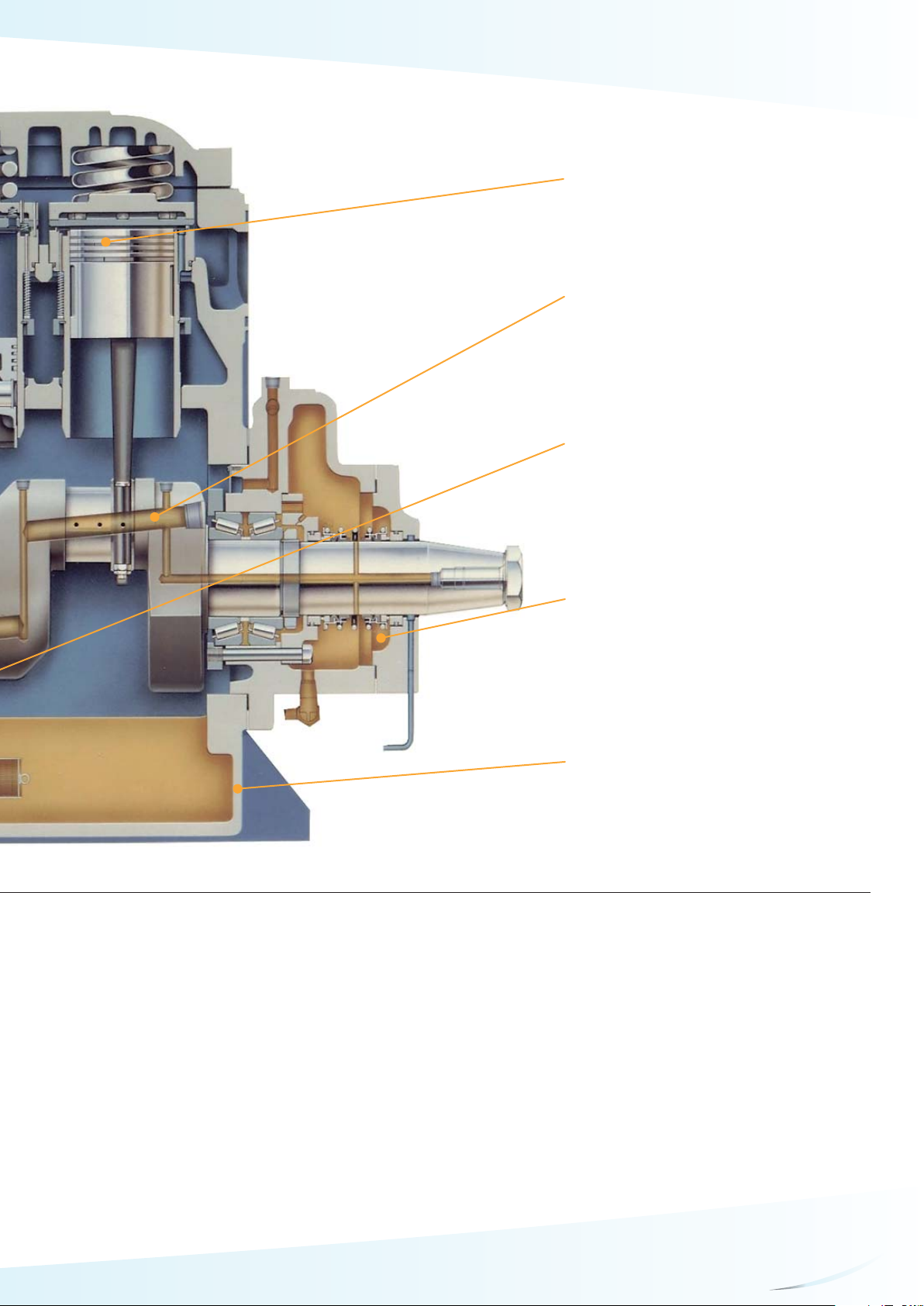

Compression and Oil Rings

The 450XL piston ring set consists of three compression rings and a single, special oil scraper ring for

keeping oil consumption to an absolute minimum.

Heavy-Duty Crankshaft*

An over-sized crankshaft pin diameter provides years

of rugged, dependable duty, while the larger bearing

surface allows for higher pressure differential capabilities.

Connecting Rod Bearings*

Vilter’s unique oil circuit drilling arrangement ensures

proper hydrodynamic lubrication of insert bearings

throughout the entire compression process. Rod

bearings are specially designed to supply lubrication

to the piston pin bushing at all times.

Double Bellows Shaft Seal

The 450XL shaft seal, designed to specifi c Vilter

specifi cations, is manufactured from materials strictly

used for industrial refrigeration applications. Seal unit

assembly consists of two opposed seals – one sealing

from the atmosphere and the other from the crankcase. Mating seal surfaces are lubricated and cooled

by circulated oil.

Even with all these built-in features, you’ll still fi nd the 450XL to be

extremely cost-effi cient. This compressor has a whopping cylinder

displacement of 84,5 m

3

/h while running at 1200 RPM. And the

high isentropic effi ciency of the 450XL means its COP is second to

none when compared to other compression systems.

The 450XL can be installed almost anywhere, even on an upper

fl oor if necessary, since vibration is kept to a minimum. Noise level

is low too, due to the use of quickacting, precise ring plate suction

and discharge valves.

Single Casting Frame

The single casting frame incorporates suction and

discharge manifolds plus bearing supports. It’s cast to

exacting tolerances from a high grade of cast iron to

withstand extreme changes in heat and pressure. The

castings are notably free from porosity and internal

strains, and display excellent wearing qualities.

*Patented Design

Far-Reaching Applications

The 450XL is so versatile it can handle almost any refrigeration

system conditions. Up to 24.1 bar maximum discharge, and up

to 10.3 bar maximum suction with a maximum 17.2 bar pressure

differential. At different compression ratios, too, from 8:1 for ammonia to 14:1 for R404A. In V-belt confi gurations all the way up to

224 kW, or

direct drive setups up to 285 kW. And it’s usable for both 50Hz and

60Hz applications up to 1200 RPM.

The graph (Figure 2) on the next page depicts the broad range of

applications that the 450XL covers.

3

Page 4

Nominal High-Stage Capacities

With its 114 mm bore and stroke, the 450XL provides up to 30%

more capacity than similar size compressor units, all while maintaining a favorable COP ratio.

Nominal high-stage ratings for the 450XL are shown in Figure 1

below.

Figure 1 | High Stage capacities 450XL ratings

Complete detailed ratings for all 450XL high-stage models, plus ratings for 450XL booster compressors, special high suction pressure

compressors, and even integral two-stage compressors, are available for all major refrigerants either from the Vilter Sales Offi ces.

Figure 2 | Broad Applications

Max. Discharge 24.1 barg

17.2 Bar ΔP Max

Cooling Capacity (kW)

Saturated Suction Temperature °C

These ratings are establised under the following conditions:

• 1200 RPM

• Saturated suction

• No subcooling

• No belt losses

• All ratings are based on 60°C condensing temperature

• Ratings are based on a 4-cylinder 450XL (454XL).

For cooling capacity and approximate kW fi gures of other 450XL

models, use a direct proportion to the number of cylinders of the

454XL. For example, use a 3.0 factor for determining the 12-cylinder 450XL cooling capacity and approximate kW fi gures.

Absorbed Power (kW)

Minimum

Allowable

Suction

Pressure (barg)

-0.8 barg

Discharge Pressure (barg)

2.07 Bar ΔP Minimum for Gas Unloading

0 Bar ΔP Minimum for Oil Unloading

Suction Pressure (barg)

Maximum Motor kW

10.5 barg Max. Suction

4516XL Belt Drive Recip Pak with VILTech Micro-Controller

4

Page 5

Time-Honored Features

Vilter’s attention to detail shows wherever you look. Over a century of experience in refrigeration compressor design goes into

each and every part that comprises the 450XL.

We have designed our component parts to work together, not just

fi t together. That’s why Vilter guarantees that all Genuine Vilter

Parts will match your Vilter compressor dimensionally, metallurgically and thermally for optimum compressor performance.

With Genuine Vilter Parts, you can be assured of getting the engineering design and special construction features that only Vilter

can offer. Consider some of the special manufacturing steps that

Vilter parts go through:

• Select surfaces are shot-peened for added strength

• Mating faces are lapped for greater compressor effi ciency

• Many parts are ultrasonically inspected for maximum reliability

• The steels used are of special alloys for durable performance

• Exacting tolerances are measured in light bands rather than in

hundredths of millimetres

The Vilter 450XL Full Two-Year Warranty

The 450XL compressor is fully warranted against defects of materials and workmanship under normal use and service, for a period

of two years from date of shipment regardless of startup date.

For example, if startup occurs one month from shipping date, the

customer will have a full twentythree (23) months of warranty

coverage after startup.

Genuine Vilter Parts

When you need parts for your 450XL

compressor – whether for repair work or

scheduled maintenance – make sure you

specify Genuine Vilter Parts.

Look for the Genuine Vilter Part mark that

is either etched or stamped directly on all major Vilter parts. It’s

your assurance of Vilter warranty protection. In some cases, where

a replacement part does not lend itself to stamping or etching,

a blue tag will identify the part as a Genuine Vilter Part. Vilter replacement parts (except those too big to box) are shipped in boxes

that have the Genuine Vilter Part mark right on the box itself.

Don’t be misled by look-alike, no-name imitations of Vilter compressor parts that carry vague warranties. Cheap parts can become

an expensive mistake. Make sure you insist on using only Genuine

Vilter Parts, and that you contact an Authorized Vilter Distributor

(or Vilter direct) for all your 450XL parts requirements.

Piston, Pin and Ring

Assembly

•A shrink-fi t wrist pin is used

to increase bearing load

capacity.

• Hardened steel wrist pins

are ground and polished to

size.

• Three cast iron compression

rings and one oil ring provide a

positive seal while wiping oil

back to the crankcase.

Connecting Rod,

Bearing and Bushing

• Replaceable insert bearing

improves lubrication and

load carrying capacity.

• Forged connecting rods

back the precision-made,

steel-backed Babbitt insert

bearing.

• Grooved wrist pin bushings

are fed with pressurized

lubricating oil.

Ductile Iron Crankshaft Spring Loaded Safety

• Designed with a bigger

crankpin diameter for greater

load bearing and bearing

surface.

• All crankshafts are statically

and dynamically balanced for

reduced vibration.

• Precision drilled crankshaft

ensures proper lubrication

through the compression

cycle.

• The 6, 8, 12, and 16-cylinder

crankshafts are shot-peened

for greater strength.

• Spring loaded safety heads

provide protection against

liquid slugging.

• The suction and discharge

porting improve compressor

effi ciency.

Heads

Capacity Reduction System

• A piston operated unloading

mechanism lifts the suction

valve plate to unload the

cylinders for reduced capacity

or unloaded starts.

• Simplifi ed unloading piston

allows easy removal for seal

servicing.

5

Page 6

General Specifi cations

The complete line of 450XL compressors is comprised of six

models ranging from a nominal 88 kW cooling capacity 2-cylinder

machine all the way to the high end of the scale – a nominal 704

kW cooling capacity 16-cylinder model. In-between are the 4, 6,

8 and 12-cylinder mid-size units. All 450XL compressors run at a

maximum of 1200 RPM, and all are provided with built-in capacity

reduction steps for economical operation at reduced loads. V-belt

and direct-connected motor operation are also available throughout the entire range of 450XL models.

We have tried to make every centimetre count in designing the

450XL to fi t into even the tightest space requirements. The 450XL

is a machine that provides displacement of 84,5 m3/h per cylinder,

giving you maximum capacity in a minimum amount of space.

There’s sure to be a 450XL model that’s a perfect match to your

refrigeration application.

Engineering Specifi cations

The compressor shall have double shaft seal, double tapered, roller

main shaft bearings.

Tri-Micro® oil fi lter and oil strainer that removes 95% of contaminants as small as 3 microns in size; dynamically and statically balanced heavy duty crankshaft of ductile iron, also shot-peened on

6, 8, 12 and 16-cylinder models; spring safety heads; die-forged,

steel connecting rods with replaceable bearing halves; aluminum

type heat treated pistons with three compression rings and one oil

ring; piston operated suction valve lifters to unload the compressor

for starting and to provide capacity control. The piston and

connecting rods shall be assembled with a shrink-fi t wrist pin for

higher load carrying capabilities and superior wearing qualities.

The compressor shall come complete with structural steel base

and be equipped with the additional following standard equipments: crankcase oil thermometer and heater; oil fi lter pressure

gauge with manual 3-way valve; oil failure switch; high and low

pressure cutout; capacity control switches and unloader solenoid

valves based on the number of steps of capacity reduction; water

or refrigerant cooled oil cooler; suction, discharge, and oil pressure

gauges complete with Stedy-Mounts® and shut-off valves; (water

or refrigerant) cooled cylinder covers following your need.

The parameters for the motors selection shall be:

- Required power (kW)

- Frequency (Hz) and Rotational speed (RPM)

- Voltage (Volt) and phasing

- Direct coupling or V-belt drive

The compressor minimal cooling capacity (kW) shall be defi ned for

given:

- Suction temperature (°C) or pressure (barg)

- Condensing temperature (°C) or pressure (barg)

Compressors are to be manufactured by Vilter Manufacturing

Corporation, Cudahy, Wisconsin, or equal as approved.

4512XL Direct Drive Recip Pak with

Superseparator and VILTech MicroController

6

Page 7

2 & 4 Cylinder Units 6 & 8 Cylinder Units 12 & 16 Cylinder Units

V-Belt Drive Ammonia

Cyl. A B C D E Cyl. A B C D E Cyl. A B C D E

12 2108 2013 1486 508 1514 6 1930 1410 1026 508 867 12 2108 2013 1486 508 1514

16 2108 2013 1581 508 1514 8 1930 1422 991 508 883 16 2108 2013 1581 508 1514

Direct Drive Ammonia

Cyl. A B C D E Cyl. A B C D E Cyl. A B C D E

2 2000 1041 1259 508 740 12 2356 1073 1026 508 867 12 3258 1280 1524 546 1514

4 2203 1054 1310 508 802 16 2419 1140 991 508 883 16 3258 1280 1616 546 1514

V-Belt Drive Halocarbon

Cyl. A B C D E Cyl. A B C D E Cyl. A B C D E

2 1753 1241 1256 508 740 6 1930 1435 1026 508 867 12 2108 2038 1448 508 1514

4 1880 1271 1310 508 802 8 1930 1448 991 508 883 16 2108 2038 1527 508 1514

Direct Drive Halocarbon

Cyl. A B C D E Cyl. A B C D E Cyl. A B C D E

2 2000 1041 1256 508 740 6 2369 1073 1026 508 867 12 3270 1280 1486 546 1514

4 2203 1054 1310 508 802 8 2432 1140 991 508 883 16 3270 1280 1565 546 1514

General Dimensions – The dimensions shown above are approximate, and should not be used for construction. Vilter issues certifi ed prints for construction purposes. These dimensions

are provided in millimeters. Space needed to remove fl ywheel 178mm. Space needed to remove crankshaft, from wall to centerline of compressor 1067mm for 2-8 cylinder models, and

2134mm for 12-16 cylinder models.

7

Page 8

General Dimensions

452XL 454XL 456XL 458XL 4512XL 4516XL

Number of Cylinders 24681216

Maximum RPM 1200 1200 1200 1200 1200 1200

Bore & Stroke (mm) 114 x 114 114 x 114 114 x 114 114 x 114 114 x 114 114 x 114

CFM @ Maximum RPM (m

Refrigeration Capacity at -12°C/+35°C, R-717 (kW) 84 172 257 341 514 686

Suction Connection (inch) 2 1/2 34456

Discharge Connection (inch) 2 2 1/2 3 3 2 x 3 2 x 3

Unit Weight Less Motor (kg) 862 1225 1406 1542 2404 2630

Oil Charge (l) 19 27 27 27 53 53

Standard Steps of Unloading (%) 0 50 33/66 24/50 33/66 25/50

Option 1 Steps of Unloading (%) 50 25/50/75 - 25/50/75 - 25/50/75

Option 2 Steps of Unloading (%) 100 50/100 33/66/100 25/50/75/100 33/66/100 25/50/75/100

Maximum Discharge Temperature (°C) 149 149 149 149 149 149

Crankcase Oil Temperature Range (°C) 43-54 43-54 43-54 43-54 43-54 43-54

Vilter reserves the right to make changes in design and specifi cations without notice.

3

/h) 169 336 507 676 1014 1352

For more details, see www.emersonclimate.eu

OTH003-EN-0512

Emerson Climate Technologies GmbH - European Headquarters - Pascalstrasse 65 - 52076 Aachen, Germany

Tel. +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.emersonclimate.eu

The Emerson Climate Technologies logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Copeland is a registered trademark and Copeland Scroll is a trademark of Emerson Climate Technologies Inc.. All other trademarks are property of their respective owners.

Information contained in this brochure is subject to change without notifi cation.

© 2012 Emerson Climate Technologies, Inc.

Loading...

Loading...