Page 1

Tambourine 20

Power Supply Installation

Guide

480VAC Model 230VAC Model

June 2014 (Ver. 1.501) www.elmomc.com

Page 2

Table of Contents

Notice

This guide is delivered subject to the following conditions and restrictions:

• This guide contains proprietary information belonging to Elmo Motion Control Ltd. Such

information is supplied solely for the purpose of assisting users of the Tambourine 20 power

supply in its installation.

• The text and graphics included in this manual are for the purpose of illustration and reference

only. The specifications on which they are based are subject to change without notice.

• Information in this document is subject to change without notice.

Document no. MAN-TAMIG (Ver. 1.501)

Copyright 2014

Elmo Motion Control Ltd.

All rights reserved.

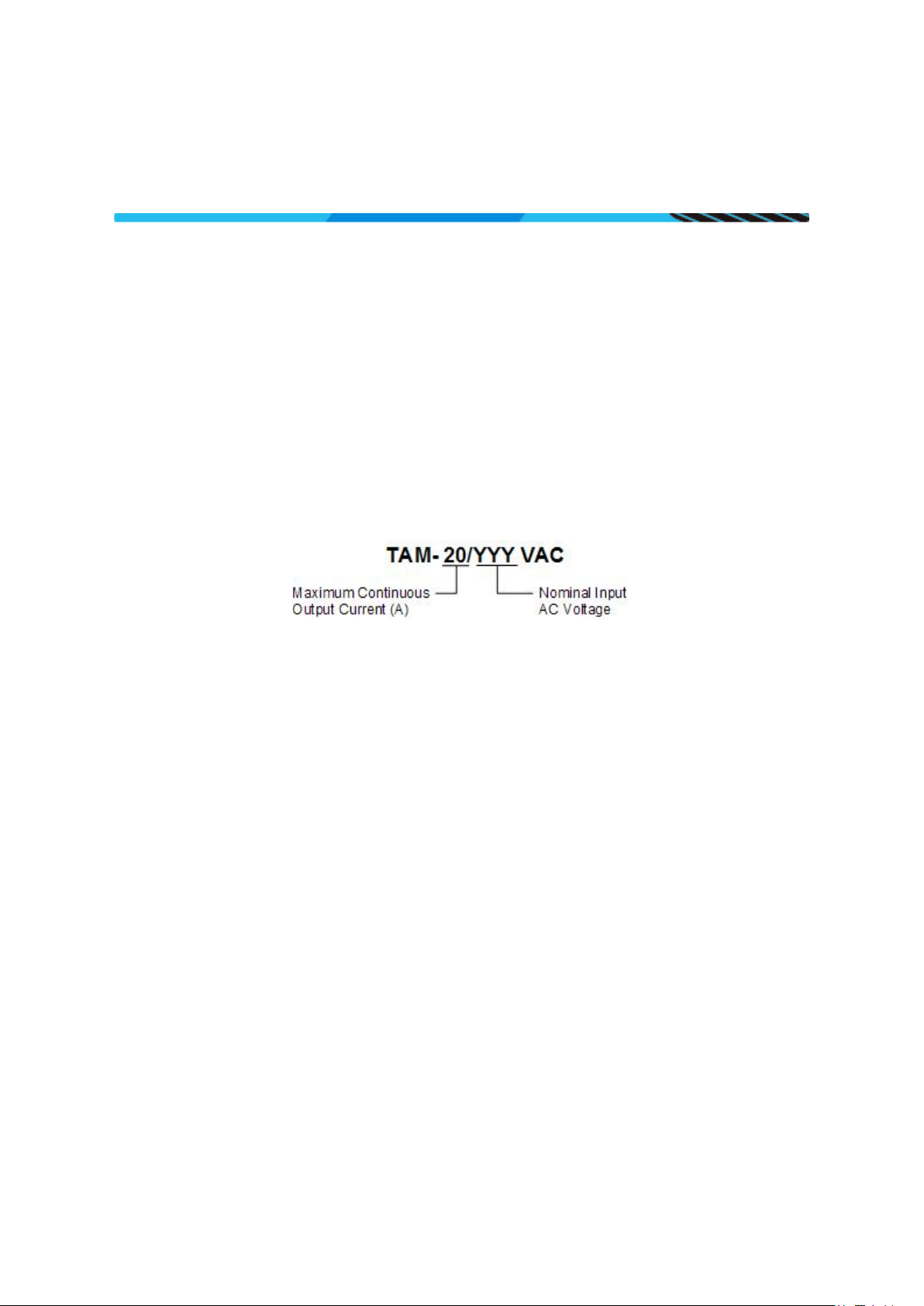

Catalog Number

|Warnings|www.elmomc.com

Page 3

Table of Contents

Revision History

Version Release Date Changes/Remarks

1.0 February 2011

1.1 July 2011 Replaced figure on Section 3.4.7

1.2 Sep 2011 Addition of Warnings and Cautions sections, Electrical and Mechanical

1.3 Jan 2012 Added two tables to section 1.1 regarding remnant charge after power

1.4 July 2012 Changes to overvoltage and shunt on pages 8, 11

1.401 February 2013 AC Input frequency Range added

1.402 February 2013 AC Input frequency changed to 20 to 500 Hz

1.500 March 2014 Added Section 3.5: Heat Dissipation

1.501 June 2014 Document update

Initial Release

specifications, and Mounting conditions.

off.

New document template

|Warnings|www.elmomc.com

Page 4

Table of Contents

Table of Contents

MAN-TAMIG (Ver. 1.501)

Chapter 1: Operating Safely .......................................................................................... 6

1.1 Warnings .................................................................................................................... 7

1.2 Cautions ...................................................................................................................... 7

1.3 Directives and Standards ............................................................................................ 8

1.4 CE Mark Conformance ................................................................................................ 8

1.5 Warranty Information ................................................................................................ 8

Chapter 2: Product Description ..................................................................................... 9

2.1 Standard Features .................................................................................................... 10

2.2 Fault Protection ........................................................................................................ 10

2.3 Technical Specifications............................................................................................ 10

2.3.1 Dimensions ................................................................................................ 11

2.3.1.1 Housing of the 36 VAC up to 230 VAC Models ......................... 11

2.3.1.2 Housing of 420 VAC up to 480 VAC Models ............................. 11

2.3.2 Electrical and Mechanical Specifications ................................................... 12

2.3.3 Shunt Regulator ......................................................................................... 13

4

Chapter 3: Installation ................................................................................................ 14

3.1 Before You Begin ...................................................................................................... 14

3.1.1 Site Requirements ..................................................................................... 14

3.1.2 Hardware Requirements ........................................................................... 14

3.1.2.1 AC Input Requirements ............................................................ 14

3.1.2.2 Recommended Wire Cross-Sections (All Models) .................... 14

3.2 Unpacking the Components ..................................................................................... 15

3.3 Connectors ............................................................................................................... 16

3.3.1 Connector Types for 36 VAC up to 230 VAC Models ................................. 16

3.3.2 Connector Types for 420 VAC up to 480 VAC Models ............................... 17

3.3.3 Main AC Input Power Connector Pinout ................................................... 18

3.3.4 4x DC-Output Connector Pinout ................................................................ 19

3.4 Mounting and Wiring the Tambourine 20 ............................................................... 20

3.4.1 Mounting ................................................................................................... 20

3.4.2 Wiring Guidelines ...................................................................................... 20

3.4.3 AC Power Source ....................................................................................... 21

3.4.4 Direct-to-Mains (No Isolation Transformer) Wiring Diagrams .................. 22

3.4.5 Isolated AC Supplies (with an Isolation Transformer) Wiring Diagrams ... 24

3.4.6 Connecting the Main Power Cable ............................................................ 26

3.4.7 Connecting the DC Output Cable .............................................................. 27

3.4.8 DC-Link Shared Connection ....................................................................... 28

3.5 Heat Dissipation ....................................................................................................... 29

3.5.1 Tambourine 20 Thermal Data.................................................................... 29

3.5.2

Heat Dissipation Data ................................................................................ 29

3.5.3 How to Use the Charts ............................................................................... 30

|Warnings|www.elmomc.com

Page 5

Table of Contents

Table of Contents

MAN-TAMIG (Ver . 1.501)

Chapter 4: Initialization .............................................................................................. 31

4.1 LED Diagnostics ........................................................................................................ 31

5

|Warnings|www.elmomc.com

Page 6

Tambourine 20 Power Supply Installation Guide

Table of Contents

Chapter 1:

Operating Safely

Warning:

Caution:

MAN-TAMIG (Ver . 1.501)

6

In order to operate the Tambourine 20 power supply safely, it is imperative that you implement the

safety procedures included in this installation guide. This information is provided to protect you and

to keep your work area safe when using the Power Supply.

Please read this chapter carefully, before you begin the installation process.

Before you start, make sure that all system components are connected to earth ground. Electrical

safety is provided through a low-resistance earth connection.

Only qualified personnel may install, adjust, maintain and repair the product. A qualified person has

the knowledge and authorization to perform tasks such as transporting, assembling, installing,

commissioning and operating power-supplies, drives and motors.

The Tambourine 20 power supply contains electrostatic-sensitive components that can be damaged

if handled incorrectly. To prevent any electrostatic damage, avoid contact with highly insulating

materials, such as plastic film and synthetic fabrics. Place the product on a conductive surface and

ground yourself in order to discharge any possible static electricity build-up.

To avoid any potential hazards that may cause severe personal injury or damage to the product

during operation, keep all covers and cabinet doors shut.

The following safety symbols are used in this manual:

This information is needed to avoid a safety hazard, which might cause bodily

injury.

This information is necessary for preventing damage to the product or to other

equipment.

|Warnings|www.elmomc.com

Page 7

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

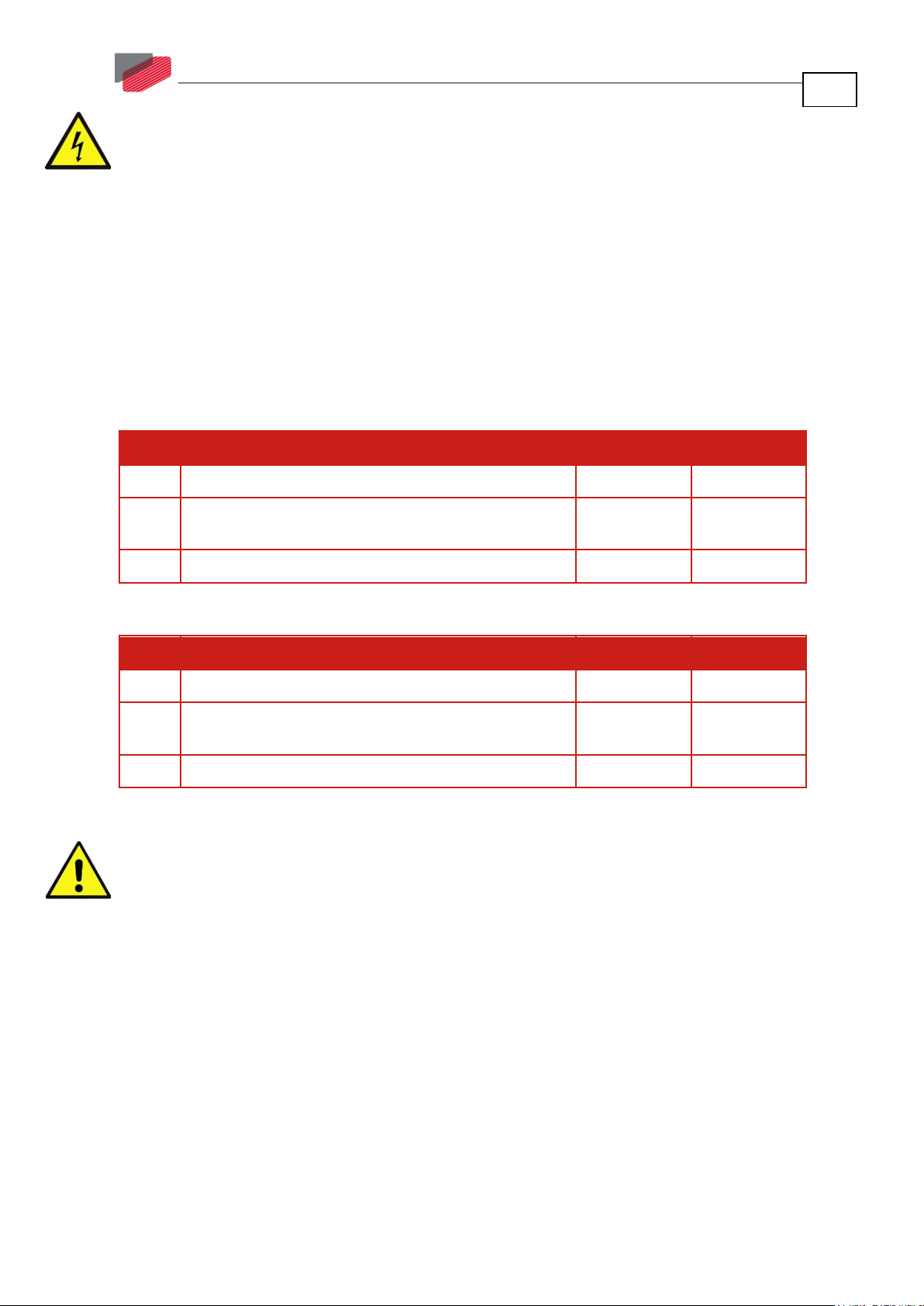

1.1 Warnings

• To avoid electric arcing and hazards to personnel and electrical contacts, never

connect/disconnect the Tambourine 20 power supply while the power source is on.

• Disconnect the Tambourine 20 power supply from all voltage sources before it is opened for

servicing.

• The Tambourine 20 power supply contains grounding conduits for electric current protection.

Any disruption to these conduits may cause the instrument to become hot (live) and

dangerous.

• After shutting off the power and removing the power source from your equipment, wait as

described in the tables below, before touching or disconnecting parts of the equipment that

are normally loaded with electrical charges (such as capacitors or contacts). It is recommended

to measure the electrical contact points with a DVM before touching the equipment.

T.P # Function Ref. Results

7

1 Discharge time with no load VP+, VN-

2 Discharge time while the TAM is connected to Elmo

VP+, VN-

~90 sec

~80 sec

drive at MO=0

3 Discharge time with maximum load up to 20 A VP+, VN-

~120 ms

Table 1: 230 VAC Model 1

T.P # Function Ref. Results

1 Discharge time with no load VP+, VN-

2 Discharge time while the TAM is connected to Elmo

VP+, VN-

~45 sec

~40 sec

drive at MO=0

3 Discharge time with maximum load up to 20 A VP+, VN-

~60 ms

Table 2: 480 VAC Model 2

1.2 Cautions

• The Tambourine 20 power supply contains hot surfaces and electrically charged components

during operation.

• The maximum AC/DC power supply connected to the instrument must comply with the

parameters outlined in this guide.

• Before switching on the Tambourine 20 power supply, verify that all safety precautions have

been observed and that the installation procedures in this manual have been followed.

|Warnings|www.elmomc.com

Page 8

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

1.3 Directives and Standards

The Tambourine 20 power supply conforms to the following industry safety standards:

Safety Standard Item

UL 508C Recognized Power Conversion Equipment

In compliance with UL 840 Insulation Coordination, Including Clearance and

Creepage Distances of Electrical Equipment

8

In compliance with UL 60950-1

(formerly UL 1950)

IEC/EN 61800-5-1 approved

Safety of Information Technology Equipment,

Including Electrical Business Equipment

Safety for adjustable speed electrical power drive

system

IEC/EN 61800-3 approved

EMC for adjustable speed electrical power drive

system

In compliance with EN 60204-1 Low Voltage Directive, 73/23/EEC

The Tambourine 20 power supply has been developed, produced, tested and documented in

accordance with the relevant standards. Elmo Motion Control is not responsible for any deviation

from the configuration and installation described in this documentation. Furthermore, Elmo is not

responsible for the performance of new measurements or ensuring that regulatory requirements

are met.

1.4 CE Mark Conformance

The Tambourine 20 power supply is intended for incorporation in a machine or end product. The

actual end product must comply with all safety aspects of the relevant requirements of the

European Safety of Machinery Directive 98/37/EC as amended, and with those of the most recent

versions of standards EN 60204-1 and EN 292-2 at the least.

According to Annex III of Article 13 of Council Directive 93/68/EEC, amending Council Directive

73/23/EEC concerning electrical equipment designed for use within certain voltage limits, the

Tambourine 20 power supply meets the provisions outlined in Council Directive 73/23/EEC. The

party responsible for ensuring that the equipment meets the limits required by EMC regulations is

the manufacturer of the end product.

1.5 Warranty Information

The products covered in this manual are warranted to be free of defects in material and

workmanship and conform to the specifications stated either within this document or in the

product catalog description. All Elmo drives are warranted for a period of 12 months from the time

of installation, or 18 months from time of shipment, whichever comes first. No other warranties,

expressed or implied — and including a warranty of merchantability and fitness for a particular

purpose — extend beyond this warranty.

|Directives and Standards|www.elmomc.com

Page 9

Tambourine 20 Power Supply Installation Guide

Table of Contents

Chapter 2:

Product Description

MAN-TAMIG (Ver . 1.501)

9

The Tambourine 20 power supply is a compact direct-to-mains power supply designed to power

multiple servo drives up to 528 VAC. It was designed to complement Elmo servo drives that do not

include an integrated power supply. It has the following features:

• Rectifies AC input voltages of up to 3×528 VAC into filtered DC voltage with an output current

of 20 A continuous and a 40 A peak.

• The number of servo drives powered by a single Tambourine 20 power supply is limited only

by the total power consumption of the servo drives and not by the output current of the

Tambourine 20.

• Can operate directly from the mains when feeding isolated servo drives, or via an isolation

transformer when non- isolated servo drives are employed.

• Has a high capacitance to offer a low output voltage drop while operating from a single-phase

source.

• Has regenerating braking capability that enables fast braking of high inertia.

• Has built-in inrush current limiters that limit the power-on currents to low levels, reducing

turn-on stress from the mains.

• Has internal EMC filtering that eliminates the necessity for external devices, therefore

complies with CE and other EMC regulations.

• Has a Book Shelf (Panel Mount) structure, enabling simple and fast mounting.

|Warranty Information|www.elmomc.com

Page 10

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

2.1 Standard Features

• 20 A continuous output current

• AC input 20 to 500 Hz

• Single- or three-phase operation

• Direct-to-mains operation capability

• High regenerative (braking) capability

• Inrush current limit

• EMC filtering “inside”

• UL, CE, compliant

2.2 Fault Protection

The Tambourine 20 power supply power supply includes a duty cycle limiter, which inhibits shunt

whenever On and Off time exceeds 2%. This feature protects the shunt regulator when high-inertia

loads are driven by the servo drive(s) or when too high AC voltage is applied to the power supply

(i.e. DC output is already above the threshold of the shunt).

10

2.3 Technical Specifications

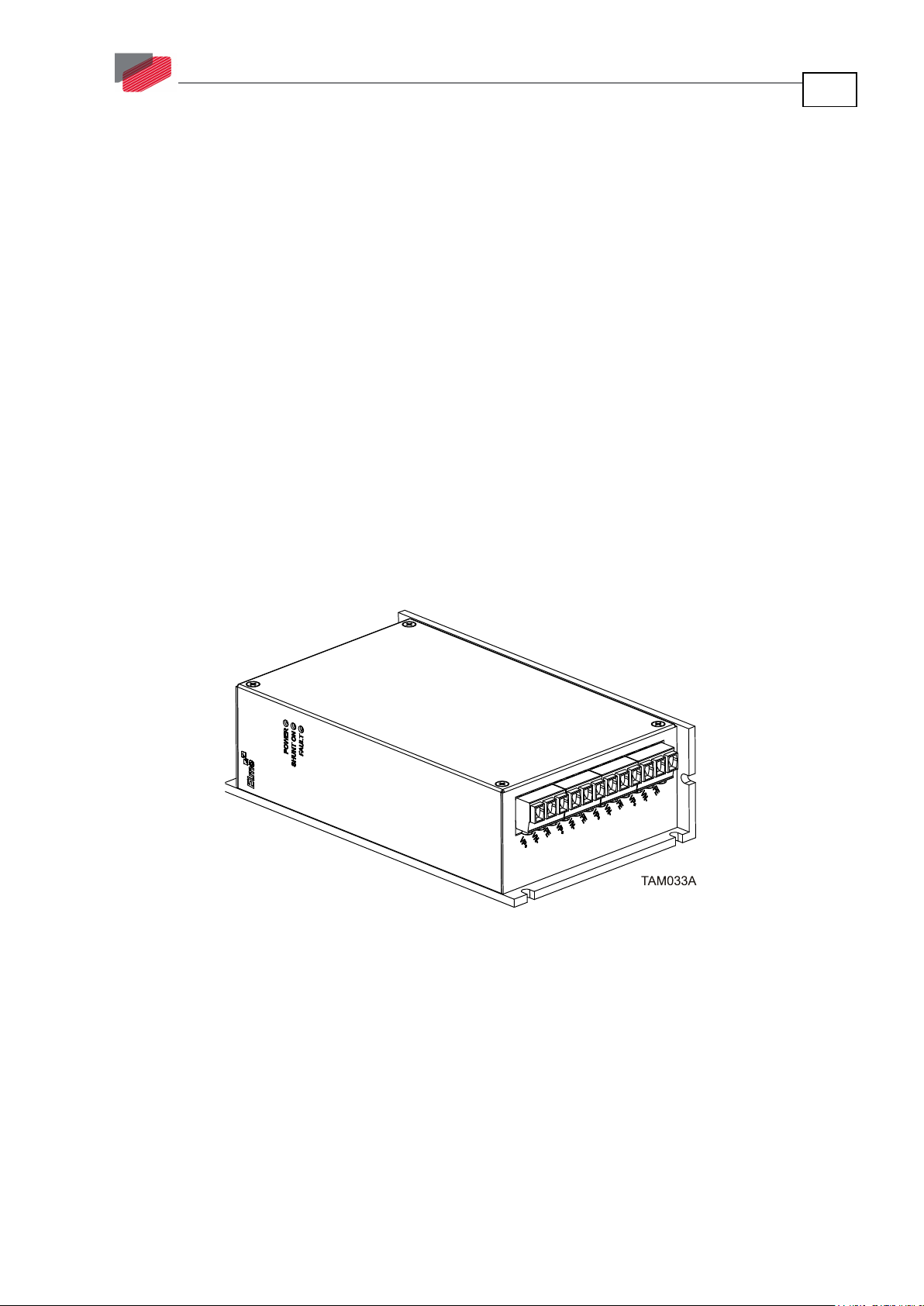

Figure 1: Tambourine 20 Power Supply

|Standard Features|www.elmomc.com

Page 11

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

2.3.1 Dimensions

2.3.1.1 Housing of the 36 VAC up to 230 VAC Models

11

2.3.1.2 Housing of 420 VAC up to 480 VAC Models

|Technical Specifications|www.elmomc.com

Page 12

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

2.3.2 Electrical and Mechanical Specifications

12

Power Supply TAM-20/36VAC TAM-20/60VAC TAM-

20/120VAC

Nominal

Input AC Voltage

20 to 500 Hz

Max

Input AC Voltage

Max Output

Power Cont.

Max Output

Power Peak

Nominal DC bus

Output

(at nominal AC

Voltage)

Shunt Power

(Peak)

DC Output Cont.

Current

1×36 VAC

3×36 VAC

1×38 VAC (L-N)

3×38 VAC (L-L)

1100 W 1800 W 3800 W 7600 W 13000 W 14000 W

2200 W 3600 W 7600 W 15200 W 26000 W 28000 W

50 VDC 85 VDC 170 VDC 325 VDC 560 VDC (for

1.8 kW 4.5 kW 5.5 kW 6 KW 5.5 kW 6.7 kW

20 A 20 A 20 A 20 A 20 A 20 A

1×60 VAC

3×60 VAC

1×61 VAC (L-N)

3×61 VAC (L-L)

1×120 VAC

3×120 VAC

1×131 VAC (L-N)

3×131 VAC (L-L)

TAM20/230VAC

1×230 VAC

3×230 VAC

1×270 VAC (L-N)

3×270 VAC (L-L)

TAM20/420VAC

3×420 VAC 3×480 VAC

3×470 VAC (L-L) 3×528 VAC (L-L)

400 VAC)

594 VDC (for

420 VAC)

TAM20/480VAC

560 VDC (for

400 VAC)

678 VDC (for

480 VAC)

DC Output Peak

Current

Mating Drives XXX-YY/60 XXX-YY/100 XXX-YY/200 XXX-YY/400 XXX-YY/700 XXX-YY/800

Weight 1155 gr 1155 gr 1155 gr 1155 gr 1155 gr 1155 gr

40 A 40 A 40 A 40 A 40 A 40 A

Table 3: Tambourine 20 Electrical Specifications

|Technical Specifications|www.elmomc.com

Page 13

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

2.3.3 Shunt Regulator

A shunt regulator is included in the power supply section of the Tambourine 20. The shunt regulator

is a switching type, wherein dissipative elements (resistors) are switched across the DC bus,

whenever the voltage reaches a predetermined level. The function of the shunt regulator is to

regulate the voltage of the DC bus during the period of motor deceleration, when there is a net

energy outflow from the motor to the servo drive. The servo drive handles this reverse energy just

as efficiently as it provides energy to the motor, hence, most of the energy is passed through the

servo drive back to the power supply, where this returning energy charges the filter capacitors

above their normal voltage level, as determined by the AC incoming voltage.

When the capacitors charge-up reaches the predetermined shunt threshold level, the shunt

regulator begins its regulating action. The bus is regulated to the specific model type voltage, until

regeneration ceases.

13

|Technical Specifications|www.elmomc.com

Page 14

Tambourine 20 Power Supply Installation Guide

Table of Contents

Chapter 3:

Installation

MAN-TAMIG (Ver . 1.501)

14

This chapter describes the installation of the Tambourine 20 power supply.

3.1 Before You Begin

3.1.1 Site Requirements

You can guarantee the safe operation of the Tambourine 20 by ensuring that it is installed in an

appropriate environment.

Feature Value

Ambient operating temperature 0 °C to 40 °C (32 °F to 104 °F)

Maximum non-condensing humidity 90%

Operating area atmosphere No flammable gases or vapors permitted in area

Models for extended environmental conditions are available.

Caution

operating temperature of 0 °C to 40 °C (32 °F to 104 °F) must not be exceeded.

: The Tambourine 20 dissipates its heat by convection. The maximum ambient

3.1.2 Hardware Requirements

3.1.2.1 AC Input Requirements

Circuit Breakers &

Contacts

Circuit breaker current rating 32 A Type D 40 A Type D

Circuit breaker voltage rating 250 VAC / 480 VAC depending upon operating AC voltage

Contactor 32 A 40 A

3.1.2.2 Recommended Wire Cross-Sections (All Models)

Feature Connection Details

AC input AC1, AC2, AC3 2.5 mm2, 12 AWG

DC Output VP+, VN- 2.5 mm2, 12 AWG

Protective earth PE 2.5 mm2, 12 AWG

Three-Phase Supply

Voltage

Single-Phase Supply

Voltage

|Before You Begin|www.elmomc.com

Page 15

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.2 Unpacking the Components

To unpack the Tambourine 20:

1. Carefully remove the power supply from the box and Styrofoam.

2. Check the product to ensure that there is no visible damage. If any damage has occurred, report

immediately to the carrier that delivered your product.

3. To ensure that the Tambourine 20 you have unpacked is the appropriate type for your

requirements, locate the part number sticker on the product.

The Part number provides the type designation.

15

4. Verify that the Tambourine 20 model is the one you ordered, and ensure that the voltage meets

your specific requirements.

|Unpacking the Components|www.elmomc.com

Page 16

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.3 Connectors

3.3.1 Connector Types for 36 VAC up to 230 VAC Models

The Tambourine 20 is delivered with the following external mating connectors:

No. Pins Type Function

16

Input Connector x1

1 × 7 pins Phoenix P/N 1911907

(MSTB 2,5HC/7-ST)

Output Connectors x4

Main AC Input

4 × 3 pins Phoenix P/N 1911868

(MSTB 2,5HC/3-ST)

Table 4: Connector Types for 36 VAC up to 230 VAC Models

DC Outputs

|Connectors|www.elmomc.com

Page 17

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.3.2 Connector Types for 420 VAC up to 480 VAC Models

The Tambourine 20 is delivered with the following external mating connectors:

No. Pins Type Function

17

Input Connector x1

1 × 7 pins Phoenix P/N 1714320

(GMSTB 2,5HCV/7-ST-7,62)

Output Connectors x4

4 × 3 pins Phoenix P/N 1714281

(GMSTB 2,5HCV/3-ST-7,62)

Main AC Input

DC Outputs

Table 5: Connector Types for 420 VAC up to 480 VAC Models

|Connectors|www.elmomc.com

Page 18

Tambourine 20 Power Supply Installation Guide

Table of Contents

TAM014A

MAN-TAMIG (Ver . 1.501)

3.3.3 Main AC Input Power Connector Pinout

Refer to section 3.4.6 for details of the connections.

Terminal Function Cable

AC1 AC Input phase #1 AC input

AC1 AC Input phase #1 AC input

AC2 AC Input phase #2 AC input

AC2 AC Input phase #2 AC input

AC3 AC Input phase #3 AC input

AC3 AC Input phase #3 AC input

PE Protective Earth AC input

18

Table 6: Main AC Input Connector Pinout

|Connectors|www.elmomc.com

Page 19

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.3.4 4x DC-Output Connector Pinout

Refer to section 3.4.7 for details of the connections.

Terminal Function Cable

VP+ Positive Power output DC output cable to a drive

VN- Negative Power output DC output cable to a drive

PE Protective earth DC output cable to a drive

19

Table 7: DC- Output Connector to Drive Pinout

|Connectors|www.elmomc.com

Page 20

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4 Mounting and Wiring the Tambourine 20

For optimum heat dissipation, the Tambourine 20 should be installed with the heat sink attached to

the machine's chassis. When mounting the Tambourine 20 make sure to leave about 1 cm (0.4“)

outward from the heatsink, to enable free air convection around the power supply.

3.4.1 Mounting

20

Figure 2: Mounting the Tambourine 20

The Tambourine 20 is designed for two standard mounting options (Figure 2):

• Wall Mount along the back (can also be mounted horizontally on a metal surface)

• Book Shelf along the side

1. Use M4 x 8 round head screws, one through each opening in the heat sink, to mount the

Tambourine 20 in position opposite the specific holes drilled.

2. Tighten the screws to just tight. Do not overtighten the screws.

3.4.2 Wiring Guidelines

1. Use flexible wires with the proper cross-section to handle the unit current. Color coding is

recommended.

2. After the wiring is completed, carefully inspect all connections in order to ensure tightness.

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 21

Tambourine 20 Power Supply Installation Guide

Table of Contents

TAMBOURINE VP+ Output Derating vs. Load current

100%

95%

92%

89%

85%

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0 3 5 8 10 13 15

18 20

Load Current [A]

VP+ Output [%]

MAN-TAMIG (Ver . 1.501)

3.4.3 AC Power Source

The AC voltage supply can be of any voltage within the range defined in the Tambourine 20

technical specifications. It must be able to deliver power to the servo drives (including peak power),

without significant drops. A three-phase supply is always recommended whenever possible, in

order to provide better DC bus voltage stability (low voltage ripple) under high load conditions.

Inrush current control is included within the Tambourine 20 power supply, which makes the

Tambourine 20 capable to be fed directly from the mains, whenever it supplies isolated drives.

When operating with a single-phase supply, a voltage drop due to loading is expected. The

magnitude of the voltage drop depends on the load current and the stiffness of the power source.

The following is a graph showing the typical expected VP+ drop, at certain load current when

supplied by a single AC phase source:

21

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 22

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4.4 Direct-to-Mains (No Isolation Transformer) Wiring Diagrams

Figure 3: Single-Phase Direct-to-Mains Connection

22

Caution

together in a shared connection.

: When using a single-phase AC source, terminals AC2 and AC3 must be paired

Figure 4: Three-Phase Direct-o-Mains Connection

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 23

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

23

Figure 5: Multiple Direct-to-Mains Connection

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 24

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4.5 Isolated AC Supplies (with an Isolation Transformer) Wiring

Diagrams

Figure 6: Single-Phase Isolated Source Connection

24

Caution:

• When using a single-phase AC source, terminals AC2 and AC3 must be paired

together in a shared connection.

• When using an isolation transformer, PR and PE must be connected together on the

Tambourine 20 side.

Figure 7: Three-Phase Isolated Source Connection

Caution

on the Tambourine 20 side.

: When using an isolation transformer, PR and PE must be connected together

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 25

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

25

Figure 8: Multiple Isolated Source Connection

All wiring guidelines for supply connections described previously apply to multiple-Tambourine 20

connections.

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 26

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4.6 Connecting the Main Power Cable

To connect the AC power cable:

1. For best noise immunity, a shielded (not twisted) cable is recommended (not mandatory) for

the AC input cable.

2. When operating with a three-phase power source, a 4-wire shielded cable should be used:

a. Connect the 3-phase leads of the main input cable to the AC1, AC2 and AC3 terminals of the

main input connector.

26

b. For safety requirements, the green/yellow-wire must be connected to the protective earth

(PE terminal). Connect the Protective Earth wire to the PE terminal on the main input

connector.

When operating with a single-phase power source, a 3-wire shielded cable should be used:

a. Connect the first phase lead of the main input cable to the AC1 terminal of the main input

connector.

For an output of 1 to 10 A:

The second lead can be connected into either terminal AC2 or AC3.

For an output of 10 A and higher:

The second lead must be connected into both terminal AC2 and AC3.

b. For safety requirements, the green/yellow-wire must be connected to the protective earth

(PE terminal). Connect the Protective Earth wire to the PE terminal on the main input

connector.

3. The gauge of the cable strands is determined by:

a. For three-phase source, the sum of the actual current consumption of the drives being fed

by the Tambourine 20.

b. For single-phase source, twice the sum of the actual current consumption of the drives

being fed by the Tambourine 20.

4. The Tambourine 20 has a dual-terminal input for each phase. Whenever the total output-

current from the Tambourine 20 exceeds 10 A – each input phase MUST be connected through

both twin-terminals.

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 27

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4.7 Connecting the DC Output Cable

To connect the DC output cable:

1. For best noise immunity, a shielded and twisted cable is recommended (not mandatory) for the

DC output cable. A 3-wire shielded cable should be used. The gauge is determined by the actual

current consumption of the drives being fed by the relevant DC output.

2. Connect the three wires of the DC output cable to the DC output connector of the

Tambourine 20:

a. Connect the DC leads to the VP+ and VN- terminals of the DC output connector.

27

b. For safety requirements, the third green/yellow-wire must be connected to the protective

earth (PE terminal). Connect the Protective Earth wire to the PE terminal on the DC output

connector.

3. When the Tambourine 20 is fed from an isolation transformer, from the safety and EMI aspects,

the PR (VN-) junction must be connected to PE junction.

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 28

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.4.8 DC-Link Shared Connection

Each Tambourine 20 contains a shunt. Its purpose is to "absorb" regenerated energy created by the

motor during braking and convert that energy into heat. If the energy regenerated by the motor

exceeds the capacity of the shunt, the drive is inhibited and an overvoltage message is sent.

To prevent this from happening, the braking-capacity of the shunt system can be extended by

connecting the DC output of several Tambourine 20s in parallel. When two or more Tambourine 20s

are connected, by DC Link cables, the regenerated energy is distributed among them. This spreads

the energy spikes over several shunts and enables the application to continue normal operation,

and avoid overvoltage interruptions.

28

Figure 9: The Tambourine 20's External DC Link Option

Caution: Tambourine 20 1 and Tambourine 20 2 must have an identical voltage

rating.

|Mounting and Wiring the Tambourine 20|www.elmomc.com

Page 29

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.5 Heat Dissipation

For full power output capability the Tambourine 20 is designed to be mounted on an external heatsink. It is highly recommended that the “Wall” on which the Tambourine 20 is mounted will have

heat dissipation capabilities. The Tambourine 20 at “free air convection” (without an additional

heat-sink) can dissipate around 12 W for 40°C ambient temperature and not exceeding 85 °C on the

heat sink.

When “Free Air Convection” is sufficient for the application it is recommended to leave

approximately 10 mm of space between the Tambourine 20's heat sink and any other assembly.

When attaching to an external heat-sink, it is recommended to use N5-N7 surface treatment and

thermal foil or smearing thermal compound.

3.5.1 Tambourine 20 Thermal Data

• Free air convection thermal resistance (θ): Approximately 5 to 6°C/W.

• Thermal time constant: Approximately 20 minutes/ 1200 seconds (thermal time constant

means that the Tambourine 20 will reach 2/3 of its final temperature after 20 minutes).

29

• Self-heat dissipation capability (no external heat sink): 12 W for 40°C/W temperature rise.

• The thermal resistance when connecting to an external heat sink using a thermal conductive

compound/foil. By proper smearing of the surface a significant improvement of the thermal

resistance is achieved: 0.03°C/W.

3.5.2 Heat Dissipation Data

Heat Dissipation is shown graphically below:

Figure 10: Dissipation versus Current Graph

|Heat Dissipation|www.elmomc.com

Page 30

Tambourine 20 Power Supply Installation Guide

Table of Contents

MAN-TAMIG (Ver . 1.501)

3.5.3 How to Use the Charts

The charts above are based upon theoretical worst-case conditions. Actual test results show 30% to

50% better power dissipation.

To determine if your application needs a heat sink:

1. Allow maximum heat sink temperature to be 85 °C or less.

2. Determine the ambient operating temperature of the Tambourine 20 as ≤ 40°C.

3. Calculate the allowable temperature increase according to the following example: For an

ambient temperature of 40 °C, ΔT = 85 to 40°C = 45°C

4. Use the chart to find the actual dissipation power of the drive. Follow the curve to the desired

output current and then find the dissipated power.

30

|Heat Dissipation|www.elmomc.com

Page 31

Tambourine 20 Power Supply Installation Guide

Table of Contents

Chapter 4:

Initialization

MAN-TAMIG (Ver . 1.501)

31

4.1 LED Diagnostics

Figure 11: Power LED Indicators

The following indication LEDs are mounted on the front panel of the Tambourine 20 (Figure 11):

LED Color Indication

POWER Green Internal supply presence

SHUNT ON Red Shunt is on (blinks whenever the shunt is activated)

FAULT Red Shunt is inhibited due to:

A DC bus level that is higher than the shunt

threshold point

A duty cycle limitation

Wait a couple of minutes to exit the fault state.

The LED will switch OFF. Then reinitialize the system.

|LED Diagnostics|www.elmomc.com

Loading...

Loading...