Elgin Pelican P, Pelican P Series Operator's Manual

Pelican® P

OPERATORS MANUAL

PELICAN®SERIES P

OPERATORS MANUAL

Sweeper Serial Number_____________________________

Elgin Sweeper Company

Subsidiary of Federal Signal Corporation

1300 W. Bartlett Rd.

Elgin, IL 6012-

847-741-5370

P/N 0701450-E

Printed in U.S.A. Copyright 2007 Elgin Sweeper Company

Welcome to the World’s Most Popular

Three-Wheel Broom Sweeper -

The Elgin Pelican®Series P

i

Read this manual carefully and completely before operating the sweeper. Working with unfamiliar equipment

can lead to accidents. Understand and follow all safety

information when operating the sweeper.

Elgin employees carefully inspected the sweeper before

it left the factory. Your Elgin equipment dealer inspected the sweeper and made certain that it was in proper

working order prior to delivery.

To keep the Pelican sweeper in good working condition,

it is important to follow all maintenance and service

schedules, including

DAILY SERVICE - After every shift or 10 hours

PERIODIC SERVICE - After each period of 50, 150,

500 or 1000 hours

Refer to the maintenance schedule in the Maintenance

Section. This schedule is also displayed on the sweeper.

Keep this manual in the cab of the sweeper for reference. If a problem develops with the sweeper, your

Elgin Dealer has the factory-trained service personnel,

genuine Elgin parts and necessary tools and equipment

to meet your specific needs.

If you should need to contact the factory regarding

operation, maintenance or repair, please feel free to call

Elgin at 847-741-5370.

This manual will assist in the proper operation and care of the Elgin Pelican Series P Sweeper. It contains specific

information on features and specifications, suggested operating techniques, preventive maintenance hints and

instructions for making repairs and adjustments.

ii

LIMITED WARRANTY

Each machine manufactured by ELGIN SWEEPER COMPANY (“ESCO” or the

“Company”) is warranted against defects in material and workmanship for a

period of 12 months provided the machine is used in a normal and reasonable

manner. This limited warranty is applicable only to the original user-purchaser

for a period of twelve (12) months (as measured from the date of delivery to the

original user-purchaser) and is not transferable.

During the Limited Warranty Period ESCO will cause to be repaired or replaced, as the Company may elect, any part or parts

of such machine that the Company’s examination discloses to be defective in material or workmanship. Repairs or replacements

are to be made at the selling Elgin distributor’s location or at other locations approved by ESCO.

The ESCO Limited Warranty shall not apply to:

1. Major components or trade accessories such as, but not limited to, trucks, engines, hydraulic pumps and motors, tires and

batteries that have a separate warranty by the original manufacturer.

2. Normal adjustments and maintenance services.

3. Normal wear parts such as, but not limited to, brooms, oils, fluids, filters, broom wire, shoe runners, rubber deflectors and

suction hoses.

4. Failures resulting from the machine being operated in a manner or for a purpose not recommended by ESCO.

5. Repairs, modifications or alterations without the express written consent of ESCO, which, in the Company’s sole judgment,

have adversely affected the machine’s stability, operation or reliability as originally designed and manufactured.

6. Items subjected to misuse, negligence, accident or improper maintenance.

iii

R

Subsidiary of Federal Signal Corporation

*NOTE* The use in the product of any part other than parts approved by ESCO may invalidate this warranty. ESCO reserves

the right to determine, in its sole discretion, if the use of non-approved parts operates to invalidate the warranty. Nothing contained in this warrant shall make ESCO liable for loss, injury or damage of any kind to any person or entity resulting from any

defect or failure in the machine.

TO THE EXTENT LIMITED BY LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

This warranty is also in lieu of all other obligations or liabilities on the part of ESCO, including but not limited to, liability for

incidental and consequential damages on the part of the Company or the seller. ESCO makes no representation that the

machine has the capacity to perform any functions other than as contained in the Company’s written literature, catalogs or

specifications accompanying delivery of the machine. No person or affiliated company representative is authorized to alter the

terms of this warranty, to give any other warranties or to assume any other liability on behalf of ESCO in connection with the

sale, servicing or repair of any machine manufactured by the Company.

ESCO reserves the right to make design changes or improvements in its products without imposing any obligation upon itself to

change or improve previously manufactured products.

ELGIN SWEEPER COMPANY, 1300 West Bartlett Road, Elgin, Illinois 60120, U.S.A.

iv

Safety

General ................................................................. S-1

Pelican P Safety Labels ....................................... S-9

Description

Elgin Pelican Series P Sweeper.......................... D-1

Principles of Operation

Why Sweep? .................................................. D-2

Mechanical/Broom Sweepers........................ D-2

Pelican ........................................................... D-2

Water Spray................................................... D-2

Brooms........................................................... D-3

Conveyor ........................................................ D-3

Hopper ........................................................... D-4

Cab ................................................................. D-4

Controls ......................................................... D-5

Drive Wheels ................................................. D-5

Guide Wheel .................................................. D-6

General Data ....................................................... D-7

Pelican P Side View............................................. D-9

Pelican P Front View......................................... D-10

Pelican P Rear View.......................................... D-10

Operation

Instruments and Controls................................... O-1

Operating Checklist ............................................ O-6

Starting the Engine............................................. O-8

Cold Weather Starting .........................................O-9

Transport............................................................ O-10

Sweeping ............................................................ O-12

Sweeping Patterns............................................. O-16

Reversing the Conveyor .................................... O-18

Dumping the Hopper......................................... O-19

Shutting Down the Unit ................................... O-21

At End of Shift....................................................O-21

Maintenance

Scheduled Maintenance.......................................M-1

Daily Service Checklist ................................ M-1

Periodic Service Checklist.............................M-2

After 50 Hours ....................................... M-2

After 150 Hours ..................................... M-2

After 500 Hours ..................................... M-3

After 1000 Hours ................................... M-3

Daily Washdown ................................................. M-7

v

Table of Contents

Bubble Window Maintenance ............................ M-9

Lubrication .........................................................M-10

Service Procedures

Towing ...............................................................SP-1

Air Cleaner......................................................... SP-3

Fuel System ....................................................... SP-5

Draining Fuel Water Separator ................. SP-5

Changing Fuel Filter .................................. SP-7

Bleeding Fuel System ................................. SP-8

Hydraulic System .............................................. SP-8

Spray Water System.......................................... SP-9

Broom Adjustment........................................... SP-10

Side Broom Adjustment .............................SP-11

Side-To-Side Angle .............................. SP-11

Front-To-Back Angle........................... SP-11

Down Pressure.................................... SP-12

Main Broom Adjustment ...........................SP-13

Standard (Chain) Suspension............ SP-13

Hydraulic Suspension ........................ SP-13

Dirt Shoe Adjustment...................................... SP-14

Dirt Deflectors ................................................. SP-15

Conveyor........................................................... SP-16

Conveyor Access .........................................SP-16

Adjusting Conveyor................................... SP-18

Conveyor Belt Adjustments ................SP-18

Other Conveyor Adjustments..............SP-22

Replacing Conveyor Belt............................SP-25

Removing Conveyor Belt ...................SP-025

Squaring Conveyor Structure .............SP-26

Structure Stop Bolt Adjustment .........SP-27

Lower Roll Offset Adjustment.............SP-27

Installing Conveyor Belt .....................SP-28

Splicing Conveyor Belt...............................SP-29

Reversing Conveyor ...................................SP-30

Main Broom Replacement................................SP-32

Cab Air Filter ................................................... SP-34

Wheels And Tires............................................. SP-34

Winter Storage................................................. SP-34

Spring Startup ................................................. SP-36

Troubleshooting .......................................................T-1

Glossary .....................................................................G-1

vi

RECOGNIZE SAFETY

INFORMATION

This is the safety-alert symbol. When you

see this symbol on your machine or in this

manual, be alert to the potential for personal

injury.

Follow recommended precautions and safe

operating practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or

CAUTION – is used with the safety-alert symbol. DANGER identifies the most serious hazards.

This symbol and these signal words appear on

the machine and in the operator’s manual.

Read and understand the following definitions

of the signal words before operating or working on the machine.

DANGER

DANGER is used to

indicate the presence of a hazard which will

cause severe personal injury, death, if the

warning is ignored.

WARNING

WARNING is used to

indicate the presence of a hazard which can

cause severe personal injury or death, if the

warning is ignored.

CAUTION

CAUTION is used to

indicate the presence of a hazard which will or

can cause minor personal injury, if the warning is ignored.

NOTICE

NOTICE indicates installation, operation, or maintenance information

which is important but not hazard-related.

!

SAFETY

S-1

SAFETY INFORMATION

!

!

!

CALIFORNIA PROPOSITION 65

WARNING

Please note this warning and remember:

• Always start and operate the engine in a

well-ventilated area;

• If in an enclosed area, vent the exhaust to

the outside;

• Do not modify or tamper with the exhaust

system.

FOLLOW SAFETY

INSTRUCTIONS

Carefully read all safety messages in this

manual and on your machine safety signs.

Keep safety signs in good

condition. Replace missing or

damaged safety signs. Be sure

new equipment components

and repair parts include the

current safety signs.

Replacement safety signs are

available from your Elgin

Sweeper dealer.

Learn how to operate the machine and how to

use controls properly. Do not let anyone operate the machine without instruction.

Keep your machine in proper working condition. Unauthorized modifications to the

machine may impair function and/or safety

and affect machine life.

If you do not understand any part of this manual and need assistance, contact your Elgin

Sweeper dealer.

SAFETY

S-2

CALIFORNIA

PROPOSITION 65 WARNING

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects and other reproductive harm.

WEAR APPROPRIATE

CLOTHING/PROTECTION

Wear close fitting clothing and safety equipment appropriate to the job. Exercise caution

with anything that could be caught in the

machinery, such as jewelry and long hair.

Operating equipment safely requires the full

attention of the operator. Do not wear radio or

music headphones while operating the

machine. Use caution while using a cellular

telephone while operating the equipment.

Always wear appropriate protection to meet

any applicable industry standard or regulations.

DRIVING THE SWEEPER

Operate the sweeper only when all guards are

fitted and in their correct position.

Before moving the machine, check the immediate vicinity of the machine for bystanders. Use

the horn as a warning immediately before

moving the machine.

For speeds over 25 mph (40 km/h), the sweeper

must be operated from the primary driving

position (left-hand or right-hand) that is standard in the country where you are driving.

Operating at these speeds from the other driving position can result in severe injury or

property damage. While the driver is changing

driving position, the sweeper must be stopped

with the gearshift in neutral and the parking

brake applied.

HANDLE FUEL SAFELY —

AVOID FIRES

Handle fuel with care. It is highly

flammable. Do not refuel the

machine while smoking or when

near open flame or sparks.

SAFETY

S-3

Always stop the engines before refueling the

machine. Fill the fuel tank outdoors.

Prevent fires by keeping the machine clean of

trash, grease, and debris. Always clean up

spilled fuel.

AVOID CONTACT WITH

MOVING PARTS

Everyone must be clear of the

sweeper before the engine is started and before the brooms are

started.

Many moving parts, such as the

side brooms, cannot be completely

shielded, due to their function.

Stay clear of these moving elements during operation.

Keep hands, feet, and clothing away from

power driven parts.

AVOID MACHINE INSTABILITY

Parking brake must be set before raising or

tilting the hopper.

If applicable, make sure the hopper door is

open before the hopper is raised or tilted.

Raise or tilt the hopper only when the sweeper

is parked on firm, level surfaces.

Lower the hopper to transport position before

moving the machine.

PARK SWEEPER SAFELY

Set the parking brake, turn off the engine,

and remove the keys.

Be sure the hopper is down before leaving

the sweeper.

SAFETY

S-4

AVOID OVERLOADS

Observe the maximum permissible

axle loads and total weights.

AVOID ELECTRICAL POWER

LINES

Do not raise the hopper while under

power lines.

Do not raise the hopper while under

trees, bridges, etc.

Lower the hopper to transport position before

moving the machine.

PRACTICE SAFE

MAINTENANCE/REPAIRS

Keep the area clean and dry. Remove any

build-up of grease, oil, or debris.

Never lubricate or service the machine while it

is moving. Keep all parts in good condition and

properly installed. Fix damage immediately.

Replace worn or broken parts.

Make sure all maintenance and repairs are

completed by qualified and authorized personnel. All applicable industry standards and

practices and regulations must be followed

during maintenance and repairs.

Make sure the parking brake is set, before you

do any work on the sweeper.

SAFETY

S-5

PREVENT BATTERY

EXPLOSIONS

Battery gas can explode. Keep

sparks and flames away from

batteries. If battery electrolyte

level must be checked, use an

electric light.

Never check battery charge by placing a metal

object across the posts. Use a voltmeter or

hydrometer.

Always remove the grounded (–) battery cable

first and connect it last.

Do not charge a frozen battery; it may explode.

Warm the battery to 60° F (16 °C).

AVOID OVERLOADING

ELECTRICAL SYSTEM

Before modifying, adding, removing,

etc. any electrical/electronic component(s), verify that the circuitry and

components do not overload the electrical system.

Contact your Elgin Sweeper dealer, if you have

any questions or need assistance.

SAFETY

S-6

AVOID HIGH PRESSURE

FLUIDS

Escaping fluid under

pressure can penetrate

the skin, causing serious injury. Avoid the

hazard by relieving

pressure before disconnecting hydraulic or

other high pressure

lines. Tighten all connections before applying

pressure. Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids. If accident occurs, seek immediate

medical attention.

Keep hands and body away from pinholes and

nozzles which eject fluids under high pressure.

USE PROPER TOOLS

Use tools appropriate

to the work. Makeshift tools and procedures can create safety hazards.

Use power tools only to loosen threaded parts

and fasteners.

For loosening and tightening hardware, use

the correct size tools. DO NOT use U.S. measurement tools on metric fasteners, or vice

versa. Avoid bodily injury caused by slipping

wrenches.

Use only service parts meeting Elgin Sweeper

specifications.

SAFETY

S-7

TIRES AND RIMS

An inflated tire and rim can be very dangerous

if improperly used, serviced or maintained. To

avoid serious injury, never attempt to reinflate a tire which has been run flat or seriously underinflated without first breaking

down the tire and wheel assembly for inspection. Do not attempt to add air to tires or

replace tires or wheels without first taking

precautions to protect persons and property.

For details see the regulations of the

Occupational Safety and Health

Administration (OSHA).

Never use a ring or other rim parts of different

manufacture or any different size or type than

original rims.

OBSERVE ENVIRONMENTAL

PROTECTION REGULATIONS

Be mindful of the environment and ecology.

Before draining any fluids,

find out the correct way to

dispose of them.

Observe the relevant environmental protection

regulations when disposing of oil, fuel, coolant,

brake fluid, filters, and batteries.

SAFETY

S-8

SAFETY

S-9

R

!

CAUTION

Towing with hubs

engaged will damage

hydrostatic drive.

Max. tow speed not to

exceed 20 MPH.

Set park brake, Remove

2 bolts & reverse cap

for disengagement at both

hubs. Release park brake

before towing vehicle.

No Step

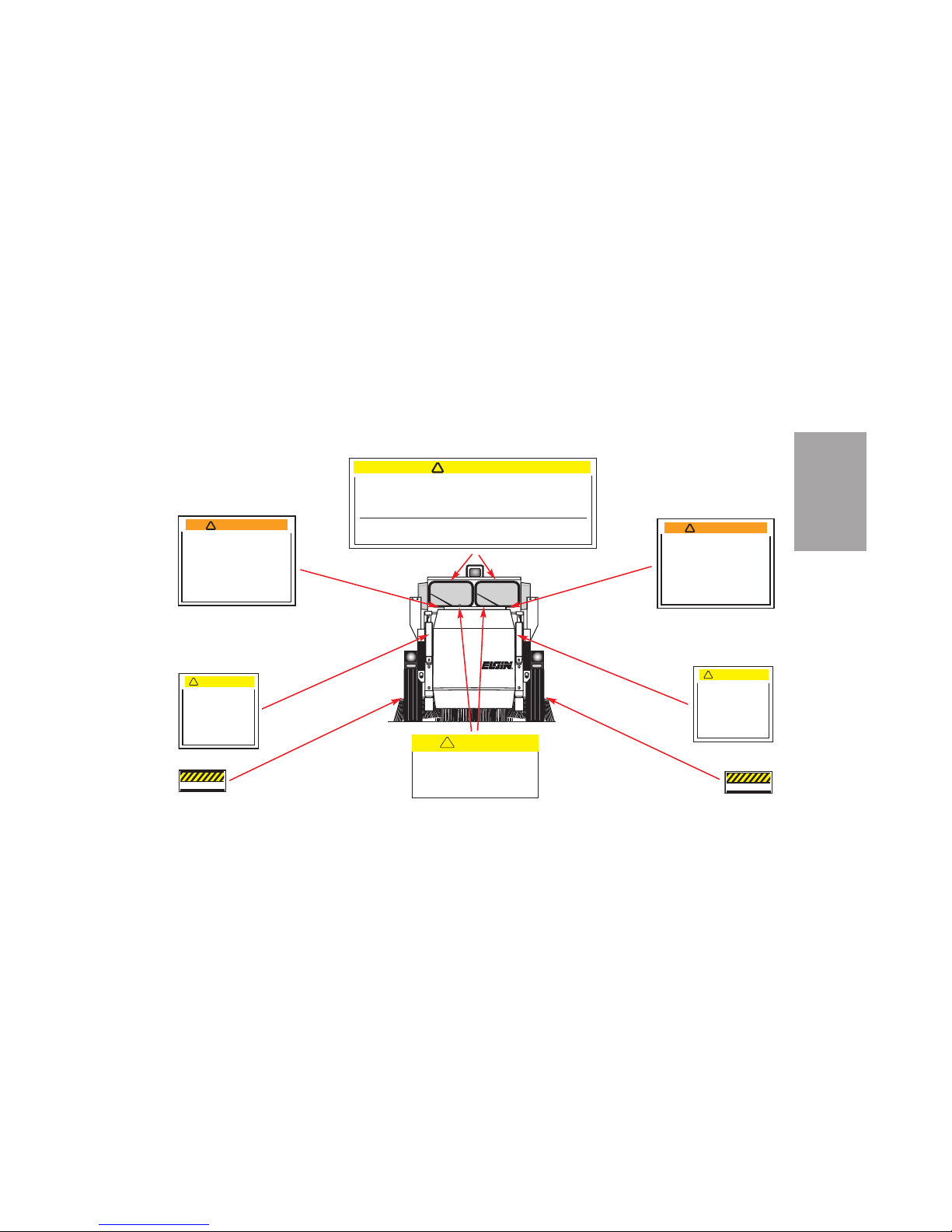

PELICAN P SAFETY LABELS - PART ONE

The operator may not be able to see

directly in front of machine, and operating

with people in front of sweeper can cause

severe injury or death.

Ensure that area in front of machine is clear

before and while moving forward. Properly

adjust front 6" round convex mirrors before

operating and monitor them for people

outside of your direct field of vision.

Refer to Elgin Sweeper Tech Tip #0713074

WARNING

!

The operator may not be able to see

directly in front of machine, and operating

with people in front of sweeper can cause

severe injury or death.

Ensure that area in front of machine is clear

before and while moving forward. Properly

adjust front 6" round convex mirrors before

operating and monitor them for people

outside of your direct field of vision.

Refer to Elgin Sweeper Tech Tip #0713074

WARNING

!

!

CAUTION

Towing with hubs

engaged will damage

hydrostatic drive.

Max. tow speed not to

exceed 20 MPH.

Set park brake, Remove

2 bolts & reverse cap

for disengagement at both

hubs. Release park brake

before towing vehicle.

No Step

CAUTION

!

Before operating this machine,

read the operator’s manual

and operator’s instructions on the

sun visor.

!

CAUTION

Turning both steering wheels

at the same time will damage

the steering system.

Use only one wheel to steer at

any time.

Exceeding 2500 + 50 RPM

can damage the hydrostatic

drive system.

Do not exceed the

recommended 2500 RPM

engine speed.

Overloading the hopper can

cause personal injury or

damage to the sweeper.

To avoid possible injury or

property damage, read the

operator's manual before

using this machine.

Refer to maintenance chart

for daily and scheduled

servicing.

Maintenance and repairs

must be done by authorized

personnel only.

Dump hopper frequently when

loading heavy materials.

(At sun

visors)

(Inside

the cab)

(Inside

the cab)

(Inside

the cab)

SAFETY

S-10

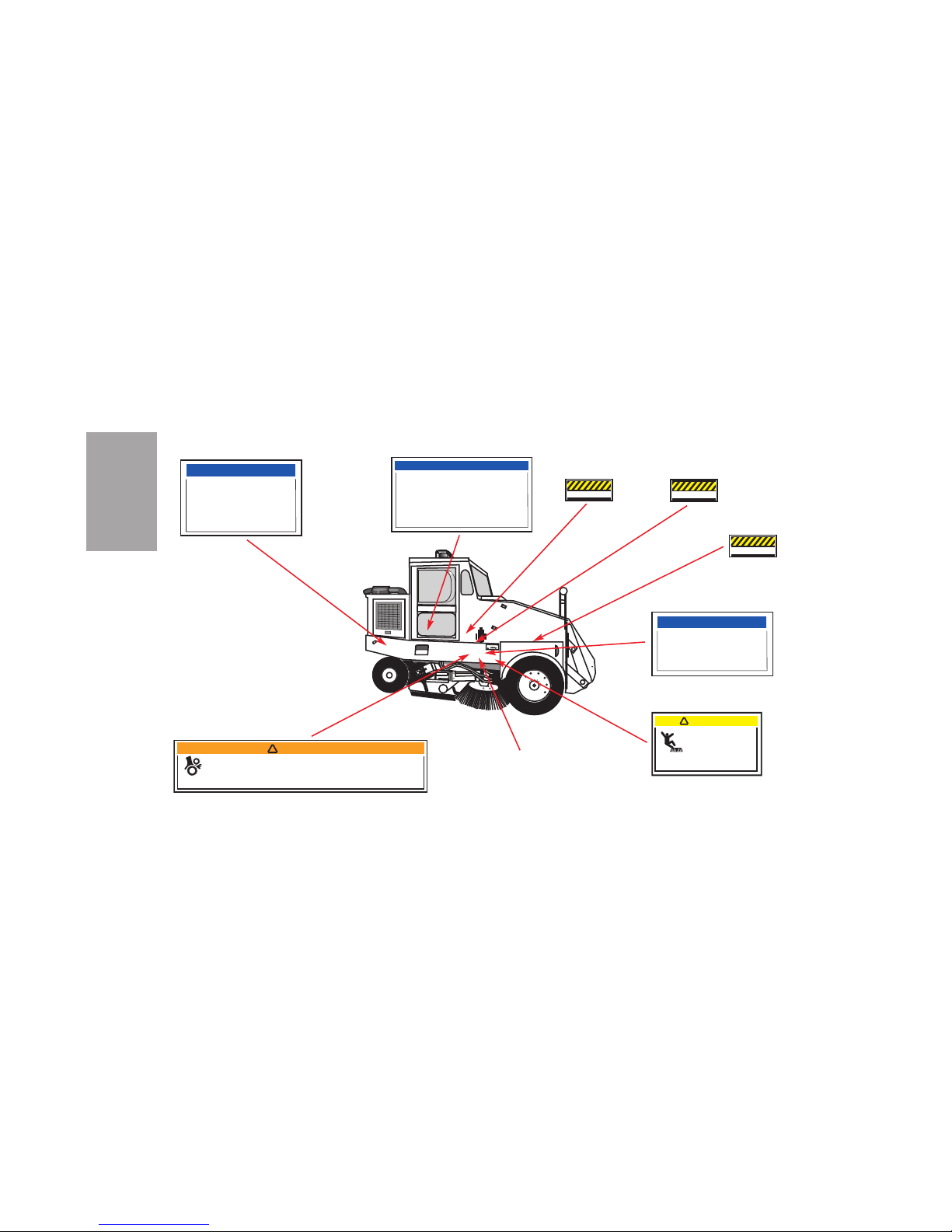

PELICAN P SAFETY LABELS - PART TWO

NOTICE

Tire Inflation Data

Front:

10:00-20 Load Range F (Tube)

10:00-20 Load Range G (Tube)

11R22.5 Load Range G (Tubeless)

Rear:

8.25-15 Load Range F (Tube)

7.50-15 Load Range H (Tube)

9R17.5HC Load Range H (Tubeless)

Maximum Rim Pressure (Tube)

Maximum Rim Pressure (Tubeless)

Maintenance Chart

on inner surface of

RH cover

No Step

No Step

No Step

Rotating Broom.

Can cause personal

injury.

Do not step on side broom

while rotating or at rest.

CAUTION

!

NOTICE

Replace the guide wheel pivot pin

(1001729) when servicing the guide

wheel assembly as a result of impact

damage. (Examples of impact damage

might be, but not limited to: Bent rim,

tire damage, axle damage, etc.)

Contact Elgin dealer with any questions.

NOTICE

Replace the guide wheel pivot pin

(1001729) on a 5000 hr interval, or

every 5 years (whichever occurs first),

or when servicing the guide wheel as

a result of impact damage.

Moving Parts.

Contact can cause

severe injury.

To avoid possible injury or property damage,

read the operator's manual before using this machine.

Maintenance and repairs must be done by authorized

personnel only.

Do not attempt repairs or

go underneath machine

with engine(s) running.

Use extreme care when

making checks or

adjustments that require

the engine(s) to be running.

WARNING

!

(On base

of seat)

(Behind RH cover)

(On inner surface

of RH cover)

(On both sides of

dual sweeper only)

(On both sides

of sweeper)

(On both sides

of sweeper)

(On both sides of

dual sweeper only)

SAFETY

S-11

R

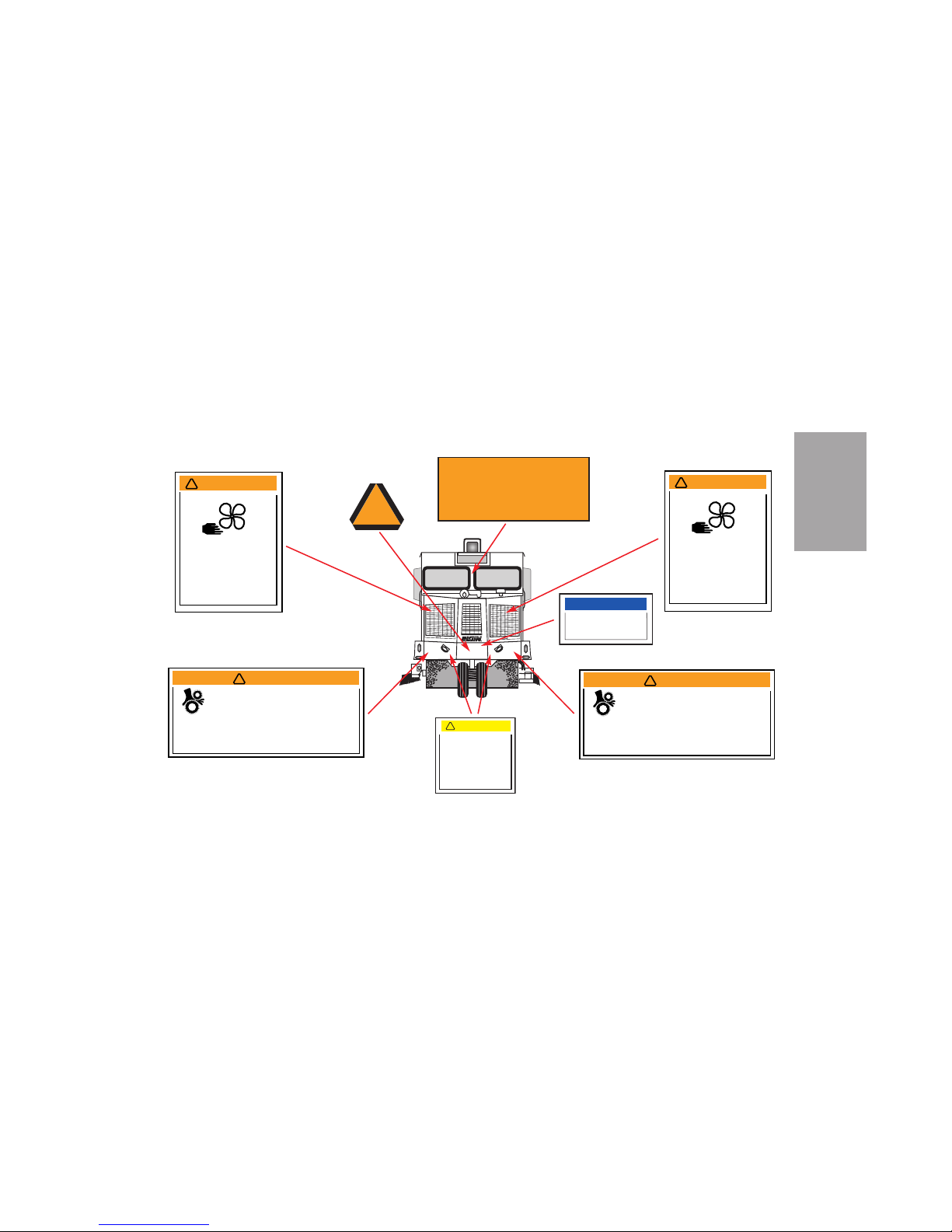

PELICAN P SAFETY LABELS - PART THREE

Moving Parts.

Contact can cause

severe injury.

To avoid possible injury or property damage,

read the operator's manual before using this machine.

Maintenance and repairs must be done by authorized

personnel only.

Do not attempt repairs or

go underneath machine

with engine(s) running.

Use extreme care when

making checks or

adjustments that require

the engine(s) to be running.

WARNING

!

Moving Parts.

Contact can cause

severe injury.

To avoid possible injury or property damage,

read the operator's manual before using this machine.

Maintenance and repairs must be done by authorized

personnel only.

Do not attempt repairs or

go underneath machine

with engine(s) running.

Use extreme care when

making checks or

adjustments that require

the engine(s) to be running.

WARNING

!

!

CAUTION

Towing with hubs

engaged will damage

hydrostatic drive.

Max. tow speed not to

exceed 20 MPH.

Set park brake, Remove

2 bolts & reverse cap

for disengagement at both

hubs. Release park brake

before towing vehicle.

Rotating Fan.

Can cause severe injury.

Keep clear of fan at all

times. Disconnect battery

before servicing.

WARNING

!

Rotating Fan.

Can cause severe injury.

Keep clear of fan at all

times. Disconnect battery

before servicing.

WARNING

!

WARNING

THIS VEHICLE IS EQUPPED WITH A

BACKUP ALARM

ALARM MUST SOUND WHEN BACKING

IT IS THE DRIVER'S RESPONSIBILITY

TO OPERATE THIS VEHICLE SAFELY

BE SURE BACKUP ALARM IS OPERATING

NOTICE

Lubricate sprung guide wheel

strut daily with lithium base

grease #2.

Slow Moving

Vehicle

(Inside

cab)

(At radiator)

(At radiator)

SAFETY

S-12

ELGIN

PELICAN

®

Series P

Sweeper

efficiently cleans

large, paved

areas, such as

streets and parking lots. It can be

equipped with a

broom on each side

to increase total

sweeping path.

Side brooms also

help to bring

debris out of the

gutter and onto

the conveyor.

D-1

DESCRIPTION

DESCRIPTION

WHY SWEEP?

Street sweeping is an essential part of sanitation.

In health, ecology and aesthetics, the community

benefits from clean streets. Clean streets reduce

dust and dust-borne contaminants, bacteria from

decomposition of organic matter, pollutants entering stormwater systems and accidents due to debris

in the roadway. Community pride is enhanced by a

clean environment. People are less likely to litter in

a clean area. Tourists have a positive first impression of the community, which may encourage them

to stay longer and return more often.

MECHANICAL/BROOM SWEEPERS

Mechanical, or broom, sweepers remove debris by

sweeping it onto a conveyor. The conveyor carries

the debris to a hopper. The No-Jam™ hopper conveyor of Elgin Pelican was originally patented. This

revolutionary design sweeps debris up onto the conveyor, eliminating the problems of jamming.

PELICAN

The Pelican is the world’s most popular sweeper.

This three-wheel design is flexible enough to get

into tight corners and around parked cars, yet

capable of picking up large objects, such as branches, hub caps and bottles. When the hopper is full,

the Pelican hopper dumps straight ahead into a

dump truck or onto the ground. This straight ahead

approach uses only one lane, to avoid blocking traffic.

WATER SPRAY

A water spray system controls dust during sweeping. Nozzles spray water at the front edge of each

side broom to moisten the dust being swept by the

brooms.

DESCRIPTION

D-2

PRINCIPLES OF OPERATION

The amount of water is adjustable through use of a

knob inside the cab. A 180-gallon (681 L) water

tank is standard on the Pelican P, with an optional

40-gallon (151 L) tank available.

BROOMS

Hydraulically-driven brooms sweep the debris on

the street onto the conveyor. The main broom is

located behind the lower edge of the conveyor and

directs the debris toward the conveyor. Side brooms

are available on both the right and left sides. For

sweeping these are lowered and rotated to move

gutter debris to the conveyor.

The pattern that the brooms produce when the

sweeper is stationary is a tool to evaluate the most

efficient positioning of the brooms. The brooms can

be adjusted to produce the best pattern and result.

CONVEYOR

The heavy-duty, multi-ply reinforced No Jam™

debris conveyor (Figure D-1) transports debris

D-3

DESCRIPTION

Pelican P conveyor system

Figure D-1

deposited on it by the main broom to the hopper.

Speed is in-cab controlled for variable forward and

reverse.

Pavement contact is maintained by rubber dirt

shoes on the sides and rubber deflectors under the

chassis.

HOPPER

Debris is collected in the 3.5 yd3(2.7 m3) volumetric capacity hopper. The forward dumping hopper

allows dumping to occur using only one lane of traffic. The dumping height is variable up to 9 ft 6 in.

(2895 mm).

After dumping the hopper should be washed down

for maximum efficiency and long life.

CAB

Visibility is a full 360° in the cab of the Pelican P

(Figure D-2). The bubble windows on each door, a

full-width windshield and rear windows allow the

operator to see everything that is happening while

sweeping.

DESCRIPTION

D-4

360° Visibility

Figure D-2

CONTROLS

All sweeping functions, including brooms and hopper, are powered through in-cab controls (Figure D-

3), located comfortably within reach.

For a complete description of all controls, see the

Operations Section.

DRIVE WHEELS

The Pelican P features a unique wheel motor

design (Figure D-4) to provide power to handle all

road conditions include steep grades. Sensors

adjust the power required according to the load.

D-5

DESCRIPTION

Pelican P in-cab controls

Figure D-3

Drive Wheel Motor

Figure D-4

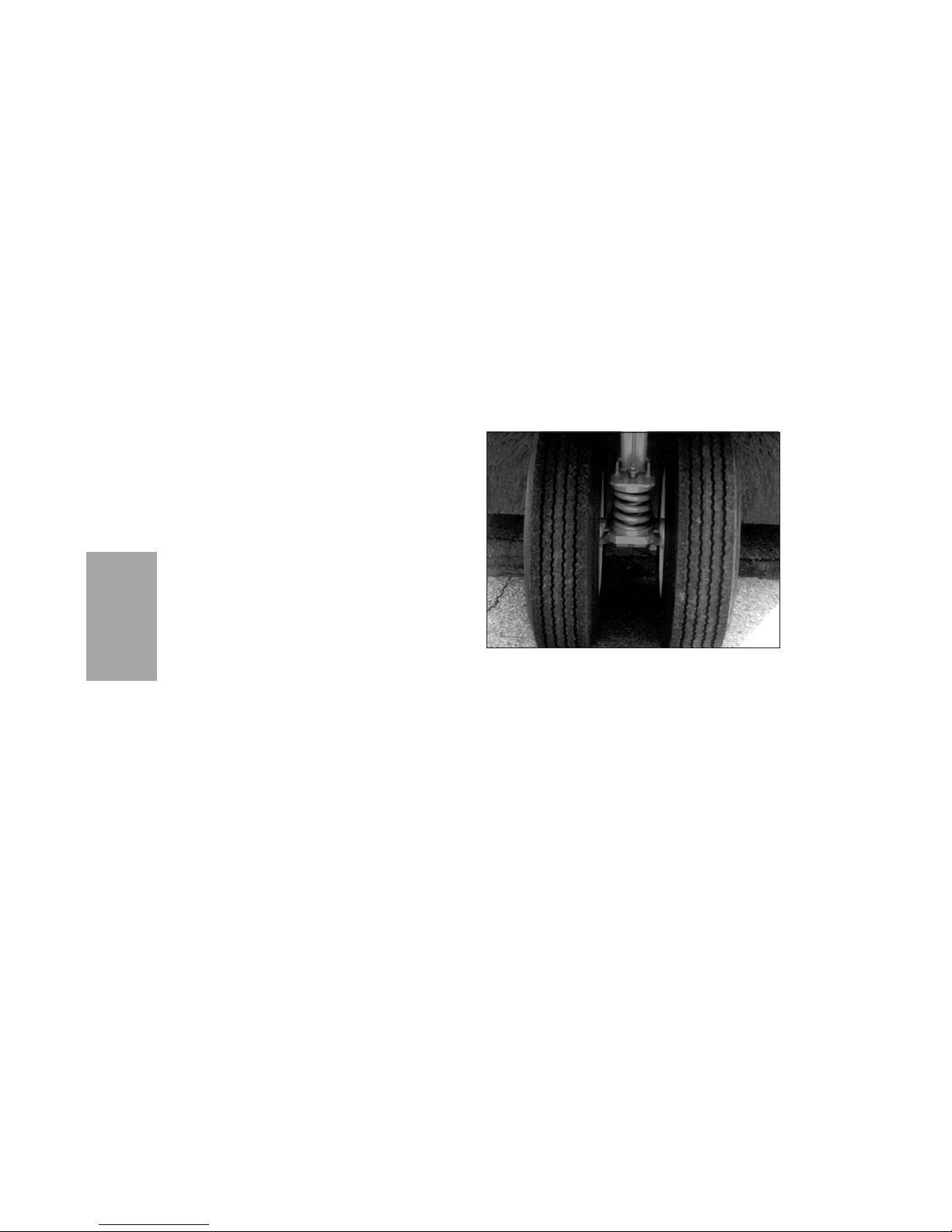

GUIDE WHEEL

The rear, dual-tire, guide wheel (Figure D-5) allows

superior maneuverability to get around parked cars

and tight corners.

An optional sprung guide wheel increases operator

comfort and decreases stress on the sweeper. The 4spring suspension absorbs shock and is especially

important in areas with a number of potholes.

DESCRIPTION

D-6

Optional Sprung Guide Wheel

Figure D-5

General Specifications

Wheel base .......................127.4 in (3236 mm)

Overall length ..............15 ft 10 in (4826 mm)

Overall height ..................9 ft 7 in (2921 mm)

Overall width ...................8 ft 6 in (2591 mm)

Turning radius (sweeping)....15 ft (4572 mm)

Brooms

Side broom diameter ..............36 in (914 mm)

Main broom diameter.............35 in (889 mm)

Main broom length ...............66 in (1676 mm)

Hydraulic system

Pump ...........................Variable displacement

Motor............................Variable displacement

Filter, return....................10 micron, full-flow

with bypass

Reservoir capacity.....................28 gal (106 L)

Refill capacity.........................35 gal (132.5 L)

Conveyor

Type ........Multiple ply reinforced rubber belt

Speed ....................Variable with engine RPM

Fuel tank capacity

Standard.................................35 gal (132.5 L)

Water system

Tank capacity..........................180 gal (681 L)

Filter .....................................100 mesh screen

Spray nozzles Atomizing, adjacent to

each broom

Fill hose length............16 ft 8 in (5.1 m) with

coupling

Washdown.................Integral cascade hopper

/conveyor wash

Pump ...............Centrifugal, 5 GPM (19 LPM)

at 40 PSI (2.8 bar)

D-7

DESCRIPTION

GENERAL DATA

DESCRIPTION

D-8

Sweeping paths

One side broom........................8 ft (2438 mm)

Two side brooms................... 10 ft (3048 mm)

Debris Hopper

Maximum dump height............Up to 9 ft 6 in

(2895 mm)

Dumping clearance height....16 ft (4877 mm)

Design lift capacity ...........9,000 lb (4,080 kg)

Volumetric capacity.................3.5 yd

3

(2.7 m3)

Material volume .........................3 yd3(2.3 m3)

Engine

John Deere Diesel 4045TF150

Cylinders ........................................................4

Displacement ............................276 in

3

(4.5 L)

Horsepower.......99 HP (74 kW) at 2500 RPM

Torque .........274 lb-ft (372 Nm) at 1400 RPM

Compression Ratio ....................................17:1

Bore .................................4.19 in (106.43 mm)

Stroke .....................................5.0 in (127 mm)

Electrical system

Alternator...........................105 amp standard

Battery.................12 volt, group 31, 925 CCA

Tires

Front ...................................11R22.5 14 ply (2)

Rear ......................................9R17.5 16 ply (2)

Loading...

Loading...