Page 1

MOTION DETECTOR KIT

MODEL AK-510

Copyright © 2013, 1994 by ELENCO®Electronics, Inc. All rights reserved. Revised 2011 REV-P 753010

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

ELENCO

®

Assembly and Instruction Manual

Page 2

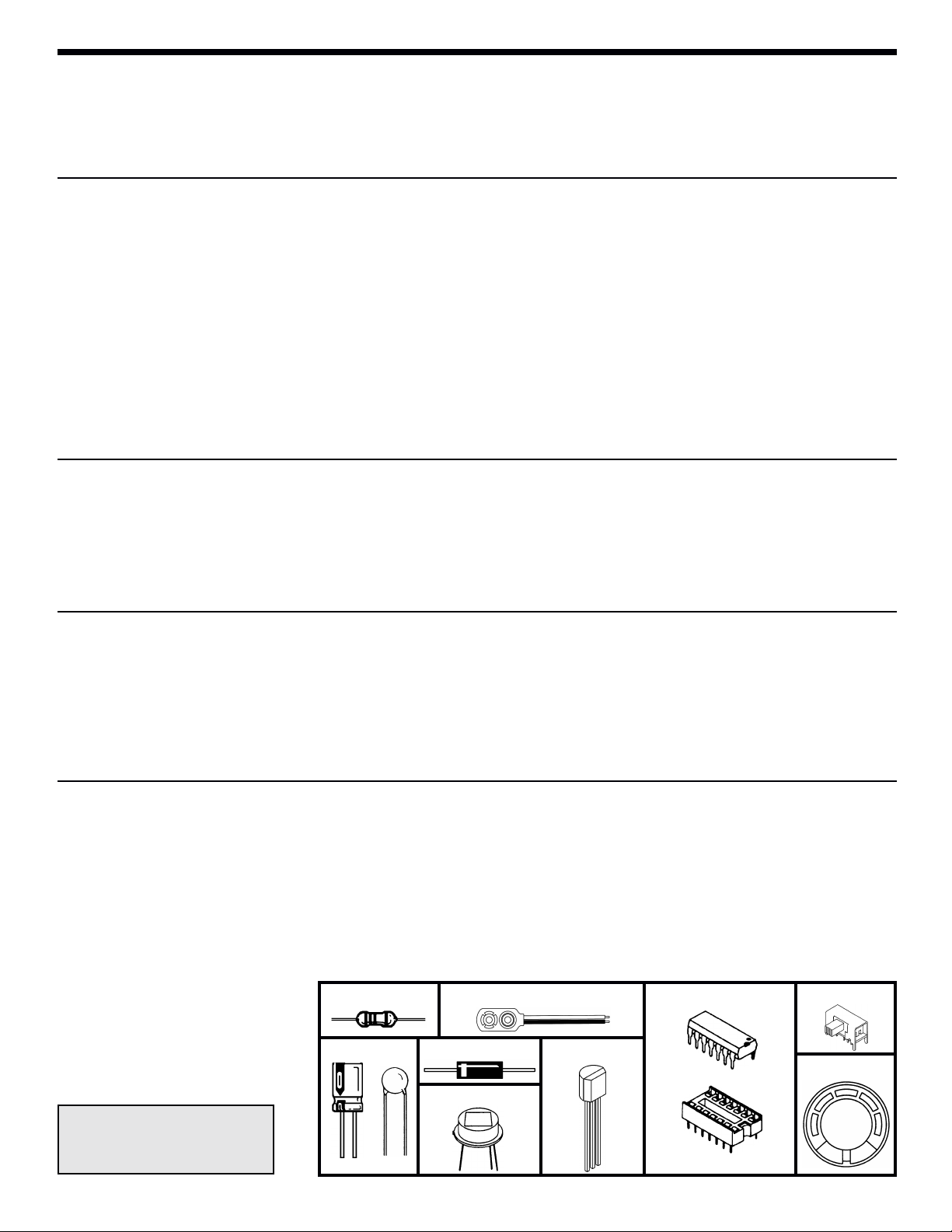

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact ELENCO®(address/phone/e-mail is at

the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase as they

will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

! 1 R16 300Ω 5% 1/4W orange-black-brown-gold 133000

! 1 R15 5.6kΩ 5% 1/4W green-blue-red-gold 145600

! 1 R5 39kΩ 5% 1/4W orange-white-orange-gold 153900

! 4 R1, 2, 8, 9 47kΩ 5% 1/4W yellow-violet-orange-gold 154700

! 1 R3 75kΩ 5% 1/4W violet-green-orange-gold 157500

! 1 R6 120kΩ 5% 1/4W brown-red-yellow-gold 161200

! 1 R14 270kΩ 5% 1/4W red-violet-yellow-gold 162700

! 2 R11, R12 300kΩ 5% 1/4W orange-black-yellow-gold 163000

! 1 R13 470kΩ 5% 1/4W yellow-violet-yellow-gold 164700

! 1 R10 510kΩ 5% 1/4W green-brown-yellow-gold 165100

! 1 R7 1.2MΩ 5% 1/4W brown-red-green-gold 171200

! 1 R4 1.6MΩ 5% 1/4W brown-blue-green-gold 171600

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C8 470pF (471) Discap 224717

! 1 C9 .01µF (103) Discap 241031

! 2 C2, C3 10µF 25V Electrolytic (lytic) 271045

! 2 C4, C5 22µF 25V Electrolytic (lytic) 272245

! 2 C1, C6 100µF 16V Electrolytic (lytic) 281044

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 D1 1N4148 Diode 314148

! 1 Q1 MPSA18 Transistor NPN 320018

! 1 IC1 LM324 Integrated circuit 330324

! 1 IC2 HT2812G Integrated circuit 332812

! 1 IC3 78L05 Integrated circuit 338L05

! 1 S1 LHI-954 / KDS245 Infrared detector 350954

MISCELLANEOUS

Qty. Description Part #

! 1 PC board 517019

! 1 Speaker w/ wires 520813

! 1 Switch key 540105

! 1 SW1 - slide switch 541007

! 1 Battery snap 590098

! 1 Front cover 623104

! 1 Back cover 623202

! 1 Mounting bracket 626004

Qty. Description Part #

! 1 Battery cover 626005

! 2 Screw #4 x 1/4” 642430

! 2 Screw #4 x 5/8” 643450

! 2 Washer #4 (fiber) 645404

! 1 Socket IC 8-Pin 664008

! 1 Socket IC 14-Pin 664014

! 1 Solder lead-free 9LF99

Note:

The text printed on

the LHI-954 Infrared

Detector is the date code.

Resistor Battery Snap

Capacitor

PARTS

IDENTIFICATION

Electrolytic

Transistor

Integrated Circuit

Discap

Diode

Infrared Detector

Integrated

Circuit

Socket

Speaker

Switch

-1-

Page 3

-2-

Warning:

If the capacitor is

connected with

incorrect polarity, it

may heat up and

either leak, or

cause the capacitor

to explode.

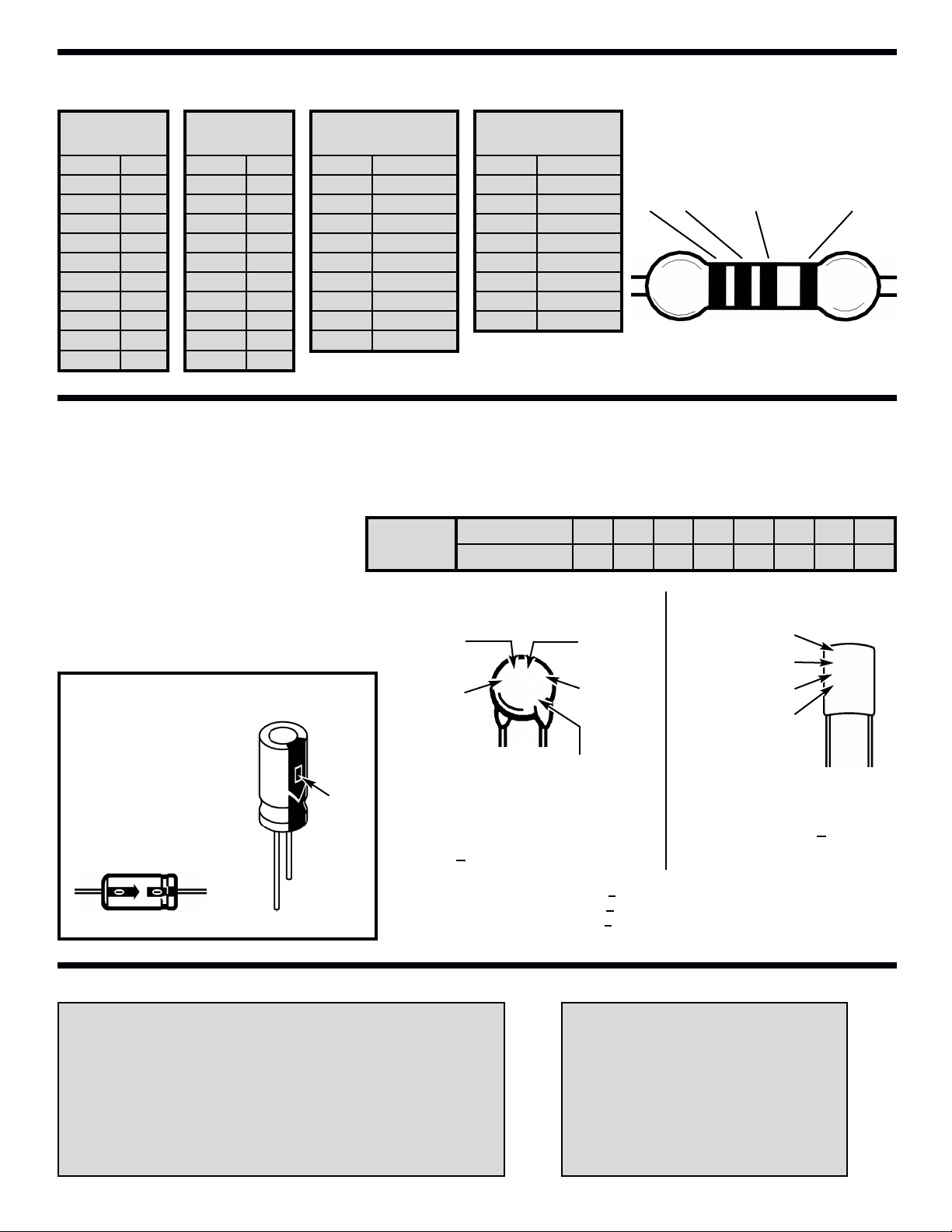

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BANDS

METRIC UNITS AND CONVERSIONS

Abbreviation Means Multiply Unit By Or

p Pico .000000000001 10

-12

n nano .000000001 10

-9

µ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1. 1,000 pico units = 1 nano unit

2. 1,000 nano units = 1 micro unit

3. 1,000 micro units = 1 milli unit

4. 1,000 milli units = 1 unit

5. 1,000 units = 1 kilo unit

6. 1,000 kilo units = 1 mega unit

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or µF (microfarads).

Most capacitors will have their actual value printed on them. Some capacitors may have their value printed in

the following manner. The maximum operating voltage may also be printed on the capacitor.

Electrolytic capacitors have a positive

and a negative electrode. The

negative lead is indicated on the

packaging by a stripe with minus

signs and possibly arrowheads. Also,

the negative lead of a radial

electrolytic is shorter than the positive

one.

Polarity

marking

BAND 1

1st Digit

Color Digit

Black 0

Brown

1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tole r ance

Color Toler ance

Silver ±10%

Gold ±5%

Brown ±1%

Red ±2%

Orange ±3%

Green ±0.5%

Blue ±0.25%

Violet ±0.1%

1

2 Multiplier Tolerance

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k 100k .01 0.1

(+)

(–)

(+)

(–)

Axial

Radial

Second digit

First digit

Multiplier

Tolerance*

Note: The letter “R” may be used at times

to signify a decimal point; as in 3R3 = 3.3

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +10%

The letter J indicates a tolerance of +5%

Maximum working voltage

(may or may not appear

on the cap)

The value is 10 x 10 =

100pF, +10%, 50V

*

CERAMIC DISC MYLAR

First digit

Second digit

Multiplier

Tolerance*

2A222J

100V

The value is 22 x 100 =

2,200pF or .0022µF, +5%, 100V

101K

50V

Page 4

-3-

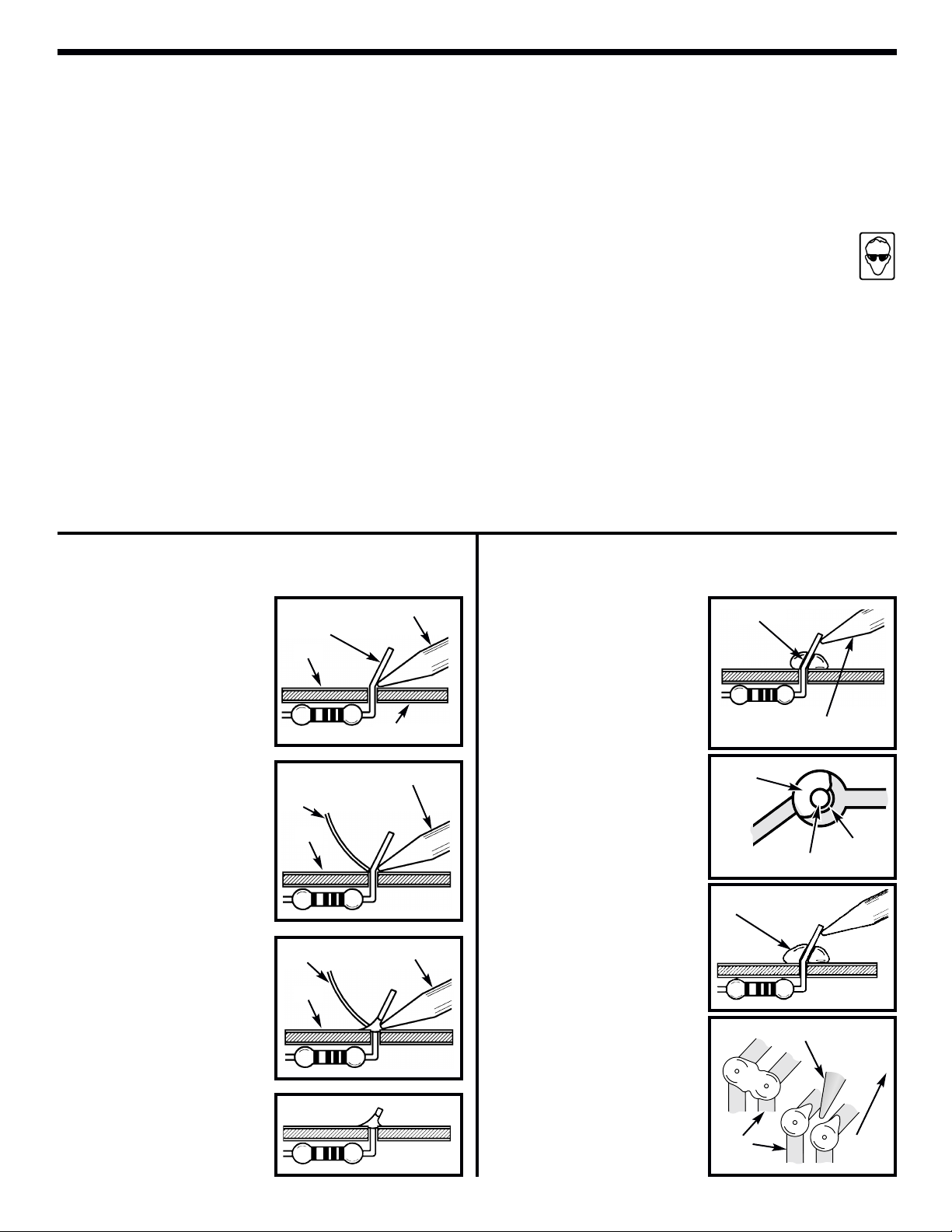

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allows the heat

to leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too

much solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Introduction

The most important factor in assembling your AK-510 Motion Detector

Kit is good soldering techniques. Using the proper soldering iron is of

prime importance. A small pencil type soldering iron of 25 watts is

recommended. The tip of the iron must be kept clean at all times

and well-tinned.

Solder

For many years leaded solder was the most common type of solder

used by the electronics industry, but it is now being replaced by leadfree solder for health reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting

point than lead solder, so you need higher temperature for the solder to

flow properly. Recommended tip temperature is approximately 700OF;

higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results.

Soldering iron tips wear out faster since lead-free solders are more

corrosive and the higher soldering temperatures accelerate corrosion,

so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when

using lead-free solder:

● Keep the iron tinned at all times.

● Use the correct tip size for best heat transfer. The conical tip is the

most commonly used.

● Turn off iron when not in use or reduce temperature setting when

using a soldering station.

●

Tips should be cleaned frequently to remove oxidation before it becomes

impossible to remove. Use Dry Tip Cleaner (Elenco®#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to clean your tip, then use

distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

● Always wear safety glasses or safety goggles to

protect your eyes when working with tools or

soldering iron, and during all phases of testing.

● Be sure there is adequate ventilation when soldering.

●

Locate soldering iron in an area where you do not have to go around

it or reach over it. Keep it in a safe area away from the reach of

children.

● Do not hold solder in your mouth. Solder is a toxic substance.

Wash hands thoroughly after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed

on the top side of the PC board unless otherwise indicated. The top

legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

Page 5

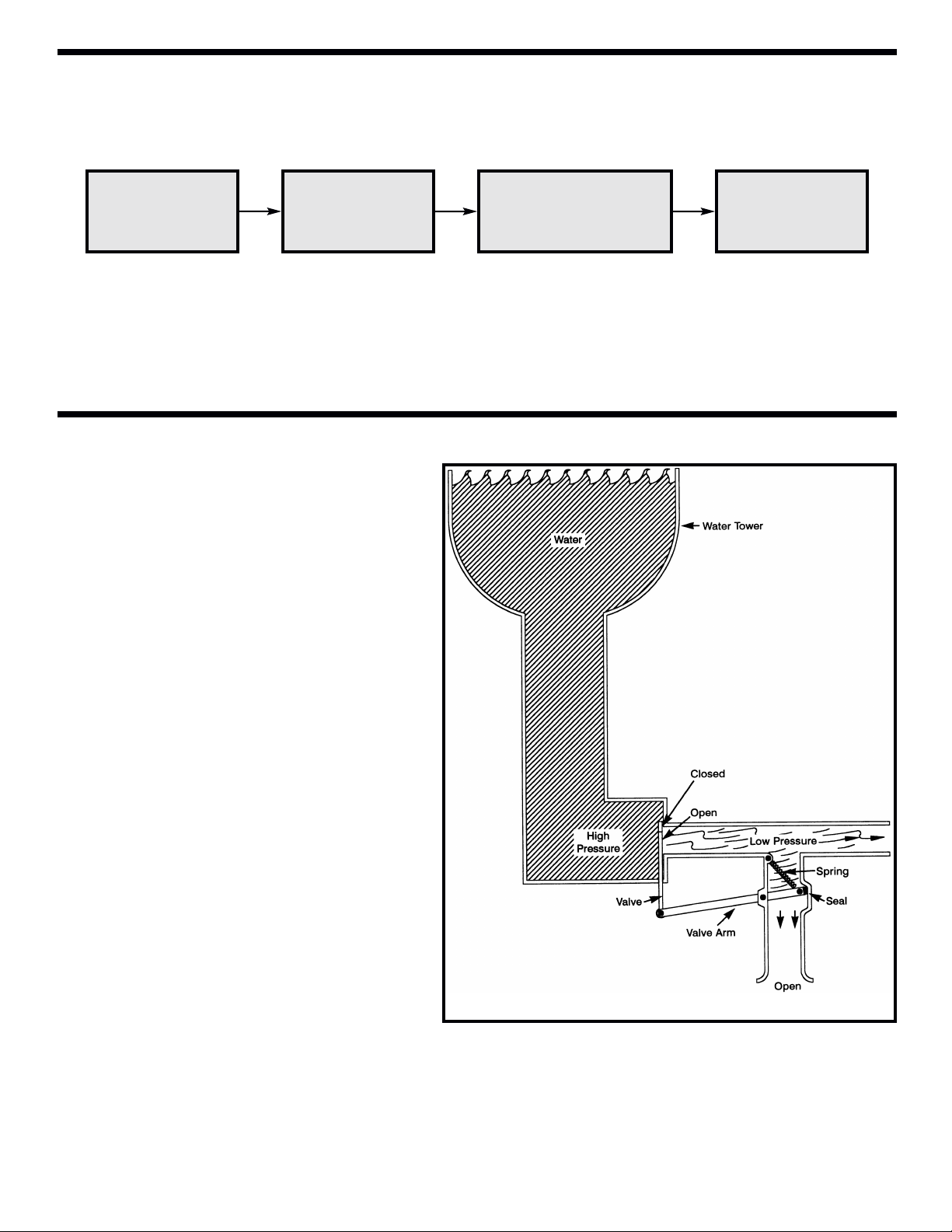

INTRODUCTION

The AK-510 is an infrared motion detector kit. The objective of the kit is to teach the operations of the four

sections that make up the kit. The four sections are shown in the block diagram below.

There are many applications for the use of the detector. The most common is in the alarm system industry.

Some of the new applications are automatic door openers, light switches in hallways, stairways and areas that

increase safety for the public. Further applications can be seen in automatic production lines, switching of

sanitary facilities, monitors and intercoms. With the ease of installation and the low suspectibility to interference

from other forms of radiation, such as heaters or windows, the IR detectors are ideal devices.

POWER SUPPLY (see page 16)

A 9 volt battery is used to supply the DC voltage to

the circuit. The battery voltage must be regulated

(held as close as possible) to 5 volts. This is done by

circuits called voltage regulators.

In order to see how this is accomplished, let’s

consider the analogy of a water tower. Voltage in

electronics can be compared to water pressure in

a water system. When water is pumped into a

water tower, the pressure at the bottom of the

tower can be quite high. In order to keep a

constant pressure in the water pipes that go to the

houses, the pressure must be lowered and held

constant.

Consider the system shown in Figure 1. As people

draw water into their homes, the pressure on the

low pressure side of the valve drops. The spring

pulls the valve arm inside the pipe up along

opening the valve and allowing more water into

the pipe. As the pressure on the low pressure side

increases, it pushes the valve arm inside the pipe

down closing the valve and stretching the spring.

By increasing the spring pressure on the arm, the

pressure on the low side will have to increase to

close the valve. The force or pressure of the

spring, therefore sets the value of the pressure on

the low pressure side of the system. The force of

the spring is called the reference pressure.

Voltage in electronics is the analogy to pressure in water pipes. A voltage greater than 7V is applied to the

input of high voltage side of the regulator. A fixed reference voltage inside the regulator will set the low voltage

output at 5 volts +5%. This is accomplished in a manner very similar to our water tower analogy. The output

voltage is filtered or made smooth (no ripples) by capacitor C6 (100µF).

POWER

SUPPLY

TONE

GENERATOR

INFRARED

DETECTOR

OPERATIONAL

AMPLIFIERS

FILTERS

-4-

Figure 1

Page 6

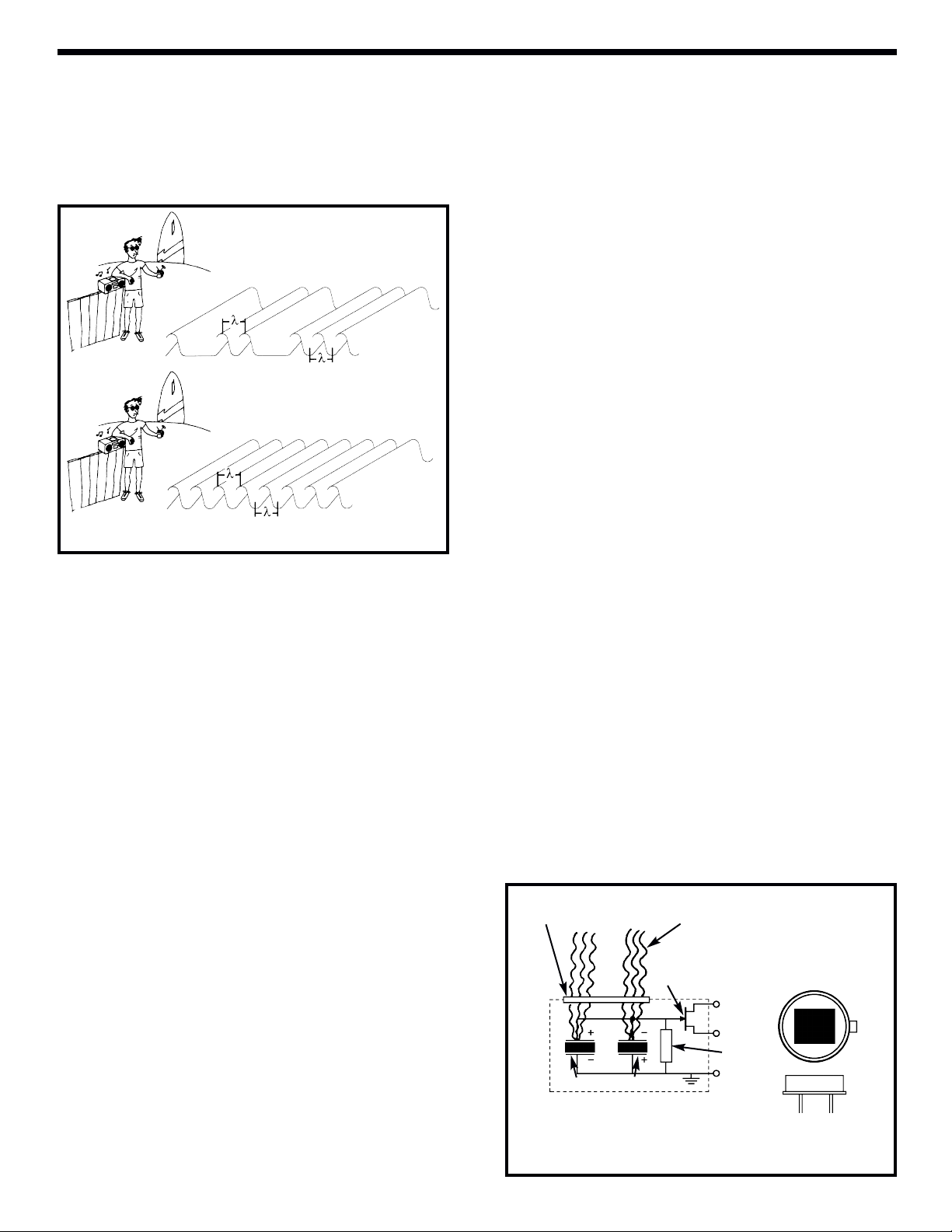

INFRARED DETECTOR

Infrared light was first discovered back in 1801 by W.

Herschel. Infrared is a form of radiated energy in

which the wavelength is longer than the wavelength

of visible light. A wavelength can best be understood

by the physical analogy shown in Figure 2.

If you were standing at the beach watching the

waves come in to shore, you would be able to see

the peaks of each wave as they approached. If you

could measure the distance from one peak to the

next, you would know the “Wavelength” of those

waves. We will use the eleventh letter of the Greek

alphabet “λ” (lambda) to represent the distance

between valleys to determine the length of the wave

(see Figure 2). A wavelength can be defined as the

distance between any two exactly equal points on

identically repeating waves.

What would happen if we reduced the distance

between the peaks to 1/2 the original distance.

Would it not be true, the peaks would strike the

shore twice as often as before? The frequency of

the peaks reaching the shore would be twice that of

the longer wave. For people who like big words, we

would say “Frequency is inversely proportional to

the wavelength”. In simple words, “If the wavelength

goes up, the frequency goes down and if the

wavelength goes down, the frequency goes up”.

The mathematics of waves applies also to the

radiation of light. It is common practice, therefore,

to talk about light as lightwaves. The wavelength of

infrared light ranges from 0.78 micrometers (µm) to

100 (µm). A micrometer is one millionth of a meter.

Infrared can be thought of as heat radiation

because the radiant energy is transformed into heat

when it strikes a solid surface. All solid bodies at a

temperature above absolute zero emit thermal

radiation. As a body’s temperature rises, the shorter

the resulting wavelengths become. The human

body’s maximum thermal radiation is between 9µm

and 10µm in the infrared stage. Motion can be

detected by special elements which are highly

sensitive in the infrared range. Such devices are

called Pyroelectric Infrared Detectors.

PYROELECTRIC EFFECT

When certain materials change temperature, they

produce electricity. A Pyroelectric crystal is an

example of such a material. If a Pyroelectric crystal

has been at the same temperature for a period of

time, there will be no voltage across it’s electrodes.

When the crystal temperature changes, a voltage is

produced at the electrodes of the crystal element.

This type of crystal is used in this motion detector kit

inside the infrared (IR) detector.

INTERNAL DESIGN

The IR detector contains two crystals connected

with each other in opposite polarity and with a 1

millimeter (mm) optical spacing. These two crystals

are located behind an optical filter or lens (see

Figure 3). The output power of the crystals is very

low. A special device called the Field Effect

Transistor (FET) is used to increase the power

output. The FET can be compared to water pipes as

shown in Figure 4. The center of a small section of

pipe is made of thin, flexible rubber surrounded by

water from a third pipe called the gate. When

pressure (voltage) is applied to the gate, the rubber

tube closes and pinches off the flow of water

(current) from source to drain. In a similar manner,

as infrared radiation is detected, the crystals

produce a voltage at the gate

of the FET.

-5-

Figure 3

Figure 2

Infrared RaysOptical Filter

Gate

Drain

Source

Resistor

Ground

Crystals

Dual Element Detector Scheme

Page 7

This causes a change in current from the drain to

source. Very little power is required at the gate to

control the larger current flow from source to drain.

The benefits of this type of detector are low radio

interference, low noise, specially suited response.

The IR detector is sealed in a metal housing to

prevent electromagnetic interference and to keep

them clean.

FIELD OF VIEW

Detectors are available with different fields of view,

depending on the application. The maximum

distance and total angle of view are important

specifications needed in choosing a motion detector.

The LHI-954 field of view is shown in Figure 5.

CIRCUIT DESCRIPTION (see page 16)

The IR Section contains only a few components,

R1, R2, C1 and the PIR sensor. As motion is

detected, the IR detector will produce a voltage at

the gate of the FET allowing current to flow from the

drain to source, causing the voltage at the input of

U1 (pin 13) to change, thus changing the output at

pin 14. Resistors R1 and R2 limit the amount of

current flow through the FET.

-6-

An amplifier is a device that uses a small amount

of power to control a larger amount of power. Just

like a small amount of power on the valve arm of

Figure 1 controlled the water pressure in the pipes

going to the houses. The amplifier does not create

power (it was already there in the water tower) but

it controls the power from a source.

In electronics, amplifiers are composed of devices

called transistors, resistors, and capacitors. The

number of these components used and the way

they are assembled determines the characteristics

of the amplifier. An amplifier that can perform many

mathematical operations such as adding,

subtracting, or multiplying voltages is called an

Operational Amplifier or Op-Amp.

The characteristics of an ideal op-amp are the

following:

A. infinite voltage gain (no voltage at all on the

input controls, large voltage on the output).

B. infinite bandwidth (no matter how fast the input

changes, the output will change just as fast).

C. infinite input impedance (no power required at

input to change output).

D. zero output impedance (the output can deliver

an infinite amount of power).

Obviously, in the real world these conditions can

never be met, but for mathematical purposes they

are assumed in designing electronic circuits with

op-amps.

The op-amp has two input terminals, inverting input

(–) and non-inverting input (+), and one output

terminal. Figure 6 shows the standard op-amp

symbol. The two input terminals are labeled 2 and 3,

and the output is 1. Most op-amps operate with two

DC power supplies, +VCC and –VEE connect to pins

11 and 4 respectively. Since a single power supply

is used in the kit, –VEE (pin 4) is tied to ground. The

op-amp multiplies the difference between the

voltage signals applied at its two input terminals

(V3-V2) times the gain of the amplifier (A). A x (V3V2) appears at the output terminal as shown in

Figure 7.

OPERATIONAL AMPLIFIERS / FILTERS

Figure 4

Gate

Drain

Source

FET Transistor

Horizontal

Figure 5

Vertical

56

O

56

O

46

O

46

O

Figure 6 Figure 7

Inverting

Input

Non-

Inverting

Input

2

3

4

11

1

Output

+Vcc

–VEE

2

3

4

11

1

Output

A (V3 - V2)

+Vcc

–VEE

V2

V3

Page 8

-7-

Figure 9

NEGATIVE FEEDBACK

The open loop gain (or maximum gain) of a typical

op-amp is very high (usually greater than 100,000),

enabling a very small input voltage to drive the opamp output to its extremes. To prevent this, a resistor

is connected between the output and inverting input

terminals allowing a portion of the output signal to be

brought back and cancel part of the input (Figure 8).

This process is called Negative Feedback. The signal

being fed back is out of phase with the input and thus

subtracts from the input signal. If the resistor was

connected between the non-inverting input and

output terminals, it would be called Positive

Feedback. The closed loop gain (or gain after

feedback) from the input Vito the output terminal

depends on the ratio of R2 to R1.

For example, if R2 = 100 and R1 = 10, the gain (G)

= R2/R1 = 100/10 = 10. Thus, the output voltage V

o

would be equal to –10(Vi). The (–) sign indicates that

the output and input voltages are of opposite polarity.

VOLTAGE COMPARATOR

Operational amplifiers can be used to compare the

amplitude of one voltage with another. As a

comparator, its function is to determine when an

input voltage exceeds a certain level. When used as

a comparator, the op-amp is used without feedback

and at maximum gain. One input is set to a

reference voltage and the other tied to the input

voltage.

Figure 8

LOW PASS FILTER

A low pass filter attenuates (decreases) all signals

above a certain frequency and passes frequencies

below that frequency. An example of a low pass filter

is a simple RC network as shown in Figure 9. Low

frequencies are passed unharmed. As the frequency

rises the output is reduced (see Figure 10).

HIGH PASS FILTER

The high pass filter attenuates frequencies below a

certain frequency and passes frequencies above that

frequency. An example of a high pass filter is a simple

RC network as shown in Figure 11. Low frequencies

are reduced when passed through the filter while high

are passed unharmed (see Figure 12).

FILTERS

Figure 10

Figure 11

Figure 12

R1

R2

V

i

2

3

1

V

o

Vo= –(R2/R1) V

i

OR

Vo= –G V

i

Page 9

-8-

Figure 15

Key

Output

BAND PASS FILTER

The combination of a low and high pass filter create

what is called a Band Pass Filter. The frequencies

passed by each filter overlap and create a bandwidth

(range), passing all signals within the bandwidth and

reducing all others. Figure 13 illustrates the general

band-pass response curve. A critical frequency is

defined as the point where the voltage is reduced to

0.707 (the square root of ½ is used because it

represents the point where power has been reduced

to ½). The bandwidth can be defined as the difference

between the upper critical frequency (fC2) and the

lower critical frequency fC1 (BW = fC2 - fC1). The

selectivity (or Quality) of a band-pass filter is

expressed as the “Q” of the filter.

It is the ratio of the center (or Resonant) frequency to

the bandwidth (Q = fr/BW). A filter with a higher value

of Q has a narrower bandwidth, thus passing fewer

frequencies than one with a lower value. Bandpass

filters can be classified as either a narrow-band (Q >

10) or a wide-band (Q < 10).

CIRCUIT DESCRIPTION (See page 16)

The op-amp IC1D shapes the frequency response

to amplify those frequencies produced when motion

is detected and rejects all others, such as those due

to noise or slow temperature changes. Frequencies

above 20Hz and below 1Hz are beyond the

bandwidth of the circuit and thus are rejected. The

output at pin 14 is about 1.6V when no motion is

detected. As motion is detected, the voltage at the

output will change and trigger either IC1C or IC1B.

The op-amps IC1A, IC1B and IC1C are configured

as voltage comparators. In the ready state, the

output of IC1A is high and IC1B and IC1C are low.

When IC1D outputs a voltage lower than 1.41V, it

will force pin 2 of IC1 high. When IC1D outputs a

voltage higher than 1.67V, it forces pin 8 and pin 2 of

IC1 to go high. A high in with one of these cases

causes the output to go low and allows C9 to

discharge through IC1A. The discharging of C9 will

pull pin 6 of IC2 low and trigger the sound generator.

Figure 13

The circuit uses the single sound generator HT2812G

IC. The HT2812G is a CMOS LSI chip designed for

use in sound effects products. Figure 14 shows the

internal design of the IC.

CIRCUIT DESCRIPTION (see page 16)

As the Key Input is brought low, the Oscillator, Speed

Generator, Tone Generator, Noise Generator and

Envelope Sections are all enabled. The Oscillator

Section begins to oscillate at a frequency determined

by the voltage across pins 7 and 8. This frequency is

then divided down and applied to the Speed

Generator. The Speed Generator controls the

frequency of the output as it is applied to the output

driver. The output consists of 15 pulses. Appling the

pulses to the base of transistor Q1, turns it on and off

rapidly, causing the speaker to sound. You can select

between a high and a low tone using switch SW1.

SOUND GENERATOR

Figure 14

Osc1

Osc2

Oscillator

Key

Key

Input

Logic

Selector

and

Envelope

Circuit

Divider

Speed

Generator

To ne

Generator

Noise

Generator

Output

Driver

Env

Output

Output

Gain

BW

100%

70.7%

fc1 fr fc2

f

Page 10

-9-

ASSEMBLE COMPONENTS TO THE PC BOARD

Note: C7 is not used in this kit.

Figure D

These capacitors are

polarized. Be sure to

mount them with the “+”

lead in the correct hole as

marked on the PC board.

Warning: If the capacitor

is connected with incorrect

polarity it may heat up and

either leak or cause the

capacitor to explode.

Figure B

Mount the device with the flat

side in the same direction as

shown on the PC board. Solder

and cut off the excess leads.

Figure C

Align the socket notch (if any)

with the notch marked on the

PC board.

Solder the socket to the PC

board. Insert the IC into the

socket with the notch as shown

below.

R2 - 47kΩ 5% 1/4W Resistor

(yellow-violet-orange-gold)

C2 - 10µF 25V Electrolytic

(see Figure D)

C4 - 22µF 25V Electrolytic

(see Figure D)

R5 - 39kΩ 5% 1/4W Resistor

(orange-white-orange-gold)

R3 - 75kΩ 5% 1/4W Resistor

(violet-green-orange-gold)

C8 - 470pF (471) Discap

D1 - 1N4148 Diode

(see Figure A)

R4 - 1.6MΩ 5% 1/4W Resistor

(brown-blue-green-gold)

(See Note)

R6 - 120kΩ 5% 1/4W Resistor

(brown-red-yellow-gold)

(See Note)

R9 - 47kΩ 5% 1/4W Resistor

(yellow-violet-orange-gold)

14-pin IC Socket

IC1 - LM324 Integrated Circuit

(see Figure C)

R12 - 300kΩ 5% 1/4W Resistor

(orange-black-yellow-gold)

R11 - 300kΩ 5% 1/4W Resistor

(orange-black-yellow-gold)

R10 - 510kΩ

5% 1/4W

Resistor

(green-brown-yellow-gold)

C9 - .01µF (103) Discap

C6 - 100µF 16V Electrolytic

(see Figure D)

IC3 - 78L05 Integrated Circuit

(see Figure B)

D2 - Use a Jumper Wire in

place of the diode.

C5 - 22µF 25V Electrolytic

(see Figure D)

Figure A

Diodes have polarity. Be sure to mount them with the band

going in the same direction as marked on the PC board.

Band

Polarity

marking

(–) (+)

Flat

Notch

Page 11

-10-

ASSEMBLE COMPONENTS (CONTINUED)

+

Inside Pads

Outside Pads

Note: The text printed

on the LHI-954

Infrared Detector is

the date code.

Figure E

Use a discarded lead for

a jumper wire.

Jumper Wire (see Figure E)

C1 - 100µF 16V Electrolytic

(see Figure D)

R1 - 47kΩ

5% 1/4W

Resistor

(yellow-violet-orange-gold)

C3 - 10µF 25V Electrolytic

(see Figure D)

R8 - 47kΩ

5% 1/4W

Resistor

(yellow-violet-orange-gold)

R7 - 1.2MΩ

5% 1/4W

Resistor

(brown-red-green-gold)

S1 - LHI-954

Infrared Detector

Mount with tab in the same direction as

marked on the PC board (see note below).

R14 - 270kΩ

5% 1/4W

Res.

(red-violet-yellow-gold)

R13 - 470kΩ

5% 1/4W

Resistor

(yellow-violet-yellow-gold)

SW1 - Slide Switch

R16 - 300Ω

5% 1/4W

Resistor

(orange-black-brown-gold)

8-pin IC Socket

IC2 - HT2812G

Integrated Circuit

(see Figure C)

Q1 - MPSA18 Transistor

(see Figure B)

R15 - 5.6kΩ 5% 1/4W Resistor

(green-blue-red-gold)

Speaker Wires - Solder the

two wires to the PC board

marked SPK +, –.

Note: If wires need resoldering;

1. First apply a small amount of

solder to the outside pad.

2. Solder the speaker wire to

the outside pads.

CAUTION: The internal

speaker wires are soldered to

the inside pads. DO NOT

unsolder these wires.

B1 - Battery Snap

Identify the battery snap B1. Insert the red and black wires

through the hole from the copper side of the PC board.

Insert the red wire into the (+) positive hole and the black

wire into the (–) negative hole as shown above.

Red

Black

–

Page 12

FINAL ASSEMBLY

-11-

! Step 1

Place the speaker into the front case as

shown in Figure 16. Use two #4 x 1/4”

screws and two #4 washers to secure it

into place.

! Step 2

Push the switch key onto the switch as

shown in Figure 17. Make sure that the

key-switch is sitting properly on the

switch.

! Step 3

Place the PC board into the front case

as shown in Figure 18. Attach the back

case to the front case with two #4 x 5/8”

screws. Note: There is a small groove

that the key switch fits into.

Figure 16

#4 x 1/4” Screws

#4 Washers

Figure 17

Switch Key

Figure 18

Page 13

-12-

! Step 4

Attach a 9V battery to the battery snap

and place it into the case. Snap the

battery cover into the back case as

shown in Figure 19.

Figure 19

Battery Cover

! Step 5

Place the unit onto a table and turn it on.

Move to one side of the detector so that

you are out of the field of view of the

detector. Walk in front of the detector and

a tone will sound from the speaker. The

unit is now ready for use.

Note: When the switch is in the OFF position, it disconnects the voltage to the

sound generator IC only. The rest of the circuit is still operating. The battery will

run down if it is left in the OFF position. To increase battery life, remove the

battery if you intend to leave the unit in the OFF position for long periods of time.

INSTALLATION

The detector can be either placed on a

flat surface or mounted onto a wall.

Adjust the angle lever to the open

position (see Figure 20). Align the two

taps on the bracket with the two grooves

on the case. Adjust for the desired angle

and move the angle lever to the lock

position.

Figure 20

Angle Lever

Open

Plastic Bracket

Angle Lever

Closed

Page 14

-13-

TROUBLESHOOTING GUIDE

The values given below are approximate.

POWER SUPPLY

1. Measure the voltage at IC3. Pin 3 = 9V, Pin 1 = 4.75 - 5.25V

A. Check soldering around IC3 and C6.

B. Check for short to GND from pins 2 and 3.

C. If no shorts are present, IC3 may be defective.

INFRARED DETECTOR

2. Measure the voltages at points: A = 5V

B = 4.25V

C = .700V

A. Voltage at point A incorrect:

1. Check R1.

2. Check for a short between point A and GND.

B. Voltage at point B incorrect:

1. Check R1, C1 for correct value.

2. Check for a short between point B and GND.

C. Voltage at point C incorrect:

1. Check R2, C2 for correct value.

2. Check for a short between point B and GND.

C

B A

OPERATIONAL AMPLIFIERS

3. Measure the voltages at IC1 while the unit is at standby.

Pin Voltage Pin Voltage

1 3.80V 8 –

2 – 9 1.62V

3 1.40V 10 1.60V

4 5.00V 11 –

5 1.40V 12 1.52V

6 1.60V 13 1.55V

7 – 14 1.50 - 1.60V

Page 15

-14-

4. Measure the voltages at IC1 when activated.

A. Incorrect voltage readings:

1. Check resistors R3 - R12 for correct value.

2. Check diode D1 polarity.

3. Check C3 and C4 polarity.

4. IC1 may be defective.

SOUND GENERATOR

Measure the voltage at the following pins on U2, as listed in the chart below.

A. No voltage at pin 3:

1. Check R13, R14, SW1 and C5.

B. No 5V at pin 5:

1. Check SW1 solder connection.

2. No 5V at pin 6.

3. Check C9.

C. Outputs two short tones:

1. Check C5.

Pin Voltage

1 0 - 3.8V

7 0 - 3.8V

8 0 - 3.8V

14 1.5 - 3.8V

U2 Voltage Voltage

Pin No Sound Sound

3 0 0 - 4V

5 5V 5V

6 5V

7 0V .735V

Q1 Voltage Voltage

Pin No Sound Sound

E 0 0V

B 0V .355V

C 9V 7 - 9V

Q1

E B C

Page 16

-15-

QUIZ

1. The 9V battery supplies a . . .

! A. positive AC voltage.

! B. DC voltage.

! C. AC voltage.

! D. rectified DC voltage.

2. A human’s maximum thermal radiation is between . . .

! A. 3 and 5µm.

! B. 9 and 13µm.

! C. 10 and 20µm.

! D. 9 and 10µm.

3. As temperature changes, the pyroelectric crystals generate . . .

! A. white light.

! B. infrared light.

! C. heat.

! D. a voltage.

4. A wavelength is the distance between two points having . . .

! A. opposite phases.

! B. two different phases.

! C. the same phase, but different voltages.

! D. the same phase and voltage.

5. Infrared can be thought of as heat radiation because the . . .

! A. electrical energy is transformed into heat.

! B. radiant energy is transformed into heat.

! C. mechanical energy is transformed into heat.

! D. solar energy is transformed into heat.

6. What are the two inputs called in an op-amp?

! A. non-inverting and inverting.

! B. V1 and V2.

! C. VEE and VCC.

! D. gates.

7. A high pass filter attenuates all signals . . .

! A. between two frequencies.

! B. below the critical frequency.

! C. above the critical frequency.

! D. with high amplitudes.

8. The formula for the closed loop gain is . . .

! A. (R2 x R1)Vo

! B. (R1/R2)Vi

! C. (R2/R1)Vo

! D. -(R2/R1)Vi

9. A low pass filter attenuates all signals . . .

! A. between two frequencies.

! B. below the critical frequency.

! C. above the critical frequency.

! D. with low amplitudes.

10. A filter with a high value in Q has a . . .

! A. wide bandwidth.

! B. narrow bandwidth.

! C. long bandwidth.

! D. attenuates less frequencies.

Answers: 1. B, 2. D, 3. D, 4. D, 5. B, 6. A, 7. B, 8. D, 9. C, 10. B

Page 17

-16-

SCHEMATIC DIAGRAM

Page 18

-17-

SPECIFICATIONS

Power

• 9V DC battery

Current

• Operating 60mA (average)

• Standby Typical less than 4mA

Detection

• Pyroelectric Infrared Sensor.

Detection Distance

• 10 feet max., best at 1’ to 6’

Output Sound

• High frequency / Low frequency tone (15-pulse siren)

• 85 - 90dB peak

Operating Range

• –10 to +50OC

GLOSSARY OF TERMS

Amplify To enlarge or increase.

Amplitude The greatest difference above a reference, usually zero.

Analogy Likeness or resemblance in relations of different objects.

Attenuate To weaken or reduce.

Bandwidth The group or number of frequencies unaffected by a filter.

Battery A device that generates an electric current through a chemical reaction.

Capacitors Devices that store electronic charges.

Circuit The entire line through which electric current may pass.

Closed Loop Gain Gain after feedback.

Comparator An electronic device to detect voltage differences.

Critical Frequency The frequency at which power in a filter falls to half.

Crystals An inorganic body with plane surfaces in a geometrical form.

Current The flow of electrons.

Detector A device that changes signals into useful information.

Electromagnetic A radiated wave having both electric and magnetic properties.

FET Field Effect Transistor.

Filter A device used to nullify certain waves without altering others.

Frequency The repeated occurance of anything at brief intervals.

Gain To increase or make larger.

Gate A device used to allow or restrict passage.

Generator A device that transforms energy into electric power or signals.

Impedance A device’s resistance to the passage of electrical current.

Infrared Light Rays past the red end of the visible light spectrum.

IR Detector A device that senses the presence of infrared light.

Kit A collection of equipment or components.

Lambda The eleventh letter of the Greek Alphabet.

Page 19

-18-

Low Pass Filter Decreases all signals above a certain frequency and passes frequencies below

that frequency.

Negative Feedback To allow a portion of the output signal to be brought back and cancel part of the

input.

Noise A random, persistent disturbance of a signal.

Open Loop Gain The maximum gain available without feedback.

Oscillator A device used to vary between alternate extremes (varies from high to low).

Peak The top of a wave or mountain.

Polarity The division of two opposites.

Power Electrical energy; strength, force, or might.

Pyroelectric Effect When certain metals change temperature, they produce energy.

RC Network An assembly of resistors and capacitors.

Reference Voltage Level of electronic element used for providing resistance in a circuit.

Resistor An electric element used for providing resistance in a circuit.

Response Curve The shape of an output produced by a circuit.

Solder An alloy (mixture) of tin and lead used in the melted state to join or repair metal

parts.

Transistor A three-terminal semiconductor device used for amplification, switching, and

detection.

Valve

A mechanical device that regulates the flow of gases, liquids, or loose materials by

blocking and uncovering openings.

Voltage An electromotive force.

Wavelength The distance in a periodic wave between 2 points of corresponding phases.\

For further information on infrared light and waves . . .

The Invisible World of the Infrared

By Jack R. White

New York: Dodd, Mead, © 1984

124 p.; ill.

Waves and Vibrations

By Brian Knapp

Danbury, CT: Grolier, © 1994

48 p.; ill.

Page 20

ELENCO

®

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Web site: www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...