Page 1

DIGITAL / ANALOG TRAINER

MODEL XK-700

A COMPLETE MINI-LAB FOR BUILDING, TESTING

AND PROTOTYPING ANALOG AND DIGITAL CIRCUITS

Instruction Manual

For Trainer with Organizer Case

Tools and meter not included.

Copyright © 2008, 1996 by Elenco®Electronics, Inc. All rights reserved. Revised 2008 REV-M 753028

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

Elenco®Electronics, Inc.

Page 2

-1-

INTRODUCTION

POWER SUPPLY

Model XK-700 has five built-in power supplies which

will satisfy most design needs. This includes two

variable power supplies giving up to +20 volts and

–20 volts at .5 amp. Below 15V the current available

is over 1 amp. Three fixed power supplies give you

+12VDC, –12VDC or +5VDC at 1 amp each. These

fixed voltages are the most commonly used

voltages for design work. All supplies are regulated

to within 150mV. This means that you can increase

the current draw from no load to .5 amp and the

voltage will change less than 150 millivolts. All

supplies are also short circuit protected by using

integrated circuit regulator devices.

The analog trainer contain a complete function

generator capable of producing sine, square and

triangle waveform. The frequency of this generator

is continuously variable from one hertz to over

100,000 hertz in five steps. A fine tuning control

makes selection of any frequency easy. The output

voltage amplitude is variable between 0 to 15Vpp.

The output impedance is approximately 330 ohms.

DIGITAL TRAINER SECTION

The digital trainer has the necessary functions to do

your digital designs. They consist of a clock

generator, two no bounce logic switches, 8 LED

indicator lamps and 8 data switches. These

functions will make it easy to do your digital

experiments.

Congratulations on your purchase of the Elenco

®

Model XK-700 Digital / Analog Trainer. This trainer

is designed to simplify designing of digital and

analog circuits. It contains most of the necessary

test equipment needed to build and test these

circuits.

Your XK-700 has four basic trainers in a single

package. They are, 5 independent power supplies,

an analog trainer, a digital and a bredblock

assembly trainer. We shall proceed in describing

each trainer in the following sections.

ANALOG TRAINER SECTION

FUNCTION GENERATOR

Page 3

-2-

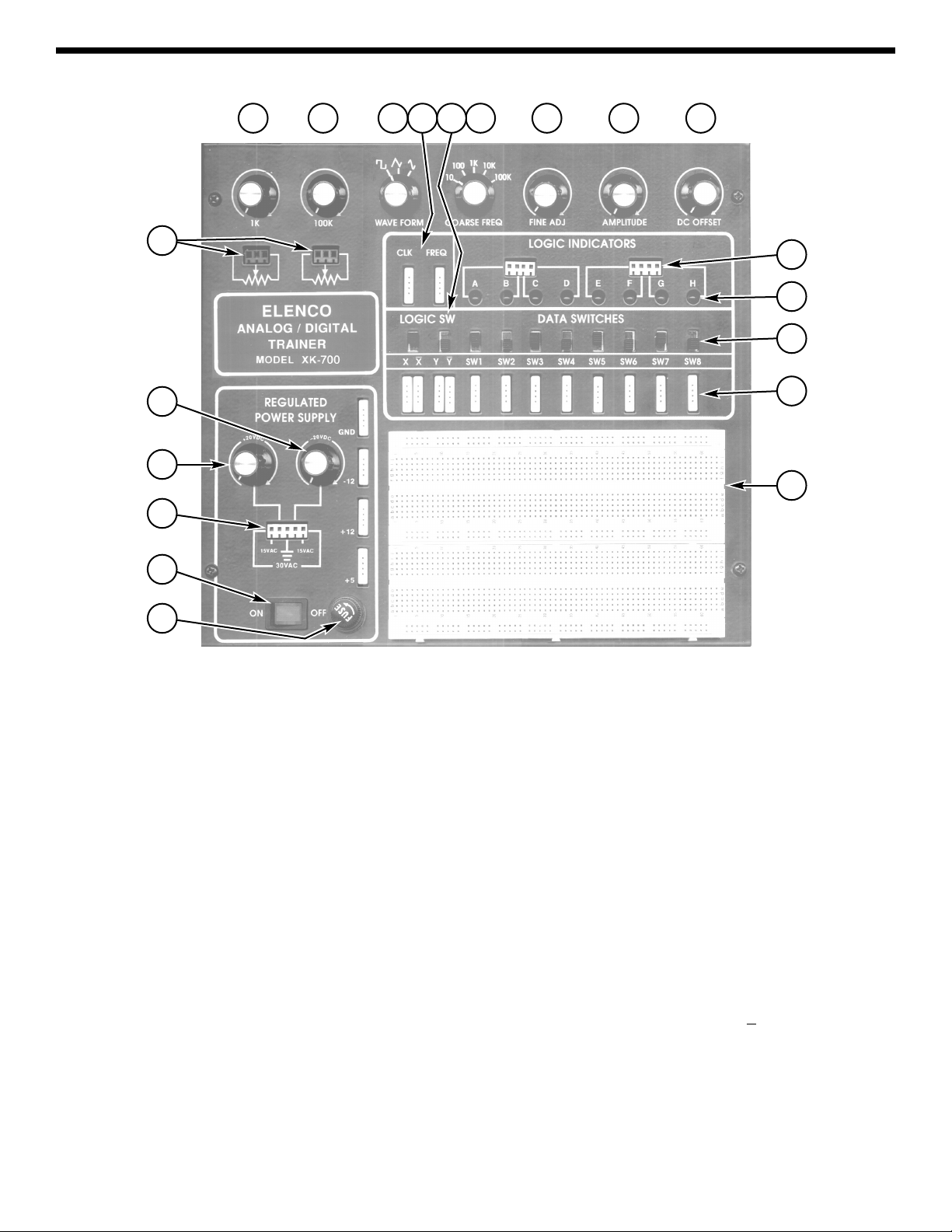

USERS DESCRIPTION OF FRONT PANEL CONTROL

1) Fuse holder - Easy access for replacement of 1.25A 250V fuse.

2) On-Off switch - Allows power to be applied to all outputs. Switch will light when on.

3) Power output terminals - This provides 30VAC center tapped at 15VAC - also provides output terminal

for positive and negative variable voltages.

4) Variable positive voltage control - Varies positive voltage from 0 to 20V at indicated output terminal.

5) Variable negative voltage control - Varies negative voltage from 0 to –20V at indicated output connector

pin.

6) Output terminals for 1kΩ and 100kΩ undedicated potentiometers.

7) 1kΩ undedicated potentiometer.

8) 100kΩ undedicated potentiometer.

9) Waveform selection control, square, triangle or sine generator waveforms.

10) Output terminals for all functions as stated, 4 pins per block.

11) Two logic switches - These are no bounce logic switches. Give one signal state change per move-

ment of switch.

12) Selects five ranges of frequencies from 10 to 100,000 hertz.

13) Fine frequency control - allows easy selection of desired function generator frequency.

14) Amplitude control - Controls the function generation output amplitude , 0-15Vpp.

15) DC offset control - controls the DC level of the generator output. DC may be varied +

10 volts from zero

level.

16) Input points for logic indicator LEDs. “A” input corresponds with A lamp, etc.

17) Logic indicators LEDs, total eight.

18) Eight data switches - Lets output of 5V or 0V depending on position.

19) Output terminals for all functions as stated, 4 pins per block.

20) Two breadboards containing a total of 1,660 tie points including 6 independent bus lines.

1

2

3

4

5

6

7 8 13 14 15

16

17

18

19

20

1211109

Page 4

-3-

GENERAL SPECIFICATIONS FOR MODEL XK-700

Power Supplies:

• 0V to 20VDC @ 0.5A (0V to 15V @ 1A)

• 0V to –20VDC @ 0.5A (0V to –15V @ 1A)

• +12V +

5% @ 1A

• –12V +

5% @ 1A

• +5V +

5% @ 1A

• 30VAC center-tapped at 15VAC @ 1A.

• Load regulation all DC supplies less than 0.2V no load to 0.5A

• Line regulation all DC supplies less than 0.2V 105 to 135V

• Hum and ripple all DC supplies less than .01V rms

• Short protection all DC supplies-Internal IC thermal cutoff

• Fuse - 1.25A 250V

Function Generator Analog Section:

• Waveforms sine, square, triangle, complimentary square

• Frequency - 1Hz to 100kHz in 5 steps continuously variable

• Fine frequency adjust - 10:1 approximate

• Amplitude variable 0-15Vpp

• Output impedance 330Ω: short protected

• DC offset change +

10V from zero crossing

Digital Section:

• Data switches, eight DPDT, Hi 5V, low 0V

• Logic switches, two no bounce with complimentary output

“On” voltage level 2.8V min., “Off” voltage level 1V max.

Input impedance 100kΩ.

• Eight LED readouts, 100kΩ input impedance

• Clock frequency, 1Hz to 100kHz in 5 steps continuously variable

• Clock amplitude, 5Vpp squarewave

• Clock rise time, better than 100nsec.

Bredboards Section:

• Two bredboards containing 830 tie points each (total 1,660 pins)

• 6 independent power bus lines for common connections

Variable Resistance (undedicated):

• 1kΩ Potentiometer

• 100kΩ Potentiometer

Page 5

-4-

TESTING THE XK-700 DIGITAL ANALOG TRAINER

The following paragraphs give detailed instructions

on testing the digital / analog trainer.

Note that in the XK-700 trainer there are five major

functions, (1) Power Supply (2) Logic Indicators (3)

Function Generator (4) Logic Switches and (5) Data

Switches. We shall proceed in testing out each

section. If any test fails, refer to the schematic

diagram and check the wiring and soldering of the

section involved.

POWER SUPPLY TESTING

Plug the trainer into a 120VAC outlet and switch to

the “ON” position (the power switch should light).

With a digital voltmeter, measure the voltage

outputs at the power blocks. The +12V should

measure between 11.4 and 12.6 volts. The 5V

supply should read between 4.75 and 5.25 volts.

The –12V supply should read between –11.4 and

12.6 volts.

Do not short the 15VAC output to ground.

Short the +12V, –12V and +5V supply to ground.

They should turn off and recover when the short is

removed. If you have a 25Ω 10 watt resistor, place

it across the output terminal (2 watt resistor will

work, but use it only for a few seconds). The output

of the 12V supply should not change more than 0.20

volts. Do the same on the 5V supply using a 10Ω 5

watt resistor. Again, the output should not change

more than 0.20 volts. In making this test, the

voltmeter leads should be clipped to the terminal

directly and no to the load leads. This is to prevent

errors due to voltage drop from contact resistance of

the load.

Check the variable voltage supplies in the same

manner. Set the output voltage between 10-15

volts. Place the 25Ω 10 watt resistor across the

output terminal. The voltage should stay within 0.20

volts of the no load voltage.

TESTING THE FUNCTION GENERATOR

To test the function generator, you will need an

oscilloscope. Connect the scope to the terminal

marked FREQ., and the ground clip to the terminal

marked GND. Adjust the waveform switch to sine,

the coarse frequency switch to 1k and the amplitude

control to maximum. Your scope should show a sine

wave with an output of about 15Vpp. If the sinewave

is clipped on top or bottom, adjust the DC offset

control for the most linear reading. Turn the FINE

ADJ control and the frequency should vary between

100 and 1,000 hertz. Check the other coarse

frequency positions.

Now, check the CLK output terminal. You should

see a square wave of about 5Vpp. If the scope is a

dual trace, connect one input to the CLK and the

other FREQ terminal. Set the waveform switch to

squarewave. You will note the two frequencies are

180

O

out of phase. If no scope is available, connect

a wire to the CLK terminal and input to “A” of the

logic indicators. Connect another wire to the FREQ

terminal and input “B”. Set the coarse frequency

switch to 10 hertz and the fine freq control to

minimum position. The two LEDs should blink

alternately.

TESTING THE LOGIC INDICATOR FUNCTION

There are eight logic indicators which you will be

checking out. Place a wire to the 5V power supply

and touch the “A” logic indicator test pin. The “A”

LED should light up. Remove the wire and the LED

should go out. Do the same for the B, C, D, E, F, G

and H test pins.

Page 6

-5-

Simplified diagram of positive power supply

120VAC

Input

17VAC 20VDC

0V - 20V

Regulated

Output

Transformer

120V to 17V

AC to DC

Converter

Voltage

Regulator

TESTING THE LOGIC SWITCHES

There are two logic switches and four conditions to

be checked out. Connect a wire from the “X” test

pin to the “A” logic indicator test pin. Connect

another from the “X” test pin to the “B” test pin.

Apply power and note that the “A” LED indicator

should be lit when the logic switch is in the “X”

positions and the “B” LED is not lit. Moving the logic

switch to “X” should reverse the indicator LEDs, that

is, the “B” LED should light and the “A” LED not light.

Check the Y logic switch in the same manner.

TESTING THE DATA SWITCHES

There are eight data switches to be checked. The

output of the switches are at 5V or ground

depending on position. Connect a wire to SW1

terminal and the “A” test pin, the “A” LED should

light when the switch is placed toward the top case.

Repeat the same test on SW2, SW3, SW4, SW5,

SW6, SW7 and SW8.

This completes the testing of the trainer.

The XK-700 power supply features two variable

output voltages and three fixed 12V, –12V and 5V,

variable output voltages are 0V to 20V and 0V to

–20V at up to 1 ampere maximum current. All

supplies are regulated to better than .2V when

going from no load to full load. Varying the input AC

voltage from 105 to 135V will have practically no

effect on the output voltages. This is because of the

specially designed IC circuits used in the XK-700

circuits. Severe overloading or even shorting the

output circuits will not damage the supplies. Special

turn-off circuits in the IC sense the overload and

turn off the output.

THE POSITIVE 0V TO 20V POWER SUPPLY

Figure 1 shows a simplified circuit diagram of the

positive supply. It consists of a power transformer, a

DC rectifier stage and the regulator stage.

TRANSFORMER

The transformer T1 serves two purposes. First, it

reduces the 120VAC input to 17VAC to allow the

proper voltage to enter the rectifier stages. Second,

it isolates the power supply output from the 120VAC

line. This prevents the user from dangerous voltage

shock should he or she be standing in a grounded

area.

AC TO DC CONVERTER

The AC to DC converter consists of diodes D1, D2

and capacitor C1. Transformer T1 has two

secondary windings which are 180

O

out of phase.

The AC output at each winding is shown in Figure

2A and 2B.

Diodes are semiconductor devices that allow current

to flow in one direction. The arrow in Figure 3 points

to the direction current will flow. Only when the

transformer voltage is positive will current flow

through the diodes. Figure 3 shows the simplest

possible rectifier circuit. This circuit is known as a

half-wave rectifier. Here the diode conducts only half

of the time when the AC wave is positive as shown

in 2C. Use of this circuit is simple but inefficient. The

big gap between cycles require much more filtering

to obtain a smooth DC voltage.

CIRCUIT DESCRIPTION

Figure 1

Page 7

-6-

By the addition of a second diode and transformer

winding we can fill in the gap between cycles as

shown in Figure 4. This circuit is called full-wave

rectification. Each diode conducts when the voltage

is positive. By adding the two outputs, the voltage

presented to capacitor C1 is more complete, thus

easier to filter, as shown in Figure 2E. When used

in 60 cycles AC input power, the output of a full

wave rectifier will be 120 cycles.

Capacitor C1 is used to store the current charges,

thus smoothing the DC voltage. The larger the

capacitor, the more current is stored. In this design

1000μF capacitors are used, which allows about 5

volts AC ripple when one amp is drawn.

In practice, the current through the diodes is not as

shown in Figure 2C. Because capacitor C1 has a

charge after the first cycle, the diode will not

conduct until the positive AC voltage exceeds the

positive charge in the capacitor. Figure 5 shows a

better picture of what the current flow looks like

assuming no loss in the diode.

It takes a few cycles for the voltage to build up on

the capacitor. This depends on the resistance of the

winding and diode. After the initial start-up, there

will be a charge and discharge on the capacitor

depending on the current drawn by the output load.

Remember, current only flows through the diodes

when the anode is more positive than the cathode.

Thus, current will flow in short bursts as shown in

Figure 5.

The DC load current may be one ampere but the

peak diode current may be three times that.

Therefore, the diode rating must be sufficient to

handle the peak current. The 1N4001 has peak

current rating of 10 amps.

REGULATOR CIRCUIT

The regulator circuit in the Model XK-700 power

supply consists of a LM-317 integrated circuit. This

IC is specially designed to perform the regulation

function. Figure 6 shows a simplified circuit of how

the LM-317 IC works.

Transistors Q1 and Q2 form a circuit known as a

differential amplifier. Transistor Q1 base is

connected to a stable 1.5V reference voltage. The

base of Q2 is connected to the regulator output

circuit through a voltage divider network. The

collector of transistor Q2 is connected to a current

source. This basically is a PNP transistor biased to

draw about 1mA current. Transistor Q2 sees the

current source as a very high resistor of about 1

meg ohms. Thus, the gain of transistor Q2 is

extremely high.

A) Transformer

Winding

B) Voltage C1

C) Current

through diodes

20V

Peak

20V

Figure 2

Figure 3

Figure 4

Voltage Waveform for Supply

A) Transformer

Winding AB

B) Transformer

Winding BC

C) Output of

diode D1.

D) Output of

diode D2.

E) Total of diodes

D1 & D2.

20V

F) Output of capacitor C1

Ripple depends on load

current (expanded).

Half Wave Rectifier

Full Wave Rectifier

2V

Output

R1

R2

Divider

Q1

Q2

1.5V

Q3

Q4

Q5

Current

Source

Equalized

to 1 Meg.

Figure 5

Figure 6

D1

D2

C1

C1

D1

Page 8

-7-

SCHEMATIC DIAGRAM

Page 9

-8-

Page 10

-9-

Transistor Q5 is called the pass transistor. It

controls the current reaching the output. Transistor

Q3 and Q4 are emitter followers. Their function is to

raise the impedance of the pass transistor. Note that

transistor Q2, Q3, Q4, Q5 and resistor R1 form a

close loop. Also note that the feedback to the base

of Q2 is negative, that is, when the base of Q2 goes

positive, the output at emitter Q5 goes negative.

Now if the 2V output voltage goes down because of

current drain at the output, the base of Q2 will drop

forcing the the collector voltage of Q2 to go higher.

This will bring the output voltage back to 2V. This is

the basis of all negative feedback regulators.

Another feature of the LM-317 regulator is to protect

the IC against overload and output shorts. If the IC

is overloaded, the junction of an overload transistor

will overheat. A transistor will sense this

overheating and shut down transistor Q5.

The LM-317 IC basically is a 1.25 volt regulator. To

be able to vary the output from 0 to 20V, you stack

the IC on the negative 1.25VDC voltage as shown in

Figure 6A. When VR1 equals 0, the output voltage

is 0 volts.

THE NEGATIVE VOLTAGE REGULATOR

The theory of the voltage regulator is the same as

the previously discussed positive regulator. The

basic difference is that diodes D1 and D2 are

reversed producing a negative voltage across

capacitor C1. The LM-337 IC is designed to operate

from a negative supply.

THE DATA SWITCHES

There are eight data switches labeled SW1 to SW8.

The circuit is very simple. To perform the desired

functions there is a double throw-double pole

switch. One end is connected to the 5V, the other to

ground and the center lug is connected to the

output.

THE LOGIC SWITCHES

The logic switches perform the same function as the

data switch, that is, they produce high or low states.

But there is one big difference. When switching the

data switches, many pulses may be produced due

to bouncing of the contacts.

In the logic switches, only one pulse is produced, no

matter how many times the contacts bounce. This

is extremely important if you are producing pulses

for counting circuits. Figure 7 shows the wiring of

the logic switch. The two NAND gates are

connected so that when X input is grounded the

output X goes high. Opening and closing the

ground at X will not change the output. Only when

X is grounded will the output change to low. Thus,

only one output change is produced with one

movement of the X switch. There are two outputs

from logic switch, X and X or Y and Y.

THE FUNCTION GENERATOR

The function generator frequencies are produced by

an XR-2206 integrated circuit. This IC is capable of

producing high quality sine, square, and triangle

waveform of high stability and accuracy. Figure 8

shows the block diagram of the XR-2206 IC.

0V - 20V

R1

VR1

LM-317

X

X

X

X

6

5

4

1

2

3

116

215

314

413

512

611

710

89

Symmetry

ADJ.

Wavefo rm

ADJ.

Ground

Sync

Output

Bypass

FKS

Input

Timing

Resistor

Timing

Capacitor

V+

Mult. Out

Sine/Saw

Output

AM Input

+1

Multiplier

and

Sine

Shaper

VCO

Current

Switches

–DC

Figure 6A

Figure 7

Figure 8

Page 11

-10-

FUSE REPLACEMENT

1. Turn the trainer off and unplug it from 120VAC power source.

2. Unscrew fuse holder cap and remove fuse.

3. Use only a 1.25A fuse. Larger fuses or other fuse bypass will void the

warranty of the trainer.

4. Place the new fuse into the fuse holder cap and screw it back into the holder.

5. Plug trainer into 120VAC power source and turn the unit on.

The XR-2206 is comprised of four functional blocks,

a voltage controlled oscillator (VCO), an analog

multiplier & sine shaper, a unity gain buffer amplifier

and a set of current switches.

The VCO actually produces an output frequency

proportional to an input current. Across pins 5 and

6, a timing capacitor, is switched on to give 5

different ranges of frequencies via COARSE FREQ.

switch. On pin 7, the FINE FREQ. ADJ. variable

resistor controls the actual frequency output. These

two components form the RC time constants for the

oscillator frequency.

The VCO produces a squarewave signal. This

squarewave is sent to a shaper and converted into

a sine wave.

THE LOGIC INDICATORS

There are eight logic indicators. Figure 9 shows the

circuit. It consists of a 74HC04 IC. When the input

is over 2.8V, the output of the IC will be low, drawing

current through the LED indicator. The 120 ohm

resistor limits the current in the LED to about 30mA.

100kΩ

100kΩ 120Ω

74HC04

LED

5V

Figure 9

Page 12

-11-

ORGANIZER CARRYING CASE

The carrying case for the XK-700 Digital/Analog Trainer has been designed to hold a meter and many of the

most important tools. The layout below shows a suggestive layout for equipment and tools. For added storage

area, the tool palette has two sides; one with pockets and elastic as shown and the other with elastic.

When ordering a meter to be used with the XK-700 trainer, specify a PSV-50 kit which will provide you with

velcro to hold the meter in place. This is supplied FREE with meter order.

(TL-8) Precision screwdriver kit

(ET-10) IC puller

Calculator - see Elenco®catalog

(ST-75) 11 pc. driver set

(ST-1) Diagonal cutters

(ST-2) Long nose pliers

(SP-4) Desoldering pump

(LP-560) Logic probe

(ST-30) Deluxe wire stripper

(SE-1) Solder ease kit

(LF-99) Lead-free solder

(SW-3) Solder wick

(SR-2B) Deluxe soldering iron

(ST-20) Safety goggles

(SL-5) Deluxe soldering station

Meters - ANY of the

following will fit the

special slope cavity

Meters available:

...and others in catalog.

M-1700

M-1750

M-2795

M-2785

M-2666K

M-2625

LCM-1950

LCR-1810

M-1000D

Soldering station not included.

Page 13

-12-

Qty. Description Part#

Resistors

2 100Ω 5% 1/4W brn-blk-brn-gold 131000

10 120Ω 5% 1/4W brn-red-brn-gold 131200

1 200Ω 5% 1/4W red-blk-brn-gold 132000

1 220Ω 5% 1/4W red-red-brn-gold 132200

2 330Ω 5% 1/4W org-org-brn-gold 133300

51kΩ 5% 1/4W brn-blk-red-gold 141000

21.2kΩ 5% 1W brn-red-red-gold 141202

12kΩ 5% 1/4W red-blk-red-gold 142000

24.7kΩ 5% 1/4W yel-vio-red-gold 144700

16.8kΩ 5% 1/4W blu-gry-red-gold 146800

18.2kΩ 5% 1/4W gry-red-red-gold 148200

1 10kΩ 5% 1/4W brn-blk-org-gold 151000

1 12kΩ 5% 1/4W brn-red-org-gold 151200

3 22kΩ 5% 1/4W red-red-org-gold 152200

1 47kΩ 5% 1/4W yel-vio-org-gold 154700

1 51kΩ 5% 1/4W grn-brn-org-gold 155100

16 100kΩ 5% 1/4W brn-blk-yel-gold 161000

1 100kΩ Pot Trim 191610

11kΩ Pot PC Mount 192412

22kΩ Pot PC Mount 192421

1 10kΩ Pot PC Mount 192531

3 100kΩ Pot PC Mount 192612

Capacitors

1 5pF 10% 50V Disc 205010

1 22pF 10% 50V Disc 212210

1 100pF 10% 50V Disc 221017

1 .001μF 10% 100V Mylar 231017

1 .0022μF 10% 50V Disc 232216

1.01μF 10% 100V Mylar 241017

4.1μF 10% 100V Mylar 251017

11μF 50V Lytic Radial 261047

210μF 25V Lytic Radial 271045

5 100μF 25V Lytic Radial 281045

2 1000μF 25V Lytic Radial 291045

4 1000μF 35V Lytic Radial 291046

Semiconductors

19 1N4001 Diode 314001

2 1N4148 Diode 314148

2 2N3904 NPN Transistor 323904

1 2N3906 PNP Transistor 323906

1 LM317 Regulator 330317

1 LM318 Integrated Circuit 330318

1 LM337 Regulator 330337

1 XR2206 Integrated Circuit 332206

1 SN7403 Integrated Circuit 337403

1 LM7805 Regulator 337805

1 LM7812 Regulator 337812

1 LM7912 Regulator 337912

8 LED Red 350002

2 74HC04 Integrated Circuit 39HC04

Qty. Description Part#

Miscellaneous

1 Transformer 44K500

1 PC Board 514550

1 Fuse 1.25A 530125

10 Switch Slide PC Mount DPDT 541009

1 Switch Rocker Illuminated 541204

1 Switch Rotary 2P5POS 542206

1 Switch Rotary 4P3POS 542405

2 Connector 3-pin 591032

2 Connector 4-pin 591042

1 Connector 5-pin 591052

4 Bracket L 4-40 Tap 613008

1 Panel Top 614108

1 Frame 614501PB

9 Knob Push On 622009

1 Case 623051

1 Bushing Insulated 624003

1 Spacer Nylon 7/16” 4-40 Tap 624013

8 Spacer 1/4” #8 Plastic 624124

2 Screw #10-32 x 3/8” Hex 641158

1 Screw #4-40 x 1/4” Phil Flat 641431

9 Screw #4-40 x 1/4” Phil Truss 641438

6 Screw #6-32 x 3/8” 641640

4 Screw #4 x 1/4” Phil AB Blk 642430

4 Screw #6 x 3/8” Phil TC 642660

4 Screw #6 x 1/2” Phil AB Blk 642662

7 Nut Pot 7mm 644101

2 Nut Pot 9mm 644102

6 Nut #6-32 Hex 644601

2 Nut #10-32 Hex 644810

7 Washer Flat 8mm ID x 14mm OD 645101

2 Washer Flat 9mm ID x 15mm OD 645103

4 Washer Flat Black #6 645400

5 Washer Fiber #4 645404

2 Lockwasher #10 External 646910

1 Fuse Holder 663000

1 IC Socket 8-Pin 664008

3 IC Socket 14-Pin 664014

1 IC Socket 16-Pin 664016

18 Bredblox 4-Pin 665204

5 Insulator Mica 780002

5 Insulator Washer 780101

5” Wire 20GA Red Top Coat 813120

2.5’ Wire 22GA Jumper 845000

1 Line Cord 862105

2” Shrink Tubing 1/2” Dia 891101-2

2” Shrink Tubing 3/4” Dia 899110-2

1 9426 Bredboard 99426

1 9830 Bredboard 99830

PARTS LIST

Page 14

POPULAR METERS THAT CAN BE USED WITH THE XK-700 TRAINER

-13-

Specifications

AC + DC volts 400mV, 4V, 40V, 400V, 600V

Accuracy +0.5% DC, +0.8% AC Resolution 100μV

AC + DC current 400μA, 4000μA, 40mA, 400mA, 10A

Accuracy +1.5% Resolution 0.1μA

Resistance 400Ω, 4kΩ, 40kΩ, 400kΩ, 4MΩ, 40MΩ

Accuracy +1% Resolution 0.1Ω

Capacitance 1pF - 200μF autoranging

Accuracy +

2% Resolution 1pF

Frequency 10Hz - 10MHz autoranging

Accuracy +0.5% Resolution 1Hz

Accessories Test leads, manual, holster, two “AA” batteries included

Dimensions 6” (H) x 2 3/4” (W) x 1 1/2” (D)

Weight 7.4 oz.

• 3 3/4 digit, 4,000 count display

• Frequency to 10MHz

• Capacitance to 200μF

• Diode and transistor test

• Audible continuity

• AC/DC current to 10A

• 3-Way overload protection

• Holster included

• Relative measurement

Features

Model M-1750

Available as a kit (M-1007K)

Compact Multimeter

Model M-1000D

Specifications

AC + DC volts 200mV, 2V, 20V, 200V, 1000V, 200VAC, 750VAC

Accuracy ±0.5% DC, ±1.2% AC Resolution 0.1mV

Input impedance 1MΩ

DC current 200μA, 2mA, 20mA, 200mA, 10A

Accuracy +

1.2% rdg + 2 Digits Resolution 0.1μA

Resistance 200Ω, 2kΩ, 20kΩ, 200kΩ, 2MΩ

Accuracy +

1% rdg + 2 Digits Resolution 0.1Ω

Accessories Test leads, manual, 9V battery included

Dimensions 5” (H) x 2 29/32” (W) x 1” (D)

Weight 4.5 oz.

• 3 3/4 digit, 4,000 count display

• Transistor test

• Audible continuity

• Diode test

• Relative measurement

• 3-way overload protection

• Pocket-size

• Low cost

Features

Specifications

AC volts 400mV, 4V, 40V, 400V, 750V

Accuracy 4V, 40V, 400V: +(0.8% + 3) 400mV, 750V: +(1.2% + 3)

DC volts 400mV, 4V, 40V, 400V, 1000V

Accuracy 400mV, 4V, 40V, 400V: +(0.5% + 3) 1000V: +(0.8% + 3)

AC current 40μA, 400μA, 4000μA, 40mA, 400mA, 10A

Accuracy 40μA, 400μA, 4000μA: +

(1.5% + 5) 40mA, 400mA: +(2% + 5) 10A: +(2.5% + 5)

DC current 40μA, 400μA, 4000μA, 40mA, 400mA, 10A

Accuracy 40μA, 400μA, 4000μA: +

(1.2% + 3) 40mA, 400mA: +(1.5% + 3) 10A: +(2% + 5)

Resistance 400Ω, 4kΩ, 40kΩ, 400kΩ, 4MΩ, 40MΩ, 400MΩ

Accuracy 400Ω, 4kΩ, 40kΩ, 400kΩ, 4MΩ: +

(1%+3) 40MΩ: +(2%+3) 400MΩ: +(3%+10)

Capacitance 4nF, 40nF, 400nF, 4μF, 4 0μF, 200μF

Accuracy 4nF: +

(5%+10) 40nF: +(3%+10) 400nF, 4μF, 4 0μF: +(2%+5) 200μF: +(4%+5)

Frequency 10Hz - 15MHz +(0.1% + 5)

Sensitivity Sine wave 0.6Vrms

Accessories Heavy-duty test leads, holster, manual, & 9V battery included

Dimensions / weight 7 1/2” (H) x 3 1/2” (W) x 1 3/4” (D) (without holster) / 10.56 oz. (without holster)

• 3 3/4 digit, 4,000 count display

• Audible continuity test

• Data hold / rel. value

• Frequency to 15MHz

• Capacitance to 200μF

• Transistor / diode / logic test

• AC/DC current to 10A

• Auto power off

• Holster included

Features

Model M-2795

Specifications

AC + DC volts 200mV, 2V, 20V, 200V, 600V

Accuracy +

(0.5% rdg +1 dgt) DC, +(1% rdg +4 dgts) AC Resolution 100μV

AC + DC current 2mA, 20mA, 200mA, 10A

Accuracy +

2.5% Resolution 100μA

Resistance 200Ω, 2kΩ, 20kΩ, 200kΩ, 2MΩ, 20MΩ

Accuracy +

(0.8% rdg +3 dgts) 200Ω, +(3.0% +3 dgts) 20MΩ Resolution 0.1Ω

Capacitance 2nF, 20nF, 200nF, 2μF, 20 μF

Accuracy +

5% Resolution 1pF

Frequency 10Hz - 20MHz autoranging

Accuracy +0.5% Resolution 1Hz

Accessories Test leads, manual, 9V battery included

Options C-90, C-17

Dimensions 6” (H) x 2 1/2” (W) x 1 1/4” (D)

Weight 7.4 oz.

• 3 1/2 digit, 2,000 count display

• Frequency to 20MHz

• Capacitance to 20μF

• Diode and transistor test

• Audible continuity

• AC/DC current to 10A

• 3-way overload protection

• Low cost

• Holster included

Features

Model M-1700

Page 15

WARRANTY POLICY

Your XK-700 Digital / Analog Trainer has been tested and conforms to our rigid requirements on performance and durability. It is

guaranteed to be free of defects in workmanship, materials and construction for a period of 2 years. If this product should fail during

normal use within the first 3 months from the date of purchase, Elenco

®

will repair or replace the unit at no cost. For the remainder of the

warranty period, a nominal service charge is required to cover shipping and handling.

When returning merchandise for repair, please include proof of purchase, a brief letter of explanation of problem and sufficient packing

material. Before returning any merchandise, please call our service department at (847) 541-3800 to obtain a return mechandise

authorization number (RMA).

Elenco®Electronics, Inc. • Service Department

150 Carpenter Avenue • Wheeling, IL 60090

-14-

Page 16

Elenco®Electronics, Inc.

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Website: www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...