Page 1

MULTI-NETWORK CABLE TESTER KIT

MODEL TCT-255K

Copyright © 2013, 2001 by ELENCO®All rights reserved. REV-D 753089

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

ELENCO

®

Assembly and Instruction Manual

Page 2

GENERAL DISCUSSION

You can see a block diagram of the TCT-255 in Figure 1 below.

The TCT-255 Cable Tester has five basic blocks:

1. Power Supply

It powers all of the circuits of the tester (not including the terminator). The power supply has a low battery

indicator (less than 7.5V) and a circuit to disconnect power 30 - 50 seconds after the last push on the

test switch.

2. Oscillator

Uses a 555 timer IC with two resistors and one capacitor. They control the free running frequency and

duty cycle.

3. Step Pulses with Counter

The outputs change by the positive pulses from the test button switch.

4. Switches and LED Indicator

It includes eight electronic switches for operating the indicators (16 LEDs).

5. Terminator

Connected to cable under test. Identifies the polarity signals.

Cable Tester TCT-200 Termina tor LD-10 0

Figure 1

COUNTER SWITCHES

INPUT & OUTPUT

CONNECTORS

INPUT & OUTPUT

CONNECTORS

STEP PULSES

OSCILLATOR

LED

INDICATOR

CIRCUIT

IDENTIFY

POLARITY

POWER

SUPPLY

-1-

The TCT-255 Cable Tester is a convenient

instrument for testing different unshielded wiring

schemed communication cable with RJ-11 and RJ45 connectors and coax cable. This tester can be

used for testing cables before and/or after they are

installed. The tester offers easy operation by having

to push only one button. Testing status is indicated by

multiple LEDs and an auto power-off function

maximizes battery life.

The unique design of the TCT-255 allows you to

place the parts over their corresponding symbol in

the schematic drawing on the surface of the PC

board during assembly. This technique maximizes

the learning process while keeping the chances of

an assembly error at a minimum. It is very

important, however, that good soldering practices

are used to prevent bad connections.

The actual assembly is broken into SEVEN

SECTIONS. After each assembly, you will be

instructed to make certain tests and measurements

to prove that each section is functioning properly.

The theory for each section, or stage, should be

read before the test is started. This will provide the

student with an understanding of what that stage

has been designed to accomplish, and how it

actually works. If a test fails to produce the proper

results, a troubleshooting guide is provided to help

you correct the problem. For testing you need to

have only a voltmeter for measuring DC and AC.

INTRODUCTION

Page 3

-2-

Warning:

If the capacitor is

connected with

incorrect polarity, it

may heat up and

either leak, or

cause the capacitor

to explode.

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BANDS

METRIC UNITS AND CONVERSIONS

Abbreviation Means Multiply Unit By Or

p Pico .000000000001 10

-12

n nano .000000001 10

-9

µ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1. 1,000 pico units = 1 nano unit

2. 1,000 nano units = 1 micro unit

3. 1,000 micro units = 1 milli unit

4. 1,000 milli units = 1 unit

5. 1,000 units = 1 kilo unit

6. 1,000 kilo units = 1 mega unit

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or µF (microfarads).

Most capacitors will have their actual value printed on them. Some capacitors may have their value printed in

the following manner. The maximum operating voltage may also be printed on the capacitor.

Electrolytic capacitors have a positive

and a negative electrode. The

negative lead is indicated on the

packaging by a stripe with minus

signs and possibly arrowheads. Also,

the negative lead of a radial

electrolytic is shorter than the positive

one.

Polarity

marking

BAND 1

1st Digit

Color Digit

Black 0

Brown

1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tole rance

Color Tol eran ce

Silver ±10%

Gold ±5%

Brown ±1%

Red ±2%

Orange ±3%

Green ±0.5%

Blue ±0.25%

Violet ±0.1%

1

2 Multiplier Tolerance

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k 100k .01 0.1

(+)

(–)

(+)

(–)

Axial

Radial

Second digit

First digit

Multiplier

Tolerance*

Note: The letter “R” may be used at times

to signify a decimal point; as in 3R3 = 3.3

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +10%

The letter J indicates a tolerance of +5%

Maximum working voltage

(may or may not appear

on the cap)

The value is 10 x 10 =

100pF, +10%, 50V

*

CERAMIC DISC MYLAR

First digit

Second digit

Multiplier

Tolerance*

2A222J

100V

The value is 22 x 100 =

2,200pF or .0022µF, +5%, 100V

101K

50V

Page 4

-3-

CONSTRUCTION

Introduction

The most important factor in assembling your TCT-255 Multi-Netwok Cable Tester Kit is good

soldering techniques. Using the proper soldering iron is of prime importance. A small pencil

type soldering iron of 25 - 40 watts is recommended. The tip of the iron must be kept clean

at all times and well tinned.

Solder

For many years leaded solder was the most common type of solder used by the electronics

industry, but it is now being replaced by lead-free solder for health reasons. This kit contains

lead-free solder, which contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting point than lead solder, so

you need higher temperature for the solder to flow properly. Recommended tip temperature is

approximately 700OF; higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results. Soldering iron tips wear

out faster since lead-free solders are more corrosive and the higher soldering temperatures

accelerate corrosion, so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when using lead-free

solder:

• Keep the iron tinned at all times.

• Use the correct tip size for best heat transfer. The conical tip is the most commonly used.

• Turn off iron when not in use or reduce temperature setting when using a soldering station.

•

Tips should be cleaned frequently to remove oxidation before it becomes impossible to remove.

Use Dry Tip Cleaner (Elenco®#SH-1025) or Tip Cleaner (Elenco®#TTC1). If you use a sponge to

clean your tip, then use distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

• Always wear safety glasses or safety goggles to protect your eyes when

working with tools or soldering iron, and during all phases of testing.

• Be sure there is adequate ventilation when soldering.

•

Locate soldering iron in an area where you do not have to go around it or reach over it. Keep

it in a safe area away from the reach of children.

• Do not hold solder in your mouth. Solder is a toxic substance. Wash hands thoroughly

after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the

PC board unless otherwise indicated. The top legend shows where each component goes.

The leads pass through the corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

Heat Sinking

Electronic components such as transistors,

IC’s, and diodes can be damaged by the heat

during soldering. Heat sinking is a way of

reducing the heat on the components while

soldering. Dissipating the heat can be

achieved by using long nose pliers, an alligator

clip, or a special heat dissipating clip. The heat

sink should be held on the component lead

between the part and the solder joint.

Heat Sink (this can be ordered as part of Elenco

®

’s Solder

Ease Kit Model SE-1).

Soldering Iron

Solder

Heat Sensitive

Component (Diode)

PC Board

Figure 6

Page 5

-4-

A poorly soldered joint can greatly affect small current flow in circuits and can cause equipment failure. You can damage

a PC board or a component with too much heat or cause a cold solder joint with insufficient heat. Sloppy soldering can

cause bridges between two adjacent foils preventing the circuit from functioning.

TROUBLESHOOTING

1. One of the most frequently occurring problems is poor

solder connections.

a) Tug slightly on all parts to make sure that they

are indeed soldered.

b) All solder connections should be shiny.

Resolder any that are not.

c) Solder should flow into a smooth puddle rather

than a round ball. Resolder any connection that

has formed into a ball.

d) Have any solder bridges formed? A solder

bridge may occur if you accidentally touch an

adjacent foil by using too much solder or by

dragging the soldering iron across adjacent foils.

Break the bridge with your soldering iron.

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allows the heat

to leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too

much solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Page 6

PARTS LIST - SECTION A

RESISTORS

Qty. Symbol Description Color Code Part #

! 2 R12, R17 1kΩ 5% 1/4W brown-black-red-gold 141000

! 1 R16 5.6kΩ 5% 1/4W green-blue-red-gold 145600

! 1 R15 12kΩ 5% 1/4W brown-red-orange-gold 151200

! 1 R9 3.3MΩ 5% 1/4W orange-orange-green-gold 173300

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C2 22µF Electrolytic Radial 272244

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 D17 1N4001 Silicon Diode 314001

! 1* 1N4736 Zener Diode 6.8V 1W 314736

! 1 D18 1N5235 Zener Diode 6.8V 0.5W 315235

! 2 Q2, Q3 2N3904 Transistor NPN 323904

! 1 Q1 2N3906 Transistor PNP 323906

! 1 D19 LED Red 350003

! 1 U4 40106 Integrated Circuit (IC) Hex Inverter 330106

MISCELLANEOUS

Qty. Symbol Description Part #

! 1 PC Board Tester TCT-200 517041

! 1 SW1 Switch Push Button DPDT 540203

! 1 Battery 9V 590009

! 1 Battery Snap 9V 590098

! 1 Spacer 624018

! 1 U4 Socket IC 14-pin 664014

! 1 Tubing #20 1/2” 890020

! 1 Solder Tube, Lead-free 9LF99

* Packaged in a separate bag, used for testing only.

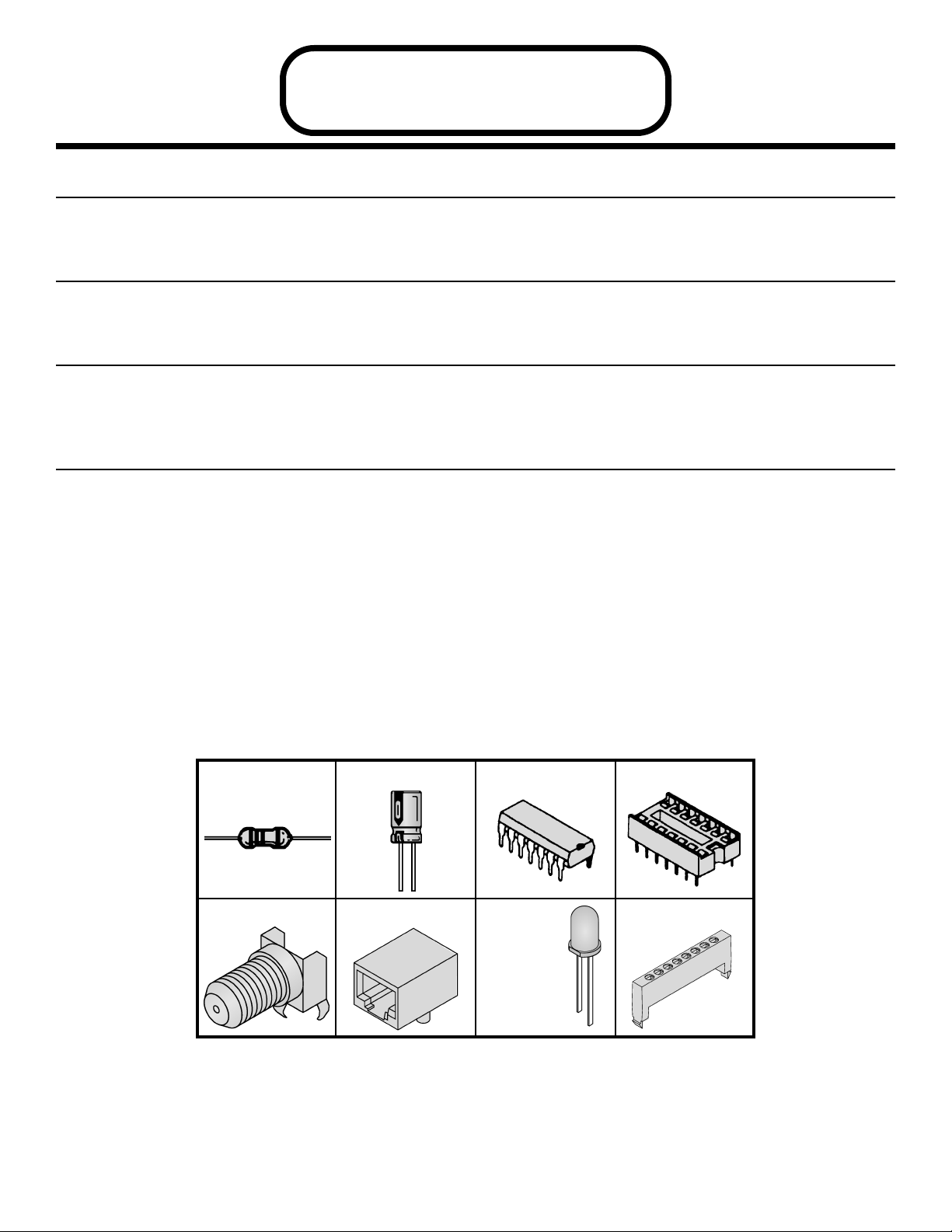

SECTION A

Power Supply

PARTS IDENTIFICATION

Integrated Circuit (IC)

-5-

Resistor DiodesElectrolytic Transistor LED

IC Socket 14-pin

PC Board (Tester)

Switch Push Button

Epoxy

Zener

Battery Snap

Spacer

Tubi ng

Page 7

Figure B

Mount the LED with the tubing and

plastic spacer to the PC board as

shown. Note the flat side of the

LED and the PC board marking.

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

In all of the following steps the components must be installed on the top legend side of the PC board. The

board is turned to solder the component leads on the foil side.

R17 - 1kΩ 5% 1/4W Resistor

(brown-black-red-gold)

(see Figure A)

D19 - LED Red

Tubing

Spacer

(see Figure B)

R9 - 3.3MΩ 5% 1/4W Resistor

(orange-orange-green-gold)

(see Figure A)

Q2 - 2N3904 Transistor NPN

(see Figure C)

D17 - 1N4001 Diode (epoxy)

(see Figure D)

Q3 - 2N3904 Transistor NPN

(see Figure C)

U4 - 14-pin IC Socket

U4 - 40106 IC Hex Inverter

(see Figure E)

SW1 - Push Button Switch

(see Figure F)

R16 - 5.6kΩ 5% 1/4W Resistor

(green-blue-red-gold)

(see Figure A)

C2 - 22µF Electrolytic

(see Figure G)

R15 - 12kΩ 5% 1/4W Resistor

(brown-red-orange-gold)

(see Figure A)

R12 - 1kΩ 5% 1/4W Resistor

(brown-black-red-gold)

(see Figure A)

D18 - 1N5235 Zener Diode 0.5W

(see Figure D)

Battery Snap

(see Figure H)

Q1 - 2N3906 Transistor PNP

(see Figure C)

Figure A

Mount the resistor

flat against the PC

board as shown.

Figure D

Diodes have polarity. Mount the

diodes in the direction marked on

the PC board as shown.

Polarity

Marking

Polarity

Marking

Epoxy

Zener

-6-

Figure F

IMPORTANT!!! Mount the push button

switch as shown. The circle MUST be

facing the other direction from the marking

“SW1” on the PC board.

Figure G

Electrolytic capacitors have polarity. Be sure

to mount them with the negative (–) lead

(marked on the side) in the correct hole.

Flat Side

Spacer

LED

Tubing

Figure C

Mount the

transistor to

the PC board

noting the flat

side.

Flat Side

Figure E

Insert the IC socket into the PC board with the

notch in the direction shown on the top

legend. Solder the IC socket into place.

Insert the IC into the socket with the notch in

the same direction as the notch on the socket.

Notch

Notch

Marking

Figure H

Mount the battery

snap as shown.

The black (–) lead

goes to –B and

the red (+) lead

goes to +B.

Circle

Red Lead

Black Lead

(–) (+)

1/8”

Warning:

If the capacitor is connected

with incorrect polarity, it may

heat up and either leak, or

cause the capacitor to

explode.

Polarity Marking

Page 8

SECTION A - POWER SUPPLY

When the SW1 (test button) is pushed, capacitor C2

(see schematic diagram, Figure 1) is charged to the

battery voltage. Transistor Q1 turns on and all of the

circuits in the tester are powered. If you don’t push

SW1, capacitor C2 begins discharging. When the

voltage on C2 is less than 0.7V, transistor Q1 and

the power turn off after 30-50 seconds.

When the voltage of the battery is less than 7.5V,

transistors Q2 and Q3 turn on and LED D19 (Low

Battery) lights. The diode D17 protects the tester

from wrong polarity input voltage.

-7-

! 1. Connect the battery to the battery snap.

! 2. Set the voltmeter to read 20VDC and connect

the COM lead to the negative (–) side of the

battery and the V lead to the positive (+) side

of the battery as shown in Figure 2. The meter

should indicate 9-10VDC. Push switch SW1.

! 3. Remove the V lead from the positive (+) side

of the battery and move to pad of pin 4 of IC

U5. The meter should indicate the same

voltage, but after 30-50 seconds, the voltage

should drop to 0V.

! 4. Push the switch SW1 again. The meter should

indicate the same voltage as in step 2. If not:

a) Check that the battery snap is connected

with the the right polarity as shown in the

assembly instructions.

b) Check that the transistor Q1 is 2N3906

and mounted with the emitter, base and

collector leads as shown in the assembly

instructions.

c) Check that R9, R12 and C2 are the

correct values.

d) Check that D17, D18, C2, U4 and SW1

are installed as shown in the assembly

instructions.

! 5.

Bend the zener diode 1N4736 (6.8V 1W,

located in a separate bag) as shown in Figure 3.

P

ush the switch SW1 again and short the

battery by the zener diode for 1-2 seconds (the

side with the band should be touching the “+”

terminal of the battery, see Figure 2). LED D19

(Lo Batt.) should be lit. Remove the zener diode

and the LED should turn off. If not:

a) Check that the transistors Q2 and Q3

are 2N3904 and mounted as shown in

the assembly instructions.

b) Check zener diode D18 and LED D19.

Be sure that they are installed as shown

in the assembly instructions.

c) Check that resistors R15, R16 and R17

are the correct values.

Remove the battery from the battery snap and

the leads from the tester.

TESTING

Figure 1

Figure 3

0.5” - 0.6”

V

COM

VDC

+

9V

Figure 2

1

8

Page 9

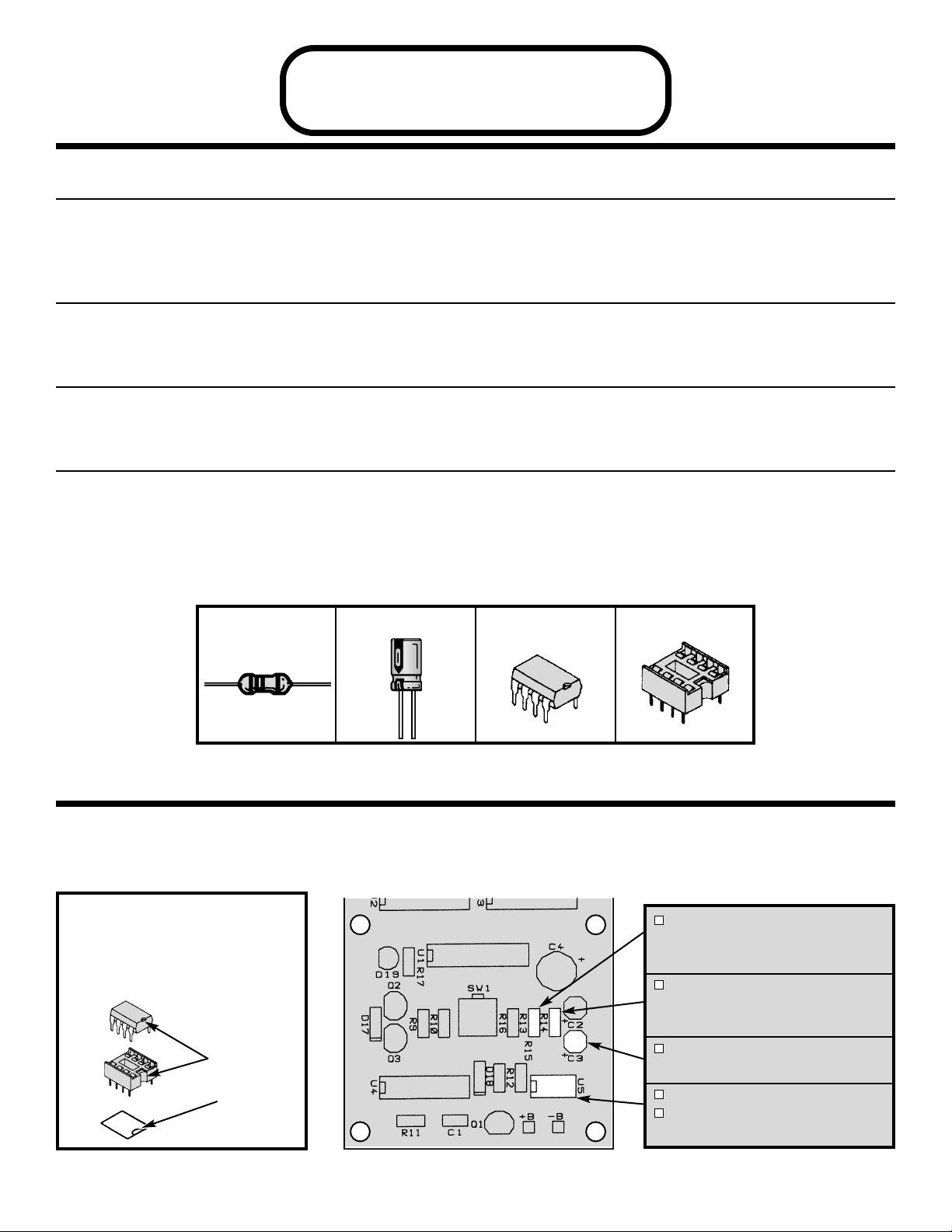

PARTS LIST - SECTION B

RESISTORS

Qty. Symbol Description Color Code Part #

! 1 R13 18kΩ 5% 1/4W brown-gray-orange-gold 151800

! 1 R14 100kΩ 5% 1/4W brown-black-yellow-gold 161000

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C3 1µF Electrolytic Radial 261047

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 U5 555 Integrated Circuit (IC) 555 Timer 330555

MISCELLANEOUS

Qty. Symbol Description Part #

! 1 U5 Socket IC 8-pin 664008

SECTION B

Oscillator

PARTS IDENTIFICATION

-8-

Resistor

Integrated Circuit (IC)

Electrolytic IC Socket 8-pin

Figure I

Insert the IC socket into the PC board with the

notch in the direction shown on the top

legend. Solder the IC socket into place.

Insert the IC into the socket with the notch in

the same direction as the notch on the socket.

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

In all of the following steps the components must be installed on the top legend side of the PC board. The

board is turned to solder the component leads on the foil side.

R13 - 18kΩ 5% 1/4W Resistor

(brown-gray-orange-gold)

(see Figure A)

R14 - 100kΩ 5% 1/4W Resistor

(brown-black-yellow-gold)

(see Figure A)

C3 - 1µF Electrolytic Radial

(see Figure G)

U5 - 8-pin IC Socket

U5 - 555 IC Timer

(see Figure I)

Notch

Notch

Marking

Page 10

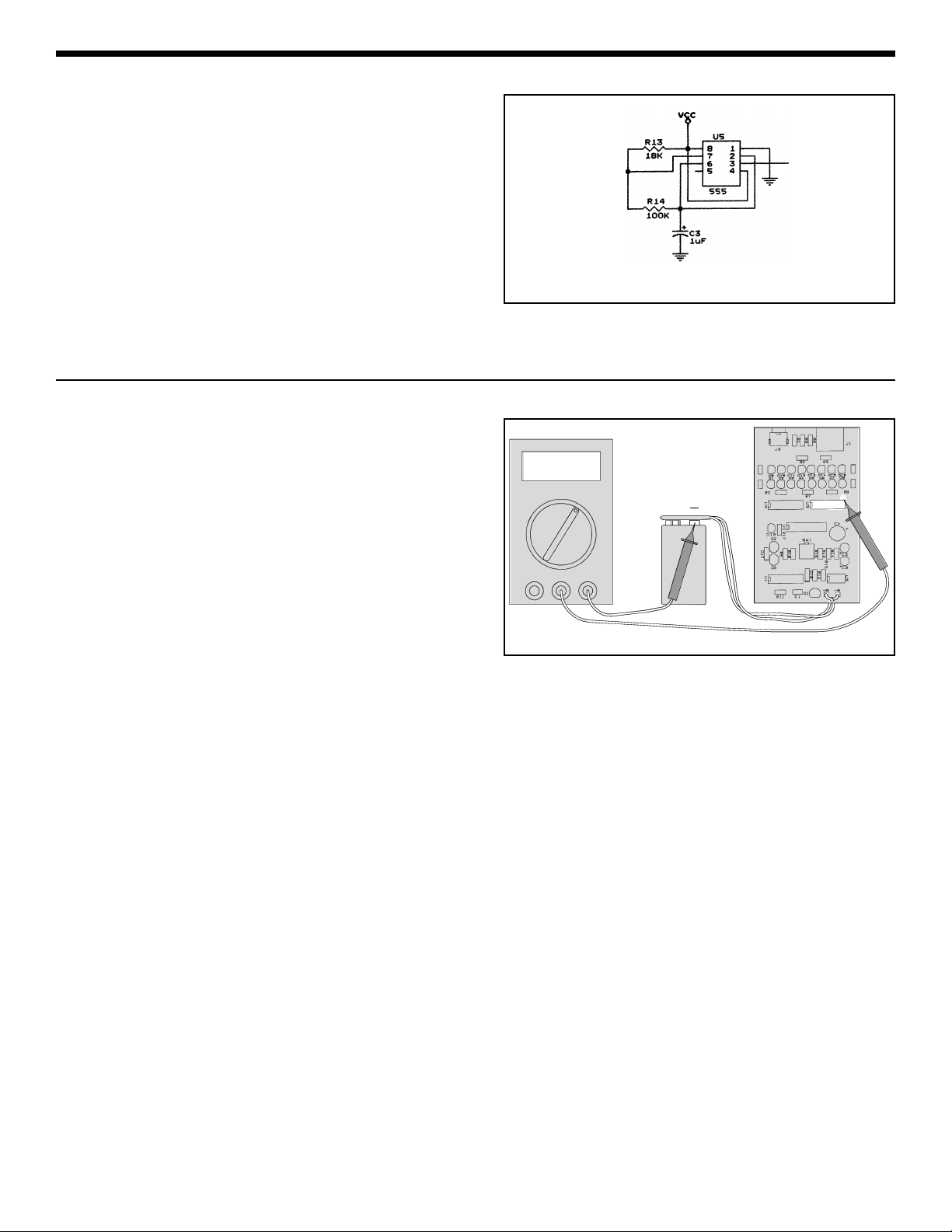

! 1. Connect the battery to the battery snap.

! 2. Set the voltmeter to read 20VAC and connect

the COM lead to the negative (–) side of the

battery and the V lead to pad of pin 8 of IC U3

as shown in Figure 5. The meter should

indicate 0V. Push switch SW1. The meter

should indicate 3-5VAC.

If not:

a) Check U5 and C3 to be sure that they

are installed as shown in the assembly

instructions.

b) Check R13 and R14 are the correct

values.

Remove the battery from the battery snap and

the leads from the tester.

-9-

SECTION B - OSCILLATOR

The oscillator section consists of a 555 timing

circuit, resistors R13, R14, and capacitor C3. The

555 IC is configured as an astable or free-running

oscillator. The values of the resistor R14 and

capacitor C3 set the output frequency at 8Hz. The

IC will produce a continuous 8Hz square wave from

pin 3 as long as it is powered.

TESTING

Figure 4

To Switches

Figure 5

V

COM

VAC

+

9V

1

14

Page 11

Figure J

Insert the IC socket into the PC board with the

notch in the direction shown on the top

legend. Solder the IC socket into place.

Insert the IC into the socket with the notch in

the same direction as the notch on the socket.

-10-

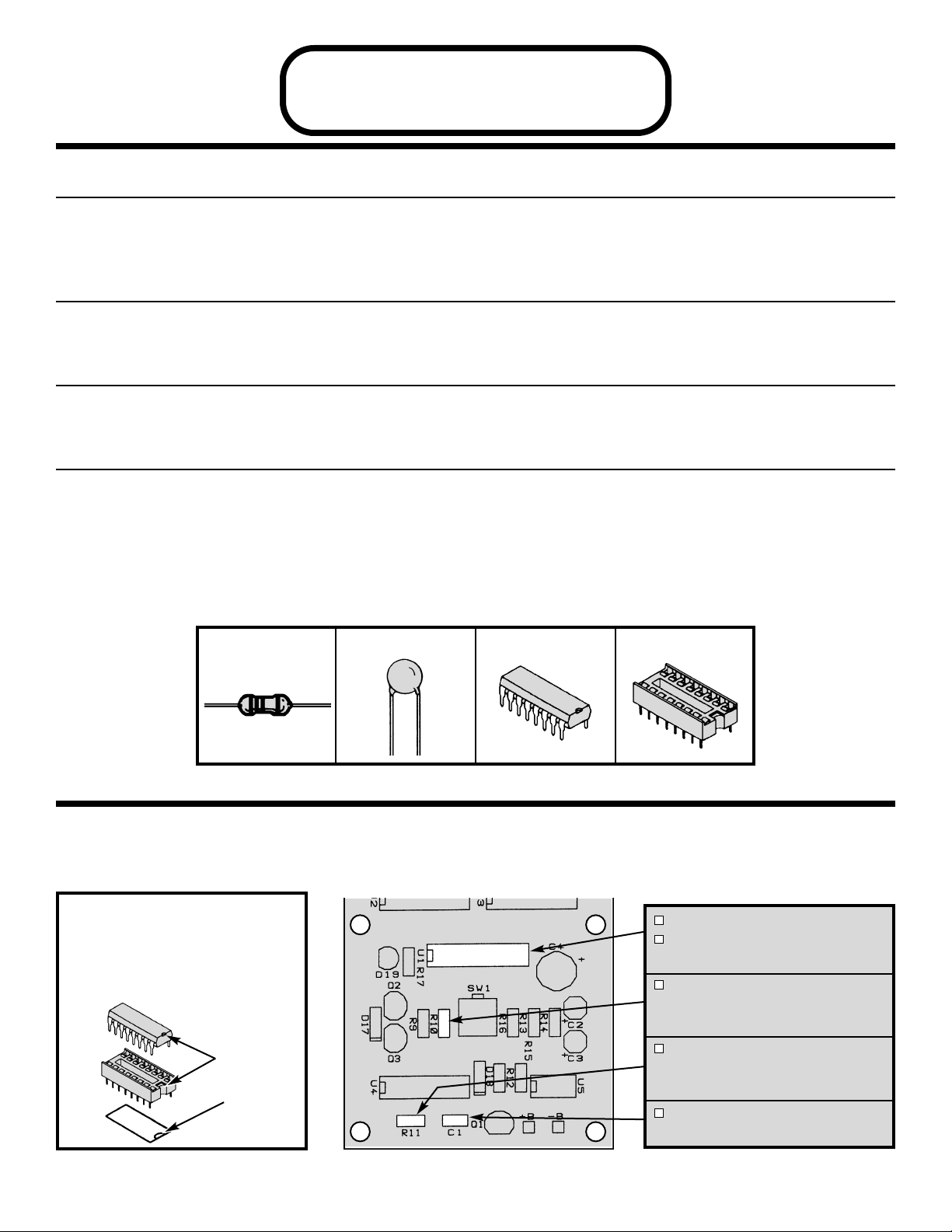

PARTS LIST - SECTION C

RESISTORS

Qty. Symbol Description Color Code Part #

! 1 R11 680kΩ 5% 1/4W blue-gray-yellow-gold 166800

! 1 R10 1.2MΩ 5% 1/4W brown-red-green-gold 171200

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C1 .001µF Discap (102 or .001) 231035

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 U1 4017 Integrated Circuit (IC) Decade Counter 334017

MISCELLANEOUS

Qty. Symbol Description Part #

! 1 U1 Socket IC 16-pin 664016

SECTION C

Step Pulses with Counter

PARTS IDENTIFICATION

Resistor

Integrated Circuit (IC)

Capacitor

IC Socket 16-pin

102

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

In all of the following steps the components must be installed on the top legend side of the PC board. The

board is turned to solder the component leads on the foil side.

U1 - 16-pin IC Socket

U1 - 4017 IC Decade Counter

(see Figure J)

R10 - 1.2MΩ 5% 1/4W Resistor

(brown-red-green-gold)

(see Figure A)

R11 - 680kΩ 5% 1/4W Resistor

(blue-gray-yellow-gold)

(see Figure A)

C1 - .001µF Discap

(102 or .001)

Notch

Notch

Marking

Page 12

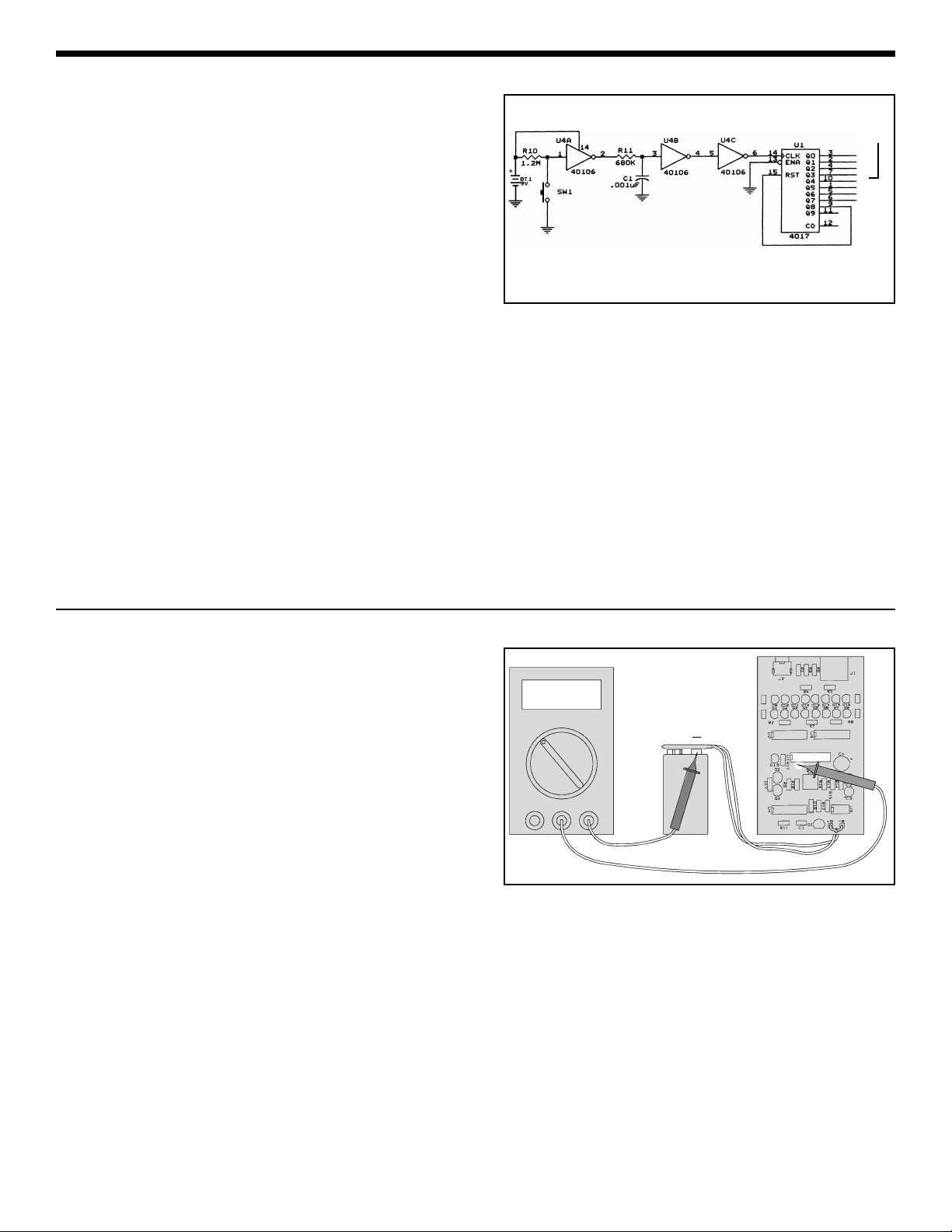

! 1. Connect the battery to the battery snap.

! 2. Set the voltmeter to read 20VDC and connect

the COM lead to the negative (–) side of the

battery and the V lead to pin 3 of IC U1 as

shown in Figure 7.

! 3.

Push switch SW1 until the voltmeter

indicates 9-10VDC.

! 4. Move the V lead of the voltmeter to pin 2. The

voltmeter should indicate 0V. Push SW1

again. The voltmeter should indicate 8-9VDC.

In the same manner, test the outputs of the

counter (pins 4, 7, 10, 1, 5, and 6).

If the test results are not satisfactory, then:

a) Check U1. Be sure that it is installed as

shown in the assembly instructions.

Remove the battery from the battery snap and

the leads from the tester.

SECTION C - STEP PULSES WITH COUNTER

In this section, a 4017 counter IC and a 40106

inverter IC are used to control eight electronic

switches. A short positive pulse must be generated

and applied to the clock input of the 4017 IC

whenever switch SW1 is depressed. This is done by

wiring three inverters in series. When switch SW1 is

depressed, the voltage at pin 1 of the 40106 is

pulled to ground. This low condition is then inverted

three times to produce a positive pulse to the CLK

pin of the 4017.

The 4017 IC is a five-stage Johnson decade

counter. The IC has 10 outputs, but only one output

will be driven high at any given time, the other nine

will be low. For each pulse at the clock (CLK) input,

the output will move one position. In this design,

only eight outputs are used, the ninth output is wired

to the reset (RST) pin. When the reset pin goes

high, it sets the Q0 output high again. The clock

enable (ENA) pin is tied to ground, so every clock

pulse will move the output.

TESTING

Figure 6

-11-

To Switches

}

1

16

VDC

9V

+

V

COM

Figure 7

Page 13

-12-

PARTS LIST - SECTION D

RESISTORS

Qty. Symbol Description Color Code Part #

! 8 R1-R8 200Ω 5% 1/4W red-black-brown-gold 132000

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C4 470µF 16V Electrolytic Radial 284744

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 16 D1-D16 LED Red 350003

! 2 U2, U3 74HC4066 Integrated Circuit (IC) Quad Analog Switch 394066

MISCELLANEOUS

Qty. Symbol Description Part #

! 1 J2 F-Connector 590500

! 1 J1 Modular Jack RJ-45 621028

! 2 Spacer 624006

! 2 U2, U3 IC Socket 14-pin 664014

SECTION D

Switches and LED Indicator

PARTS IDENTIFICATION

Resistor

Integrated Circuit (IC)

Electrolytic IC Socket 14-pin

F-Connector Modular Jack LED

Spacer

Page 14

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

In all of the following steps the components must be installed on the top legend side of the PC board. The

board is turned to solder the component leads on the foil side.

R6 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

R3 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

R1 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

J2 - F-Connector

(see Figure K)

R4 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

R2 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

R7 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

U2 - 14-pin IC Socket

U2 - 74HC4066 IC

(see Figure E)

J1 - Modular Jack RJ-45

(see Figure L)

R5 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

R8 - 200Ω 5% 1/4W Resistor

(red-black-brown-gold)

(see Figure A)

U3 - 14-pin IC Socket

U3 - 74HC4066 IC

(see Figure E)

C4 - 470µF Electrolytic Radial

(see Figure G)

-13-

Figure K

Mount and solder the F-connector to the PC board in the

location shown. Note: The connector must be

soldered in straight.

Figure L

Mount and solder the modular jack to the PC board as

shown.

Page 15

-14-

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD (cont.)

Spacer

(see Figure M)

D9 - LED

D10 - LED

D11 - LED

D12 - LED

D13 - LED

D14 - LED

D15 - LED

D16 - LED

(see Figure N)

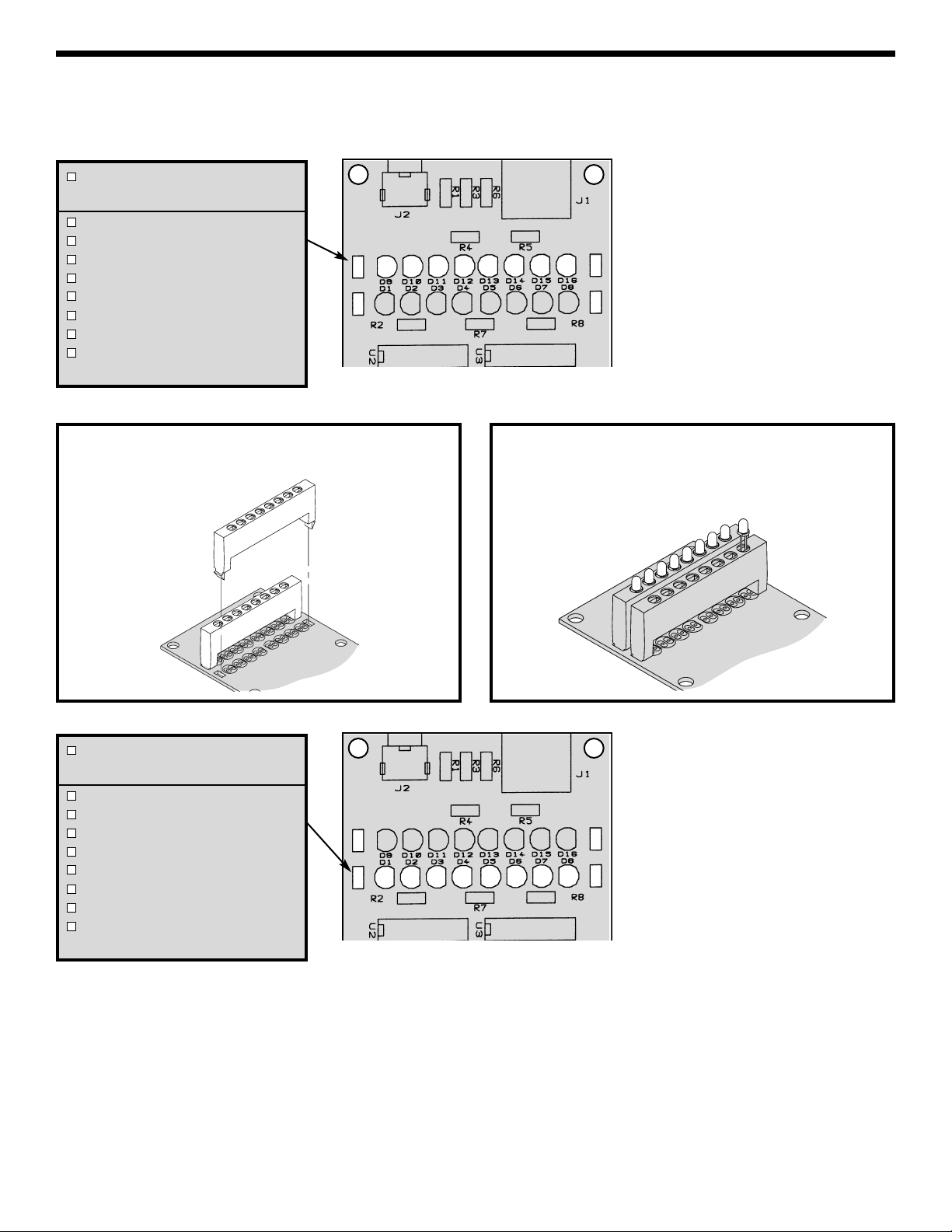

Figure M

Mount the spacer to the PC board as shown.

Figure N

Mount the LEDs onto the spacer as shown. Note the flat

side of the LED in relation to the marking on the PC

board. Solder and cut off the excess leads.

Spacer

(see Figure M)

D1 - LED

D2 - LED

D3 - LED

D4 - LED

D5 - LED

D6 - LED

D7 - LED

D8 - LED

(see Figure N)

Page 16

! 1. Connect the battery to the battery snap.

! 2. Push the switch SW1. Two vertical LEDs

should be blinking at a frequency of

approximately 8Hz.

! 3. Test the other pairs of LEDs by pushing switch

SW1. For every step, there should be only two

vertical blinking LEDs. If not, then:

a) Check U2, U3, C4 and diodes D1-D16.

Be sure that they are installed as shown

in the assembly instructions.

b) Check that the resistors R1-R8 installed

are the correct values.

c) Check the soldering on the modular jack

and F-connector.

TESTING

Figure 10

SECTION D - SWITCHES AND LED INDICATOR

In this section, two quad analog switches

(74HC4066) and 16 LEDs are used to indicate

which pins are being tested and the type of cable.

Figure 8 shows the logic diagram for each switch.

Each switch contains an input, output and a control

pin. The inputs are connected to the oscillator

section and the outputs to two LEDs and connector.

The control pins connect to the outputs of the 4017

IC (see Figure 10).

When switch A is closed, capacitor C charges and

discharges at the oscillator frequency. This causes

LEDs D1 and D2 to blink at the same rate (see

Figure 9a).

Connecting a straight cable, LED D3 will light only

during the charging cycle. The diode in the

terminator only allows the current flow in one

direction (see Figure 9b).

Connecting a cross-pinning cable, LED D4 will light

only during the discharging cycle (see Figure 9c).

Figure 8

Without Terminator

Figure 9a

ON/OFF Control

Analog

Input/Output

Analog

Output/Input

-15-

{

From

Counter

From Oscillator

Charge

Discharge

Straight Cable

Figure 9b

Cross-Pinning Cable

Figure 9c

A

B

A

B

A

B

Page 17

-16-

PARTS LIST - SECTION E

SEMICONDUCTORS

Qty Symbol Value Description Part #

! 4 D1-D4 1N4148 Diode 314148

MISCELLANEOUS

Qty Symbol Description Part #

! 1 PC Board Terminator LD-100 510005

! 1 J2 F-Connector 590500

! 1 J1 Modular Jack RJ-45 621028

SECTION E

Terminato r

PARTS IDENTIFICATION

F-Connector Modular Jack Diode PC Board

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

In all of the following steps the components must be installed on the top legend side of the PC board. The

board is turned to solder the component leads on the foil side.

D4 - 1N4148 Diode

D3 - 1N4148 Diode

D2 - 1N4148 Diode

D1 - 1N4148 Diode

(see Figure D)

Note: R1 is not used.

Modular Jack (RJ-45)

(see Figure L)

J2 - F-Connector

Note: The connector must be

soldered in straight.

(see Figure K)

IMPORTANT: Cut off the excess

leads after soldering the FConnector to the PC board.

Page 18

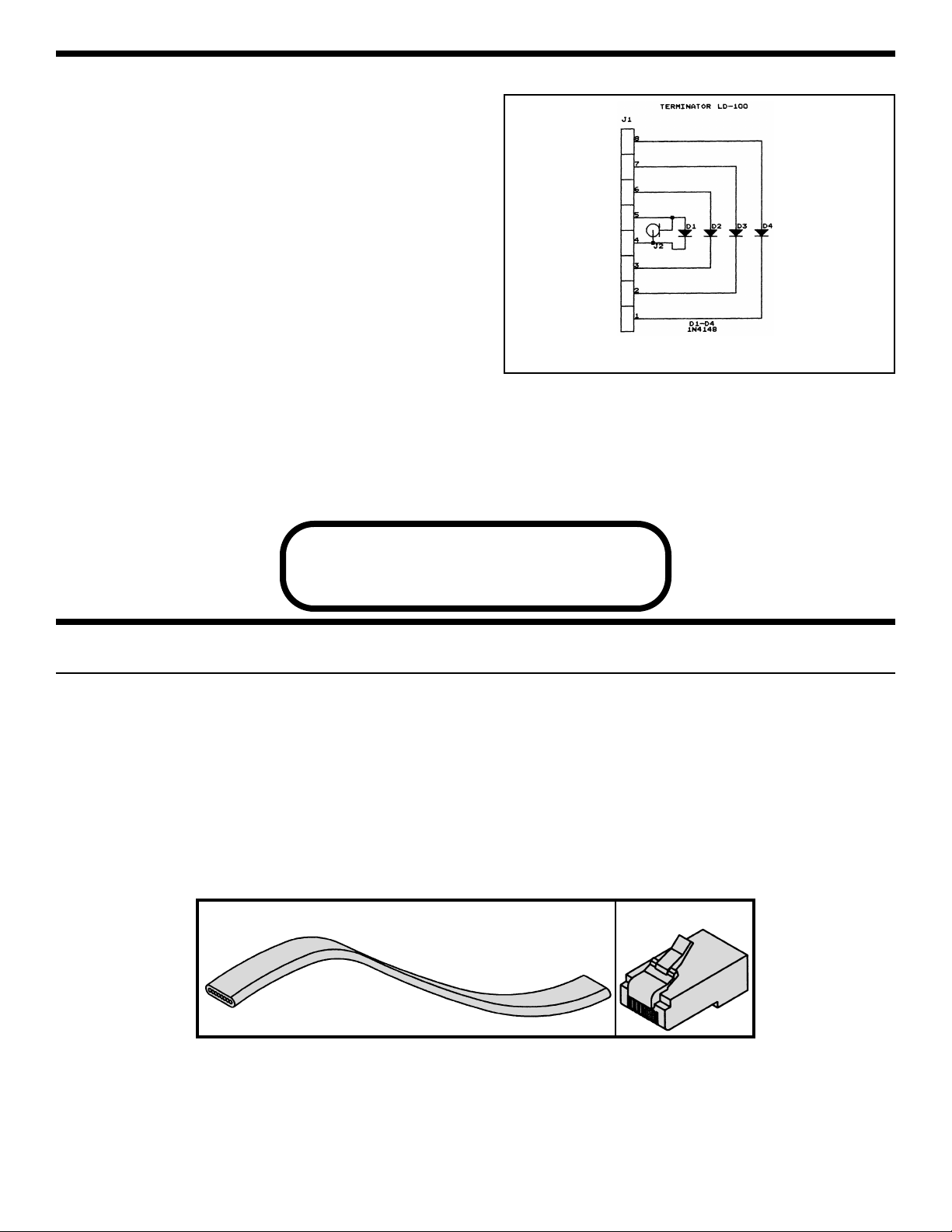

SECTION E - TERMINATOR

The terminator uses four diodes to identify the

polarity of the input signals. The diodes are placed

in series with wires 1-8, 2-7, 3-6, and 4-5 (see

Figure 11).

Figure 11

PARTS LIST - SECTION F

MISCELLANEOUS

Qty. Symbol Description Part #

! 4 Plug RJ-45 621032

! 2’ Cable Flat 8 Wires 870984

SECTION F

Assemble Telecom Cables

PARTS IDENTIFICATION

Plug RJ-45

8 Wire Flat Cable

-17-

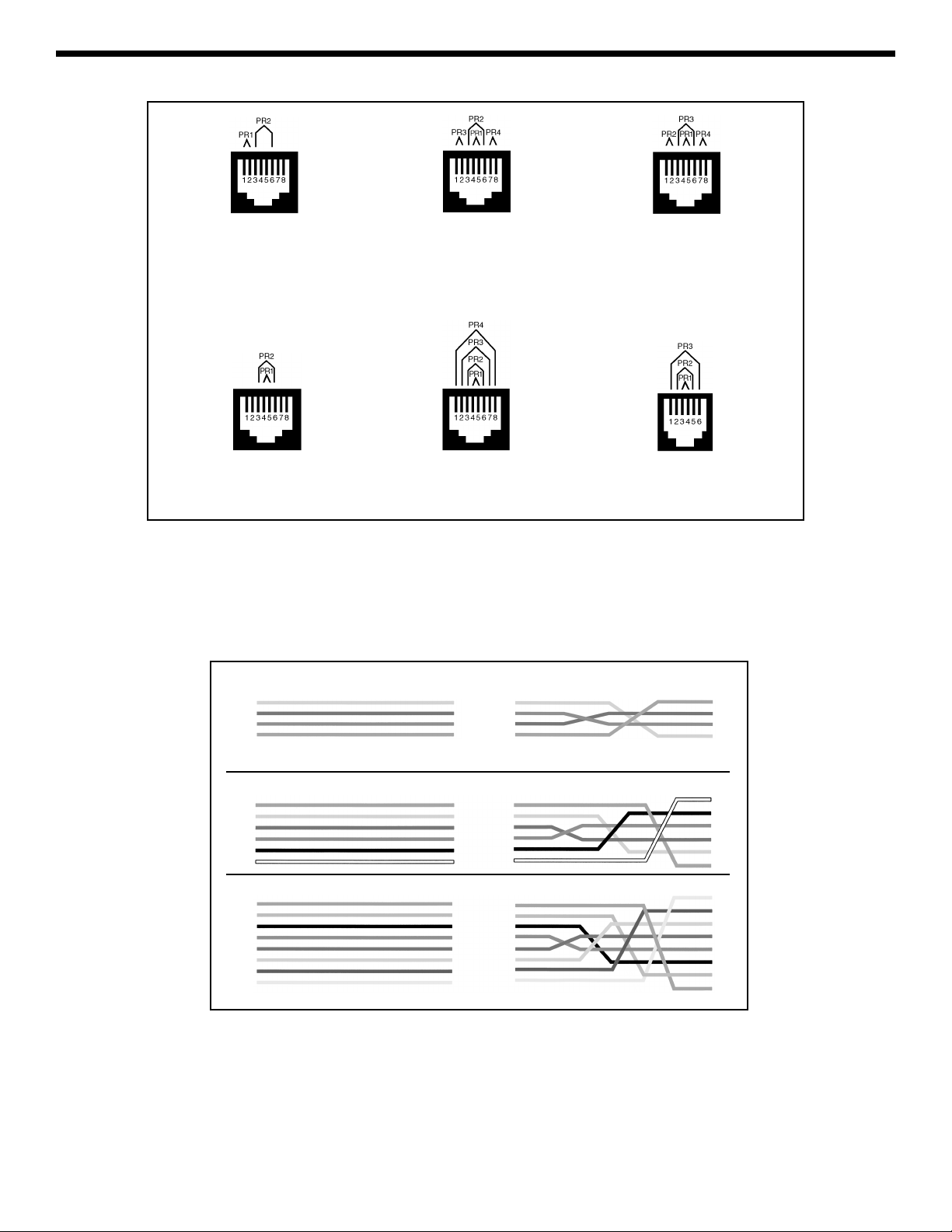

Page 19

-18-

ASSEMBLE THE TELECOM CABLES

For testing and troubleshooting the tester, you need to assemble straight and cross-pinning cables.

For cutting, stripping, and crimping, use a standard tool for RJ-45 plugs (flat cable).

ELENCO®has modular crimping tools Models ST-500 and HT-568.

! Cut the 2’ telecom cable in half (see Figure 12).

! Using the instructions for your tool, make two

cables (straight and cross-pinning) as shown in

Figures 13 - 15. Make sure that you make a

clean cut on the cable.

Figure 12 Cutting Figure 13 Stripping

Figure 15 Crimping

Figure 14

(BL) 1

(OR)2

(BK) 3

(R) 4

(G) 5

(Y) 6

(BN) 7

(S) 8

1

2

3

4

5

6

7

8

(BL) 1

(OR)2

(BK) 3

(R) 4

(G) 5

(Y) 6

(BN) 7

(S) 8

1

2

3

4

5

6

7

8

Straight Cable

Cross-Pinning Cable

Note the orientation of the

RJ-45 plug for each cable.

Page 20

-19-

PARTS LIST - SECTION G

MISCELLANEOUS

Qty. Symbol Description Part #

! 2 F to BNC Adapter 596020

! 1 Button Cap 622006

! 1 Case Top Tester 623114

! 1* Case Top Terminator 623115

! 1 Case Bottom Tester 623211

! 1* Case Bottom Terminator 623212

! 1 Cover Battery 623401

! 1 Velcro Hook and Loop Set 628002

! 2 Screw 2.6 x 8mm Thread Cutting Phillips Pan Head 642109

! 4 Screw 3 x 12mm Thread Cutting Phillips Flat Head 643104

! 1 Screw M3 x 10mm Machine Phillips Flat Head 643105

! 1* Screw 2.6 x 10mm Thread Cutting Phillips Flat Head 643107

! 1* Label Terminator 727050

! 1 Label Tester 727051

* Used for the assembly of the terminator.

SECTION G

Final Test and Assembly

PARTS IDENTIFICATION

Button Cap Case Top Terminator

Case Top Tester Case Bottom Tester

Case Bottom Terminator Cover Battery

Velcro Hook & Loop Set Screws (actual size) Label Tester Label Terminator

2.6 x 8mm Thread

Cutting Phillips Pan Head

3 x 12mm Thread Cutting

Phillips Flat Head

2.6 x 10mm Thread

Cutting Phillips Flat Head

Hook

Loop

F to BNC

Adapter

M3 x 10mm Machine

Phillips Flat Head

Page 21

Straight Cable

! 1.

Connect one end of the straight cable to the

modular jack on the PC board of the terminator

and the second end to the PC board of the

cable tester as shown in Figure 16a.

! 2. Push switch SW1 until the two vertical LEDs

D1 and D9 are blinking alternately and LED

D16 should be blinking too.

! 3.

Check the other LEDs by pressing switch SW1

and referring to Table 1 below. The single

blinking LED should always be on the top row.

If the LEDs are not functioning properly, then:

a) Check the cable using a master tester.

b) Check the ICs U2, U3 and LEDs D1-D16

on the PC board of the tester. They

should be mounted as shown in the

assembly instructions.

c)

Check that resistors R1-R8 on the PC board

of the tester are the correct values (200Ω).

d) Check diodes D1-D4 on the PC board of

the terminator. Be sure that the diodes

are installed as shown in Figure D in the

assembly instructions.

Cross-Pinning Cable

! 1. Remove the straight cable and connect the

cross-pinning cable to the modular jacks on

the PC boards of the tester and terminator.

! 2. Push switch SW1 until the two vertical LEDs

D1 and D9 are blinking alternately and LED

D8 should be blinking too.

! 3.

Check the other LEDs by pressing switch SW1

and referring to Table 2 below. The single LED

should always be on the bottom row. If not, then:

a) Check the cable using the master tester.

b) Check diodes D1-D4 on the PC board of

the terminator. Be sure that the diodes

are installed as shown in Figure D in the

assembly instructions.

Short Test

! 1. Push switch SW1 until the two vertical LEDs

D4 and D12 are blinking alternately and LED

D5 is blinking too.

! 2.

Using a short piece of wire or a discarded lead from

one of the components, short the F-connector on

the terminator PC board as shown in Figure 16b.

The LED D13 should be blinking too. Remove the

jumper and LED D13 should turn off. If not, then:

a) Check the F-connector on the terminator PCB.

!3.Short the F-connector on the tester PC board. The

LED D13 should be blinking again. If not, then:

a) Check the F-connector on the terminator PCB.

! 4. Remove the cable from the modular jacks on

the PC board and proceed to the final

assembly.

-20-

SECTION G - FINAL TEST

Two Ver t ical Straight Cable

# Blinking LEDs Single Blinking

LED on Top Row

1 D1 and D9 D16

2 D2 and D10 D15

3 D3 and D11 D14

4 D4 and D12 D13

5 D5 and D13 D12

6 D6 and D14 D11

7 D7 and D15 D10

8 D8 and D16 D9

Figure 16b

Figure 16a

Two Ver t ical Cross-Pinning Cable

# Blinking LEDs Single Blinking

LED on Bottom Row

1 D1 and D9 D8

2 D2 and D10 D7

3 D3 and D11 D6

4 D4 and D12 D5

5 D5 and D13 D4

6 D6 and D14 D3

7 D7 and D15 D2

8 D8 and D16 D1

Table 1

Table 2

Page 22

-21-

SECTION G - FINAL ASSEMBLY OF TESTER

!

Push the button cap onto the switch as shown in Figure O.

! Mount the PC board to the top case, as shown in

Figure P, with two 2.6 x 8mm phillips screws.

Note: The button cap should be centered in the

top case hole. Make sure that the Lo Batt LED

goes through the hole in the case.

! Wrap the wires from the battery snap around the

battery housing as shown in Figure Q.

! Mount the bottom case to the front case, as

shown in Figure Q, using four 3 x 12mm flat

phillips screws. Be sure that the battery snap is

through the battery compartment hole as shown.

! Connect the 9V battery to the battery snap and

place it into the case. Slide the battery cover onto

the case as shown in Figure R.

Figure O

Figure P Figure R

2.6 x 8mm Screws

PC Board

Top Case

Battery Cover

9V Battery

Button Cap

Bottom Case

3 x 12mm Screws

Figure Q

Page 23

-22-

M3 Phillips

Screw

! Insert the M3 x 10mm machine phillips screw into

the battery cover hole, as shown in Figure S, and

tighten.

! Peel the backing off of the label and stick it onto

the front case as shown in Figure T. Use the hole

in the middle to line up the label. Note: Be very

careful when applying this label. The adhesive is

very sticky and when the label is on, it’s on!

Figure S

Figure U

Figure T

FINAL ASSEMBLY OF TESTER (cont.)

! Before assembling, check that the excess leads

from the F-connector are cut off (see page 16).

! Assemble the terminator as shown in Figure U.

Insert the 2.6 x 10mm flat phillips screw and

tighten down.

!

Peel the backing off of the terminator label and

carefully place it onto the unit as shown in Figure V.

Note: Be sure that the terminator has been

tested and is in working order before you apply

the label.

FINAL ASSEMBLY OF TERMINATOR

2.6 x 10mm Flat

Phillips Screw

Top Load Case

Load PC Board

Bottom Load Case

Label

Figure V

Load Label

Page 24

-23-

CATEGORY OF CABLE

• Unshielded communication cable with RJ-11 and

RJ-45 connectors.

• Ethernet 10 Base-T, Token Ring, EIA/TIA-568A/B,

AT&T 258A, and USOC.

• 50 or 75Ω coaxial cable with F connectors.

• 50 or 75Ω coaxial cable with BNC connectors.

Must use F to BNC adapters.

Maximum testing length for all cable types is

1,000 feet.

MULTIPLE FUNCTIONS

• Testing cables before or after their installation.

• Mapping Function (to test individual wire pairs or

coaxial cables).

• Cable identification (straight or cross-pinning).

• Pair identification (straight or cross-pinning).

• Open/short wiring test.

ENVIRONMENTAL CONDITIONS

• Operating Conditions: 0OC - 45OC / 32OF - 113OF

70% RH max.

• Storage Conditions: -10OC - 50OC / 14OF - 122OF

80% RH max.

POWER

• Standard or alkaline 9V battery

• Low battery indicator (Lo Batt.)

• Auto power-off function (30 s)

SPECIFICATIONS

! Peel off the two backings, and attach the two

velcro pieces onto the terminator and the tester

in the location shown in Figure W.

FINAL ASSEMBLY (cont.)

Figure W

Velcro Pieces

Page 25

-24-

Configuration

for Testing

Communication

Cable

Configuration

for Testing

Coaxial Cable

1. Connect one end of the cable to be tested to the

terminator and the other end to the cable tester

as shown in Figure 17.

2.

Push the TEST (power) button and read the result.

Good Pair: Two vertical and one single blinking

LEDs. The location of the single LED indicates a

straight or cross-pinning for the pair.

Open Pair: Only two vertical LEDs blinking.

Short: Four or more LEDs are blinking (two or

more wires are shorted).

3. Push the TEST button again and read the result

for the next pair.

4.

For testing coax cable, use the middle LEDs (boxed

in as coax on the unit).

5.

If you do not push the button for 30 seconds, it will

automatically shut off.

CAUTION

DO NOT test cable connected to electric power. To avoid electric

shock, disconnect the power to the cable under test. Connection to

an active power cable can result in injury or even death.

*

*

*

*

*

*

*

*

*

Open Pair

For straight open wire #3

For Cross-Pinning

open wire #6

Short

Cross-Pinned cable

short wires 6 & 7

*

= Blinking LED

*

*

*

Good Pair (Cross-Pinning)

3 & 6 Wires

Good Pair (Straight)

3 & 6 Wires

OPERATION INSTRUCTIONS

Figure 17

Page 26

-25-

Ethernet

10Base-T

EIA/TIA-568A EIA/TIA-568B

AT&T 258A

8-Position

Token Ring

USOC USOC

(Prs. 1,2 & 3)

(Y) 1

(G) 2

(R) 3

(BL) 4

(Y) 1

(G) 2

(R) 3

(BL) 4

1

2

3

4

(BL) 1

(Y) 2

(G) 3

(R) 4

(BK) 5

(W) 6

1

2

3

4

5

6

(BL) 1

(Y) 2

(G) 3

(R) 4

(BK) 5

(W) 6

1

2

3

4

5

6

(BL) 1

(OR)2

(BK) 3

(R) 4

(G) 5

(Y) 6

(BN) 7

(S) 8

1

2

3

4

5

6

7

8

(BL) 1

(OR)2

(BK) 3

(R) 4

(G) 5

(Y) 6

(BN) 7

(S) 8

1

2

3

4

5

6

7

8

RJ-11 (4-Wire) Straight-Pinning RJ-11 (4-Wire) Cross-Pinning

RJ-11 (6-Wire) Straight-Pinning

RJ-11 (6-Wire) Cross-Pinning

RJ-45 (8-Wire) Straight-Pinning RJ-45 (8-Wire) Cross-Pinning

NOTE: Cross-Pinning is for typical telephone use.

WIRING SCHEMES

1

2

3

4

Page 27

-26-

GENERAL MAINTENANCE

To clean, wipe the case with a damp cloth and

detergent (do not use abrasives or solvents).

When the Lo Batt. LED lights up, you need to

replace the battery. The terminator does not use

a battery.

BATTERY REPLACEMENT

The tester is powered by a single standard or

alkaline 9V battery. Use the following procedure to

replace the battery.

1. Disconnect the cables from the tester.

2. Using a phillips screwdriver, remove the battery

cover screw and open the battery cover.

3. Carefully remove the old battery and replace with

a new battery.

4. Reinsert the battery into the case, dressing the

battery leads so that they will not be pinched

between the case and the battery cover.

5. Reinstall the battery cover and screw.

MAINTENANCE

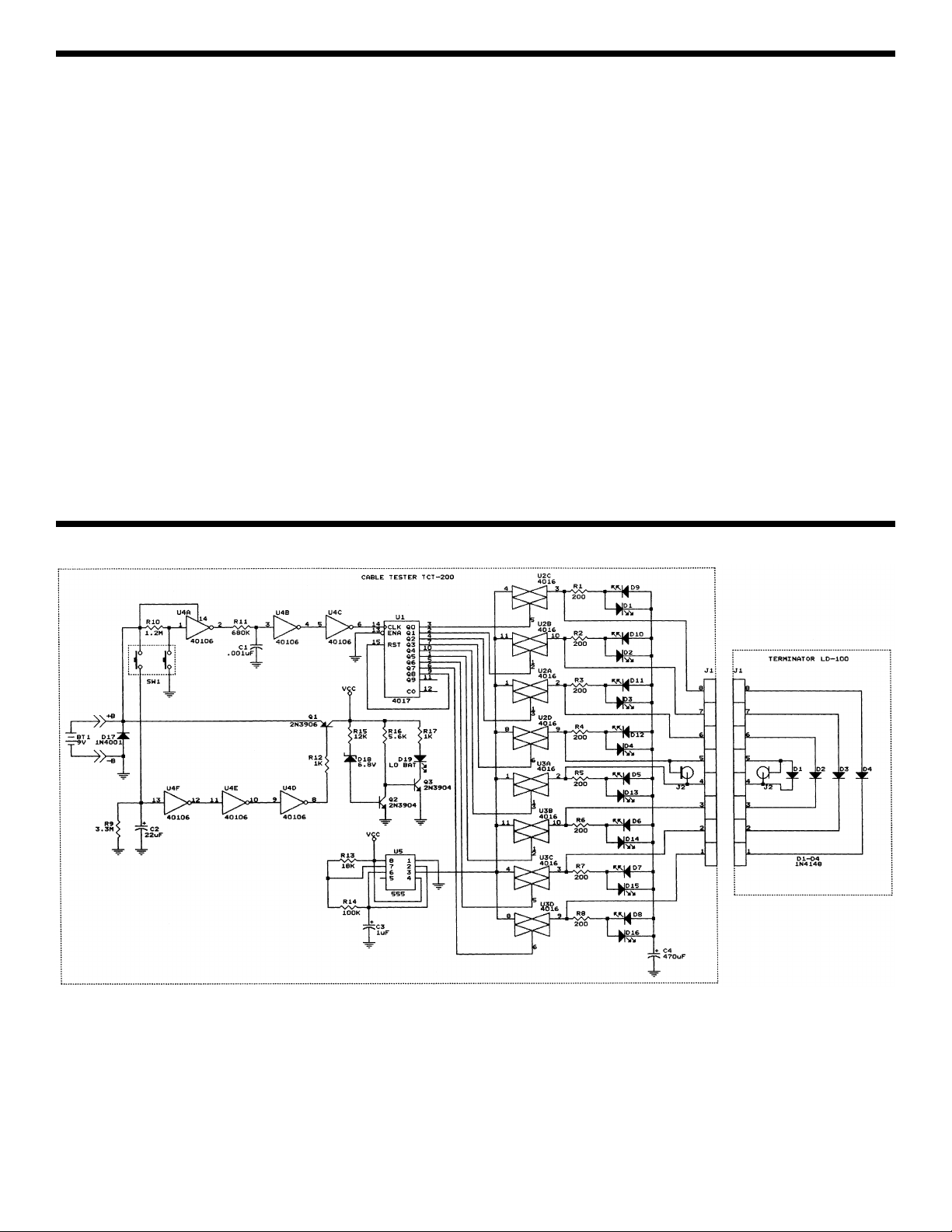

SCHEMATIC DIAGRAM

Page 28

ELENCO

®

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

www.elenco.com

email: elenco@elenco.com

Loading...

Loading...