Page 1

AM/FM RADIO KIT

MODEL AM/FM-108K

INTEGRAL CIRCUIT, 9 TRANSISTORS, 4 DIODES

Elenco®Electronics, Inc.

Copyright © 2009, 1989 by Elenco®Electronics, Inc. All rights reserved. Revised 2009 REV-Z 753508

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

Assembly and Instruction Manual

Page 2

-1-

The AM/FM Radio project is divided into two parts, the AM Radio Section and the FM Radio Section. At this time, only

identify the parts that you will need for the AM radio as listed below. DO NOT OPEN the bags listed for the FM radio. A

separate parts list will be shown for the FM radio after you have completed the AM radio.

PARTS LIST FOR THE AM RADIO SECTION

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco®Electronics (address/phone/email is at the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase

as they will not be able to help you.

RESISTORS

Qty. Symbol Value Color Code Part #

r 1 R45 10Ω 5% 1/4W brown-black-black-gold 121000

r 1 R44 47Ω 5% 1/4W yellow-violet-black-gold 124700

r 2 R38, 43 100Ω 5% 1/4W brown-black-brown-gold 131000

r 1 R41 470Ω 5% 1/4W yellow-violet-brown-gold 134700

r 1 R37 1kΩ 5% 1/4W brown-black-red-gold 141000

r 1 R42 2.2kΩ 5% 1/4W red-red-red-gold 142200

r 2 R33, 36 3.3kΩ 5% 1/4W orange-orange-red-gold 143300

r 1 R40 10kΩ 5% 1/4W brown-black-orange-gold 151000

r 1 R32 12kΩ 5% 1/4W brown-red-orange-gold 151200

r 1 R35 27kΩ 5% 1/4W red-violet-orange-gold 152700

r 1 R39 39kΩ 5% 1/4W orange-white-orange-gold 153900

r 1 R31 56kΩ 5% 1/4W green-blue-orange-gold 155600

r 1 R34 1MΩ 5% 1/4W brown-black-green-gold 171000

r 1 Volume/S2 50kΩ / SW Pot/SW with nut and washer 192522

CAPACITORS

Qty. Symbol Value Description Part #

r 1 C30 150pF Discap (151) 221510

r 2 C31, 38 .01μF Discap (103) 241031

r 5 C29, 33, 35, 36, 37 .02μF or .022μF Discap (203) or (223) 242010

r 1 C44 .047μF Discap (473) 244780

r 2 C28, C45 .1μF Discap (104) 251010

r 4 C32, 40, 41, 42 10μF Electrolytic Radial (Lytic) 271045

r 1 C34 100μF Electrolytic Radial (Lytic) 281044

r 2 C39, 43 470μF Electrolytic Radial (Lytic) 284744

r 1 C1 Variable Tuning Gang AM/FM 299904

SEMICONDUCTORS

Qty. Symbol Value Description Part #

r 1 D4 1N4148 Diode 314148

r 3 Q7, 8, 9 2N3904 Transistor NPN 323904

r 1 U1 LM386 Integrated Circuit 330386

COILS MAGIC WAND

Qty. Symbol Color Description Part # Qty. Description Part #

r 1 L5 Red AM Oscillator 430057 r 1 Iron Core 461000

r 1 T6 Yellow AM IF 430260 r 1 Brass Core 661150

r 1 T7 White AM IF 430262 r 4” Shrink Tubing 890120

r 1 T8 Black AM IF 430264

r 1 L4 AM Antenna with Holders 484004

MISCELLANEOUS

**** SAVE THE BOX THAT THIS KIT CAME IN. IT WILL BE USED ON PAGES 23 & 52. ****

Qty. Description Part #

r 1 PC Board 517055

r 1 Switch 541023

r 1 Battery Holder 590096

r 1 Speaker 590102

r 1 Speaker Pad 780128

r 1 Knob (dial) 622040

r 1 Knob (pot) 622050

r 1 Earphone Jack with Nut 622130 or 622131

r 1 Radio Stand 626100

r 1 Earphone 629250

Qty. Description Part #

r 3 Screw M1.8 x 7.5mm (battery holder) 641100

r 1 Screw M2.5 x 7.5mm (dial) 641107

r 2 Screw M2.5 x 3.8mm (gang) 641310

r 3 Nut M1.8 644210

r 1 Plastic Washer 645108

r 1 Socket 8-pin 664008

r 8 Test Point Pin 665008

r 1 Label AM/FM 723059

r 8” Wire 22AWG insulated 814520

r 1 Solder Lead-Free 9LF99

Page 3

-2-

IDENTIFYING RESISTOR VALUES

Use the following infor mation as a guide in proper ly identifying the value of resistors.

BANDS

METRIC UNITS AND CONVERSIONS

Abbreviation Means Multiply Unit By Or

p Pico .000000000001 10

-12

n nano .000000001 10

-9

μ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1. 1,000 pico units = 1 nano unit

2. 1,000 nano units = 1 micro unit

3. 1,000 micro units = 1 milli unit

4. 1,000 milli units = 1 unit

5. 1,000 units = 1 kilo unit

6. 1,000 kilo units = 1 mega unit

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or μF (microfarads).

Most capacitors will have their actual value printed on them. Some capacitors may have their value printed in

the following manner. The maximum operating voltage may also be printed on the capacitor.

Second Digit

First Digit

Multiplier

Tolerance*

Note: The letter “R”

may be used at times

to signify a decimal

point; as in 3R3 = 3.3

103K

100V

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +

10%

The letter J indicates a tolerance of +5%

Maximum Working Voltage

The value is 10 x 1,000 =

10,000pF or .01μF 100V

*

Electrolytic capacitors have a positive

and a negative electrode. The

negative lead is indicated on the

packaging by a stripe with minus

signs and possibly arrowheads.

Warning:

If the capacitor

is connected

with incorrect

polarity, it may

heat up and

either leak, or

cause the

capacitor to

explode.

Polarity

Marking

BAND 1

1st Digit

Color Digit

Black 0

Brown

1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tolerance

Color Tolerance

Silver ±10%

Gold ±5%

Brown ±1%

Red ±2%

Orange ±3%

Green ±0.5%

Blue ±0.25%

Violet ±0.1%

1

2 Multiplier Tolerance

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k 100k .01 0.1

Page 4

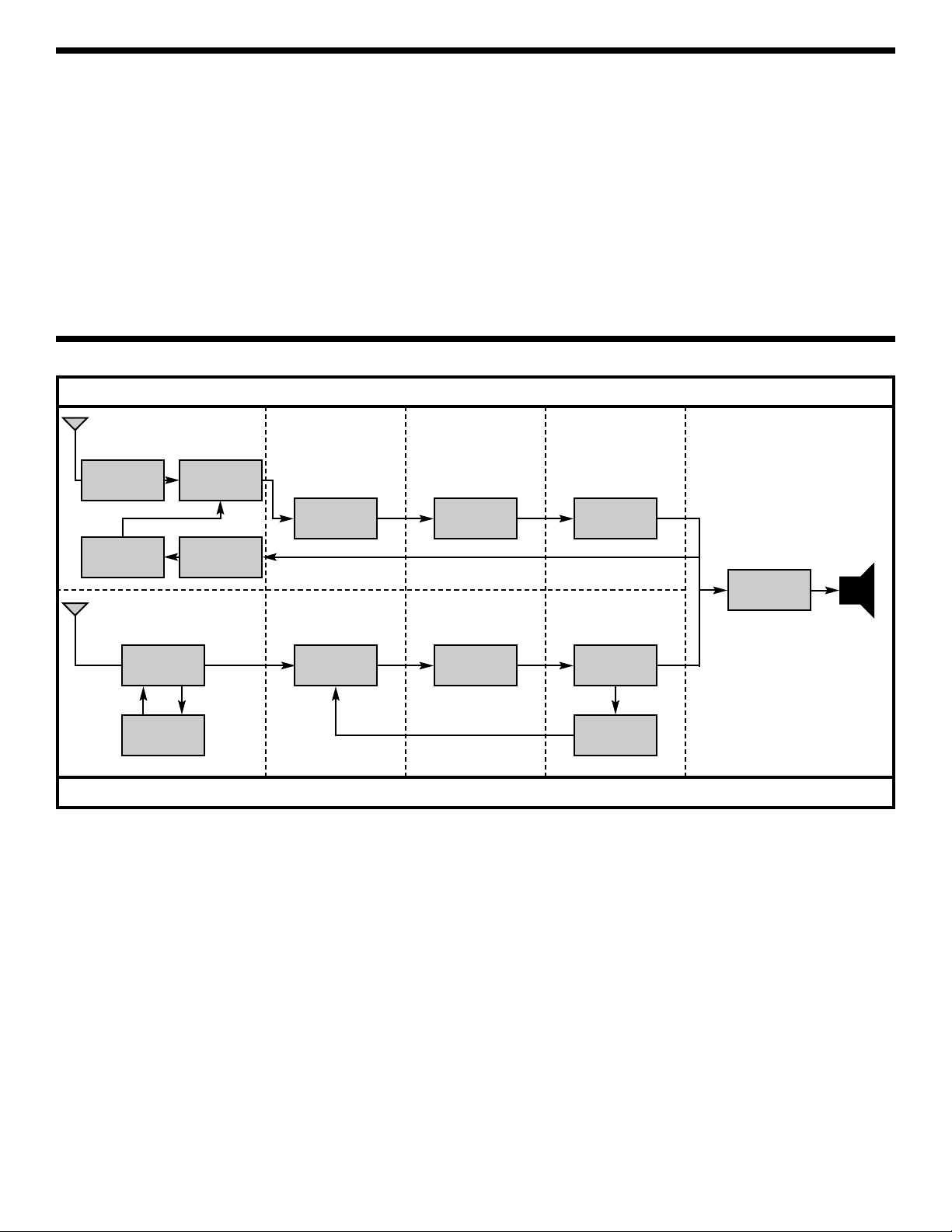

Section 9

-3-

FM RF

AMPLIFIER

FM

OSCILLATOR

1ST FM IF

AMPLIFIER

AFC

Figure 1

Section 8

Section 7 Section 6

Section 1Section 5 Section 4

Section 3 Section 2

FM MIXER

2ND FM IF

AMPLIFIER

FM

DETECTOR

AM MIXER

AM

OSCILLATOR

1ST AM IF

AMPLIFIER

2ND AM IF

AMPLIFIER

AM

DETECTOR

AGC

AUDIO

AMPLIFIER

Speaker

FM RADIO

AM RADIO

The purpose of Section 1, the Audio Amplifier Stage, is to

increase the power of the audio signal received from either

detector to a power level capable of driving the speaker.

Section 2 includes the AM detector circuit and the AGC

(automatic gain control) stage. The AM detector converts the

amplitude modulated IF (intermediate frequency) signal to a

low level audio signal. The AGC stage feeds back a DC

voltage to the first AM IF amplifier in order to maintain a near

constant level of audio at the detector . Section 3 is the second

AM IF amplifier. The second AM IF amplifier is tuned to

455kHz (Kilohertz) and has a fixed gain at this frequency of

50. Section 4 is the first AM IF 2 amplifier which has a

variable gain that depends on the AGC voltage received from

the AGC stage. The first AM IF amplifier is also tuned to

455kHz. Section 5 includes the AM mixer, AM oscillator and

AM antenna stages. When the radio w a ve passes through the

antenna, it induces a small voltage across the antenna coil.

This voltage is coupled to the mixer, or converter, stage to be

changed to a frequency of 455kHz. This change is

accomplished by mixing (heterodyning) the radio frequency

signal with the oscillator signal. Section 6 is the FM ratio

detector circuit. The FM ratio detector has a fixed gain of

about 20. Section 7 is the second FM IF amplifier. The second

FM IF amplifier is tuned to 10.7MHz (Megahertz) and has a

set gain of approximately 20. The 3dB bandwidth of this stage

should be approximately 350kHz. Section 8 is the first FM IF

amplifier. The first FM IF amplifier is also tuned to 10.7MHz

and has a set gain of approximately 10. It also has a 3dB

bandwidth of 350kHz. Section 9 includes the FM mixer, FM

oscillator, FM RF (Radio Frequency) amplifier, AFC

(Automatic Frequency Control) stage, and the FM antenna.

The incoming radio waves are amplified by the FM RF

amplifier, which is tuned to a desired radio station in the FM

frequency bandwidth of 88MHz to 108MHz. These amplified

signals are then coupled to the FM mixer stage to be

changed to a frequency of 10.7MHz. This change, as in AM,

is accomplished by heterodyning the radio frequency signal

with the oscillator signal. The AFC stage feeds back a DC

voltage to the FM oscillator to prevent the oscillator from

drifting. Each of these blocks will be explained in detail in the

Theory of Operation given before the assembly instructions

for that stage.

GENERAL DISCUSSION

INTRODUCTION

The Elenco®Superhet 108 AM/FM Radio Kit is a

“superheterodyne” receiver of the standard AM (amplitude

modulation) and FM (frequency modulation) broadcast

frequencies. The unique design of the Superhet 108 allows

you to place the parts over their corresponding symbol in the

schematic drawing on the surface of the printed circuit board

during assembly. This technique maximizes the learning

process while keeping the chances of an assembly error at a

minimum. It is ver y important, however, that good soldering

practices are used to prevent bad connections . The Soldering

Guide should be reviewed before any soldering is attempted.

The actual assembly is broken down into 9 sections. The

theory of operation for each section, or stage, should be read

before the assembly is started. This will provide the student

with an understanding of what that stage has been designed

to accomplish, and how it actually works. After each

assembly, you will be instructed to make certain tests and

measurements to prove that each section is functioning

properly. If a test fails to produce the proper results, a

troubleshooting guide is provided to help you correct the

problem. If test equipment is available, further measurements

and calculations are demonstrated to allow each student to

verify that each stage meets the engineering specifications.

After all of the stages have been built and tested, a final

alignment procedure is provided to peak the performance of

the receiver and maximize the Superhet 108’s reception

capabilities.

Page 5

-4-

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allo ws the heat to

leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too much

solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Introduction

The most important factor in assembling your Superhet 108 AM/FM

Radio Kit is good soldering techniques. Using the proper soldering iron

is of prime importance. A small pencil type soldering iron of 25 - 40 watts

is recommended. The tip of the iron must be kept clean at all times

and well tinned.

Solder

For many years leaded solder was the most common type of solder

used by the electronics industry, but it is now being replaced by leadfree solder for health reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting

point than lead solder, so you need higher temperature for the solder to

flow properly. Recommended tip temperature is approximately 700

O

F;

higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results.

Soldering iron tips wear out faster since lead-free solders are more

corrosive and the higher soldering temperatures accelerate corrosion,

so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when

using lead-free solder:

• Keep the iron tinned at all times.

• Use the correct tip size for best heat transfer. The conical tip is the

most commonly used.

• Turn off iron when not in use or reduce temperature setting when

using a soldering station.

•

Tips should be cleaned frequently to remove oxidation before it becomes

impossible to remove. Use Dry Tip Cleaner (Elenco

®

#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to clean your tip, then use

distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

• Always wear safety glasses or safety goggles to

protect your eyes when working with tools or

soldering iron, and during all phases of testing.

• Be sure there is adequate ventilation when soldering.

•

Locate soldering iron in an area where you do not have to go around

it or reach over it. Keep it in a safe area away from the reach of

children.

• Do not hold solder in your mouth. Solder is a toxic substance.

Wash hands thoroughly after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed

on the top side of the PC board unless otherwise indicated. The top

legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

'

Page 6

-5-

SEMICONDUCTOR PARTS FAMILIARIZATION

This section will familiarize you with the proper method used to test the transistors and the diode.

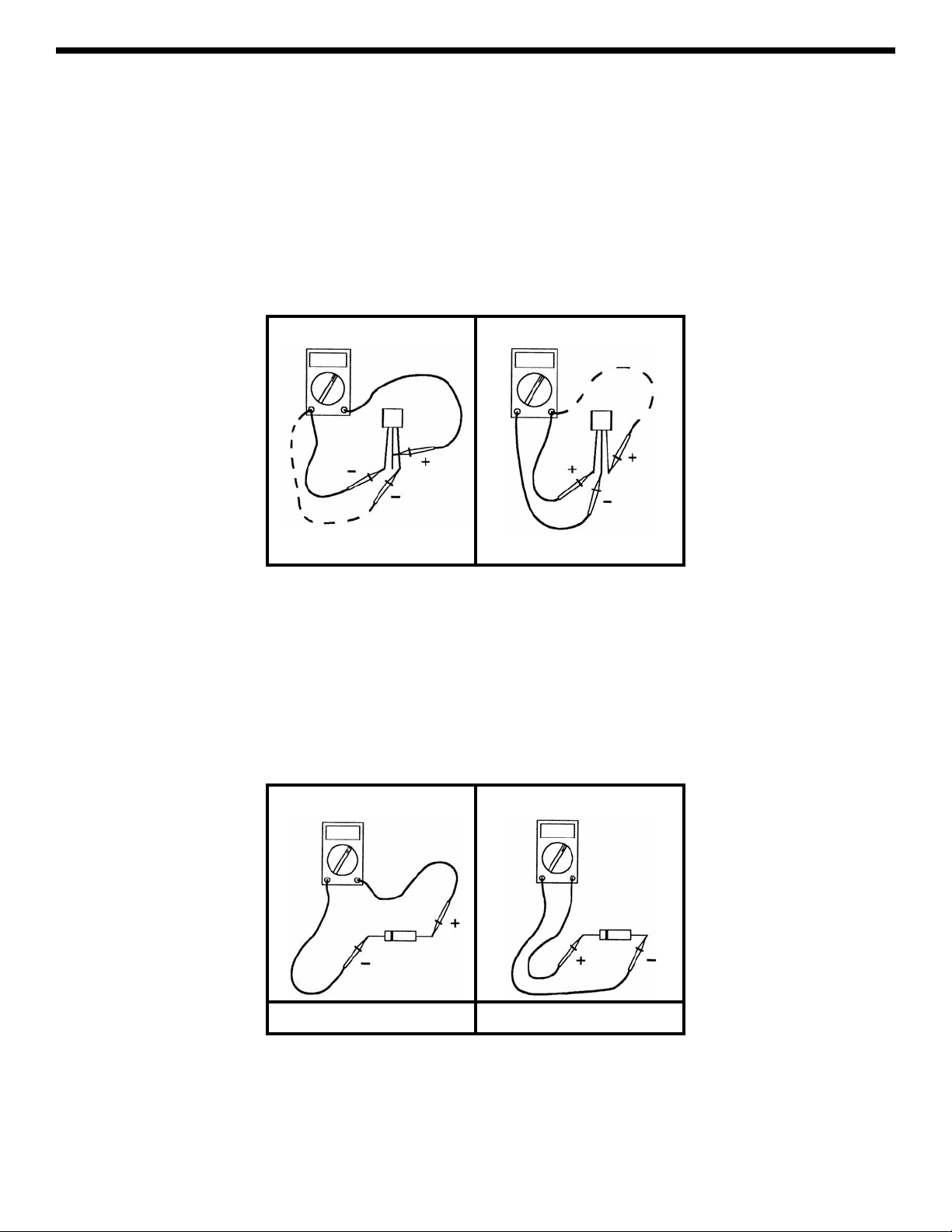

TRANSISTOR TEST

TEST C

TEST D

High Resistance

Diode

Low Resistance

Diode

Ω

Ω

COM

Ω

Ω

COM

TEST A

TEST B

Low Resistance

NPN

EBC

High Resistance

NPN

EBC

Ω

Ω

COM

Ω

Ω

COM

Refer to the parts list and find transistors. These are

NPN transistors. Refer to Test A for locating the

Emitter, Base and Collector. Using an Ohmmeter,

connect the transistor as shown in Test A. Your meter

should be reading a low resistance. Switch the lead

from the Emitter to the Collector. Your meter should

again be reading a low resistance.

Using an Ohmmeter, connect the transistor as sho wn

in Test B. Your meter should be reading a high

resistance. Switch the lead from the Emitter to the

Collector. Your meter should again be reading a high

resistance. Typical results read approximately 1MΩ

to infinity.

DIODE TEST

Refer to the parts list and find a diode. This is a

silicon 1N4148 diode. Refer to Test C for locating the

Cathode and Anode. The end with the band is the

cathode. Using an Ohmmeter, connect the diode as

shown in Test C. Your meter should be reading a low

resistance. Using an Ohmmeter , connect the diode as

shown in Test D. Your meter should be reading a high

resistance. Typical results read approximately 1MΩ to

infinity.

Page 7

-6-

SECTION 1

AUDIO AMPLIFIER

Figure 3

The purpose of the Audio Amplifier is to increase the

audio power to a lev el sufficient to drive an 8 ohm speak er .

To do this, DC (direct current) from the battery is

converted by the amplifier to an AC (alternating current) in

the speaker. The ratio of the power delivered to the

speaker and the power taken from the battery is the

efficiency of the amplifier. For the Audio Amplifier, we use

the integrated circuit (IC) LM-386. In Figure 2, you can

see equivalent schematic and connection diagrams.

In a Class A amplifier (transistor on over entire cycle), the

maximum theoretical efficiency is .5 or 50%. But, in a

Class B amplifier (transistor on for 1/2 cycle), the

maximum theoretical efficiency is .785 or 78.5%. Since

transistor characteristics are not ideal in a pure Class B

amplifier, the transistors will introduce crossover

distortion. This is due to the non-linear transf er curve near

zero current or cutoff. This type of distortion is shown in

Figure 3.

In order to eliminate crossover distortion and maximize

efficiency, the transistors of the audio amplifier circuit are

biased on for slightly more than 1/2 of the cycle, Class AB.

In other words, the transistors are working as Class A

amplifiers for very small lev els of pow er to the speaker , b ut

they slide toward Class B operation at larger po w er levels.

To make the LM-386 a more versatile amplifier, two pins

(1 and 8) are provided for gain control. With pins 1 and

8 open, the 1.35kΩ resistor sets the gain at 20 (see

Figure 4a). The gain will go up to 200 (see Figure 4b) if

a capacitor is placed between pins 1 and 8. The gain can

be set to any value from 20 to 200 if a resistor is placed

in series with the capacitor. The amplifier with a gain of

150 is shown in Figure 4c.

The amplifier in our kit with a gain of 150 is shown in

Figure 5. Capacitor C40 couples the audio signal from the

volume control to the input of the audio amplifier.

Capacitor C43 blocks the DC to the speaker, while

allowing the AC to pass.

Figure 2

Figure 4a

Figure 4c

Figure 4b

Figure 5

Typical Applications

Amplifier with Gain = 20

Minimum Parts

VIN

VS

2

6

1

8

5

7

4

LM386

+

+

–

.05μF

10Ω

10kΩ

Amplifier with Gain = 150

Amplifier with Gain = 200

3

V

IN

VS

2

6

1

8

5

7

4

LM386

+

–

10kΩ

3

+

.05μF

10Ω

BYPASS

+

10μF

VIN

VS

2

6

1

8

5

7

4

LM386

+

–

10kΩ

3

.05μF

10Ω

BYPASS

47Ω

10μF

+

+

Equivalent Schematic and Connection Diagrams

VOUT

VS

6

5

7

4

15kΩ

BYPASS

GND

15kΩ

2

– INPUT

150Ω

1.35kΩ

8

GAIN

1

GAIN

15kΩ

50kΩ

50kΩ

+ INPUT

Dual-In-Line and Small Outline Packages

Top Vie w

GAIN

– INPUT

+ INPUT

GND

GAIN

BYPASS

V

S

VOUT

4

1

2

3

5

8

7

6

3

Page 8

Diode

Test Point Pin

ASSEMBLY INSTRUCTIONS

We will begin by installing resistor R43. Identify the resistor by its color and install as shown on page 4. Be

careful to properly mount and solder all components. Diodes, transistors and electrolytic capacitors are

polarized, be sure to follow the instructions carefully so that they are not mounted backwards. Check the box

when you have completed each installation.

Wear safety goggles during all assembly stages in this manual.

Foil side of PC board

Figure A

NPN T ransistor

Figure C

Mount so E lead is in the arrow

hole and flat side is in the same

direction as shown on the top

legend. Leave 1/4” between the

part and PC board.

Figure D

-7-

EBC

E

B

C

Flat side

Band

CathodeAnode

Integrated Circuit

C39 - 470μF Lytic

(see Figure Ba)

Mount on copper side.

C40 - 10μF Lytic

(see Figure B)

C41 - 10μF Lytic

(see Figure B)

C43 - 470μF Lytic

(see Figure B)

C44 - .047μF Discap (473)

TP1 - Test Point Pin

(see Figure A)

R45 - 10Ω Resistor

(brown-black-black-gold)

R43 - 100Ω Resistor

(brown-black-brown-gold)

TP2 - Test Point Pin

(see Figure A)

C42 - 10μF Lytic

(see Figure B)

R44 - 47Ω Resistor

(yellow-violet-black-gold)

U1 - IC Socket 8-pin

U1 -

LM386 Integrated Circuit

(see Figure E)

1/8”

Notch

J3 - Jumper Wire

(use a discarded lead)

TP-15 - Test Point Pin

(see Figure A)

Lytic Capacitor

Figure B

Be sure that the

negative lead is

in the correct

hole on the PC

board.

Warning:

If the capacitor is connected with

incorrect polarity, it may heat up

and either leak, or cause the

capacitor to explode.

Figure Ba

Polarity

Mark

+

–

Be sure that the band is in

the same direction as

marked on the PC board.

Figure E

r Inser t the IC socket into the

PC board with the notch in

the direction shown on the

top legend. Solder the IC

socket into place.

r Inser t the IC into the socket

with the notch in the same

direction as the notch on the

socket.

'

Polarity

mark

(–)

(+)

0.1μF Capacitor

Pin 2

r C45 - Solder the 0.1μF

capacitor across pins 2 & 6

of IC U1 as shown. The

capacitor prevents the IC

from oscillating.

Pin 6

Page 9

-8-

ASSEMBLY INSTRUCTIONS

Figure F

Knob

Nut

Washer

Cut off

locating pin

Solder all 5 tabs to PC board

Plastic Washer

Figure H

Mount the jack with the nut from the foil side of the PC board (terminal #1

on the GND pad of the PC board). Be sure to line up the tab with the pad

on the copper side of the PC board. Solder terminal #1 to the pad of the

PC board.

Part # 622131

1 - GND

2 - Tip

3 - N.C. Tip

1

3

2

Your kit may contain a different type of earphone jack. Before installing

the jack, determine which one you have.

Nut

Figure I

GND

Pad

Cut three wires 1”, 1.5” and 2” and strip 1/4” of insulation off

of both ends. Solder the 3 wires as shown.

***

Save the extra wire for the FM Section.

***

Part # 622130

Part # 622131

Figure G

If the speaker pad has center and outside pieces, then

remove them. Peel the backing off of the speaker pad and

stick the pad onto the speaker. Then stick the speaker

onto the solder side of the PC board as shown.

Pad

Speaker

Backing

Remove

Battery Holder

3 Screws M1.8 x 7.5

3 Nuts M1.8

Solder and cut off

excess leads.

Volume/S2

(50kΩ Pot / SW)

with Nut & Washer

Plastic Washer

Knob (pot)

(see Figure F)

Earphone Jack

with Nut

(see Figure H)

Speaker

Speaker Pad

Wire #22AWG Insulated

(see Figures G & I)

Backing

Foil Side

Foil Side

1

Part # 622130

1 - GND

2 - Tip

3 - N.C. Tip

2

3

Nut

GND

Pad

Note: Mount the Pot/SW, earphone

jack, and speaker to the foil side of the

PC board.

2” Wire

1.5” Wire

1” Wire

1” Wire

From Terminal 3

2” Wire

1.5” Wire

Page 10

-9-

OUTPUT BIAS TEST

Put the battery into the holder.

STATIC MEASUREMENTS

POWER TEST

TP15

COM

V

V

For all measurements, connect y our equipment GND

to circuit GND TP15. Set your VOM (Volt-OhmMillimeter) to read 2 amps DC. Connect the meter to

the circuit as shown in Figure 6. Make sure that the

volume control is in the OFF position (turned fully

counter-clockwise). While watching your VOM, turn

the volume to the ON position (rotate clockwise until

a “click” is heard). The VOM should indicate a very

low current. Adjust your meter for a more accurate

reading if necessary. If the current is greater than 20

milliamps, immediately turn the power off. The

current should be less than 10 milliamps. This is the

current drawn by the battery when no input signal is

present (the “idle current”). Turn OFF the power. If

your circuit fails this test, check that all of the parts

have been installed correctly, and check for shorts or

poor solder connections.

Amps

Amps

COM

–

+

+

–

Figure 6

Figure 7

Adjust your VOM to read 9 volts and connect it as

shown in Figure 7. Make sure that the batter y, or a 9

volt power supply (if a v ailable), is properly connected

and turn the power ON. The voltage at TP1 should be

between 3 to 6 volts. If you get this reading, go on to

the next test. If your circuit fails this test, turn the

power OFF and check that the integrated circuit is

correctly inserted in the correct location. The notch of

the IC must be in the same direction as marked on

the PC board. Check that all resistor values are the

correct value and not interchanged. All static tests

must pass before proceeding to the Dynamic Tests or

the next section.

Page 11

DYNAMIC MEASUREMENTS

GAIN

-10-

Figure 8

TP15

COM

V

V

TP15

Hz

Generator

If you do not have an audio generator, skip the following test and go directly to Section 2.

Connect the VOM and audio generator to the circuit

as shown in Figure 8.

Normally the AC gain is measured at a frequency of

1kHz. Your VOM however, may not be able to

accurately read AC voltages at this frequency.

Therefore, it is recommended that this test be

performed at 400Hz. Set the audio generator at

400Hz and minimum voltage output. With the power

ON, set your VOM to read an AC voltage of 1 volt at

test point TP1. Increase the volume control about half

way. Slowly increase the amplitude of the audio

generator until your VOM reads 1 volt AC. Leave the

audio generator at this setting and move the positive

lead of your VOM to the Jumper J3. Record the AC

input voltage to the amplifier here:

Vin = _________ volts.

You may have to change scales on your VOM for the

most accurate reading. Turn the power OFF. The AC

voltage gain of your audio amplifier is equal to the A C

output voltage divided by the AC input voltage, or

1/Vin.

Calculate the gain. The gain should be 100–180.

Gain = _________

Page 12

-11-

Figure 9

AC BANDWIDTH

Connect the oscilloscope and audio generator to

your circuit as shown in Figure 9. Set the audio

generator for a frequency of 1kHz and minimum

voltage output. Set the oscilloscope to read .5 volts

per division. Turn on the power and slowly increase

the volume control to a comfortable level. Increase

the amplitude of the audio generator until the

oscilloscope displays 2 volts peak to peak, (Vpp), at

TP1. It may be necessary to adjust the volume

control. Move the oscilloscope probe to jumper J3

and record the input voltage here:

Vin = _______ Vpp

(at this point, you may want to verify the AC gain).

Move the oscilloscope probe back to TP1 and slowly

increase the frequency from the audio generator until

the wavefor m on the oscilloscope drops to .7 of its

original reading 1.4Vpp or 2.8 divisions. The

frequency of the generator when the output drops to

.7 of its original value is called the high frequency 3

decibel (dB) corner. Record this frequency here:

(f high 3dB) = __________ kHz.

Slowly decrease the frequency of the generator until

the output drops to .7 of its original reading, 1.4Vpp

or 2.8 divisions. This frequency is called the low

frequency 3dB corner. Record your answer.

(f low 3dB) = __________ kHz.

Calculate the AC bandwidth:

(f high 3dB – f low 3dB) = __________ kHz.

AC Bandwidth = __________

Your calculated answer should be greater than

30kHz.

DISTORTION

Connect the generator and oscilloscope as shown in

Figure 9. Set the generator at a frequency of 1kHz,

turn the power ON. Adjust the generator output and

turn the volume until the peaks of the sinewave at

TP1 are clipped for maximum signal as shown in

Figure 10A. One side of the sine w av e ma y clip bef ore

the other depending on the DC centering at TP1. If

oscillations are seen, connect a clip lead from the

GND of your generator to the GND of the circuit.

Measure the maximum voltage peak to peak when

clipping first occurs and record that value here:

Vclp = _______ Vpp.

Turn the power OFF.

Battery

Generator

Hz

TP15

TP15

If an oscilloscope is not available, skip the following test and go directly to Section 2.

Page 13

MAXIMUM POWER OUTPUT

The maximum power output before distortion due to

“clipping” can be calculated using the voltage Vclp

obtained in the Distortion Step as follows:

Vpeak (Vp) = Vclp/2

Vroot mean squared (Vrms) = Vp x .7

Max power out = (Vrms)

2

/8 ohms = (Vclp x .35)2/8

Maximum power output should be greater than 200

milliwatts.

EFFICIENCY

-12-

Figure 10

A

B

Clipped

Crossover

Distortion

By measuring the DC power taken from the battery

at the maximum power output level, the efficiency to

the audio amplifier can be calculated. Power from

the battery is equal to the current taken from the

battery times the voltage of the battery during

maximum power output. Efficiency can then be

calculated as follows: Eff = Max audio power/Battery

power. It is best to use a power supply (if available)

to prevent supply v oltage from changing during these

measurements.

Connect the generator, oscilloscope, power supply

(or battery) and current meter as shown in Figure 11.

Set your current meter to read 1 amp DC. Tur n the

power ON and rotate the volume control to

maximum. Slowly increase the amplitude of the

audio generator until the output is clipped as shown

in Figure 10A.

Record Vclp here:

Vclp = _________ Vpp.

This should be equal to Vclp in the Distortion Step.

Record the DC current drawn from the 9 volt supply

here:

Current (I) max = ________ A.

Measure the supply voltage and record the V supply

here:

V supply = ________ volts.

Turn the power OFF.

Calculate the maximum power output as done in the

Maximum Power Output Step.

Record your answers on page 13.

Page 14

-13-

Vp = Vclp/2 Vp = ______

Vrms = Vp x .7 Vr ms = ______

Max power out = (Vrms)

2

/8 Max power out = ______

Since the battery power equals the battery voltage times the current taken from the battery; calculate the battery

power:

Battery power = Imax x V supply Battery power = ______

Since the efficiency (N) is equal to the Max power out divided by the Battery power, we can now calculate the

efficiency of the audio amplifier.

N = Max power out/Battery power N = _______

N in % = N x 100 N = _______%

Your calculated answer should be around .6 or 60%.

Figure 11

Generator

Hz

TP15

Amps

Amps COM

Power Supply

If you do not have a power supply, use a 9

volt battery instead.

TP15

Page 15

SECTION 2

AM DETECTOR AND AGC STAGE

-14-

Figure 12

Switch

J2 - Jumper Wire

(use a discarded lead)

The purpose of the automatic gain control (AGC)

circuit is to maintain a constant level at the detector,

regardless of the strength of the incoming signal.

Without AGC, the volume control would have to be

adjusted for each station and ev en moderately strong

stations would clip in the final IF amplifier causing

audio distortion. AGC is accomplished by adjusting

the DC bias of the first IF amplifier to lower its gain

as the signal strength increases. Figure 12 shows

that the audio at the top of the volume control is

actually “riding” on a negative DC voltage when

strong signals are encountered. This negative DC

component corresponds to the strength of the

incoming signal. The larger the signal, the more

negative the component. At test point five (TP5), the

audio is removed by a low pass filter, R36 and C32,

leaving only the DC component. Resistor R35 is

used to shift the voltage at TP5 high enough to bias

the base of transistor Q8 to the full gain position

when no signal is present. Resistors R35 and R36

also forward bias diode D4 just enough to minimize

“On Condition” threshold voltage.

The purpose of the detector is to change the

amplitude modulated IF signal back to an audio

signal. This is accomplished by a process called

detection or demodulation. First, the amplitude

modulated IF signal is applied to a diode in such a

way as to leave only the negative portion of that

signal (see Figure 12). The diode acts like an

electronic check valve that only lets current pass in

the same direction as the arrow (in the diode symbol)

points. When the diode is in conduction (On

Condition), it will force the capacitors C33 and C38 to

charge to approximately the same voltage as the

negative peak of the IF signal. After conduction stops

in the diode (Off Condition), the capacitors will

discharge through resistors R36 and R42. The

discharge time constant must be small enough to

follow the audio signal or high frequency audio

distortion will occur. The discharge time constant

must be large enough, however, to remove the

intermediate frequency (455kHz) and leave only the

audio as shown in Figure 12.

ASSEMBLY INSTRUCTIONS

1/8”

Page 16

STATIC MEASUREMENTS

AGC ZERO SIGNAL BIAS

With the power turned OFF, connect your V OM to TP5 as shown in Figure 13. Make sure that the AM/FM switch

is in the AM position.

Check that the VOM is adjusted to

read 9 volts DC and turn the power

ON. The voltmeter should read

approximately 1.5 volts DC. If your

reading varies by more than .5 volts

from this value, turn the power OFF

and check the polarity of D4. Also

check R36 and R35 and check that

transformer T6 is properly installed.

T8 TEST

-15-

ASSEMBLY INSTRUCTIONS

C34 - 100μF Lytic

(see Figure B)

T6 - AM IF Coil

(Yellow Dot)

R35 -

27kΩ Resistor

(red-violet-orange-gold)

TP5 - Test Point Pin

(see Figure A)

C32 - 10μF Lytic

(see Figure B)

R36 - 3.3kΩ Resistor

(orange-orange-red-gold)

C33 - .02μF Discap (203)

or .022μF Discap (223)

R38 - 100Ω Resistor

(brown-black-brown-gold)

TP3 - Test Point Pin

(see Figure A)

T8 - AM IF Coil

(Black Dot)

D4 - 1N4148 Diode

(see Figure D)

C38 - .01μF Discap (103)

R42 - 2.2kΩ Resistor

(red-red-red-gold)

TP15

V

COM V

If you do not have an RF generator, skip to Section 3.

With the power turned OFF, connect the positive lead

of the VOM to TP3 and the negative lead to ground

pin TP15. Make sure that the VOM is set to read 9

volts DC and turn the power ON. The voltage on the

VOM should be the same as your battery voltage or

power supply voltage . If not, turn the power OFF and

check that T8 is properly installed. Tur n the power

OFF.

Figure 13

Page 17

DYNAMIC MEASUREMENTS

AM DETECTOR AND AGC TEST

Connect your VOM and RF generator as shown in Figure 14.

-16-

Figure 15

TP15

GENERATOR

Hz

TP15

.001μF

If your RF generator does not have amplitude modulation and

you do not have an oscilloscope, skip to Section 3.

TP15

.001μF

TP15

COM

V

V

GENERATOR

Hz

Figure 14

Set the VOM to accurately read 2 volts DC and set

the output of the RF generator for 455kHz, no

modulation, and minimum voltage output. Turn the

power ON and slowly increase the amplitude of the

generator until the voltage at TP5 just star ts to drop.

This point is called the AGC threshold with no IF

gain. Make a note of the amplitude setting on the RF

generator here: ____________.

Set the RF generator at 455kHz, 1kHz at 80%

modulation and minimum voltage output. Turn the

power ON and set the volume control at maximum.

Slowly adjust the amplitude of the RF generator

output until you hear the 1kHz tone on the speaker. If

this test fails, turn the power OFF and chec k R42 and

D4. Turn the power OFF.

SYSTEM CHECK

Connect your equipment as shown in Figure 15.

Page 18

SECTION 3

-17-

AM DETECTOR BANDWIDTH TEST

Figure 16

kHz

kHz

kHz

Connect your test equipment as shown in Figure 15.

Set the generator at 455kHz with 80% modulation at

a modulation frequency of 1kHz. Set the oscilloscope

to read .1 volts per division. Turn the power ON and

set the volume at the minimum. Increase the

amplitude of the generator until the signal on the

oscilloscope is 4 divisions peak to peak. Check the

signal to make sure that it is free of distortion. Leave

the frequency of the generator at 455kHz, but

increase the modulation frequency until the output

drops to .28Vpp. Record the modulation frequency

on the generator here:

__________

This frequency should be greater than 5kHz. T urn the

power OFF.

The purpose of the second IF amplifier to increase

the amplitude of the intermediate frequency (IF) and

at the same time provide SELECTIVITY. Selectivity is

the ability to “pick out” one radio station while

rejecting all others. The second IF transformer (T8)

acts as a bandpass filter with a 3dB bandwidth of

approximately 6kHz. The amplitude versus frequency

response of the second IF amplifier is shown in

Figure 16.

Both IF amplifiers are tuned to a frequency of

455kHz and only need to be aligned once when the

radio is assembled. These amplifiers provide the

majority of the gain and selectivity needed to

separate the radio stations.

The gain at 455kHz in the second IF amplifier is fixed

by the AC impedance of the primary side of

transformer T8, and the DC current in Q9. The

current in Q9 is set by resistors R39, R40 and R41.

Both C36 and C37 bypass the 455kHz signal to

ground, making Q9 a common emitter amplifier. The

signal is coupled from the first IF amplifier to the

second IF amplifier through transformer T7. The IF

transformers not only supply coupling and selectivity,

they also provide an impedance match between the

collector of one stage and the base of the next stage.

This match allows maximum power to transfer from

one stage to the next.

SECOND AM IF AMPLIFIER

Page 19

-18-

ASSEMBLY INSTRUCTIONS

STATIC MEASUREMENTS

Q9 BIAS

Figure 17

T7 - AM IF Coil

(White Dot)

TP4 - Test Point Pin

(see Figure A)

R40 - 10kΩ Resistor

(brown-black-orange-gold)

R41 - 470Ω Resistor

(yellow-violet-brown-gold)

R39 - 39kΩ Resistor

(orange-white-orange-gold)

C36 - .02μF Discap (203)

or .022μF Discap (223)

Q9 - 2N3904 transistor

(see Figure C)

C37 - .02μF Discap (203)

or .022μF Discap (223)

TP15

V

COM V

Connect your VOM as shown in Figure 17. Set the

VOM to read 9 v olts DC and turn the power ON. The

voltage at the emitter of Q9 should be approximately

1 volt. If your reading is different by more than .5

volts, turn the power OFF and check components

R39, R40, R41 and Q9.

If you do not have an RF generator and oscilloscope, skip to Section 4.

Page 20

-19-

DYNAMIC MEASUREMENTS

AC GAIN

Connect your test equipment as shown in Figure 18.

Figure 18

TP15

GENERATOR

Hz

TP15

.001μF

Set the generator at 455kHz, no modulation and

minimum voltage output. Set the oscilloscope at 1

volt per division. The scope probe must have an

input capacitance of 12pF or less or it will detune T8.

Turn the power ON and slowly increase the

amplitude of the generator until 4 volts peak to peak

are seen on the scope. With an alignment tool or

screwdriver, tune T8 for a peak on the scope while

readjusting the generator’s amplitude to maintain 4

Vpp at the oscilloscope. After T8 is aligned, move

the scope probe to the base of Q9 and record the

peak to peak amplitude of the signal here:

Vb=________ Vpp.

Turn the power OFF. The AC gain of the second IF

amplifier at 455kHz is equal to 4/Vb and should be

greater than 100. If your value is less than 50 check

components R39, R40, R41, C36 and C37. Also

make sure that Q9 is properly installed. Turn the

power OFF.

BANDWIDTH

Reconnect your test equipment as shown in Figure 18.

Turn the power ON and adjust the generator for 4

volts peak to peak at TP3. Realign T8, if necessary,

for maximum output while adjusting the output of the

generator to maintain 4Vpp at TP3. Slowly decrease

the frequency of the RF generator until the signal at

TP3 drops to .707 of its original value or 2.8Vpp.

Record the frequency of the RF generator here:

Fl = _______kHz.

Now increase the frequency of the generator past the

peak to a point where the signal drops to .707 of its

peak value. Record that frequency here:

Fh = __________kHz.

By subtracting the frequency of the lower 3dB corner

from the frequency of the higher 3dB corner you get

the bandwidth of the second IF amplifier.

Calculate the bandwidth by (FI–Fh)

Bandwidth = __________kHz.

Your results should be similar to the values shown in

Figure 16. Turn the power OFF.

Page 21

-20-

SECTION 4

FIRST AM IF AMPLIFIER

Q8 BASE BIAS

Connect your V OM to the circuit as sho wn in Figure 13.

Set your VOM to read 2 volts DC and turn the power

ON. The voltage at TP5 should be approximately 1.5

volts. If your circuit fails this test, check Q8 and R37.

Turn the power OFF.

Q8 CURRENT

Connect the positive lead of your VOM to the emitter

of Q8 and connect the negative lead to ground point

TP15. Turn the power ON. The voltage should be

approximately .8 volts. Since the current in Q8 is

equal to the current in R37, I(Q2) = .8/R37 or

approximately .8 milliamps. Tur n the power OFF.

R34 - 1MΩ Resistor

(brown-black-green-gold)

TP6 - Test Point Pin

(see Figure A)

CAUTION: Test point must

not touch can of IF Coil.

Q8 - 2N3904 Transistor

(see Figure C)

C35 - .02μF Discap (203)

or .022μF Discap (223)

R37 - 1kΩ Resistor

(brown-black-red-gold)

The operation of the first IF amplifier is the same as

the second IF amplifier with one important difference.

The gain of the first IF amplifier decreases after the

AGC threshold is passed to keep the audio output

constant at the detector and prevent overload of the

second IF amplifier. This is accomplished by making

the voltage on the base of transistor Q8 lower as the

signal strength increases. Since the voltage from

base to emitter is fairly constant, the drop in voltage

at the base produces a similar drop in voltage at the

emitter of Q8. This drop lowers the voltage across

R37 and thus, reduces the DC current through R37.

Since all of the DC current from the emitter of Q8

must go through R37, the DC current in Q8 is

therefore lowered. When the DC current in a

transistor is lowered, its effective emitter resistance

increases. The AC gain of transistor Q8 is equal to

the AC collector load of Q8 divided by its effective

emitter resistance. Raising the value of the effective

emitter resistance, thus, lowers the AC gain of Q8.

ASSEMBLY INSTRUCTIONS

STATIC MEASUREMENTS

If you do not have an RF generator and oscilloscope, skip to Section 5.

Page 22

-21-

DYNAMIC MEASUREMENTS

AC GAIN

Connect your test equipment as shown in Figure 19.

The scope probe must have an input capacitance of

12pF or less, otherwise it will detune transformer T7.

Using a clip lead, short TP3 to R38 as shown. This

short prevents the AGC from lowering the gain of the

first IF amplifier. Set the generator to 455kHz, no

modulation, and minimum voltage output. Set the

scope to read 1 volt per division and turn the power

ON. Increase the amplitude of the generator until

approximately 4Vpp is seen on the scope. Retune

the IF transformer T7 to maximize the 455kHz at

TP4. After tuning T7, adjust the generator amplitude

in order to keep 4Vpp at TP4. Now move the scope

probe to the base of Q8 and record the peak to peak

level of the 455kHz signal here:

Vb=___________Vpp.

The AC gain of the first IF amplifier is equal to 4/Vb.

The AC gain should be greater than 100. DO NOT

TURN THE POWER OFF, GO TO THE NEXT TEST.

AGC ACTION

Move the scope probe back to TP4 and adjust the

generator for 4Vpp if necessary. Remove the clip

lead shorting TP3 to R38. The AGC should reduce

the signal level at TP4 to approximately .8 volts. Turn

the power OFF.

SECTION 5

In a superheterodyne type receiver , the radio w av e at

the antenna is amplified and then mixed with the

local oscillator to produce the intermediate frequency

(IF). Transistor Q7 not only amplifies the RF signal,

but also simultaneously oscillates at a frequency

455kHz above the desired radio station frequency.

Positive feedback from the collector to the emitter of

Q7 is provided by coil L5 and capacitor C31. During

the heterodyning process the following four

frequencies are present at the collector of Q7.

1. The local oscillator frequency, OF.

2. The RF carrier or radio station frequency.

3. The sum of these two frequencies, OF + RF.

4. The difference of these two frequencies, OF – RF.

AM MIXER, AM OSCILLATOR, AND AM ANTENNA

Figure 19

Short TP3 to R38 as shown below.

TP15

Generator

Hz

.001μF

TP15

Page 23

-22-

The “difference frequency” is used as the

intermediate frequency in AM radios. The collector of

Q7 also contains an IF transformer (T6) tuned only to

the difference frequency. This transformer rejects all

frequencies except those near 455kHz. T6 also

couples the 455kHz signal to the base of Q8 to be

processed by the IF amplifiers. The antenna and the

oscillator coils are the only two resonant circuits that

change when the radio is tuned for different stations.

Since a radio station may exist 455kHz above the

oscillator frequency, it is impor tant that the antenna

rejects this station and selects only the station

455kHz below the oscillator frequency. The

frequency of the undesired station 455kHz above the

oscillator is called the image frequency. If the

selectivity of the antenna (Q factor) is high, the image

will be reduced sufficiently.

The oscillator circuit must also change when the

radio is tuned in order to remain 455kHz above the

tuning of the desired radio station. The degree of

accuracy in keeping the oscillator frequency exactly

455kHz above the tuning of the antenna is called

tracking accuracy.

White

Black

Red

White

Black

Red

Green

}

}

}

R=9 - 11Ω

R=1 - 1.5Ω

R=9 - 11Ω

R=1 - 1.5Ω

4 Wire3 Wire

C28 - .1μF Discap (104)

R31 - 56kΩ Resistor

(green-blue-orange-gold)

C30 - 150pF Discap (151)

L5 - AM Oscillator Coil

(Red Dot)

J1 - Jumper Wire

(use a discarded lead)

TP7 - Test Point Pin

(see Figure A)

C31 - .01μF Discap (103)

Q7 - 2N3904 Transistor

(see Figure C)

R32 - 12kΩ Resistor

(brown-red-orange-gold)

R33 - 3.3kΩ Resistor

(orange-orange-red-gold)

C29 - .02μF Discap (203)

or .022μF Discap (223)

Figure J

Resistance measurements

will be used to check the

configuration of the coil. Slide

one holder off the ferrite core

of the antenna assembly.

Then slide the coil off the the

ferrite core. Measure the

resistance of the coil. Your

readings should match the

approximate values as sho wn.

}

ASSEMBLY INSTRUCTIONS

L4 - AM Antenna w/ holders

(see Figures J & K)

C1 - Tuning Gang Capacitor

2 Screws M2.5 x 3.8mm

(see Figure L)

Knob (dial)

Screw M2.5 x 7.5mm

Label AM/FM

(See Figure M)

1/8”

Note: Mount the tuning gang

capacitor to the foil side of

the PC board.

Page 24

-23-

It is important to know which of the two types of the tuning gang capacitor you have received with your kit. Look at the

gang capacitor that you have.

Mount the tuning gang capacitor to the foil side of the PC board with the

AM and FM sides in the correct direction. Fasten the gang in place with

two screws from the front of the PC board. Solder the leads in place and

cut off the excess leads coming through the PC board on the front side.

Knob Post

Screw Holes

FM Antenna

Trimmer

FM Oscillator

Trimmer

AM Antenna

Trimmer

AM Oscillator

Trimmer

Locator Lead

FM SIDE

AM SIDE

AM Antenna

Trimmer

FM Antenna

Trimmer

AM Oscillator

Trimmer

FM Oscillator

Trimmer

Locator Lead

FM SIDE

AM SIDE

IMPORTANT: Before installing the antenna coil, determine if you have a 3 wire coil or a 4 wire coil. Assemble it to the

PC board as shown below. Mount the antenna assembly to the PC board.

Put the tab of the first holder into the right hole and twist the tab 90O.

Put the tab of the second holder into the left hole and twist the tab 90O.

Slide the ferrite core through the holders.

Slide the antenna coil through the ferrite core.

Note: If the end of a wire from the antenna should break off, strip the

insulation off the end with a hot soldering iron. Lay the wire down on a hard

surface and stroke the wire with your iron. The insulation should come off

very easily . CAUTION: The soldering iron will burn the hard surface that you

are working on.

3 Wire Type Antenna: Solder the 3 colored wires to

the PC board: Wire A (red) to the hole marked

“RED”, Wire B (black) to the hole mark ed “BLK” and

Wire C (white) to the hole marked “WHT”.

4 Wire Type Antenna: Solder the 4 colored wires to the PC board: Wire A (green) to the

hole marked “RED”, Wire B (red and black twisted together) to the hole marked “BLK” and

Wire C (white) to the hole marked “WHT”.

Figure K

Tabs

Tabs

C (white)

B (black)

A (red)

C (white)

B

A (green)

Twisted Together

Red

Black

A (green)

Red

Black

B Twisted Together

C (white)

OR

Punch out one antenna shim from the front flap of the box.

Insert the cardboard antenna shim between the ferrite core and the

antenna coil. This will temporarily hold the coil in place.

Figure L

Page 25

-24-

Figure M

Fasten the knob to the shaft of the

capacitor with a screw.

Rotate the knob fully clockwise.

Peel off the protective backing on

the label. Line up the long white

lines on the label with the arrows

on the PC board.

ASSEMBLY INSTRUCTIONS

PC Board Stand

Insert the PC board into the stand as shown.

Screw

M2.5 x 7.5mm

Knob

Page 26

STATIC MEASUREMENTS

Q7 BIAS

Connect your VOM to the circuit as shown in Figure 20.

-25-

Figure 21

Figure 20

TP15

V

COM V

TP15

Connect a clip lead from TP6 to the collector of Q7.

This short prevents Q7 from oscillating. Set the VOM

to read 2 volts DC and turn the power ON. The DC

voltage at TP7 should be about 1.6 volts. If the

voltage in your circuit differs by more than .5 volts,

leave the pow er ON and chec k the battery voltage . If

the battery voltage is greater than 8.5 volts, check

components R31, R32, R33 and Q7.

Turn the power OFF.

Set the scope to read 1 volt per division and turn the

power ON. The scope should display a low voltage

sinewave. The frequency of the sinewave should

change when the tuning gang is turned. If your

circuit fails this test, check components Q7, gang

capacitor, C28, C29, C30, C31, L4 and L5. Tur n the

power OFF.

DYNAMIC MEASUREMENTS

AM OSCILLATOR CIRCUIT

Connect your test equipment to the circuit as shown in Figure 21.

Short TP6 to the

collector of Q7

as shown.

If you do not have an oscilloscope, skip to the AM Final Alignments.

Page 27

-26-

AM FINAL ALIGNMENTS

There are two different AM alignment procedures.

The first alignment procedure is for those who do not

have test equipment and the second is for those who

do have test equipment.

Included in your kit is a special device called a

“magic wand” which is used for aligning resonant

circuits. It usually has a piece of brass on one end

and a piece of iron on the other. When the brass end

of the “magic wand” is placed near the AM antenna,

the antenna coil will react as if inductance has been

removed. Likewise, when the iron end of the “magic

wand” is placed near the AM antenna, the antenna

coil will react as if inductance has been added.

Therefore, when either brass or iron is placed near

the antenna coil, it will change the inductance of the

antenna coil. This change in the inductance will

cause the resonant frequency of the circuit to

change, thus changing the frequency at which the

antenna was selective. When aligning the antenna

and oscillator circuits, coils L4 and L5 are adjusted at

the lower end of the band, while the oscillator and

antenna trimmer capacitors are adjusted at the

higher end of the band. This is done so that the

antenna and the oscillator will track correctly.

AM ALIGNMENT WITHOUT TEST

EQUIPMENT

It is best to use an earphone for this procedure.

Make sure that the switch is in the AM position. With

an alignment tool or screwdriver , turn coils L5, T6, T7

and T8 fully counter clockwise until they stop. DO

NOT FORCE THE COILS ANY FURTHER. Turn

each coil in about 1 1/4 to 1 1/2 turns. Set the AM

antenna coil about 1/8” from the end of its ferrite rod.

Refer to Figure K.

IF ALIGNMENT

Turn the power ON and adjust the volume to a

comfortable lev el. Turn the dial until a weak station is

heard. If no stations are present, slide the antenna

back and forth on its ferrite core, and retune the dial

if necessary. Adjust T6 until the station is at its

loudest. Reduce the volume if necessar y. Adjust T7

until the station is at its loudest and reduce the

volume if necessary. Adjust T8 until the station is at

its loudest and reduce the volume if necessary.

Retune the radio for another weak station and repeat

this procedure until there is no more improvement

noticed on the weakest possible station. This

process peaks the IF amplifiers to their maximum

gain.

OSCILLATOR ALIGNMENT

Tune the radio until a known AM station around

600kHz is heard. It may be necessary to listen to the

station until their broadcast frequency is announced.

If no stations are present at the low side of the AM

band, adjust L5 until a station is heard. Once a

station is found and its broadcast frequency is

known, rotate the dial until the white pointer is

aligned to that station’s frequency marking on the

dial. Adjust L5 until the station is heard. Tune the

radio until a known station around 1400kHz is heard.

It may be necessary to listen to the station until their

broadcast frequency is announced. If no stations are

present, adjust the AM oscillator trimmer on the gang

until a station is heard (refer to Figure L). Once a

station is found and its broadcast frequency is

known, rotate the dial until the white pointer is

aligned to that station’s frequency marking on the

dial. Adjust the AM oscillator trimmer on the gang

until the station is heard. Repeat these 2 steps until

the oscillator alignment is optimized. This process

sets the oscillator range at 955kHz to 2055kHz.

Magic Wand Assembly

Place the piece of brass inside the end of the

shrink tubing, with 1/4” outside. Heat the brass up

with your soldering iron until the tubing shrinks

around the brass. Assemble the iron piece to the

other end in the same manner.

Soldering Iron Tip

Shrink Tubing

Iron Slug

Brass Slug

Page 28

AM ALIGNMENT WITH TEST EQUIPMENT

IF ALIGNMENT

-27-

.001μF

GENERATOR

Hz

TP15

Tune the radio for a station around 600kHz. With the

“magic wand” place the brass end near the antenna

coil as shown in Figure 22. If the signal heard at the

output increases, it means that the antenna coil needs

less inductance. To remove inductance, carefully slide

the antenna coil along its ferrite core in the direction

shown in Figure 22. Place the iron end of the “magic

wand” near the antenna coil. If the signal heard at the

output increases, this means that the antenna coil

needs more inductance. To add more inductance,

carefully slide the antenna coil along its ferrite core in

the direction shown in Figure 22. Repeat these steps

until the signal heard decreases for both ends of the

“magic wand”. Tune the radio for a station around

1400kHz. With the “magic wand”, place the brass end

near the antenna coil. If the signal heard at the output

increases, it means that the antenna coil needs more

capacitance. Adjust the antenna tr immer on the back

of the gang until the signal is at its loudest. Refer to

Figure L for the location of the antenna trimmer . Place

the iron end of the “magic wand” near the antenna

coil. If the signal heard at the output increases, it

means that the antenna coil needs less capacitance.

Adjust the antenna trimmer on the back of the gang

until the signal is at its loudest. Repeat these steps

until the signal heard decreases for both ends of the

“magic wand”. Since the adjustment of both the

antenna trimmer and antenna coil will effect the

antenna alignment, it is advisable to repeat the entire

procedure until the antenna alignment is optimized.

This process sets the tracking of the AM radio section.

Once the antenna is properly aligned, CAREFULLY

APPLY CANDLE WAX or glue to the antenna coil and

the ferrite rod to prev ent it from moving (see Figure 23).

Cut the shim flush with the antenna.

This concludes the alignment of the AM radio

section. If no stations are heard, verify that AM

signals are present in your location by listening to

another AM radio placed near the Superhet 108. If

the AM section is still not receiving, go back and

check each stage for incorrect values and for poor

soldering. Proceed to the FM assembly section.

ANTENNA ALIGNMENT

Figure 23

Wax

Wax

Connect your RF generator and oscilloscope as

shown in Figure 24. Make sure that the switch is in

the AM position. Place a short from the collector of

Q7 to TP6. This shor t “kills” the AM oscillator.

Figure 24

Antenna Coil

Ferrite Core

Antenna Holder

If the antenna needs:

• More inductance, slide the coil

• Less inductance, slide the coil

Magic Wand

Antenna

Shim

Figure 22

TP15

Page 29

-28-

Set the RF generator at 455kHz, modulation of

400Hz 80% and minimum voltage out. Set the

oscilloscope to read .1 volts per division and turn the

power ON. Increase the amplitude of the generator

until the oscilloscope shows a 400Hz sinewave 5

divisions or .5 volts pp. With an alignment tool or

screwdriver adjust T6 for a peak. Reduce the

generator amplitude so that 5 divisions are

maintained. Adjust T7 for a peak and reduce that

amplitude again if necessary. Repeat these steps to

optimize the IF alignment. This process aligns the IF

amplifiers to 455kHz.

After the IF alignment is complete, lower the

frequency of the generator until the voltage drops

.707 of its peaked value or .35Vpp. Record the

frequency of the lower 3dB corner here:

Fl = _________kHz.

Increase the frequency of the generator past the

peak until the voltage seen on the scope drops .707

of its peaked value or .35Vpp. Record the frequency

of the high 3dB corner here:

Fh = __________kHz.

The bandwidth of the IF is equal to BW = Fh - Fl. The

IF’s bandwidth should be around 6kHz. Turn the

power OFF and remove the short from the

collector of Q7 to TP6.

Calculate the bandwidth: __________kHz.

OSCILLATOR ALIGNMENT

Set the RF generator at 540kHz, 400Hz 80% AM

modulation and a low level of output. Turn the power

ON and set the volume control to a comfortable le v el.

Turn the tuning knob counter-clockwise until the

white pointer is aligned at the 540kHz marking on the

dial. With an alignment tool or screwdriver adjust L5

until a 400Hz tone is heard. Adjust L5 for a peak on

the oscilloscope. Adjust the amplitude of the RF

generator to maintain a level of .5 volts peak to peak

or less. After peaking L5, set the generator

frequency to 1600kHz. Turn the tuning knob

clockwise until the white pointer is aligned to the

1600kHz marking on the dial. With an alignment tool

or screwdriver, adjust the AM oscillator trimmer on

the back of the tuning gang until a 400Hz tone is

heard. Adjust the trimmer for a peak on the

oscilloscope. Refer to Figure L for the location of the

AM oscillator trimmer. Repeat these steps to

optimize the oscillator alignment. This process sets

the oscillator range at 955kHz to 2055kHz.

ANTENNA ALIGNMENT

With the power turned OFF, connect your test

equipment as shown in Figure 25.

Figure 25

Battery

Generator

Hz

TP15

Wire loop

close to

antenna

Page 30

-29-

Set the generator at 600kHz, 400Hz 80%

modulation, moderate signal strength. Set the

oscilloscope to read .1 volts per division. Turn the

tuning knob fully counter-clockwise and turn the

power ON. Slowly turn the tuning knob clockwise

until a 400Hz sinewave is seen on the scope. Adjust

the volume control to a comfortable level. If a station

exists at 600kHz, then lower the frequency of the

generator and repeat the previous steps. With the

“magic wand”, place the brass end near the antenna

coil as shown in Figure 22. If the signal on the scope

increases, it means that the antenna coil needs less

inductance. To add more inductance, carefully slide

the antenna coil along it’s ferr ite core in the direction

shown in Figure 22. Repeat these steps until the

signal seen decreases for both ends of the “magic

wand”. Increase the frequency of the generator to

1400kHz and turn the tuning knob clockwise until a

400Hz sinewave is seen on the scope. If a station

exists at 1400kHz, increase the frequency of the

generator and repeat the previous steps. Place the

brass end of the “magic wand” near the antenna coil.

If the signal increases, it means that the antenna coil

needs less capacitance. Adjust the antenna trimmer

for a peak. Refer to Figure L for the location of the

AM antenna trimmer. Since the adjustment of both

the antenna alignment is optimized. This process

sets the AM tracking of the Superhet 108.

Once the antenna is properly aligned, carefully apply

candle wax or glue the antenna coil to the ferrite rod

to prevent it from moving as shown in Figure 23. Cut

the shim flush with the antenna. Proceed to the FM

assembly section.

This concludes the alignment of the AM radio

section. If no stations are heard, verify that AM

signals are present in your location by listening to

another AM radio placed near the Superhet 108. If

the AM section is still not receiving, go back and

check each stage for incorrect values and for poor

soldering. Proceed to the FM assembly section.

1. The number of vibrations (or cycles) per second

produced by a sound is called the frequency, and

is measured in hertz.

2. The distance between peaks of sound waves is

called the wavelength.

3. Sound waves are produced as a certain number

of vibrations per second. The more vibrations per

second, the higher the frequency; the fewer

vibrations, the lower the frequency.

4. Waves of very high frequency are called radio

waves and travel great distances through the air

without the use of wires.

5. Carrier waves are radio w a v es used b y broadcast

stations to carry audio waves.

6. The process of adding the audio waves to the

radio waves is called modulation, and the

process of removing the radio wave from the

audio wave is called demodulation, which is

performed in an AM radio by the detector.

7. The amount of signal picked up by the antenna

will depend on the power of the signal transmitted

and the distance the signal travelled.

8.

Rectification is the process of removing half the

signal, while filtering is the process of smoothing

that signal.

9. Heterodyning is the process of mixing two signals

(the incoming RF signal and the RF signal from

the local oscillator) to produce a third signal (the

IF signal).

DC V OL TAGES

Q7 B1.5U1 11.3

E1.02 0

C8.8 3 0

40

TP5 (AGC) 1.4 5 4.5

69.0

Q8 B 1.4 7 4.6

E.881.3

C8.8

Q9 B1.7TP1 4.5

E1.0

C9.0

Test Conditions

1. Volume set to minimum.

2. Connect side of capacitor C29 (that goes

to L4) to TP15 with a jumper wire.

3. Battery voltage = 9V

4. All voltages are referenced to circuit

common.

5. Voltage readings can var y +

10%

AM RADIO HIGHLIGHTS

The voltage readings below should be used in troubleshooting the AM section. (Switch at AM position).

Page 31

-30-

Answers: 1. D, 2. D, 3. A, 4. A, 5. C, 6. A, 7. D, 8. A, 9. B, 10. D

1. The number of cycles produced per second by a

source of sound is called the ...

r A) amplitude.

r B) vibration.

r C)sound wave.

r D)frequency.

2. The radio frequencies used by AM broadcast

stations are between ...

r A) 20kHz and 400kHz.

r B) 5kHz and 20kHz.

r C)2400kHz and 6000kHz.

r D)550kHz and 1600kHz.

3. The process of removing the audio wave from

the radio wave is called ...

r A) demodulation.

r B) frequency reduction.

r C)modulation.

r D)vibrating.

4. When an electromagnetic wav e (modulated r adio

wave) passes an antenna, it ...

r A) induces a voltage and current in the

antenna.

r B) changes an audio wave into a radio

wave.

r C)changes the carrier frequency.

r D)produces sidebands.

5. The power of the signal transmitted by the

broadcast station and the distance, the signal

travelled from the transmitter to the receiver,

determine the ...

r A) frequency of the modulation.

r B) wavelength of the audio waves.

r C)amount of signal picked up by the

antenna.

r D)type of filter that is used.

6. When the two metal plates on a variable

capacitor are unmeshed the ...

r A) capacitance is minimum.

r B) capacitance is maximum.

r C)capacitance is not affected.

r D)inductance is increased.

7. The process of mixing two signals to produce a

third signal is called ...

r A) filtering.

r B) detecting.

r C)rectification.

r D)heterodyning.

8. The magic wand is used to determine ...

r A) whether more or less inductance is

required in a tuned circuit.

r B) whether more or less capacitance is

required in a tuned circuit.

r C)the gain of an RF amplifier.

r D)whether the oscillator is functioning.

9. The IF frequency of your AM radio is ...

r A) 1600kHz.

r B) 455kHz.

r C)550kHz.

r D)910kHz.

10. The purpose of the AGC circuit is to ...

r A) automatically control the frequency of

the oscillator circuit.

r B) control the band width of the IF stages.

r C)reduce distor tion in the audio circuit.

r D)

maintain a constant audio level at the

detector, regardless of the strength of

the incoming signal.

QUIZ - AM SECTION

INSTRUCTIONS: Complete the following examination, check your answers carefully.

Page 32

-31-

PARTS LIST FOR FM SECTION

RESISTORS

Qty. Symbol Value Color Code Part #

r 2 R9, 23 100Ω 5% 1/4W brown-black-brown-gold 131000

r 1 R25 220Ω 5% 1/4W red-red-brown-gold 132200

r 1 R3 470Ω 5% 1/4W yellow-violet-brown-gold 134700

r 5 R18, 22, 24, 26, 27 1kΩ 5% 1/4W brown-black-red-gold 141000

r 1 R11 1.8kΩ 5% 1/4W brown-gray-red-gold 141800

r 2 R6, 15 2.2kΩ 5% 1/4W red-red-red-gold 142200

r 2 R2, 7 6.8kΩ 5% 1/4W blue-gray-red-gold 146800

r 7 R10,12,14,16,19,20,28 10kΩ 5% 1/4W brown-black-orange-gold 151000

r 2 R1, 8 22kΩ 5% 1/4W red-red-orange-gold 152200

r 2 R4, 5 33kΩ 5% 1/4W orange-orange-orange-gold 153300

r 3 R13, 17, 21 47kΩ 5% 1/4W yellow-violet-orange-gold 154700

r 2 R29, 30 390kΩ 5% 1/4W orange-white-yellow-gold 163900

CAPACITORS

Qty. Symbol Value Description Part #

r 1 C9 15pF Discap (15) 211510

r 1 C10 30pF Discap (30) 213010

r 1 C6 33pF Discap (33) 213317

r 1 C11 220pF Discap (221) 222210

r 2 C4, 5 470pF Discap (471) 224717

r 3 C3, 7, 27 .001μF Discap (102) 231036

r 3 C2, 8, 12 .005μF Discap (502) 235018

r 10 C13 - 22 .01μF Discap (103) 241031

r 1 C23 .02μF or .022μF Discap (203) or (223) 242010

r 1 C26 .1μF Discap (104) 251010

r 1 C25 10μF Electrolytic Radial (Lytic) 271045

r 1 C24 470μF Electrolytic Radial (Lytic) 284744

SEMICONDUCTORS

Qty. Symbol Value Description Part #

r 1 D1 FV1043 Varactor Diode 310176

r 2 D2, 3 1N34A Point-contact Germanium Diode 311034

r 6 Q1 - Q6 2N3904 Transistor 323904

COILS

Qty. Symbol Value Description Part #

r 1 T5 Blue FM Detector 430110

r 1 T4 Pink FM Detector 430120

r 2 T2, 3 Green FM IF 430130

r 1 T1 Orange FM Mixer 430140

r 1 L1 6 Turns FM RF Amp 430160

r 1 L2 2 Turns FM RF Amp 430170

r 1 L3 5 Turns FM Oscillator 430180

MISCELLANEOUS

Qty. Symbol Description Part #

r 1 Antenna FM 484005

r 2 Screw M1.8 x 7.5mm 641100

r 2 Antenna Screw M2 x 5mm 643148

r 2 Nut M1.8 644210

r 7 TP8 - 14 Test Point Pin 665008

r 1 Coil Spacer 669108

Page 33

SECTION 6

THE FM RADIO

Figure 26

μF

.01μF

μF

In the AM DETECTOR section we observed that the

audio was detected from changes in the amplitude of

the incoming signal. In FM detection, the audio is

detected from changes in frequency of the incoming

signal. The RATIO DETECTOR has built-in limiting

action which limits the signal so that any noise riding

on the FM carrier will be minimized. The RATIO

DETECTOR is redrawn below for ease of

explanation.

When an incoming signal is present at T4 and T5, a

current flows through D2, R26, R28, R27 and D3. At

no modulation, the current through the diodes D2

and D3 are equal because T5 is center-tapped.

Thus, no current is drawn through C23 resulting in

zero audio output voltage. When the incoming signal

is modulated, the current through one diode will be

greater than the other. This causes a current to flow

in C23 which will produce an audio voltage across

C23. If the modulation is of opposite direction than

before, more current will flow in the other diode,

which will again cause current to flow in C23 in the

opposite direction resulting in an audio voltage being

produced across C23. The large current drawn from

the audio which causes the battery voltage to vary.

The ratio detector is decoupled further by the resistor

R23 and capacitor C21.

Section 6 begins the construction of the FM radio.

The stages that we will build are shown in the block

diagram below. We will begin with the FM Ratio