Page 1

OPERATOR’S

INSTRUCTION MANUAL

M-2625

AUTO RANGING

DIGITAL MULTIMETER

with Temperature Probe

Copyright © 2007 Elenco®Electronics, Inc.

Page 2

Contents

1. Safety Information 3,4

2. Safety Symbols 5

3. Front Plate of the Meter 5

Input Terminal 6

Function Rotary Switch 7

Function Press Button 8,9

LCD Display 10

4. Power On Option 11

5. Auto Power Off 11

6. Measurement Range 11

7. Making Measurements 12

Preparation 12

Measuring Voltage 12

Measuring DC Voltage 13

Measuring AC Voltage 14,15

Measuring Current 16

Measuring DC Current 17-19

Measuring AC Current 19-21

Measuring Resistance 21,22

Testing Diodes 23

Testing for Continuity 24

Measuring for Capacitance 25,26

Measuring Frequency 27

Measuring Duty Cycle 28,29

Measuring Temperature 29,30

8. Maintenance 31

Battery Replacement 31

Fuse Replacement 32

9. General Specifications 33-35

-2-

Page 3

Introduction

This series LCD auto ranging and auto power-off digital multimeter

is a portable, compact, 3¾ digit multimeter. It is ideally suited for

field, lab, shop, car, and home.

CAUTION: Read, understand and follow all Safety Rules and

Operating Instructions in this manual before using this product.

1. Safety Information

Use the meter only as specified in this manual. Otherwise, the

protection provided by the meter may be impaired. Refer to safety

information in Table 1.

Table 1. Safety Information

Warning

!

To avoid possible electric shock or personal injury, follow these

guidelines:

• Do not use the meter if it is damaged. Before you use the meter,

inspect the case. Look for cracks or missing plastic. Pay particular

attention to the insulation surrounding the connectors.

• Inspect the test leads for damaged insulation or exposed metal.

Check the test leads for continuity. Replace damaged test leads

before you use the meter.

• The RESPONSIBLE BODY shall be made aware that, if the

equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

• Do not use the meter if it operates abnormally. Protection may be

impaired. When in doubt, have the meter serviced.

• Do not operate the meter around explosive gas, vapor, or dust.

• Do not apply more than the rated voltage, as marked on the meter,

between terminals or between any terminal and earth ground.

• Before use, verify the meter’s operation by measuring a known

voltage.

• When measuring current, turn off circuit power before connecting

the meter in the circuit. Remember to place the meter in series with

the circuit.

-3-

Page 4

Table 1. Safety Information (continued)

Warning

• When servicing the meter, use only specified replacement parts.

• Use caution when working above 30VAC rms, 42V peak, or 60VDC.

Such voltages pose a shock hazard.

• Avoid working alone.

• When using the probes, keep your fingers behind the finger guards

on the probes.

• Connect the common test lead before you connect the live test lead.

When you disconnect test leads, disconnect the live test lead first.

• Remove test leads from the meter with the battery door or portions

of the cover removed or loosened.

• To avoid false readings which could lead to possible electric shock

or personal injury, replace the batteries as soon as the low battery

indicator ( ) appears.

• Use only type “AA” batteries or equivalent, properly installed in the

meter case, to power the meter.

• To avoid the potential for fire or electrical shock, do not connect the

thermocouples to electrically live circuits.

+

!

Caution

To avoid possible electric shock or personal injury, follow these

guidelines:

• Disconnect circuit power and discharge all high-voltage capacitors

before testing resistance, continuity, diodes, or capacitance.

• Use the proper terminals, function, and range for your

measurements.

• Before measuring current, check the meter’s fuses and turn power

OFF to the circuit before connecting the meter to the circuit.

-4-

Page 5

2. Safety Symbols

Symbols used on the meter and in this manual are explained in

Table 2.

Table 2. International Electrical and Relative Symbols

AC (Alternating Current) Important Information

~

DC and AC

~

DC (Direct Current) Earth Ground

Equipment Safety Standard

Double Insulated

3. Front Plate of Meter

LCD Display

Function Press

Button

Function

Rotary Switch

!

Caution, risk of electric shock

Low Battery Indicator

+

Input Terminal

Figure 1. Front plate of the meter

-5-

Page 6

Input Terminal

About terminal function refer to Table 3 and Figure 2.

Figure 2. Input Terminal

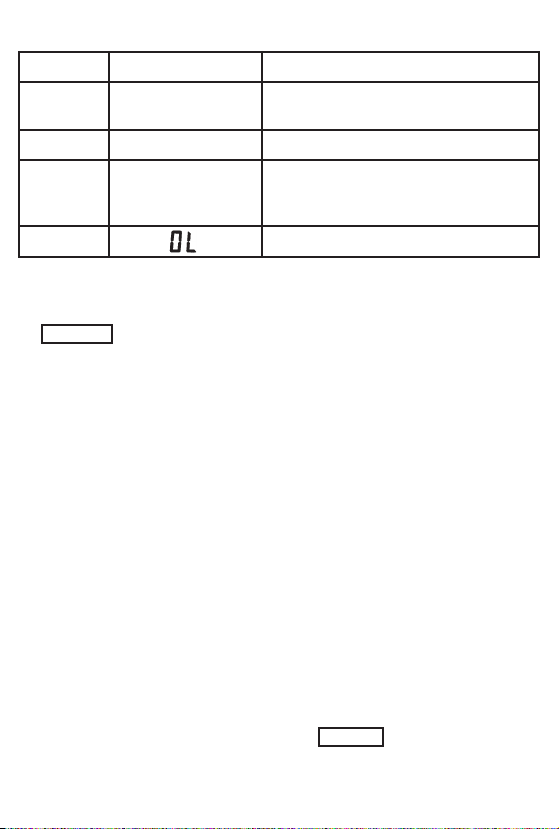

Table 3. Input Terminal

Terminal Function Description

/ /)/OF

V /ΩΩ/ Hz

mA

COM

10A

Volts, ohm, diode, frequency, DUTY, temperature and

capacitance measurement, and testing for continuity terminal

Milliampere current, microampere current measurement terminal

Common terminal for all measurements

Ampere current measurement terminal

Function Rotary Switch

About function rotary switch refer to Table 4 and Figure 3.

-6-

Page 7

Table 4. Function Rotary Switch Symbols

Position of Switch

V

~

ΩΩ

)

Hz

Figure 3. Function Rotary Switch

Function

DC/AC voltage measurement

Resistance measurement, diode test, testing for continuity

Capacitance measurement

Frequency measurement / Duty cycle measurement

-7-

Page 8

Table 4. Function Rotary Switch Symbols (continued)

Position of Switch

O

F

µµ

A

~

mA

~

A

~

OFF

Temperature measurement

DC/AC microampere current measurement

DC/AC milliampere current measurement

DC/AC ampere current measurement

Power off position

Function

Function Press Button

About press function button refer to Figure 4.

Figure 4. Function Press Button

1. SELECT (state choice)

There are several functions at one rotary switch position; press the

SELECT button to select the desired function: ~V,

A~ range for AC or DC voltage, AC or DC current, resistance,

diode, or audible continuity measurement.

2. RANGE (range selection)

With the power on and the meter on the auto range mode, press the

RANGE button to select the desired measurement range manually.

The range goes from minimum to maximum by pressing the

RANGE button multiple times, and returns to minimum after

reaching the maximum range. Pressing and holding the RANGE

button for over two seconds returns the meter to auto range. This

button does not affect the frequency, capacitance, diode or

continuity range.

ΩΩ

, µµA~, mA~,

-8-

Page 9

3. REL∆∆(relative measurement)

Press the REL

a “REL∆” symbol appears on the LCD. The result of the relative

measurement is the difference between the measuring value and

the reference value. The reference value is produced the same as

the momentary value by press the REL

button again to exit this function and the “REL∆” symbol disappears

from the display. This button does not affect the frequency, duty

cycle, diode and continuity test functions.

4. HOLD (data hold)

Pressing the HOLD button enables the data hold function and an

“ H ” symbol appears on the display. The momentary value appears

on the display. Press the HOLD button again to exit this function

and the “ H ” symbol disappears from the display. This button does

not affect the frequency measurement function.

∆∆

button to use the relative measuring function and

∆∆

button. Press the REL

∆∆

5. Hz/DUTY

When making a frequency, DC or AC voltage measurement, press

this button to switch between the Hz or duty cycle test mode.

6. RESET (reset button)

Press this button to clear all values and to restart the meter.

(frequency and duty cycle measurement switch button)

LCD Display

About function rotary switch refer to Table 5 and Figure 5.

-9-

Page 10

Figure 5. LCD Display

Table 5. LCD Display Symbols

Sequ. No. Symbol Description

1 8.8.8.8

2 –

3 AC

4

+

5 RS232

6 Auto

7 REL

8

H

9

10

11 hFE

ΩΩ

12

/ kΩΩ/ M

Hz / kHz / MHz

∆∆

The display digit group

Negative symbol

AC (alternating current) indicator

Battery power is weakening

Serial transmission (not used on this meter)

Auto range indicator

Relative measurement

Data hold

Diode symbol

Audible continuity function indicator

Transistor gain indicator (not used)

Resistance units

ΩΩ

Frequency units

-10-

Page 11

Table 5. LCD Display Symbols (continued)

Sequ. No. Symbol Description

13

O

C OF

14 %

mV / V

15

nF / µµF

mA / A

16

Temperature units

O

C not used on this meter)

(

Percent symbol

Voltage units

Capacitance units

Current units

Overload

4. Power On Option

To release the Auto Power Off function, press and hold the

SELECT button when the meter is on.

5. Auto Power Off

When the meter has been on for 30 minutes without any action from

the user, the meter will automatically switch to the standby mode.

To bring back the display, turn the rotary switch to a different

position, push any button, or restart the meter.

6. Measurement Range

A measurement range determines the maximum measurement

value. Most of the functions of the meter have more than one range.

1. It is important to select the correct range

• If the range is too small, “OL” shows on the display for

overload.

• If the range is too large, the value of the reading will be very

small with less resolution.

2. Auto range and manual range options

• In the auto range mode, the meter automatically selects the

best range for the input detected.

• In the auto range mode, press the RANGE button to enter the

manual range and select the desired range.

-11-

Page 12

• When you change the measurement function, the meter will

regard its auto range as current range.

• In the auto range mode, the “AUTO” symbol will appear on

display and the manual range disappears.

3. Enter or exit manual range mode

• Press the RANGE button to select the manual range mode

and the “AUTO” symbol disappears. Each press of the

RANGE button increases the range. When the maximum

range is reached, the meter restarts at the lowest range.

• Press and hold the RANGE button for more than two

seconds to return to the autorange mode and the “AUTO”

symbol will appear on the display.

7. Making Measurements

Preparation

Checking the Battery Voltage

Rotate the Function Rotary Switch to any position away from the

OFF position. The battery voltage is adequate when the indication

is clear and the symbol is not on the display.

+

If the symbol appears on the display, or nothing shows on the

display at all, follow the battery replacement procedure shown in

related items in this manual and replace with new batteries specified.

Measuring Voltage

Voltage is the difference in electrical potential between two points.

The polarity of AC (alternating current) voltage varies over time, while

the polarity of DC (direct current) voltage is constant.

+

Danger

!

To avoid the danger of electric shock, never make measurements

on a circuit over 600V AC/DC (electrical potential to ground 300V

DC/AC). Do not operate the Function Rotary Switch during

measurement. Do not make a measurement when opening the

battery cover and the meter case.

-12-

Page 13

Measuring DC Voltage

1. Turn on the meter, then set up the meter to measure DC volts as

shown in Figure 6.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the ~V position (then, “AUTO”

and “mV” symbols are indicated on the display).

4. Connect the black test lead to the negative side of the circuit

under test and the red test lead to the positive side of the circuit.

The measured value is indicated on the display. If you connect

the test leads to the opposite polarity, the “–” symbol appears on

the display.

Figure 6. DC Voltage Measurement

-13-

Page 14

Measuring AC Voltage

1. Turn on the meter, then set up the meter to measure AC volts as

shown in Figure 7.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the ~V position and press

SELECT to select the AC voltage measuring mode (then,

“AUTO”, “AC” and “V” symbols are indicated on the display).

4. Connect the test leads to the circuit under test, then the

measured value is indicated on the display.

5. When measuring voltage less than 400mV, press the RANGE

button to switch to manual range mode and select the AC 400mV

range. Doing so will provide a better resolution for your

measurement.

6. You can press the Hz/DUTY button to read the signal frequency

or duty cycle under measurement from the display.

-14-

Page 15

Figure 7. AC Voltage Measurement

Note: When taking a measurement of less than 20mV at the 400mV

AC range, the measurement value cannot be indicated correctly.

Even if shorted, the input line at the 4V AC range, 1 ~ 3 digits may

remain indicated. In that case, by pressing the REL

be indicated.

∆

∆

button, “0” will

-15-

Page 16

Measuring Current

Warning

!

Never attempt an in-circuit current measurement where the

open-circuit potential to earth is greater than 300V. You may

damage the meter or be injured if the fuse blows during

such a measurement.

Caution

To avoid possible damage to the meter or to the equipment

under test, check the meter’s fuses before measuring

current. Use the proper terminals, function, and range for

your measurement. Never place the probes across (in

parallel with) any circuit or component when the leads are

plugged into the current terminals. Maximum measurement

time allowed at the 10A current range function is 15

seconds. If you carry on making a measurement

continuously over 15 seconds, it can cause an erroneous

measurement and damage the meter.

Danger

!

Do not operate the Function Rotary Switch during

measurement. Do not make a measurement when opening

the battery cover or the meter case.

Current is the flow of electrons through a conductor. To measure

current, you must open the circuit under test, then place the meter

in series with the circuit.

To measure AC or DC current, proceed as follows:

-16-

Page 17

Measuring DC Current

1. Turn off power to the circuit. Discharge all high-voltage

capacitors.

2. Turn on the meter, then set up the meter to measure DC current

as shown in Figure 8.

3. Insert the black test lead into the COM terminal and the red lead

into an input appropriate for the measurement range as shown

in Table 6.

4. Connect the black test lead to the negative side of the circuit

under test and the red test lead to the positive side of the circuit

so the meter is in series with the circuit.

5. Turn the on the power for the circuit under test.

6. The measured value is indicated on the display.

If you connect the test leads to the reverse polarities, a “–” symbol

will be shown on the display.

Note: To avoid blowing the meter’s 500mA fuse, use the mA

terminal only if you are sure the current is less than 400mA.

Table 6. Current Measurement

Rotary Switch Input Ranges

µµ

A

mA

A

~

~

~

mA

mA

10A

40µA / 400µA

40mA / 400mA

4A / 10A

-17-

Page 18

Figure 8. DC Current Measurement

-18-

Page 19

Figure 8. DC Current Measurement (continued)

Measuring AC Current

1. Turn off power to the circuit. Discharge all high-voltage

capacitors.

2. Turn on the meter, then set up the meter to measure AC current

as shown in Figure 9.

3. Insert the black test lead into the COM terminal and the red lead

in an input appropriate for the measurement range as shown in

Table 6.

4. Connect the test leads to the circuit under test so the meter is in

series with the circuit.

5. Set the meter to AC mode by pressing the SELECT button

(then, “AUTO” “AC” and “µA”, “mA”, or “A” symbols are indicated

on the display).

6. Turn on the power to the circuit under test.

7. The measured value is shown on the display.

-19-

Page 20

Note: To avoid blowing the meter’s 500mA fuse, use the mA

terminal only if you are sure the current is less than 400mA.

Figure 9. AC Current Measurement

-20-

Page 21

Figure 9. AC Current Measurement (continued)

Measuring Resistance

Caution

To avoid possible damage to the meter or to the equipment

under test, disconnect the circuit power and discharge all

high-voltage capacitors before measuring resistance.

Resistance is an opposition to current flow. The unit of resistance is

the ohm (Ω). The meter measures resistance by sending a small

current through the circuit.

-21-

Page 22

1. To measure resistance, turn on the meter, then set up the meter

as shown in Figure 10.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the position (then,

“AUTO” “OL” and “MΩ” symbols are indicated on the display).

4. Connect the test leads to both ends of the resistance under test,

then the measured value is shown on the display.

Keep the following in mind when measuring resistance:

• Because the meter’s test current flows through all possible paths

between the probe tips, the measured value of a resistor in a

circuit is often different from the resistor’s rated value.

• The test leads can add 0.1Ω to 0.2Ω of error to resistance

measurements. To test the leads, touch the probe tips together

and read the resistance of the leads. If necessary, you can press

the REL

∆∆

button to automatically subtract its value.

Figure 10. Resistance Measurement

-22-

Page 23

Testing Diodes

Caution

To avoid possible damage to the meter or to the equipment

under test, disconnect the circuit power and discharge all

high-voltage capacitors before testing diodes.

Use the diode test to check diodes, transistors, silicon controlled

rectifiers (SCRs), and other semiconductor devices. The test sends

a current through a semiconductor junction, then measures the

junction’s voltage drop. A typical junction drops 0.5V to 0.8V.

To test a diode out of a circuit, set up the meter as shown in Figure

11. In a circuit, a similar diode should still indicate a forward-bias

reading of 0.5V to 0.8V; however, the reverse-bias reading can vary

depending on the resistance of other pathways between the probe

tips.

Figure 11. Diode Test

-23-

Page 24

Note: Open-circuit voltage between measuring terminals is

approximately 1.5V (measuring current approximately 1.5mA).

Testing for Continuity

Caution

To avoid possible damage to the meter or to the equipment

under test, disconnect the circuit power and discharge all

high-voltage capacitors before testing for continuity.

Continuity is the presence of a complete path for current flow. The

continuity test features a beeper that sounds if a circuit is complete

(the resistance less than 120Ω approx.). The beeper allows you to

perform quick continuity tests without having to watch the display.

The continuity function detects intermittent opens and shorts lasting

as little as 1 millisecond (0.001 second). These brief contacts

cause the meter to emit a short beep. Refer to Figure 12 for

continuity testing setup instructions.

Figure 12. Continuity Test

-24-

Page 25

Keep the following in mind while doing a continuity test:

• Even with the test leads shorted, the indicated value may not be

“0”. This is because of the resistance of the test leads and not a

fault. If necessary, you can press the REL

automatically subtract its value, then “0” will be indicated.

∆∆

button to

Measuring Capacitance

Caution

To avoid possible damage to the meter or to the equipment under

test, disconnect the circuit power and discharge all high-voltage

capacitors before measuring capacitance. Use the DC voltage

function to confirm that the capacitor is indeed discharged.

Capacitance is the ability of a component to store an electrical

charge. The unit of capacitance is the farad (F). Most capacitors

are in the nanofarad (nF) to microfarad (µF) range.

The meter measures capacitance by charging the capacitor with a

known current for a known period of time according to the

measuring capacitance:

Measuring capacitance <4µF Measuring time is about 2 seconds

Measuring capacitance <40µF Measuring time is about 7 seconds

Measuring capacitance <100µF Measuring time is about 15 seconds

To measure capacitance, proceed as follows:

1. Turn on the meter, then set up the meter as shown in Figure 13.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the ) position (then, “AUTO”

and “nF” symbols are indicated on the display).

4. Connect the test leads to both ends of the capacitor under test,

then the measured value is shown on the display. If the capacitor

is polarized, connect the red test lead to the positive lead and

the black test lead to the negative lead.

The following are some tips for measuring capacitance:

• To improve the measurement accuracy of small value

capacitors, press the REL

to subtract the residual capacitance of the meter and leads.

∆∆

button with the test leads open

-25-

Page 26

Figure 13. Capacitance Measurement

-26-

Page 27

Measuring Frequency

Frequency is the number of cycles a signal completes each second.

The meter measures the frequency of a voltage or current signal

by counting the number of times the signal crosses a threshold level

each second.

To measure frequency, proceed as follows:

1. Turn on the meter, then set up the meter as shown in Figure 14.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the Hz position (then, the “Hz”

is shown on the display).

4. Connect the test leads to the circuit under test. The meter auto

ranges to one of the frequency ranges, then the measured value

is shown on the display.

Figure 14. Frequency Measurement

-27-

Page 28

Measuring Duty Cycle

Duty cycle (or duty factor) is the percentage of time a signal is

above or below a trigger level during one cycle (Figure 16).

To measure duty cycle, proceed as follows:

1. Turn on the meter, then set up the meter as shown in Figure 15.

2. Insert the black test lead into the COM terminal and the red test

lead into the terminal.

3. Set the Function Rotary Switch to the Hz position. Then press

Hz/DUTY once to select DUTY Cycle measurement (then, a “%”

symbol is indicated on the display).

4. Connect the test leads to the circuit under test. The measured

value is shown on the display.

Figure 15. Duty Cycle Measurement

-28-

Page 29

Figure 16. Duty Cycle Measurement

Measuring Temperature

Warning

!

To avoid the potential of fire or electrical shock, do not

connect the thermocouples to electrically live circuits.

To measure temperature, proceed as follows:

1. Turn on the meter, then set up the meter as shown in Figure 17.

O

2. Set the Function Rotary Switch to the

“AUTO” and “OF” symbols are indicated on the display).

3. Plug the positive leg (+) of the type K thermocouples into the

and read the value on the display. The range of the TP-03

thermocouples is –58

4. Opening the input will display the temperature at the meter

terminals.

terminal and the negative leg (–) into the COM terminal

O

F~+752OF.

F position (then, the

-29-

Page 30

Figure 17. Temperature Measurement

-30-

Page 31

8. Maintenance

General Maintenance

Periodically wipe the case with a damp cloth and mild detergent.

Do not use abrasives or solvents. Dirt or moisture in the terminals

can affect readings. Clean the terminals as follows:

1. Turn the meter off and remove all test leads.

2. Shake out any dirt that may be in the terminals.

3. Soak a new swab with alcohol. Work the swab around each

terminal.

Replacing the Batteries

Replace the batteries with two “AA” batteries (R6P) or equivalent.

Warning

!

To avoid false readings, which could lead to possible

electric shock or personal injury, replace the batteries as

soon as the low battery indicator ( ) appears.

Replace the batteries as follows (refer to Figure 18):

1. Turn the Function Rotary Switch to the OFF position and remove

the test leads from the terminals.

2. Remove the battery door by using a screwdriver to turn the

battery door screw counterclockwise.

3. Replace the batteries. Secure the door by turning the screws

clockwise.

+

Screw

Battery: Two R6P

(AA) or equivalent

Figure 18. Battery Replacement

-31-

Page 32

Replacing the Fuses

Warning

!

To avoid electrical shock or damage to the meter, only use

replacement fuses

10A/250V FAST.

Referring to Figure 19, examine or replace the meter’s fuses as

follows:

1. Turn the Function Rotary Switch to the OFF position and remove

the test leads from the terminals.

2. Remove the holster from the meter. Then, using a screwdriver,

unscrew the two screws on the back case and remove it.

3. Remove either fuse by gently prying one end loose, then sliding

the fuse out of its bracket.

4. Install ONLY the specified replacement fuses with the amperage,

voltage, and speed ratings:

10A/250V FAST.

5. Reinstall the back case. Secure the back case by turning the

screws clockwise.

Screw

∅∅

5x20 0.5A/250V FAST or ∅∅6x25

∅∅

5x20 0.5A/250V FAST or ∅∅6x25

∅6x25 10A/250V FAST

®

Elenco

part # 531101

∅5x20 0.5A/250V FAST

®

Elenco

part # 533004

Figure 19. Fuse Replacement

-32-

Page 33

9. General Specifications

Display: 3¾ digit LCD with a maximum reading of 3999.

Range Control: Auto range or manual range control.

Polarity: Automatic negative polarity indication.

Zero Adjustment: Automatic

Overrange Indication: Only the “OL” display.

Low Battery: The symbol “ ” is displayed when the battery

voltage is below approximately 2.4V.

Auto Power Off: 30 minutes after stopping the switch or no keyinput, the meter automatically enters the power off mode.

Safety Standards: EMC/LVD. The meter is up to the standards

of IEC1010 pollution degree 2; overvoltage category II (double

insulation).

Operating Environment: Temperature 32

humidity <80% RH.

Storage Environment: Temperature –4

humidity <85% RH.

Power: Two 1.5V “AA” batteries.

Dimensions: 6 3/32”/155mm (H) x 2 15/16”/75mm (W) x 1 5/16”/

33mm (D)

Weight: Approx. 9.2oz./260g. (including battery and holster)

Detailed Accuracy Specifications

Accuracies are ± (% of reading + number in last digit) at 73OF

±41OF/23OC ±5OC, <75% RH.

The detailed accuracy specifications are shown in Tables 7 to 18.

Table 7. DCV Detailed Accuracy Specifications

Range Resolution Accuracy Note

400mV 0.1mV

4V 1mV

40V 10mV

400V 100mV

600V 1V ±(0.8% rdg + 5)

+

±(0.5% rdg + 5)

O

- 104OF (0Oto 40OC),

O

- 140OF (–20Oto 60OC),

Input Resistance: 10MΩ

Overload Protect: 400mV

range 250V rms. The rest

600VDC or 600VAC rms.

-33-

Page 34

Table 8. ACV Detailed Accuracy Specifications

Range Resolution Accuracy Note

400mV 0.1mV ±(1.5% rdg + 8) Frequency Response:

4V 1mV

40V 10mV

400V 100mV

600V 1V ±(1.2% rdg + 5)

±(0.8% rdg + 5)

50Hz - 400Hz

Input Resistance: 10MΩ

Overload Protect: 400mV

range 250V rms. The rest

600VDC or 600VAC rms.

Table 9. DCA Detailed Accuracy Specifications

Range Resolution Accuracy Note

40µA 0.1µA

400µA 1µA

40mA 10µA

400mA 100µA

4A 1mA

10A 10mA

±(2.0% rdg + 5)

±(1.5% rdg + 5)

±(2.0% rdg + 5)

Overload Protect: Fast fuse

0.5A/250V and fast fuse

10A/250V.

10A for 15sec. maximum

Input Voltage Drop: <0.4V

Table 10. ACA Detailed Accuracy Specifications

Range Resolution Accuracy Note

40µA 0.1µA

400µA 1µA

40mA 10µA

400mA 100µA

4A 1mA

10A 10mA

±(2.5% rdg + 3)

±(2.0% rdg + 5)

±(2.5% rdg + 5)

Overload Protect: Fast fuse

0.5A/250V and fast fuse

10A/250V.

10A for 15sec. maximum

Input Voltage Drop: <

Frequency Response:

50Hz - 400Hz

Table 11. Resistance Detailed Accuracy Specifications

Range Resolution Accuracy Note

400Ω 100mΩ

4kΩ 1Ω

40kΩ 10Ω

400kΩ 100Ω

4MΩ 1kΩ

40MΩ 10kΩ ±(2.0% rdg + 5)

±(1.0% rdg + 5)

Overload Protect: 250V rms

0.4V

-34-

Page 35

Table 12. Capacitance Detailed Accuracy Specifications

Range Resolution Accuracy Note

40nF 10pF ±(3.5% rdg + 10)

400nF 100pF

4µF 1nF

40µF 10nF

100µF 100nF ±(3.5% rdg + 5)

±(3.0% rdg + 5)

Overload Protect: 250V rms

Table 13. Diode Detailed Accuracy Specifications

Range Description Note

Display reads approximate

forward voltage of diode

Forward DC current approx. 1.5mA;

Reversed DC voltage approx. 1.5V.

Overload protection: 250V rms

Table 14. Frequency & Duty Cycle Detailed Accuracy Specifications

Range Resolution Accuracy Sensitivity Note

5.12Hz

-

10MHz

0.1% - 99.9% 0.1% ±(2.5% rdg + 5) 1.5V rms

0.001Hz

-

10kHz

±(0.1% rdg + 5)

<1MHz:

0.7V rms;

>1MHz:

1.5V rms

Overload

Protect:

250V rms

Duty Cycle:

10Hz-1kHz

Table 15. Temperature Detailed Accuracy Specifications

Range Accuracy Note

–58OF - 752OF

±0.75% ±5OF

±1.5% ±5OF

5OF (room temperature)

-35-

Page 36

Elenco®Electronics, Inc.

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Web site: www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...