Page 1

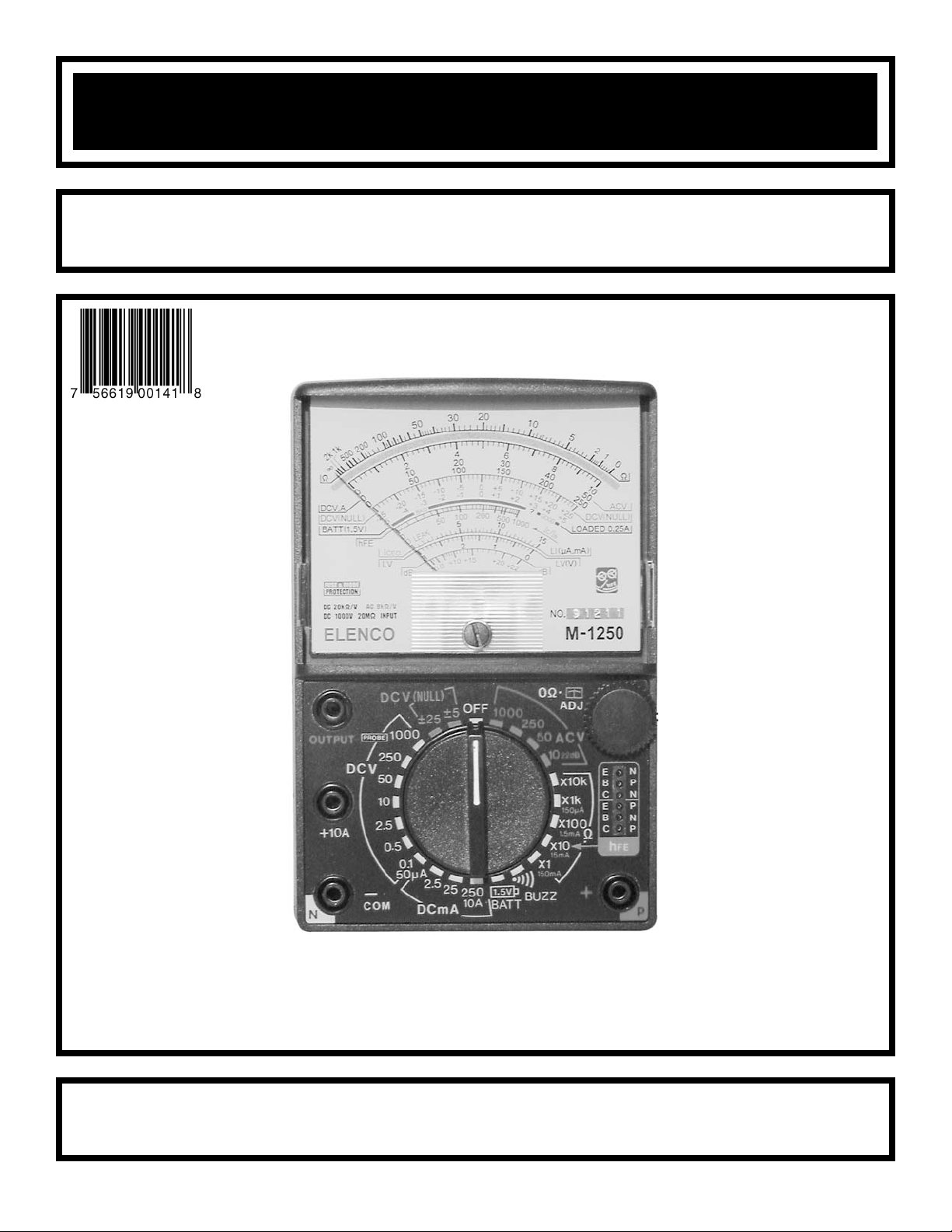

ANALOG MULTIMETER KIT

MODEL M-1250K

Copyright © 2007, 2000 by Elenco®Electronics, Inc. All rights reserved. Revised 2007 REV-H 753070

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

Elenco®Electronics, Inc.

Assembly and Instruction Manual

Page 2

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco

®

Electronics (address/phone/email is at the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase

as they will not be able to help you.

RESISTORS

Qty. Symbol Value Color Code Part #

1 R10 .04Ω Shunt Wire 100269

1R9 .97Ω 1% 1/2W black-white-violet-silver-brown 109731

1 R27 4.5Ω 1% 1/4W yellow-green-black-silver-brown 114530

1 R11 10Ω 1% 1/4W brown-black-black-gold-brown 121030

1 R22 18.5Ω 1% 1/4W brown-gray-green-gold-brown 121832

1 R12 102Ω 1% 1/4W brown-black-red-black-brown 131034

1 R21 200Ω 1% 1/4W red-black-black-black-brown 132030

1 R7 240Ω 1% 1/4W red-yellow-black-black-brown 132430

1 R20 2.08kΩ 1% 1/4W red-black-gray-brown-brown 142034

1 R13 3kΩ 1% 1/4W orange-black-black-brown-brown 143033

1R6 5kΩ 1% 1/4W green-black-black-brown-brown 145030

1 R31 5.6kΩ 1% 1/4W green-blue-black-brown-brown 145630

1 R32 8.2kΩ 1% 1/4W gray-red-black-brown-brown 148230

1 R25 18kΩ 1% 1/4W brown-gray-black-red-brown 151830

2 R35, R36 24kΩ 1% 1/4W red-yellow-black-red-brown 152430

1 R26 31kΩ 1% 1/4W orange-brown-black-red-brown 153130

1 R19 34kΩ 1% 1/4W orange-yellow-black-red-brown 153430

1 R5 40kΩ 1% 1/4W yellow-black-black-red-brown 154030

1 R23 44kΩ 1% 1/4W yellow-yellow-black-red-brown 154430

1 R17 83.3kΩ 1% 1/4W gray-orange-orange-red-brown 158330

1 R34 100kΩ 1% 1/4W brown-black-black-orange-brown 161030

1 R4 150kΩ 1% 1/4W brown-green-black-orange-brown 161533

1 R33 165kΩ 1% 1/4W brown-blue-green-orange-brown 161630

1 R18 195kΩ 1% 1/4W brown-white-green-orange-brown 161930

1 R30 260kΩ 1% 1/4W red-blue-black-orange-brown 162630

1 R16 360kΩ 1% 1/4W orange-blue-black-orange-brown 163630

1 R3 800kΩ 1% 1/4W gray-black-black-orange-brown 168030

1 R29 820kΩ 1% 1/4W gray-red-black-orange-brown 168230

1 R15 1.8MΩ 1% 1/2W brown-gray-black-yellow-brown 171831

1 R28 3MΩ 1% 1/2W orange-black-black-yellow-brown 173031

1R2 4MΩ 1% 1/2W yellow-black-black-yellow-brown 174031

1 R14 6.75MΩ 1% 1/2W blue-violet-green-yellow-brown 176731

1 R1 15MΩ 1% 1/2W brown-green-black-green-brown 181531

1 R24 10kΩ

Potentiometer 191508

1 R8 680Ω Potentiometer 191660

* NOTE: All fixed resistors are 1% tolerance (last stripe, brown). In some cases, resistors with a .5% tolerance

(last stripe, green) may be used in place of the 1% resistors.

CAPACITORS AND INDUCTORS

Qty. Symbol Value Marking Part #

1 C4 .001μF Discap (102) 231036

1 C3 .047μF Discap (473) 234710

1 C1 .047μF, 400V Mylar (473) 245028

1 L1 57.4mH Coil 455577

Note:

C2 is not used.

-1-

Caution: Do not mix alkaline, standard (carbon-zinc), or rechargeable (nickel-cadmium) batteries.

Page 3

-2-

* These parts are part of the main rotary switch assembly. This may come preassembled by the factory.

SEMICONDUCTORS

Qty. Symbol Value Description Part #

2 D1, D2 2CZ Diode 314148

1 Q2 A1015 Transistor 321015

2 Q1, Q3 C1815 Transistor 321815

MISCELLANEOUS

Qty. Description Part #

1 PC Board 516001

1 Fuse 0.5A, 250V 533004

2 1.5V Battery 590001

1 9V Battery 590009

1Buzzer 595225

1 Selector Knob 622011

1 Zero Adjust Knob 622013

1 Case Bottom 623213

1 Top Cover Assembly 623116

1 Buzzer Case Top 623117

1 Buzzer Case Bottom 623214A

1 Selector Wiper 622014

1 Selector Base 622021

1 Screw M4 x 10 642309

2 Fuse Clip 663060

4 Input Sockets M-1250 664003

6 Transistor Socket M-1250 664004

1 Ball Bearing 666401

1 Selector Spring 680020

1 Battery Clip Double 680027

4 Battery Clip Single 680028

1 Wire 30AWG Stranded, 65mm (2.5”) Red 828202

1 Wire 30AWG Stranded, 65mm (2.5”) Yellow 828204

2 Wire 30AWG Stranded, 90mm (3.5”) Red 828220

1 Wire 30AWG Stranded, 90mm (3.5”) Green 828250

1 Wire 30AWG Stranded, 65mm (2.5”) Violet 828270

2 Wire 30AWG Stranded, 90mm (3.5”) White 828290

1 Wire 27AWG Bare 65mm (2.55”) or two 25.4mm (1”) wires 83J400

1 Lead-Free Solder Tube 9LF99

1 Test Lead Set 9TL11

*

*

*

*

*

Specifications

Measurement Ranges Accuracy Remarks

DC Voltage (DCV) All ranges ±3% FS Input impedance 20kΩ/V

1,000V ±5% FS

DCV Null Meter 0 - ±5V 0 - ±25V ±5% FS Zero centering meter type input impedance 40kΩ/V

DC Current 50μA - 2.5mA - 25mA - 250mA (50μA at the DC 0.1V position) ±3% FS Terminal Voltage drop: 250mV

10A ±5% FS 100mV . . . . 50μA

AC Voltage 0 - 10V - 50V - 250V ±4% FS Input impedance 9kΩ/V

1,000V ±5% FS

AF Output (dB) –10dB ~ +22dB (AC10V) ~ +62dB Input impedance 9kΩ/V for output terminal.

0dB/0.775V (1mW through 600Ω impedance circuit)

Resistance All ranges ±3% of arc Internal batteries: (2) 1.5V “AA”, (1) 9V

Buzzer Conduct indicator (buzzer is emitted at 20Ω or less.) Same Ω range, Power supply optional.

Battery Test (BATT) GOOD _? _BAD Color Coded Scale Load current 250mA

Leakage Current

0 - 150μA at X1k range 0 - 15mA at X10k range

Current across terminals.

(Iceo) (LI)

0 - 1.5mA at X100 range 0 - 15mA at X1 range

Terminal to Terminal Voltage (LV)

Common to each Ω range 3V - 0V (Reverse of LI scale) Voltage applied across terminal while Ω is measured.

DC Current Amplification Transistor h

FE

: 0 - 1000 Insert hFEterminal (on scale) directly.

Fact or ( h

FE

) (in x 10Ω range)

Size - 6 x 3 7/8 x 1 1/2 inches

Weight - 0.62 pounds

Page 4

Introduction

Assembly of your M-1250 Analog Multimeter Kit will prove to be an exciting

project and give you much satisfaction and personal achievement. If you

have experience in soldering and wiring techniques, then you should have

no problem with the assembly of this kit. Care must be given to identifying

the proper components and in good soldering habits. Above all, take your

time and follow these easy step-by-step instructions. Remember, “An

ounce of prevention is worth a pound of cure”. Avoid making mistakes and

no problems will occur.

CAUTION: WEAR SAFETY GLASSES WHEN ASSEMBLING

THIS KIT.

Safety Procedures

• Wear eye protection when soldering and during all phases of this kit.

• Locate soldering iron in an area where you do not have to go around it

or reach over it.

• Do not hold solder in your mouth. Solder contains lead and is a toxic

substance. Wash your hands thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

Assemble Components

In all of the following assembly steps, the components must be installed on

the top side of the PC board unless otherwise indicated. The top legend

shows where each component goes. The leads pass through the

corresponding holes and the board is turned to solder the component leads

on the foil side. Solder immediately unless the pad is adjacent to another

hole which will interfere with the placement of the other component. Cut

excessive leads with a diagonal cutter. Then, place a check mark in the box

provided next to each step to indicate that the step is completed. Be sure

to save the extra leads for use as jumper wires if needed.

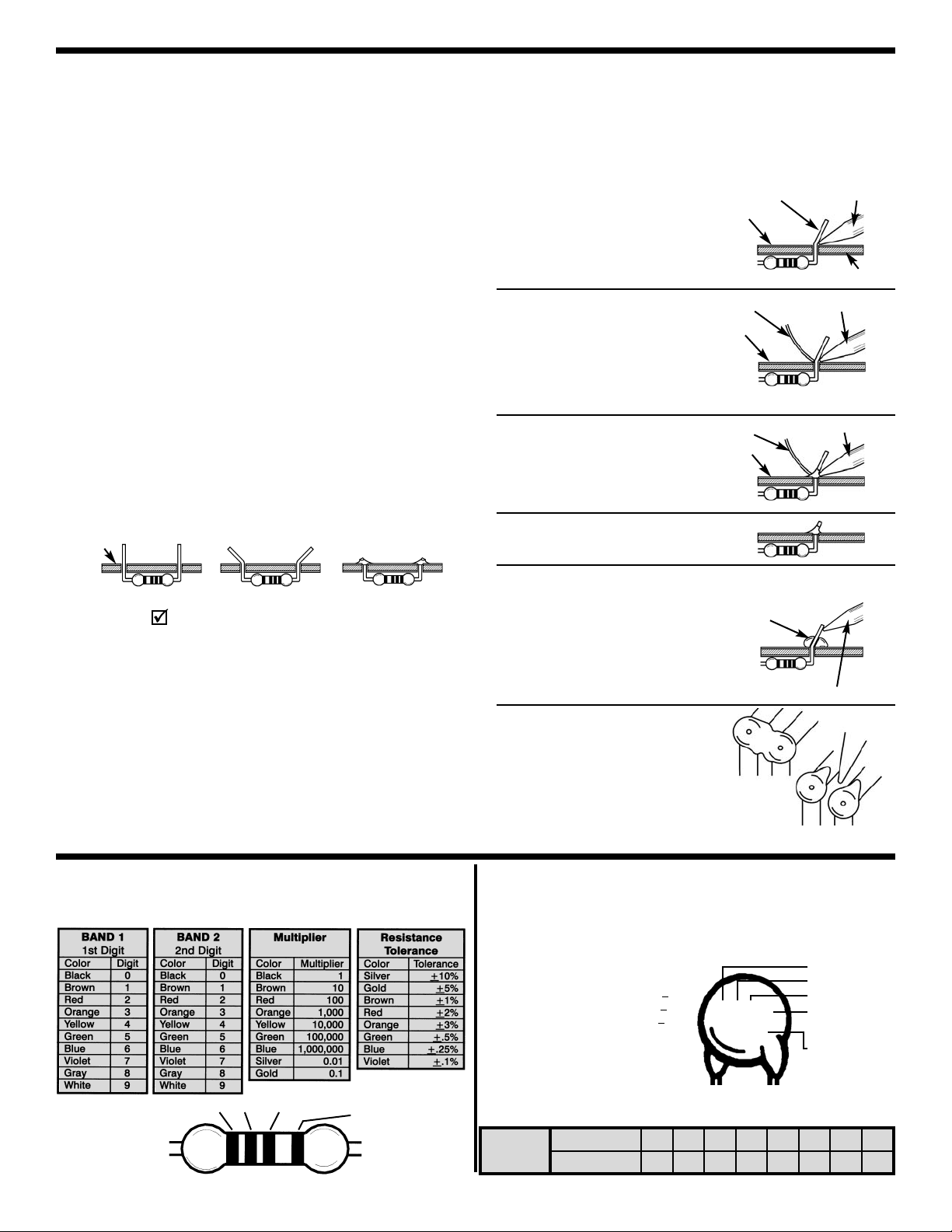

Soldering

The most important factor in assembling your Analog Multimeter is good

soldering techniques. Using the proper soldering iron is of prime

importance. A small pencil type soldering iron of 25 - 40 watts is

recommended. The tip of the iron must be kept clean at all times and

well tinned. Many areas on the PC board are close together and care

must be given not to form solder shorts. Size and care of the tip will

eliminate problems.

For a good soldering job, the areas being soldered must be heated

sufficiently so that the solder flows freely. Apply the solder

simultaneously to the component lead and the component pad on the PC

board so that good solder flow will occur. Be sure that the lead extends

through the solder smoothly indicating a good solder joint. Use only

rosin core solder.

DO NOT USE ACID CORE SOLDER! Do not blob the solder over the

lead because this can result in a cold solder joint.

-3-

CONSTRUCTION

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

Component Lead

Soldering Iron

Circuit Board

Foil

Example 1

Poor solder connections occur when

the lead is not heated sufficiently. The

solder will not flow onto the lead as

shown. To correct, reheat the

connection and, if necessary, apply a

small amount of additional solder to

obtain a good connection.

Solder does not flow onto the lead. A hard

rosin bead surrounds and insulates the

connection.

Poor solder

connection

Soldering iron positioned incorrectly.

Example 2

A solder bridge occurs when solder

runs between circuit paths and creates

a short circuit. This is usually caused

by using too much solder. To correct

this, simply drag your soldering iron

across the solder bridge as shown.

4. Here is what a good solder

connection looks like. Cut off excess

leads.

Mount Part

Bend Leads to Hold Part

Solder & Cut Off Leads

Foil Side

Rx - 100Ω 5% 1/4W Resistor

(brown-black-brown-gold)

2. First apply a small amount of solder

to the iron tip. This allows the heat to

leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the heated

component and the circuit foil to melt

the solder.

Solder

Soldering Iron

Foil

3. Allow the solder to flow around the

connection. Then, remove the

solder and the iron and let the

connection cool. The solder should

have flowed smoothly and not lump

around the wire lead.

Solder

Soldering Iron

Foil

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the

value of resistors.

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF

(picofarads), nF (nanofarads), or μF (microfarads). Most

capacitors will have their actual value printed on them. Some

capacitors may have their value printed in the following manner.

1 2 Multiplier

Tolerance

BANDS

Second Digit

First Digit

Multiplier

Tolerance

103K

100V

Maximum

Working Voltage

The value is 10 x 1,000 = 10,000pF or

.01μF 100V

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +

10%

The letter J indicates a tolerance of +

5%

Note:

The letter “R” may be used at times

to signify a decimal point; as in 3R3 = 3.3

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k

100k

.01 0.1

Page 5

-4-

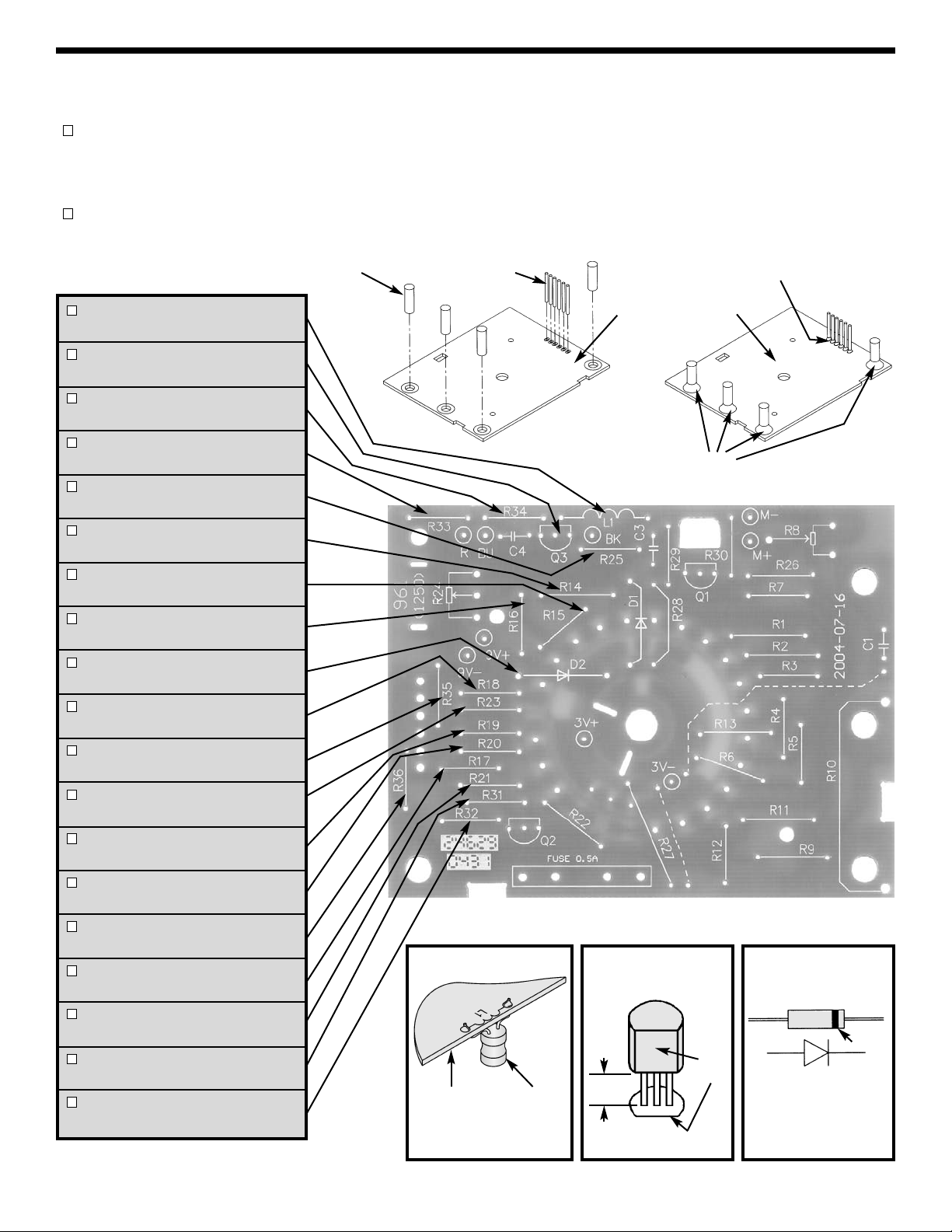

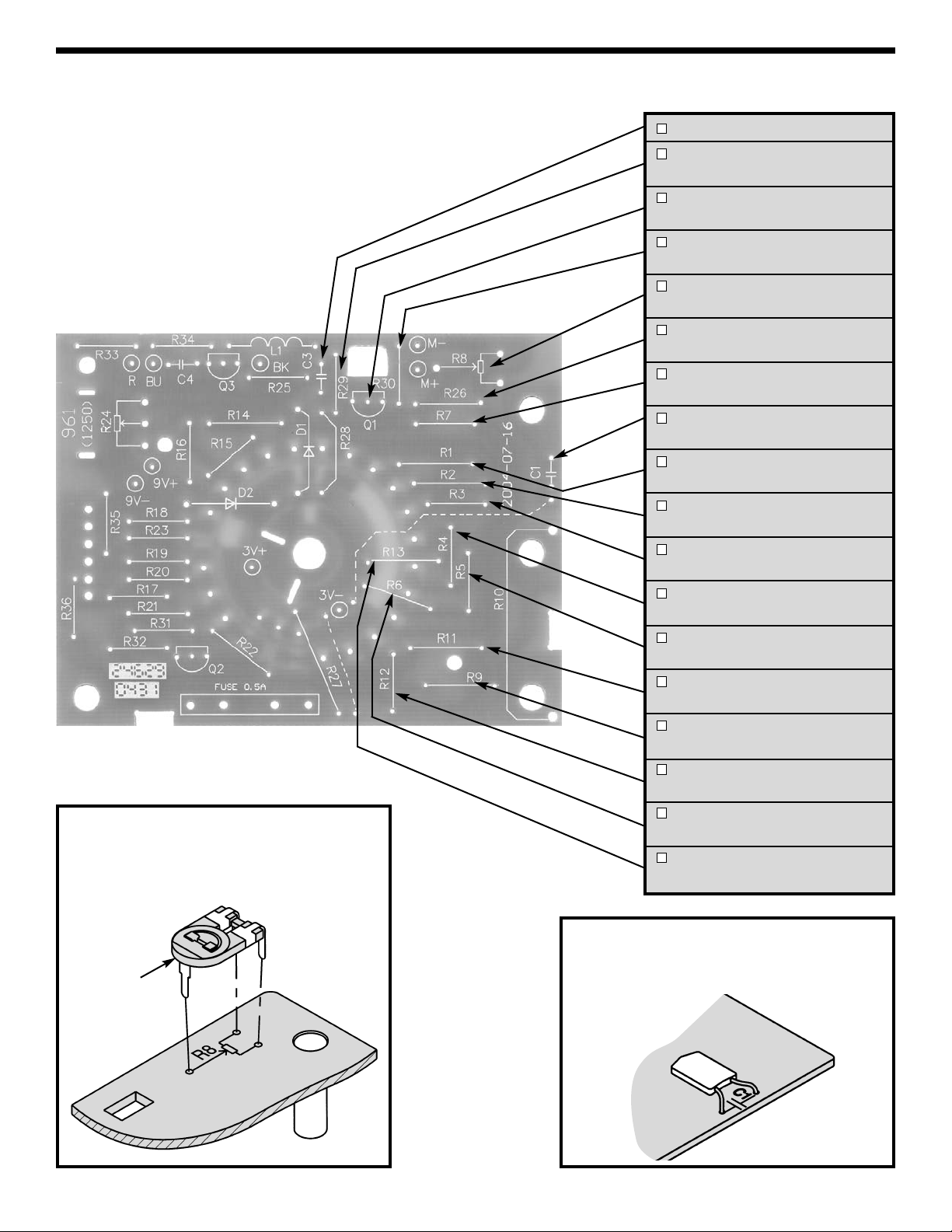

ASSEMBLE COMPONENTS TO THE PC BOARD

After each step, put a check in the box located next to the step that you have completed.

Place the PC board on a table with the copper side facing up and insert the four input sockets into the PC

board holes as shown in Figure A. Solder the input sockets to the PC board as shown in Figure A. Apply

enough heat to allow the solder to flow around the input socket.

Insert the six transistor sockets into the PC board as shown in Figure 1 and then solder into place.

Figure B

Figure C

Figure D

Diodes have polarity.

Mount them with the

band as shown on the

top legend.

L1 - 57.4mH Coil

(see Figure B)

Q3 - C1815 Transistor

(see Figure C)

R34 - 100kΩ 1% 1/4W Resistor

(brown-black-black-orange-brown)

R33 - 165kΩ 1% 1/4W Resistor

(brown-blue-green-orange-brown)

R25 - 18kΩ 1% 1/4W Resistor

(brown-gray-black-red-brown)

R14 - 6.75MΩ 1% 1/2W Resistor

(blue-violet-green-yellow-brown)

R15 - 1.8MΩ 1% 1/2W Resistor

(brown-gray-black-yellow-brown)

R16 - 360kΩ 1% 1/4W Resistor

(orange-blue-black-orange-brown)

D2 - 2CZ Diode

(see Figure D)

R18 - 195kΩ 1% 1/4W Resistor

(brown-white-green-orange-brown)

R35 - 24kΩ 1% 1/4W Resistor

(red-yellow-black-red-brown)

R23 - 44kΩ 1% 1/4W Resistor

(yellow-yellow-black-red-brown)

R19 - 34kΩ 1% 1/4W Resistor

(orange-yellow-black-red-brown)

R20 - 2.08kΩ 1% 1/4W Resistor

(red-black-gray-brown-brown)

R36 - 24kΩ 1% 1/4W Resistor

(red-yellow-black-red-brown)

R17 - 83.3kΩ 1% 1/4W Resistor

(gray-orange-orange-red-brown)

R21 - 200Ω 1% 1/4W Resistor

(red-black-black-black-brown)

R31 - 5.6kΩ 1% 1/4W Resistor

(green-blue-black-brown-brown)

R32 - 8.2kΩ 1% 1/4W Resistor

(gray-red-black-brown-brown)

Flat

Side

0.1”

Band

Foil Side of PC Board

Solder

Solder

Figure A

Transistor SocketsInput Socket

Coil

Solder the coil to the foil

side of the PC board.

Foil Side

Page 6

-5-

C3 - .047μF Discap (473)

R29 - 820kΩ 1% 1/4W Resistor

(gray-red-black-orange-brown)

Q1 - C1815 Transistor

(see Figure C)

R30 - 260kΩ 1% 1/4W Resistor

(red-blue-black-orange-brown)

R8 - 680Ω Potentiometer

(see Figure E)

R26 - 31kΩ 1% 1/4W Resistor

(orange-brown-black-red-brown)

R7 - 240Ω 1% 1/4W Resistor

(red-yellow-black-black-brown)

C1 - .047μF 400V (473) Mylar Cap.

(see Figure F)

R1 - 15MΩ 1% 1/2W Resistor

(brown-green-black-green-brown)

R2 - 4MΩ 1% 1/2W Resistor

(yellow-black-black-yellow-brown)

R3 - 800kΩ 1% 1/4W Resistor

(gray-black-black-orange-brown)

R4 - 150kΩ 1% 1/4W Resistor

(brown-green-black-orange-brown)

R5 - 40kΩ 1% 1/4W Resistor

(yellow-black-black-red-brown)

R11 - 10Ω 1% 1/4W Resistor

(brown-black-black-gold-brown)

R9 - .97Ω 1% 1/2W Resistor

(black-white-violet-silver-brown)

R12 - 102Ω 1% 1/4W Resistor

(brown-black-red-black-brown)

R6 - 5kΩ 1% 1/4W Resistor

(green-black-black-brown-brown)

R13 - 3kΩ 1% 1/4W Resistor

(orange-black-black-brown-brown)

Figure E

Mount the 680Ω pot to the PC board as

shown. Solder the leads to the foil side of the

PC board.

ASSEMBLE COMPONENTS TO THE PC BOARD

After each step, put a check in the box located next to the step that you have completed.

Figure F

Mount and bend the mylar capacitor as

shown. Solder and cut off the excess leads.

680Ω Po t

Page 7

-6-

ASSEMBLE COMPONENTS TO THE PC BOARD

After each step, put a check in the box located next to the step that you have completed.

R28 - 3MΩ 1% 1/2W Resistor

(orange-black-black-yellow-brown)

C4 - .001μF (102) Capacitor

D1 - 2CZ Diode

(see Figure D)

R24 - 10kΩ Potentiometer

(see Figure H)

2.5” Violet Wire (tin both ends)

Jumper Wire

(see Figure I)

R27 - 4.5Ω 1% 1/4W Resistor

(yellow-green-black-silver-brown)

R22 - 18.5Ω 1% 1/4W Resistor

(brown-gray-green-gold-brown)

Q2 - A1015 Transistor

(see Figure C)

F1 - Fuse Clips, Fuse 0.5A

(see Figure J)

R10 - .04Ω Shunt Wire

(see Figure G)

Mount the 10kΩ potentiometer

to the foil side of the PC board

in the location shown. Solder

and cut off the excess leads.

Use the 65mm bare wire (27AWG) as a jumper wire

and mount it flush against the PC board as shown.

Figure I

Jumper Wire

Mount the fuse clips to the location shown on the PC

board. Make sure that the tabs are in the direction

shown below. Solder and cut off the excess leads.

Insert the fuse.

Figure J

Mount the shunt

wire in the

location shown.

Give about 1/8”

clearance from

the PC board.

Solder into

place.

Figure H

10kΩ Po t

Figure G

Shunt Wire

Fuse Clips

Fuse

Tabs

Tabs

Page 8

ASSEMBLE THE BUZZER

Tin the buzzer in the three locations shown in Figure Ka.

Tin both ends of the 3.5”

red, white, and green

wires as shown in Figure Kb.

Solder the red, white, and green wires to the buzzer (see Figure Kc).

Place the buzzer into the holder and snap together (see Figure L).

Figure L

SOLDER BUZZER AND BATTERY CLIP WIRES TO PC BOARD

Solder the red buzzer wire to point R on the PC board.

Solder the white buzzer wire to point BU on the PC board.

Solder the green buzzer wire to point BK on the PC board.

Tin both ends of the 3.5” red wire and solder to point 3V+ on the PC board.

Tin both ends of the white wire and solder to point 3V– on the PC board.

Tin both ends of the 2.5” red wire and solder to point 9V+ on the PC board.

Tin both ends of the 2.5” yellow wire and solder to point 9V– on the PC board.

-7-

Tin Buzzer

Wire

Solder

Soldering Iron

Figure Ka

Figure Kb

Figure Kc

Red Wire

Green Wire

White Wire

Figure M

Red Wire

White Wire

Red Wire

White Wire

Green Wire

Yellow Wire

Red Wire

Page 9

SOLDER METER MOVEMENT WIRES TO PC BOARD

Tin the ends of the meter wires. Solder the red meter wire to M+ and the black wire to M– on the foil side of

the PC board (see Figure N).

-8-

M–

M+

M–

M+

Buzzer Assembly

Red Wire

Figure N

Black Wire

Page 10

-9-

INSTALL BATTERY CLIPS

Install the PC board into the case (see Figure O).

Align the buzzer holder over the two posts and press it down in place (see Figure O).

Install the two single and one double battery clip as shown in Figure O.

Solder the red and white wires from the PC board locations 3V+ and 3V– to the single battery contacts (see

Figure P).

Solder the red and yellow wires from the PC board locations 9V+ and 9V– to the single battery contacts (see

Figure P).

Figure O

Double Battery Clip

Single Battery Clips

Buzzer Assembly

Figure P

Red Wire from 3V+ White Wire from 3V–

Red Wire from 9V+

Yellow Wire from 9V–

Page 11

-10-

CALIBRATION

Batteries

Install the following parts:

1. Install the 9V and the two 1.5V (AA) batteries as shown in Figure 1. Be sure to observe the polarity markings

on the bottom of the battery compartment.

2. Place the thumb wheel knob onto the 0Ω ADJ pot located at the lower right side of the meter dial.

Meter Calibration (See Operating and Testing the Multimeter Section for meter operating instructions).

1. Before starting tests, set the meter needle to zero . The zero adjust screw is located on the meter face next

to the base of the needle. With no test leads connected, slowly turn this screw until the needle points to zero

on the 0-10 scale immediately below the meter mirror.

2.

Obtain a voltage source of 0.4V as measured by an accurate voltmeter. The circuit of Figure 2 will work fine.

3. Set the range switch to 0.5VDC.

4. Connect the test leads as shown in Figure 2.

5. Adjust R8 for a reading of 0.4V (40 on 50 scale) on the M-1250 meter.

If a DC power supply or an accurate voltmeter is not available, then use a fresh 1.5V battery and adjust R6 to

read 1.55V on the 2.5V scale (155 on 250V scale).

Shunt Wire Calibration

To calibrate the shunt wire, you will need a 5A current

source like a 5V power supply and a 1Ω 25 watt resistor.

If a 5A source is not available, you can use a lower

current (2A). If no supply is available, it is not important

to do this test. Set the range switch to 250A/10A position

and connect the red and black test leads as shown in

Figure 3. Read the current on the 0-10 scale immediately

below the meter mirror. If the meter reads high, resolder

the shunt wire so that there is less wire between the two

mounting holes (move the shunt wire closer to the PC

board). If the meter reads low, resolder the shunt wire so

that there is more wire between the two mounting holes

(move the shunt wire away from the PC board).

Figure 2

Figure 3

Figure 1

Caution: Do not mix alkaline, standard (carbon-zinc), or rechargeable (nickel-cadmium) batteries.

9V Battery

1.5V Batteries

Page 12

-11-

INSTALL BACK COVER AND 0Ω ADJ KNOB

Install the bottom case and mount into place with an M4 x 10 screw as shown in Figure Q.

Place the 0Ω ADJ knob onto the front of the unit on the upper right of the panel.

Figure Q

M4 x 10 Screw

Back Case

Page 13

-12-

TROUBLESHOOTING CHART

This chart lists the condition and possible causes of several malfunctions. If a particular part is mentioned as

a possible cause, check that part to see if it was installed correctly. Also, check that part and the parts

connected to it for good solder connections.

PROBLEM POSSIBLE CAUSE

No DC voltage reading 1. Check for open fuse.

Refer to Figure 2 for a better understanding 2. Check resistors R1 - R8, R13 for correct values

of how the meter works. and good solder connections.

3. Check that the PC board is seated properly and that

the three board clamps are engaged.

4. Check the meter movement. Unsolder the red wire

from the meter movement to the PC board. Place a

75kΩ resistor between the red wire and the positive

side of a 1.5V battery. Connect the negative side of

the battery to the black wire from the meter movement.

The meter should read a little over half scale.

Wrong meter readings 1. Check resistors R1 - R7, R13, R24 & R25 for correct

values and good solder connections.

No AC voltage reading 1. Check for open fuse.

Refer to Figure 3 for a better understanding 2. Check diodes D1, D2 for opens and shorts.

of how the meter works. 3. Check resistors R8, R14 - R17

for correct values and good solder connections.

No DC current reading 1. Check for open fuse.

Refer to Figure 4 for a better understanding 2. Check resistors R7 - R13 for correct values and good

of how the meter works. solder connections.

Ohms 1. If meter cannot be zeroed:

Refer to Figure 5 for a better understanding A. Check for open fuse.

of how the meter works. B. Check for weak or improperly installed

batteries.

C. Check that the battery snap and battery con-

tacts are installed correctly.

D. Check resistors R23 - R25 for correct value

and good solder connections.

2. If meter does not read correctly:

A. Check R18 - R25 for correct value and good

solder connections.

No h

FE

reading 1. Check resistors R21, R23 - R25, R35, and R36.

Refer to Figure 6 for a better understanding

of how the meter works.

Buzzer not working. 1. Check the following components: R31 - R34, Q2, Q3,

C4, L1, and the fuse for correct values and good solder

connections.

Null not working. 1. Check the following components: R3 - R6, R28 - R30,

Q1, and C3 for correct values and good solder

connections.

Page 14

-13-

OPERATING AND TESTING THE MULTIMETER

CAUTION: When measuring an unknown voltage or current, always start with the range switch set to the

highest scale. Then, if necessary, move the range switch down until the meter reads in the middle or right half

of the dial.

Checking your multimeter for proper operation is fairly easy. Of prime importance is knowing which scale is read

for each setting of the range switch. DC voltage is read on the dial immediately below the meter mirror. This

dial is marked with three scales with full scale readings of 10, 50 and 250. The 0-10 scale is used for DC voltage

ranges of .1, 10 and 1000VDC. The 0-50 scale is used for DC voltage ranges of .5 and 50VDC and the 0-250

scale is used for DC voltage ranges of 2.5 and 250VDC. The readings taken on these scales must be multiplied

by the proper scale factor. For example, when the range switch is in 2.5VDC, a full scale reading on the 0-250

scale is actually 2.5 volts. You should therefore multiply your reading by .01 (move the decimal point 2 places

to the left). DCmA are read using the same three scales as DC volts.

AC volts are read on the red dial marked ACV using the same 0-10, 0-50 and 0-250 scales as used for DC volts.

AC volts may also be read in decibels using the dB scale. The reference voltage (0dB) for the dB scale is .775

volts. This voltage across 600 ohms dissipates 1mW of power. When dBs are read with the range switch at

10ACV, the dB scale is read directly to 22dB. With the range switch at 50ACV add 14dB. With the range switch

at 250ACV add 28dB and at 1000ACV add 40dB. The maximum dB readable is 22 + 40 = 62 (dB) measured

on the 1000ACV scale.

Ohms are read on the top scale. Multiply the reading by the appropriate factor 1, 10, 1k or 10k as indicated by

the range switch.

If you are new to reading analog meter scales, assemble and try the Dial Scale Reading Exercise

included with this kit.

Before starting tests, set the meter needle to zero . The zero adjust screw is located on the meter face next to

the base of the needle. With no test leads connected, slowly turn this screw until the needle points to zero on

the 0-10 scale immediately below the meter mirror. We will now test each meter function. If the meter should

fail to perform as indicated, refer to the troubleshooting section for assistance.

DC Voltage Test

1) Plug the red test lead into the positive (+) socket, and the black lead into the –COM socket.

2) Set the range switch to 2.5VDC.

3) Connect the red lead to the positive side of a 1.5V battery (you may remove and use one of the 1.5V

batteries from the meter). Connect the black lead to the negative side of the battery. The meter should read

about 150 on the 0-250 scale. Move the decimal point 2 places to the left to obtain 1.5VDC.

4) Set the range switch to 10VDC. The meter should read 1.5 on the 0-10 volt scale.

5) Set the range switch to 50VDC. The meter should move about 1 1/2 small divisions on the 0-50 volt scale.

Ohms Test

CAUTION: When measuring ohms, be sure that there is no voltage across the circuit being tested.

1) Plug the red test lead into the positive (+) socket, and the black lead into the –COM socket.

2) If you removed the 1.5 volt battery from the multimeter for the DC voltage test, replace it now.

3) Set the range selector switch to X1.

4) Short the test leads together and adjust the 0Ω ADJ pot for a zero reading on the ohms (top) scale.

5) Connect the test leads to a known resistor between 1 and 100 ohms and observe the meter reading. Multiply

by the scale factor to obtain the resistance.

6) Set the range switch to X10 and repeat steps 4 and 5 using a 10 to 1k ohm resistor.

7) Set the range switch to X100 and repeat steps 4 and 5 using a 1k to 10k ohm resistor.

8) Set the range switch to X1k and repeat steps 4 and 5 using a 10k to 100k ohm resistor.

9) Set the range switch to X10k and repeat steps 4 and 5 using a 100k to 1M ohm resistor.

Page 15

-14-

AC Voltage Test

In reading AC voltage, it is necessary to obtain a known source of AC. A 12 volt transformer is preferred. If one

is not available, use the 120VAC line.

CAUTION: Be very careful when working with 120VAC. Be sure that the range switch is in the 250 or 1000VAC

position before connecting the test leads to 120VAC.

1) Plug the red test lead into the + socket, and the black lead into the –COM socket.

2) Set the range switch to the appropriate ACV position. Touch the test leads to the power source and observe

the meter reading. Then, multiply by the appropriate scale factor.

DC Current Test

The DC current circuit is protected by a 0.5 amp fuse. Be sure that the test current is below this level.

Obtain a 68kΩ resistor and a 1.5 volt battery (you may again use one of the 1.5V meter batteries).

Proceed as follows:

1) Plug the red test lead into the + socket and the black lead into the –COM socket.

2) Set the range switch to the 50μ ADC position.

3) Connect the 68kΩ resistor to the positive side of the battery. Connect the red test lead to the other side of

the resistor. Connect the black test lead to the negative side of the battery. The meter should read about

22 on the 0-50 scale. This converts directly to 22μA.

4) Set the range switch to the 2.5mADC position. Repeat step 3 using a 1kΩ resistor. The meter should read

about 150 on the 0-250 scale. Move the decimal point two places to the left to obtain 1.5mADC.

5) Check the remaining scales using a power supply and suitable resistors.

6) See Calibration Section for 10 amp range.

hFE Test

The hFE of a transistor is read using the six small input sockets. To measure the hFE (beta) of an NPN transistor,

proceed as follows.

1) If you removed the 1.5 volt battery from the multimeter, replace it now.

2) Set the range switch to the ohms X10 position.

3) Adjust the 0ΩADJ pot for a zero reading on the ohms scale.

4) Insert the transistor into the NPN section.

5) Read the h

FE of the transistor on the blue hFE scale immediately below the BATT (1.5V) scale.

8) To measure a PNP transistor, insert the transistor into the PNP section.

Transistor Leakage Test (Iceo)

1) Plug the red test lead into the P (+) and the black test lead in into N (–COM) sockets.

2) Set the range switch to the ohm X10 (15mA) position for small size transistors, for X1 (150mA) position for

large size transistors.

3) Adjust the 0Ω ADJ for a zero reading on the ohms scale.

4) Connect the transistor as follows:

NPN Connect the test lead from the P terminal to the EMITTER (E) of the transistor.

Connect the test lead from the N terminal to the COLLECTOR (C) of the transistor.

PNP Connect the test lead from the P terminal to the COLLECTOR (C) of the transistor.

Connect the test lead from the N terminal to the EMITTER (E) of the transistor.

5) Read the leakage current on the Iceo scale. If you are on the 150mA scale, move the decimal point one

place to the right.

Battery Test

1. Set the range switch to the BATT position.

3. Plug the red test lead into the positive (+) socket and the black test lead into the –COM socket.

3. Connect 1.5V battery to the test leads and read the scale.

Good battery: The pointer stays within the GOOD (BLUE) range.

Low battery: The pointer stays within the ? range. The battery may be only good for low current equipment.

Bad battery: The pointer stays within the BAD (RED) range.

Page 16

-15-

THEORY OF OPERATION

Introduction

Your multimeter is of professional quality using 1% precision resistors throughout the design. The accuracy at

full scale reading will be within 3% of full scale DC voltage or current (1,000V - 5%, 10A - 5%) and 4% of full

scale (for 1,000V - 5%) AC voltage. The accuracy of the ohms measurement is 3% of arc.

On the DC volts range, the loading impedance of the meter is 20,000 ohms per volt. This means that if the

range switch is on the 250V position, the loading to the circuit under test will be 20,000 x 250 = 5MΩ.

The input loading of the meter is a very important factor to be considered when measuring the voltage of a high

resistance circuit. Take the example where two 1MΩ resistors are connected in series across a 9V battery. The

voltage at the junction of the resistors will be 4.5V. When measured on the 10V scale, the input loading will be

about 200kΩ (20,000 ohms/volt times 10V). The voltage at the junction will therefore drop to 1.28V and the

meter will read this voltage. If the meter is switched to the 50V position, the loading will be 1MΩ and the meter

will read 3V. For reasonably accurate measurement, the circuit under test should have an impedance of less

than 100kΩ or you should use the higher ranges. The loading on the 250V and 1,000V ranges will be 5MΩ and

20MΩ respectively, but it will be hard to read 4.5V on these ranges.

DC Voltage Measurement

Figure 4 shows a simplified diagram of the DC voltage

measuring circuit. Here resistors are switched in series

with the meter to provide the desired ranges.

Figure 4

Buzzer Test

1. Set the range switch to the BUZZ position.

2. The buzzer will sound if there are 20Ω or less across the leads.

DCV (NULL) Test

1. Set the range switch to either the ± 5 or ±25 scale in the DCV (NULL) position.

2. Adjust the 0Ω ADJ pot for a zero center position

3. Plug the red test lead into the positive (+) socket and the black test lead into the –COM socket.

4. Connect voltage to the test leads and read the voltage.

Output Jack Test (allows measurement of AC voltage when superimposed on a DC voltage.)

1. Plug the red lead into the OUTPUT socket and the black lead into _COM.

2. Set the range switch to the appropriate ACV position. Touch the test leads to the power source and observe

the reading. Then, multiply by the appropriate scale factor.

Diode Tests

The diode forward current If and reverse current Ir are read LI scale. To check a diode in the forward direction

proceed as follows:

1) Plug the red test lead into the + socket and the black lead into the –COM socket.

2) Select the approximate forward current desired 150μA, 1.5mA, 15mA or 150mA and set the range switch to

this position (blue markings in ohms range).

3) Short the test leads together and adjust the 0ΩADJ pot for a zero reading on the ohms (top) scale.

4) Connect the red test lead to the cathode (striped end) of the diode and the black test lead to the anode of

the diode.

5) Read the forward current on the LI scale. The voltage drop across the diode is shown on the LV scale

immediately below the LI scale.

Page 17

-16-

DC Current Measurement

Figure 6 shows a simplified diagram of the DC current measuring circuit. Here the resistors are placed across

the meter to shunt the current. On the 50μA range, the current is fed directly to the meter and the voltage drop

across the meter at full scale deflection is .1 volt. On all of the other ranges, the full scale voltage drop across

the meter is .25 volts. A .5 amp fuse is added to the circuit for protection against overload.

Figure 6

Figure 7

AC Voltage Measurement

Figure 5 shows a simplified diagram of the AC voltage measuring circuit. Two diodes are added to the series

resistors to rectify the AC voltage. The input impedance on the AC voltage ranges is 9kΩ per volt. On the

250VAC range, the input impedance is therefore 2MΩ.

Figure 5

Resistance Measurement

Figure 7 shows a simplified diagram of the resistance measuring circuit. Here a known 1% resistor, in parallel

with the meter and the zero adjust resistors, is compared to the external resistor in a series circuit. The current

is supplied by the 3V battery on the X1, X10 and X1k ranges. On the X10k range, a 9V battery is placed in

series with the 3V battery to supply more current to the series circuit. To calibrate the ohms circuit, the external

resistor is made zero ohms by shorting the test leads together. This places the full battery voltage across the

internal resistors. The current in the meter is adjusted to full scale deflection, or zero reading on the dial. When

an external resistor is made equal to the internal resistance, the meter will deflect to half scale and the dial

marking will show its value.

Page 18

hFE Measurement

Figure 8 shows a simplified diagram of the hFE measuring circuit for PNP transistor. Here the range switch is in

the X10 ohms position and the transistor circuit takes the place of the external resistor in the ohms measurement.

The higher the h

FE of the transistor, the more current flows in the external circuit and the lower the effective

resistance. The meter reads this resistance and the h

FE of the transistor may be read on the hFE scale.

Figure 8

-17-

Battery Test

Figure 9 shows a simplified diagram of the battery measuring circuit. The battery voltage is measured under a

0.25A load.

DC NULL Test

Figure 11 shows a simplified diagram of the DCV (NULL) circuit. The meter is set to 0 on the DCV (NULL) scale.

Positive or negative voltage applied to the terminals causes the meter to swing in either direction.

Buzzer Test

Figure 10 shows a simplified diagram of the audio continuity circuit. When a 20Ω load or less is place across

the terminals, transistor Q3 conducts and allows Q3 to oscillate.

Figure 9

Figure 10

Figure 11

Page 19

SCHEMATIC DIAGRAM M-1250K

-18-

Pin-out

2SC1815

2SA1015

E C B

Page 20

Elenco®Electronics, Inc.

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Web site: www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...