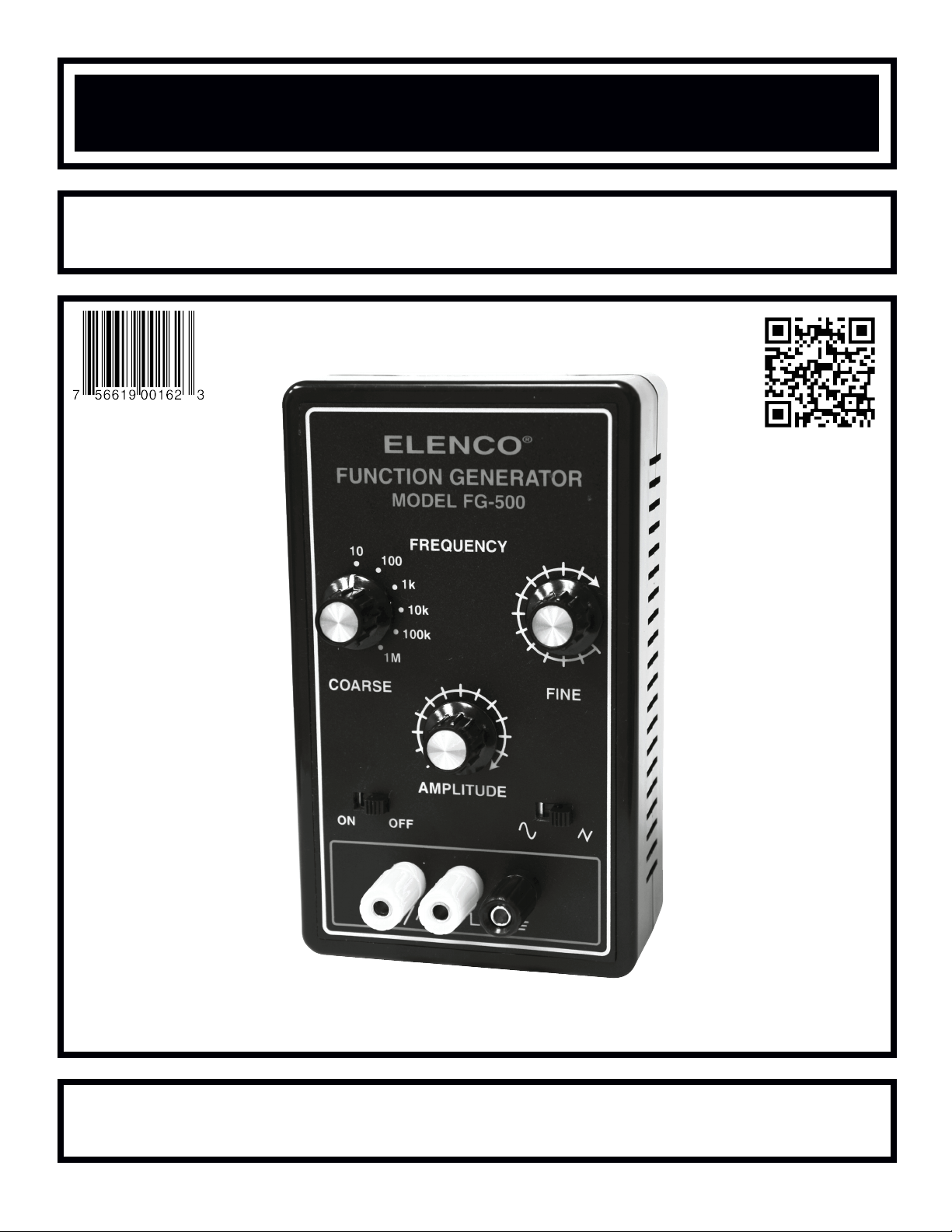

Elenco 100kHz Function Generator in Kit Form User Manual

FUNCTION GENERATOR KIT

MODEL FG-500K

Assembly and Instruction Manual

ELENCO

®

Copyright © 2013 by Elenco®Electronics, Inc. All rights reserved. Revised 2013 REV-G 753069

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact ELENCO®(address/phone/e-mail is at

the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase as they

will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

! 1 R6 200Ω 5% ¼W red-black-brown-gold 132000

! 1 R1 620Ω 5% ¼W blue-red-brown-gold 136200

! 1 R5 3.9kΩ 5% ¼W orange-white-red-gold 143900

! 1 R7 8.2kΩ 5% ¼W gray-red-red-gold 148200

! 1 R8 10kΩ 5% ¼W brown-black-orange-gold 151000

! 1 R4 22kΩ 5% ¼W red-red-orange-gold 152200

! 1 R9 100kΩ 5% ¼W brown-black-yellow-gold 161000

! 1 R2 10kΩ Potentiometer 192531

! 1 R3 100kΩ Potentiometer 192612

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C6 820pF (821) 10% Discap 228210

! 1 C5 .01µF (103) 10% Mylar 240119

! 1 C4 .1µF (104) 10% Mylar 251017

! 1 C3 1µF 50V Electrolytic (Lytic) 261047

! 3 C2, C7, C8 10µF 16V Electrolytic (Lytic) 271045

! 1 C1 100µF 16V Electrolytic (Lytic) 281044

! 1 C9 1,000µF 16V Electrolytic (Lytic) 291044

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 U1 XR-2206 Integrated circuit (IC) 332206

MISCELLANEOUS

-1-

Qty. Description Part #

! 1 PC board 511003

! 2 DPDT switch PC mount 541009

! 1 Switch rotary 2p6pos 542207

! 1 Battery snap 590098

! 1 Battery holder 590099

! 3 Knob 622009

! 1 Case top 623061

! 1 Case bottom 623062

! 1 Binding post black 625031

! 3 Nut binding post 625031HN

! 3 Lockwasher binding post 625031LW

! 2 Binding post yellow 625034

Qty. Description Part #

! 4 Screw 2.8 x 8mm 641102

! 3 Hex nut 7mm 644101

! 1 Hex switch nut 9 x 15mm 644102

! 2 Flat washer 8 x 14mm 645101

! 1 Flat washer 9mm 645103

! 4 Rubber foot 662015

! 1 16-pin IC socket 664016

! 1 Label top panel 721008

! 1” Double-sided tape 740020

! 9” Black wire 22ga. 814120

! 1 Lead-free solder 9LF99

-2-

PARTS VERIFICATION

Before beginning the assembly process, familiarize yourself with the components and this instruction book.

Verify that all of the parts are present. This is best done by checking off the parts in the parts list.

RESISTORS CAPACITORS SEMICONDUCTOR

Electrolytic

(radial)

Potentiometer

Knob

MISCELLANEOUS

PC board

Case top

Case bottom

Screws

2.8 x 8mm

7mm

Nuts Washers

Flat

8 x 14mm

Rubber foot

Label

Lead-free solder

Carbon film

Discap

Battery snap

Black wire 22ga.

Double-sided tape

Mylar

16-pin IC socket

XR-2206 Integrated

circuit (IC)

Rotary switch

DPDT switch

Binding posts

Black Yell ow

Binding post nut

Binding post

lockwasher

Battery holder

9mm

Flat

9 x 15mm

-3-

INTRODUCTION

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads) or µF (microfarads). Most

capacitors will have their actual value printed on them. Some capacitors may have their value printed in the following manner.

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BAND 1

1st Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yello w 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yello w 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yello w 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tolerance

Color Tolerance

Silver +10%

Gold +5%

Brown +1%

Red +2%

Orange +3%

Green +.5%

Blue +.25%

Violet +.1%

Bands

1 2

Multiplier

Tolerance

Electrolytic capacitors have a positive and a

negative electrode. The negative lead is

indicated on the packaging by a stripe with

minus signs and possibly arrowheads. Also, the

negative lead of a radial electrolytic is shorter

than the positive one.

Warning:

If the capacitor is connected

with incorrect polarity, it may

heat up and either leak, or

cause the capacitor to

explode.

OUTPUT:

• Waveforms: Sine, Triangle, Square

• Impedance: 600Ω + 10%.

• Frequency: 1Hz - 1MHz in 6 decade steps with variable

ranges.

SINE WAVE:

• Amplitude: 0 - 3Vpp

• Distortion: Less than 1% (at 1kHz)

• Flatness: +0.05dB 1Hz - 100kHz

SQUARE WAVE:

• Amplitude: 8V (no load)

• Rise time: Less than 50ns (at 1kHz)

• Fall time: Less than 30ns (at 1kHz)

• Symmetry: Less than 5% (at 1kHz)

TRIANGLE WAVE:

• Amplitude: 0 - 3Vpp

• Linearity: Less than 1% (up to 100kHz)

POWER REQUIREMENTS:

• Standard 9V battery

OPERATING TEMPERATURE:

• 0OC to 50OC

Polarity

marking

(+)

(–)

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k 100k .01 0.1

Second digit

First digit

Multiplier

Tolerance*

Note: The letter “R” may be

used at times to signify a

decimal point; as in 3R3 = 3.3

103K

100V

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +10%

The letter J indicates a tolerance of +5%

Maximum working voltage

The value is 10 x 1,000 =

10,000pF or .01µF 100V

*

Assembly of your FG-500 Function Generator will

prove to be an exciting project and give much

satisfication and personal achievement. The FG-500

contains a complete function generator capable of

producing sine, square and triangle wave forms. The

frequency of this generator can be contiuously varied

from 1Hz to 1MHz in 6 steps. A fine frequency control

makes selection of any frequency in between easy.

The amplitude of the wave forms are adjustable from

0 to 3Vpp. This complete function generator system

is suitable for experimentation and applications by

the student. The entire function generator is

comprised of a single XR-2206 monolithic IC and a

limited number of passive circuit components.

SPECIFICATIONS

-4-

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allows the heat

to leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too

much solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Introduction

The most important factor in assembling your FG-500K Function

Generator Kit is good soldering techniques. Using the proper soldering

iron is of prime importance. A small pencil type soldering iron of 25 watts

is recommended. The tip of the iron must be kept clean at all times

and well-tinned.

Solder

For many years leaded solder was the most common type of solder

used by the electronics industry, but it is now being replaced by leadfree solder for health reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting

point than lead solder, so you need higher temperature for the solder to

flow properly. Recommended tip temperature is approximately 700OF;

higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results.

Soldering iron tips wear out faster since lead-free solders are more

corrosive and the higher soldering temperatures accelerate corrosion,

so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when

using lead-free solder:

● Keep the iron tinned at all times.

● Use the correct tip size for best heat transfer. The conical tip is the

most commonly used.

● Turn off iron when not in use or reduce temperature setting when

using a soldering station.

●

Tips should be cleaned frequently to remove oxidation before it becomes

impossible to remove. Use Dry Tip Cleaner (Elenco®#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to clean your tip, then use

distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

● Always wear safety glasses or safety goggles to

protect your eyes when working with tools or

soldering iron, and during all phases of testing.

● Be sure there is adequate ventilation when soldering.

●

Locate soldering iron in an area where you do not have to go around

it or reach over it. Keep it in a safe area away from the reach of

children.

● Do not hold solder in your mouth. Solder is a toxic substance.

Wash hands thoroughly after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed

on the top side of the PC board unless otherwise indicated. The top

legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

Loading...

Loading...