Page 1

ELENBERG LTV-1521

Page 2

Page 3

1

CABINET FRONT

2

SPEAKER

3

FUNCTIONAL KNOB

4

BRACKET

5

SHIELD BOX

6

INTEFACE BOARD

7

CABINET BACK

8

CONNECTION BOARD

9

ROTATE COVER

10

BASE

11

BASE BOARD

12

SCREEN

13

LENS

14

BRACKET(LEFT)

15

BRACKET(RIGHT)

REMOTE HANDSET

KK-Y298

34003794

32001259

SPEAKER YDT6090N-6rc(8Ω/4W)

21000391

FUSE 20N-020H/L-2A/250V

15"L.C.D SVA150XG04TB

31003232

Spare Parts List (LTV -1521)

DescriptionItem QTY

(Код ЗЧД=Номер ЗЧД)

1 36032541

2

1 36032509

1 37009817

1 37009832

1 37009814

1 36029368

1 37006803

1 36022512

1 36032508

1 36032510

1

1 36032506

1 37009819

1 37009830

AC POWER JSI-150206(LF)TUNER AFT1/3100

TOUCH SWITCH KFC-A06-L4-4.5×6.5-4.3B 23000611

IR REMOTE CONTROL RECEIVER

SMD ZENERDIODE BZV55-C/8V2-PHILIPS 16002081

Part №

29001071

27001227

MAIN BOARD 090*KLC-1521QS-2-01/00/A 35009717

KEY BOARD 090*LC-TM1509S01/00/A 35009707

REMOTE CONTROL RECEIVER BOARD 35009433

REMOTE CONTRO BOARD 090*Y27401/01-T/A 35009435

FRONT CABINET200*KLC1521US10/102P 36032541

BACK CABINET 202*KLC1521US10/102P 36032505

MODEL PLATE 412*KLC-1521QS10/02-KONKA 36033736

*FUNCTION BUTTON 291*KLC1521US10/101D 36032509

*POLYFOAM L 300*KLC1521US10/00 39018938

*POLYFOAM R 300*KLC1521US20/00 39018943

*PACKINGBAG310*080080/034R-800X800X0.025 39011083

*CARTON BOX 510*KLC-1521QS10/03 39020551

*MANUAL570*KLC-1521QS/02-ENGLISH 39020552

SOCKET 21 SCART CS-2110VEP 25002363

VGA SOCKETDP-001-01EP 25002364

*STEREO JACK CKX-035-114C-01EP 25002362

Page 4

IMPORTANT SERVICE SAFETY INFORMATION

Operating the receiver outside of its cabinet or with its back removed involves a shock hazard. Work on these

models should only be performed by those who are thoroughly familiar with precautions necessary when working on

high voltage equipment.

Exercise care when servicing this chassis with power applied. if carelessly contacted, can cause serious shock or

result in damage to the chassis. Maintain interconnecting ground lead connections between chassis, escutcheon, picture

tube dag and tuner when operating chassis.

When it is necessary to make measurements or tests with AC power applied to the receiver chassis, an Isolation

Transformer must be used as a safety precaution and to prevent possible damage to transistors. The Isolation

Transformer should be connected between the TV line cord plug and the AC power outlet.

It is important to maintain specified values of all components and anywhere else in the received that could cause

a rise in operating supply voltages. No changes should be made to the original design of the receiver.

Components shown in the shaded areas on the schematic diagram and/or identified by in the replacement parts

list should be replaced only with exact factory recommended replacement parts. The use of unauthorized substitute

parts man creates may create shock, fire, or other hazards.

Before returning the receiver to the user, perform the following safety checks:

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged between the chassis

and other metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs, insulating fish papers, cabinet backs, adjustment

and compartment covers of shields, isolation resistor-capacitor networks, mechanical insulators etc.

3. To be sure that not shock hazard exists, a check for the presence of leakage current should be made at each exposed

metal part having a return path to the chassis (antenna, cabinet metal, screw heads knobs and/or shafts, escutcheon,

etc.) in the following manner.

Plug the AC line cord directly into a 110V/220V/240V, AC receptacle. (Do not use an Isolation Transformer

during these checks.) All checks must be repeated with the AC line cord plug connection reversed. (If necessary, a

non-polarized adapter plug must be used only for the purpose of completing these checks.)

PLEASE READ BEFORE ATTEMPTING SERVICE

1. Use an Isolation Transformer when performing any service on this chassis.

2. Never disconnect any leads while receiver is in operation.

3. Disconnect all power before attempting any repairs.

4. Do not short any position of the circuit while the power is on.

5. For safety reasons, replace components any with identical replacement parts (SEE PARTS LIST).

6. Before alignment, warm up the TV for at least 30 minutes.

7. When removing a PCB or related component, after unfastening or changing a wire, be sure to put the

wire back in its original position.

8. Inferior silicon grease can damage IC's and transistors. When replacing IC's and transistors, use only

specified silicon grease. Remove all old silicon when applying new silicon.

9. Before removing the anode cap, discharge eletricity because it contains high voltage.

Page 5

A. SPECIFICATION

System : PAL- D/K,I,B/G;SECAM-L/L’,B/G,D/K

Channel : 45.25MHz~855.25MHz

IF Frenquency Video: 38.9MHz

Chroma: 34.47MHz

Sound: 32.4 MHz(DK)

33.4MHz(BG)

32.9 MHz(I)

Audio output power 10%THD 1W×2

Antenna Impedance 75Ω(Unbalance)

Power Consumption 36W

Power Supply : AC~100-240V,50/60Hz

KLC-1521QS

item Port list

1 RF cable

2 SCART

3 PC VGA input

4 Y、Pb/Cb、Pr/Cr

5 Video

6 Audio input

7 Headphone audio output

8 Power port

Page 6

ADJUSTMENT MANUAL

TEST NOTE

1. Please follow the pointed test steps and choose the right test equipment to conduct

adjustment, otherwise good effect of Unit could not be obtained. The unit should be warmed

up for 30 minutes before adjustment and every parameter should be adjusted repeatedly till

the optimum value obtained, the pointed voltage value should be ensured during test to get

satisfied test result.

2. Test environment

1) Temperature 15°C

~35°C

2) Relative Humidity 45%~75%

3) Air pressure 86KPa~106KPa

3 Test equipments(The following equipment should be calibrated before testing)

1) Computer 1 set

2) Multi-meter (VICTOR VC9801) 1 set

3) Video Signal Generator (Chroma Model 2227/2327) 1 set

4) Color Analyzer (Chroma Model 7120 ) 1 set

5) DDC card (DYNACOLOR, INC D8330) 1 slice

6) TV Video Signal Generator (FLUKE PM54200) 1 set

4 Factory mode adjustment

4.1 Enter factory mode adjustment

Using the remote control, press Menu button once first , then press RECALL button five

times,and you can see manufacture menu on the LCD panel.

4.2 Factory menu operation method

Press the PROG

▲/▼ button to selection the sub menu of factory menu(including F、E、

UOCⅢ、Temp), and press the VOL ► to enter the sub menu and setting the value.

4.3 Exit the factory menu

Press the MUTE button again and again or turn off the TV, it can exit the factory menu.

4.4 AGC adjustment

In TV mode, receive 60dB split field signal.Enter factory mode menu “UOCⅢ” item, press

PROG

▲/▼ to select “RF AGC” ,then use VOL◄/► to adjust the item until the voltage of Pin

1 of N100 to be about 2.5V±0.2V, then noise wave of the picture point disappears.

4.5 White calibration adjustment

4.5.1 Receive black or white signal under AV or PC mode, adjusting brightness and contrast to

set the brightness to 15Nit in dark area and 90 Nit in bright area.

4.5.2 Adjust white balance.Press MENU button once, then press RECALL button five times to

enter factory menu, select “Temp” Menu,

Adjust Red 0-100

Green

Blue

0-100

0-100

4.5.3 Adjusting chromaticity coordinates of black and white to fit the requirement, or plug

automatic calibration system to adjust white calibration automatically.

Page 7

BLOCK DIAGRAM

SCART CVBS,

VIF

SIF

SCART RGB

AUDIO L,R

MAIN IC

TDA15021H

Signal Block Diagram

N100

Tuner

+12V

Supply

AGC

X101

M3953

X102

M9453

LED R,G

N401

KEY B1、B0

IR

PWRON

DDC/HWI2C

Earphone

speaker

port

Y

Pb

Pr

Port

VG

A

Audio

N201

TDA1517

+12V

Supply

Audio 2

L,R

Y,Pb/Cb,Pr/Cr

VGA

Audio IN

VGA R,G,B

VGA Hs,Vs

VGA-CLK

VGA-DAT

AMP_L

AMP_R

AU2IN_L,R

AU3IN_L,R

UOC R,G,B

N303

PI5V330

Y_G

Pb_B

Pr_R

N301

PI5V330

YUVHs

YUVVs

N501

MST518

SCL

SDA

M_Rst

M_CLK

M_SDA

M_CS

To N401

N302

24LC21

BKLON

VCC-5Ua

VCC-3.3VUSB

VCC+1.8a

VCC+1.8b

VCC-PAN

LCD

PANEL

3.3V Supply

2.5V Supply

DDC/HWI2C

Page 8

Page 9

IC BLOCK DIAGRAM

1 N401(TDA15021H1)

2 N501 (MST518)

Page 10

Trouble Shooting

Key IC list

Item Type Maker Package Circuit No. Qty.

1 TDA15021H1 Philips QFP128 N401 1

2

MST518 MSTAR PQFP160 N501 1

3 24LC32A MICROCHIP SOIC-8 N402 1

4 24LC21A MICROCHIP SOIC-8 N302 1

5 MP1410ES-SOIC-8 MPS SOIC-8 N801,N802 2

6 FDS9435A FAIRCHILD SOIC-8 N803 1

8

11

12

14

TDA1517 PHILIPS SIL9MPF N200

FSAV330 FAIRCHILD9

TSSOP-16 N301 1

TS5V330 TI

1117-3.3V BCD SOT223 N804,N806 2

1117-2.5V AAC SOT223 N805 1

Tuner AFT1/3100G Qingjia N100 1

1

Start order:

Turn on the

power

N401 RESET and

IO port initialize

N501 electrify ,

reset, initialize

Turn on back

light lamp

Successful start

and LCD display

1)Verify the state of TV set.Please switch the TV on ,then verify the LED color. Red is

standby state and green is working state.

2)Checking Supply Power.If the color of LED is yellow,the power supply for signal board 。

N801 supply 5V and N802 supply 3.3V,N804、N806 supply 3.3V power(Test the PIN 2).N805

supply 2.5V(Test the PIN 2),D803 supply 8.3V,V401 and V402 supply 1.8V. All these are

for main IC N401,N501.

3)After turning on the power, if blank screen appears (no back light lamp), just

press POWER button several times, if blank screen still there.Check if the voltage of

every power supply is normal.

4)Check if the crystal oscillator X501(14.318180MHz) X401(24.576MHz) oscillate or not,

and oscillate frequency is right or not.

5)Back light control signal (BKLON) of XS801 has high level (about 2.5V)

or not, if not, check whether fault soldered or short circuit happened。

6) If back light lamp is on while there is no display,check N407 and N501’s reset circuit

and the output of the oscillator to confirm the CPU and SCALER are working or not.If RGB

is abnormal,check N501;If RGB is working correctly and the other channel is

abnormal ,please check N501.

Page 11

PDF 文件以 "PDF 制作工厂" 试用版创建 À http://www.fineprint.com

Page 12

PDF 文件以 "PDF 制作工厂" 试用版创建 À http://www.fineprint.com

Page 13

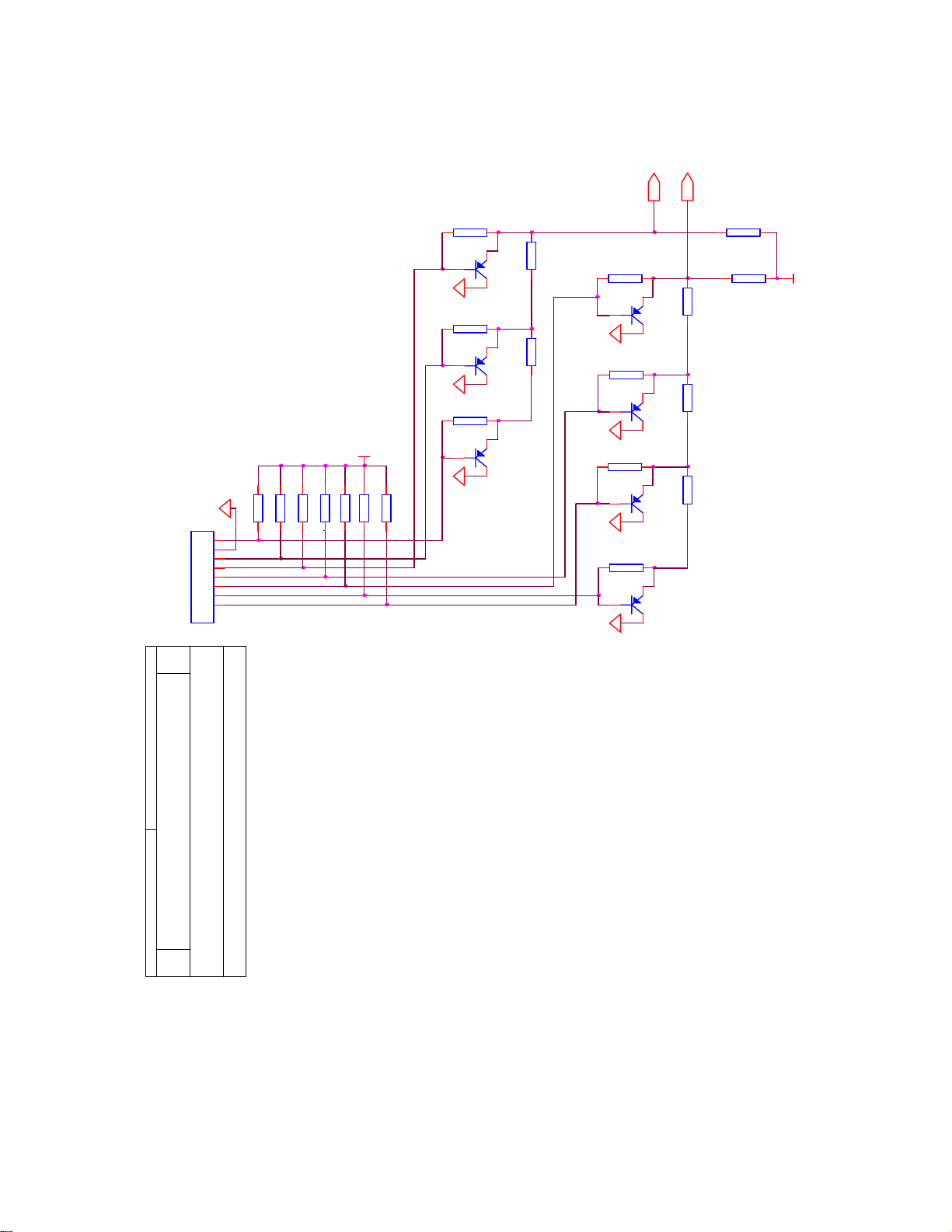

KEYB0

2

KEYB1

2

NC

1

R695

1.2K

1

2

PMBTA64

R606A

1.2K

V605

2

NC

1

2

R691

1.2K

PMBTA64

NC

1

R696

1.2K

NC

VCC_5V

1

1

1

R616

R615 1.2K

R617 1.2K

1.2K

2

2

XS307A CON8

1

2

3

4

5

6

7

8

Size Document Number Rev

Date: Sheet

A

2

Title

1

1

1

R612 1.2K

R6111.2K

R614

1.2K

2

2

2

1

R697

1.2K

1

R613

1.2K

2

1

2

R607A

1.2K

PMBTA64

V606

2

2

PMBTA64

V607

NC

1

2

R692

1.2K

PMBTA64

NC

1

2

R693

1.2K

PMBTA64

NC

1

2

R694

1.2K

PMBTA64

2

1

2

R602A

1.2K

V601

2

1

R603A

1.2K

V602

2

1

R604A

1.2K

V603

2

V604

1

R605A

1.2K

VCC_3.3USB

1

R601A

1.2K

KEY_BOARD

11Monday , Decem ber 05, 2005

of

<RevCode>

Page 14

2

C840

10u/10V

BA18BC0FP

1

2

1

VCC_ADPLL is for MST Vadpll

VCC_AMPLL is for MST Vmpll

VCC_OP is for MST Voutput

VCC_ADC is for MST Vadc

VCC_CORE is for MST Vcore

Titl e

Size Document Number Rev

Date: Sheet

A3

<Title>

KONKA CO.LTD (NDA)

C841

10u/16V

L813 FB

L812

FB

VCC_OP

C857

10u/10V

3

BA18BC0FP

IN VO

1

GND

VO

2

4

C859

10u/16V

VCC_5Ua is for UOC and TUNER an alog

2

0.22

VCC_8U is for UOC audio 8V

VCC_ADC

C855

10u/10V

VCC_Usb

N805

L814 FB/1206

VCC_CORE

3.3K

V803

BC847

2

2

0.1

V804

BC847

4

3

1

R811 3.3K

G

9435A

1

C836

2

S

1

5

6

VCC_5V

R812

22K

2

PWRON 2,4

2

C838

10u/10V

D803

8V

1

POWER

47u/16V

C830

55Monday, D ec em ber 05, 2005

of

+

VCC_Usb

1

3

IN VO

GND

N804

VO

2

4

VCC_3.3

2

1

1

C807

L811 FB

L810 FB

VCC_ADPLL

VCC_AMPLL

C851

10u/10V

C853

10u/10V

R861

3.3K

NC

V862

BC847

2

1

C860

0.1

NC

2

1

BC847

NC

R810

1

1

C835

VCC_5V

2

1

DDD

N803

L820FB

SSS

7

8

NC

VCC_5U

L808

FB

1

VCC_12V

2

R815

510

VCC_8U

NC

V861

4

3

2

1

DDD

G

N860

9435A

1

R860

3.3K

NC

2

VCC_5Ua

NC

SSS

S

5

6

7

8

D802

FM5820

C827

470u/10V

2

2

+

C828

10u/10V

C847

10u/10V

3.3V

410K

15K

2K

1

R807

2K

VCC_LP

1

L807

FB

VCC_PAN

VCC_PAN is for Pannel 5V or 3.3V

5.0V

SET

R809

390K

R805

30K

1.5K

R807

0.1

2

1

R826

10K

L804 FB

C819

470u/25V

+

C820

0.22/25V

C821

0.22/25V

10n

4

3

2

1

BSINSW

GND FB

MP1410ES

L815

15uH

COMP

N/C

EN

8

7

6

5

1

R805

15K

2

R806

10K

1

C825 180p

R809

410K

2

C826

3.3n

V805

BC847

2

1

C824

0.1

1

R808

10K

2

PWRON 2,4

R821A1K

1

R821 1K

NC

2

2

2

1

R820

10K

BKLON 2

VCC_12V

C823

N802

10u/16V

VCC_Usb

1

10K

NC

VCC_5Usb is for 5V STANDBY

C842 close to N805

VCC_3.3U is for UOC III 3.3V

TO POWER

1

1

R8311K

R830

1K

2

2

NC

0.1/25V

C802

C808

+

1

1

R823 470

R823A1K

NC

V802

BC847

2

NC

NC

2

1

R822 1K

NC

2

1

R825

R824 1K

2

VCC_Usb

NC

2

BKLBT 2

470u/10V

C816

2

+

C817

10u/10V

L809

FB

2

1

C842

10u/10V

3

BA18BC0FP

IN VO

1

GND

VO

2

4

2

1

C843

10u/10V

12345

FM5820

1.5K

N806

XP8 01

6

12V_IN

0.1/25V

C852

NC

C804

C803

470u/25V

+

D801

2

1

R804

1

VCC_5V

VCC_Usb

VCC_3.3Usb

CN6_3

XS8 08

123

4

4

3

2

1

0.22/25V

F801

3A

4

3

2

1

XS803

CN6_3

123

4

L805FB

VCC_12V

L801 FB

470u/25V

C809

+

C810

0.22/25V

C813

10n

4

3

2

1

BSINSW

GND FB

N801

MP1410ES

L803

15uH

COMP

N/C

EN

8

7

6

5

1

R803

30K

2

1

R802

10K

C815 180p

R801

390K

2

C814

3.3n

1.0

Page 15

VGA_HSYNC3

VGA_VSYNC3

YUV_HSYNC3

41

HSYNC1

VSYNC0

HSYNC0

HWRESET

DDC_CLK

DDC_DAT

BYPASS

160

VCC_ADPLL

GND

XOUT

XIN

NC

NC

RB[7]

RB[6]

RB[5]

RB[4]

VDDP

GND

GND

VDDC

RB[3]

RB[2]

RB[1]

RB[0]

GB_7

GB_6

GB_5

GB_4

VDDP

GND

GB_3

GB_2

GB_1

GB_0

BB[7]

BB[6]

GND

VCC_OP

YUV_VSYN C3

VCC_ADC

VCC_AMPLL

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

N501

C501

22p

14.318MHz

X501

C502

22p

C500

1u

VCC_OP

VCC_CORE

M_RST 2

VCC_OP

C503 0. 1

3

3

3

Y_G

Pr_R

Pb_B

VGA_B3

VGA_G3

VGA_R3

C534

C537

C535

C538

C536

C508

0.1u

VCC_ADPLL

C509

0.1u

VCC_AMPLL

VCC_ADC

C510

0.1u

C511

0.1u

C512

0.1u

VCC_CORE

M_SDA 2

M_CS 2

M_IN T 2

M_CLK 2

VCC_CORE

C513

0.1u

C514

0.1u

C515

0.1u

C516

0.1u

C517

0.1u

VCC_OP

C518

0.1u

C519

0.1u

C520

0.1u

DBE7

DBE6

DBE5

DBE4

DBE3

DBE2

DBE1

DBE0

VCC_OP

VCC_CORE

DGE7

DGE6

DGE5

DGE4

DGE3

DGE2

0.1

0.1

81

GND

82

CS

83

SDA

84

SCL

85

INT

86

PWM0

87

PWM1

88

VDDP

89

GND

90

VCLK

91

VD0

92

VD1

93

VCC_OP

VD2

94

VD3

95

VD4

96

VD5

97

VD6

98

VD7

99

VDDP

100

GND

101

GND

102

VDDC

103

BA[0]

104

BA[1]

105

BA[2]

106

BA[3]

107

BA[4]

108

BA[5]

109

BA[6]

110

BA[7]

111

VDDP

112

GND

113

GND

114

VDDC

115

GA[0]

116

GA[1]

117

GA[2]

118

GA[3]

119

GA[4]

120

GA[5]

1n

C506

47n

47n

47n

C505

70

71

72

73

74

75

76

77

78

79

80

BIN0

GIN0M

GIN0

SOGIN0

RIN0M

RIN0

GND

AVDD

RMID

REFP

REFM

RA[0]/LVACKP

GA[7]/LVA3M

GA[6]/LVA3P

VDDP

GND

GND

NC

NCNCNC

NC

121

131

130

129

128

127

126

125

124

123

122

DGE1

DGE0

DRE7

C531

C533

47n

47n

C532

47n

R507

1n

390

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

SOGIN1

GIN1

GIN1M

RIN1

RIN1MNCNC

BIN0M

GND

CLK+

CLK-

AVDD

REXT

AVDD_PLL

GND

AVDD

GND

BIN1

BIN1M

VSYNC1

GNDR+R-

GNDG+G

AVDDB+B-

AVDD_MPLL

DDCROM_DAT

DDCROM_CLK

MST518_PQF160

LVSYNC/LVB3M

LHSYNC /LVB3P

RA[1]/LVACKM

RA[3]/LVA2M

RA[4]/LVA1P

RA[2]/LVA2P

134

133

132

DRE4

DRE5

DRE6

OCLK/LVBCKP

LDE/LVBCKM

RA[7]/LVA0M

RA[5]/LVA1M

RA[6]/LVA0P

VDDC

VDDP

GND

GND

143

142

141

140

139

138

137

136

135

DRE0

DRE2

DRE1

DHS

DRE3

VCC_CORE

BB[5]/LVB0M

BB[3]/LVB1M

BB[1]/LVB2M

BB[4]/LVB0P

BB[2]/LVB1P

BB[0]/LVB2P

VDDP

GND

NCNCNCNCNC

NC

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

DBO3

DEN

DBO7

DVS

DBO2

DBO4

DBO5

DCLK

DBO6

DBE4

DBE7

2

1

C527

VCC_PAN

0.1u

C528

0.1u

C530

0.1u

Title

Size Document Number Rev

Date: Sheet

C

SCALER_MST518

15Monday, D ec em ber 0 5, 2005

of

RP51047R

VCC_PAN

1234567891011121314151617181920212223242526272829303132333435

CON36

DGE5

DBE5

DBE2

DBE0

DBE3

DBE1

DBE6

DGE7

DGE4

DGE6

RP512 47R

8

6

4

1

3

5

7

1

3

5

7

3

5

7

8

1

2

3

4

1

2

8

6

4

2

6

4

2

RP51147R

RP51847R

10

11

12

13

14

5

6

7

8

9

TTL_EVEN_PIXEL

DRE3

DGE3

DRE2

DRE1

DRE7

DRE0

DRE4

DRE6

DGE2

DGE0

DRE5

DGE1

DBO7

DBO4

DBO6

DBO5

DCLK

DVS

DHS

DEN

DBO2

DBO3

2

8

6

4

2

8

6

2

8

6

4

2

8

6

4

3

5

7

2

8

6

4

1

3

5

7

1

3

5

7

8

6

4

1

3

5

7

RP51547R

RP51647R

RP51747R

VCC_PAN

LVACKM

LVA3P

LVA2P

LVA3M

LVACKP

10

11

12

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

12345678910111213141516171819202122232425262728293031

36

CON32

XS50 2

13

3

4

5

6

7

8

9

4

R510

NC

1

3

5

7

1

3

5

7

RP51347R

RP51447R

1

2

LVA1P

LVA0P

LVA0M

LVA1M

LVA2M

14

15

16

17

18

LVB1M

LVBCKP

LVB0M

LVB0P

LVB2P

LVBCKM

LVB2M

LVB1P

LVB3M

LVB3P

19

20

21

22

23

24

25

26

27

28

29

30

31

32

32

XS501

LVDS

Page 16

SCARTYCbCr_Y

SCARTYCbCr_Cb

SCARTYCbCr_Cr

17

15

13

3

1

XS3 11

RGB&Compos it e F ull SC AR T

Audio Left Out

Audio Right Out

Audio Return(GND )

Audio Right In

4

VCC_5Ua

2

3

1

V320

BAV99

R367 75

R366

1K

R364

22K

47

Q1

BC847

R363

22K

C381 22u/16V

+

VCC_5Ua

1

3

2

V321

BAV99

1

3

2

V322

BAV99

VCC_5Ua

R365

NC

100

330

1508QS c304

10K

R369

C329

NC

100

R368

22u/16V

330

C382

+

1

2

1

2

10K

R379

C300

R378

22u/16V

C383

+

2

VCC_5Ua

3

V323

BAV99

3

V324

BAV99

R360

1K

C385

100

R361

47K

C384 1u

11

7

9

5

Blue Return(GND)

Audio Left I n

R371

Red Ruturen(GND)

Blue Input

Green return(GND)

Green Input

Comms Data 1(NC)

Comms Data 2(NC)

Video State In

12

10

8

6

R370

1K

C387

100

47K

C386 1u

19

21

Sync Return(GND)

Red Input

Composit e Out put

Blank Return(GND)

1

2

1

2

1

2

Shield

RGB State(GND)

Composit e I nput

Blanking

20

18

16

14

3

V325

BAV99

3

V326

BAV99

3

V327

BAV99

VCC_5Ua

NC

R384

75

R388

82

R389 100

C389

100

C388 0.1

1

3

2

V328

BAV99

1

3

2

V329

BAV99

1

3

2

V330

BAV99

VCC_5Ua

R390

75

R391

75

R392

75

R393100

R395100

R394100

R385 100

C392

100

C391

100

C390

R38610K

100

R387 3.3K

Date: Sheet

11Monday, D ec em ber 05, 2005

of

B

<RevCode>

AU2IN_R

SCVO

Titl e

Size Docum ent Number Rev

SCALO

SCARO

AU2IN_L

SCFS

VIDEO1

FBLIN

SCBIN

SCRIN

SCGIN

SCART

Page 17

SCL _HW

SDA_HW

PWRON2,5

MUTE2

AMP_R2

1

1

R210

R209

10K

10K

NC

2

2

NC

V201

BC847

33K

R118

1

R211

10u/16V

C100

N100

2

AGC

R100 100

R109 10K

2,3

2,3

R101 100

R102 100

C101

0.01

10u/16V

C102

L100 47uH

1

AGC

2

TU

3

AS

TUNER

4

SCL

5

SDA

6

NC

7

VCC

8

AFC

9

VT

10

GND

11

IF

R103

100

131415

C103

12

12

13

14

15

0.01

10K

Audio AMP

2

2

47u/16V

V203

BC857

2

10K

V202

BC847

D201

R212

C207

1

R214

10K

2

1N4148

470K

1

+

2

D200

1N4148

1

1

R213

1K

HEADPHONE

2

VCC_12V

VCC_12V

1

1

2

R208

R206

10K

C205

0.1

2

1

2

C211

10

0.1

R207

2

22K

1

2

+

C210

4.7u/12V

10

XS305

VCC_12V

1

R200

470u/25V

C203

+

0.1/25V

C204

1

R204

1

R219

C221 470u/16V

+

2.2K

2

1

2

C200 0.1

R201

2.2K

1

N200

-INV 1

2

C109

100u/16V

C222 470u/16V

+

2

2.2K

SGND

3

SVRR

+

4

OUT1

5

TDA1517

PGND

6

OUT2

7

Vp

8

M/SS

9

-INV 2

C201 0.1

1

2

R203

R202 2.2K

1

R105

L10347uH

TUNER

Titl e

Size Document Number Rev

Date: Sheet

A3

<Title>

R104

1K

VCC_5Ua

VCC_5U

R107

33

KONKA CO.LTD (NDA)

TUNER & AMP

45Monday, Dec em ber 05, 2005

of

<Rev Code >

4.7K

R106 1. 2K

C104

0.01

V100

C388

C107 0.01

IF 2

C105

0.01

C106

10u/16V

R108

470

VCC_5T

L101 47uH

L102

12uH

VCC_5Ua

2

2

100

100

4

5

3

2

7

8

1

R375

10K

R374

10K

C377

C376

XS201A

D2006-2

1

NC

1

1

C374

+

2

R376

100

1

2

XS201

D2006-2

1

2

2

SPEAKER_R

100u/16V

100u/16V

C375

+

2

R377

100

1

AMP_L 2

D2006-2

1

2

XS200A

NC

XS200

D2006-2

1

SPEAKER_L

Page 18

VCC_5Ua

AMOUT/QSSO/AUDEEM

P2.5/PWM4

LEDG

C452 3.3n

90

91

DECSDEM

VDDC3

6

5

R468 180

VCC_+1.8b

SCARO

4.7u

+

C451

92

93

AUDIOIN5R

AUDOUTSL

AUDOUTSR

DVBIN2/SIFIN2

DVBIN1/SIFIN1

VGUARD/SWIO

P1.2/INT2

P1.4/RX

VSSC3

4

3

SYS

L423 FB

RX

24LC32

H

L

SCALO

94

95

96

SSIF/REFOUT

AUDIOIN5L

AGCOUT

AVL/EWD

XTALOUT

VDDA3(3.3V)

P1.5/TX

2

1

TX

3

2

NC0

NC1

NC2

GND

WP

4

0.1

SYS

DK/I/BG/L

SECAM-L'

EHTO

GNDIF

IREF

VSC

VIFIN2

VIFIN1

VDRA

VDRB

DECBG

SECPLL

GND1

PH1LF

PH2LF

DECDIG

VSSA1

XTALIN

VDDC4

VSSC4

VSSP2

SDA_HW3,4

1

SDA

7

C478

VP1

NC

NC

NC

NC

NC

R461

4.7K

R462

4.7K

SCL_HW3,4

6

5

SCL VCC

8

L406

VCC_8U

FB

220u/16V

0.01

4

AU1IN_R3

AU2IN_L4

SV1_Y4

AU2IN_R

AMP_R4

AMP_L4

YUVH SYNC3

VCC_5Ua

65

66

67

68

69

70

71

72

73

74

75

76

77

78

AUDIOIN4R

CVBS4/Y4C4AUDIOIN2L/SSIF

AUDIOIN2R

CVBS2/Y2

AUDIOIN3L

AUDIOIN3R

CVBS3/Y3

C2/C3

AUDOUTLSL

AUDOUTLSR

AUDOUTHPL

AUDOUTHPR

L410 FB

C465

10u/16V

VCC_5Ua

FBLIN

SCRIN

SCGIN

SCBIN

L411

C46810u/16V

C469 0.01

C47010u/16V

VCC_3.3Us b

C4711n

UOC_R

UOC_G

UOC_B

C472100u/10V

C474

0.1

Title

Size Document Number Rev

Date: Sheet

A3

<Title>

KONKA CO.LTD (NDA)

UOC III

25Monday, D ecem ber 05, 2005

of

1.0

C4660.01

C467

0.1

FB

3

3

3

+

L412 FB

VCC_3.3Us b

C480

0.22

C481

10u/16V

PWRON_RST (IO mode)

100u/10V

L413

FB

VCC_3.3Us b

C498 100n

0.1

C473

C475

+

C4760.1

10u/16V

1K

150K

1u

C497100n

C499100n

R438510

R439510

R440510

C482

0.22

C483

L414

FB

VCC_+1.8a

R463

R475 4.7K

4.7K

VCC_3.3Usb

UOC_RST

R489

D401

1N4148

R490

R491

15K

C496

V406

BSH103

CVBSO/PIP

64

SVM

63

FBISO/CSY

62

HOUT

61

VSScomb

60

VDDcomb

59

VIN(R/PR-2/C-X)

58

UIN

57

YIN(G/Y-2/CVBS/Y-X)

56

YSYNC

55

YOUT

54

UOUT(INSW-2)

53

VOUT(SWO1)

52

INSSW3

51

R/PR-3

50

G/Y-3

49

B/PB-3

48

GND3

47

VP3

46

BCLIN

45

BLKIN

44

RO

43

GO

42

BO

41

VDDA1(3.3V.)

40

VREFAD_N EG

39

VREFAD_POS

38

NC

37

GNDA

36

VDDA(1.8V)

35

VDDA2(3.3V)

34

VSSadc

33

VDDadc(1.8)

P1.O/IN T1

INT0/P0.5

VDDC2

P1.1/T0

32

31

30

Face Down version

UOC III

R464

4.7K

VCC_+1.8b

29

N401

IR

DDC/HWI2C 3

M_IN T

1

R473

R470 4.7K

R474 4.7K

4.7K

C484

0.22

DECDIG

C493

1u

C494

0.22

R482 4.7K

V403

BC847

V405

BSH103

V404

PMBTA64

VCC_+1.8b

Hercules

VDDP(3.3V)

P2.1/PWM0

P2.0/PMW

P1.7/SDA

P1.6/SCL

P1.3/T1

VSSC2

P0.0

P0.1

P0.2

P0.3

P0.4

28

27

26

25

24

23

22

21

20

19

18

R460 100

R459 100

BKLON 5

BKLBT 5

SDA_HW 3,4

SCL_HW 3,4

UOC/YUV 3

M_CS 1

M_RS T 1

M_SD A 1

M_CL K 1

PWRON 4,5

L420 FB

C486

0.1

VCC_+1.8b

C485

10u/16V

R481

10u/16V

4.7K

R483 4.7K

R484 4.7K

V401

BC847

V402

PMBTA64

VCC_+1.8a

SCVO

C459

L405

FB

C458

AU1IN_L3

VIDEO13

C453 0.1

C454 1

C45510u/16V

R430 390

C457 1u

C456 0.01

79

80

81

82

83

84

85

86

87

88

89

GND2

PLLIF

SIFAGC/ DVBAGC

DVBO//IFVO/FMRONCVCC8VNCVP2

SVO/IFOU T/CVBSI

AUDIOIN4L

UOC III

VDDC1(1.8)

P2.3/PWM2

P2.2/PWM1

17

16

MUTE 4

0.22

10u/16V

FB

C495

P2.4/PWM3

P3.1/ADC1

P3.0/ADC0

P3.3/ADC3

P3.2/ADC2

DECV1V8

VSSC1/P

15

14

13

12

11

10

9

8

7

R465 3.3K

R467 180

R466 3. 3K

SCFS

UOC_RST

KEYB1

LEDR

KEYB0

C489

0.01

C487

C490

10u/16V

C488

L422 FB

VCC_3.3Usb

L421

NVRAM

VCC_3.3Us b

R4854.7

R486

4.7

R4874.7

R488

4.7

SYS

R110

1.2K

R111

1.2K

V110

BC847

47K

R116

V111

BC847

K9453M

1

X102

2

3

4

AGC4

C182 0.01

NC

C432

24.576MHz

C446

L404 FB

VCC_+1.8b

5

R115 39K

R423

R424

47K

DECDIG

22p

C433

X401

C444

22p

C445

0.01

10u/16V

C447

0.01

C448

10u/16V

2

VCC_Usb

R117 100K

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

0.22

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

C491

0.01

C492

10u/16V

VCC_5Ua

R471

3.3K

R472

3.3K

N402

VCC_3.3Us b

R121

10K

D111

2

BA792

1

C112 0.15

10u/16V

+

0.22

R425 1K

L402

FB

L403 FB

VCC_3. 3Usb

2

0.01

2

NC

C438

2

1

0.01

NC

1

NC

C437

0.01

6

CON6

LEDG

LEDR

KEYB,IR

C430

C431

C439

IF4

2

D110 BA792

R120

10K

1

0.01

R112

4.7K

R113

4.7K

C111

0.1

K3953M

1

X101

2

3

4

5

3

UOC_VSYSN C

VCC_3.3Us b

C440

1

NC

1

IR

12345

R114100

NC

VCC_5UA

R421

12K

C426

1u

C427

0.01

100u/16V

C428

0.01

+

C425

L407 FB

VCC_5V

SCL_HW

SDA_HW

VCC_5V

4

3

2

1

XS888

123

4

CN4

XS3 06

VCC_3. 3USB

KEYB0

KEYB1

NC

2

1

C436

0.01

NC

2

1

C434

0.01

2

1

NC

C435

0.01

4

3

2

1

XS307

123

4

CN4

NC

Page 19

Date: Sheet

35Monday, Dec ember 05, 2005

of

R306

R304 12K

R301

12K

100

C305

100

R305

47K

47K

C306 1u

AU1IN_R 2

Title

Size Document Number Rev

A3

<Title >

KONKA CO.LTD (NDA)

SCALER INPUTPORT

82

R302

C303

R303

AU1IN_L 2

2

YUVH SYNC

R335100

YUV_HSYNC

1

100

C301

100

C302 0.1

C304 1u

SV1_Y 2

UOC/YUV2

UOC/YPbPr

R325 1K

C206

0.1

R332

220K

R441

2.2K

C462

47p

C463

47p

UOC_VSY SNC2

UOC_VSY SNC

C334 NC

1

R426

1K

2

R427

10K

NC

VCC_USB

2

YUV_VSY NC 1

2

4

75

R326

10

C321

75

R327

10

C322

75

R328

10

C323

V310

BAV99

2

3

1

2

3

V311

BAV99

1

2

3

1

V312

BAV99

VCC_USB

C461

47p

13

1

IN

S1D

PI5V330A

GND

/EN

8

15

R505NC

R504

NC

R503NC

1

VCC_USB

13

1

9

5

6

10

12

AV/YPbPr/ YCbCr

11

7

8

3

XS3 09

Y

PR/CR

PB/CB

C354 10u

C352 10u

C353 10u

R355 1.2K

R356 1.2K

R357 1.2K

R358 1.2K

R359 1.2K

R362 1.2K

L301 BEAD

L302 BEAD

L303 BEAD

UOC_B2

UOC_G2

UOC_R2

U_R

U_G

U_B

10

11

14

12

2

3

5

6

S1A

S2A DA

S1B

S2B

S2C

S1CDDS2D

DC

Y_G 1

N303

VCC

DB

4

7

9

16

M_G

R331 0

10u/16V

M_R

M_B

0.1

R330 0

R329 0

Pr_R 1

Pb_B 1

H->HW

L->DDC

0.1

10K

VCC_USB

XS5 05

1

VCC_USB

C332

VCC_Usb

C333

TX

RX

2

2

R383

R382

100

100

1

1

FOR COLOR

AUTO_ADJUST

1

2

123

GND

KEY1

KEY0

DAT_DDC_VGA

CLK_DDC_VGA

C335

0.1

VCC_USB

12

15

8

GND

/EN

PI5V330A

S1D

IN

C336

1

13

14

R337

R338

CON2

2

2K

R380100

DDC/HWI2C 2

SDA_HW 2,4

24LC21

C378 0.1

VCC_5Ua

3

4

XS666

4

+5V

16

4

7

9

DB

DC

VCC

N301

S2C

S1CDDS2D

S1A

S2ADA

S1B

S2B

2

3

5

6

10

11

R381100

SCL_HW 2,4

R3394.7K

VCC_5D

R340

4.7K

5

6

7

8

N302

SCL

VCLK

VCC

GNDSDA

NCNCNC

1

2

3

4

BAV99

1

3

A_VSYNC

R354 100

R351 2.2K

C351 220P

R353 10K

NC

2K

R502

VGA_VSYNC 1

VCC_5D

V305

BAV99

2

3

1

2

3

1

BAV99

V306

CLK_DDC_VGA

DAT_DDC_VGA

A_VSYNC

DSUB-15

14

15

16

17

4

9

5

10

DDC_PWR

VCC_Usb

1

2

V301

BAV70

3

+

C337

10u/16V

VCC_5D

VCC_USB

BAV99

V307

2

3

VCC_Usb

VCC_Usb

BAV99

2

1

2

V315

C350 NC

VCC_Us b

R501

V316

3

VGA_HSYN C 1

1

2

3

V308

BAV99

1

2

2K

3

1

V309

BAV99

R341

75

C340

10

R342

75

C341

10

R343

75

C342

10

RGB Hs Vs connect to DVII

VGA_HSYN C

11

12

13

XS3 08

1

6

2

7

3

8

A_R

A_B

A_G

L306

L305

L304

BEAD

BEAD

BEAD

R344

R346 100

R345 100

100

VGA_G 1

VGA_B 1

VGA_R 1

1.0

Page 20

Appendix 1

Пиложение 1.

ambient illumination

viewing angle

большую яркость чем соседние)

случайный

≤ 1

b) N = 0

≤ 8

≤ 2

Low dot random

, (Fig.1)

Fig 1.

Fig 2.

Electrical Outgouing Inspection Specification TFT LCD

Спецификация для электрических проверокЖК панелей

1. Conditions Условие проведения проверок

viewing distance 60 ~ 80 cm

300 ~ 400 Lux (nominal 350 Lux)

90 градусов к поверхности панели (45' лево/45'

display pattern Pure R, G, B, Black and White

inspection area active area

2. Типы Дефектов

Defect Type Accept

Bright dot Яркий субпиксель (имеет

a) random

b) two adjacent два вместе

c)three adjacent три вмете

Dark dot Темный субпиксель (имеет

чёрный цвет) a)

random случайный b)

two adjacent два вместе (Fig. 2)

c) three adjacent три вместе

Не яркий (имеет яркость такую же как

соседние точки/субпиксели либо

меньшую) субпиксель, случайный

Minimum distance between defects

a) N

c)N = 0

a) N

b)N

c)N = 0

N ≤ 8

L ≥ 5mm

Page 21

Внутренние дефекты матрицы.

Пятна яркости.

Допускаются пятна яркости по краям экрана размером не более 20 мм в длину и 8 мм в ширину.

5 mm

15 mm

Page 22

Appendix 1

Пиложение 1.

Спецификация для электрических проверокЖК панелей

1. Conditions

Условие проведения проверок

ambient illumination

viewing angle

display pattern

inspection area

большую яркость чем соседние)

случайный

≤ 6

≤2

чёрный цвет)

Low dot random

меньшую) субпиксель,

, (Fig.1)

Fig 2.

По вертикали

Electrical Outgouing Inspection Specification TFT LCD BOE

viewing distance 30 ~ 50 cm

300 ~ 700 Lux (nominal 500 Lux)

Угол по вертикали ±25о, по горизонтали ±40

Vertical viewing angle ±25o, horizontal viewing angle

Угол обзора (осмотра)

проверочное

изображение Pure R, G, B, Black and White

зона проверки active area/ активная зона

o

±40

по горизонтали

о

o

2. Типы Дефектов

o

Defect Type Accept

Bright dot Яркий субпиксель (имеет

a) random

b) two adjacent два вместе

c)three adjacent три вмете

a) N

b) N

c)N = 0

Dark dot Темный субпиксель (имеет

a) random случайный

b) two adjacent два вместе (Fig. 2)

c) three adjacent три вместе

a) N ≤ 6

b)N ≤ 2

c)N ≤ 1

Dark dot + Bright dot Яркий + тёмный

субпиксель

N ≤ 7

Не яркий (имеет яркость такую же как

соседние точки/субпиксели либо

a) случайный

b) two adjacent два вместе

с) three adjacent три вместе

Minimum distance between defects

a) N ≤ 6

b)N ≤ 2

c)N ≤ 1

L ≥ 5mm

Fig 1.

Page 23

Внутренние дефекты матрицы.

Пятна яркости.

Допускаются пятна яркости по краям экрана размером не более 20 мм в длину и 8 мм в ширину.

5 mm

15 mm

Loading...

Loading...