Electrolux Premium, Standard Quick Reference Manual

Doc. No: 560001 EG

Page:1 Ed.1" 08-2014

From ser. no.:

Quick reference manual

Thermoregulator

Management controller

Premium

&

Standard

Standard Model

Model for Ecostore Premium

CONTENTS

Page Description

2 Buttons

3 Icons

4 Programming

5 to 7 Parameters view

8 to 9 Service/ Temperature alarms

10 Defrost algorithm

11 to 14 Spare part code of controller

15 to 40 Parameter descriptions

Doc. No.: 560001 EG

Page:2 Ed.1" 08-2014

From ser. no.:

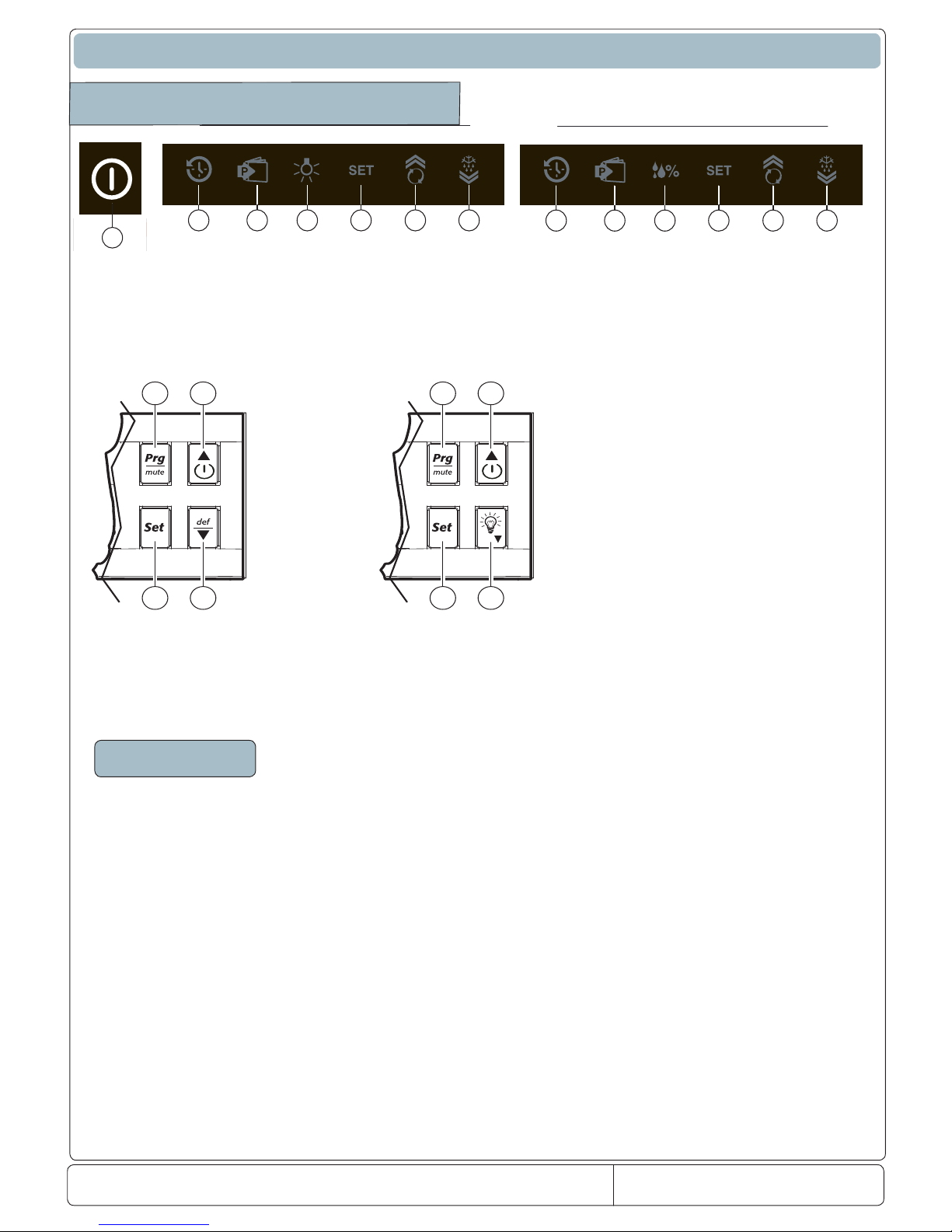

GENERAL DESCRIPTION OF INSTRUMENT

Description of buttons

1

2 3 4 5 6 7

PREMIUM

2 3 8 5 6 7

PREMIUM

Description

1. ON/OFF

2. History button

3. Programming confi rmation button

4. Light button

5. Temperatura/Programming button

6. Temperature decrease /Turbo cooling button

7. Temperature increase/Manual defrost button

8. Umidity button

3

6/1

75

3

6/1

45

Standard Control

Doc. No: 560001 EG

Page:3 Ed.1" 08-2014

From ser. no.:

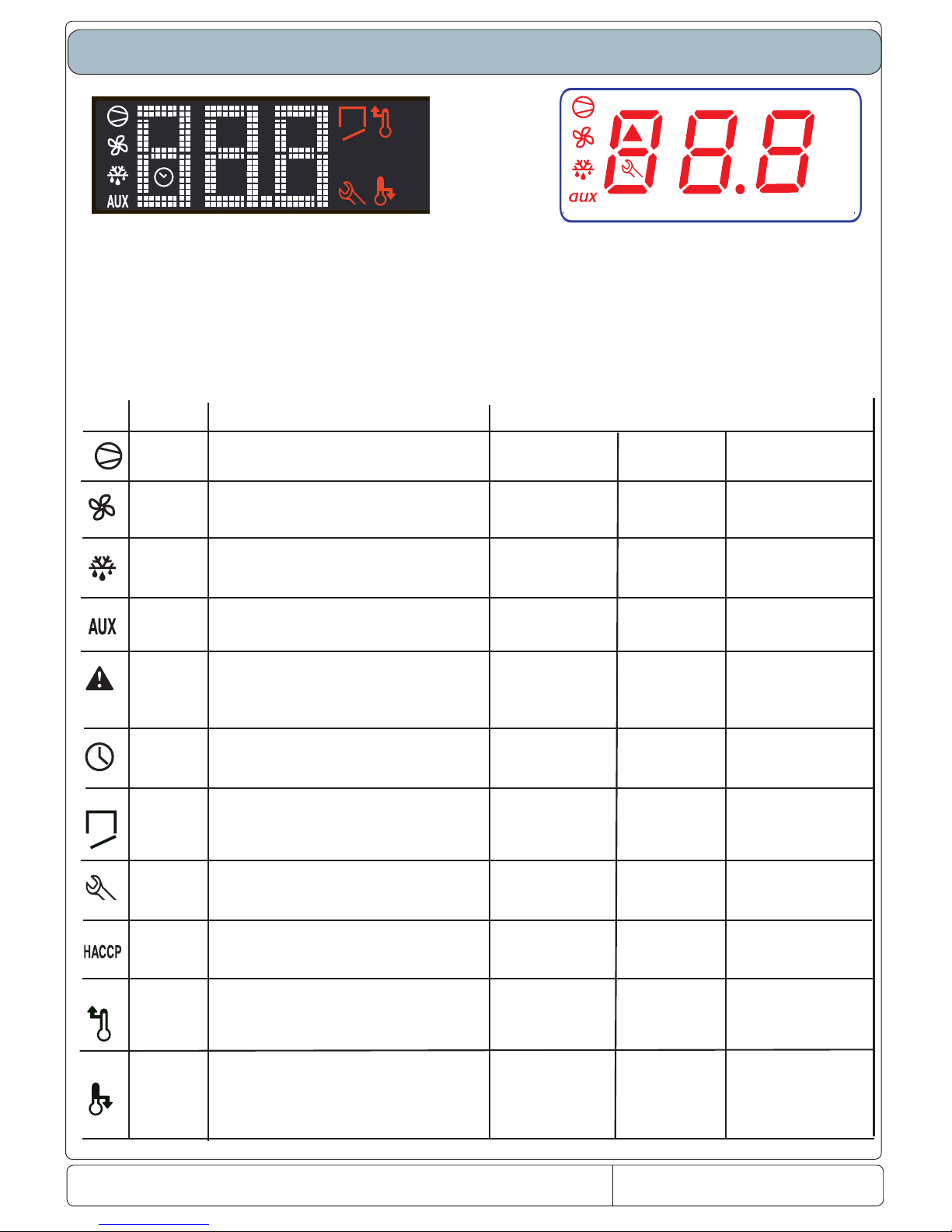

Description of Icons

Standard Control

Premium

ICON

FUNCTION

DESCRIPTION

NORMAL FUNCTIONING

ON OFF

BLINK

COMPRESSOR

ON when the compressor starts. Flashes when the activation

of the compressor is delayed by safety times.

Compressor on

Compressor o Awaiting activation

FAN

ON when the fan starts.Flashes when the activation of the fan is

prevented due to external disabling or procedures in progress.

Fan on

Fan o Awaiting activation

DEFROST

ON when the defrost is activated. Flashes when the activation of

the defrost is prevented due to external disabling or

procedures in progress.

Defrost in progress

Defrost not in progress Awaiting activation

AUX

Si accende all’attivazione dell’uscita ausiliaria selezionata come

AUX (LUCE)ON when the auxiliary output selected as

AUX (or LIGHT) is activated.

AUX auxiliary output active

AUX auxiliary output not

active

ALARM

ON following pre-activation of the delayed external digital input

alarm. Flashes in the event of alarms during normal operation

(e.g. high/low temperature) or in the event of alarms from an

immediate or delayed external digital input.

Delayed external alarm

(before the time ‘A7’ elapses)

No alarm present

Alarms in norm. operation

(e.g. High/low temperature)

or immediate or delayed alarm

from external digital input

CLOCK

On in case of consultation history temperature . History temperature History temperature not

consulting

DOOR

Blinking in case of door open/On in case of alarm door open Auxiliary exit Light ON Auxiliary exit Light ON

Door closed

Door open

Service

Flashes in the event of malfunctions, for example E2PROM errors or

probe faults

Programming , set temperature

No malfunction Malfunction (e.g. E2PROM error or

probe fault). Contact service

HACCP

ON if the HACCP function is enabled.Flashes when there are new

HACCP alarms stored (HA and/or HF alarm shown on the display)

HACCP function enabled HACCP function not

enabled

HACCP alarm saved

(HA and/or HF)

TEMPERATURE

ON in case of high Temperature Alarm High temperature

Alarm low temperatutre in

history

No alarm

No alarm

Actual alarm ( high temperature)

Actual alarm ( low temperature)

DISPLAY

ON in case Low temperature

Doc. No.: 560001 EG

Page:4 Ed.1" 08-2014

From ser. no.:

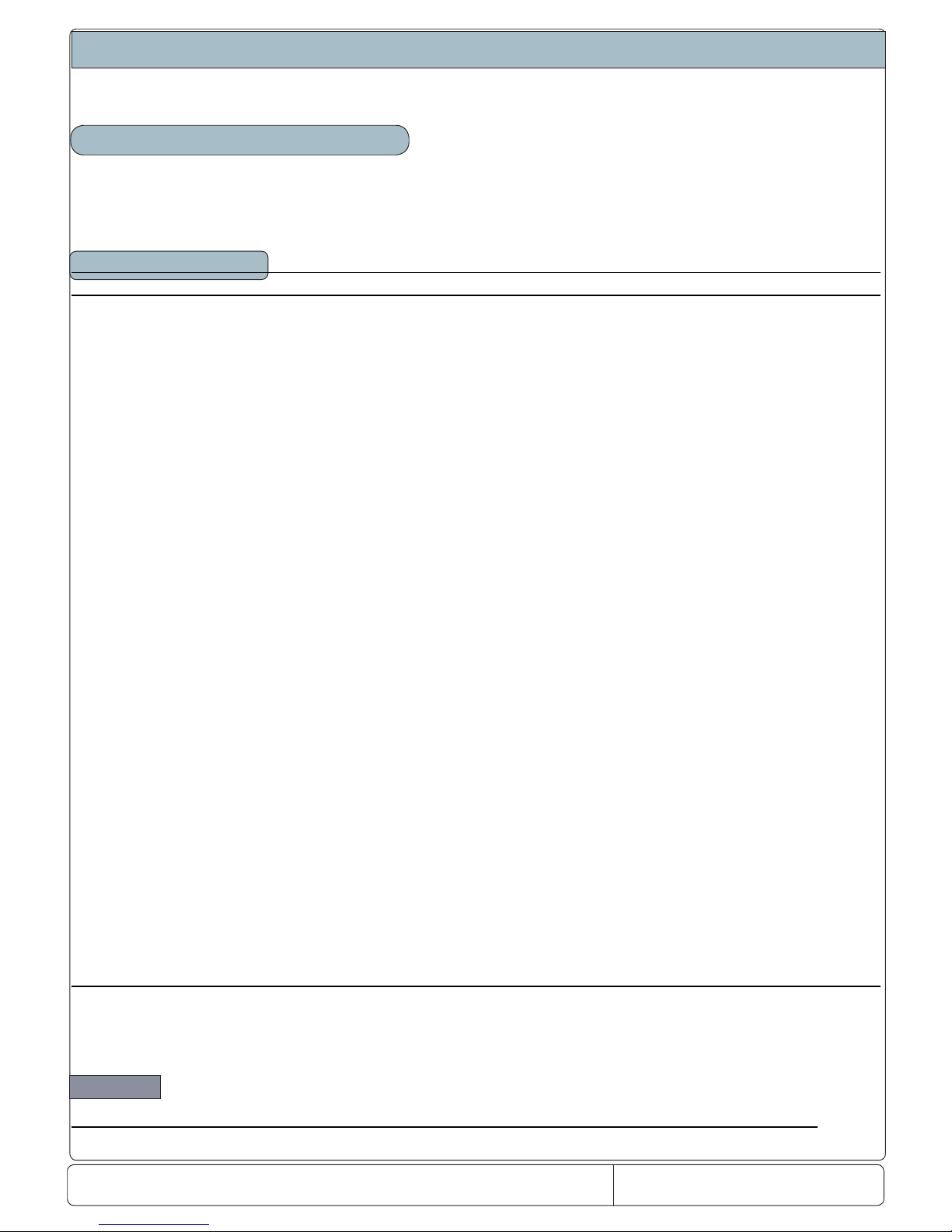

INSTRUMENT PROGRAMMING

Operation parameters, completely modi able from front keypad. Access to these is protected by a password that prevents random changes or modi cations by

unauthorised persons.

Accessing parameters (confi guration):

1. press the PRG and SET buttons together for more than 5 seconds and the display will show "00", password required;

2. use the buttons or to scroll the numbers until displaying "11" (Password for accessing parameters);

3. con rming with SET, the rst modi able parameter will appear on the display.

Modifying parameters

After displaying the parameter, proceed as follows:

1. use the buttons or to scroll the parameters to the one to be modi ed. Scrolling is accompanied by lighting up of an icon on the display, representing the

parameter category. Alternatively, press the PRG button to display a menu of the categories or parameters for quickly accessing the family of parameters to be

changed;

2. scroll the menu with the buttons and and the codes of the various parameter categories (see "Summary of operation parameters") are displayed, together

with lighting up of the corresponding icon (if present);

3. on accessing the category, press SET to go straight to the rst parameter of the selected category (if no parameter is visible, pressing the SET button will

have no e ect);

4. it is possible to continue consulting the parameters or return to the categories menu with the PRG button;

5. press SET to display the value associated with the parameter;

6. increase or decrease the value respectively with the buttons and ;

7. press SET to temporarily save the new value and return to the display of the parameter. Repeat the procedure from step 1 or step 2;

8. if the parameter has subparameters, press SET to display the rst subparameter;

9. press the buttons or to view all the subparameters;

10. press SET to display the associated value;

11. increase or decrease the value respectively with the buttons or ;

12. press SET to temporarily save the new value and return to the display of the subparameter code;

13. press PRG to return to the display of the parent parameter.

Saving new values assigned to parameters

To permanently save the values of the modi ed parameters, press the PRG button for more than 5 seconds, thus exiting the parameter modi cation proce-

dure. It is possible to cancel all the parameter modi cations, temporarily stored in RAM, and return to "normal operation" by not pressing any button for 60 seconds,

thus allowing the parameter modi cation session to expire for TIMEOUT.

Attention: If the modi cation session expires for timeout, the parameters will not be not restored.

If the power to the instrument is switched o before pressing the PRG button, all changes made to the parameters and temporarily saved will be lost.

Doc. No: 560001 EG

Page:5 Ed.1" 08-2014

From ser. no.:

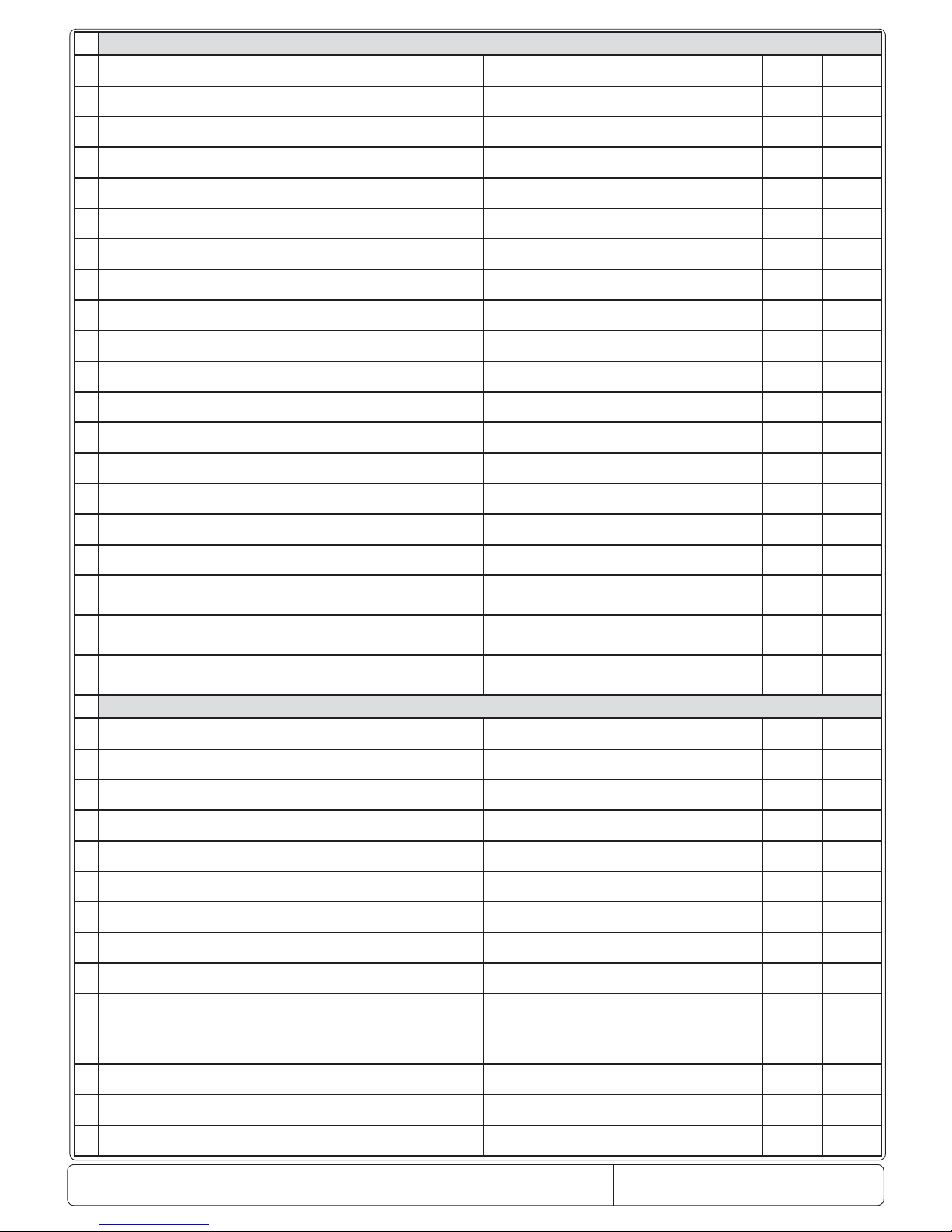

Classifi cation of parameters

As well as being divided according to TYPE, the parameters are grouped into logical CATEGORIES identi ed by the initial symbols or letters.

Given below are the existing categories with respective letters.

Parameters Category Text Icon

/

Temperature probe management parameters

Pro

r

Temperature control parameters

CtL

c

Compressor safety time and activation parameters

CMP

d

Defrost management parameters

dEF

A

Alarm management parameters

ALM

F

Fan management parameters

fan

H

General conguration parameters (addresses, enabling, etc.…)

CnF

Default parameters

fo tinUegnaRnoitpircseDenoizircseDretemaraP

1

/

/2

Stabilità misura 51...4ytilibats tnemerusaeM

2

/3

Rallentamento visualizzazione sonda 51...0esnopser yalpsid eborP

3

/5

Selezione °C o°F galF1/0F° ro C° noitceleS

4

/6

Punto decimale galF1/0tniop lamiceD

5

/tl

Visualizzazione su terminale interno 7…1lanimret no yalpsiD

6

/A2

Configurazione sonda 2 4…02 eborp noitarugifnoC

7

/A3

Configurazione sonda 3 4…03 eborp noitarugifnoC

8

/c1

Calibrazione sonda CELLA 0.02..0.02- 1 eborp noitarbilaC

C/F (/10)

9

/c2

Calibrazione sonda 2 0.02..0.02- 2 eborp noitarbilaC

C/F (/10)

10

/c3

Calibrazione sonda 3 0.02..0.02- 3 eborp noitarbilaC

C/F (/10)

11

St

2r…1rtniop teStniop teS

C/

F

12

rd

Delta Regolatore

02…1.0atled lortnoC

C/ F

13

r1

Set minimo ammesso

2r...05-dewolla tniop tes muminiM

C/ F

14

r2

Set massimo ammesso

002…1rdewolla tniop tes mumixaM

C/ F

15

r5

Abilitazione monitoraggio temperatura

1...0 gnirotinom erutarepmet elbanE

C/ F

16

c0

Ritardo start compressore. ,ventole e aux zona neutra

all’accensione

niM51...0no rewop morf tuptuO yaleD

17

c1

Tempo minimo tra accensioni successive niM51…0no rewop neewteb yaleD

18

c2

Tempo minimo di On del compressore niM51...0emit FFO rosserpmoc muminiM

19

c4

Duty setting niM001…0gnittes ytuD

20

cc

Durata ciclo continuo sruoH51…0noitarud elcyc suounitnoC

21

c6

Esclusione allarme dopo ciclo continuo sruoH51…0elcyc suounitnoc retfa ssapyb mralA

PARAMETERS RELEVANT TO TEMPERATURE PROBE MANAGEMENT

PARAMETRI RELATIVI ALLA REGOLAZIONE DELLA TEMPERATURA\PARAMETERS RELEVANT TO TEMPERATURE CONTROL MANAGEMENT

PARAMETRI RELATIVI ALLA GESTIONE DEL COMPRESSORE\PARAMETERS RELEVANT TO COMPRESSOR MANAGEMENT

Doc. No.: 560001 EG

Page:6 Ed.1" 08-2014

From ser. no.:

22

d

d0

Tipo di defrost galF4...0tsorfed fo epyT

23

dI

Intervallo tra i defrost sruoH052…0stsorfed neewteb lavretnI

24

dt1

Temperatura di fi ne defrost evap. End defrost temperature, evaporator -50…200

C/ F

25

dtP

002...0pots tinu ta erutarepmet tsorfed dnEoppurg id atamref a otnemanirbs enif id arutarepmeT

C/ F

26

dP1

Durata massima defrost evaporatore Maximum defrost duration, evaporator 1…250 Min

27

d3

Ritardo inserimento defrost niM052...0yaled trats tsorfeD

28

d4

Abilitazione defrost allo start up galFy/npu-trats no tsorfed elbanE

29

d5

Ritardo defrost allo start up niM052…0pu-trats no yaled tsorfeD

30

d6

Blocco display durante il defrost 2...0tsorfed gnirud dloh no yalpsiD

31

dd

Tempo di gocciolamento dopo il defrost niM51…0tsorfed retfa emit gnippirD

32

d8

Esclusione allarmi dopo il defrost sruoH51…0tsorfed retfa ssapyb mralA

33

d8d

Esclusione allarmi dopo aperture porta niM/sruoH052…0mrala gninepo rood no yaleD

34

d9

Priorità defrost su protezioni compressore Defrost priority over compressor protectors n/y Flag

35

dC

Base dei tempi per defrost galF1/0)s/m=1;m/h=0( tsorfed esab emiT

36

dC1

Base dei tempi per allarmi galF1/0)s/m=1;m/h=0( smrala esab emiT

37

d10

Running time del compressore sruoH052...0tsorfed rof emit gninnur rosserpmoC

38

d11

0.02..0.02-tsorfed rof erutarepmet emit gninnuRemit gninnur id arutarepmet id ailgoS

C/ F

39

dF0

Numero di ore del compressore attivo dopo il quale lo

sbrinamento deve essere attivato

NUM_COMP_ON number of hours the compressor is on

after which defrost must start

0...12 Hours

40

dF1

Numero di aperture porta dopo il quale il parametro DFO deve

decrementare

number of door openings after which dF0 must be

decreased

0...500 Units

41

dF2

Minuti da sottrarre al parametro DF0 per anticipare lo

sbrinamento

minutes to be subtracted to dF0 in order to anticipate

defrost

0...240 Min

42

A0

Differenziale allarmi e ventole 0.02…1.0laitnereffid )naf( mralA

C/ F

43

A1

Tipo di soglia AL e AH galf1/0mralA etulosbA ro evitaleR

44

AL

Soglia di allarme di bassa temperatura 002…05-dlohserht mrala erutarepmet woL

C/ F

45

AH

Soglia di allarme di alta temperatura 002…05-dlohserht mrala erutarepmet hgiH

C/ F

46

Ad

Ritardo segnalazione bassa e alta temperatura Low and high temperature signal delay 0…250 Min

47

A4

Confi gurazione ingresso digitale 1 galf51…0noitarugifnoc 1 tupni latigiD

48

A5

Confi gurazione ingresso digitale 2 galF51…0noitarugifnoc 2 tupni latigiD

49

A6

Blocco compressore da allarme esterno Stop compressor from external alarm 0…100 Min

50

A7

Ritardo rilevazione allarme esterno niM052…0yaled noitceted mrala lanretxE

51

A8

Abilitazione allarmi Ed1 ed Ed2 galF

0(off)-9(0n)

’2dE‘ dna ’1dE‘ smrala elbanE

52

A9

Segnale virtuale 2( usato per connttere la almpada a led)

Virtual input 2 configuration(Used in connection with

LED

_

Lam

p)

0…15 Flag

53

Ac

Allarme alta temperatura condensatore 002...0mrala erutarepmet resnednoc hgiH

C/ F

54

AE

Differenziale allarme alta temperatura condensatore High condenser temperature alarm differential 0.1...20

C/ F

55

Acd

Ritardo allarme alta temperatura condensatore High condenser temperature alarm delay 0…250 Min

PARAMETRI RELATIVI ALLA GESTIONE DELLO SBRINAMENTO\PARAMETERS RELEVANT TO DEFROST MANAGEMENT

PARAMETRI RELATIVI ALLA GESTIONE DEGLI ALLARMI\PARAMETERS RELEVANT TO ALARM MANAGEMENT

Doc. No: 560001 EG

Page:7 Ed.1" 08-2014

From ser. no.:

56

A

ACS

002+....05-tniopteS naelC mralAnaelC emralla rep erutarepmet id ailgoS

C/ F

57

ACd

Ritardo allarme alta temperatura condensatore Alarm Clean differential

C/ F

58

F0

Gestione ventilatori galF3...0tnemeganam naF

59

F1

Temperatura accensione ventilatore

002...05-erutarepmet pots naF

C/ F

60

F2

Ventilatore off con compressore off

galF1/0FFO rosserpmoc htiw FFO naF

61

F3

Ventilatore in sbrinamento

galF1/0tsorfed ni snaF

62

Fd

niM51…0gnippird retfa FFO naFotnemaloiccogs ol opod otneps erotalitneV

63

F10

2...0LVL_ytidimuHàtidimU

64

F11

ces006..0edom ytidimuh wol ni emit NO naFàtidimu assab ni osecca erotalitneV

65

F12

ces006..0edom ytidimuh wol ni emit FFO naFàtidimu assab ni otneps erotalitneV

66

F13

ces006..0edom ytidimuh muidem ni emit NO naFàtidimu aidem ni osecca erotalitneV

67

F14

ces006..0edom ytidimuh muidem ni emit FFO naFàtidimu aidem ni otneps erotalitneV

68

F15

ces006..0edom ytidimuh hgih ni emit NO naFàtidimu atla ni osecca erotalitneV

69

F16

ces006..0edom ytidimuh hgih ni emit FFO naFàtidimu atla ni otneps erotalitneV

70

F17

Differenziale del compressore in accensione con umidita bassa temperature differential for compressor ON in low hum. 0,1..20 sec

71

F18

Differenziale del compressore in accensione con umidita media

temperature differential for compressor ON in medium

hum.

0,1..20 sec

72

F19

Differenziale del compressore in accensione con umidita alta temperature differential for compressor ON in high hum. 0,1..20 sec

73

H0

702…0sserdda eciveDovitisopsid ozziridnI

4 yaler fo noitcnuF4 eler led otnemanoiznuF

)41 = evlavortcele

wolF()41 =alovlavorttele ossulF(

)51 = ecnatsiser emarF()51 =ecinoc aznetsiseR(

) 8 = thgil rood ssal

G()8 =ortev atrop ecuL(

) 2 = ecnatsiser epip niarD()2=asnednoc ociracs id aznetsiseR(

75

H2

galF6...0)6=N;1=Y( FFO/NO elbanE)6=N;1=Y ( FFO/NO otsat atilibasid/atilibA

76

H4

galF1/0rezzub elbasiDonilaciC atilibasiD

77

H6

552...0dapyek kcoLareitsat occolB

78

H7

Percentuale di umidità (H7=0 , disabilita controllo umidità F0=3)Attivazione Luce (H7=1) -Tipo di controllo : Versione Mass ( H7=2)

keyboard type: HUM% key (H7 = 0, enable humidity

management with F0=3) or LIGHT key (H7 = 1).

Controller t

yp

e: Mass version (H7 = 2

)

1...3

79

CCd

syaD999.......0syaD retnuoC naelCaizilup id inoig oiggetnoC

80

Cd

syaD999.......0syad naelCaizilup id inroiG

81

SAn

galF552.......0 rebmun smralA ecivreSitunevva ecivreS opit id imralla oremuN

82

SAr

galF1.......0naS teser retnuoc smralA ecivreSsmralA ecivreS ied erotatnoc led otnemarezzA

83

CAn

galF552.......0retnuoc mralA naelCteser omitlu’llad itunevva naelC imralla id oremuN

84

CAr

galF1.......0teser retnuoc mralA naelCnaelC id imralla ilged erotatnoc led otnemarezzA

85

4r1

Spazio tra il differnziale corrente e il flusso della temperatura della

elettrovalvola

Gap between current differential and flow electro-valve

tem

p

erature differential

0,1..20

C/ F

86

4r2

Abilita/disabilita la resistenza cornice mobile con la referenza

della tem

p

eratura impostata

Parameter (temperature) enabling/disabling frame

resistance with reference to chosen cell set

p

oint

-20..20

C/ F

87

4r3

Ritardo per la resistenza di scarico( il tempo deve includere la

durata del defrost

)

Delay for drain pipe switch-off (the value must include the

defrost duration

)

0...60 min

74

PARAMETRI GENERALI DI CONFIGURAZIONE

PARAMETRI RELATIVI ALLA GESTIONE DEL VENTILATORE EVAPORATORE\PARAMETERS RELEVANT TO EVAPORATOR FAN MANAGEMENT

H1

0...16 Flag

Doc. No.: 560001 EG

Page:8 Ed.1" 08-2014

From ser. no.:

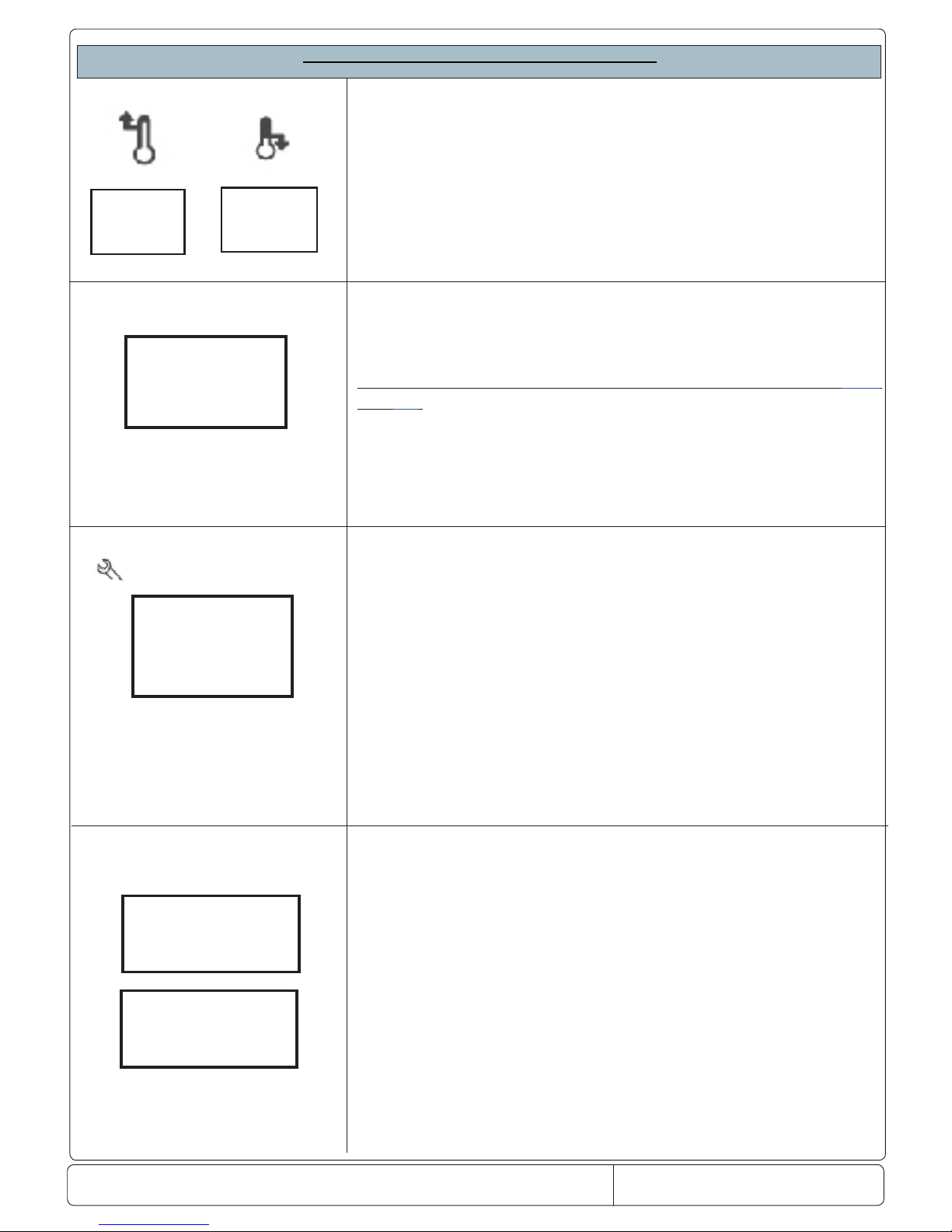

In case of faulty thermostatting probe, the display shows the message rE alternating with E0 (compartment probe S1). The appliance still

works and compressor activation and/or deactivation is time managed (15 min. ON and 15 min. OFF). The alarm condition is automatically reset as soon as compartment probe operation is restored.

In case of faulty room probe, the display shows the message E1 (room

probe S2). The alarm condition is automatically reset as soon as compartment probe operation is restored.

The service alarm signalling icon fl ashes whereas the controller buzzer

is deactivated

The service alarm signalling icon fl ashes whereas the controller buz-

zer is deactivated. In case of faulty condenser probe (if installed on

the machine), the display alternately shows the message SEr/E2. The

alarm condition is automatically reset as soon as compartment probe

operation is restored.

Clean alarm: when the condenser is very dirty on the display will

appear the label

CLn; this alarm dosen’t stop the cycle but only

advises the customer to clean the condenser. The

CLn alarm

appears only after 90 days to work of compressor and when the

temperature of the condenser and ambient is over to delta of the

parameter

ACS

The alarm disapears when the temperature decrease from parameter

ACd.( differential) or pressing the button Prg.

With the LED lamp disconnected, the display will show the message

ce in sequence of temperature.

This happens when the lamp is disconnected or damaged.

In case of no lamp connection, the controller does not diagnose any fault.

The alarm disappears when the lamp is reconnected.

Parameter to be confi gured for lamp A9=9

THERMOSTATTING PRO-

BE FAULT ALARM

ROOM PROBE

FAULT ALARM

CONDENSER PROBE

FAULT ALARM (IF PRESENT)

CLEAN ALARM (ACTIVA-

TABLE IF CONDENSER PRO-

BE IS PRESENT)

LED LIGHT CE ALARM

(in Premium models only)

SERVICE ALARMS AND SIGNALLING

SERVICE ALARMS

ALL THE SERVICE ALARMS GENERATED FOR APPLIANCE FAULTS ARE SIGNALLED ON THE DISPLAY THROUGH

THE ASSISTANCE REQUEST ICON

E0

rE

E1

E2

CLn

00cn

Doc. No: 560001 EG

Page:9 Ed.1" 08-2014

From ser. no.:

To manually activate a defrost cycle it is necessary to keep the temperature decrease button pressed for at least 3 seconds.

The display shows the message dFb/defrost

start for a few seconds

and the icon signalling activation of the defrost cycle lights up.

Defrost can be manually stopped by pressing the DEF/decrease temperature button again for at least 3 seconds. The display shows the

message dFE/defrost

end.

Defrost in the range models is carried out following the algorithm values: 1) parameter dF0, associating the actual hours of compressor

operation, 2) parameter dF1, number of door openings, where parameter dF0 must be reduced ,3)parameter dF2, minutes to be add to

parameter dF1 from subtracted to parameter dF0,to anticipate defrost .

Parameter dl remains active if these values are not respected.

In case of activation of continuous cycle, by pressing the temperature

decrease button for more than 5 seconds the display will show the

message ccb, at the same time as the temperature the message tc

will appear, meaning that “turbo cooling” has been activated. The cycle

will end for time, by parameter CC, or for temperature by parameter

AL, or by pressing the button again.

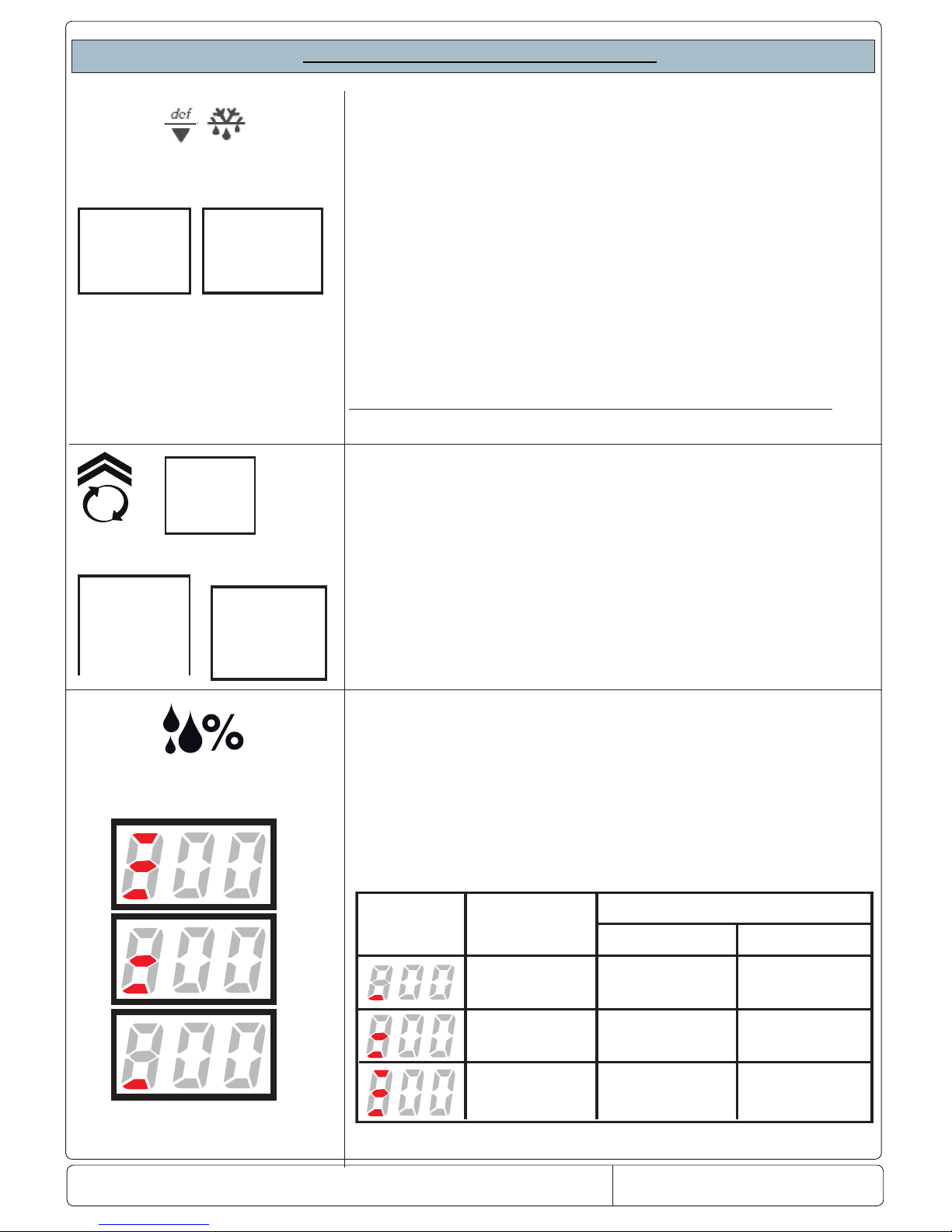

The humidity value is activated by pressing the corresponding button.

Three modes can be activated: low, medium, high % .F0= 3

The function activates the evaporator fans following the logic of low,

medium and high humidity % to be obtained in the compartment.

The parameters functioning in this are:

MANUAL DEFROST

ACTIVATION OF “TURBO COOLING” CONTINUOUS CYCLE

ccb

ACTIVATION OF HUMIDITY

CYCLE

SERVICE ALARMS AND SIGNALLING

DFb

dFE

ccE

tC

Selection

Correspondence

Low humidity

Medium humidity

High humidity

Fans always ON

Fans always ON

Fans always ON

F11= Fans ON

F12= Fans Off

F13= Fans ON

F14= Fans Off

F15= Fans ON

F16= Fans Off

Compressor OFF

Compressor ON

Evaporator fans functionality

Doc. No.: 560001 EG

Page:10 Ed.1" 08-2014

From ser. no.:

dor

When the time set on parameter d8d is expired, the alarm dor

appear on the display, following from buzzer signaling and the red

light on blinking , (premium model only).

The alarm disappear when the door is closed.

The buzzer is off pressing the icon on display.

If the alarm is On with the door closed, this is due to :

- door not aligned

- control panel not aligned

- sensor broken

The calibration of infrared sensor is of 9 mm: over this distance

the sensor not more close the contact and the alarm will be always present.

0

0

EE

0

EF

When one of the other alarms apper on the display , check the

parameter list.

If the parameters setted are not kept in memory replace the

instrument.

EPROM ALARM

SERVICE ALARMS AND SIGNALLING

HI

LO

TEMPERATURE ALARM

TEMPERATURE ALARM

"SER"

SEr

The icon light up and audible alarm sound when the compartement

temperature exceeds the set maximun value. The alarm ceases

when the temperature returns to Set point.

A Parameter AL and AH determine the threshold of alarm of hight

or lower temperature.

Another parameter as Ad determine the delay of alarm .

When the temperature return to set point, and the icon stay again

ON , press the button PRG or directly on icon.

When the temperature of condenser is over of delta parameter AC

with a delay time to

Acd , the alarm “SEr” appears on the display

and the compressor if

stopped.

The alarm can be resetted pressing togheter the buttons PRG

and

UP and the delay Acd will be re setted. The compressor will

be ON only if the temperature reaches the value of AC-AE and the

time of value ( C1 ( compressor delay at power on) will expired. If

the alarm “

Ser” appears again check if the condenser fan works or

not.

DOOR OPEN

Doc. No: 560001 EG

Page:11 Ed.1" 08-2014

From ser. no.:

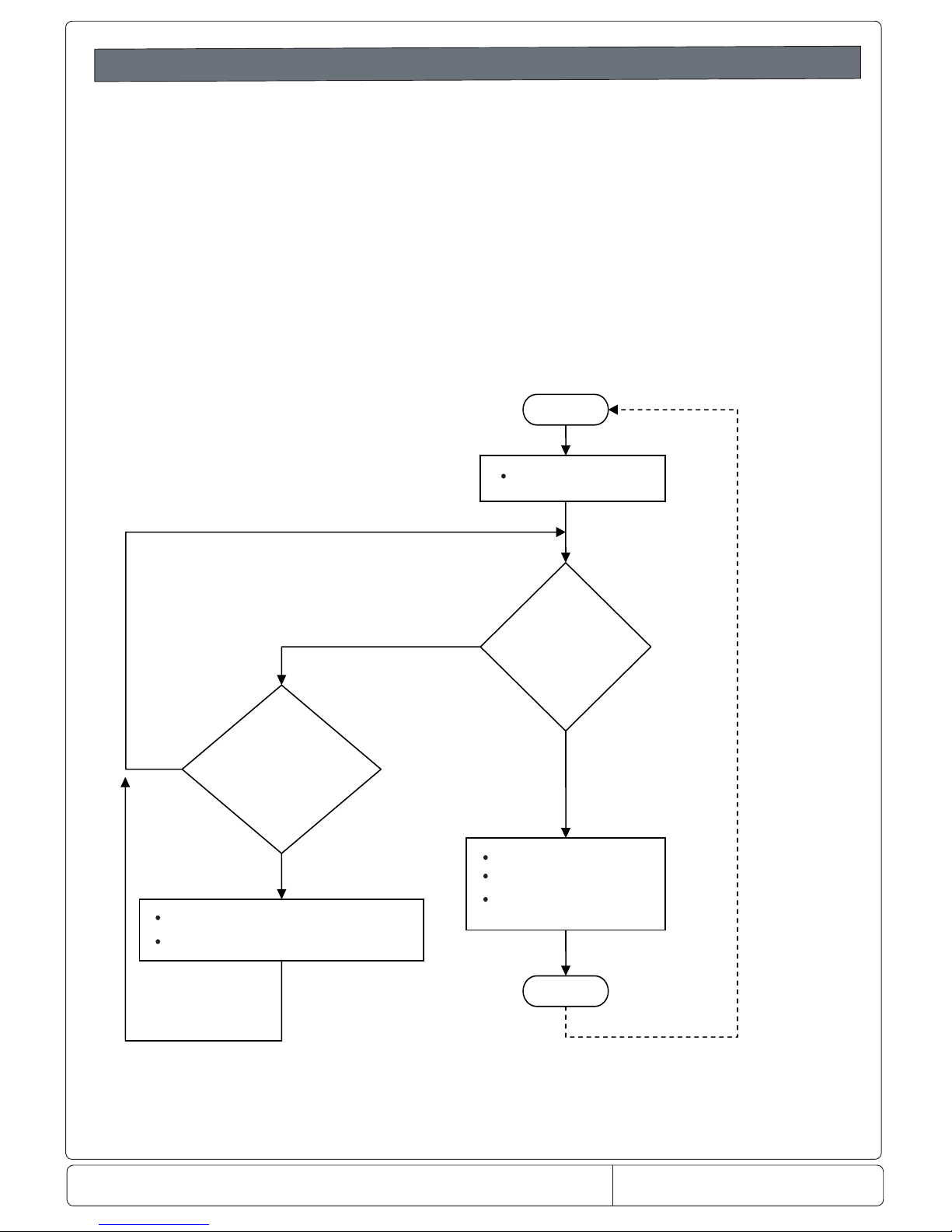

Algoritmo defrost/defrost algorithm Ecostore ONLY

Defrost

Defrost management has in principle the same features of the current FW: however, as the evaporator probe is

not present, defrost will be managed by counting working hours of the compressor and will end for timeout.

A programmed defrost will be done every defined number (parameter dF0) of working hours.

In addition, the algorithm will count the number of openings of the door as well. The aim is to anticipate of a

number of minutes (dF2) the programmed defrost with reference to the total number of openings of the d

oor.

Every time the programmed defrost is done, the total on-time hours of compressor and the number of door

openings will be reset. Proper parameters will be employed in order to manage this algorithm.

In order to do this, consider flux diagram of Figure 3.4. For instance, t_on_cmpr is the variable counting on-time

hours of compressor starting from last defrost, whereas n_open_door is the number of openings of the door.

t_on_cmpr is reset after each defrost, while n_open_door is reset every time it reaches dF1 value.

Figure

3.4: ux diagram for defrost algorithm.

START

t_on_cmpr

≥

defrost_cycle

do defrost

t_on_cmpr = 0

n_open_door = 0

END

n_open_door

≥

dF1

defrost_cycle = defrost_cycle - dF2

n_open_door = 0

?

YES

NON

O

YES

?

defrost_cycle = dF0

Doc. No.: 560001 EG

Page:12 Ed.1" 08-2014

From ser. no.:

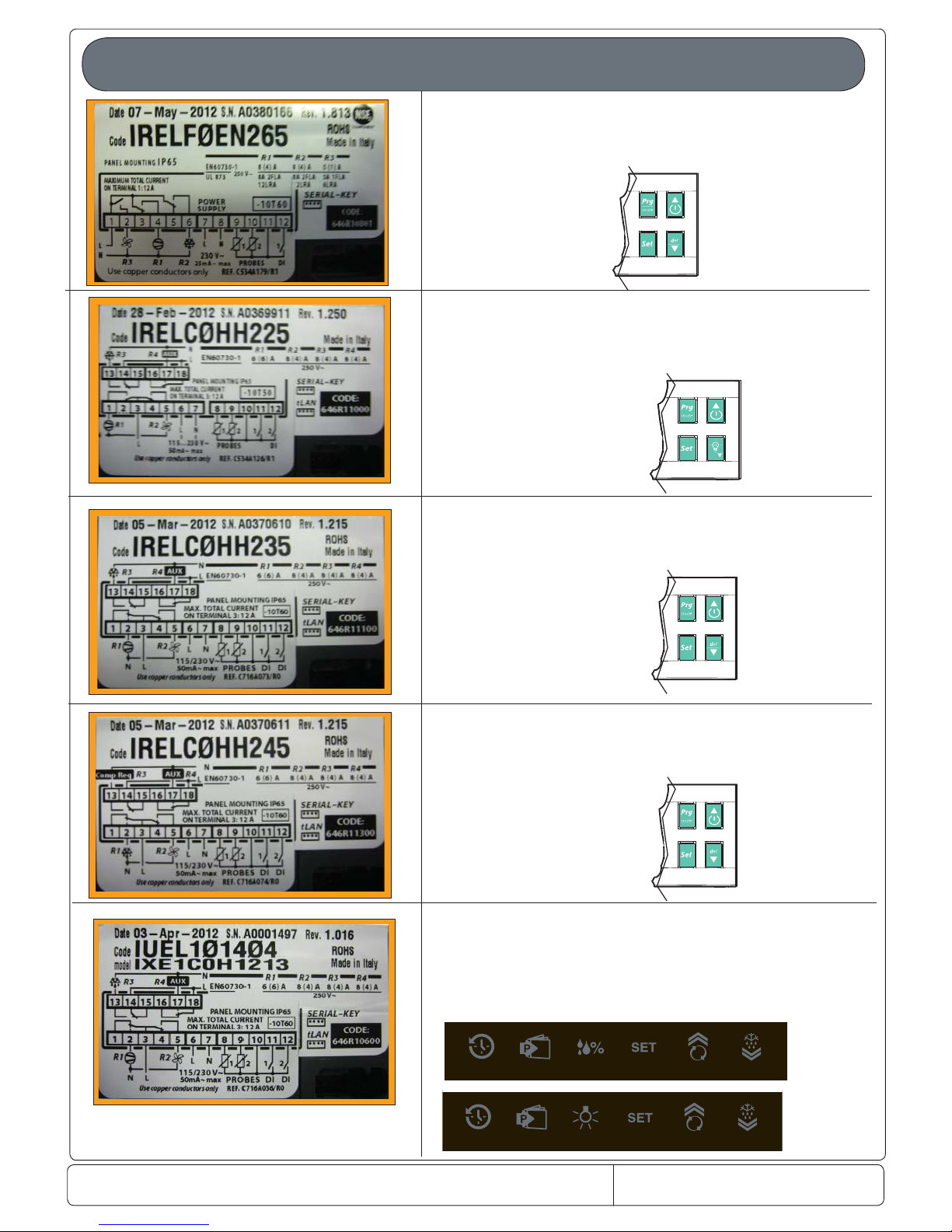

Main termoregulator and where used

Factory code 646R10802

SPC = 093328

used on Mass and Gab freezer and refrigerated

3 relay ( 8A -8A-5A)

Factory code 646R11001

SPC = 093329

used on Mass and Gab glass door freezer and refrigerated

4 relay ( 16A -8A-8A-8A)

Factory code 646R11101

SPC = 093434

used on Mass dual temp MASTER freezer and refrigerated

4 relay ( 16A-8A -8A-8A)

Factory code 646R11301

SPC = 093438

used on Mass dual temp SLAVE freezer and refrigerated

4 relay ( 16A-8A -8A-8A)

Factory code 646R10602

SPC = 093437

used on Premium all and as Master on dual temperature

4 relay ( 16A-8A -8A-8A)

Loading...

Loading...