Page 1

OWNERS GUIDE - Range Hood

PLHV36W6CC

GUIDE DE LUTILISATEUR - Hotte de cuisine

MANUAL PARA EL PROPIETARIO - Campana extractora

READ AND SAVE THESE INSTRUCTIONS

LISEZ ET CONSERVEZ CES INSTRUCTIONS

LEER Y GUARDAR ESTAS INSTRUCCIONES

UK

PLHV36W6CC - P/N 316137227 (Pub. No 5995392122)

F

E

Page 2

Contents 2

Table des matières 11

Indice 21

Contents

Product Registration....................................................................................... 2

Important Safety Instructions.......................................................................... 3

Installation.................................................................................................. 4 -7

Use and Care ................................................................................................. 8

Hood Cleaning ................................................................................................ 8

Lights Replacement ....................................................................................... 9

Warranty ...................................................................................................... 10

Product Registration

Register your Product

The self-addressed PRODUCT

REGISTRATION CARD should be

filled in completely, signed and returned

to the Frigidaire Canada.

This Owners Guide contains general

operating instructions for your range

hood and feature information for several

models. Your range hood may not have

all the described features.

Thank you for choosing this appliance. The information contained within this

Owners Guide will instruct you on how to properly operate and care for your range

hood. Please read through the information contained in your literature pack to learn

more about your new appliance.

Record Your Model and Serial Numbers

Record in the space provided below the model and serial numbers found on the serial

plate located on the right hand side of the range hood.

Model Number: ________________________________________________

Serial Number: ________________________________________________

Date of Purchase: ______________________________________________

Note: The instructions appearing in this

Owners Guide are not meant to cover

every possible condition and situation

that may occur. Common sense and

caution must be practiced when

installing, operating and maintaining any

appliance.

2

Page 3

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS

Take care when using cleaning agents or detergents.

Suitable for use in household cooking area

CAUTION - To reduce risk of fire and to properly exhaust air, be sure to duct air outside Do not vent exhaust air into

spaces within walls or ceilings or into attics, crawl spaces, or garages.

CAUTION - For General Ventilating Use Only. Do Not Use To Exhaust Hazardous Or Explosive Materials And Vapors.

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

WARNING TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite.

Heat oils slowly on low or medium settings.

b. Always turn hood ON when cooking at high heat or when cooking flaming foods.

c. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d. Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

a. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b. NEVER PICK UP A FLAMING PAN You may be burned.

c. DO NOT USE WATER, including wet dishcloths or towels a violent steam explosion will result.

d. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent back drafting. Follow the heating equipment manufacturers guideline and safety standards such

as those published by the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d) Ducted fans must always be vented to the outdoors.

WARNING - TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING

Electrical Shock Hazard - Can result in serious injury or death.

Disconnect appliance from electric power before servicing.

If equipped, the fluorescent light bulb contains small amounts of mercury which must be

recycled or disposed of according to Local, State, and Federal Codes.

3

Page 4

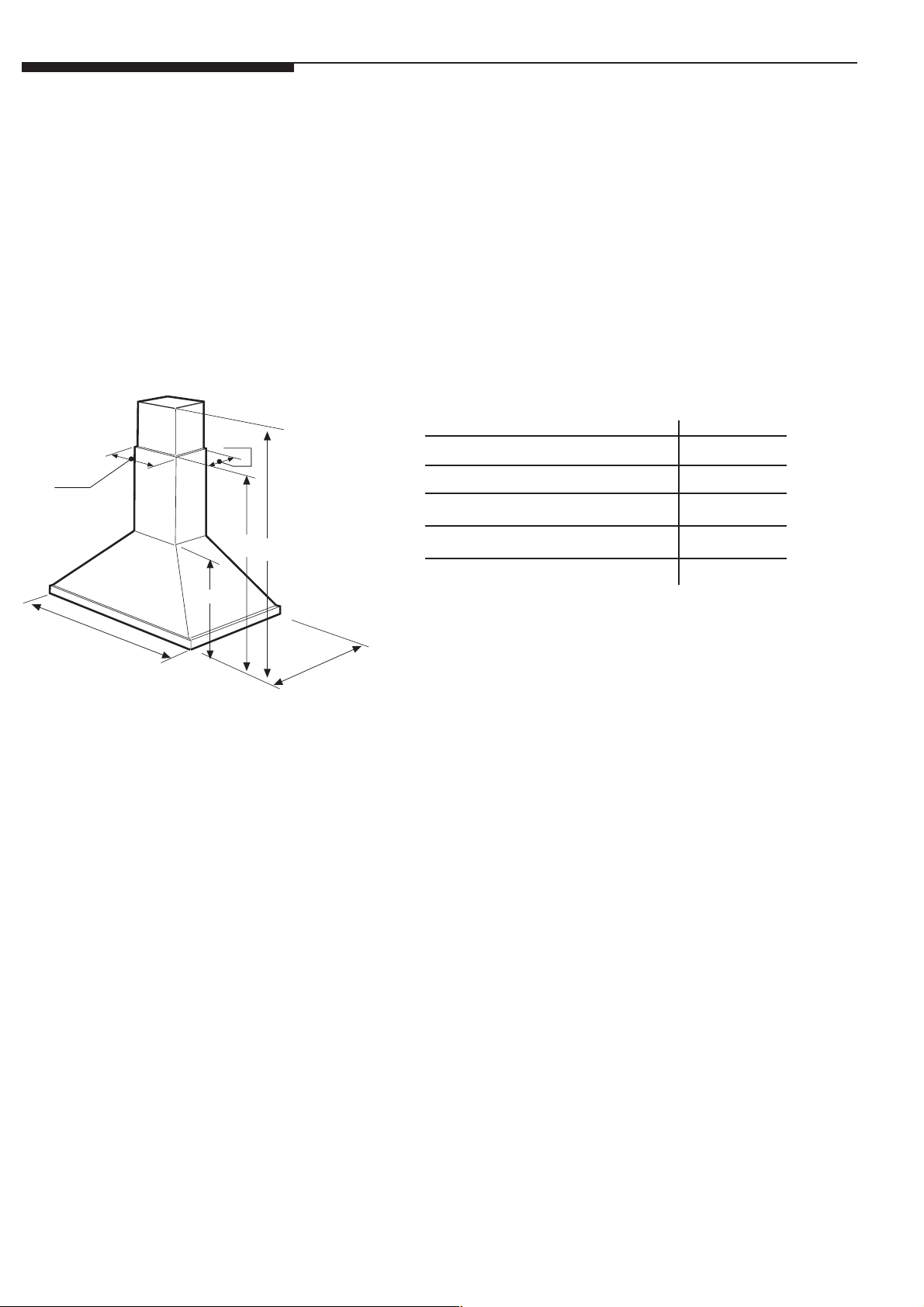

Installation

Dimensions

FOR RESIDENTIAL USE ONLY

NOT TO BE INSTALLED OVER GAS GRILLS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspectors use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at the service entrance and lock out panel,

before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A

6

7/8

"

8

3/16

"

B

9

15/16

"

36"

Figure 1*

Note: All dimensions are shown

in inches.

* Dimensions are given from

base of hood to ceiling, and

include clearance required for

installation.

A

Dimensions

A (Range of adjustable ht.)* 33 7/

- 42 3/

16

8

B (Min. ht. with one cover)* 26

W (widht) x D (depth) 8 3/16 x 6 7/

AA (Cover adjustable ht.) 23 7/16 - 32 15/

8

16

BB (Cover min. height) 16

Weight: 42 lbs

Diameter of Transition: 6

20 1/4"

Diameter of exhaust Duct required: 6

Considerations before installing Hood

1. For the most efficient air flow exhaust, use a straight run or as few elbows as

possible.

CAUTION: Vent unit to outside of building, only.

2. If allowed in your area, use metallic flex ducting only to connect rigid duct directly

to transitions.

3. COLD WEATHER installations should have an additional backdraft damper

installed to minimize backward cold air flow and a nonmetallic thermal break to

minimize conduction of outside temperatures as part of the ductwork. The

damper should be on the cold air side of the thermal break. The break should be

as close as possible to where the ducting enters the heated portion of the house.

4. Hood installation height above cooktop is the users preference. The lower the

hood above the cooktop, the more efficient the capturing of cooking odors, grease

and smoke. We recommend the hood be installed 30-36" above the countertop.

The lower height may be inconvenient for tall people and large cooking vessels.

Check your ceiling height and the hood height maximum before you select your

hood.

4

Page 5

Installation

Tools required for installation

Screw driver

(flat head, pozidrive n°2 and torx 10)

Allen key 4mm

Electric drill with twist bit Ø 10 mm

C

L

Figure 2

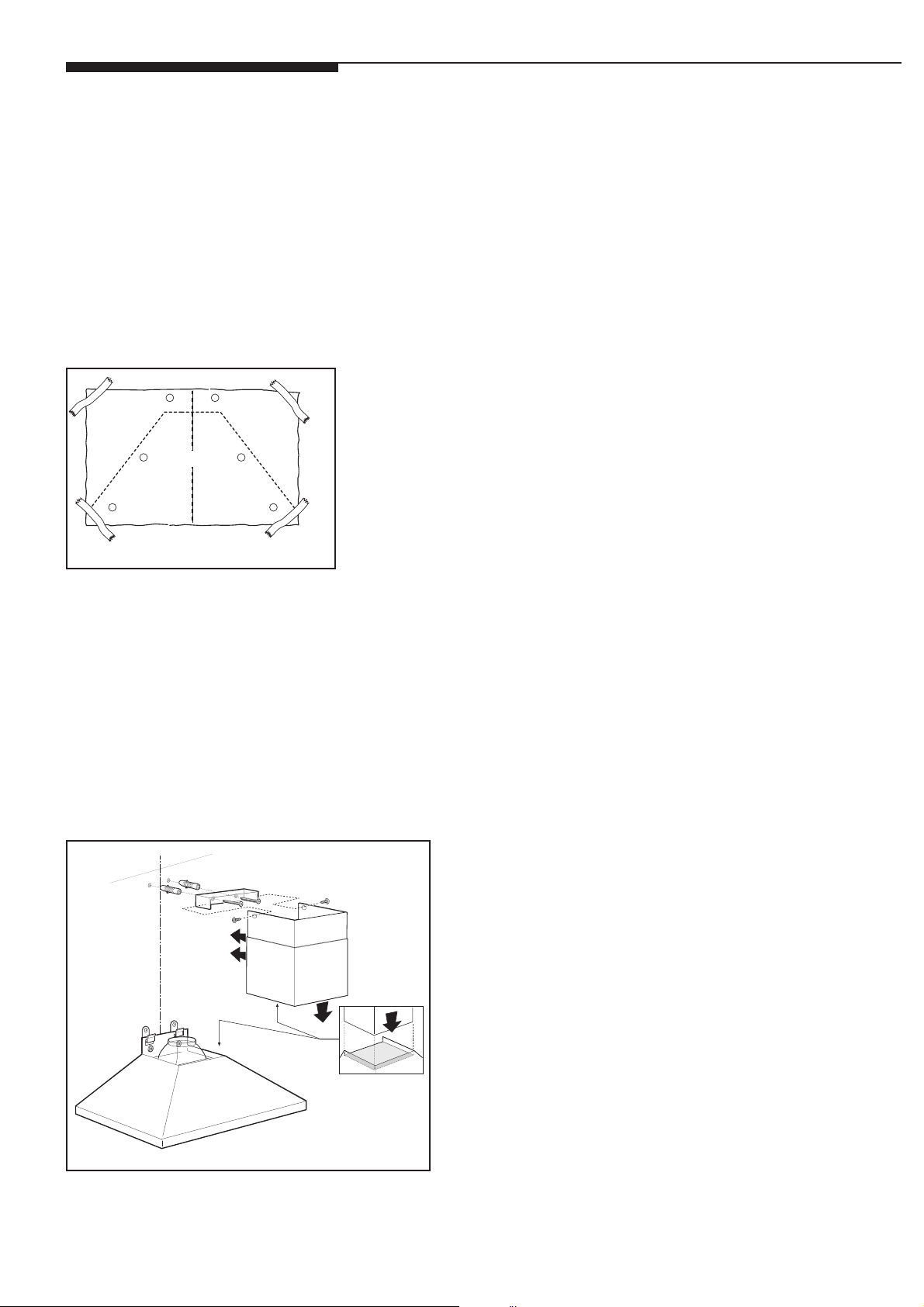

Preparation of mounting surface (Drywall)

1. Select a mounting height comfortable for the user and mark on wall behind

cooktop.

2. Mark center line of cooktop and draw vertical line from bottom of hood to the

ceiling.

3. Tape template, matching center-line and hood bottom as shown in Figure 2.

4. Mark centers of the 6 fastener locations through template on wall then remove

template.

5. Mark wall with horizontal line 1" above highest and 1" below lowest fastener

location.

6. Find studs behind drywall by

tapping wall or using a stud finder. Mark the center of the studs with a vertical

line to the right and left of the marked fastener location.

Note: 2 x 6's must span at least 2 studs side to side.

7. Cutout drywall along marked lines. Install 2 x 6's between studs firmly flush with

stud front. Make sure all mounting screws will anchor to added lumber. Replace

drywall and refinish.

8. Remark center line and hood bottom on same location as before and tape

template on wall as in step 3 above.

9. Mount 2 mounting hooks with wood screws (supplied in mounting hardware kit)

on locations marked on template, then remove template.

10. Install duct cover ceiling bracket to wall flush to ceiling with drywall anchors

supplied. Figure 3.

16

16

Figure 3

5

Page 6

Installation

Starting

Collar

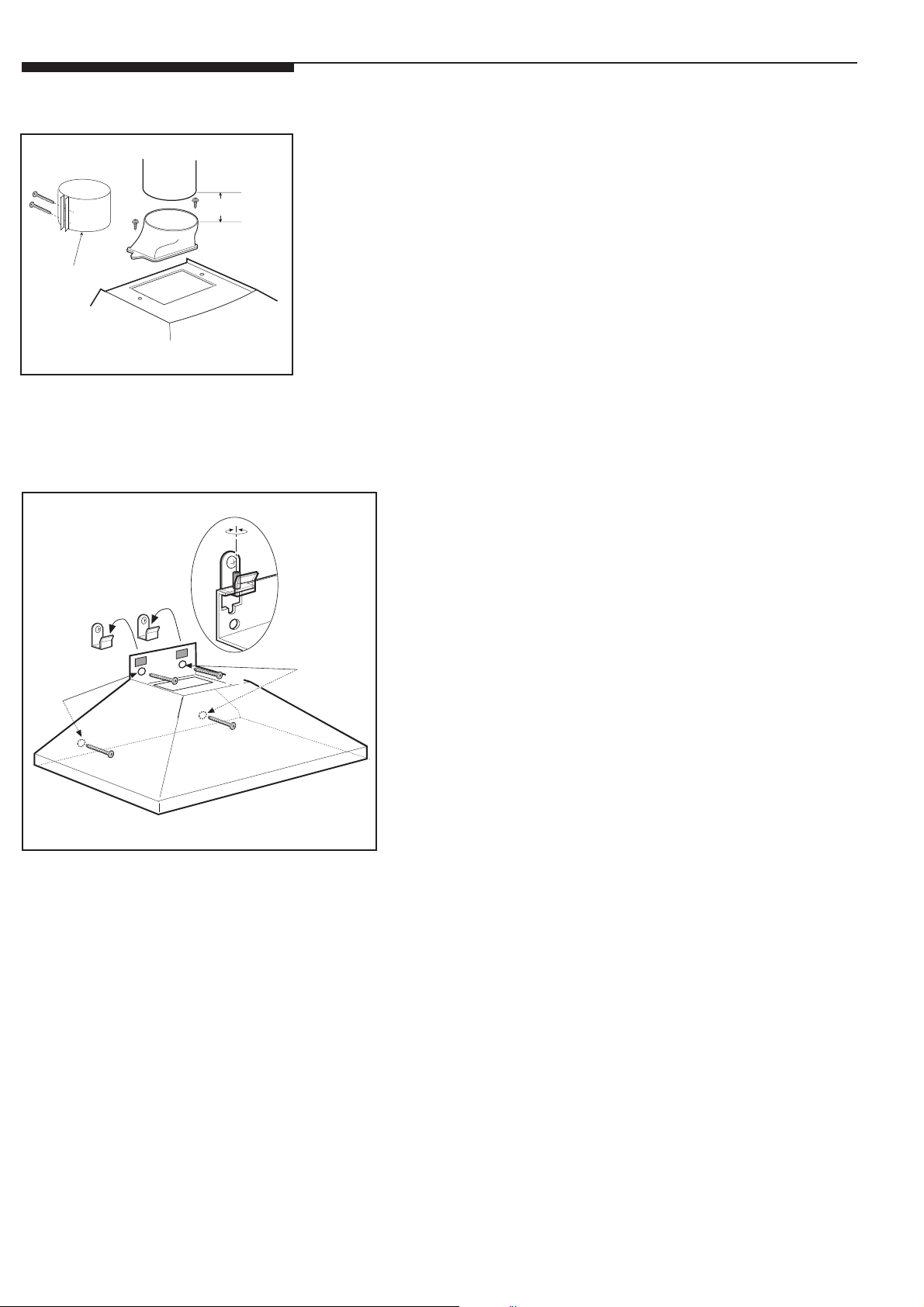

Figure 4

1"

Appliance Installation:

11. Install transition on top of hood if removed for shipping. Figure 4.

12. Hang hood on 2 mounting hooks through the rectangular cutouts on back of

hood. Figure 5

13. Level the appliance, using a carpenters level across bottom of hood with leveling

screws in mounting hooks or rectangular cutouts.

14. Secure hood with 2 screws on top and 2 screws on bottom. See Figure 5.

15. Connect ducting (Figure 4).

Note: for blower serviceability, leave a gap of 1" minimum between top of

transition and sheet metal duct and cover gap with a starting collar wrapped

around duct and transition. Locate collar screws so they fit into corner of duct

cover. Secure collar to transition and duct with three sheet metal screws each.

Seal with duct tape.

Do not use duct smaller than the transition.

Figure 5

13

6

Page 7

Installation

Figure 6

Wiring to Power Supply

WARNING!

ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS FITTED WITH AN ELECTRICAL JUNCTION BOX WITH

3 WIRES, ONE OF WHICH (GREEN/YELLOW) SERVES TO GROUND THE

APPLIANCE. TO PROTECT YOU AGAINST ELECTRIC SHOCK, THE

GREEN AND YELLOW WIRE MUST BE CONNECTED TO THE GROUNDING

WIRE IN YOUR

HOME ELECTRICAL SYSTEM, AND IT MUST UNDER NO CIRCUMSTANCES

BE CUT OR REMOVED.

Warning: Turn off power circuit at the service panel before wiring this unit.

120 VAC, 15 or 20 Amp circuit required.

16. Remove the knockout and install the conduit connector (1/2") in junction box.

17. Run 3 wires; black, white and green (#16AWG) in 1/2" conduit from service panel

to junction box.

18. Connect black wire from service panel to black or red in junction box, white to

white and green to green-yellow. Figure 6.

19. Close junction box cover. Check all light bulbs to make sure they are secure in

their sockets. Turn power on in service panel. Check lights and blower operation

per Care & Use section of this manual. Install filters.

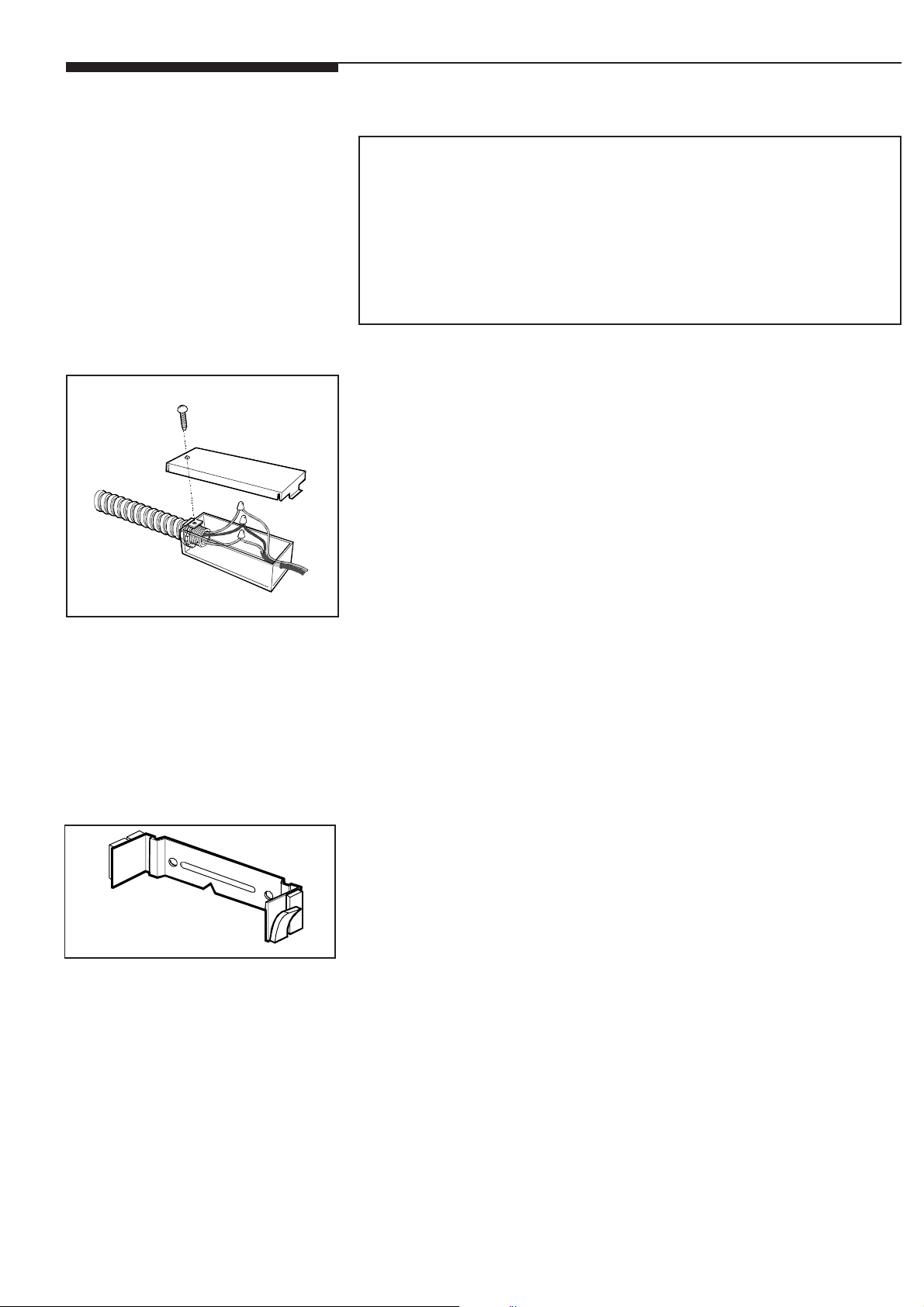

Final Assembly

Figure 7

20. Install duct cover per Figure 3. Make sure to leave this manual for the home

owner.

21. Make sure to leave this manual for the home owner.

Alternate - reduced ceiling height Installation:

The hood may be installed with only the lower part of the duct cover to reduce the

overall height.

For the duct cover to slide down and engage the top of the hood, the ceiling bracket

must be mounted 1/4" below the ceiling.

The resulting space on top of the chimney can be filled with a 1/4 thick piece of

plywood cut to the inside cross section of the chimney cover and finished to match

the ceiling.

Cut the self-adhesive rubber tape supplied with the hood in 4 identical sections.

Attach two pieces of tape to each side of the ceiling bracket. Figure 7.

Snap lower chimney duct cover into place around ceiling bracket.

Rear discharge:

A 90° elbow may be installed immediately above the hood. For serviceability, a

mounting similar to the straight up discharge shown in Figure 4 should be used.

7

Page 8

Use and Care

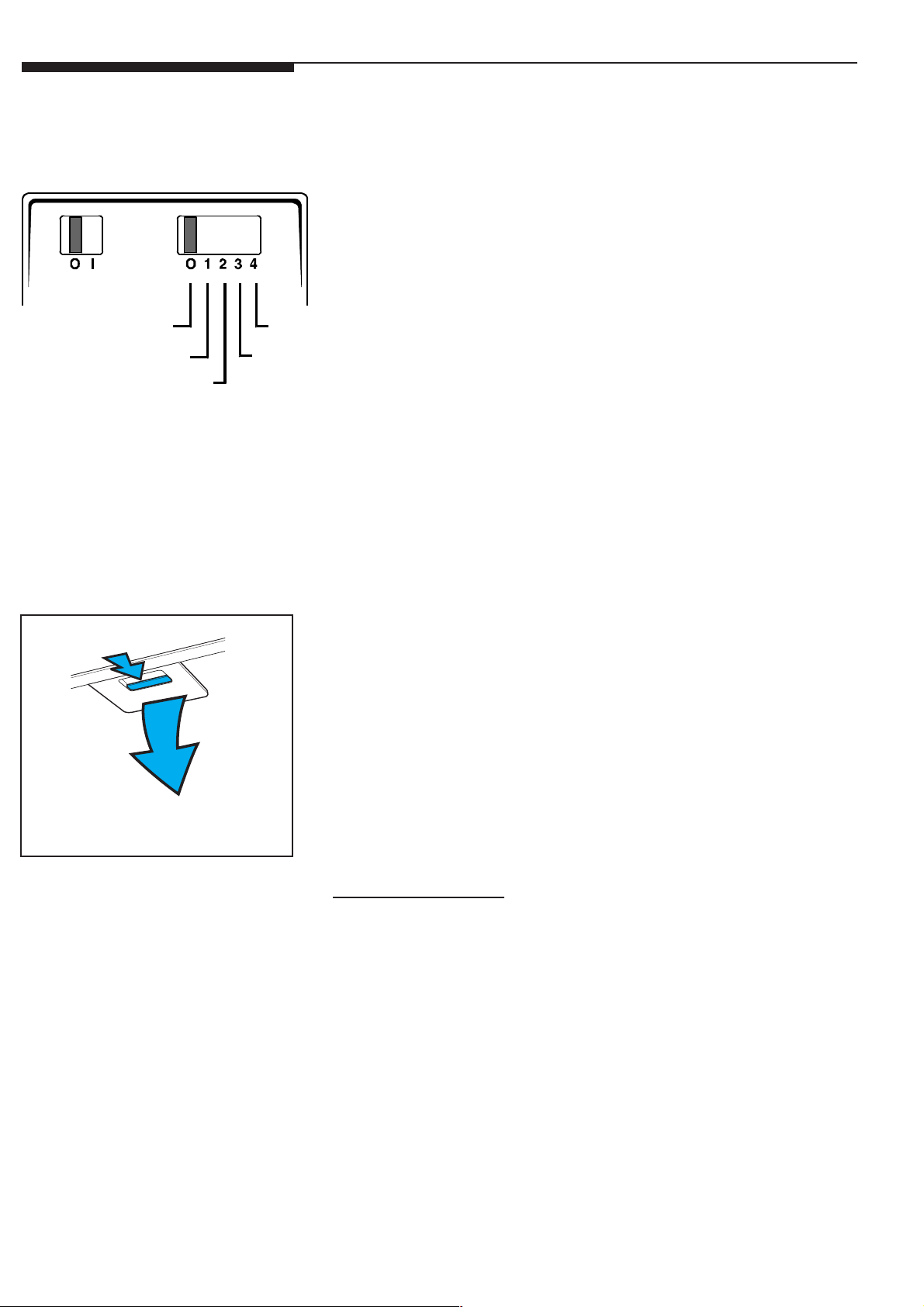

AB

C

READ THE INSTRUCTIONS CAREFULLY BEFORE USING THE HOOD.

For satisfactory use of your hood, become familiar with the various functions of the

hood as described below

A. Light ON-OFF switch

B. Motor ON-OFF switch

C. Motor OFF

D. Motor speed 1 (low)

E. Motor speed 2 (med)

F. Motor speed 3 (high)

G

G. Motor speed 4 (very high)

Figure 8

Hood Cleaning

a

D

b

E

F

Operating Instructions

The blower should be turned on for about 5 minutes before cooking in order to

establish air currents upward through the hood.

Use the low speeds for normal use and the higher speeds for strong odors or fumes.

Minimize cross drafts which will reduce the effectiveness of the hood.

Be sure lights are cool before cleaning the hood.

To Clean Filters

The metal grease filters will last forever.

They are made of anodized aluminum

It is recommended that the filters be washed at least once a month; they can be

washed by hand or in the dishwasher.

Drain water through edge holes and let each filter dry thoroughly before replacing

it.

Figure 9

To Remove The Metal Grease Filters

Turn blower and lights off.

Push each handle towards the center and pull downwards Figure 9.

To Replace The Metal Grease Filters

Reverse procedure.

To Clean Hood Surface

For general care, wipe the outside of the stainless steel, white, black or glass

hood with sudsy water or household cleaners such as Fantastic® or Formula

409®, rinse well and dry with clean soft cloth to avoid water marks.

Wipe and dry brushed stainless steel in the same direction as the grain.

Do not use abrasive products.

To remove finger prints and give added shine use spray cleaners such as

Stainless Steel Magic® and Shimmer®.

8

Page 9

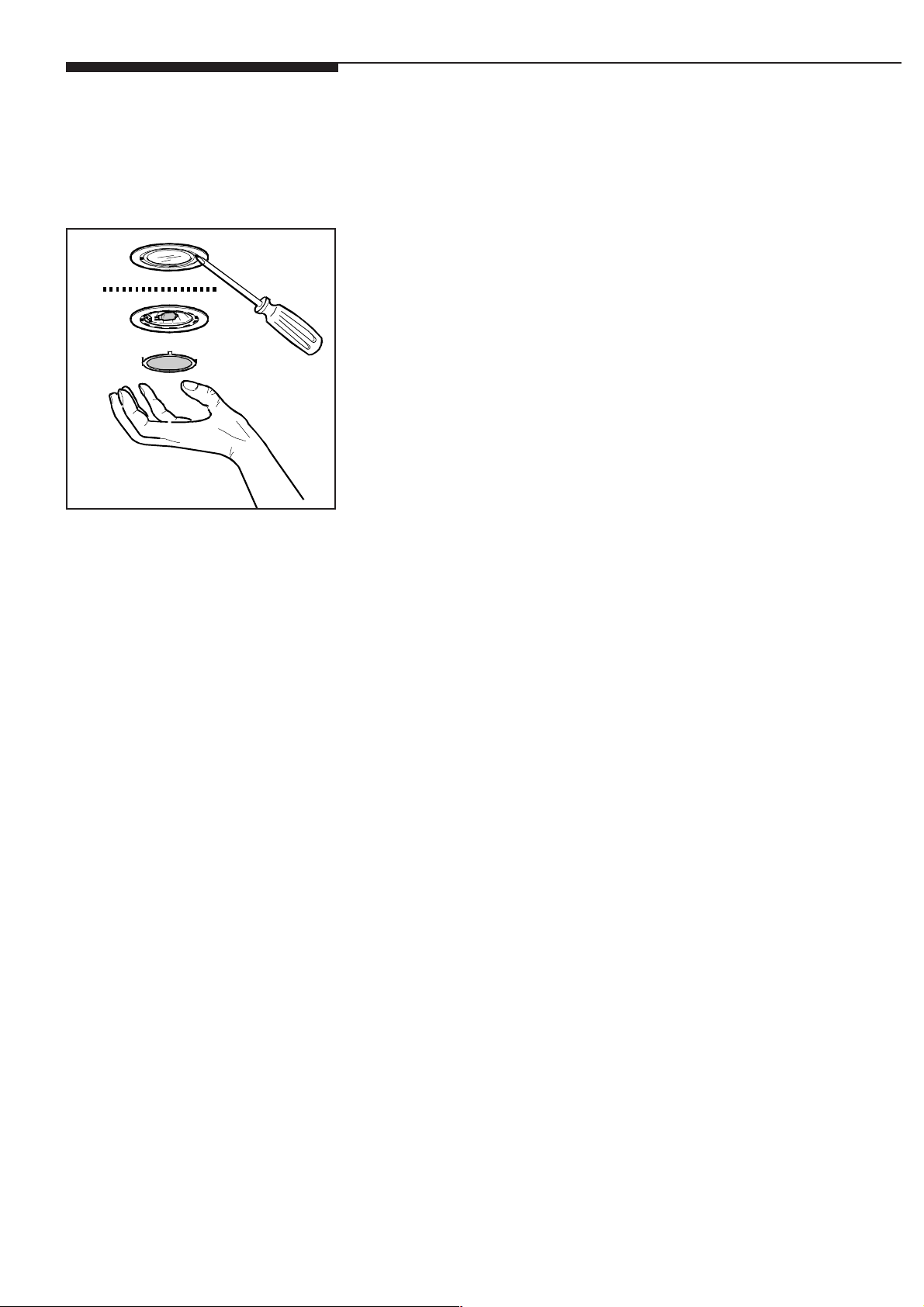

Lights replacement

Figure 10

Turn off electric power to hood before

removing light cover.

Figure 10

NOTE: Turn blower and lights off. Make sure the lights are cool. If new lights

do not operate be sure lights are inserted correctly before calling service.

Using a flat head screwdriver or equivalent tool, carefully pry loose the light cover.

Remove the damaged light and replace with a new 12 Volt, 20 Watt (maximum)

halogen light made for a G-4 base. Follow package directions and do not touch

new light with bare hands.

Reinstall the light cover.

9

Page 10

10

Page 11

Contents 2

Table des matières 11

Indice 21

Table des matières

Enregistrement de lappareil ......................................................................... 11

Informations importantes relatives à la sécurité ............................................ 12

Installation............................................................................................... 13-17

Emploi et entretien ....................................................................................... 18

Nettoyage de la hotte ................................................................................... 18

Remplacement des lampes .......................................................................... 19

Garantie ....................................................................................................... 20

Enregistrement de

lappareil

Enregistrer lappareil

La CARTE DENREGISTREMENT

préalablement adressée doit être

remplie en entier, signée et retournée

à Frigidaire Canada.

Le présent guide de lutilisateur décrit le

mode demploi général de cette hotte

ainsi que les caractéristiques de plusieurs

autres modèles. Certaines des

caractéristiques décrites peuvent donc

ne pas sappliquer à votre hotte.

Merci davoir choisi cet appareil. Les renseignements contenus dans ce guide

de lutilisateur expliquent comment utiliser et entretenir la hotte. Lire les documents

qui accompagnent lappareil pour en savoir davantage sur cette hotte.

Noter le numéro de modèle et le numéro de série

Noter ci-dessous le numéro de modèle et le numéro de série inscrits sur la plaque

signalétique située sur le côté droit du cadre avant, dans le tiroir de rangement.

Numéro de modèle: ____________________________________________

Numéro de série: _______________________________________________

Date dachat: __________________________________________________

Remarque: Les directives qui figurent

dans ce guide de lutilisateur ne sauraient

couvrir toutes les circostances et les

situations possibles. Il faut donc faire

preuve de jugement et de prudence

pendant linstallation, lutilisation et

lentretien de tout appareil

électroménager.

11

Page 12

Informations importantes relatives

à la sécurité

LIRE ET CONSERVER LES PRÉSENTES INSTRUCTIONS

Faire extrêmement attention lors de lemploi

de substances nettoyantes ou détergentes.

Aptitude à lemploi dans lenvironnement domestique/cuisine

ATTENTION Afin de réduire le risque dincendies et de garantir une évacuation de lair appropriée il faut prévoir une

conduite pour lévacuation de lair à lextérieur. Ne pas évacuer lair dans des espaces délimités par des parois/plafonds,

attiques, passages ou garages.

ATTENTION Uniquement pour la ventilation générale. Ne pas utiliser lappareil pour lévacuation de matériaux et

vapeurs dangereux ou explosifs.

AVERTISSEMENT AFIN DE RÉDUIRE LE RISQUE DINCENDIES, CHOCS ÉLECTRIQUES OU ACCIDENTS,

RESPECTER LES PRESCRIPTIONS SUIVANTES:

a. Utiliser lappareil sur la base des instructions fournies par le constructeur. En cas de doutes ou pour toute explication

ultérieure, sadresser à la société constructrice.

b. Avant deffectuer le nettoyage ou lentretien, couper lalimentation du panneau de commandes puis bloquer le dispositif

de déconnexion du courant électrique afin déviter tout risque dactionnement involontaire. Sil devait se révéler

impossible de bloquer le dispositif de déconnexion, appliquer un signal davertissement approprié (par exemple: un

panneau), bien visible et en position stable, sur le panneau de commandes.

AVERTISSEMENT POUR RÉDUIRE LES RISQUES DINCENDIES PROVOQUÉS PAR LE RENVERSEMENT DE

GRAISSE SUR LE PLAN DE LA CUISINE:

a. Ne jamais laisser sans surveillance les appareils de cuisson réglés au maximum. La cuisson à puissance élevée

est susceptible de générer des fumées et de provoquer le renversement de graisse pouvant senflammer.

Réchauffer lentement et à faible puissance lhuile ou la graisse.

b. Allumer toujours la hotte (position ON) pendant le réchauffement à température élevée ou la cuisson à la flamme.

c. Nettoyer fréquemment les rotors de ventilation. Ne pas laisser que la graisse saccumule sur le rotor de ventilation

ou sur le filtre.

d. Utiliser des poêles ou casseroles de dimensions appropriées. Choisir toujours des outils de cuisine appropriés

en fonction des dimensions du plan.

AVERTISSEMENT POUR RÉDUIRE LES RISQUES DACCIDENTS SUITE AUX INCENDIES PROVOQUÉS PAR

LE RENVERSEMENT DE GRAISSE SUR LE PLAN DE LA CUISINE, SUIVRE LES INSTRUCTIONS SUIVANTES:

a. Essayer dÉTOUFFER LES FLAMMES au moyen dun couvercle de petites dimensions, un plateau métallique ou une

feuille de papier daluminium, puis éteindre le brûleur. EFFECTUER LES OPÉRATIONS NÉCESSAIRES AVEC

PRÉCAUTIONS, AFIN DÉVITER TOUT RISQUE DE BRÛLURES. Si les flammes ne séteignent pas immédiatement,

ÉVACUER LES LOCAUX PUIS CONTACTER LES SAPEURS-POMPIERS.

b. NE JAMAIS SOULEVER UNE CASSEROLE EN FLAMMES: il y a le risque de se brûler.

c. NE PAS UTILISER DE LEAU, des torchons ou serviettes mouillés: il existe le risque quune violente explosion de vapeur

se produise.

d. Utiliser un extincteur UNIQUEMENT à condition que:

1. Lon soit sûrs de pouvoir disposer dun extincteur de Classe ABC, et lon soit déjà en mesure de lutiliser.

2. Lincendie soit réduit et limité à la zone dans laquelle il sest développé.

3. Lon ait déjà contacté les sapeurs-pompiers.

4. Lon puisse utiliser lextincteur en ayant les épaules tournées vers la sortie.

12

Page 13

Informations importantes relatives à la sécurité (suite)

AVERTISSEMENT POUR RÉDUIRE LES RISQUES DINCENDIES, CHOCS ÉLECTRIQUES OU ACCIDENTS,

SUIVRE LES INDICATIONS SUIVANTES:

a) Confier linstallation et ladaptation des connexions électriques à un personnel qualifié qui opère conformément aux

normes et aux dispositions établies, y compris aux normes de construction antiincendie.

b) Dans les installations alimentées avec du combustible, il faut quil y ait une quantité dair suffisante, afin de garantir

une combustion appropriée et une correcte évacuation des gaz à travers le carneau montant (cheminée), de façon à

éviter le retour des fumées. Suivre les directives fournies par le constructeur de lappareil de chauffage ainsi que les

normes de sécurité émises par des associations telles que la «National Fire Protection Association (NFPA), la

«American Society for Heating», la

»Refrigeration and Air Conditioning Engineers (ASHRAE) , et les autorités locales compétentes.

c) Lors du percement de parois ou de plafonds, effectuer les opérations nécessaires avec précaution, afin de ne pas

endommager les connexions électriques et les autres branchements des services généraux non visibles.

d) Les rotors de ventilation carénés doivent toujours être équipés dun système dévacuation à lextérieur.

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES DINCENDIES, UTILISER UNIQUEMENT DES

CONDUITES MÉTALLIQUES.

Av e rtissement

Risque de choc électrique. Peut occasioner des blessures sérieuses ou la mort.

Débranchez lappareil de la source dalimentation avant de procéder au service dentretien.

Si lappareil est muni dune lampe fluorescente, celle-ci contient des petites quantités de

mercure qui doivent être recyclées ou mises aux rebuts conformément aux réglements

municipaux ainsi quaux lois provinciales et fédérales.

13

Page 14

Installation

UNIQUEMENT POUR EMPLOI RÉSIDENTIEL.

NE PAS INSTALLER SUR LES GRILLES AVEC CHAUFFAGE AU GAZ.

AVANT DUTILISER LAPPAREIL, LIRE ATTENTIVEMENT LES PRÉSENTES INSTRUCTIONS.

LINSTALLATION DOIT ÊTRE EFFECTUÉE CONFORMÉMENT AUX REGLEMENTS LOCAUX.

IMPORTANT: Conserver les présentes instructions pour lemploi destinées à lInspecteur de la société électrique.

INSTALLATEUR: Conserver avec lappareil les présentes instructions pour lemploi destinées au propriétaire.

PROPRIÉTAIRE: Conserver les présentes instructions pour toute éventuelle consultation à lavenir.

Avertissements concernant la sécurité: Avant deffectuer le branchement de lappareil, couper le circuit dalimentation et

bloquer le panneau de commandes.

Alimentation requise: 120 V C.A., 60 Hz. 15 ou 20 A

Dimensions

Dimensions

6

7/8

"

8

3/16

"

A (Intervalle de réglage hauteur)* 33 7/

B (

Hauteur minimum avec une seule couverture

)* 26

- 42 3/

16

8

B

A

9

15/16

"

36"

Figure 1*

Remarque: Toutes les

dimensions sont exprimées en

pouces.

* Les dimensions sont calculées

en partant de la base de la hotte

jusquau plafond et elles

comprennent lespace libre

requis pour linstallation.

W (largeur) x D (profondeur) 8 3/16 x 6 7/

AA (Hauteur réglable couverture) 23 7/16 - 32 15/

8

16

BB (Hauteur minimum couverture) 16

Poids: 42 lbs

Diamètre de raccordement: 6

20

1/4

"

Diamètre requis pour la conduite dévacuation: 6

Avant deffectuer linstallation de la hotte

1. Afin dobtenir une efficacité maximum dévacuation de lair, utiliser une conduite

linéaire ou réduire au maximum le nombre des coudes présents.

ATTENTION: Évacuer lair de lunité exclusivement à lextérieur de lédifice.

2. Utiliser des canalisations flexibles en métal, si autorisées dans votre région,

uniquement pour connecter la conduite rigide directement aux dispositifs de

raccordement.

3. Les équipements installés dans des régions au CLIMAT FROID doivent avoir un

clapet de retenue des fumées pour réduire au maximum lécoulement de lair froid

de retour, outre à une protection thermique non métallique pour minimiser

linfluence de la température externe à travers le réseau des canalisations. Il est

opportun dinstaller le clapet sur le côté de lair froid de la protection thermique

et de placer la protection le plus près possible du point dentrée des canalisations

dans la partie réchauffée de lédifice.

4. La hauteur pour linstallation de la hotte sur le plan de la cuisine doit être établie

en fonction des exigences de lutilisateur. Plus la hotte sera placée en bas, par

rapport à la cuisine, plus laspiration des vapeurs et des odeurs de cuisson, de

la graisse et de la fumée sera efficace. Nous recommandons dinstaller la hotte

à une hauteur de 30-36" par rapport au plan de cuisson. Une installation à une

hauteur inférieure pourrait se révéler inconfortable pour les personnes très

grandes et peu pratique lors de lemploi de récipients particulièrement amples.

Avant de choisir la hotte, vérifier la hauteur du plafond et la hauteur maximum

utilisable par rapport à la hotte.

14

Page 15

Installation

Préparation de la surface de montage (placoplâtre)

1. Choisir une hauteur pour le montage pratique pour lutilisateur et marquer cette

dernière sur la paroi, derrière le plan de cuisson.

Outils requis pour linstallation

Tournevis

(vis à tête plate, pozidrive n°2 et torx 10)

Clé pour vis Allen 4mm.

Perceuse électrique avec mèche

hélicoïdale de Ø 10 mm

C

L

Figure 2

2. Marquer laxe du plan de cuisson et tracer une ligne verticale allant du fond de

la hotte jusquau plafond.

3. Fixer le gabarit de perçage avec du ruban adhésif, en faisant correspondre laxe

du plan de cuisson avec le fond de la hotte, comme illustré dans la Figure 2.

4. À travers le gabarit de perçage, marquer au milieu les 6 positions de fixation

contre la paroi, puis retirer le gabarit.

5. Marquer une ligne horizontale sur la paroi, à une distance de 1 au-dessus de

la position de fixation la plus élevée et à 1 au-dessous de la position de fixation

la plus basse.

6. Localiser les couples du châssis derrière le placoplâtre en tapotant légèrement

la paroi ou en utilisant un «chercheur de châssis» spécial. Marquer au milieu

tous les couples du châssis, en traçant une ligne verticale à droite et à gauche

de la position de fixation marquée.

Remarque: Deux des six positions marquées doivent recouvrir au moins 2

couples du châssis, dun côté à lautre.

7. Percer le placoplâtre le long des lignes marquées. Installer 2 des 6 positions

marquées entre les couples du châssis en les maintenant parfaitement alignées

avec le côté avant du couple. Veiller à ce que toutes les vis de montage soient

ancrées au bois dans lequel elles ont été introduites. Reconstruire le placoplâtre

puis effectuer le finissage.

8. Marquer laxe du plan et le fond de la hotte en correspondance du même point

précédemment marqué puis fixer le gabarit de perçage contre la paroi avec du

ruban adhésif, comme décrit au point 3.

9. Fixer 2 crochets de montage avec des vis à bois (pièces fournies avec les outils

de montage) en correspondance des points marqués sur le gabarit, puis retirer

le gabarit de la paroi.

10. En utilisant les dispositifs dancrage fournis, installer la bride de support pour la

couverture de la conduite contre la paroi, en la maintenant parfaitement alignée

avec la bride (voir Figure 3).

16

16

Figure 3

15

Page 16

Installation

Installation de lappareil:

11. Si le raccord a été retiré pour effectuer le transport, il faudra ensuite linstaller

sur la partie la plus haute de la hotte (Figure 4).

Anneau de

connexion

Figure 4

1"

12. Suspendre la hotte aux 2 crochets de montage, en utilisant les ouvertures

rectangulaires qui se trouvent sur la partie arrière de la hotte (Figure 5).

13. Stabiliser lappareil en appliquant un niveau sur le fond de la hotte et en

introduisant les vis de niveau spécialement prévues dans les crochets de

montage ou dans les ouvertures rectangulaires.

14. Fixer la hotte en appliquant 2 vis sur la partie la plus haute et 2 vis sur le fond

(Figure 5).

15. Connecter les canalisations (Figure 4).

Remarque: afin de garantir un fonctionnement correct du rotor de ventilation, il

faut laisser un espace minimum de 1 entre la partie la plus haute du raccord et

la conduite en tôle métallique puis recouvrir lespace avec un collier de

connexion quil faudra insérer sur la conduite et le raccord. Positionner les vis

du collier de façon à ce quelles sinsèrent aux coins de la couverture de la

conduite. Fixer le collier contre la conduite et le raccord, au moyen de trois vis

à métal pour chaque pièce et, pour terminer, sceller avec du ruban spécial pour

tuyaux.

Ne pas utiliser un tuyau plus petit du raccord.

Figure 5

13

16

Page 17

Installation

Figure 6

Branchement au réseau dalimentation électrique

AVERTISSEMENTS!

INSTRUCTIONS POUR LE BRANCHEMENT ÉLECTRIQUE DE TERRE

LE PRÉSENT APPAREIL EST ÉQUIPÉ DUNE BOÎTE DE CONNEXION

ÉLECTRIQUE ÉQUIPÉE DE 3 FILS, DONT UN (VERT/JAUNE) EST DESTINÉ

À LA CONNEXION DE TERRE DE LAPPAREIL.

POUR LA PROTECTION CONTRE LE RISQUE DE CHOCS ÉLECTRIQUES,

LE FIL VERT ET JAUNE DOIT ÊTRE CONNECTÉ AU FIL DE TERRE DE

LINSTALLATION ÉLECTRIQUE DOMESTIQUE ET IL NE DOIT PAS POUR

QUELQUE RAISON QUE CE SOIT ÊTRE COUPÉ OU ENLEVÉ.

Avertissement: Avant de préparer les connexions électriques, interrompre le circuit

dalimentation du panneau de commande. Alimentation requise: 120 V C.A., 15 ou

20 Amp.

16. Retirer la partie prédécoupée et installer le connecteur de la conduite (1/2") dans

la boîte de connexion.

17. Installer les 3 fils noir, blanc et vert (#16AWG) dans la conduite de 1/2" entre le

panneau de commandes et la boîte de connexion.

18. Connecter le fil noir du panneau de commandes au fil noir ou rouge de la boîte

de connexion, le fil blanc au fil blanc et le fil vert au fil vert/jaune (Figure 6).

19. Fermer le couvercle de la boîte de connexion. Contrôler toutes les lampes pour

vérifier quelles soient correctement fixées aux douilles correspondantes.

Activer lalimentation du panneau de commandes. Contrôler les lampes et le

fonctionnement du rotor de ventilation, en suivant les instructions fournies dans

la section Emploi et Entretien du présent manuel. Installer les filtres.

Figure 7

Montage final

20. Installer la couverture de la conduite, comme décrit dans la Figure 3. Ne pas

oublier de laisser le présent manuel à disposition du propriétaire.

21. Ne pas oublier de laisser le présent manuel à disposition du propriétaire.

Installation alternative avec hauteur réduite par rapport au

plafond:

Il est également possible dinstaller la hotte uniquement avec la partie inférieure de

la couverture de la conduite, de façon à réduire la hauteur totale de linstallation. Pour

faire en sorte que la couverture de la conduite descende pour sinsérer sur la partie

la plus haute de la hotte, il faut monter la bride à une distance de 1/4" par rapport

au plafond.

Lespace obtenu sur la partie la plus haute de la cheminée peut être remplie avec

un élément en contre-plaqué ayant une épaisseur de 1/4, qui sera coupé en fonction

de la section interne de la couverture de la cheminée avec finition parfaitement

alignée avec le plafond.

Couper le ruban adhésif fourni avec la hotte en 4 parties ayant la même longueur.

Fixer deux bandes de ruban adhésif de chaque côté de la bride au plafond (Figure

7).

Encliqueter la couverture de la conduite sur la bride.

Évacuation arrière:

Il est possible dinstaller un coude à 90° immédiatement au-dessus de la hotte.

Afin de garantir lefficacité du fonctionnement, nous conseillons deffectuer un

montage analogue pour lévacuation verticale illustrée dans la Figure 4.

17

Page 18

Emploi er Entretien

AB

LIRE ATTENTIVEMENT LES INSTRUCTIONS AVANT DUTILISER LA HOTTE.

Afin de pouvoir utiliser la hotte de façon satisfaisante il faut se familiariser avec

toutes ses fonctions:

A. Interrupteur ON/OFF dallumage et extinction des lumières

B. Interrupteur ON-OFF dallumage et extinction du moteur

C. Moteur éteint (OFF)

D. Vitesse moteur 1 (faible)

E. Vitesse moteur 2 (moyenne)

F. Vitesse moteur 3 (grande)

G. Vitesse moteur 4 (très grande)

C

D

E

Figure 8

Nettoyage de la Hotte

a

b

G

F

Instructions relatives au fonctionnement

Nous conseillons dallumer le rotor de ventilation environ 5 minutes avant de

commencer la cuisson, afin dactiver le tirage des courants dair à travers la hotte.

Définir une vitesse réduite pour les conditions demploi normales et une vitesse plus

élevée en cas de fumée ou odeurs intenses.

Réduire au maximum les courants de tirage transversaux susceptibles de

réduire lefficacité de la hotte.

Sassurer que les lampes se soient refroidies avant deffectuer le nettoyage de la

hotte.

Nettoyage des filtres

Les filtres métalliques anti-graisse sont réalisés en aluminium anodisé et leur

durée de vie est illimitée.

Nous recommandons de nettoyer les filtres au moins une fois pas mois. Les filtres

peuvent être lavés à la main ou au lave-vaisselle.

Évacuer leau à travers les trous sur le bord puis laisser sécher totalement les

filtres avant de les remonter.

Figure 9

Retrait des filtres métalliques anti-graisse

Éteindre le rotor de ventilation et les lampes.

Pousser chaque poignée au milieu et vers le bas (Figure 9).

Remplacement des filtres métalliques anti-graisse

Suivre la procédure à rebours.

Nettoyage de la surface de la hotte

Pour le nettoyage général des hottes blanches ou noies, en acier inox ou en verre,

passer sur la surface externe un chiffon imbibé deau savonneuse ou de détergent

pour emploi domestique (type Fantastic®, Formula 409®, etc.), puis rincer avec

soin et sécher avec un chiffon souple et sec afin déliminer toute trace.

Nettoyer puis sécher lacier inox usiné, en suivant le sens de lusinage.

Ne pas utiliser des produits abrasifs.

Pour éliminer les traces dempreintes et intensifier léclat des surfaces, utiliser

des sprays détergents, par exemple: Stainless Steel Magic® et Shimmer®.

18

Page 19

Remplacement

des lampes

Figure 10

Débrancher la hotte avant de sortir la

protection de la lampe.

Figure 10

REMARQUE: Éteindre le rotor et les lampes. Sassurer que les lampes soient

froides. Si les lampes neuves ne fonctionnent pas, vérifier quelles soient insérées

correctement avant de contacter le Service après-vente.

En utilisant un tournevis à tête plate ou un outil équivalent, retirer le plafonnier, en

faisant très attention.

Retirer la lampe endommagée puis remplacer celle-ci par une lampe halogène 12

Volts, 20 Watt (maximum) pour un socle G-4. Suivre les instructions reportées

sur lemballage. Ne pas toucher la lampe neuve des mains nues.

Remonter le plafonnier.

19

Page 20

GARANTIE DE LA HOTTE DE CUISINE

La hotte de cuisine que vous avez acheté est couverte par la présente garantie

PÉRIODE

DE GARANTIE

GARANTIE TOTALE

DUNE ANNÉE

GARANTIE LIMITÉE

(applicable pour

lAlaska)

Lappareil acheté aux Etats-Unis est couvert par la garantie Electrolux Home Products North America, une division de White Consolidated

Industries, Inc. Les soussignés nautorisent aucune modification ou adjonction aux obligations assumées en vertu de la présente garantie.

Laccomplissement des obligations assumées pour le service après-vente et la fourniture de pièces de rechange en vertu de la présente

garantie est exclusivement du ressort des soussignés ou dun centre de service après-vente autorisé par Electrolux Home Products North

America. Au Canada, lappareil acheté est couvert par la garantie WCI Canada, Inc.

*RESPONSABILITÉ

DE LACHETEUR

Une année à compter de

la date dachat initiale.

Périodes indiquées

ci-dessus

La présente garantie concerne uniquement les produits destinés à un emploi normal dans un

contexte domestique et elle attribue à lacheteur les responsabilités suivantes:

1. Emploi correct de lappareil, conformément aux instructions fournies avec le produit.

2. Installation correcte effectuée par un centre de service après-vente autorisé, conformément aux instructions

fournies avec lappareil et en plein respect des règlements locaux en matière dinstallations électriques,

hydrauliques et/ou du gaz.

3. Connexion à une source dalimentation avec mise à la terre ayant une tension appropriée, remplacement des

fusibles grillés, réparation des connexions interrompues ou rectification des pannes de linstallation électrique

domestique.

4. Frais soutenus afin de garantir laccès à lappareil pour les interventions dentretien ou de réparation, y

compris le retrait de fournitures, meubles, armoires suspendues, etc. qui ne font pas partie de lappareil au

moment de la livraison de la part de lusine de production.

5. Dommages aux finitions à la suite de linstallation.

6. Remplacement des lampes et/ou tubes fluorescents (sur les modèles équipés de ces éléments).

SERVICES OFFERTS À TRAVERS NOS CENTRES DE

SERVICE APRÈS-VENTE AUTORISÉS:

Couverture de tous les frais de réparation ou

remplacement des pièces de lappareil qui se révèlent

défectueuses au niveau des matériaux ou de lusinage.

Couverture des frais sur la base des clauses des

garanties totales et limitées mentionnées ci-dessus et

des exclusions de garantie indiquées ci-dessous.

RESPONSABILITÉ DE LACHETEUR :

Paiement des frais pour les appels au service

après-vente indiqués dans le paragraphe

RESPONSABILITÉS NORMALES DE

LACHETEUR.

Paiement des frais de déplacement et

dintervention du technicien au domicile de

lacheteur ainsi que les frais de retrait et de

livraison de lappareil pour le service aprèsvente.

EXCLUSIONS

SI LON DEMANDE

ASSISTANCE

La présente garantie est valable uniquement dans les 50 Pays qui constituent les Etats-Unis dAmérique, au Porto Rico et au Canada. Les

caractéristiques et les spécifications techniques décrites ou illustrées pour les produits sont peuvent subir des variations, et cela sans

préavis. Toutes les garanties offertes sont assurées par Electrolux Home Products North America, une division de White Consolidated

Industries, Inc. In Canada, lappareil bénéficie de la garantie de WCI Canada, Inc.

La présente garantie nintervient pas dans les cas suivants:

1. DOMMAGES DÉCLARÉS OU INDIRECTS, PARMI LESQUELS LES DOMMAGES À LA PROPRIÉTÉ, ET LES FRAIS

INDIRECTS DÉRIVANT DE LA VIOLATION DE LA PRÉSENTE GARANTIE ÉCRITE OU DE TOUTE AUTRE

GARANTIE IMPLICITE.

REMARQUE: Certains Pays nautorisent pas lexclusion ou la limitation des dommages déclarés ou indirects

par rapport à la garantie. Pour ce motif, ladite exclusion ou limitation peut ne pas concerner lappareil que vous

avez acheté.

2. Appels au service après-vente ne concernant pas le fonctionnement défectueux ou les défauts du matériau/

de lusinage ou relatifs aux appareils non destinés à lemploi normal dans le contexte domestique. Lacheteur

est tenu de régler le paiement pour lesdits appels au service après-vente.

3. Dommages consécutifs aux prestations des techniciens dun service après-vente non appartenant à

Electrolux Home Products North America ou à ses centres autorisés; emploi de pièces de rechange non

originales obtenues dans des centres non appartenant à Electrolux Home Products; causes externes telles

que: abus, emploi impropre, installation dalimentation non appropriée ou causes de force majeure.

4. Produits dont les numéros de série originaux ont été retirés ou altérés et ne pouvant pas être identifiés

immédiatement.

Conserver la facture dachat, le bulletin de livraison ou tout autre reçu attestant le paiement. La date reportée sur

la facture établit les termes de la validité de la garantie pour la demande dassistance. Il est dans vos intérêts

dobtenir et conserver tous les reçus, dans léventualité où une intervention du service après-vente devait se

révéler nécessaire. La présente garantie écrite vous confère des droits légaux spécifiques. Des droits ultérieurs

pourront vous être conférés sur la base de la législation en vigueur dans les différents Pays. pour la demande

dassistance en garantie, sadresser à Electrolux Home Products:

Canada

USA

8009449044

Electrolux Home Products North America

P.O. Box 212378

Augusta, GA 30917

8662139397 (Anglais)

8662949911 (Français)

Electrolux Home Products North America

6150 McLaughlin Road

Mississauga, Ontario, Canada

L5R 4C2

20

Page 21

Contents 2

Table des matières 11

Indice 21

Indice

Registro del aparato .......................................................21

IInstrucciones muy importantes para la seguridad .......... 22

Instalacion................................................................23 -26

Uso y mantenimiento .....................................................27

Limpieza de la campana ................................................27

Cambio de las lámparas .................................................28

Registro del aparato

Registre su aparato

La tarjeta con la dirección para registrar el aparato tiene que completarla

completamente, firmarla y enviarla a

ELECTROLUX, CANADA.

Este manual para el propietario contiene las instrucciones generales de

funcionamiento para su campana y

presenta la información referente y

válida para los distintos modelos. Su

campana podría no tener todas las

características que aparecen descritas.

Le agradecemos que haya elegido este aparato. La información contenida en

este manual para el propietario le dirán cómo utilizar y cuidar de forma adecuada

su campana de cucina.

Le aconsejamos que lea la información contenida en el kit de documentación para

saber todo lo que se refiere a su nuevo aparato.

Registro de los números del modelo y la serie

Escriba en los espacios los números de modelo y de serie que encontrará en la

etiqueta de serie situada en la parte derecha de la campana.

Númro de modelo (código) : _____________________________________

Número de serie: _______________________________________________

Fecha de compra: ______________________________________________

Nota: las instrucciones que aparecen

en este manual para el propietario

puede que no indiquen todas las

condiciones y situaciones que se

pueden encontrar. Hay que tener

mucha precaución cuando se instale

la campana, durante su funcionamiento

y durante las labores de mantenimiento.

21

Page 22

Instrucciones muy importantes para la seguridad

LEA Y CONSERVE ESTAS INSTRUCCIONES

Tenga cuidado cuando use productos de limpieza o detergentes.

Solamente para uso doméstico.

ATENCION. Para evitar el riesgo de incendio y para que la campana aspire correctamente el aire, asegúrese de que el

aire es expulsada al exterior. No expulse el aire aspirada dentro de habitaciones ,techos ,buhardillas, trasteros o garajes.

ATENCION . Hay que utilizar la campana solamente para aspiración en general. No la utilice para aspirar materiales

pericolosos explosivos o para humos.

ADVERTENCIA. PARA REDUCIR EL PELIGRO DE INCENDIO , DE CORTOCIRCUITO O DañOS A TERCEROS, SIGA

ESTAS NORMAS.

a. Utilice el aparato solamente como dice el fabricante. Si tiene dudas, consulte a éste.

b. Antes de reparar o limpiar el aparato desconecte la corriente del cuadro de mandos y bloquee todos los medios de

servicio para evitar que la corriente se conecte de forma accidental. riattivata accidentalmente.

Si no se pudieran bloquear, ponga en el cuadro de mandos algo que asome y que pueda avisar del estado del cuadro

de mandos como por ejemplo un buril.

ADVERTENCIA. PARA REDUCIR EL PELIGRO DE INCENDIO CAUSADO POR LA GRASA.

a. No deje nunca el aparato sin vigilancia cuando está funcionando a alta velocidad.

b. La eboliciónexcesiva hace que los vapores y la grasa salgan y se puedan incendiar.

Caliente el aceite a fuego lento o medio.

c. Encienda siempre la campana cuando cocina con fuego alto o cuando preparar alimentos al flambè.

d. Limpie las aspas periodicamente. No debe acumularse la grasa en ellas o en el filtro.

e. Utilice cazuelas o sartenes de la medida adecuada . Utilice simpre cazuelas o sartenes de la medida de los

quemadores.

ADVERTENCIA. PARA REDUCIR EL PELIGRO DE DañOS A LAS PERSONAS EN CASO DE INCENDIO PROVOCADO

POR LA GRASA. SIGA ESTAS INSTRUCCIONES:

a. Apague las llamas con una tapa adherente, una bandeja para dulces o una bandeja de metal y apague el quemador.

ATENCION A LAS QUEMADURAS. Si las llamas no se apagaran inmediatamente. LLAME A LOS BOMBEROS.

b. NO AGARRE UNA SARTEN EN LLAMAS. Corre el riesgo de quemarse.

c. NO USE NUNCA AGUA, ni siquiera trapos o toallas humedas, porque causaría una violenta explosión de vapor de agua.

d. Utilice un extintor SOLAMENTE si:

1) Usted posee un extintor de tipo ABC y sabe cómo utilizarlo.

2) Se trata de un pequeño incendio localizado en la zona donde se ha producido.

3) Ha llamado a los bomberos.i pompieri sono stati chiamati

4) Si puede combatir el fuego teniendo una salida a su espalda.

ADVERTENCIA. . PARA REDUCIR EL PELIGRO DE INCENDIO, CORTOCIRCUITO O DAñOS A TERCEROS SIGA

ESTAS NORMAS.

a. La instalación y la conexión eléctrica tiene que realizarlas personal especializado según todas las normativas

aplicables incluida la construcción antiincendio.

b. Es necesario tener aire suficiente para adecuada combustión y una evacuación de los gases por un conducto

(chimenea) del aparato para evitar la salida posterior de los mismos.

. Siga las instrucciones del manual de instrucciones del aparato de calefacción del fabricante y las normas de seguridad

como las que ha publicado la National Fire Protection Association ( NFPA) y po la American Society for Heating,

Refrigeration and Air Conditioning Engineers ( ASHRAE) ed las normas de las autoridades locales.

c. No estropee las conexiones eléctricas u otras conexiones útiles que están escondidas, cuando realice taladros en la

pared o en el techo.

d. Las aspas que aspirant tienen que tener un conducto de evacuación al exterior.

ADVERTENCIA. PARA REDUCIR EL PELIGRO DE INCENDIO USE SOLAMENTE TUBOS METALICOS.

ADVERTENCIA

Peligro de cortocircuito.- Puede causar daños serios o incluso la muerte.

Desconecte el aparato de la red eléctrica antes de realizar las labores de mantenimiento.

Si la campana contiene lámpara de neón , ésta contiene restos de mercurio que hay que

eliminar segun las Normas locales Estatales y Federales.

22

Page 23

Instalacion

HAY QUE UTILIZARLA SOLAMENTE PARA INSTALACION FIJA.

NO HAY QUE INSTALARLA ENCIMA DE REJILLAS DE GAS.

POR FAVOR, LEA COMPLETAMENTE LAS INSTRUCCIONES ANTES DE REALIZAR LA INSTALACION

LA INSTALACION TIENE QUE ADECUARSE A LAS NORMAS LOCALES.

IMPORTANTE: Conserve estas instrucciones para el Inspector local de la Electricidad.

INSTALADOR: Por favor deje estas instrucciones del aparato para que las pueda usar el propietario.

PROPIETARIO: Por favor conserve estas instrucciones para posibles consultas.

Advertencia de seguridad: apague el circuito eléctrico de entrada de la corriente y apague el cuadro eléctrico antes de

conectar el aparato.

Requisitos: 120V AC, 60Hz. 15 o 20 A.

Dimensiones

Dimensiones

6

7/8

"

8

3/16

"

A (Ajuste de la altura.) * 33 7/

B (Altura mínima con una chimenea)* 26

- 42 3/

16

8

B

A

9

15/16

"

36"

Figura 1*

Nota : todas las dimensiones son

en pulgadas.

* Las dimensiones son desde la

base de la campana hasta el

techo e incluyen la alteza

requerida para la instalación.

W (Anchura)*x D (Longitud)* 8 3/16 x 6 7/

AA ( Ajuste de la altura de la chimenea ) 23 7/16 - 32 15/

8

16

BB (Altura mínima de la chimenea) 16

Peso: 42 lbs

Diámetro para la abrazadera de transición 6

20 1/4"

Diámetro del tubo de aspiración 6

Indicaciones que hay que tener en cuenta antes de instalar la

campana.

1. Para una mayor aspiración use un conducto de salida del aire recto o use el

menor número posible de curvas.

ATENCION: El aparato tiene que expulsar el aire al exterior.

2. Si está permitido en su zona use solamente tubos de metal flexible para conectar

el tubo a la junta de transición.

3. Las instalaciones con el FRIO tendrían que incluir una válvula de no retorno

posterior adjunta para reducir la cantidad posterior de aire frío y un interruptor

térmico no metálico para reducir la conductividad de la temperatura externa en

el interior del tubo.

La válvula de no retorno tendría que que estar en la parte de entrada del aire frío

del interruptor térmico. El interruptor tendría que estar situado lo más cerca

posible o donde el entubado entra en contacto con la parte caldeada de la casa.

4. La distancia de la campana a la encimera no aparece regulada de antemano.

Cuanto m-0s cerca está la campana a la encimera, mayor es la capacidad de

aspiración de los humos y grasas. Nosotros recomendamos que se instale la

campana a una distancia de 30 o-36 de la encimera.

Una distancia inferior podría resultar incómoda a personas altas o si se usan

recipientes altos.

Compruebe la altura del techo de la casa y la altura máxima de la campana antes

de elegir su su campana.

23

Page 24

Instalacion

Herramientas necesarias para la

instalación

Desatornillador

( cabeza plana , pozidrive n. 2 e torx 10)

Llave inglesa 4mm

Taladro eléctrico con punta Ø 10 mm

C

L

Figura 2 - Máscara de taladrar.

Preparación de la superficie de instalación (cartón yeso)

1. Seleccione una altura de instalación adecuada para el usuario y señálela en la

pared detrás de la encimera.

2. Señale el centro de la encimera y trace una línea vertical desde el fondo de la

campana hasta el techo..

3. Sujete con cinta adesiva la máscara de taladrar incluyendo la línea central y el

fondo de la campana como aparece indicado en la figura n.2

4. Señale el centro de la posición de los 6 orificios para los soportes de pared en

la máscara de taladrar y despues quítela.

5. Señale la pared con una línea horizontal 1 más alta que los orificios para los

soportes superiores y 1"más baja de los orificios para los soportes inferiores.

6. Encuentre los mástiles del cartón yeso golpeando en la pared o utilizando un

detector de mástiles. Señale el centro de los mismos con una línea vertical a

la derecha y a la izquierda de los orificios para colocar los soportes indicados..

Nota:Cada 2 x 6 soportes tienen que atravesar de parte a parte por lo menos

2 mástiles.

7. Corte el cartón yeso por la línea indicada.

Instale 2x6 mástiles de forma estable en plano respecto al mástil. Asegúrese

de que todos los tornillos de sujeción se agarren a la madera. Vuelva a colocar

el cartón yeso y remate

8. Vuelva a señalar la línea central y el fondo de la campana en el mismo sitio de

antes y sujete la máscara de taladrar con cinta adesiva como aparece indicado

en el punto n.3.

9. Coloque dos ganchos de sujeción con tornillos especiales para madera ( que

encontrará en el kit de sujeción de la campana) en los orificios señalados en la

máscara de taladrar y después quítela.

10. Coloque las escarpias que sujetan la chimenea en la pared en plano respecto

al techo con los tornillos especiales para cartón yeso que encontrará en el kit.

Figura 3.

Figura 3

16

16

24

Page 25

Instalacion

Starting

Collar

Figura 4

1"

Instalación del aparato:

11. Instale la escarpia arriba de la campana si la han quitado para trasnsportar el

aparato..

12. Cuelque la campana con dos ganchos de sujeción que pasen por los cortes

rectangulares colocados en la parte posterior de la campana.

13. Nivele el aparato utilizando un nivelador de carpintero de un lado a otro del fondo

d ela campanay de los tornillos de nivelado en los cortes rectangulares..

14. Sujete la campana con 2 tornillos en la parte inferior y 2 tornillos en la parte

superior de la misma vea fig n.5

15. Coloque la chimenea ( figura n.4 )

Nota: para realizar las labores de mantenimiento del motor, deje un espacio

mínimo de 1 entre la parte superior de la junta de transición y el metal del tubo

y cubra el espacio con una chapa enrollada en la junta y en el tubo. Coloque los

tornillos de la chapa de manera que se introduzcan en el ángulo de la chimenea.

Sujete la chapa a la junta y al tubo utilizando 3 tornillos especiales para metal

en cada uno..

Tape todo con cinta adesiva.

Nota: No utilice nunca tubos más pequeños que la junta.

Figura 5

13

25

Page 26

Instalacion

Figura 6

Conexión eléctrica

ATENCION !

INSTRUCCIONES PARA LA INSTALACION A TIERRA

ESTE APARATO CONTIENE UNA CAJA DE CONEXIONES CON TRES

CABLES , UNO DE ELLOS (AMARILLO\VERDE) SIRVE PARA INSTALARLO

A TIERRA. PARA PROTEGERSE DEL PELIGRO DE CORTOCIRCUITO EL

CABLE AMARILLO\VERDE TIENE QUE ESTAR CONECTADO AL CABLE

DE TIERRA DEL SISTEMA ELECTRICO DE SU CASA Y DE NINGUNA

MANERA HAY QUE CORTARLO O QUITARLO.

Atención : corte la corriente del cuadro eléctrico antes de conectar el aparato.

Es necesario un circuito derivado a 120VAC, 15 AMP

16. Quite el knockout y coloque el tubo protector ( ½) en la caja de conexiones

eléctricas..

17. Coja 3 cables; uno negro , otro blanco otro verde ( # 16AWG) e introdúcalos

en el tubo del cuadro elèctrico a la caja de conexiones.

18. Conecte el cable eléctrico negro del cuadro al cable negro o rojo de la caja de

conexiones , el blanco con el blanco y el verde con el armarillo\verde. figura n.

6.

19. Cierre la tapa de la caja de conexiones. Compruebe todas las lámparas para

asegurarse de que estánt todas bien sujetas en sus respectivos portalámpara.

Conecte la corriente del cuadro eléctrico Compruebe que las lámparas y el motor

funcionen bien siguiendo las instrucciones del capítulo de uso y cuidados de

este manual. Instale los filtros.

Figura 7

Montaje final

20. Monte la chimenea como aparece indicado en la figura n. 3

21. Asegúrese de que el propietario posea este manual.

Alternativa instalación con techo bajo.

La campana se puede montar solamente con la chimenea inferior para disminuir su

altura total.

Para que la chimenea deslice hacia abajo y ocupe la parte superior de la campana,

la escarpia de sujeción hay que montarla ¼ por debajo del techo .

El espacio que queda arriba de la chimena puede cubrirlo con un trozo fino de ¼

de compensado que hay que cortar para introducirlo en la sección de la chimenea

para que coincida con el techo. Corte la cinta adesiva de goma adjunta con la

campana en 4 partes iguales

Pegue dos trozos de cinta adesiva en cada lado de la escarpia para el techo. Figura

n.7

Introduzca la chimenea inferior en su sitio alrededor de la escarpia para el techo.

Salida de aire posterior.

Tiene que instalar un tubo angular de 90° justo encima de la campana. Por razones

prácticas se podría utilizar una sujeción similar ala que aparece en la figura 4.

26

Page 27

Uso y Mantenimiento

AB

C

LEA ATENTAMENTE LAS INSTRUCCIONES ANTES DE UTILIZAR LA CAMPANA.

Para utilizar de forma correcta su campana es necesario que aprenda las distintas

funciones de la misma que aparecen descritas a continuación.

A INTERRUPTOR PARA ENCENDER Y APAGAR LA LUZ.

B INTERRUPTOR PARA ENCENDER Y APAGAR EL MOTOR

C MOTOR APAGADO.

D MOTOR EN LA PRIMERA VELOCIDAD ( BAJA)

E MOTOR EN LA SEGUNDA VELOCIDAD ( MEDIA)

F MOTOR EN LA TERCERA VELOCIDAD ( ALTA)

G

G MOTOR EN LA CUARTA VELOCIDAD ( MUY ALTA)

D

F

E

Figura 8

Limpieza de la campana

a

b

Instrucciones para el funcionamiento

Tiene que hacer funcionar el motor al menos 5 minutos antes de empezar a cocinar

para que se estabilicen las corrientes de aire hacia arriba en el interior de la

campana.

Utilice las velocidades bajas para un uso normal y las velocidades más altas para

olores fuertes y humos densos

Reduzca al mínimo las corrientes de aire cruzadas , pues pueden disminuir la

eficacia de la campana.

Asegúrese de que las lámparas se hayan enfriado antes de limpiar la campana.

Limpieza de los filtros.

Los filtros antigrasa metálicos duran para siempre. Se han realizado en aluminio

anodizado.

Se aaconseja lavar los filtros una vez al mes; se pueden lavar a mano o en

lavavajillas..

Saque el agua de los bordes y deje que se seque completamente antes de volver

a montarlo.

Figura 9

Cómo extraer los filtros antigrasa metálicos

Desconecte la campana de la red eléctrica.

Empuje de las asas hacia el centro y tire de los filtros hacia abajo.figura n. 9

Cómo volver a montar los filtros antigraso metálicos

Siga el procedimiento a la inversa.

Limpieza de la superficie de la campana

Para la limpieza ordinaria frote las campanas de acero, blanco , negro o de crisal

con agua y jabón o con productos para la limpieza de la casa como Fantastic®

o Formula 409®, enjuague bien y seque con un paño blando húmedo para evitar

las manchas producidas por el agua.

Frote y deje secar el aluminio cepillado en la misma dirección de las vetas.

Para quitar las huellas de dedos y dar mayor brillo al acero, utilice productos en

spray como por ejemplo Stainless Steel Magic® y Shimmer®.

27

Page 28

Cambio de las lámparas.

Figura 10

Turn off electric power to hood before

removing light cover.

Figura 10

Nota: apague el motor y la luz. Asegúrese de que las lámparas se hayan enfriado.

Si las lámparas nuevas no funcionan asegúrese de que estén correctamente

instaladas antes de avisar el servicio de asistencia tècnica.

Quite el cubrelámpara utilizando un destornillador pequeño con la punta plana

o una herramienta similar a una palanca.

Quite la lámpara estropeada y cámbiela por otra nueva halógena de 12 Volt, 29

Watt ( máximo) con base G-4. Siga las indicaciones que se encuentran en la

caja y no toque la lámpara nueva con las manos desnudas..

Vuelva a montar el cubrelámpara ( apriete hasta que no suene el clik).

28

Page 29

29

Page 30

Page 31

Page 32

LI1NSC Ed. 01/04

Loading...

Loading...