Page 1

SERVICE MANUAL

WASHING

Front-Loading Washing

Machines

with electronic control

system

EWX13611

EWX11831

Technical and functional

characteristics

PILOT 2

Styling

P6 - P3.0

P49

ELECTROLUX HOME PRODUCTS

Customer Care - EMEA

Training and Operations Support

Technical Support

Publication

number

599 77 39-16

Edition: 01/2014 - Rev. 00

EN

P6 P3.0

Page 2

Technical Support - MDM

2/104

599 77 39-16 R ev. 00

Page 3

Technical Support - MDM

3/104

599 77 39-16 R ev. 00

INDEX

1

PURPOSE OF THIS MANUAL .................................................................................................................. 6

1.1 Low consumption mode ...................................................................................................................... 6

1.1.1 P6 P3.0 with universal motor (EWX13611) ................................................................................... 6

1.1.2 P6 P3.0 with three-phase motor and Inverter (EWX11831) .......................................................... 7

2 WARNINGS .............................................................................................................................................. 8

3 Styling P6 .................................................................................................................................................. 9

3.1 EWX13611 General characteristics..................................................................................................... 9

3.2 EWX11831 General characteristics................................................................................................... 10

3.3 Control panel .................................................................................................................................... 11

3.3.1 Display board ............................................................................................................................ 11

3.3.2 Control panel configuration ........................................................................................................ 12

3.3.2.1 Programme configuration .................................................................................................... 12

3.3.2.2 Sensors – LEDs .................................................................................................................. 12

3.3.2.3 Buttons – Sensors – LEDs .................................................................................................. 13

3.3.2.4 Buzzer ................................................................................................................................ 16

4 STYLING P3.0......................................................................................................................................... 17

4.1 EWX13611 General characteristics................................................................................................... 17

4.2 EWX11831 General characteristics................................................................................................... 18

4.3 Control panel .................................................................................................................................... 19

4.3.1 Display board ............................................................................................................................ 19

4.3.2 Control panel configuration ........................................................................................................ 20

4.3.2.1 Programme configuration .................................................................................................... 20

4.3.2.2 Buttons – Sensors – LEDs .................................................................................................. 20

4.3.2.3 Display ............................................................................................................................... 21

4.3.2.4 Buzzer ................................................................................................................................ 21

5 DEMO MODE .......................................................................................................................................... 22

5.1 Accessing the DEMO setting for P6 and P3.0 stylings ....................................................................... 22

5.2 Exiting DEMO mode ......................................................................................................................... 22

6 DIAGNOSTICS SYSTEM ........................................................................................................................ 23

6.1 Accessing the diagnostics for P6 and P3.0 stylings ........................................................................... 23

6.2 Quitting the diagnostics system ........................................................................................................ 23

6.3 Phases of the diagnostics test .......................................................................................................... 24

7 ALARMS ................................................................................................................................................. 26

7.1 Displaying user alarms ..................................................................................................................... 26

7.1.1 Styling P6 .................................................................................................................................. 26

7.1.2 Styling P3.0 ............................................................................................................................... 27

7.2 Alarm reading/display ....................................................................................................................... 28

7.2.1 Displaying the alarm (P3.0) ........................................................................................................ 28

7.2.2 Displaying the alarm (P6) ........................................................................................................... 28

7.2.3 Example of alarm display ........................................................................................................... 28

7.2.4 Behaviour of the alarms during diagnostic testing....................................................................... 29

7.2.5 Rapid reading of alarms ............................................................................................................. 30

7.2.6 Deleting the last alarm ............................................................................................................... 30

8 OPERATING TIME COUNTER (styling P3.0 only) ................................................................................... 31

8.1 Reading the operating time ............................................................................................................... 31

8.2 Display of total operating time ........................................................................................................... 31

9 OPTIONS ................................................................................................................................................ 32

9.1 Compatibility between options .......................................................................................................... 32

9.2 Description of options ....................................................................................................................... 33

10 TECHNICAL CHARACTERISTICS ....................................................................................................... 34

10.1 Construction characteristics (universal motor) ................................................................................... 34

10.2 Construction characteristics (three-phase motor, Inverter)................................................................. 35

10.3 Detergent dispenser ......................................................................................................................... 36

10.4 Detergent drawer .............................................................................................................................. 37

10.5 Washing unit .................................................................................................................................... 38

10.6 Water circuit ..................................................................................................................................... 39

10.6.1 OKO/IDB version drain circuit .................................................................................................... 39

10.7 Electronic control .............................................................................................................................. 40

10.7.1 Programming/Updating the main circuit board ............................................................................ 40

10.7.2 Electrical characteristics with universal motor............................................................................. 41

10.7.3 Electrical characteristics with three-phase motor and Inverter .................................................... 41

11 ELECTRICAL COMPONENTS ............................................................................................................. 42

11.1 Noise filter ........................................................................................................................................ 42

11.1.1 General characteristics .............................................................................................................. 42

Page 4

Technical Support - MDM

4/104

599 77 39-16 R ev. 00

11.2

Display board ................................................................................................................................... 42

11.3 Drainage pump ................................................................................................................................. 43

11.3.1 General characteristics .............................................................................................................. 43

11.4 Heating element ............................................................................................................................... 44

11.4.1 General characteristics .............................................................................................................. 44

11.5 Temperature probe ........................................................................................................................... 45

11.5.1 General characteristics .............................................................................................................. 45

11.6 Analogue pressure switch ................................................................................................................. 46

11.6.1 General characteristics .............................................................................................................. 46

11.7 Door safety interlock PTO (Pull To Open) ......................................................................................... 47

11.7.1 General characteristics .............................................................................................................. 47

11.7.2 Operating principle .................................................................................................................... 47

11.7.2.1 Mechanical operation .......................................................................................................... 48

11.7.3 Manual opening of the appliance door........................................................................................ 49

11.8 Universal motor ................................................................................................................................ 50

11.8.1 General characteristics .............................................................................................................. 50

11.8.2 Operating principle .................................................................................................................... 50

11.8.2.1 Motor speed control ............................................................................................................ 50

11.8.2.2 Direction of rotation of the motor ......................................................................................... 51

11.8.2.3 Tachometric generator ........................................................................................................ 51

11.8.3 Power supply to motor ............................................................................................................... 52

11.9 Three-phase asynchronous motor – Inverter ..................................................................................... 53

11.9.1 General characteristics .............................................................................................................. 53

11.9.2 Power supply to motor ............................................................................................................... 53

11.10 Inverter ............................................................................................................................................. 54

11.10.1 General characteristics .............................................................................................................. 54

11.11 Anti-foam control system .................................................................................................................. 55

11.12 Solenoid valves ................................................................................................................................ 56

11.12.1 General characteristics .............................................................................................................. 56

11.12.2 Operating principle .................................................................................................................... 56

11.12.3 Mechanical jamming of the solenoid valve ................................................................................. 56

11.12.4 Low water pressure ................................................................................................................... 56

12 ALARM SUMMARY TABLE ................................................................................................................. 57

13 DIAGRAMS.......................................................................................................................................... 61

13.1 Operating Circuit Diagram EWX13611 (with universal motor) ............................................................ 61

13.2 Key to operating circuit diagram EWX13611 (with universal motor) ................................................... 62

13.3 Operating Circuit Diagram EWX11831 (with three-phase motor) ....................................................... 63

13.4 Key to operating circuit diagram EWX11831 (with three-phase motor) .............................................. 64

14 ACCESSIBILITY (appliances with universal motor) .............................................................................. 65

14.1 Worktop ............................................................................................................................................ 65

14.2 From the worktop, you can access .................................................................................................... 65

14.2.1 Main board ................................................................................................................................ 65

14.2.2 Solenoid valve ........................................................................................................................... 68

14.2.3 Display board assembly ............................................................................................................. 68

14.2.4 Control panel ............................................................................................................................. 70

14.2.5 Analogue pressure switch .......................................................................................................... 73

14.2.6 Detergent dispenser .................................................................................................................. 74

14.2.7 Upper counterweight .................................................................................................................. 75

14.3 Accessing the front part .................................................................................................................... 76

14.3.1 Door hinge – Door ..................................................................................................................... 76

14.3.2 Door safety interlock .................................................................................................................. 76

14.3.3 Blade ......................................................................................................................................... 79

14.3.4 Front panel ................................................................................................................................ 81

14.4 From the front panel, you can access ............................................................................................... 82

14.4.1 Front counterweight ................................................................................................................... 82

14.4.2 Bellow seal ................................................................................................................................ 82

14.4.3 Welded tub assembly ................................................................................................................ 82

14.4.4 Tub suspension springs ............................................................................................................. 83

14.5 Accessing the rear part ..................................................................................................................... 84

14.5.1 Back panel ................................................................................................................................ 84

14.6 From the back panel, you can access ............................................................................................... 84

14.6.1 Belt ............................................................................................................................................ 84

14.6.2 Plastic pulley (Ø 273 mm) .......................................................................................................... 85

14.6.3 Motor ........................................................................................................................................ 85

14.6.4 Heating ...................................................................................................................................... 85

14.7 From the base of the appliance, you can access ............................................................................... 86

Page 5

Technical Support - MDM

5/104

599 77 39-16 R ev. 00

14.7.1

Drain water circuit ...................................................................................................................... 86

14.7.1.1 Drainage pump ................................................................................................................... 86

14.7.1.2 Drain filter ........................................................................................................................... 87

14.7.1.3 IDB (Integrated Drain Body) ................................................................................................ 87

14.7.2 Pressure chamber ..................................................................................................................... 89

14.7.3 Shock absorbers........................................................................................................................ 91

14.7.4 Shock absorber pin .................................................................................................................... 91

14.7.5 Main drain pipe .......................................................................................................................... 92

15 ACCESSIBILITY (appliances with INVERTER motor control) ............................................................... 94

15.1 Worktop ............................................................................................................................................ 94

15.2 From the worktop, you can access .................................................................................................... 94

15.2.1 Main board ................................................................................................................................ 94

15.2.2 Solenoid valve ........................................................................................................................... 95

15.2.3 Display board assembly ............................................................................................................. 95

15.2.4 Control panel ............................................................................................................................. 96

15.2.5 Analogue pressure switch .......................................................................................................... 96

15.2.6 Detergent dispenser .................................................................................................................. 96

15.2.7 Upper counterweight .................................................................................................................. 96

15.3 Accessing the front part .................................................................................................................... 96

15.3.1 Door hinge - Door ...................................................................................................................... 96

15.3.2 Door safety interlock .................................................................................................................. 96

15.3.3 Blade ......................................................................................................................................... 96

15.3.4 Front panel ................................................................................................................................ 96

15.4 From the front panel, you can access ............................................................................................... 97

15.4.1 Front counterweight ................................................................................................................... 97

15.4.2 Bellow seal ................................................................................................................................ 97

15.4.3 Welded tub assembly ................................................................................................................ 97

15.4.4 Tub suspension springs ............................................................................................................. 97

15.5 Accessing the rear part ..................................................................................................................... 97

15.5.1 Back panel ................................................................................................................................ 97

15.6 From the back panel, you can access ............................................................................................... 97

15.6.1 Belt ............................................................................................................................................ 97

15.6.2 Plastic pulley (Ø 273 mm) .......................................................................................................... 98

15.6.3 Motor ......................................................................................................................................... 98

15.6.4 Heating ...................................................................................................................................... 98

15.6.5 UIMC ......................................................................................................................................... 98

15.6.6 Drainage pump ........................................................................................................................ 100

15.6.7 Drain filter ................................................................................................................................ 101

15.7 From the base of the appliance, you can access ..............................................................................102

15.7.1 Drain water circuit .................................................................................................................... 102

15.7.1.1 Drainage pump ................................................................................................................. 102

15.7.1.2 Drainage filter ................................................................................................................... 102

15.7.1.3 IDB (Integrated Drain Body) .............................................................................................. 103

15.7.2 Pressure chamber ................................................................................................................... 103

15.7.3 Shock absorbers...................................................................................................................... 103

15.7.4 Main drain pipe ........................................................................................................................ 103

Page 6

Technical Support - MDM

6/104

599 77 39-16 R ev. 00

1 PURPOSE OF THIS MANUAL

The purpose of this manual is to provide service engineers who are already familiar with the repair procedures

for traditional washing machines with information regarding washing machines fitted with the EWX13611

(P6-P3.0) and EWX11831 (P6-P3.0) electronic control systems.

Previous platforms (electronic/mechanical) used a safety pressure switch that checked the minimum water level

in the tub, below which the supply to the heating element was interrupted.

The current electronic appliances manufactured use a heating element with thermal fuses (inside its branches)

as safety, which interrupt if the water level drops below the minimum level permitted.

The incorporated NTC probe contacts have a 2.5 mm pitch.

The manual deals with the following topics:

General characteristics

Control panel and compatibility between washing programmes and options

Settings: Demo, Diagnostics

Alarms

Technical and functional characteristics

Access

1.1

Low consumption mode

In order to reduce electricity waste when the cycle is not running, the appliances on this platform are designed

to enter consumption reduction mode:

1.1.1 P6 P3.0 with universal mo to r (EWX13611)

“Stand-Off” mode

When the appliance is switched off at the ON/OFF button, it is in the “Stand-Off” or “virtual” off status. The LEDs

and the LCD screen are turned off and the buttons are disabled, although the main circuit board and certain

electrical components are electrically powered.

You have to unplug the appliance to cut off the power supply

“Auto-off” mode

If, after 5 minutes, during the programme selecting phase or after the end of the cycle, the appliance receives

no further instructions, it is automatically turned off (for energy savings in conformity with the standards on

energy consumption).

All the settings are stored so that when the appliance is turned back on, the programme is ready or if the autooff mode was triggered after the end of the cycle, the user can see that the cycle ended normally, and can

restart it if necessary.

You have to unplug the appliance to cut off the power supply

If an alarm goes off when a wash programme is running, the automatic turn off is disabled showing the alarm.

Page 7

Technical Support - MDM

7/104

599 77 39-16 R ev. 00

1.1.2 P6 P3.0 with three-phase motor and Inverter (EWX11831)

Some appliances are fitted with a circuit (in the main circuit board) called Zero Watt (0 Watt with an actual

consumption

~

50 mW) which cuts off the power supply to the appliance:

a. When you press the ON/OFF button to turn off the appliance, the Zero Watt circuit is triggered and cuts off

the supply voltage after a few seconds, just long enough to secure the washing machine (motor off, door

locked, etc…), the cycle and any options selected are reset, so that the next time the appliance is turned on,

it is ready to perform the programme.

(To open the door, you will have to wait one or two minutes for the door safety lock to be released.)

b. If, after 5 minutes, during the programme selecting phase or after the end of the cycle, the appliance

receives no further instructions, it is automatically turned off and the Zero Watt circuit which cuts off the

supply voltage is triggered (for energy savings in conformity with the standards on energy consumption).

All the settings are stored so that when the appliance is turned back on, the programme is ready or if the

auto-off mode was triggered after the end of the cycle, the user can see that the cycle ended normally,

and can restart it if necessary.

If an alarm goes off when a wash programme is running, the automatic turn off is disabled showing the alarm.

The appliances which are not equipped with the Zero Watt (0 Watt) circuit in: “Stand-Off” or “Auto-off” mode,

see para. 1.1.1.

Page 8

Technical Support - MDM

8/104

599 77 39-16 R ev. 00

2 WARNINGS

Any work on electrical appliances must only be carried out by qualified personnel.

Before carrying out wo rk on the appliance, use suitable instruments to check that

the power supply system in the house is fully efficient. Fo r exampl e: ref er to the

indications provided/illustrat ed in the <<metratester>> co urse at the address

(http:// electrolux.edvantag e.n et ) on the Elect rolux Learning Gateway portal.

On completing operations, check that the applian ce has been rest ored to the same

state of safety as when it came off the assembl y li ne.

If the circuit boar d has t o be han dled/rep laced, use t he ESD k it (C od. 405 50 63-95/4) to av oi d

static electricity from damaging the circuit board, see S.B. No. 599 72 08-09 or consult the

course <<Electrostatic charges>> at the address (http://electrolux.edvantage.net) on the

Electrolux Learning Gateway portal.

This platform is no t fitted wit h an ON/OFF switch. Before you access int ernal

components, take th e plug out of the socket t o cu t the power su pp ly.

Make resistance measurements, rather than direct vol t age and current measurements.

Warning the senso rs lo cat ed in the di splay board could be at a potential of 220 Volts.

When replacing the heatin g element, replace it with one th at has

the same characterist ics (2 thermal fuses) in order no t to

compromise the safety o f the appliance. NEVER remove/switch

the NTC sensors betw een heati ng elemen t s.

Always empty the appliance of all the water before laying it on its side

(see the relevant paragraph).

Never place the appli ance on its rig ht side (electronic control syst em sid e) :

some of the water in the deterg ent di spen ser cou ld leak onto the electrical/electronic

components and cau se these to bu rn.

When replacing components, please refer to the code shown in th e list of spare parts

relating to the appli ance.

Do not place any kind of container under the appliance to catch any drip s of wat er.

Make sure you wear gloves, becau se parts of the cabinet are sharp.

Page 9

Technical Support - MDM

9/104

599 77 39-16 R ev. 00

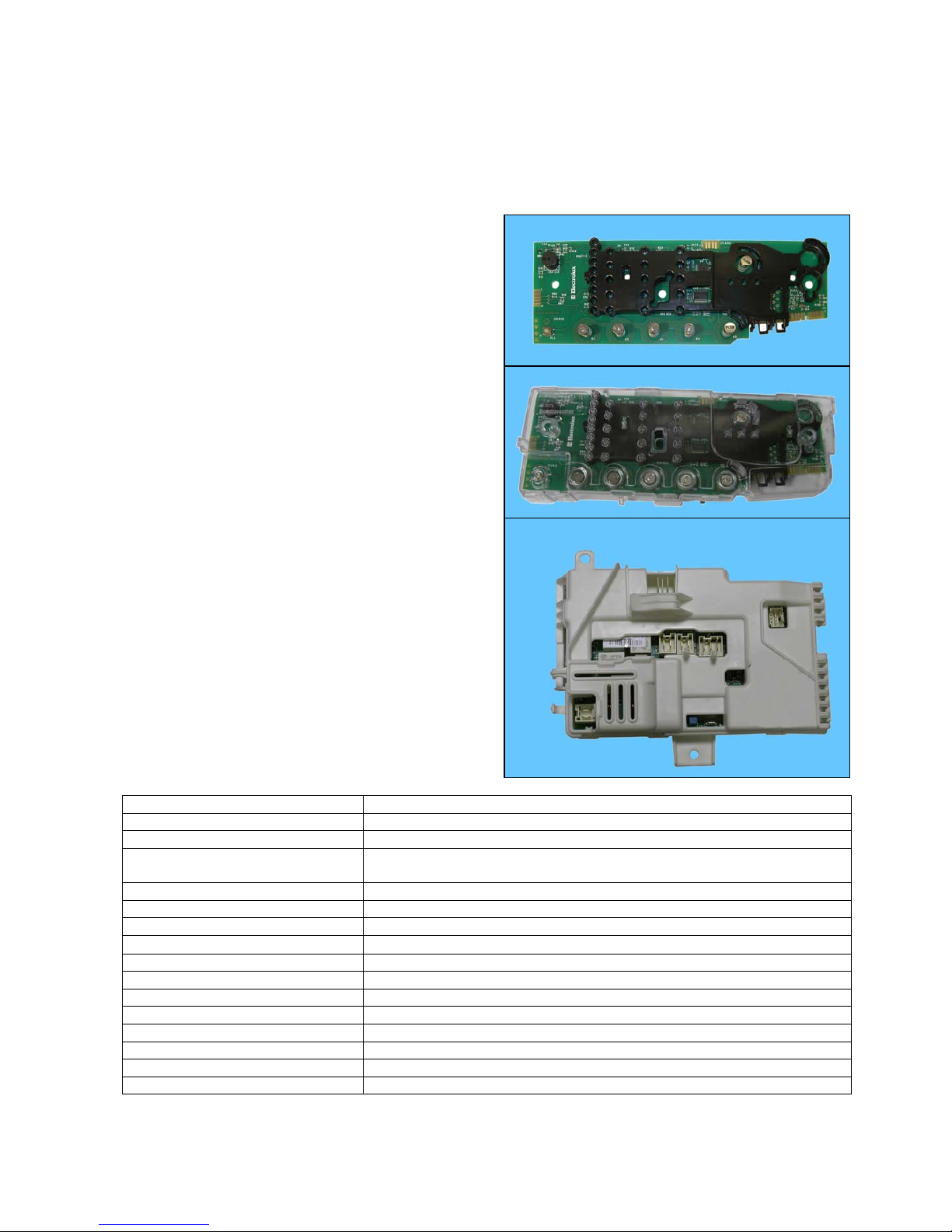

3 Styling P6

3.1

EWX13611 General characteristics

The electronic control system consists of two circuit boards.

In the event of problems with the touch sensors (difficulty selecting/adjusting them), clean and dry the display

and do not wear gloves when setting the chosen programme.

The control/display board, which is inserted in

a plastic container fixed to the control panel

(the figure shows: the display board and the

display board assembly).

Main board, positioned at the rear of the appliance.

It powers the electrical components and receives

commands from the display board.

No. butto ns

1 Maximum

No. of touch-sensitive keys

Maximum 6 (5 options + start/pause)

No. LEDs

Maximum 27 yellow + 1 red LED + Digit (made up of 22 LEDs)

Power supply voltage

220/240 V

50/60 Hz (configurable)

Washing type

Traditional with “Eco-IDB”

Rinsing system

Traditional with “Eco-IDB”

Motor

Collector, with tachometric generator (Universal)

Spin speed

1,0001,400 rpm

Anti-unbal ancing system

AGS

Cold water fill

1 solenoid valve with 1 inlet – 2 outlets

Detergent dispenser

2 compartments: wash, conditioners

Control of water level in the tub

Electronic/analogue pressure switch

Door safety interlo ck Instant “Pull To Open”

Heating element heat output

1,750 W with thermal fuses incorporated

Temperature ch eck

NTC probe incorporated in the heating element

Buzzer

Traditional incorporated in the PCB

Page 10

Technical Support - MDM

10/104

599 77 39-16 R ev. 00

3.2

EWX11831 General characteristics

The electronic control system consists of three circuit boards.

In the event of problems with the touch sensors (difficulty selecting/adjusting them), clean and dry the display

and do not wear gloves when setting the chosen programme.

The control/display board, which is inserted in

a plastic container fixed to the control panel

(the figure shows: the display board and the

display board assembly).

The main circuit board is positioned at the rear of the appliance and powers the electrical components,

receiving commands from the display board as well as communicating with the motor control board

(Inverter UIMC).

No. of buttons

Maximum 1

No. of touch-sensitive keys

Maximum 6 (5 options + start/pause)

No. LEDs

Maximum 27 yellow + 1 red LED + Digit (made up of 22 LEDs)

Power supply voltage

220/240 V

50/60 Hz (configurable)

Washing type

Traditional with “Eco-IDB”

Rinsing system

Traditional with “Eco-IDB”

Motor

Two-pole asynchronous (three-phase)

Spin speed

1,0001,600 rpm

Anti-unbal ancing system

AGS

Cold water fill

1 solenoid valve with 1 inlet – 2 outlets

Detergent dispenser

2 compartments: wash, conditioners

Control of water level in the tub

Electronic/analogue pressure switch

Door safety interlo ck Instant “Pull To Open”

Heating element heat output

1,750 W with thermal fuses incorporated

Temperature ch eck

NTC probe incorporated in the heating element

Buzzer

Traditional incorporated in the PCB

Inverter UIMC

EWX11831 Main Board

Page 11

Technical Support - MDM

11/104

599 77 39-16 R ev. 00

3.3

Control panel

Max. 1 Button

Max. 6 touch sensors

30 yellow LEDs + 1 red LED

3.3.1 Display board

Display board assembly, exploded view

1 Display board

2 Light divider

1

2

Page 12

Technical Support - MDM

12/104

599 77 39-16 R ev. 00

3.3.2 Control panel configuration

The washing programmes and the functions and the various touch sensors vary according to the model,

since these are determi ned by the configuration of the appli ance.

3.3.2.1 Programme configuration

The table below lists the parameters that can be used to define the washing programmes.

Types of fa br ic

Cotton/linen, Synthetic fabrics, Delicates, Wool, Hand-wash,

Shoes, Jeans, Duvet, Silk.

Special programmes

Cotton/linen + pre-wash, Soak, Miniprogramme, Easy-Iron,

Conditioner, Rinse, Drain, Spin, Economy.

Temperature

Normal, Minimum, Maximum: the initial temperature is the one

proposed for the washing programme.

Spin

Normal, Minimum, Maximum.

Options (Normal/Possible)

Rinse Hold, Pre-wash, Extra rinse, Easy-Iron, Economy (energy

label), Normal, Super quick, Reduced spin speed, No spin.

Programme phases

Pre-wash, Wash, Rinses, Spin, Delayed start.

3.3.2.2 Sensors – LEDs

The function of each touch sensor is defined via the configuration of the appliance (the data and images are for

guidance only).

The touch sensors are positioned under the silk-screen printed symbols on the control panel (circled here in red).

A light touch on the centre of the symbol is enough to activate/deactivate the function linked to the sensor with

the switching on/off of the relative Led confirming that the enabling/disabling has taken place.

At the same time as the enabling/disabling of options, the cycle duration time is updated via the digits (styling

P3.0 only).

You need to keep your finger pressed down for a longer period of time with the Start/Pause sensor to confirm

both the cycle’s start and pause, in order to avoid unwanted starts or accidental pauses.

S1

S2 S3

S4

S5

S7

P1

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L17

L16

L15

L18

L19

L20

L21

L22

L23

L24

L25

L26

L27

L28 L29

L30

Page 13

Technical Support - MDM

13/104

599 77 39-16 R ev. 00

Every time you touch a sensor, you need to lift your finger up by a centimetre and half a second needs to

elapse before touching it again, otherwise the electronic system does not recognise that the sensor has been

touched for a second time.

The sensors used for adjusting the: Temperature, Spin, delayed Start and Time Manager have a continued

variation of values as long as your finger is in contact with the sensor.

3.3.2.3 Buttons – Sensors – LEDs

Button no. 1: ON/OFF – ON

Press it to turn the appliance on, at the same time the buzzer will sound a tone (if enabled), the LEDs of the first

four touch sensors (S1÷S4) will light up from the bottom up, then the LEDs relating to the following will stay on:

the main programme, the recommended spin speed and temperature.

The operation of the ON/OFF depends on the configuration of the main circuit board.

It can cut the appliance off from the electricity mains completely (0 Watt circuit) or

set the appliance to low energy consumption mode (without 0 Watt circuit) in which

case you will need to take the plug out of the socket to cut off the electricity supply

completely.

Press the ON/OFF button to cancel the chosen programme.

To switch the appliance off, hold down the button for 1 second, at the same time the

buzzer will sound a tone (if enabled), all the LED will switch off, all the options

selected and any programme that is running will be cancelled.

Sensor no. 1: PROGRAMMES

The programmes are associated with the second sensor, combined with eight LEDs (L1÷L8).

As soon as the appliance is switched on, the first LED at the top corresponding to the

main programme lights up.

To the left of each LED, there is a description of the programme and each time the sensor

is touched, the LED underneath it lights up, so the programme selection occurs from the

top down; once the last programme has been reached, if you touch the sensor again, the

selection returns to the top, i.e. the initial programme.

The selected programme is shown by the LED beside the description silk-screen printed

on the control panel lighting up.

For a quicker selection, hold your finger down on the sensor for longer.

Sensor no. 2: TEMPERATURE

The temperature is associated with the second sensor, combined with five LEDs (L9÷L13).

The initial temperature displayed is that set for the chosen programme.

By touching the sensor you can lower the temperature. Once this has been reached the

selection starts again from the highest available one for the selected programme.

The selected temperature is shown by turning on the LEDs near the silk-screen printed

value on the control panel.

The temperatures available are: 90 °C, 60 °C, 40 °C, 30 °C, cold cycle.

The initial temperature set for each programme is configurable;

For a quicker selection, hold your finger down on the sensor for longer.

P1

S1

L1

L8

S2

L9

L13

Page 14

Technical Support - MDM

14/104

599 77 39-16 R ev. 00

Sensor no. 3: SPIN SPEED (configurable)

The function of the third sensor is dedicated to the spin speed selection, combined with

the five LEDs (L14÷L18) above; the related speed is silk-screen printed beside them on

the control panel.

The initial spin speed is that set for the chosen programme.

Touch the sensor to reduce the spin speed, indicated by the LED near the silk-screen

printed value on the control panel lighting up at the same time to confirm your selection.

Once the lowest speed has been reached, you can, if you wish, select “Rinse hold” and

the related LED beside the symbol silk-screen printed on the control panel lights up.

The next selection will be the highest speed available for the selected programme.

For a quicker selection, hold your finger down on the sensor for longer.

The speeds that can be combined with the five LEDs are shown in the following table.

Max spin

speed (rpm)

800 1,000 1,000 1,200 1,200÷1,400 1,200÷1,400 1,400-1,600 1,400-1,600 1,400-1,600

Inter me d iate 600 800 800 800 1,000 1,000 1,200 1,200 1,200

Inter me d iate 400 400 600 400 800 800 800 800 1,000

Intermediate 0 0 400 0 0 400 0 400 800

Min. speed

Rinse

hold

Rinse

hold

0

Rinse

hold

Rinse

hold

0

Rinse

hold

0 0

The recommended intermediate spin speeds are:

800 rpm for the following programmes: Lingerie, Duvet, Shirts, Sport, 14 min., Silk, etc…

1,000 rpm for the Easy-Iron option

1,200 rpm for synthetic fabrics, delicates, wool

If you select the “Rinse hold” option when the cycle ends, the related LED flashes to remind the end user to

drain the water before opening the appliance door.

With the “Easy-Iron” option, the spin speed is reduced to 1000 rpm even if the spin speed selected is higher;

if the option is deselected, the speed automatically returns to the chosen value.

Sensor no. 4: OPTIONS (configurable)

The function of the fourth sensor is dedicated to the choice of option to combine with the

programme, combined with five LEDs (L19÷L23) above, beside which the name of the

related option is silk-screen printed on the control panel.

Touch the sensor when no option has been enabled (all the LEDs are switched off) to light

up the first LED relating to the most important option in the list.

Continue your selection to light up the subsequent LED (from the top down) and the previous

one is switched off, all the way to the last option at the bottom. The next time you press the

sensor all the LEDs will remain switched off.

You can only select one option per programme, as no combinations are possible.

For a quicker selection, hold your finger down on the sensor for longer.

The following options can be combined with the first three LEDs (at the top):

Super Quick

Easy Iron

Intensive

Pre-wash

Daily

Half-load

Soak

The two LEDs (at the bottom) are combined with:

Rinse Only – performs the last rinse cycle for the selected programme. If “Extra Rinse” is set, two or more rinse

cycles are added (depending on the configuration).

Spin/Drain – performs the spin cycle for the selected programme, if the selected option is “No Spin” it only

drains off the water.

S3

L14

L18

S4

L19

L23

Page 15

Technical Support - MDM

15/104

599 77 39-16 R ev. 00

Sensor no.5: START/PAUSE

This sensor has the START/PAUSE function, used to start up a washing programme,

after selecting the washing cycle and required options; it can also pause a cycle that

has already started: to allow you to change selected option or open the door (if the

temperature conditions or water level allow for this).

The cycle re-starts if you touch the sensor again.

The (L24) LED combined with this sensor flashes slowly: in the selection phase, during

the pause and at the end of a cycle with water in the tub.

It stays lit when a cycle is running and turns off when the cycle has ended and the door

is unlocked.

While other sensors when touched immediately change from selected to de-selected,

in the case of this sensor, more time is needed to avoid unwanted cycle start ups

or pauses.

In the event of an incorrect selection by the end user, such as: an option that is not

compatible with the selected programme or that has been made after the programme

has commenced, this is indicated by three quick red flashes. The same LED is used to

notify the user of any specific problems with the appliance. The buzzer does not play

any particular tune.

Sensor no.6:- DELAYED START (configurable)

This sensor works as the DELAYED START and it is combined with the three

LEDs (L25÷L27) that surround it.

Touch it in sequence to choose from one of the three delayed start options: 3 h6 h-9 h with the related LED coming on.

In order to reset the delay time, reach the maximum delay time and the next time

the sensor is pressed the delay time is cancelled and no LED is lit up, or if the

delayed start has already been set, put the appliance on PAUSE and reset the time

as described earlier.

Indicator LEDs

In addition to lighting up when their functions have been enabled, in combination with the red

LED of the START/PAUSE sensor, they notify the end user of any specific problems with the

appliance that may be solved without having to call for technical assistance (see page 26).

Padlock:

When the related LED (L28) is lit, it indicates that all the sensors are disabled to prevent

children from altering, starting or pausing the cycle.

When enabled, touch any sensor and the LED flashes three times to remind the end user

that the appliance is locked.

Use the combination of two sensors (touch for approximately 5 seconds) illustrated in the figure below to

enable/disable this option.

S5

L24

L25

S6

L26

L27

L28 L29 L30

P6 P3.0

Page 16

Technical Support - MDM

16/104

599 77 39-16 R ev. 00

Extra Rinse:

When the related LED (L29) is lit up, this indicates that the option is enabled (it lights up during

the washing and rinse cycles, and it remains switched off during the drain and spin cycle).

The option remains enabled even after the appliance has been turned off (for subsequent

programmes).

Use the combination of two sensors illustrated in the figure below to enable/disable this option.

Door loc k :

When the related LED (L30) is lit up, the safety device prevents the door opening and

switches off when the door can be opened.

Flashes when the device is about to unlock the door (with door interlock with PTC,

which needs one/two minutes to open).

3.3.2.4 Buzzer

This comprises a multi-tone buzzer and sounds in the following cases:

When the machine is turned on and off it emits two different tunes.

When a sensor is pressed it emits a short “Click”

When the cycle ends this is indicated by a special sequence of “three long beeps” repeated at intervals of

15” for a total of 2 minutes. The sequence can only be stopped by opening the door in appliances where the

instant door safety device with micro-switch is fitted.

In the event of a malfunction in the machine this is indicated by a special sequence of “three short beeps”

repeated 3 times at intervals of 15” for a total of 5 minutes.

All appliances are fitted with the buzzer, and leave the factory with the option enabled. To disable it use the

combination of sensors.

The volume level is set in the factory and cannot be adjusted by the user.

When the buzzer is disabled (using the combination of sensors) it only emits the short “Click” and the sequence

of “three short beeps” when an alarm is triggered.

During the programme selection phase, the buzzer can be enabled/disabled with a sensor combination (which

may be silk-screen printed on the control panel or described in the instruction manual), but the alarm signalling

remains enabled.

To enable it, touch the sensors simultaneously for 3 seconds. A short beep will confirm that it has been

enabled, whereas two short beeps will confirm that it has been disabled.

P6 P3.0

P6 P3.0

Page 17

Technical Support - MDM

17/104

599 77 39-16 R ev. 00

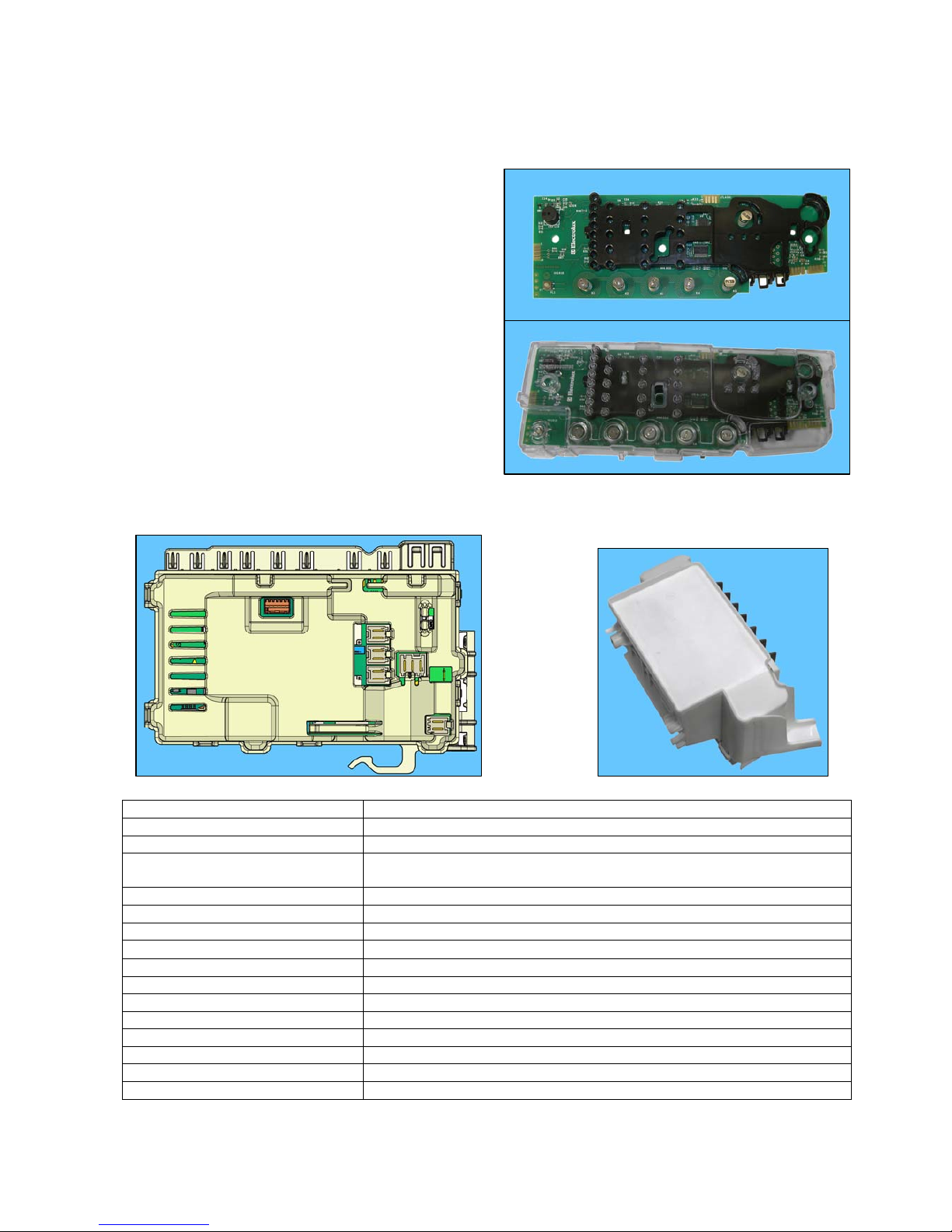

4 STYLING P3.0

4.1

EWX13611 General characteristics

The electronic control system consists of two circuit boards.

In the event of problems with the touch sensors (difficulty selecting/adjusting them), clean and dry the display

and do not wear gloves when setting the chosen programme.

The control/display board, which is inserted in

a plastic container fixed to the control panel (the

figure shows: the display board and the display

board assembly).

Main board, positioned at the rear of the appliance.

It powers the electrical components and receives

commands from the display board.

No. of buttons

1 Maximum

No. of touch-sensitive keys

Maximum 6 (5 options + start/pause)

No. LEDs

Maximum 24 yellow + 1 red LED + Digit (made up of 22 LEDs)

Power supply voltage

220/240 V

50/60 Hz (configurable)

Washing type

Traditional with “Eco-IDB”

Rinsing system

Traditional with “Eco-IDB”

Motor

Collector, with tachometric generator (Universal)

Spin speed

1,0001,600 rpm

Anti-unbal ancing system

AGS

Cold water fill

1 solenoid valve with 1 inlet – 2 outlets

Detergent dispenser

2 compartments: wash, conditioners

Control of water level in the tub

Electronic/analogue pressure switch

Door safety interlo ck

Instant “Pull To Open”

Heating element heat output

1,750 W with thermal fuses incorporated

Temperature ch eck

NTC probe incorporated in the heating element

Buzzer

Traditional incorporated in the PCB

Page 18

Technical Support - MDM

18/104

599 77 39-16 R ev. 00

4.2

EWX11831 General characteristics

The electronic control system consists of three circuit boards.

In the event of problems with the touch sensors (difficulty selecting/adjusting them), clean and dry the display

and do not wear gloves when setting the chosen programme.

The control/display board, which is inserted in

a plastic container fixed to the control panel

(the figure shows: the display board and the

display board assembly).

The main circuit board is positioned at the rear of the appliance and powers the electrical components,

receiving commands from the display board as well as communicating with the motor control board

(Inverter UIMC).

No. of buttons

1 Maximum

No. of touch-sensitive keys

Maximum 6 (5 options + start/pause)

No. LEDs

Maximum 24 yellow + 1 red LED + Digit (made up of 22 LEDs)

Power supply voltage

220/240 V

50/60 Hz (configurable)

Washing type

Traditional with “Eco-IDB”

Rinsing system

Traditional with “Eco-IDB”

Motor

Two-pole asynchronous (three-phase)

Spin speed

1,0001,600 rpm

Anti-unbal ancing system

AGS

Cold water fill

1 solenoid valve with 1 inlet – 2 outlets

Detergent dispenser

2 compartments: wash, conditioners

Control of water level in the tub

Electronic/analogue pressure switch

Door safety interlo ck Instant “Pull To Open”

Heating element heat output

1,750 W with thermal fuses incorporated

Temperature ch eck

NTC probe incorporated in the heating element

Buzzer

Traditional incorporated in the PCB

Inverter UIMC

Page 19

Technical Support - MDM

19/104

599 77 39-16 R ev. 00

4.3

Control panel

Max. 1 Button

Max. 6 sensors

25 LEDs

1 LCD

4.3.1 Display board

Display board assembly, exploded view

1 Display board

2 Light divider

3 Light diffuser

1

2

3

Page 20

Technical Support - MDM

20/104

599 77 39-16 R ev. 00

4.3.2 Control panel configuration

All the functions of button P1 and of sensors S1 to S5 are the same as those described for styling P6 (see page 12).

4.3.2.1 Programme configuration

(See page 12.)

4.3.2.2 Buttons – Sensors – LEDs

All the functions: of button P1, of sensors S1 to S5 are the same as those described for styling P6 (see page 13).

Sensor no .6 : THE CYCLE FINISHES IN (Finish In)

This sensor allows the end user to programme in how many hours’ time the

washing cycle will finish.

In detail, the cycle start can be delayed so as to have the cycle end at the desired time.

You can select from a minimum of 3 hours to a maximum of 20 hours.

The first time you press the sensor, the display indicates 3 hours and the related

LED (26) lights up to indicate the option is enabled. The next time you press it,

the time increases by 1 hour, up to a total of 10 hours. The increase is of 2 hours

every time you press the button for the range between 10 and 20 hours.

If the display indicates 20 hours, the next time you press the sensor, “Finish In”

will be disabled and the washing cycle time will be displayed and the LED (26)

will switch off.

For a quicker selection, hold your finger down on the sensor for longer.

Setting an option after selecting “Finish In”

“Finish In” must be enabled after an option has been selected (if necessary) and before you start the cycle. If

the end user, after setting “Finish In”, modifies the programme settings, “Finish In” will be disabled, the LED (26)

will flash once and the display will once again indicate the washing cycle time.

“Finish In” after touching the START sensor

Once you have selected the programme and the option (if necessary) and set “Finish In”, the washing cycle

starts when you touch the START sensor; the appliance door is locked and the countdown begins, and is

indicated on the display at one-hour intervals until the start of the washing cycle. Once the “Finish In” time is up,

the display indicates the amount of time necessary to perform the washing cycle, starting the countdown of the

cycle with one-minute intervals, until the end of the cycle.

If the appliance is paused during the countdown of the “Finish In” option to change the option and including “Finish

In”, the delay time is deleted and “Finish In” is disabled; touch the sensor and the display will indicate “error”.

S6

S

1

P1

S2S3S4S5

S6

L1

L28

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

L19

L20

L21

L22

L23

L24

L25

L26

L27

L26

Page 21

Technical Support - MDM

21/104

599 77 39-16 R ev. 00

4.3.2.3 Display

Padlock

(See page 15.)

Extra Rinse

(See page 16.)

The following information also appears on the display:

Washing programme time

This appears after a washing programme has been selected. This time

corresponds to the time required for the maximum wash load for each type

of programme.

After the programme has started, the time decreases (and is updated)

minute by minute.

When the time is less than an hour, the initial zeros are not displayed.

End of cycle

End of the programme is indicated by a permanently l it z ero

(when the door can be opened).

Selection incorrect

Displays the flashing message “Err”, for one second.

Appears on selecting option that is incompatible with the programme selected,

or when the selector is turned while a cycle is running.

Alarm code

Indicates an anomaly during operation of the machine. Simultaneously to the

displaying of the code on the LCD display, the LED above the START/PAUSE

sensor flashes.

Calculate amount of washing

Only for appliances with PROPORTIONAL programmes

After starting the washing programme the dot starts to flash. At this point the

washing machine calculates the amount of washing inside the drum. When this

phase ends the dot lights up fixed and the three digits display the programme time.

4.3.2.4 Buzzer

(See page 16.)

Page 22

Technical Support - MDM

22/104

599 77 39-16 R ev. 00

5 DEMO MODE

A special cycle is designed to demonstrate the operation of these appliances in shops, without connecting them

to the water mains. This way, any one of the programmes can be selected and, once the start button/sensor

has been pressed/touched (START/PAUSE), the appliance will only perform some of the phases of the

programme, skipping those which cannot be performed (water fill, drain, heating).

The cycle takes place as follows:

The door lock is enabled as usual (door locked during operation, possibility of opening it at the end of the

cycle or when paused).

Motor: all low speed movements are enabled, the pulses and spin are disabled.

The water fill solenoid valves and the drain pump are disabled.

Display: as the cycle phases are very fast (one second in the demo cycle corresponds to approximately one

minute in the actual cycle) the end time decreases by 1 unit per second. Bear in mind that the end time

does not always correspond to the actual cycle time.

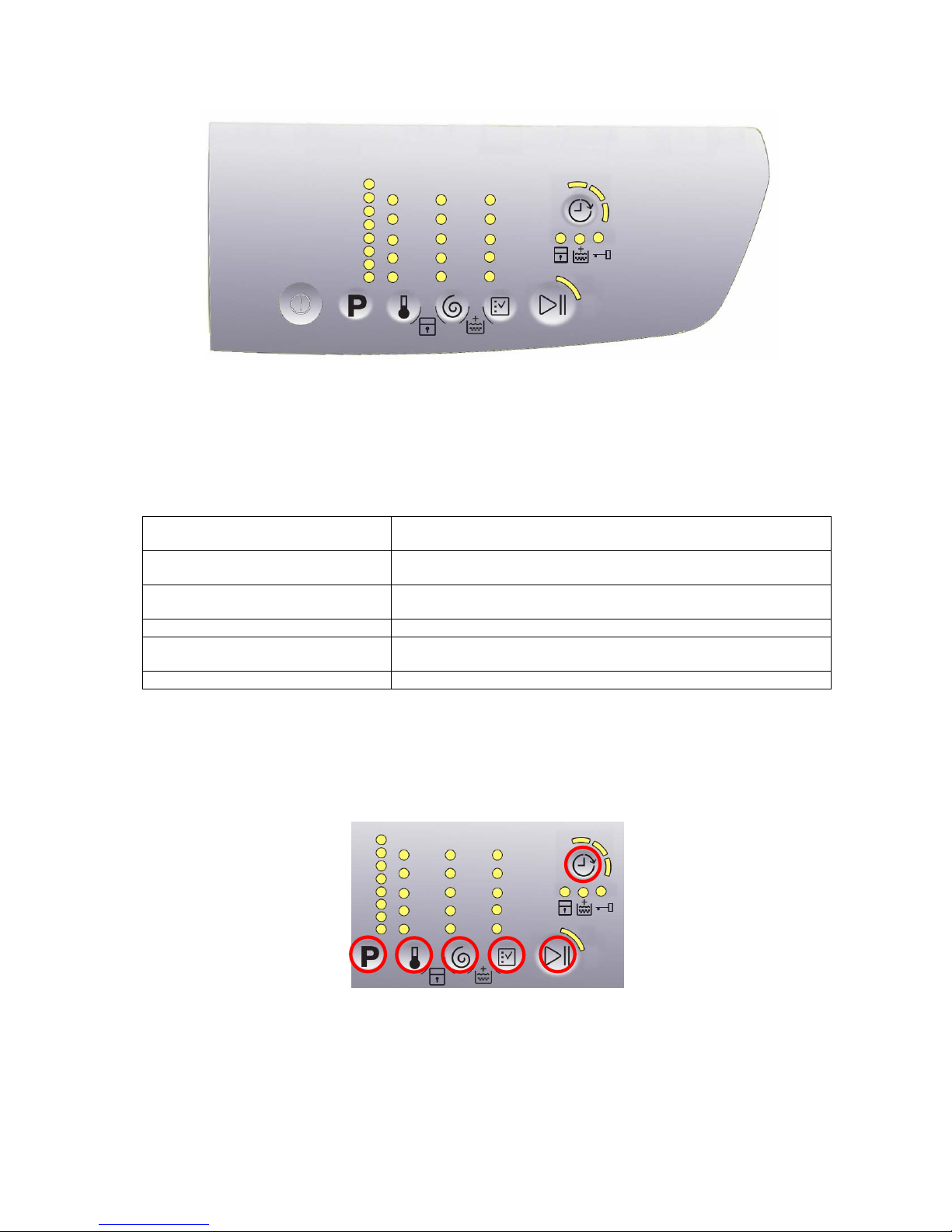

5.1

Accessing the DEMO setting for P6 and P3.0 stylings

The operations listed below must be carried out within 7 seconds.

STEPS P6 P3.0

1

Switch on the appliance using the ON/OFF button

2

Use sensor S1 to select the third LED from the top down

3

Simultaneously press the START/PAUSE button and the nearest option sensor

(as shown in the diagram).

Keep your finger above the sensors (for approximately three to five seconds) until:

P6 all the LEDs relating to Sensors S2/S3/S4 flash.

P3.0 the display indicates a flashing “dEM” for a short while.

5.2

Exiting DEMO mode

Disconnect the power supply to exit demo mode.

Page 23

Technical Support - MDM

23/104

599 77 39-16 R ev. 00

6 DIAGNOSTICS SYSTEM

6.1

Accessing the diagnostics for P6 and P3.0 stylings

The operations listed below must be carried out within 7 seconds.

STEPS P6 P3.0

1

Switch on the appliance using the ON/OFF button an wait for the main programme

LED to light up.

2

Simultaneously press the START/PAUSE button and the nearest option sensor

(as shown in the diagram).

Keep your fingers on the sensors (for approximately 3 seconds) until the LEDs

begin to flash in sequence (P3.0, also the symbols inside the display).

6.2

Quitting the diagnostics system

In order to exit the diagnostic system turn the appliance off and on again using the ON/OFF button.

If “ELE” appears on the display (P3.0) when you turn the appliance on, repeat the operation of switching

it on and off.

Page 24

Technical Support - MDM

24/104

599 77 39-16 R ev. 00

6.3

Phases of the diagnostics test

Irrespective of the type of electronic board and of the configuration, once the diagnostics system has been activated,

touch sensor S1 to run a diagnostic check of the various components and the alarm reading (touch sensor S1

(Programme) to progress in sequence from the top down, or touch sensor S2 (Temperature) to go back).

Where featured, the Display (P3.0) indicates the description provided in the last column of the table below.

(All alarms are enabled in the diagnostic cycle.)

LED lit up Components activat ed Working conditio ns Function tested Displa

y

- Door safety interlock

- Wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 min.

Water fill to wash

compartment

Water level in

the tub (mm)

- Door safety interlock

- Pre-wash solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 min.

Water fill to

pre-wash

compartment

Water level in

the tub (mm)

- Door safety interlock

- Pre-wash and

wash solenoid valves

Door closed

Water level below

anti-flooding level

Maximum time 5 min.

Water fill to

conditioner

compartment

Water level in

the tub (mm)

- Door safety interlock

- Third solenoid valve

Door closed

Water level below

anti-flooding level

Maximum time 5 min.

Water fill to Third

solenoid valve

compartment

Water level in

the tub is

displayed (mm)

- Door safety interlock

- Fourth solenoid (hot water,

if present)

Door closed

Water level below

anti-flooding level

Maximum time 5 min.

Water fill to Fourth

solenoid valve

compartment

Water level in

the tub is

displayed (mm)

Page 25

Technical Support - MDM

25/104

599 77 39-16 R ev. 00

LED lit up Components activat ed Working conditio ns Function tested Displa

y

- Door safety interlock

- Wash solenoid, if the water in

the tub is not enough to cover

the heating element

- Heating element

- Recirculation pump

Door closed

Water level above

the heating element

Maximum time 10 min.

up to 90 °C (*)

Reheating

Circulation

Temperature in

°C measured

using the

NTC probe

- Door safety interlock

- Wash solenoid, if the water in

the tub is not enough to cover

the heating element

- Motor (55 rpm clockwise,

55 rpm anti-clockwise,

250 rpm pulse)

Door closed

Water level above

the heating element

Check for leaks

from the tub.

Drum speed

in rpm/10

- Door safety interlock

- Drainage pump

- Motor up to 650 rpm then

at maximum spin speed (**)

Door closed

Water level lower

than anti-boiling level

for spinning

Drain, calibration

of analogue

pressure switch

and spin.

Drum speed

in rpm/10

----- ----- ----- -----

Reading/Deleting the last alarm ----- ----- -----

- The LEDs light up in sequence,

the symbols on the LCD display

light up in in groups and the

backlighting comes on

- Touch a sensor to turn on the

group of icons in the LCD

screen or the corresponding

LED and the buzzer sounds

at the same time

Always active

User interface

functions

(*) In most cases, this time is sufficient to check the heating. However, the time can be increased by repeating the phase without draining the

water: pass for a moment to a different phase of the diagnostic cycle and then back to the heating contr ol phase (if the temperature is higher

than 80 °C, heat ing does not take place).

(**) The check at the maximum speed occurs without control of the A.G.S. and no garments must be inside the appliance.

Page 26

Technical Support - MDM

26/104

599 77 39-16 R ev. 00

7 ALARMS

7.1

Displaying user alarms

7.1.1 Styling P6

The alarms are displayed by the flashing red LED of the START/PAUSE button; the three codes E10, E20,

E40 are also shown in combination with one of the three LEDs above the START/PAUSE sensor.

Alarms E9x and EHx show the entire code with the red LED + yellow LED, only alarm EHx is not accompanied

by the buzzer sounding.

The table below illustrates the various combinations of LED lightings.

E10 E20 E40

Water fill

difficulty

(tap closed)

Drain

difficulty

(filter fouled)

Door ope n

The aforementioned alarms (for both versions) can be remedied directly by the end user.

Once the problem has been remedied, the alarm is no longer displayed, the red LED is switched off, returning

to normal operation with the lighting of the yellow LED.

On the other hand, the alarms listed below (for both versions):

EF0 – Water leakage (Aqua Control Syst em)

It is displayed to the user, but technical assistance is required to resolve it.

EH0 – Voltage or frequency outside the no rmal values

It is necessary to wait for power supply voltage and/or frequency to restore nominal conditions.

The alarms are enabled du ring the execution of the washing programme. With the exception of alarms

associated with th e con figu rat ion and the power supply voltage/frequency, which are also di spl ayed

during the programme selection phase.

The door can normally be opened (except where specified) when an alarm condition has occurred, on the

condition that:

The water in the tub is below a certain level.

The water temperature is lower than 55 °C.

The motor has stopped.

Certain alarm conditions require a drain phase to be performed before the door can be opened for safety reasons:

Cooling water fill if the temperature is higher than 65 °C.

Drain until the analogue pressure switch is on empty, during a max. 3-minute interval.

Page 27

Technical Support - MDM

27/104

599 77 39-16 R ev. 00

7.1.2 Styling P3.0

When a problem arises with the appliance, “WARNING” appears on the LCD screen, represented by a code

(three digits, indicating the time required for the cycle to end). At the same time the buzzer gives off three short

“beeps” every 20” for a period of 5 minutes.

Once the fault has been repaired the buzzer does not give off any “beeps” and the selected programme

appears on the LCD screen.

Alarms E9x and EHx show the entire code with the red LED + yellow LED, only alarm EHx is not accompanied

by the buzzer sounding.

The alarms displayed to t he user are listed below and can also be eliminated by the user:

E10 – Water fill difficulty (tap closed)

E20 – Drain difficulty (filter dirty)

E40 – Door open

EF0 – Excessive detergent (if displayed)

E91 – No communication between the display board and the main board. Switch ON/OFF

E92/E93/E94 – Main board not configured correctl

y

.

EF0 – Water leakage (Aqua Control Syst em)

It is displayed to the user, but technical assistance is required to resolve it.

EH0 – Voltage or frequency outside the no rmal values

It is necessary to wait for power supply voltage and/or frequency to restore nominal conditions.

The alarms are enabled du ring the execution of the washing programme. With the exception of alarms

associated with th e con figu rat ion and the power supply voltage/frequency, which are also di spl ayed

during the programme selection phase.

The door can normally be opened (except where specified) when an alarm condition has occurred, on the

condition that:

The water in the tub is below a certain level.

The water temperature is lower than 55 °C.

The motor has stopped.

Certain alarm conditions require a drain phase to be performed before the door can be opened for safety reasons:

Cooling water fill if the temperature is higher than 65 °C

Drain until the analogue pressure switch is on empty, during a max. 3-minute interval.

Page 28

Technical Support - MDM

28/104

599 77 39-16 R ev. 00

7.2

Alarm reading/display

7.2.1 Displaying th e alarm (P 3.0)

The last three alarms stored in the FLASH memory of the PCB can be displayed:

Enter the diagnostic mode (para. 6.1).

Irrespective of the type of circuit board and of the configuration, use sensor S1 to select

the LED (see figure opposite) and the display indicates the last alarm.

To display previous alarms, touch the sensor closest to the START/PAUSE sensor in

sequence (as shown in the figure)

To return to the last alarm, touch the START/PAUSE sensor.

7.2.2 Displaying th e alarm (P 6)

The alarm is displayed by a repeated flashing sequence of the START/PAUSE button red and green lights

(0.5 seconds on, 0.5 seconds off with a 2.5 second pause between sequences).

START/PAUSE button indicator with red light indicates the first digit of the

alarm code (family).

START/PAUSE button indicator with yellow light indicates the second digit

of the alarm code (number inside the family).

These two LEDs can be found on all models.

Notes:

The first letter of the alarm code “E” (Error) is not displayed, since this letter is common to all alarm codes.

Alarm code families are expressed in hexadecimals; and therefore the letters:

A is represented by 10 flashes

B is represented by 11 flashes

...

F is represented by 15 flashes

Configuration errors are displayed by all LEDs flashing (user interface not configured).

7.2.3 Example of alarm display

If we take alarm E43 (problem with the door safety TRIAC) as an example; the following will be displayed:

The sequence of four flashes of the START/PAUSE button with the red light indicates the first number E

4

3.

The sequence of three flashes of the START/PAUSE button with the yellow light indicates the second number E4

3

.

Page 29

Technical Support - MDM

29/104

599 77 39-16 R ev. 00

7.2.4 Behaviour of the alarms du rin g diagn ostic testing

All alarms are enabled during diagnostic testing of the components.

START

/

PAUS E but ton with red lig h

t

START/PAUSE button with yellow light

On/off

Time

(Sec.)

Value On/off

Time

(Sec.)

Value

0.5

1

0.5

1

0.5

0.5

0.5

2

0.5

2

0.5

0.5

0.5

3

0.5

3

0.5

0.5

0.5

4

2.5 Pause

0.5

1.5 Pause

Page 30

Technical Support - MDM

30/104

599 77 39-16 R ev. 00

7.2.5 Rapid reading of alarms

It is possible to display the last alarm even if the selector is not in the eleventh diagnostics position or the

machine is in normal operation (e.g. while a washing programme is in progress):

→ Touch the START/PAUSE sensor and the nearest option sensor simultaneously (as if you were entering

DIAGNOSTIC mode) and hold for at least 2 seconds: the LCD display shows the last alarm.

→ The alarm will continue to be displayed until a sensor is touched.

→ The alarm reading system is as described in para. 7.2.

→ While the alarm is being displayed, the appliance continues to perform the cycle or, if in the programme

selection phase, it stores the previously selected options.

7.2.6 Deleting the last alarm

It is good practice to cancel the alarms stored:

after reading the alarm codes, to check whether the alarm re-occurs during the diagnostic cycle

after repairing the appliance, to check whether it re-occurs during testing

N.B. With this operation all the alarms stored are deleted.

P3.0 P6

Enter the diagnostic mode (para. 6.1).

Using sensor S1, select the position in which the LED lights up to display the alarms.

Simultaneously press the START/PAUSE sensor and the nearest option sensor (as shown in the diagram).

Keep your finger above the sensors (for approximately 5 seconds) until for styling P3.0 the display shows

“E00”, while for styling P6 the START/PAUSE LED stops flashing.

S1

S1

Page 31

Technical Support - MDM

31/104

599 77 39-16 R ev. 00

8 OPERATING TIME COUNTER (styling P3.0 only)

Using a specific procedure, the operator can display the total operating time for the appliance, which is counted

from the moment it is first switched on.

The unit can count up to a maximum of 6,550 hours of operating time.

Only the operating time of normal programmes (and not diagnostic cycles) is counted.

The actual operating time for the cycle is counted (which does not include pauses, delayed start time, rinse

hold time and soaking phases).

The precision of the counter is 30 seconds per programme.

Only whole hours of operation are counted (1hr and 59 min. = 1 hr).

8.1

Reading the operating time

The operations listed below must be carried out within 7 seconds.

Switch on the appliance using the ON/OFF button

Use sensor S1 to select the position which lights up the fifth LED.

Simultaneously press the START/PAUSE button and the nearest option sensor (as shown in the diagram).

Keep your fingers over the sensors until the hours of operation appear on the display (at least 5 seconds).

8.2

Display of total operating time

This time is displayed with a sequence of two digits at a time: the first two digits indicate thousands and

hundreds, the second two digits indicate tens and units.

For example, if the operating time is 6,550 hours, the display will show the following sequence:

Phase 1 Phase 2 Phase 3

For two seconds

It displays: Hr

For two seconds, the

following digits are displayed:

thousands (6)

hundreds (5).

For the next two seconds the

following digits are displayed:

tens (5)

units (0).

At the end of phase three (after the tens and units are displayed), the cycle is repeated.

To return to normal mode, either: switch off the appliance, press a key.

S1

Page 32

Technical Support - MDM

32/104

599 77 39-16 R ev. 00

9 OPTIONS

9.1

Compatibility between options

The delayed start is c ompatible with all pr ogrammes exc ept for Drain; the maximum time s electable is 20 hours.

The selection of the sp in cycle is available for all progr ammes, except for Drain/E xtra Silent.

OPTIONS

Rinse hold

Pre-wash

Extra-rinse

Easy-iron

Econom

y

Cupboard Dry

Super Quick

Spin Speed Reduction

No Spin

Compa tibili ty with

OPTIONS

Rinse hold

X X X X X X

Pre-wash

X

X X X X X X X

Extra-rinse

X X

X X X X X X

Easy Iron

X X X

X X X X X

Economy

X X X X

X X X

Cupboard Dry

X X X X

X X

Super Quic k

X X X X X

X X

Spin Speed Reduction

X X X X X X

No Spin

X X X X X X

Phases where

selection/

modification

is possible

Selection

X X X X X X X X X

Pre-wash

X

X X

X X

Wash

X

X X

X X

Rinses

X

Spin

Page 33

Technical Support - MDM

33/104

599 77 39-16 R ev. 00

9.2

Description of options

Rinse hold