Electrolux AOS Q Service Manual

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS NXT (AOS_Q) OVENS

AOS_Q OVENS – Service Manual

(593802300 - ENG)

- Service manual -

CONTENTS:

PROJECT REF:

AUTHORS:

CONTRIBUTION BY:

DOCUMENT HISTORY:

This document contains the information about parameters that can be

read and/or modified by means of user interface, service utilities, ....

AOS NXT ovens

S. Gant

F. Ornella

A. Canova

Rel. Date: File: Author: Note:

00 01/08/2007 AOS NXT service manual (ENG).00 S. Gant

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.1/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

INDEX

1 Programming the default parameters .......................................................................................4

2 Advanced programming .............................................................................................................5

3 By-pass calibration (only for lev. B ovens)...............................................................................6

4 Lambda probe calibration (only for lev. A ovens)....................................................................7

5 Cavity offset calibration (only for lev. A ovens) .......................................................................7

6 Error codes ..................................................................................................................................8

6.1 Errors.....................................................................................................................................8

6.2 Warnings ...............................................................................................................................8

7 Firmware release .........................................................................................................................9

8 Working temperatures ................................................................................................................9

9 Service utilities ............................................................................................................................9

9.1 Utilities that can be activated with oven switched on.......................................................9

9.2 Utilities that can be activated in parameter programming .............................................10

10 Selection of the language for the recipe menu (lev. A) .........................................................11

11 Cleaning cycles (lev. A) ............................................................................................................11

12 Cycles, utilities, important parameters ...................................................................................11

13 Gas system ................................................................................................................................13

13.1 Gas valve...........................................................................................................................15

13.2 Offeset pressure calibration............................................................................................16

13.3 Use of manometer (for offset pressure measure) .........................................................17

14 Change of the microprocessor board .....................................................................................18

APPENDIX A – WATER BOILING POINT......................................................................................19

APPENDIX B – CONTACTORS DIAGRAM ...................................................................................20

APPENDIX C – CONNECTIONS ON MAIN BOARD......................................................................21

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.2/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

APPENDIX D – LAMBDA PROBE..................................................................................................24

APPENDIX E – PARAMETER DESCRIPTIONS ............................................................................25

APPENDIX F – WATER TREATMENT ...........................................................................................27

APPENDIX G – CONNECTION TO HACCP SYSTEM ...................................................................29

APPENDIX H – RELAY DESCRIPTIONS.......................................................................................30

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.3/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

1 Programming the default parameters

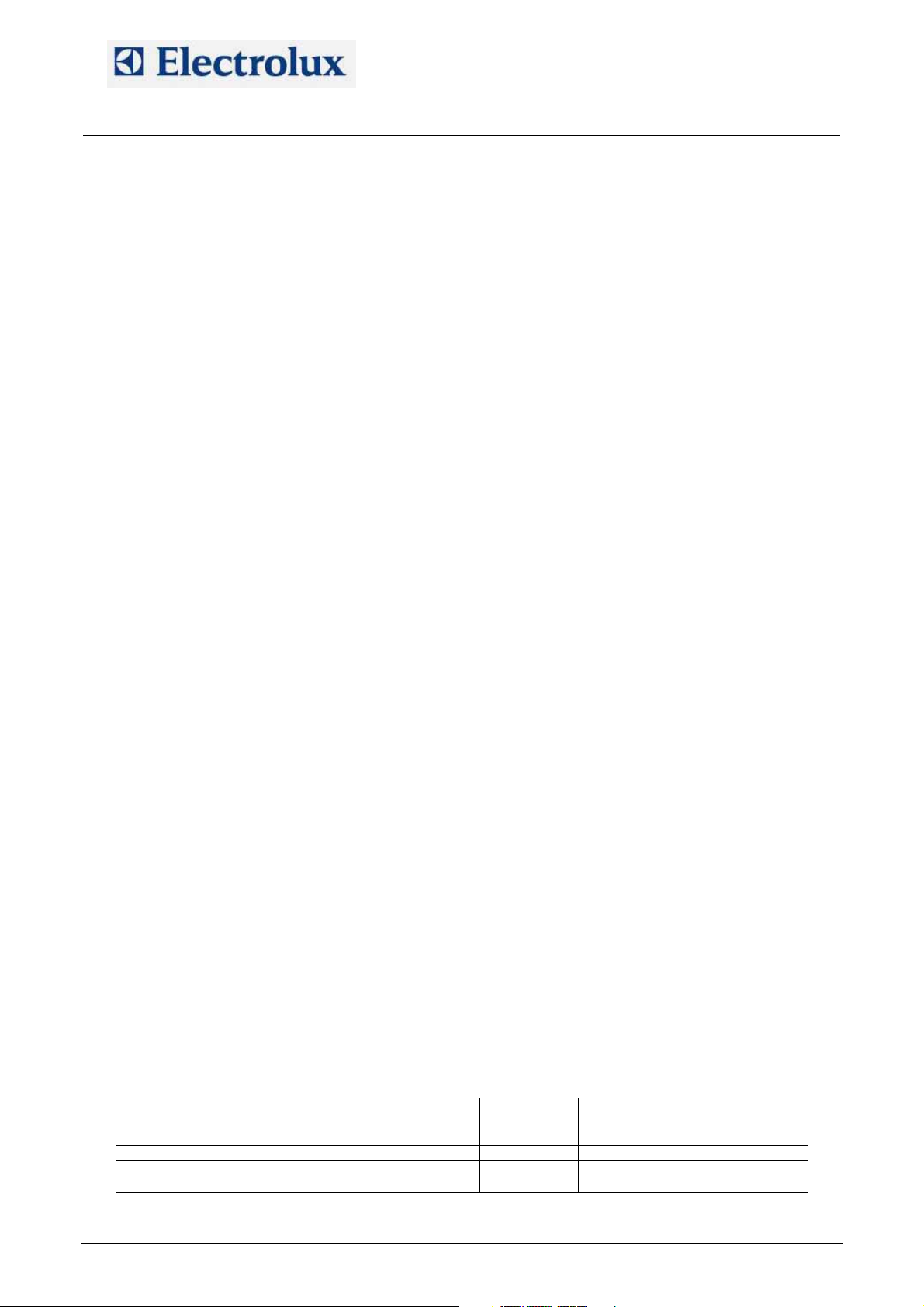

Switch on the oven (fig. 1).

Just after the switching on, a lamp test will take place (fig 2).

At this point, during the lamp test phase, press the external service buttons (fig.3) till you hear a beep.

1

At this point press the right buttons till you hear a beep (fig. 4).

Press then the left service buttons till the beep (fig. 5).

At this point release the left buttons keeping pressed the middle one (fig. 6) till you hear 2 beeps.

Release the middle button and on the temperature display you will see “PdEF”: the oven will switch off and

on automatically.

Fig. 1

Fig. 4 Fig. 5 Fig. 6

1

Fig. 2

Fig. 3

1

1 2

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.4/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

2 Advanced programming

The procedure to enter in advanced programming is similar to the procedure for programming the defaults

parameters.

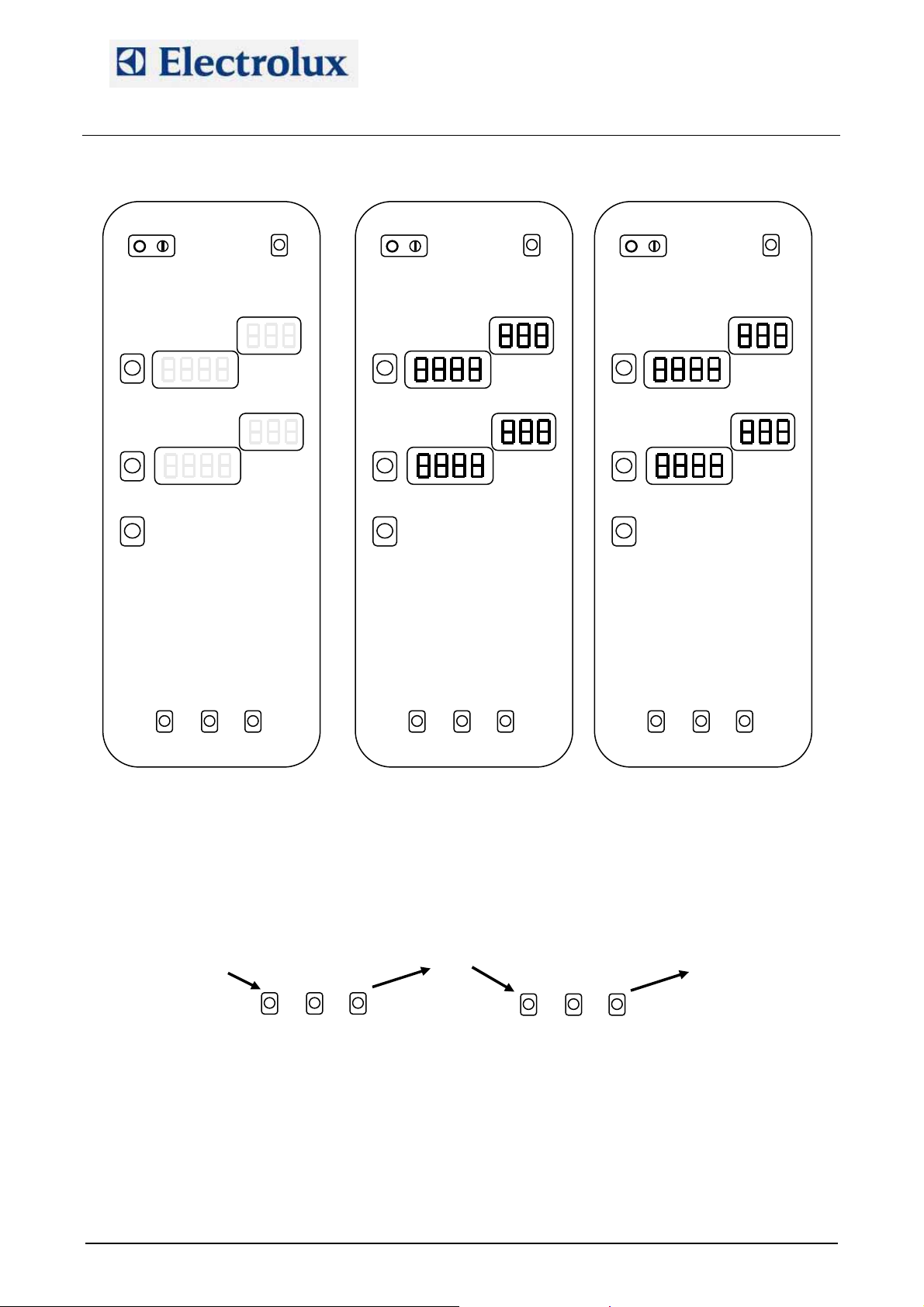

Switch on the oven (fig. 7).

Just after the switching on, a lamp test will take place (fig. 8).

At this point, during the lamp test, press the external service buttons (fig.9) till you hear a beep.

At this point press the right buttons till you hear a beep (fig. 10).

Press then the left service buttons till the beep (fig. 11).

Release the button and on the temperature display you will see “P 1” while on the little display the name of

the parameter will appear (fig. 12).

With the external service buttons it is possible to scroll the list of the parameters.

Pressing the middle button it is possible to see the value of the parameter (fig. 13) and pressing at this

point the external buttons it is possible to modify the value. Press again the middle button returning to the

displaying of the number of the parameter to store the new value.

Fig. 7

1

Fig. 10 Fig. 11

Fig. 8 Fig. 9

1

1

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.5/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

Switch off the oven to exit from programming.

Fig. 12 Fig. 13

3 By-pass calibration (only for lev. B ovens)

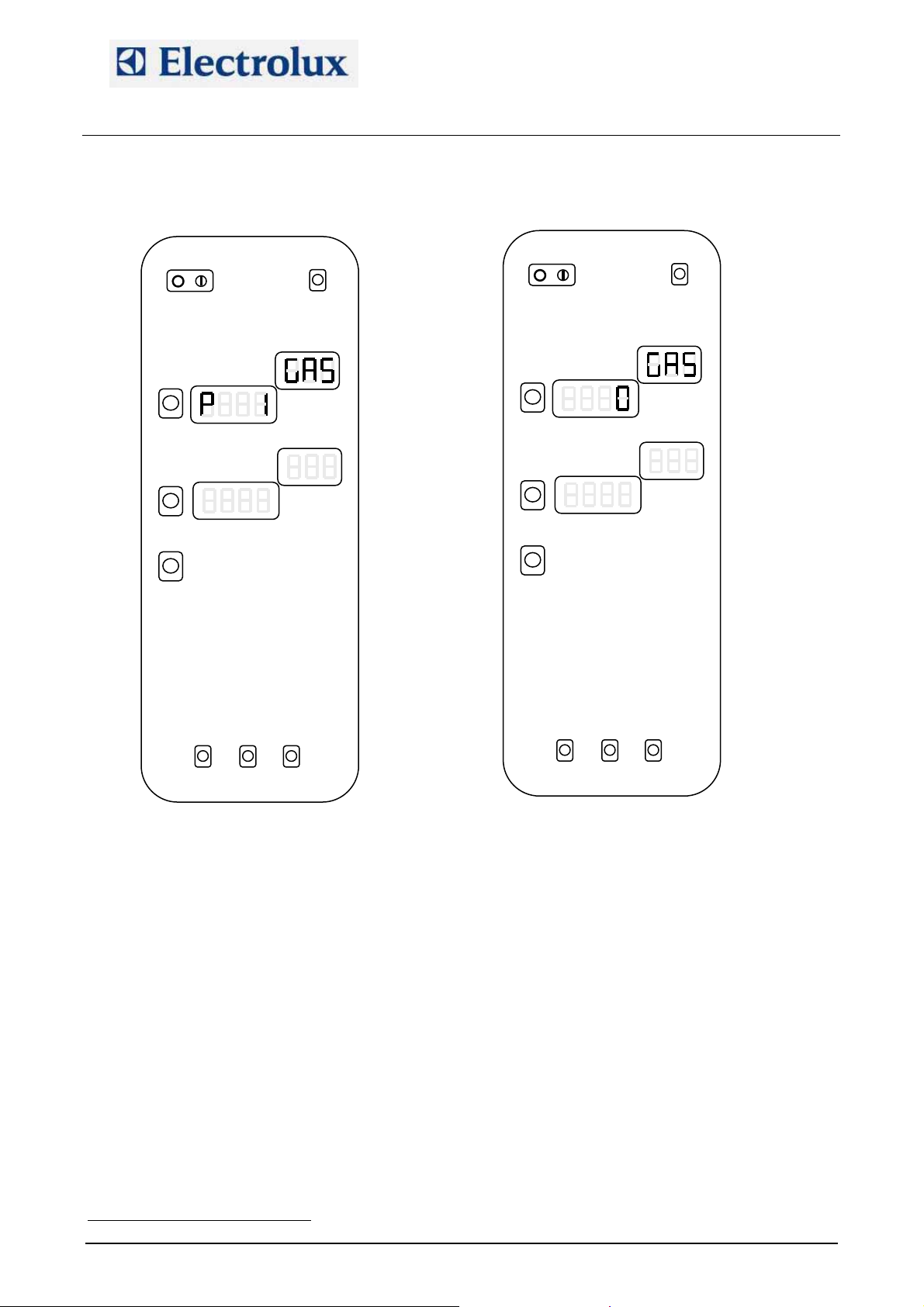

In order to calibrate the by-pass probe on lev. B ovens, follow these steps:

1) Switch on the oven

2) Enter in parameter programming and set parameters cort and OCA1 to 0

3) Exit from programming and switch on again the oven

4) Wait for the end of the pre-heating cycle

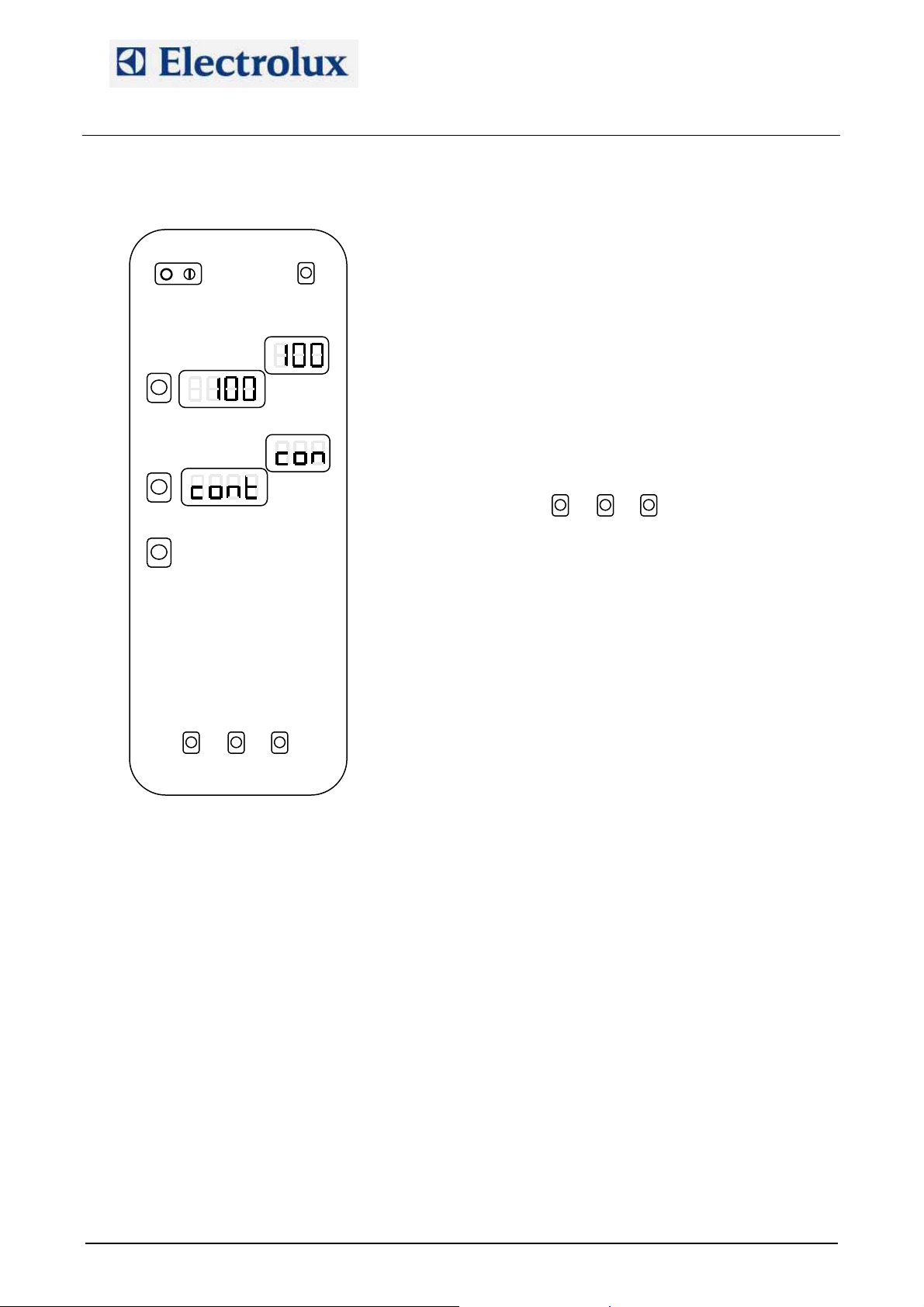

5) Select a steam cycle (100 °C)

6) Select continuous time (indication “cont” on time display)

7) Press and hold down the left service buttons and at the same time press the START button (fig. 14);

the oven will give a long beep

8) Release the service buttons and wait for the stabilization of the temperature reading by the by-pass

probe

9) When the temperature has stabilized, press the three service button together in order to memorize the

value (fig. 15); the oven will confirm the storing with a long beep

10) Allow the oven to work for several minutes in steam mode checking the oven cavity temperature, which

should stabilize at the water boiling point. If this reading is greater or less than the correct water boiling

1

point

TPF

FPT, a corrective value can be stored in the parameter OCA1. Pushing the 3 service buttons to store

the bypass temperature, the microprocessor will calculate and store also the value of OCA1.

11) Set parameter cort to 1.

1

TP

PT See Appendix A

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.6/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

12) Set the altitude above sea level of the site on parameter SEAL

Fig. 15

Fig. 14

4 Lambda probe calibration (only for lev. A ovens)

The calibration of the lambda probe is necessary for the right working of the oven in case of cycle with set

point under 100 °C. With this procedure we have to find the point of 0% of humidity.

The procedure is done in a way similar to the by-pass calibration. These are the steps:

1) Set an hot air cycle, 150 °C, time over 15 minutes, open flap;

2) Start the cycle pressing together the left and middle service buttons and the START button. The

oven will give a long beep;

3) Wait around 10-15 minutes to dry completely the cavity;

4) Close the flap and wait around 20 seconds to stabilize the humidity inside the cavity;

5) To store the value press together the 3 service buttons. The oven will confirm with a long beep.

6) Stop the cycle with the START button.

This calibration is very important and has to be done with care. If the dry point (0% of humidity) is not

correctly stored, the reading of the relative humidity could be overestimated or underestimated.

5 Cavity offset calibration (only for lev. A ovens)

In order to adjust the offset of the cavity probe, enter in parameter programming and set parameters cort

and OCA1 to 0.

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.7/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

Then run a steam cycle for several minutes and check the cavity temperature, which should stabilize at the

water boiling point. If the stabilized cavity temperature is less or greater than the correct water boiling

2

pointTPF

FPT, a corrective value can be stored in parameter OCA1.

After this, set parameter cort to 1and set parameter SEAL (altitude above sea level).

6 Error codes

Errors can be divided into 2 categories: errors (they stop the appliance) and warnings (they do not stop the

appliance).

6.1 Errors

EE2P: Communication error with the EEPROM

E---: If the controller detects one or more parameters which have values not permitting the minimum

operational requirements, an error code will appear on the display, i.e. “E---” followed by the parameter

number. Enter the programming mode and set the correct value according to the parameter list.

EtUC: Cavity over temperature; cavity temperature exceeded value stored in parameter cot.

EtUB: Boiler over temperature; boiler temperature exceeded value stored in parameter bot.

EFUN: Activation of the thermal protection of the motor. On the little temperature display it will appear “UP”

or “DOWN” according it is the thermal protection of the upper motor (and the motor of 6-10 grid ovens) or

lower motor on 20-grid oven. The thermal protection has an automatic reset but in order to continue with

the cooking process, parameter ALFn has to be reset to 0.

Etc: Tripping out of cavity limiter

Etb: Tripping out of boiler limiter

ESCH: Over temperature on the electronic board; check the cooling fan and the ventilation openings on the

bottom of the control panel.

Ept1: cavity probe in open circuit (only the steam cycle – 100 °C can be selected)

Ept2: boiler probe in open circuit (only hot air cycle can be selected)

Ept3: meat probe in open circuit (only time cooking can be selected)

Ept4: by-pass probe in open circuit (only hot air, regeneration or low temperature steam cycle can be

selected)

Ept8: NTC probe in short or open circuit

ECAD: A/D converters not working

E PM: Communication error with PWM system

E SL: Water level probe error. If the boiler heating elements or burners are on for a tiem over that one

defined in parameter tbon without a water charging phase, this error message is activated. To reset it,

parameter ALFn has to be reset to 0.

burn CAUP: Lockout of cavity burner (gas oven) (the upper one in the 20 grid ovens)

burn CAdo: Lockout of lower cavity burner (gas oven) in 20 1/1 and 2/1 ovens

burn boUP: Lockout of boiler burner (gas oven) (the upper one in 20 2/1 ovens)

burn bodo: Lockout of lower boiler burner (gas oven)

6.2 Warnings

EH2O: Before the starting of the cleaning system and during its working, there are some check points of

the water pressure. If the water pressure is too low this warning message appears on the display. Check

the water pressure (1.5÷2.5 bar), check the correct working of the water pressure switch, check if there are

obstructions on the cleaning water inlet pipe (its inner diameter must be 20 mm).

EFLP: Cavity ventilation flap failure; check the motoreducer or the micro switch that detects the close

position of the flap. If the motoreducer does not close the flap within the time set in parameter FLto, EFLP

error appears.

ECLO: Clock error, it appears if the clock was never adjusted

EPrG: Error in reading the phases of a multiphase recipe

EIND: Error in reading the index of the recipes

EDES: Error in reading the description of a recipe

ERAM: Communication error with the RAM

nFIP: Communication error of recipe display

FILL: Safety level probe of the boiler out of water

PrEH: Preheating phase of the boiler; it indicates the preheating phase of the cavity if the warning message

appears on temperature display.

2

TP

PT See Appendix A

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.8/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

OPEN: boiler drain activated

COOL: Cavity cooling phase

dEt: low level of detergent

rAI: low level of rinser

rCLN: request for a cleaning cycle (manual or automatic); parameter FCLn is set to a value different from

da 0.

LOAD: end of pre-heating phase of the cavity; if nothing is done, the cavity is maintained at the pre-heating

set-point.

Strt: push START button.

rES: reset procedure of the burners is activated

AOS_Q OVENS – Service manual

(593802300 - ENG)

7 Firmware release

In order to check the version of the firmware, switch on the oven and wait for the lamp test and the end of

the start-up phase (4 lines on the temperature display). When on the temperature display, the actual cavity

temperature appears, pressing the three service buttons together on the display temperature the firmware

version will appear. Pressing again these buttons, the board temperature will be displayed.

8 Working temperatures

While the oven is working, it is possible to see the temperature of the several probes pressing the service

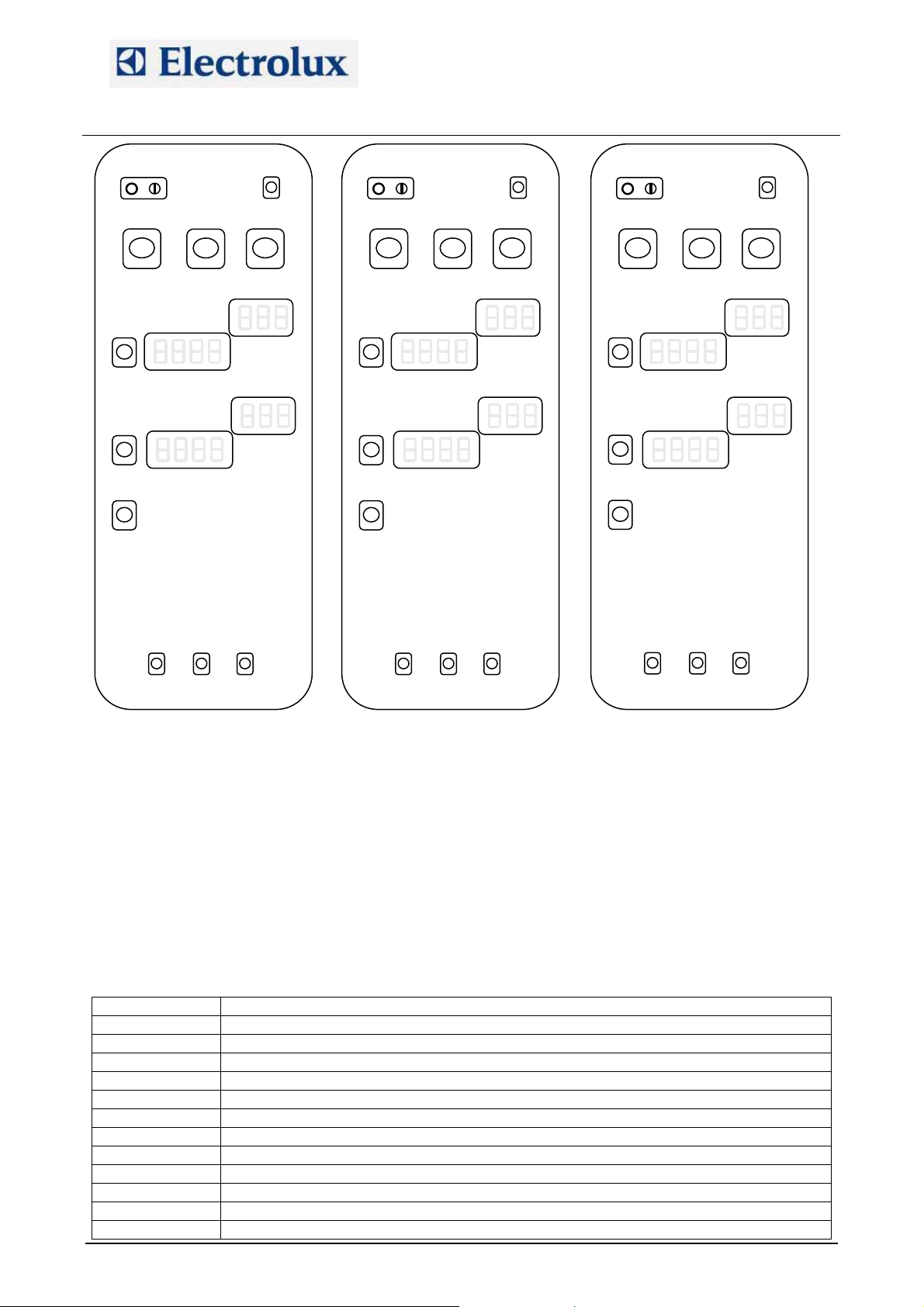

buttons. See the following figures:

Fig. 16

Boiler temperature

“tbol” on the display

Fig. 18

Meat probe temperature

“tPrb” on the display

Fig. 17

By-pass temperature

“tbyp” on the display

Fig. 19

PCB temperature

“tntc” on the display

9 Service utilities

These utilities can be divided in 2 sets: utilities that can be activated with the oven switched on, utilities that

can be activated with the oven in parameter programming

9.1 Utilities that can be activated with oven switched on

With the oven switched on and not in a cooking phase, pressing simultaneously the following buttons it is

possible to activate the detergent, rinser pumps and water valve of the cleaning system:

• Steam cycle, combi cycle, temperature buttons (fig. 20): activation of detergent pump

• Steam cycle, combi cycle, time buttons (fig. 21): activation of rinser pump

• Steam cycle, combi cycle, utility buttons (fig. 22): activation of water valve of the cleaning system

These routines are achievable only on lev. A ovens, i.e. with the parameter dCLn set to 0, closed door and

cavity temperature less than 80 °C and with the oven not blocked with password.

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.9/31

Electrolux Professional S.p.A.

Ovens Platform Customer Support

Technical Training & Service

AOS_Q OVENS – Service manual

(593802300 - ENG)

Fig. 20 Fig. 21 Fig. 22

9.2 Utilities that can be activated in parameter programming

• Pressing the steam cycle and hot air cycle buttons, all the output relays are sequentially activated and

on the time display it will be displayed the activated relay with the message do1, do2, ... (dox=RLx on

the EWD)

o The steam cycle button acts as main switch: if it is released, the test stops.

o Each time the hot air cycle button is pressed, the next relay is activated and remains activated till

the next pressure of the hot air cycle button.

o If the hot air cycle button is kept pressed, the relays are sequentially activated.

• Pressing the time buttons, the time will be displayed

• Pressing the utility button, on the time display a 4-characters message will be displayed while on the

little display will be shown a number with the following meanings

Big display Meaning of the number on the little display

ntc

Prb1

Prb2

Prb3

Prb4

Prb5

Prb6

First meat probe temperature (lev. A)

Second meat probe temperature (lev. A)

Third meat probe temperature (lev. A)

Fourth meat probe temperature (lev. A)

Fifth meat probe temperature (lev. A)

Sixth meat probe temperature (lev. A)

CEL1

CEL2

boL1

boL2

byP

File: AOS NXT service manual (ENG).00.doc ©Copyright 2007 by Electrolux Professional P.10/31

PCB temperature

First cavity temperature

Second cavity temperature

First boiler probe

Second boiler probe

Bypass probe

Loading...

Loading...