Page 1

k

Originalbetriebsanleitung

Universal-Kappsäge

t

Original Operating Instructions

Universal Crosscut Saw

p

Mode d’emploi d’origine

Scie tronçonneuse universelle

C

Istruzioni per l’uso originali

Troncatrice universale

U

Original-bruksanvisning

Universal-kapsåg

N

Originele handleiding

Universele afkortzaag

m

Manual de instrucciones original

Sierra oscilante universal

q

Alkuperäiskäyttöohje

Yleiskatkaisusaha

.

Originaalkasutusjuhend

Universaalne järkamissaag

z

Πρωτότυπες Οδηγίες χρήσης

Φαλτσοπρίονο γενικής χρήσης

Art.-Nr.: 43.007.90 I.-Nr.: 01019

RT-XM

305 U

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:28 Uhr Seite 1

Page 2

k Vor Inbetriebnahme Bedienungsanleitung und Sicherheitshinweise lesen und beachten.

t Read and follow the operating instructions and safety information before using the

equipment for the first time.

p Avant la mise en service, lire le mode d’emploi ainsi que les consignes de sécurité et les

respecter

C Prima della messa in esercizio leggete e osservate le istruzioni per l’uso e le avvertenze di

sicurezza.

U Läs igenom och beakta bruksanvisningen och säkerhetsanvisningarna före användning.

N Vóór ingebruikneming de handleiding en de veiligheidsvoorschriften lezen en in acht

nemen!

m Leer detenidamente las instrucciones de uso y las advertencias de seguridad antes de

poner en marcha el aparato

q Ennen käyttöönottoa tulee lukea käyttöohje ja turvallisuusmääräykset ja noudattaa niitä

. Enne kasutuselevõttu lugege kasutusjuhendit ja ohutuseeskirju ning järgige neid

z Πριν τη θέση σε λειτουργία διαβάστε την Οδηγία χρήσης και ακολουθήστε τις

Υποδείξεις ασφαλείας

2

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:28 Uhr Seite 2

Page 3

2 3

25

29

20

26

29

19

1

1

2

4

7

9

10

11

15

1617

10

9

23

21

8

22

12

14

33

34

3

13

32

31

31

24

35

27

30

18

5

6

28

3

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:29 Uhr Seite 3

Page 4

4 5

7

6

C

8

D

A

L

K

I

H

C

F

E

18

9

A

C

N

C

B

A

C

E

F

P

23

A

29

30

10

A

B

B

G

M

ON

9

10

Q

R

8

21

D

F

A

4

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:29 Uhr Seite 4

Page 5

9 10

11

1

12

1

13

14

L

L

H,G

E

E

C

C

B

A

K,I

C

B

A

B

L

C

A

B

A

C

5

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:29 Uhr Seite 5

Page 6

15 16

17

1

18

F

L

B

19

20

B

E

C

K,I

F

B

F

D

D

K,I

F

F

E

B

A

B

B

E

F

6

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:29 Uhr Seite 6

Page 7

22

23

24

25

31

37

22

21

F

E

38

B

C

Q

R

B

2.

1.

7

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:29 Uhr Seite 7

Page 8

26 27

28

7

29

38

O

30

31

17

7

b

17

20

19

37

O

19

20

a

8

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 8

Page 9

33

34

36

35

37

23

1.

2.

32

4039

34

35

23 33

9

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 9

Page 10

39

40

42

41

43

21

29

38

5

6

P

25

24

7

8

10

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 10

Page 11

4544

11

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 11

Page 12

Inhaltsverzeichnis: Seite

1. Sicherheitshinweise 13

2. Gerätebeschreibung 13

3. Lieferumfang 13

4. Bestimmungsgemäße Verwendung 14

5. Technische Daten 14

6. Vor Inbetriebnahme 15

7. Betrieb als Holz-/Kunststoffsäge 16

8. Betrieb als Metallsäge 18

9. Transport 18

10. Austausch der Netzanschlussleitung 18

11. Reinigung, Wartung und Ersatzteilbestellung 18

12. Entsorgung und Wiederverwertung 19

D

12

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 12

Page 13

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut auf,

damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen zur Folge haben.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

2. Gerätebeschreibung

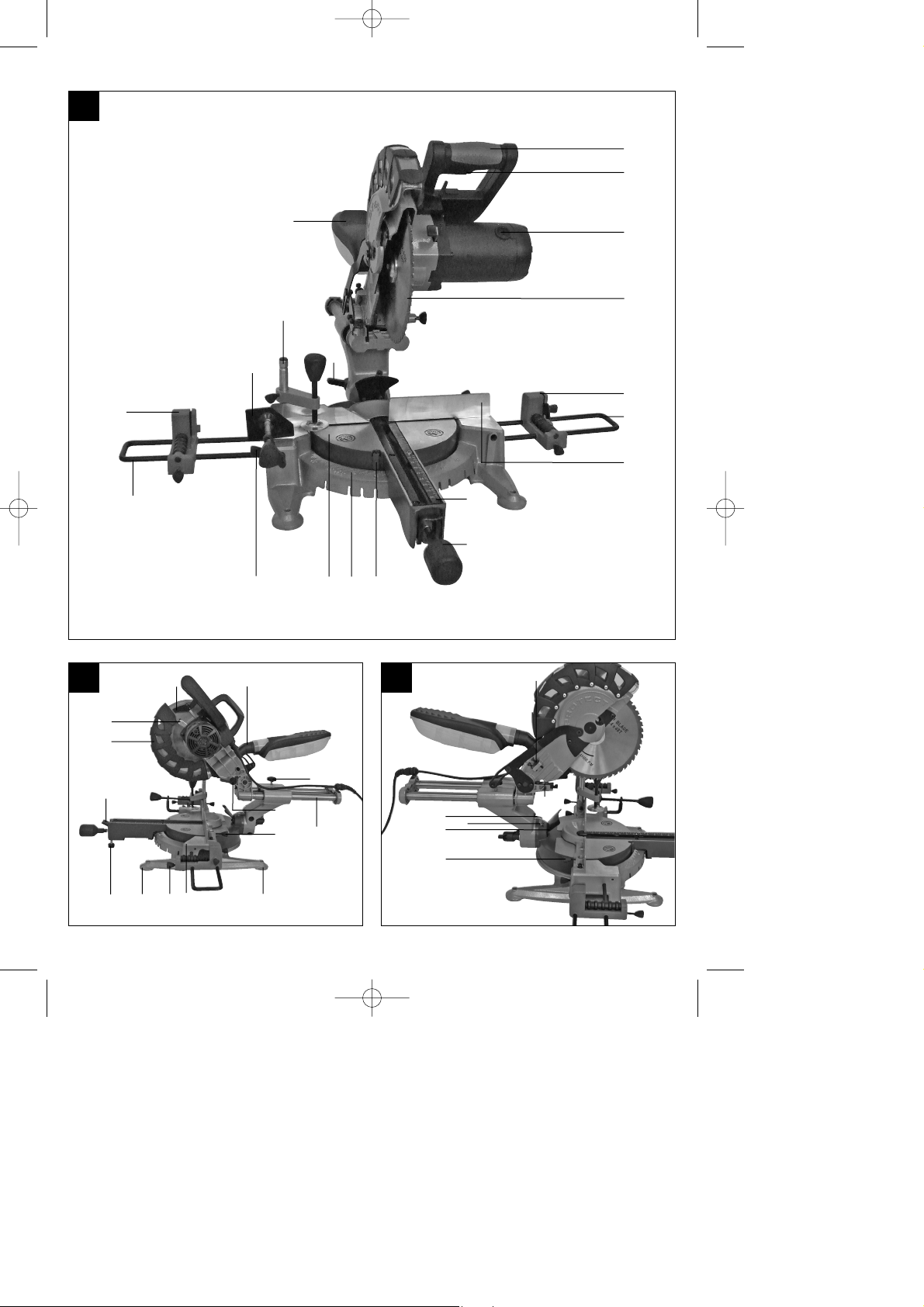

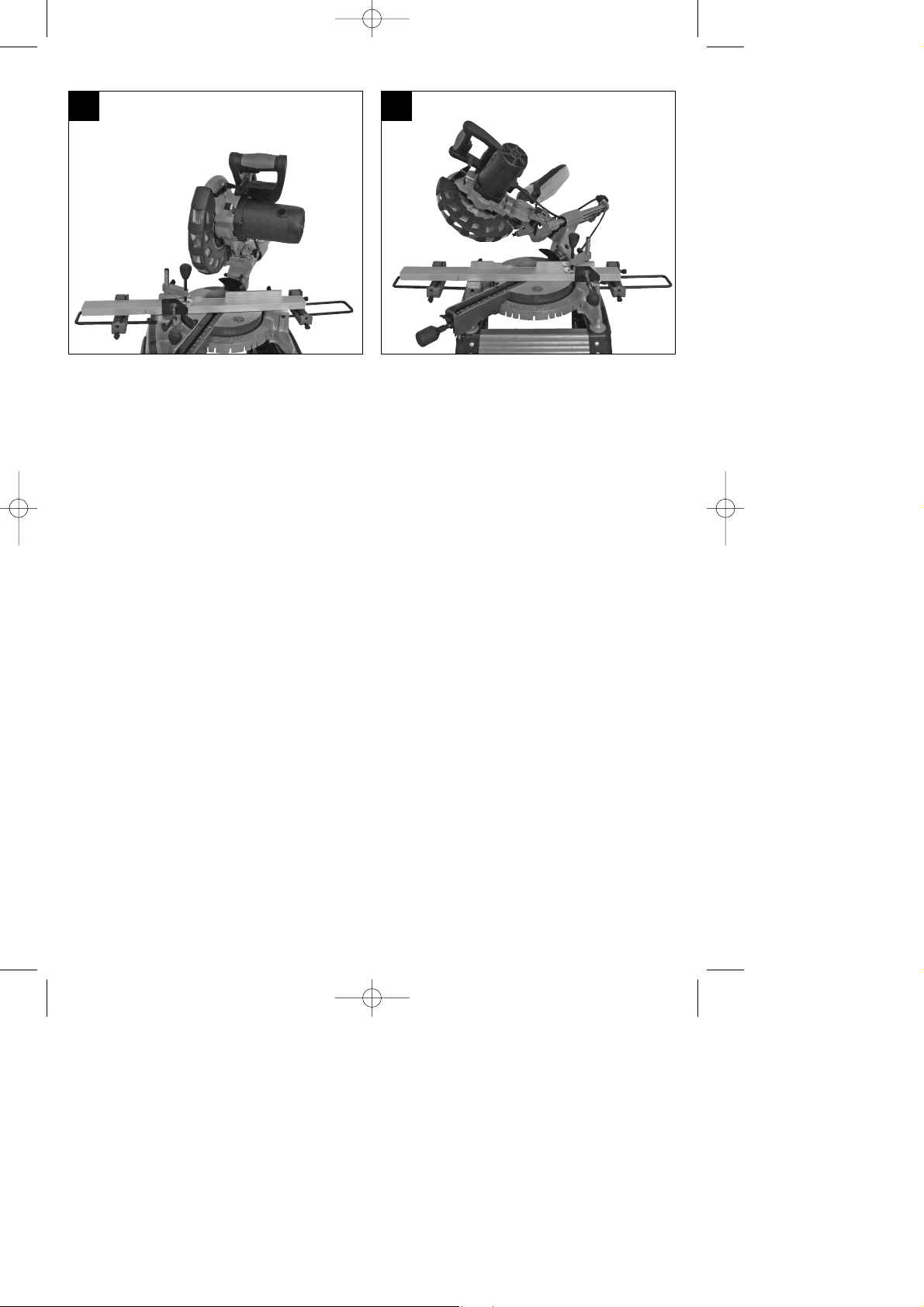

2.1 Zug-, Kapp- und Gehrungssäge (Bild 1-3)

1. Handgriff

2. Ein-/Ausschalter

3. Entriegelungshebel

4. Maschinenkopf

5. Sägewellensperre

6. Sägeblattschutz beweglich

7. Sägeblatt

8. Spannvorrichtung senkrecht

9. Rollauflage mit Endanschlag

10. Haltebügel für Rollauflage

11. Anschlagschiene

12. Tischeinlage mit Skala für Schnittlänge

13. Raststellungshebel

14. Feststellgriff

15. Zeiger

16. Skala

17. Drehtisch

18. feststehender Sägetisch

19. Skala

20. Zeiger

21. Spannvorrichtung waagrecht

22. Feststellschraube

23. Spänefangbox

24. Zugführung

25. Feststellschraube für Zugführung

26. Schutz

27. Sicherungsbolzen

28. Feststellschraube für waagrechte

Spannvorrichtung

29. Feststellschraube für senkrechte

Spannvorrichtung

30. Feststellschraube für Rollauflage

31. Standfuß mit Gummipuffer

32. Stützfuß

33. Absaugadapter

34. Rändelschraube für Schnitttiefenbegrenzung

35. Anschlag für Schnitttiefenbegrenzung

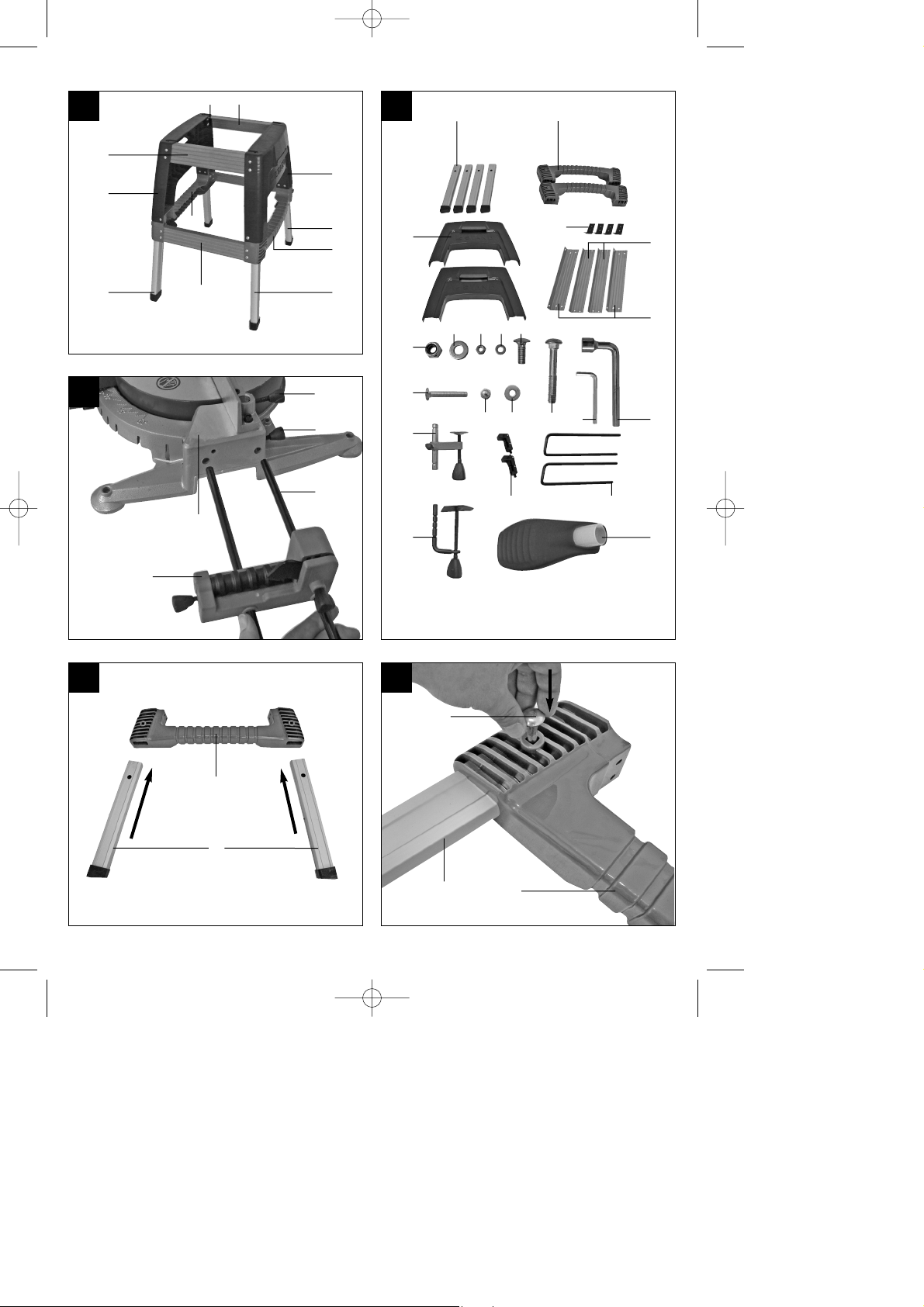

2.2 Untergestell (Bild 4)

A. Standfüße

B. Seitenteil

C. Zwischenstrebe

D. Eckversteifung

E. Untere Querstreben

F. Obere Querstreben

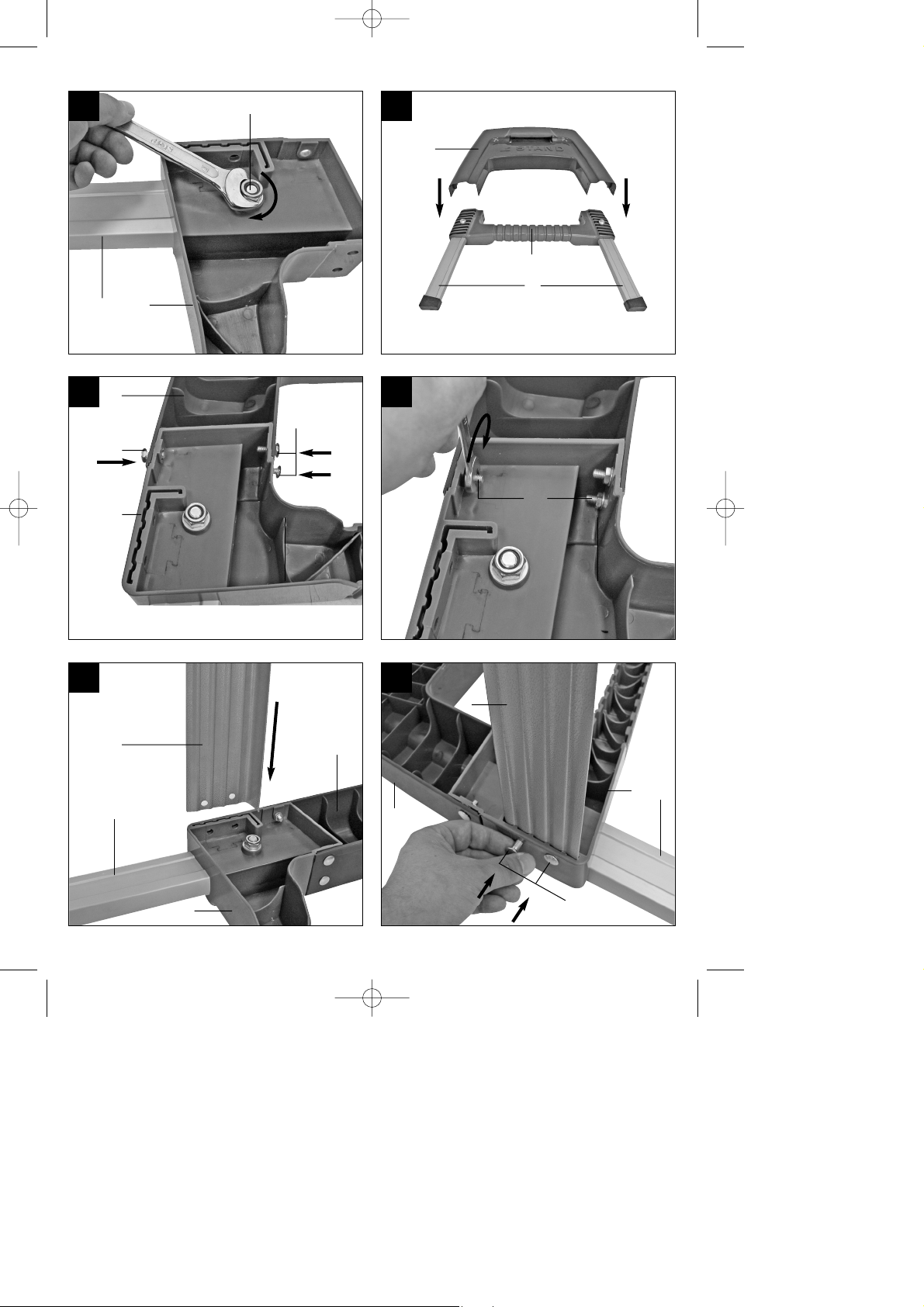

3. Lieferumfang (Bild 1, 5)

Zug-, Kapp und Gehrungssäge

Spannvorrichtung (8)

Rollauflage mit Endanschlag (9)

2 x Haltebügel für Rollauflage (10)

Spänefangbox (23)

4 x Standfüße (A)

2 x Seitenteil (B)

2 x Zwischenstrebe (C)

4 x Eckversteifung (D)

2 x Untere Querstreben (E)

2 x Obere Querstreben (F)

4 x Mutter (G)

4 x Beilagscheibe (H)

28 x Mutter (I)

28 x Beilagscheibe (K)

28 x Schraube (L)

4 x Schraube (N)

Inbusschlüssel (O)

Inbusschlüssel (P)

4 x Schraube (M)

4 x Beilagscheibe (Q)

4 x Hutmutter (R)

D

13

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 13

Page 14

4. Bestimmungsgemäße Verwendung

Die Universalsäge dient zum Kappen von Holz und

Kunststoff. Sie kann entsprechend der

Betriebsanleitung auch zum Sägen von hohlen

Metallprofilen mit rechteckigem Querschnitt

verwendet werden. Das Sägen von Metallprofilen

darf nur mit Kappschnitten erfolgen. Die Maschine ist

ausdrücklich nicht geeignet zum Sägen von Metall

mit einer Zugfestigkeit über 400 N/mm², gehärteten

Metallen, entzündlichen und reaktiven Metallen (wie

z.B. Magnesium und Magnesiumlegierungen),

Rundmaterial aller Art, Brennholz.

Die Maschine darf nur nach ihrer Bestimmung

verwendet werden. Jede weitere darüber hinausgehende Verwendung ist nicht bestimmungsgemäß.

Für daraus hervorgerufene Schäden oder

Verletzungen aller Art haftet der Benutzer/Bediener

und nicht der Hersteller.

Bitte beachten Sie, dass unsere Geräte

bestimmungsgemäß nicht für den gewerblichen,

handwerklichen oder industriellen Einsatz konstruiert

wurden. Wir übernehmen keine Gewährleistung,

wenn das Gerät in Gewerbe-, Handwerks- oder

Industriebetrieben sowie bei gleichzusetzenden

Tätigkeiten eingesetzt wird.

Es dürfen nur für die Maschine geeignete Sägeblätter

verwendet werden. Die Verwendung von

Trennscheiben aller Art ist untersagt.

Bestandteil der bestimmungsgemäßen Verwendung

ist auch die Beachtung der Sicherheitshinweise,

sowie die Montageanleitung und Betriebshinweise in

der Bedienungsanleitung.

Personen, die die Maschine bedienen und warten,

müssen mit dieser vertraut und über mögliche

Gefahren unterrichtet sein. Darüber hinaus sind die

geltenden Unfallverhütungsvorschriften genauestens

einzuhalten. Sonstige allgemeine Regeln in

arbeitsmedizinischen und sicherheitstechnischen

Bereichen sind zu beachten.

Veränderungen an der Maschine schließen eine

Haftung des Herstellers und daraus entstehende

Schäden gänzlich aus. Trotz bestimmungsgemäßer

Verwendung können bestimmte Restrisikofaktoren

nicht vollständig ausgeräumt werden. Bedingt durch

Konstruktion und Aufbau der Maschine können

folgende Punkte auftreten:

Berührung des Sägeblattes im nicht abgedeckten

Sägebereich.

Eingreifen in das laufende Sägeblatt

(Schnittverletzung)

Rückschlag von Werkstücken und

Werkstückteilen.

Sägeblattbrüche.

Herausschleudern von fehlerhaften

Hartmetallteilen des Sägeblattes.

Gehörschäden bei Nichtverwendung des nötigen

Gehörschutzes.

Gesundheitsschädliche Emissionen von Metall-

und Holzstäuben bei Verwendung in

geschlossenen Räumen.

Schnittverletzungen an Spänen und

Werkstücken.

Augenverletzungen durch Metallspäne.

5. Technische Daten

Wechselstrommotor: 230V ~ 50Hz

Leistung: 1800 W

Betriebsart: S1

Leerlaufdrehzahl n0: 2500 min

-1

Hartmetallsägeblatt: ø 250 x ø 30 x 2,2 mm

Anzahl der Zähne: 48

Schwenkbereich: -52° / 0°/ +60°

Gehrungsschnitt: 0° bis 45° nach links

Sägebreite bei 90°:

Holz: 305 x 75 mm

Metall: 105 x 75 mm

Sägebreite bei 45°:

Holz: 210 x 75 mm

Metall: 70 x 75 mm

Sägebreite bei 2 x 45° (Doppelgehrungsschnitt):

Holz: 210 x 40 mm

Metall: 70 x 40 mm

Gewicht: ca. 17,5 kg

Geräusch und Vibration

Die Geräusch- und Vibrationswerte wurden

entsprechend EN 13898 ermittelt.

Schalldruckpegel L

pA

93,7 dB(A)

Unsicherheit K

pA

2 dB

Schallleistungspegel L

WA

108,5 dB(A)

Unsicherheit K

WA

2 dB

Tragen Sie einen Gehörschutz.

Die Einwirkung von Lärm kann Gehörverlust

bewirken.

D

14

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 14

Page 15

”Die angegebenen Werte sind Emissionswerte und

müssen damit nicht zugleich auch sichere

Arbeitsplatzwerte darstellen. Obwohl es eine

Korrelation zwischen Emissions- und

Immissionspegeln gibt, kann daraus nicht

zuverlässig abgeleitet werden, ob zusätzliche

Vorsichtsmaßnahmen notwendig sind oder nicht.

Faktoren, welche den derzeitigen am Arbeitsplatz

vorhandenen Immissionspegel beeinflussen können,

beinhalten die Dauer der Einwirkungen, die Eigenart

des Arbeitsraumes, andere Geräuschquellen usw.,

z.B. die Anzahl der Maschinen und anderen

benachbarten Vorgängen. Die zuverlässigen

Arbeitsplatzwerte können ebenso von Land zu Land

variieren. Diese Information soll jedoch den

Anwender befähigen, eine bessere Abschätzung von

Gefährdung und Risiko vorzunehmen.”

Schwingungsgesamtwerte (Vektorsumme dreier

Richtungen) ermittelt entsprechend EN 61029.

Schwingungsemissionswert a

h

= 1,068 m/s

2

Beschränken Sie die Geräuschentwicklung und

Vibration auf ein Minimum!

Verwenden Sie nur einwandfreie Geräte.

Warten und reinigen Sie das Gerät regelmäßig.

Passen Sie Ihre Arbeitsweise dem Gerät an.

Überlasten Sie das Gerät nicht.

Lassen Sie das Gerät gegebenenfalls

überprüfen.

Schalten Sie das Gerät aus, wenn es nicht

benutzt wird.

Tragen Sie Handschuhe.

6. Vor Inbetriebnahme

6.1 Allgemein

Die Maschine muss standsicher aufgestellt

werden, d.h. auf einer Werkbank, dem

serienmäßigen Untergestell o. ä. festschrauben.

Vor Inbetriebnahme müssen alle Abdeckungen

und Sicherheitsvorrichtungen ordnungsgemäß

montiert sein.

Das Sägeblatt muss frei laufen können.

Bei bereits bearbeitetem Holz auf Fremdkörper

wie z.B. Nägel oder Schrauben usw. achten.

Bevor Sie den Ein- / Ausschalter betätigen,

vergewissern Sie sich, ob das Sägeblatt richtig

montiert ist und bewegliche Teile leichtgängig

sind.

Überzeugen Sie sich vor dem Anschließen der

Maschine, dass die Daten auf dem Typenschild

mit den Netzdaten übereinstimmen.

6.2 Säge montieren (Bild 1-3; 6)

Zum Verstellen des Drehtisches (17) den

Feststellgriff (14) ca. 2 Umdrehungen lockern um

den Drehtisch (17) zu entriegeln.

Raststellungshebel (13) drücken, Drehtisch (17)

und Zeiger (15) auf das gewünschte Winkelmaß

der Skala (16) drehen und mit dem Feststellgriff

(14) fixieren. Die Säge besitzt Raststellungen bei

den Positionen -45°, -30°, -22,5°, -15°, 0°, 15°,

22,5°, 30°, 45° und 60°, an denen man den

Raststellungshebel einrasten lassen kann.

Durch leichtes Drücken des Maschinenkopfes (4)

nach unten und gleichzeitiges Herausziehen des

Sicherungsbolzens (27) aus der Motorhalterung,

wird die Säge aus der unteren Stellung

entriegelt. Drehen Sie den Sicherungsbolzen

(27) um 90° bevor sie ihn loslassen, damit die

Säge entriegelt bleibt.

Maschinenkopf (4) nach oben schwenken, bis

der Entriegelungshebel (3) einrastet.

Die Vorrichtungen (8, 21) können sowohl links

als auch rechts am feststehenden Sägetisch (18)

montiert werden.

Feststellschrauben für Rollauflage (30) lösen.

Die Rollauflage mit Endanschlag (9) über einen

der Haltebügel für Rollauflage (10) führen und

diese am feststehenden Sägetisch (18)

montieren, entsprechende Feststellschraube (30)

anziehen (Bild 6).

Den zweiten Haltebügel für Rollauflage (10) auf

der gegenüberliegenden Seite der Säge

montieren und mit der entsprechenden

Feststellschraube (30) sichern.

Der Maschinenkopf (4) kann durch lösen der

Feststellschraube (22), nach links auf max. 45°

geneigt werden.

Wird die Säge ohne Untergestell verwendet, so

dient der Stützfuß (32) dazu, dass die Säge im

Betrieb nicht nach vorne kippen kann. Drehen

Sie dazu den Stützfuß (32) heraus, bis er die

Stellfläche der Säge berührt.

6.3 Untergestell montieren und Säge am

Untergestell verschrauben (Bild 4-24)

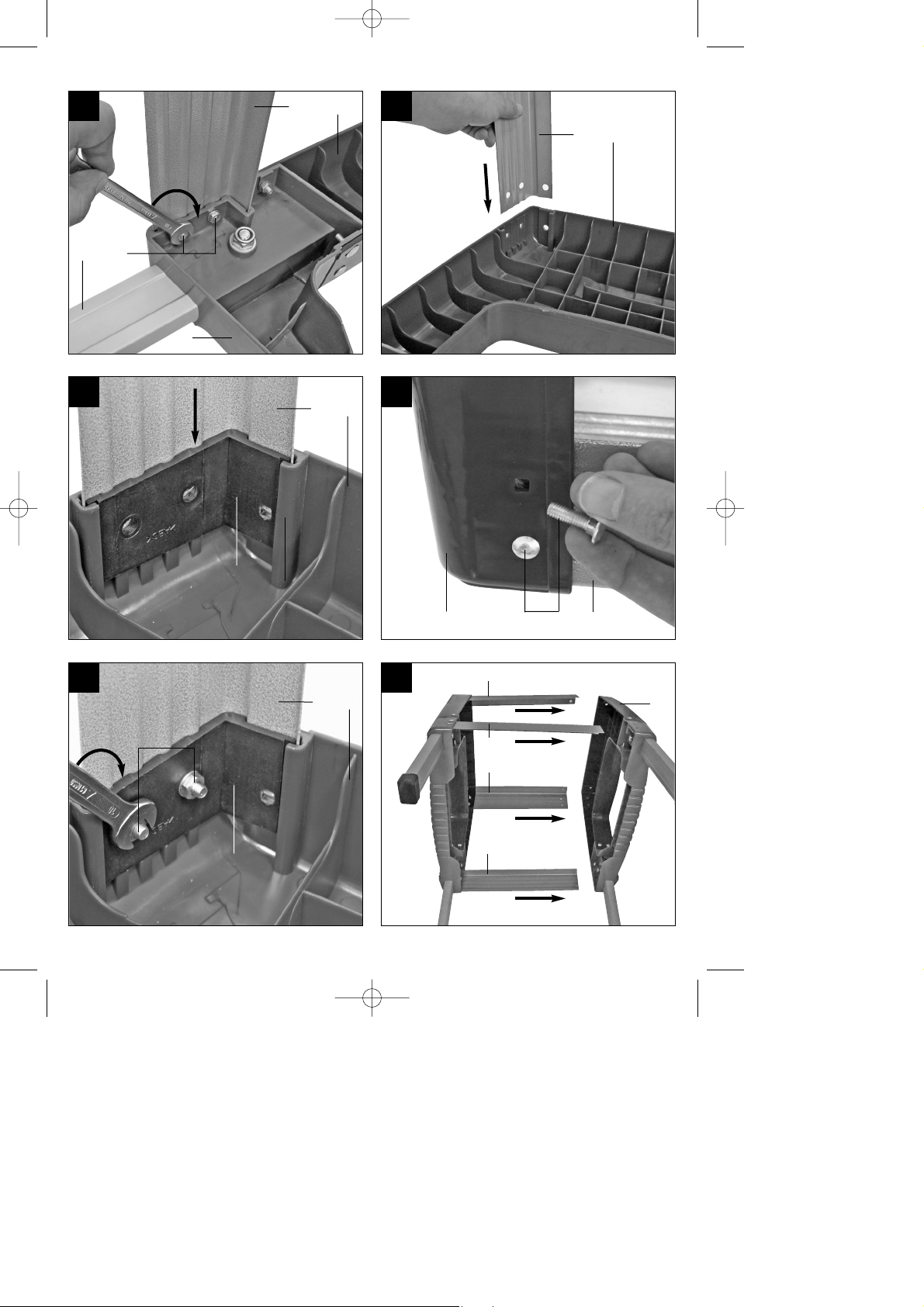

1. Die Standfüße (A), wie in Bild 7 dargestellt, von

unten in die Zwischenstreben (C) stecken.

Beachten, dass die Gummifüße an den

Standfüßen (A) so ausgerichtet sind, dass die

Auflageflächen gerade sind.

2. Standfüße (A) mit den Schrauben (N), den

Beilagscheiben (H) und Muttern (G), wie in den

Bildern 8 - 9 dargestellt, an den Zwischenstreben

(C) verschrauben.

3. Seitenteile (B) von oben über die

Zwischenstreben (C) führen (Bild 10).

4. Seitenteile (B) an jeder Verbindungsstelle mit 3

D

15

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 15

Page 16

Schrauben (L), Beilagscheiben (K) und Muttern

(I) mit den Zwischenstreben (C) verschrauben

(Bild 11 - 12).

5. Die beiden unteren Querstreben (E) bis zum

Anschlag in die entsprechenden Aussparungen

einer der Zwischenstreben (C) stecken (Bild 13).

Untere Querstreben (E) mit jeweils 2 Schrauben

(L), Beilagscheiben (K) und Muttern (I), wie in

Bild 14 – 15 dargestellt, an der Zwischenstrebe

(C) verschrauben.

6. An der selben Untergestellhälfte die beiden

oberen Querstreben (F) bis zum Anschlag in die

entsprechenden Aussparungen des Seitenteils

(B) führen (Bild 16). Jeweils eine Eckversteifung

(D) mit in die Aussparung des Seitenteils (B)

stecken. Beachten Sie, dass die

Eckversteifungen (D) jeweils nur an einer Seite

des Untergestells passen, dies ist der Fall wenn

die Löcher in Seitenteil (B), oberen Querstreben

(F) und Eckversteifungen (D) deckungsgleich

sind (Bild 17).

7. Nun obere Querstreben (F), Eckversteifungen

(D), Seitenteil (B), wie in Bild 18 – 19 dargestellt,

mit jeweils 2 Schrauben (L), Beilagscheiben (K)

und Muttern (I) verschrauben.

8. Die beiden Untergestellhälften so zusammen

stecken, dass die unteren und oberen

Querstreben (E, F) in den entsprechenden

Aussparungen an Seitenteil (B) und

Zwischenstrebe (C) sitzen (Bild 20).

9. Untere Querstreben (E) wie unter 5. beschrieben

an der zweiten Untergestellhälfte verschrauben

(Bild 21/1.).

10. Obere Querstreben (F) wie unter 6. beschrieben

an der zweiten Untergestellhälfte verschrauben

(Bild 21/2.).

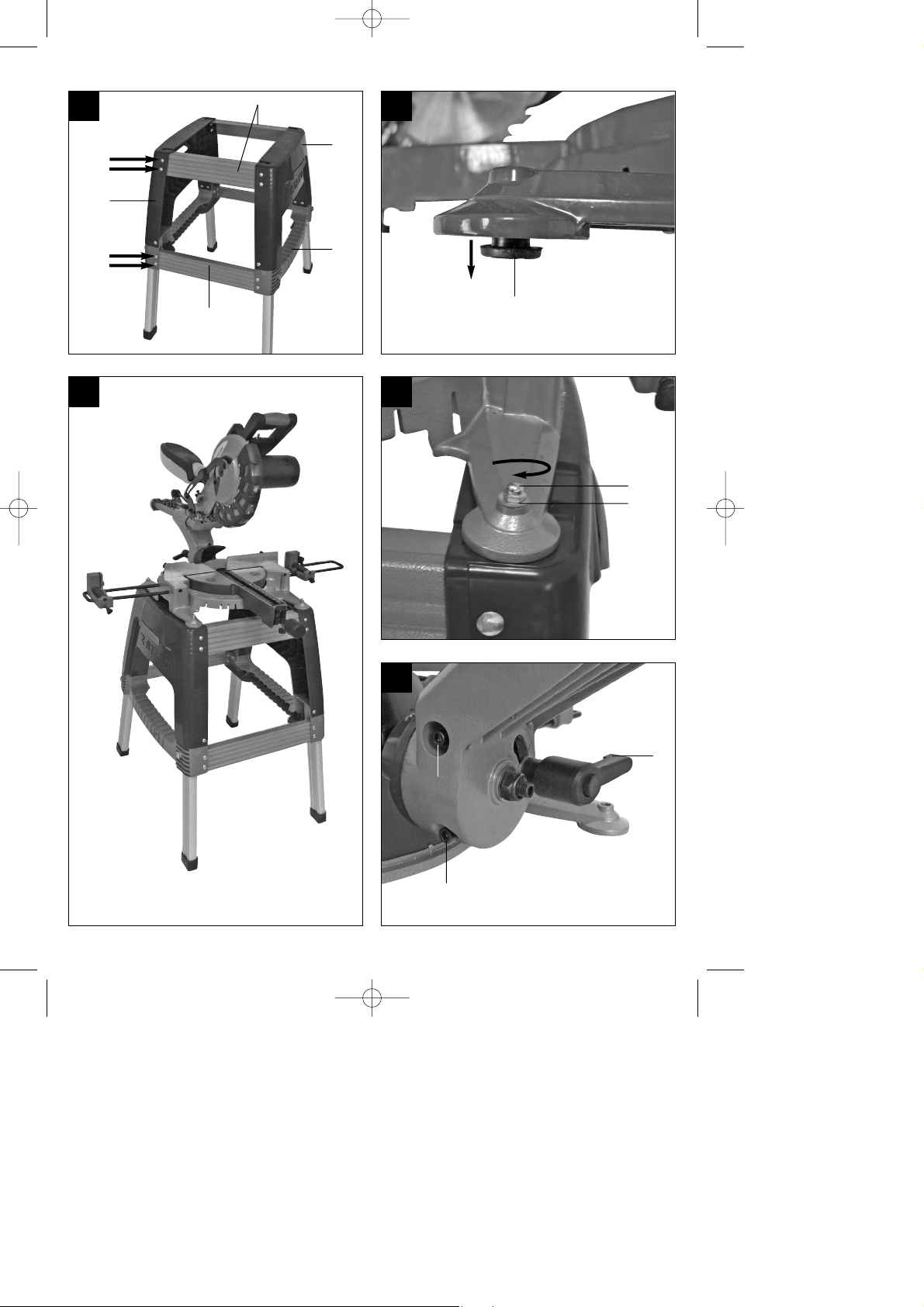

11. Die vier Gummipuffer (32) an der Unterseite der

Säge abziehen (Bild 22).

12. Die Säge so auf das Untergestell stellen, dass

die Löcher, in denen sich die Gummipuffer (32)

befunden haben, deckungsgleich mit den 4

Löchern an der Oberseite der Sägeaufnahmen

(J) sind. Nun die 4 Schrauben (M) von oben

durch die Sägefüße stecken und Säge mit dem

Untergestell verschrauben (Bild 23 – 24).

6.4 Feinjustierung des Anschlags für

Kappschnitt 90° (Bild 1, 25-27)

Den Drehtisch (17) auf 0° Stellung fixieren.

Feststellschraube (22) lockern und mit dem

Handgriff (1) den Maschinenkopf (4) ganz nach

rechts neigen.

90° Anschlagwinkel (a) zwischen Sägeblatt (7)

und Drehtisch (17) anlegen.

Justierschraube (38) soweit verstellen, bis der

Winkel zwischen Sägeblatt (7) und Drehtisch

(17) 90° beträgt.

Überprüfen Sie abschließend die Position des

Zeigers (20) an der Skala (19) Falls erforderlich,

Zeiger (20) mit Kreuzschlitzschraubendreher

lösen, auf 0°-Position der Skala (19) setzen und

Halteschraube wieder festziehen.

Anschlagwinkel nicht im Lieferumfang

enthalten.

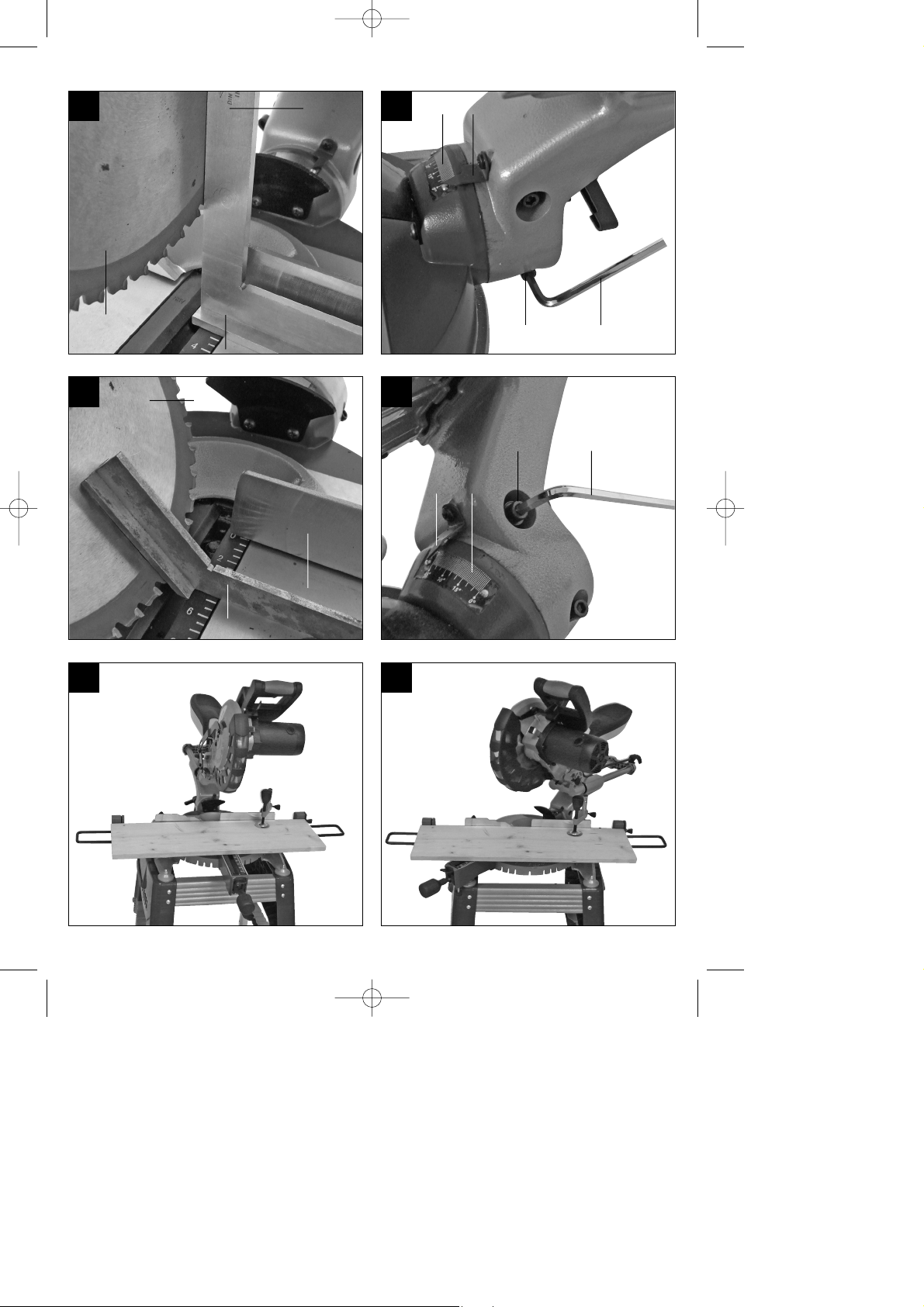

6.5 Feinjustierung des Anschlags für

Gehrungsschnitt 45° (Bild 1, 25, 28-29)

Den Drehtisch (17) auf 0° Stellung fixieren.

Feststellschraube (22) lösen und mit dem

Handgriff (1) den Maschinenkopf (4) ganz nach

links, auf 45° neigen.

45°-Anschlagwinkel (b) zwischen Sägeblatt (7)

und Drehtisch (17) anlegen.

Justierschraube (37) soweit verstellen, dass der

Winkel zwischen Sägeblatt (7) und Drehtisch

(17) genau 45° beträgt.

Anschlagwinkel nicht im Lieferumfang

enthalten.

7. Betrieb als Holz-/Kunststoffsäge

7.1 Kappschnitt 90° und Drehtisch 0°

(Bild 1–3, 30)

Bei Schnittbreiten bis ca. 100 mm kann die

Zugfunktion der Säge mit der Feststellschraube für

Zugführung (25) in der hinteren Position fixiert

werden. Sollte die Schnittbreite über 100 mm liegen,

muss darauf geachtet werden, dass die

Feststellschraube für Zugführung (25) locker und der

Maschinenkopf (4) beweglich ist.

Maschinenkopf (4) in die obere Position bringen.

Maschinenkopf (4) am Handgriff (1) nach hinten

schieben und gegebenenfalls in dieser Position

fixieren. (je nach Schnittbreite)

Legen Sie das zu schneidende Holz an die

Anschlagschiene (11) und auf den Drehtisch

(17).

Das Material mit der Spannvorrichtung (8) auf

dem feststehenden Sägetisch (18) feststellen,

um ein Verschieben während des

Schneidvorgangs zu verhindern.

Entriegelungshebel (3) drücken um den

Maschinenkopf (4) freizugeben.

Ein-/ Ausschalter (2) drücken, um den Motor

einzuschalten.

Bei fixierter Zugführung (24): Maschinenkopf (4)

mit dem Handgriff (1) gleichmäßig und mit

leichtem Druck nach unten bewegen, bis das

Sägeblatt (7) das Werkstück durchschnitten hat.

Bei nicht fixierter Zugführung (24):

Maschinenkopf (4) nach ganz nach vorne ziehen

16

D

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 16

Page 17

und dann mit dem Handgriff (1) gleichmäßig

und mit leichtem Druck ganz nach unten

absenken. Nun Maschinenkopf (4) langsam und

gleichmäßig ganz nach hinten schieben, bis das

Sägeblatt (7) das Werkstück vollständig

durchschnitten hat.

Nach Beendigung des Sägevorgangs

Maschinenkopf (4)wieder in die obere

Ruhestellung bringen und Ein-/ Ausschalter (2)

loslassen.

Achtung! Durch die Rückholfeder schlägt die

Maschine automatisch nach oben, d.h. Handgriff (1)

nach Schnittende nicht loslassen, sondern

Maschinenkopf (4) langsam und unter leichtem

Gegendruck nach oben bewegen.

7.2 Kappschnitt 90° und Drehtisch -52°...+60°

(Bild 1-3, 31)

Mit der Kappsäge können Kappschnitte von 0° - 52°

nach links und 0° - 60° nach rechts zur

Anschlagschiene ausgeführt werden.

Den Drehtisch (17) durch Lockern des

Feststellgriffes (14) lösen.

Raststellungshebel (13) drücken, Drehtisch (17)

und Zeiger (15) auf das gewünschte Winkelmaß

der Skala (16) drehen und mit dem Feststellgriff

(14) fixieren. Die Säge besitzt Raststellungen bei

den Positionen -45°, -30°, -22,5°, -15°, 0°, 15°,

22,5°, 30°, 45° und 60°, an denen man den

Raststellungshebel einrasten lassen kann.

Den Feststellgriff (14) wieder festziehen, um den

Drehtisch (17) zu fixieren.

Schnitt wie unter Punkt 7.1 beschrieben

ausführen.

7.3 Gehrungsschnitt 0°- 45° und Drehtisch 0°

(Bild 1–3, 32)

Mit der Kappsäge können Gehrungsschnitte nach

links von 0°- 45° zur Arbeitsfläche ausgeführt

werden.

Spannvorrichtung (8) gegebenenfalls

demontieren oder auf der gegenüberliegenden

Seite des feststehenden Sägetisches (18)

montieren.

Maschinenkopf (4) in die obere Stellung bringen.

Den Drehtisch (17) auf 0° Stellung fixieren.

Die Feststellschraube (22) lösen und mit dem

Handgriff (1) den Maschinenkopf (4) nach links

neigen, bis der Zeiger (20) auf das gewünschte

Maß auf der Skala (19) zeigt.

Feststellschraube (22) wieder festziehen und

Schnitt wie unter Punkt 7.1 beschrieben

durchführen.

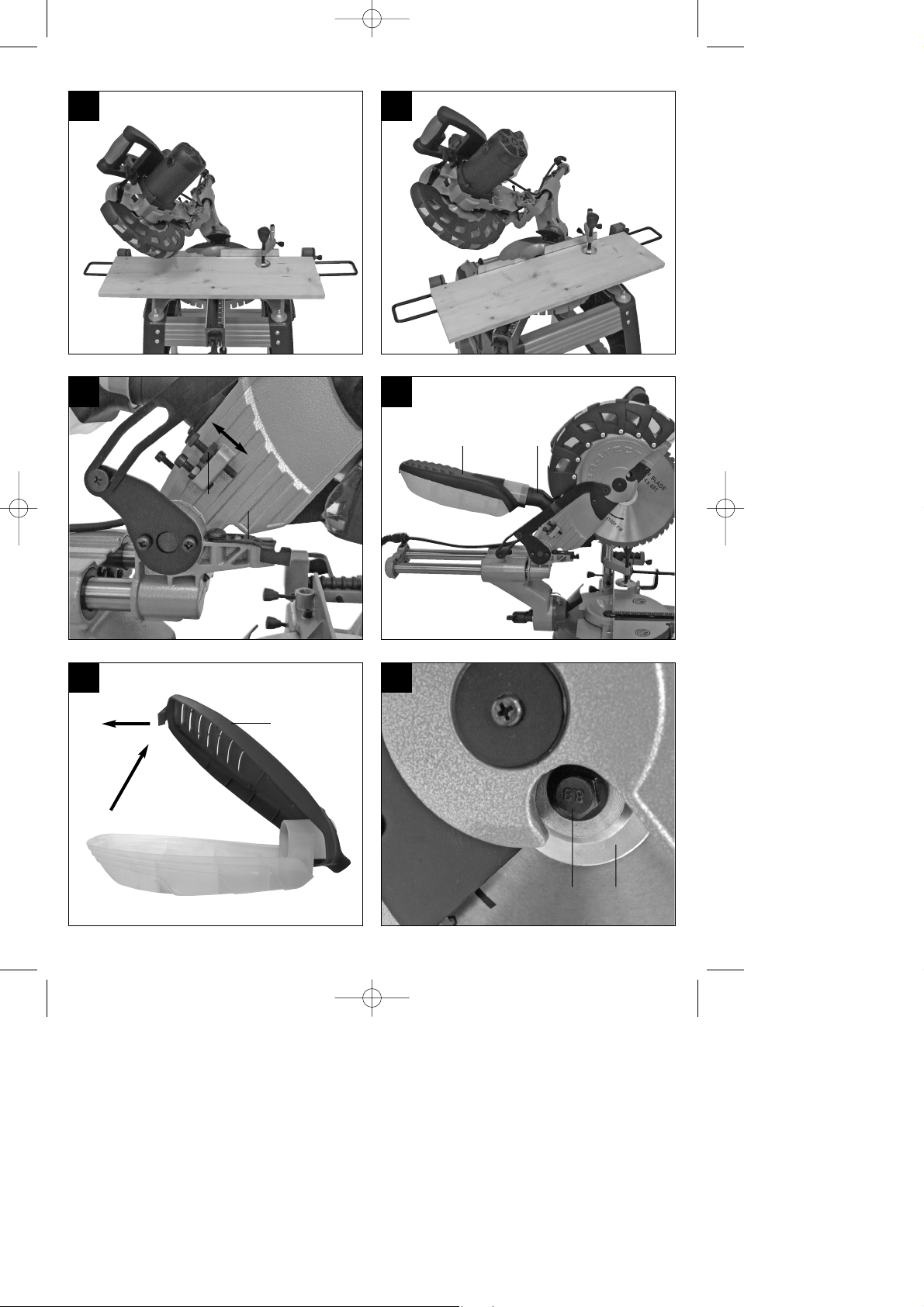

7.4 Gehrungsschnitt 0°- 45° und Drehtisch 0°- 45°

(Bild 1–3, 33)

Mit der Kappsäge können Gehrungsschnitte nach

links von 0°- 45° zur Arbeitsfläche und gleichzeitig

0°- 52° nach links bzw. 0° - 60° nach rechts zur

Anschlagschiene ausgeführt werden

(Doppelgehrungsschnitt).

Spannvorrichtung (8) gegebenenfalls demon-

tieren oder auf der gegenüberliegenden Seite

des feststehenden Sägetisches (18) montieren.

Maschinenkopf (4) in die obere Stellung bringen.

Den Drehtisch (17) durch Lockern des

Feststellgriffes (14) lösen.

Mit dem Handgriff (1) den Drehtisch (17) auf den

gewünschten Winkel einstellen (siehe hierzu

auch Punkt 7.2).

Den Feststellgriff (14) wieder festziehen, um den

Drehtisch zu fixieren.

Die Feststellschraube (22) lösen und mit dem

Handgriff (1) den Maschinenkopf (4) nach links,

auf das gewünschte Winkelmaß neigen (siehe

hierzu auch Punkt 7.3).

Feststellschraube (22) wieder festziehen.

Schnitt wie unter Punkt 7.1 beschrieben

ausführen.

7.5 Schnitttiefenbegrenzung (Bild 34)

Mittels der Schraube (34) kann die Schnitttiefe

stufenlos eingestellt werden. Lösen Sie hierzu

die Rändelmutter an der Schraube (34) und

klappen Sie den Anschlag für Schnitttiefenbegrenzung (35) nach außen. Stellen Sie die

gewünschte Schnitttiefe durch Eindrehen oder

Herausdrehen der Schraube (34) ein und ziehen

Sie die Rändelmutter an der Schraube (34)

anschließend wieder fest.

Überprüfen Sie die Einstellung anhand eines

Probeschnittes.

7.6 Spänefangbox (Bild 35–36/Pos. 23)

Die Säge ist mit einer Spänefangbox (23) für Späne

ausgestattet. Die Spänefangbox (23) kann auf den

Absaugadapter (33) aufgesteckt werden.

Zum Entleeren der Spänefangbox (23) diese wie in

Bild 36 gezeigt aufklappen und vorsichtig ausklopfen.

Am Absaugadapter (33) kann auch eine geeignete

Staubabsaug-Vorrichtung angeschlossen werden.

7.7 Austausch des Sägeblatts (Bild 1, 37-40)

Netzstecker ziehen!

Den Maschinenkopf (4) nach oben schwenken

und durch den Sicherungsbolzen (27) in dieser

Position arretieren.

Entriegelungshebel (3) drücken und

17

D

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 17

Page 18

D

18

Sägeblattschutz (6) so weit nach oben klappen,

dass die Aussparung im Sägeblattschutz (6)

über der Flanschschraube (39) ist.

Mit einer Hand drücken Sie die

Sägewellensperre (5) mit der anderen Hand

setzen Sie den Schlüssel (P) auf die

Flanschschraube (39).

Drücken Sie fest auf die Sägewellensperre (5)

und drehen Sie die Flanschschraube (39)

langsam im Uhrzeigersinn. Nach max. einer

Umdrehung rastet die Sägewellensperre (5) ein.

Jetzt mit etwas mehr Kraftaufwand

Flanschschraube (39) im Uhrzeigersinn lösen.

Drehen Sie die Flanschschraube (39) ganz her-

aus und nehmen Sie den Außenflansch (40) ab.

Das Sägeblatt (7) vom Innenflansch abnehmen

und nach unten herausziehen.

Flanschschraube (39), Außenflansch (40) und

Innenflansch sorgfältig reinigen.

Das neue Sägeblatt (7) in umgekehrter

Reihenfolge wieder einsetzen und festziehen.

Achtung! Die Schnittschräge der Zähne d.h. die

Drehrichtung des Sägeblattes (7), muss mit der

Richtung des Pfeils auf dem Gehäuse

übereinstimmen.

Bevor Sie mit der Säge weiter arbeiten, ist die

Funktionsfähigkeit der Schutzeinrichtungen zu

prüfen.

Achtung! Nach jedem Sägeblattwechsel prüfen,

ob das Sägeblatt in senkrechter Stellung sowie

auf 45° gekippt, frei in der Tischeinlage (12)

läuft.

Achtung! Das Wechseln und Ausrichten des

Sägeblattes (7) muss ordnungsgemäß

ausgeführt werden.

8. Betrieb als Metallsäge

Achtung! Tragen sie Handschuhe (Schnittgefahr)

und eine geeignete Schutzbrille.

Es können Kappschnitte mit und ohne Gehrung

in den bei 7.) angegebenen Winkelbereichen

durchgeführt werden. Für Metall sind wegen der

Rückschlaggefahr ausschließlich Kappschnitte

möglich. Dazu muss die Zugführung (24) mit der

Feststellschraube fixiert werden.

Kehren sie vor der Benutzung Metallspäne von

der Maschine, um Verletzungen zu vermeiden.

Spannen Sie das Werkstück immer mit

senkrechter Spannvorrichtung (8) und

waagrechter Spannvorrichtung (21).

Drücken Sie den Ein-/Ausschalter (2). Lassen

Sie das Sägeblatt vor dem Schnitt auf volle

Drehzahl laufen.

Den Entriegelungshebel (3) drücken. Bei fixierter

Zugführung (24) den Maschinenkopf (4) mit dem

Handgriff (1) gleichmäßig, zügig und mit leichtem

Druck nach unten bewegen, bis das Werkstück

durchschnitten ist

Nach Beendigung des Sägevorganges

Maschinenkopf (4) wieder in die obere

Ruhestellung bringen und Ein-/Ausschalter (2)

loslassen.

Vor dem Entnehmen des Werkstücks das

Sägeblatt auslaufen lassen

Achtung: Durch die Rückholfeder schlägt die

Maschine automatisch nach oben, d.h. Handgriff

(1) nach Schnittende nicht loslassen, sondern

Maschinenkopf (4) langsam und unter leichtem

Gegendruck nach oben bewegen.

9. Transport (Abb. 1-3)

Feststellgriff (14) festziehen, um den Drehtisch

(17) zu verriegeln

Entriegelungshebel (3) betätigen, Maschinenkopf

(4) nach unten drücken und mit

Sicherungsbolzen (27) arretieren. Die Säge ist

nun in der unteren Stellung verriegelt.

Zugfunktion der Säge mit der Feststellschraube

für Zugführung (25) in der hinteren Position

fixieren.

Tragen Sie die Maschine am feststehenden

Sägetisch (18) oder, falls die Säge auf dem

Untergestell montiert ist, an den entsprechenden

Griffmulden des Untergestells.

Um die Maschine erneut aufzubauen, gehen Sie

nach Punkt 6.2 vor.

10. Austausch der

Netzanschlussleitung

Wenn die Netzanschlussleitung dieses Gerätes

beschädigt wird, muss sie durch den Hersteller oder

seinen Kundendienst oder eine ähnlich qualifizierte

Person ersetzt werden, um Gefährdungen zu

vermeiden.

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 18

Page 19

D

19

11. Reinigung, Wartung und

Ersatzteilbestellung

Ziehen Sie vor allen Reinigungsarbeiten den

Netzstecker.

11.1 Reinigung

Halten Sie Schutzvorrichtungen, Luftschlitze und

Motorengehäuse so staub- und schmutzfrei wie

möglich. Reiben Sie das Gerät mit einem

sauberen Tuch ab oder blasen Sie es mit

Druckluft bei niedrigem Druck aus.

Wir empfehlen, dass Sie das Gerät direkt nach

jeder Benutzung reinigen.

Reinigen Sie das Gerät regelmäßig mit einem

feuchten Tuch und etwas Schmierseife.

Verwenden Sie keine Reinigungs- oder

Lösungsmittel; diese könnten die Kunststoffteile

des Gerätes angreifen. Achten Sie darauf, dass

kein Wasser in das Geräteinnere gelangen kann.

11.2 Kohlebürsten

Bei übermäßiger Funkenbildung lassen Sie die

Kohlebürsten durch eine Elektrofachkraft überprüfen.

Achtung! Die Kohlebürsten dürfen nur von einer

Elektrofachkraft ausgewechselt werden.

11.3 Wartung

Im Geräteinneren befinden sich keine weiteren zu

wartenden Teile.

11.4 Ersatzteilbestellung:

Bei der Ersatzteilbestellung sollten folgende

Angaben gemacht werden;

Typ des Gerätes

Artikelnummer des Gerätes

Ident-Nummer des Gerätes

Ersatzteilnummer des erforderlichen Ersatzteils

Aktuelle Preise und Infos finden Sie unter

www.isc-gmbh.info

12. Entsorgung und Wiederverwertung

Das Gerät befindet sich in einer Verpackung um

Transportschäden zu verhindern. Diese Verpackung

ist Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus

verschiedenen Materialien, wie z.B. Metall und

Kunststoffe. Führen Sie defekte Bauteile der

Sondermüllentsorgung zu. Fragen Sie im

Fachgeschäft oder in der Gemeindeverwaltung nach!

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 19

Page 20

GB

20

Table of contents: Page

1. Safety Information 21

2. Layout 21

3. Items supplied 21

4. Intended use 22

5. Technical data 22

6. Before starting the equipment 23

7. Operation as wood/plastics saw 24

8. Operation as metal saw 26

9. Transport 26

10. Replacing the power cable 26

11. Cleaning, maintenance and ordering of spare parts 26

12. Disposal and recycling 26

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 20

Page 21

GB

21

Important.

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety information with due care. Keep this manual in

a safe place so that the information is available at all

times. If you give the equipment to any other person,

hand over these operating instructions and the safety

information as well. We cannot accept any liability for

damage or accidents which arise due to a failure to

follow these instructions and the safety information.

1. Safety Information

Please refer to the booklet included in delivery for the

safety information.

CAUTION

Read all the safety information and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

2. Layout

2.1 Drag, crosscut and miter saw (Fig. 1-3)

1. Handle

2. ON/OFF switch

3. Release lever

4. Machine head

5. Saw shaft lock

6. Movable blade guard

7. Saw blade

8. Vertical clamping device

9. Roll base with limit stop

10. Holding bar for the roll base

11. Stop rail

12. Table insert with cutting depth scale

13. Latched position lever

14. Locking grip

15. Pointer

16. Scale

17. Turntable

18. Fixed saw table

19. Scale

20. Pointer

21. Horizontal clamping device

22. Locking screw

23. Chip box

24. Drag guide

25. Locking screw for drag guide

26. Guard

27. Fastening bolt

28. Locking screw for the horizontal clamping device

29. Locking screw for the vertical clamping device

30. Locking screw for the roll base

31. Foot with rubber stopper

32. Foot

33. Extractor adapter

34. Knurled screw for cutting depth limiter

35. Stop for cutting depth limiter

2.2 Base frame (Fig. 4)

A. Feet

B. Side part

C. Intermediate strut

D. Corner bracing

E. Bottom cross strut

F. Top cross strut

3. Items supplied (Fig. 1, 5)

Drag, crosscut and miter Saw

Clamping device (8)

Roll base with limit stop (9)

2 x Holding bar for the roll base (10)

Chip box (23)

4 x Foot (A)

2 x Side part (B)

2 x Intermediate strut (C)

4 x Corner bracing (D)

2 x Bottom cross strut (E)

2 x Top cross strut (F)

4 x Nut (G)

4 x Washers (H)

28 x Nut (I)

28 x Washer (K)

28 x Screw (L)

4 x Screw (N)

Allen key (O)

Allen key (P)

4 x Screw (M)

4 x Washer (Q)

4 x Cap nut (R)

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 21

Page 22

4. Intended use

The universal saw is designed for cross-cutting wood

and plastic. In accordance with the operating

instructions the equipment can also be used to saw

hollow metal profiles with a rectangular cross-section.

Sawing metal profiles may only be carried out with

crosscuts. The equipment is expressly not permitted

to saw metal with a tensile strength of more than 400

N/mm², hardened metal, combustible and reactive

metals (such as magnesium and magnesium alloys),

all kinds of round materials and firewood.

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse.

The user / operator and not the manufacturer will be

liable for any damage or injuries of any kind caused

as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

The equipment is to be operated only with suitable

saw blades. It is prohibited to use any type of cuttingoff wheel.

To use the equipment properly you must also observe

the safety regulations, the assembly instructions and

the operating instructions to be found in this manual.

All persons who use and service the equipment have

to be acquainted with this manual and must be

informed about the machine’s potential hazards. It is

also imperative to observe the accident prevention

regulations in force in your area. The same applies for

the general rules of health and safety at work.

The manufacturer will not be liable for any changes

made to the equipment nor for any damage resulting

from such changes. Even when the equipment is

used as prescribed it is still impossible to eliminate

certain residual risk factors. The following hazards

may arise in connection with the machine’s

construction and design:

Contact with the saw blade in the uncovered saw

zone.

Reaching into the running saw blade (cut

injuries).

Kick-back of workpieces and parts of workpieces.

Saw blade fracturing.

Catapulting of faulty carbide tips from the saw

blade.

Damage to hearing if ear-muffs are not used as

necessary.

Harmful emissions of metal and wood dust when

used in closed rooms.

Cut injuries through contact with chips and

workpieces.

Eye injuries caused by small metal chips.

5. Technical data

AC motor: 230V ~ 50Hz

Power: 1800 W

Operating mode: S1

Idle speed n0: 2,500 min

-1

Carbide saw blade: ø 250 x ø 30 x 2.2 mm

Number of teeth: 48

Swiveling range: -52° / 0°/ +60°

Miter cut: 0° to 45° to the left

Saw width at 90°:

Wood: 305 x 75 mm

Metal: 105 x 75 mm

Saw width at 45°:

Wood: 210 x 75 mm

Metal: 70 x 75 mm

Saw width at 2 x 45° (double miter cut):

Wood: 210 x 40 mm

Metal: 70 x 40 mm

Weight: approx. 17.5 kg

Sound and vibration

Sound and vibration values were measured in

accordance with EN 13898.

LpAsound pressure level 93.7 dB(A)

KpAuncertainty 2 dB

LWAsound power level 108.5 dB(A)

KpAuncertainty 2 dB

Wear ear-muffs.

The impact of noise can cause damage to hearing.

“The quoted values are emission values and not

necessarily reliable workplace values. Although there

is a correlation between emission and immission

levels it is impossible to draw any certain conclusions

as to the need for additional precautions.

Factors with a potential influence on the actual

immission level at the workplace include the duration

of impact, the type of room, and other sources of

22

GB

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 22

Page 23

noise etc., e.g. the number of machines and other

neighboring operations. Reliable workplace values

may also vary from country to country. With this

information the user should at least be able to make a

better assessment of the dangers and risks involved.”

Total vibration values (vector sum of three directions)

determined in accordance with EN 61029.

Vibration emission value a

h

= 1.068 m/s

2

Reduce noise generation and vibration to a

minimum!

Use only equipment that is in perfect condition.

Maintain and clean the equipment regularly.

Adapt your working methods to the equipment.

Do not overload the equipment.

Have the equipment checked if necessary.

Switch off the equipment when not in use.

Wear gloves.

6. Before starting the equipment

6.1 General information

Before commissioning the machine, it must be

firmly mounted on a workbench; fully assemble

the underframe that came with the unit or similar.

All covers and safety devices have to be properly

fitted before the machine is switched on.

It must be possible for the blade to run freely.

When working with wood that has been

processed before, watch out for foreign bodies

such as nails or screws, etc.

Before you actuate the On/Off switch, make sure

that the saw blade is correctly fitted and that the

machine’s moving parts run smoothly.

Check that the voltage on the rating plate is the

same as your supply voltage before you connect

the machine to the power supply.

6.2 Assembling the saw (Fig. 1-3; 6)

To adjust the turntable (17), loosen the locking

grip (14) by approx. 2 turns, which frees the

turntable (17).

Press the latched position lever (13), turn the

turntable (17) and scale pointer (15) to the

desired angular setting on the dial (16) and lock

into place with the locking grip (14). The saw has

locking positions at angles of - -45°, -30°, -22.5°, 15°, 0°, 15°, 22.5°, 30°, 45° and 60°, at which you

can engage the latched position lever.

To release the saw from its position at the bottom,

pull the fastening bolt (27) out of the motor

mounting while pressing down lightly on the

machine head (4). Turn the fastening bolt (27)

through 90° before releasing it, so that the saw

remains unlocked.

Swing the machine head (4) up until the release

lever (3) latches into place.

The clamping devices (8, 21) can be fitted on the

left or right of the fixed saw table (18).

Undo the locking screws for the roll base (30).

Guide roll base with limit stop (9) over one of the

holding bars for the roll base (10) and install on

the fixed saw table (18), tightening the

appropriate locking screw (30) (Figure 6).

Mount the second holding bar for the roll base

(10) on the opposite side of the saw and secure

with the appropriate locking screw (30).

When the locking screw (22) is loosened, you can

tilt the machine head (4) to the left by up to 45°.

If the saw is used without the base frame, the foot

(32) will prevent the saw from tipping forwards

during operation. In this case, turn out the foot

(32) until it touches the surface on which the saw

is standing.

6.3 Assembling the base frame and bolting the

saw to the base frame (Fig. 4-24)

1. Insert the feet (A) from the bottom into the

intermediate struts (C) as shown in Figure 7.

Ensure that the rubber stoppers on the feet (A)

are aligned so that the support surfaces are level.

2. Screw the feet (A) to the intermediate struts (C)

together with the screws (N), washers (H) and

nuts (G), as shown in Figures 8 - 9.

3. Guide the side parts (B) from the top over the

intermediate struts (C).

4. At each connection point screw the side parts (B)

to the intermediate struts (C) using three screws

(L), washers (K) and nuts (I) (Figures 11-12).

5. Insert the two bottom cross struts (E) into the

appropriate openings on one of the intermediate

struts (C) as far as the stop (Figure 13). Screw

the bottom cross struts (E) to the intermediate

strut (C) using two screws (L), washers (K) and

nuts (I) in each case, as shown in Figures 14 - 15.

6. On the same side of the base frame, slide the two

top cross struts (F) as far as the stop into the

appropriate openings on the side part (B) (Figure

16). Insert a corner bracing (D) into each opening

on the side part (B). Note, that each of the corner

bracings (D) only fits on one side of the base

frame; this is the case when the openings on the

side part (B), the top cross struts (F) and the

corner bracings are positioned precisely on top of

each other (Figure 17).

7. Now screw the top cross struts (F), corner

bracings (D), side parts (B) together using two

screws (L), washers (K) and nuts (I) in each case,

23

GB

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 23

Page 24

as shown in Figures 18 - 19.

8. Insert the two base frame parts in such a way that

the bottom and top cross struts (E, F) are

positioned in the relevant openings on the side

part (B) and the cross strut (C) (Figure 20).

9. Screw the bottom cross struts (E) to the other part

of the base frame (Figure 21/1) as described

under 5.

10. Screw the top cross struts (F) to the other part of

the base frame (Figure 21/2) as described under

6.

11. Pull the four rubber stoppers (32) from the bottom

side of the saw (Figure 22).

12. Place the saw onto the base frame so that the

openings in which the rubber stoppers (32) were

held are in line with the four openings on the top

side of the saw mounts (J). Then insert the four

screws (M) through the feet from the top and

screw the saw onto the base frame (Fig. 23 – 24).

6.4 Precision adjustment of the stop for crosscut

90° (Fig. 1, 25/-27)

Fasten the turntable (17) in 0° position.

Undo the locking screw (22) and move the

machine head (4) all the way to the right using the

handle (1).

Place the 90° angular stop (a) between the blade

(7) and the turntable (17).

Adjust the adjustment screw (38) until the angle

between the blade (7) and the turntable (17)

equals 90°.

Finally, check the position of the pointer (20) on

the scale (19). If necessary, release the pointer

(20) with a crosstip screwdriver, move to the 0°

position of the scale (19) and retighten the

holding screw.

No stop angle included.

6.5 Precision adjustment of the stop for miter cut

45° (Fig. 1, 25, 28-29)

Fasten the turntable (17) in 0° position.

Undo the locking screw (22) and move the

machine head (4) all the way to the left using the

handle (1), until it coincides at 45°.

Place the 45° stop angle (b) between the blade

(7) and the turntable (17).

Adjust the adjustment screw (37) so that the

angle between the blade (7) and the turntable

(17) equals exactly 45°.

No stop angle included.

7. Operation as wood/plastics saw

7.1 Cross cut 90° and turntable 0° (Fig. 1-3, 30)

For cutting widths up to approx. 100 mm it is possible

to fix the saw’s drag function with the locking screw

for drag guide (25) in rear position. If the cutting width

exceeds 100 mm you must ensure that the locking

screw for drag guide (25) is slackened and that the

machine head (4) can be moved.

Move the machine head (4) to its upper position.

Use the handle (1) to push back the machine

head (4) and fix it in this position if required

(dependent on the cutting width).

Place the piece of wood to be cut at the stop rail

(11) and on the turntable (17).

Lock the material with the clamping device (8) on

the fixed saw table (18) to prevent the material

from moving during the cutting operation.

Push down the release lever (3) to release the

machine head (4).

Press the ON/OFF switch (2) to start the motor.

With the drag guide (24) fixed in place: Use the

handle (1) to move the machine head (4) steadily

and with light pressure downwards until the saw

blade (7) has completely cut through the

workpiece.

With the drag guide (24) not fixed in place: Pull

the machine head (4) all the way to the front and

then use the handle (1) to move it downwards

steadily and with light pressure. Now push the

machine head (4) slowly and steadily to the very

back until the saw blade (7) has completely cut

through the workpiece.

When the cutting operation is completed, move

the machine head (4) back to its upper (home)

position and release the ON/OFF button (2).

Important. The integral resetting springs will

automatically lift the machine head. Do not simply let

go of the handle (1) after cutting, but allow the

machine head (4) to rise slowly, applying slight

counterpressure as it does so.

7.2 Cross cut 90° and turntable -52°...+60°

(Fig. 1-3, 31)

The crosscut saw can be used to make crosscuts of

0°- 52° to the left and 0° - 60° to the right in relation to

the stop rail.

Release the turntable (17) by slackening the

locking grip (14).

Press the latched position lever (13), turn the

turntable (17) and scale pointer (15) to the

desired angular setting on the dial (16) and lock

into place with the locking grip (14). The saw has

locking positions at angles of - -45°, -30°, -22.5°, 15°, 0°, 15°, 22.5°, 30°, 45° and 60°, at which you

can engage latched position lever.

24

GB

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 24

Page 25

Retighten the locking grip (14) to secure the

turntable (17) in place.

Cut as described under section 7.1.

7.3 Miter cut 0°- 45° and turntable 0° (Fig. 1-3, 32)

The crosscut saw can be used to make miter cuts of

0° - 45° in relation to the work face.

If necessary, dismantle the clamping device (8) or

mount it on the opposite side of the fixed saw

table (18).

Move the machine head (4) to its upper position.

Fasten the turntable (17) in 0° position.

Undo the locking screw (22) and use the handle

(1) to tilt the machine head (4) to the left until the

pointer (20) coincides with the required value on

the scale (19).

Retighten the locking screw (22) and make the

cut as described in section 7.1.

7.4 Miter cut 0°- 45° and turntable 0°- 45°

(Fig. 1-3, 33)

The crosscut saw can be used to make miter cuts to

the left of 0°- 45° in relation to the work face and, at

the same time, 0° - 52° to the left or 0° - 60° to the

right in relation to the stop rail (double miter cut).

If required, dismantle the clamping device (8) or

mount on the opposite side of the fixed saw table

(18).

Move the machine head (4) to its upper position.

Release the turntable (17) by slackening the

locking grip (14).

Use the handle (1) to adjust the turntable (17) to

the angle required (in this connection see also

section 7.2).

Retighten the locking grip (14) to secure the

turntable in place.

Undo the locking screw (22) and use the handle

(1) to tilt the machine head (4) to the left until it

coincides with the required angle value (in this

connection see also section 7.3).

Re-tighten the fixing screw (22).

Cut as described under section 7.1.

7.5 Limiting the cutting depth (Fig. 34)

The cutting depth can be infinitely adjusted using

the screw (34). To do so, undo the knurled nut on

the screw (34) and move the stop for the cutting

depth limiter (35) to the outside. Turn the screw

(34) in or out to set the required cutting depth and

then retighten the knurled nut on the screw (34).

Check the setting by completing a test cut.

7.6 Chip box (Fig. 35-36/Item 23)

The saw is equipped with a chip box (23) for sawdust

and chips. The chip box (23) can be fitted onto the

extractor adapter (33).

To empty the chip box (23), flip the box open as

shown in Figure 36 and carefully empty it by tapping.

Alternatively, a suitable dust extraction device can be

fitted to the extractor adaptor (33).

7.7 Changing the saw blade (Fig. 1, 37-40)

Pull out the power plug!

Swing the machine head (4) upwards and lock in

this position with the fastening bolt (27).

Press the release lever (3) and swing up the saw

blade guard (6) to the point where the recess in

the saw blade guard (6) is above the flange bolt

(39).

Press the saw shaft lock (5) with one hand while

holding the wrench (P) on the flange bolt (39) with

the other.

Firmly press on the saw shaft lock (5) and slowly

rotate the flange bolt (39) in clockwise direction.

The saw shaft lock (5) engages after no more

than one rotation.

Now, using a little more force, slacken the flange

bolt (39) in the clockwise direction.

Turn the flange screw (39) right out and remove

the external flange (40).

Take the blade (7) off the inner flange and pull out

downwards.

Carefully clean the flange screw (39), outer flange

(40) and inner flange.

Fit and fasten the new saw blade (7) in reverse

order.

Important. The cutting angle of the teeth, in other

words the direction of rotation of the saw blade

(7) must coincide with the direction of the arrow

on the housing.

Check to make sure that all safety devices are

properly mounted and in good working condition

before you begin working with the saw again.

Important. Every time that you change the saw

blade, check to see that it spins freely in the table

insert (12) in both perpendicular and 45° angle

settings.

Important. The work to change and align the saw

blade (7) must be carried out correctly.

25

GB

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 25

Page 26

GB

26

8. Operation as metal saw

Important. Wear gloves (risk of injury) and

suitable safety goggles.

You can make crosscuts with and without miter in

the angle ranges listed in section 7.) When

working with metal, you can only make crosscuts

due to risk of kick-back. In this case the drag

guide (24) must be fixed with the locking screw.

Before using the equipment, sweep any small

metal chips away from the machine to protect

yourself against injury. Always clamp the

workpiece with the vertical clamping device (8)

and the horizontal clamping device (21).

Press the ON/OFF switch (2). Wait until the saw

blade reaches full speed before making a cut.

Press the release lever (3). With the drag guide

(24) fixed in place, use the handle (1) to move the

machine head (4) downwards steadily, quickly

and exerting slight pressure until the workpiece is

completely cut through.

When the cutting operation is completed, move

the machine head (4) back to its upper (home)

position and release the ON/OFF button (2).

Let the saw blade run to a complete stop before

removing the workpiece.

Important: The integral resetting springs will

automatically lift the machine head. Do not simply

let go of the handle (1) after cutting but allow the

machine head (4) to rise slowly, applying slight

counterpressure as it does so.

9. Transport (Fig. 1-3)

Retighten the locking grip (14) to secure the

turntable (17) in place.

Activate the release lever (3), press the machine

head (4) downwards and secure with the

fastening bolt (27). The saw is now locked in its

bottom position.

Fix the saw’s drag function with the locking screw

for the drag guide (25) in the rear position.

Carry the machine on the fixed saw table (18), or

if the saw is mounted to the base frame, on the

relevant trough handles on the base frame.

To set up the equipment again, proceed as

described in section 6.2.

10. Replacing the power cable

If the power cable for this equipment is damaged, it

must be replaced by the manufacturer or its aftersales service or similarly trained personnel to avoid

danger.

11. Cleaning, maintenance and

ordering of spare parts

Always pull out the mains power plug before starting

any cleaning work.

11.1 Cleaning

Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

down with compressed air at low pressure.

We recommend that you clean the equipment

immediately after you use it.

Clean the appliance regularly with a damp cloth

and some soft soap. Do not use cleaning agents

or solvents; these may be aggressive to the

plastic parts in the appliance. Ensure that no

water can get into the interior of the equipment.

11.2 Carbon brushes

In case of excessive sparking, have the carbon

brushes checked only by a qualified electrician.

Important. The carbon brushes should not be

replaced by anyone but a qualified electrician.

11.3 Servicing

There are no parts inside the equipment which

require additional maintenance.

11.4 Ordering replacement parts:

Please provide the following information on all orders

for spare parts:

Model/type of the equipment

Article number of the equipment

ID number of the equipment

Spare part number of the required spare part

For our latest prices and information please go to

www.isc-gmbh.info

12. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled.

The equipment and its accessories are made of

various types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 26

Page 27

F

27

Sommaire : Page

1. Consignes de sécurité 28

2. Description de l’appareil 28

3. Limite de fourniture 28

4. Utilisation conforme à l’affectation 29

5. Caractéristiques techniques 29

6. Avant la mise en service 30

7. Fonctionnement comme scie à bois/plastique 32

8. Fonctionnement comme scie à métaux 33

9. Transport 34

10. Remplacement de la ligne de raccordement réseau 34

11. Nettoyage, maintenance et commande de pièces de rechange 34

12. Mise au rebut et recyclage 34

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 27

Page 28

Attention !

Lors de l’utilisation d’appareils, il faut respecter

certaines mesures de sécurité afin d’éviter des

blessures et dommages. Veuillez donc lire

attentivement ce mode d’emploi/ces consignes de

sécurité. Veillez à le conserver en bon état pour

pouvoir accéder aux informations à tout moment. Si

l’appareil doit être remis à d’autres personnes, veillez

à leur remettre aussi ce mode d’emploi/ces

consignes de sécurité. Nous déclinons toute

responsabilité pour les accidents et dommages dus

au non-respect de ce mode d’emploi et des

consignes de sécurité.

1. Consignes de sécurité

Vous trouverez les consignes de sécurité

correspondantes dans le petit manuel ci-joint !

AVERTISSEMENT

Veuillez lire toutes les consignes de sécurité et

instructions. Tout non-respect des consignes de

sécurité et instructions peut provoquer une décharge

électrique, un incendie et/ou des blessures graves.

Conservez toutes les consignes de sécurité et

toutes les instructions pour l’avenir.

2. Description de l’appareil

2.1 Scie passe-partout, tronçonneuse à onglet

(figures 1-3)

1. Poignée

2. Interrupteur Marche / Arrêt

3. Levier de déverrouillage

4. Tête de la machine

5. Blocage de l’arbre de scie

6. Capot de protection de lame de scie amovible

7. Lame de scie

8. Dispositif tendeur vertical

9. Support roulant avec butée en fin de course

10. Etrier de retenue pour support roulant

11. Rail de butée

12. Insertion de table avec graduation pour la

longueur de coupe

13. Levier de l’échelle des degrés

14. Poignée de blocage

15. Pointeur

16. Graduation

17. Table tournante

18. Table de menuisier fixe

19. Graduation

20. Pointeur

21. Dispositif tendeur horizontal

22. Vis de fixation

23. Boîte collectrice de copeaux

24. Guidage tiré

25. Vis de fixation du guidage tiré

26. Dispositif de protection

27. Boulon de sécurité

28. Vis de fixation du dispositif tendeur horizontal

29. Vis de fixation du dispositif tendeur vertical

30. Vis de fixation du support roulant

31. Pied avec butoirs en caoutchouc

32. Pied de support

33. Adaptateur d’aspiration

34. Vis moletée de limitation de la profondeur de

coupe

35. Butée de limitation de la profondeur de coupe

2.2 Support (figure 4)

A. Pieds d’appui

B. Pièce latérale

C. Entretoise intermédiaire

D. Renfort d’angle

E. Entretoises transversales inférieures

F. Entretoises transversales supérieures

3. Volume de livraison (figures 1, 5)

Scie passe-partout, tronçonneuse à onglet

Dispositif tendeur (8)

Support roulant avec butée en fin de course (9)

2 x étriers de retenue pour support roulant (10)

Boîte collectrice de copeaux (23)

4 x pieds (A)

2 x pièces latérales (B)

2 x entretoises intermédiaires (C)

4 x renforts d’angle (D)

2 x entretoises transversales inférieures (E)

2 x entretoises transversales supérieures (F)

4 x écrous (G)

4 x rondelles (H)

28 x écrous (I)

28 x rondelles (K)

28 x vis (L)

4 x vis (N)

Clé à six pans creux (O)

Clé à six pans creux (P)

4 x vis (M)

4 x rondelles (Q)

4 x écrous borgnes (R)

28

F

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 28

Page 29

4. Utilisation conforme à l’affectation

La scie universelle sert à tronçonner le bois et le

plastique. Conformément au mode d’emploi, elle peut

également être utilisée pour scier des profilés

métalliques creux à coupe transversale rectangulaire.

Sciez les profilés métalliques uniquement par

tronçonnage. La machine ne convient absolument

pas au tronçonnage du métal ayant une résistance à

la traction supérieure à 400 N/mm², des métaux

trempés, des métaux inflammables et réactifs

(comme par ex. le magnésium et les alliages de

magnésium), des matériaux ronds de tout genre, du

bois de chauffage.

La machine doit exclusivement être employée

conformément à son affectation. Chaque utilisation

allant au-delà de cette affectation est considérée

comme non conforme.

Pour les dommages en résultant ou les blessures de

tout genre, le producteur décline toute responsabilité

et l’opérateur/l’exploitant est responsable.

Veillez au fait que nos appareils, conformément au

règlement, n’ont pas été conçus pour être utilisés

dans un environnement professionnel, industriel ou

artisanal. Nous déclinons toute responsabilité si

l’appareil venait à être utilisé professionnellement,

artisanalement ou par des sociétés industrielles, tout

comme pour toute activité équivalente.

Seules les lames de scie adéquates à la machine

doivent être utilisées. L’utilisation de plaques de

séparation de tous genres est interdite.

Le respect des consignes de sécurité, le mode

d’emploi et les remarques de service dans le mode

d’emploi sont aussi partie intégrante de l’utilisation

conforme à l’affectation.

Les personnes commandant la machine et en

effectuant la maintenance doivent le connaître et

avoir été instruites sur les différents risques possibles

en découlant. En outre, il faut strictement respecter

les règlements de prévoyance contre les accidents. Il

faut respecter toutes les autres règles des domaines

de la médecine du travail et de la technique de

sécurité.

Toute modification de la machine entraîne

l’annulation de la responsabilité du producteur, aussi

pour les dommages en découlant. Malgré l’emploi

conforme à l’affectation, certains facteurs de risque

résiduels ne peuvent être complètement supprimés.

En raison de la construction et de la conception de la

machine, les points suivants peuvent avoir lieu:

Contact avec la lame de scie dans la zone de la

scie n’étant pas recouverte.

Toucher la lame de scie en fonctionnement

(blessure coupante).

Retour de pièces à usiner et de parties de celles-

ci.

Ruptures de lame de scie.

Expulsion de pièces de métal dur défectueuses

de la lame de scie.

Troubles de l’ouïe si vous n’employez pas de

protection des oreilles.

Emissions nocives de poussière de métal et de

bois en cas d’emploi de la scie dans des pièces

fermées.

Coupures au niveau des copeaux et pièces à

usiner.

Blessures aux yeux dues aux copeaux

métalliques.

5. Caractéristiques techniques

Moteur à courant alternatif : 230V ~ 50 Hz

Puissance : 1800 W

Mode de service : S1

Vitesse de rotation à vide n0: 2500 tr/mn

Lame de scie en métal dur : Ø 250 x Ø 30 x 2,2 mm

Nombre de dents : 48

Zone de pivotement : -52° / 0°/ +60°

Coupe d’onglet : de 0° à 45° vers la gauche

Largeur de scie à 90° :

Bois : 305 x 75 mm

Métal : 105 x 75 mm

Largeur de scie à 45° :

Bois : 210 x 75 mm

Métal : 70 x 75 mm

Largeur de la scie à 2 x 45° (double coupe en onglet):

Bois : 210 x 40 mm

Métal : 70 x 40 mm

Poids : env. 17,5 kg

Bruit et vibrations

Le bruit et les vibrations ont été déterminés

conformément à EN 13898.

Niveau de pression acoustique L

pA

93,7 dB(A)

Insécurité K

pA

2 dB

Niveau de puissance acoustique L

WA

108,5 dB(A)

Insécurité K

WA

2 dB

29

F

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 29

Page 30

Portez une protection de l’ouïe.

L’exposition au bruit peut entraîner une perte de

l’ouïe.

“Les valeurs indiquées sont des valeurs d’émission et

ne doivent donc pas représenter simultanément aussi

des valeurs de poste de travail sûres. Bien qu’il y ait

une corrélation entre le niveau d’émission et celui

d’immission, on ne peut déduire avec certitude si des

mesures de précaution supplémentaires sont

nécessaires ou non.

Les facteurs pouvant influencer le niveau d’immission

présent sur le moment au poste de travail

comprennent la durée des effets, la sorte de salle de

travail, les autres sources de bruit, etc. par ex. le

nombre de machines et autres processus voisins.

Les valeurs de poste de travail fiables peuvent aussi

varier d’un pays à l’autre. Cette information est

cependant destinée à rendre les personnes utilisant

l’outil capables de mieux estimer les risques et

dangers.”

Les valeurs totales des vibrations (sommes

vectorielles dans trois directions) ont été déterminées

conformément à EN 61029.

Valeur d’émission de vibration hauteur de travail = 1,068 m/s

2

Limitez le niveau sonore et les vibrations à un

minimum !

Utilisez exclusivement des appareils en excellent

état.

Entretenez et nettoyez l’appareil régulièrement.

Adaptez votre façon de travailler à l’appareil.

Ne surchargez pas l’appareil.

Faites contrôler l’appareil le cas échéant.

Mettez l’appareil hors circuit lorsque vous ne

l’utilisez pas.

Portez des gants.

6. Avant la mise en service

6.1 Généralités

La machine doit être placée de façon à être bien

stable, autrement dit vissée à fond sur un établi

ou le support fixe fourni en série, ou autre.

Avant la mise en service, les recouvrements et

dispositifs de sécurité doivent être montés dans

les règles de l’art.

La lame de scie doit pouvoir tourner sans

obstacle.

Dans le cas de bois ayant déjà été traité, veillez

aux corps étrangers, comme par ex. les clous ou

vis, etc.

Avant d’actionner l’interrupteur Marche/Arrêt,

assurez-vous que la lame de scie est

correctement montée et que les pièces

amovibles le sont sans obstacle.

Assurez-vous avant de connecter la machine que

les données se trouvant sur la plaque de

signalisation correspondent bien aux données du

réseau.

6.2 Monter la scie (figures 1 à 3 ; 6)

Pour ajuster la table tournante (17) dévissez la

poignée de blocage (14) d’env. 2 tours pour

déverrouiller la table tournante (17).

Appuyez sur le levier de l’échelle des degrés

(13), tournez la table tournante (17) et le pointeur

(15) jusqu’à la cote d’angle désirée de la

graduation (16) et fixez à l’aide de la poignée de

blocage (14). La scie dispose de degrés l’échelle

au niveau des positions -45°, -30°, -22,5°, -15°,

0°, 15°, 22,5°, 30°, 45° et 60° auxquelles on peut

encranter le levier de l’échelle des degrés.

En appuyant légèrement sur la tête de la machine

(4) vers le bas et en retirant simultanément le

boulon de sécurité (27) du support du moteur, la

scie est déverrouillée à partir de la position

inférieure. Tournez le boulon de sécurité (27) de

90° avant de la relâcher, afin que la scie reste

déverrouillée.

Pivotez la tête de la machine (4) vers le haut

jusqu’à ce que le levier de déverrouillage (3)

s’enclenche.

Les dispositifs (8, 21) peuvent être montés tout

autant à gauche qu’à droite, de la table de scie

fixe (18).

Desserrez les vis de fixation du support roulant

(30).

Guidez le support roulant avec la butée de fin de

course (9) au-dessus d’un étrier de retenue du

support roulant (10) et montez-le à la table de

menuisier fixe (18), serrez la vis de fixation

correspondante (30) (figure 6).

Montez le deuxième étrier de retenue du support

roulant (10) sur le côté opposé de la scie et

bloquez-le avec la vis de fixation (30)

correspondante.

La tête de la machine (4) peut être inclinée vers la

gauche de maxi. 45° en dévissant la vis de

serrage (22).

Lorsque l’on utilise la scie sans support, le pied

d’appui (32) sert alors à empêcher la scie de

basculer vers l’avant pendant le service. Pour ce

faire, dévissez le pied d’appui (32) jusqu’à ce qu’il

effleure la surface d’appui de la scie.

30

F

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 30

Page 31

6.3 Montez le support et vissez la scie sur le

support (figures 4-24)

1. Enfichez les pieds (A), comme indiqué dans la

figure 7, par le bas dans les entretoises

intermédiaires (C). Attention au fait que les pieds

en caoutchouc sur les pieds d’appui (A) soient

alignés de telle manière que les surfaces d’appui

restent droites.

2. Vissez les pieds d’appui (A) sur les entretoises

intermédiaires (C) à l’aide des vis (N), des

rondelles intermédiaires (H) et des écrous (G),

comme représentés dans les figures 8 à 9.

3. Faites passer les pièces latérales (B) par le haut,

au-dessus des entretoises intermédiaires (C)

(figure 10).

4. Vissez les pièces latérales (B) sur chaque point

de raccord avec 3 vis (L), rondelles (K) et écrous

(I) aux entretoises intermédiaires (C) (figures 11 -

12).

5. Enfichez les deux entretoises transversales

inférieures (E) jusqu’à la butée dans les

encoches correspondantes de l’une des

entretoises intermédiaires (C) (figure 13). Visser

les entretoises transversales inférieures (E) avec

à chaque fois 2 vis (L), et écrous (K) et écrous (I),

comme indiqué dans la figure 14 – 15, à

l’entretoise intermédiaire (C).

6. Mettez sur la même moitié inférieure du support

les deux entretoises transversales supérieures

(F) jusqu’à la butée dans les encoches

correspondantes de la pièce latérale (B) (figure

16). Enfichez un renfort d’angle (D) à chaque fois

dans l’encoche de la pièce latérale (B). Veillez à

ce que les renforts d’angle (D) ne conviennent

respectivement qu’à un seul côté du support, ce

qui est le cas lorsque les trous dans la pièce

latérale (B), les entretoises transversales

supérieures (F) et les renforts d’angle (D)

coïncident (figure 17).

7. Vissez à présent les entretoises transversales

supérieures (F), les renforts d’angle (D) et la

pièce latérale (B), comme indiqué dans la figure

18 – 19, avec à chaque fois 2 vis (L), écrous (K)

et écrous (I).

8. Enfichez les deux moitiés de support de telle

manière que les entretoises transversales

inférieure et supérieure (E, F) se trouvent dans

les encoches correspondantes sur la pièce

latérale (B) et l’entretoise intermédiaire (C) (figure

20).

9. Vissez les entretoises transversales inférieures

(E) comme indiqué au point 5. sur la deuxième

moitié de support (figure 21/1.).

10. Vissez les entretoises transversales supérieures

(F) comme indiqué au point 6. sur la deuxième

moitié de support (figure 21/2.).

11. Retirez les quatre amortisseurs en caoutchouc

(32) sur la face inférieure de la scie (figure 22).

12. Placez la scie sur le support de manière que les

trous dans lesquels vous avez trouvé les butoirs

en caoutchouc (32) coïncident aux quatre trous

sur la partie supérieure des logements de scie

(J). Enfichez à présent les quatre vis (M) par le

haut à travers les pieds de la scie et vissez la scie

à son support (figures 23 – 24).

6.4 Réglage de précision de la butée pour coupe

en bout de 90° (figures 1, 25-27)

Fixez la table tournante (17) en position 0°.

Débloquez la vis de fixation (22) et pencher avec

la poignée (1) la tête de la machine (4)

complètement à la droite.

Amenez une équerre à chapeau de 90° (a) entre

la lame (7) et la table tournante (17).

Déplacez la vis d’ajustage (38) jusqu’à ce que

l’angle entre la lame (7) et la plaque tournante

(17) soit de 90°.

Contrôler ensuite la position du pointeur (20) sur

l’échelle (19). Si nécessaire, desserrez le

pointeur (20) avec un tournevis cruciforme,

amenez-le sur 0° de l’échelle (19) et serrez à

nouveau la vis.

L’équerre de butée ne fait pas partie des

pièces livrées.

6.5 Réglage de précision de la butée pour coupe

d’onglet de 45° (figures 1, 25, 28-29)

Fixez la table tournante (17) en position 0°.

Desserrez la vis de fixation (22) et avec la

poignée (1), amenez la tête de la machine (4)

complètement sur la gauche, sur 45°.

45°-Amenez l’équerre de butée 45° (b) entre la

lame (7) et la table tournante (17).

Déplacez la vis d’ajustage (37) jusqu’à ce que

l’angle entre la lame (7) et la table tournante (17)

soit de 45°.

L’équerre de butée ne fait pas partie des

pièces livrées.

31

F

Anleitung_RT_XM_305_U_SPK7:_ 22.10.2009 15:30 Uhr Seite 31

Page 32

7. Fonctionnement comme scie à

bois/plastique

7.1 Tronçonnage de 90° et table de rotation 0°

(figures 1–3, 30)

Pour les largeurs de coupe de 100 mm max., la

fonction de tirage de la scie peut être fixée en position

arrière à l’aide de la vis de fixation pour guidage tiré

(25). Si la largeur de coupe dépasse 100 mm, il faut

veiller à ce que la vis de fixation du guidage tiré (25)

soit lâche et que la tête de la machine (4) puisse être

bougée.

Mettez la tête de la machine (4) en position

haute.

Poussez la tête de la machine (4) vers l’arrière

avec la poignée (1) et fixez-la dans cette position.

(en fonction de la largeur de coupe)

Placez le bois à découper contre le rail de butée

(11) et sur la table tournante (17).

Fixez le matériel à l’aide de l’étau (8) sur la table

de menuisier fixe (18) afin d’éviter qu’il ne se

déplace pendant la coupe.

Appuyez sur le levier de déverrouillage (3) pour

libérer la tête de la machine (4).

Appuyez sur l’interrupteur Marche/Arrêt (2) pour

mettre le moteur en circuit.

Lorsque le guidage tiré (24) est fixé : Déplacez la

tête de la machine (4) à l’aide de la poignée (1)