Page 1

k

Originalbetriebsanleitung

Elektro-Bodenhacke

t

Original operating instructions

Electric Hoe

p

Mode d’emploi d’origine

de la bineuse électrique

C

Istruzioni per l’uso originali

Elettrozappa

U

Original-bruksanvisning

Elektrisk jordfräs

N

Originele handleiding

elektrische bodemfrees

m

Manual de instrucciones original

Motoazada eléctrica

O

Manual de instruções original

Enxada eléctrica

z

Πρωτότυπες Οδηγίες χρήσης

Hλεκτρικό σκαπτικό εδάφους

Art.-Nr.: 34.310.30 I.-Nr.: 11010

BG-RT

1340 M

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 1

Page 2

2

Vor Inbetriebnahme Bedienungsanleitung und

Sicherheitshinweise lesen und beachten

Read and follow the operating instructions and safety information

before using for the first time.

Avant la mise en service, lisez le mode dʼemploi et les consignes de

sécurité et respectez-les.

Prima della messa in esercizio leggete e osservate le istruzioni per

lʼuso e le avvertenze di sicurezza.

Läs igenom och beakta bruksanvisningen och

säkerhetsanvisningarna före användning.

Vóór ingebruikneming de handleiding en de veiligheidsvoorschriften

lezen en in acht nemen!

Leer detenidamente las instrucciones de uso y las advertencias de

seguridad antes de poner en marcha el aparato.

Leia e respeite as instruções de serviço e de segurança antes de

colocar o aparelho em funcionamento.

¶ЪИУ ЩЛ ı¤ЫЛ ЫВ ПВИЩФ˘ЪБ›· ‰И·‚¿ЫЩВ О·И ·ОФПФ˘ı‹ЫЩВ ЩЛУ √‰ЛБ›·

¯Ú‹Û˘ Î·È ÙȘ Àԉ›ÍÂȘ ·ÛÊ·Ï›·˜

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 2

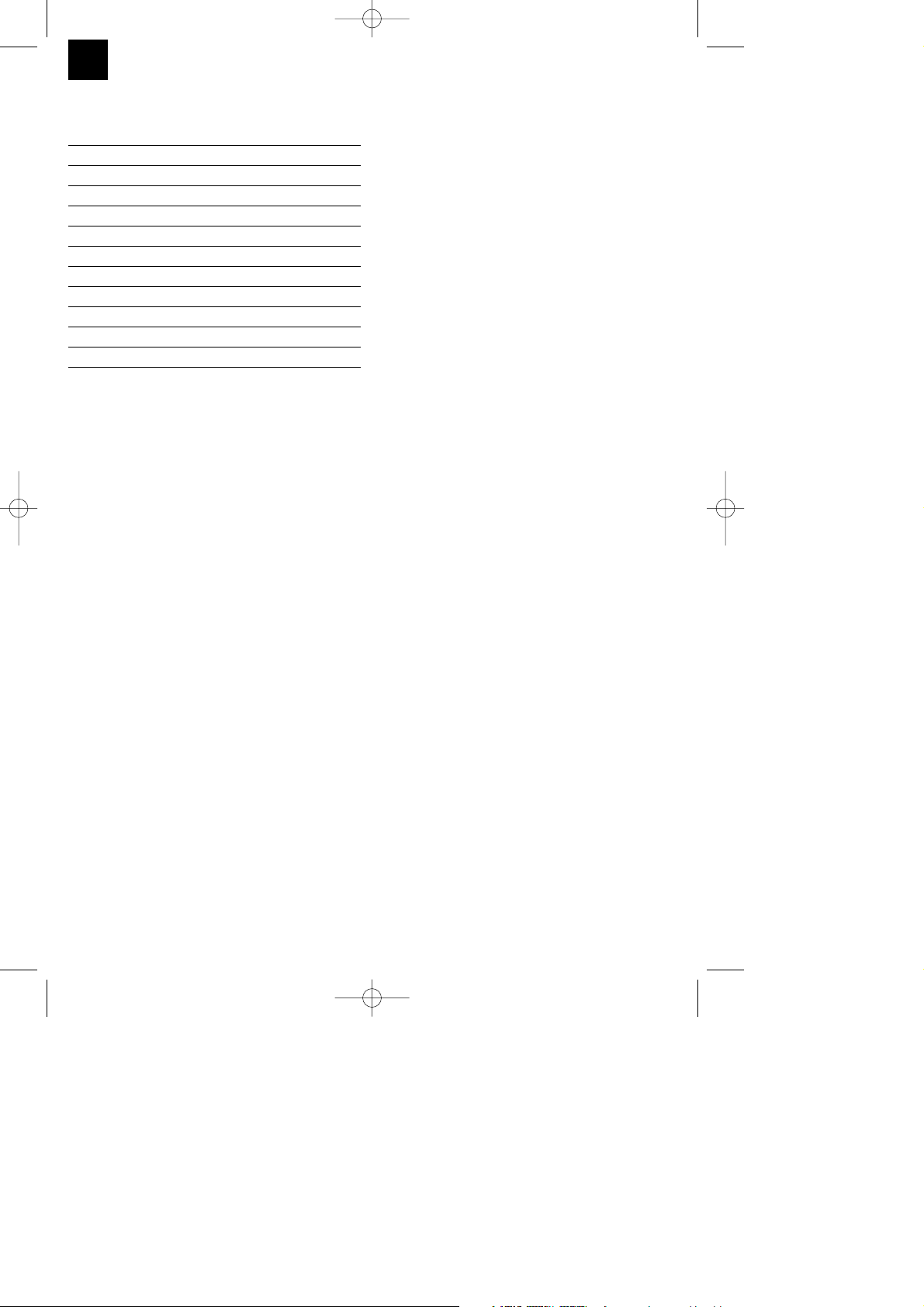

Page 3

3

9

9

9

10

11

12

8

7

5

1

6

2

1

2

3

4

13

2

2

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 3

Page 4

4

3 4

5 6

7 8

9

2

7

7

11

A

B

C

D

E

12

B

B

13

10

1

5

9

5

A

A

2

8

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 4

Page 5

5

D

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut auf,

damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

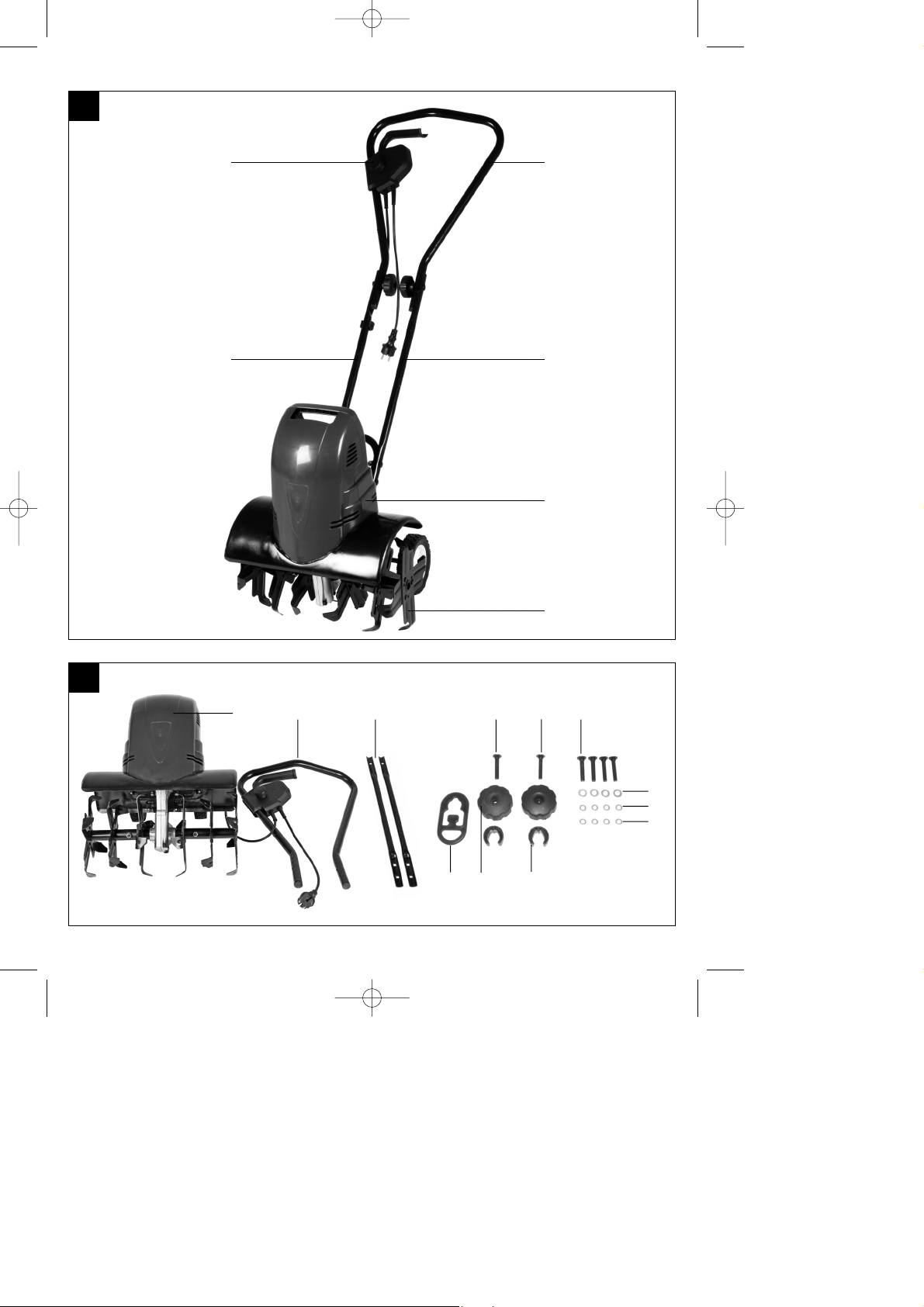

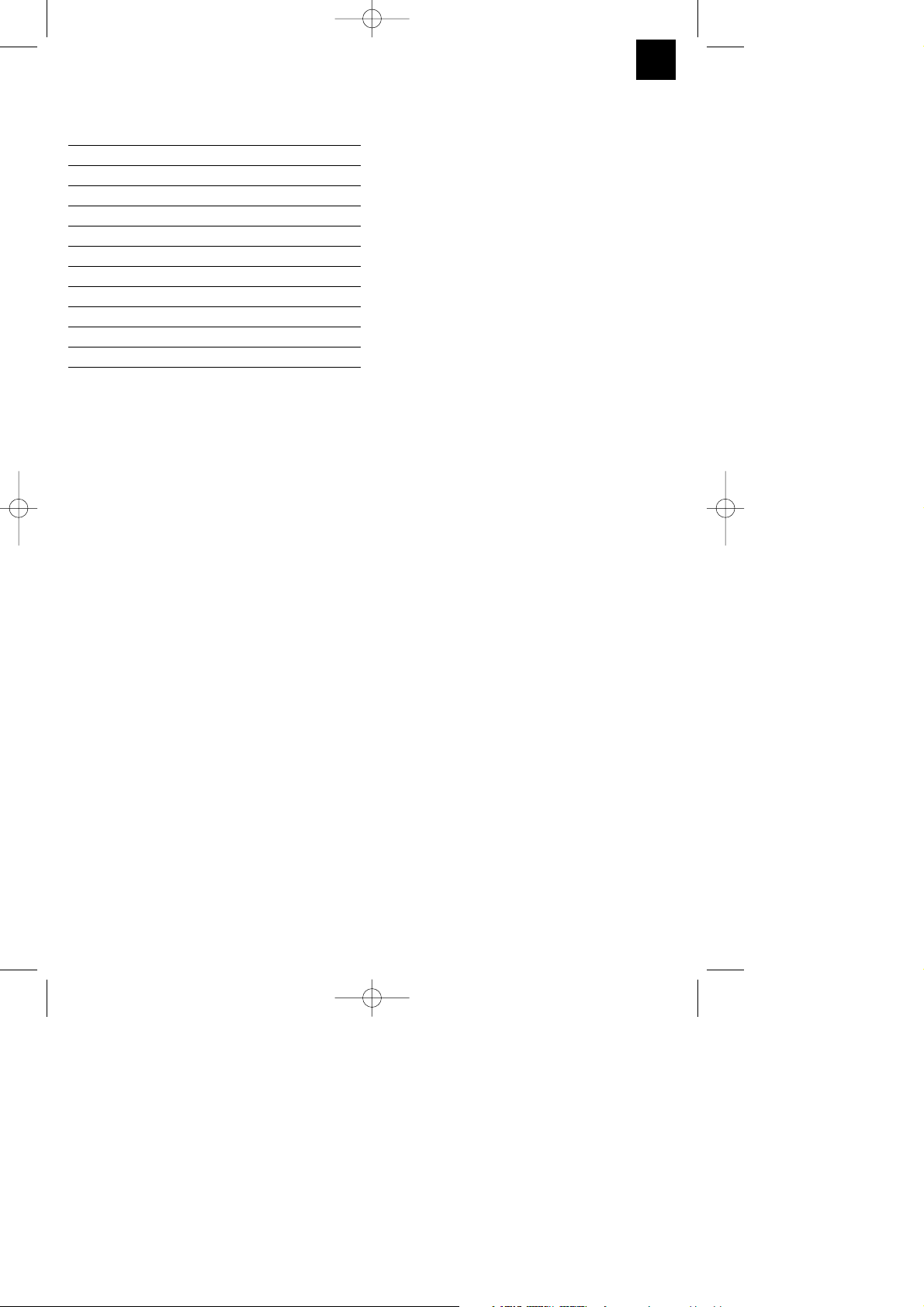

2. Gerätebeschreibung und

Lieferumfang (Bild 1/2)

2.1 Gerätebeschreibung

1. Oberer Schubbügel

2. Unterer Schubbügel

3. Motoreinheit

4. Hackmesser

5. Kabelzugentlastung

6. 2-Hand-Sicherheitsschalter

7. Kabelbefestigungsclips

8. 2x Sternmutter

9. 6x Schraube

10. 4x Beilagscheibe

11. 4x Sprengring

12. 4x Mutter

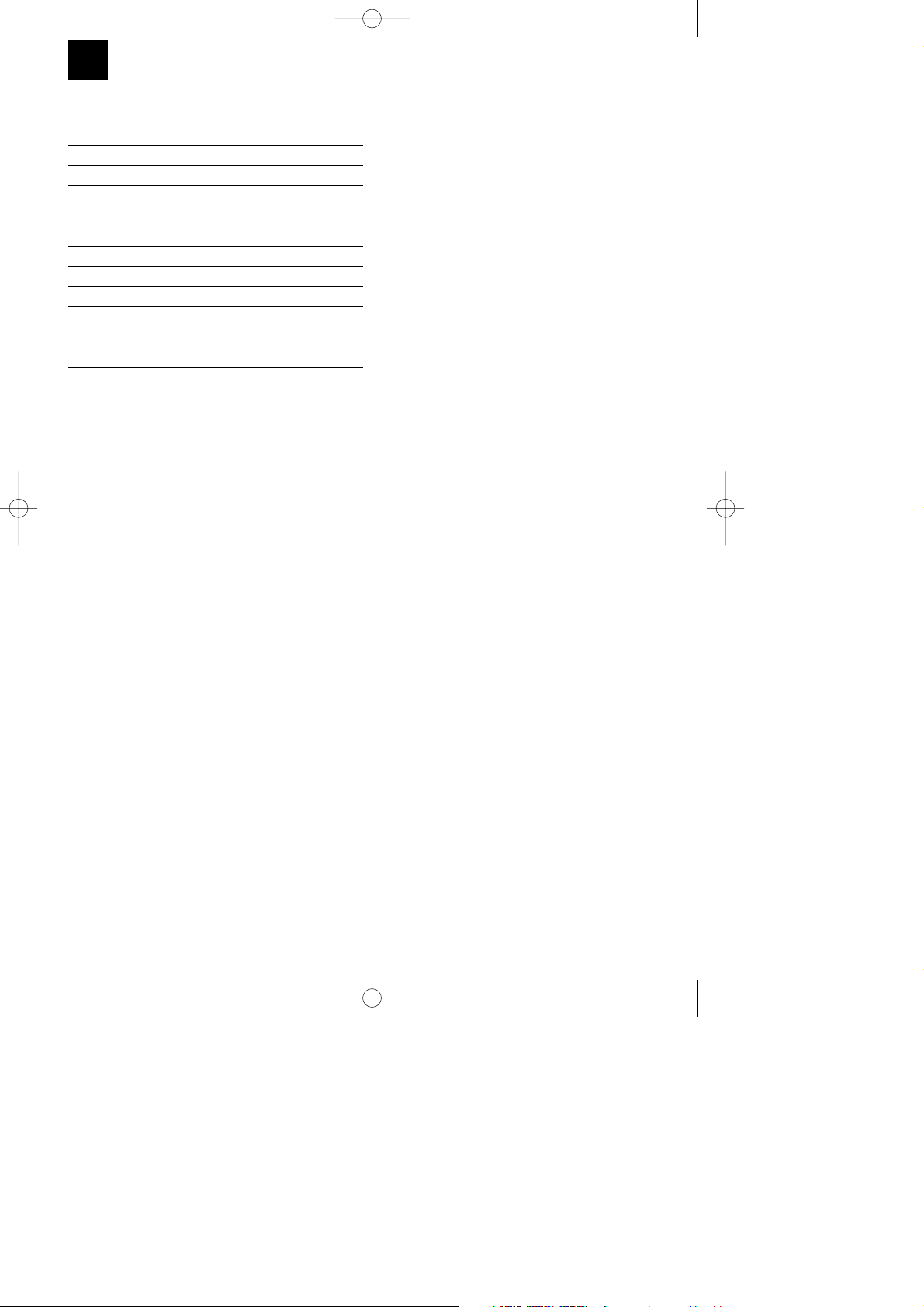

2.2 Lieferumfang

Öffnen Sie die Verpackung und nehmen Sie das

Gerät vorsichtig aus der Verpackung.

Entfernen Sie das Verpackungsmaterial sowie

Verpackungs-/ und Transportsicherungen (falls

vorhanden).

Überprüfen Sie, ob der Lieferumfang vollständig

ist.

Kontrollieren Sie das Gerät und die Zubehörteile

auf Transportschäden.

Bewahren Sie die Verpackung nach Möglichkeit

bis zum Ablauf der Garantiezeit auf.

ACHTUNG

Gerät und Verpackungsmaterial sind kein

Kinderspielzeug! Kinder dürfen nicht mit

Kunststoffbeuteln, Folien und Kleinteilen spielen!

Es besteht Verschluckungs- und

Erstickungsgefahr!

Motoreinheit mit oberem Schubbügel

2x unterer Schubbügel

Kabelzugentlastung

2x Kabelbefestigungsclips

2x Sternmutter

6x Schraube

4x Beilagscheibe

4x Sprengring

4x Mutter

Originalbetriebsanleitung

Sicherheitshinweise

3. Bestimmungsgemäße Verwendung

Das Gerät ist geeignet zum Umgraben von Erde (z.B.

Gartenbeete). Beachten Sie unbedingt die

Einschränkungen in den Sicherheitshinweisen.

Das Gerät darf nur nach seiner Bestimmung

verwendet werden. Jede weitere darüber

hinausgehende Verwendung ist nicht

bestimmungsgemäß. Für daraus hervorgerufene

Schäden oder Verletzungen aller Art haftet der

Benutzer/Bediener und nicht der Hersteller.

Bitte beachten Sie, dass unsere Geräte

bestimmungsgemäß nicht für den gewerblichen,

handwerklichen oder industriellen Einsatz konstruiert

wurden. Wir übernehmen keine Gewährleistung,

wenn das Gerät in Gewerbe-, Handwerks- oder

Industriebetrieben sowie bei gleichzusetzenden

Tätigkeiten eingesetzt wird.

Die Einhaltung der vom Hersteller beigefügten

Gebrauchsanweisung ist Voraussetzung für den

ordnungsgemäßen Gebrauch des Gerätes. Die

Gebrauchsanweisung enthält auch die Betriebs-,

Wartungs- und Instandhaltungsbedingungen.

Aus Sicherheitsgründen darf das Gerät nicht

verwendet werden als Antriebsaggregat für andere

Arbeitswerkzeuge und Werkzeugsätze jeglicher Art.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 5

Page 6

6

D

4. Technische Daten

Netzspannung: 230V ~ 50Hz

Leistungsaufnahme: 1300 W

Arbeitsbreite: 40 cm

Hacken Ø: 23 cm

Leerlaufdrehzahl: 110 min

-1

Anzahl der Messer: 6 Stück

Schalldruckpegel LpA: 80 dB(A)

Unsicherheit K: 2 dB(A)

Schallleistungspegel LWA: 93 dB(A)

Unsicherheit K: 2 dB(A)

Vibration am Holm ahv: < 2,5 m/s

2

Unsicherheit K: 1,5 m/s

2

Zusätzliche Informationen für Elektrowerkzeuge

Warnung!

Der angegebene Schwingungsemissionswert ist nach

einem genormten Prüfverfahren gemessen worden

und kann sich, abhängig von der Art und Weise, in

der das Elektrowerkzeug verwendet wird, ändern

und in Ausnahmefällen über dem angegebenen

Wert liegen.

Der angegebene Schwingungsemissionswert kann

zum Vergleich eines Elektrowerkzeuges mit einem

anderen verwendet werden.

Der angegebene Schwingungsemissionswert kann

auch zu einer einleitenden Einschätzung der

Beeinträchtigung verwendet werden.

Beschränken Sie die Geräuschentwicklung und

Vibration auf ein Minimum!

Verwenden Sie nur einwandfreie Geräte.

Warten und reinigen Sie das Gerät regelmäßig.

Passen Sie Ihre Arbeitsweise dem Gerät an.

Überlasten Sie das Gerät nicht.

Lassen Sie das Gerät gegebenenfalls

überprüfen.

Schalten Sie das Gerät aus, wenn es nicht

benutzt wird.

Tragen Sie Handschuhe.

Restrisiken

Auch wenn Sie dieses Elektrowerkzeug vorschriftsmäßig bedienen, bleiben immer Restrisiken bestehen. Folgende Gefahren können im

Zusammenhang mit der Bauweise und Ausführung dieses Elektrowerkzeuges auftreten:

1. Lungenschäden, falls keine geeignete Staubschutzmaske getragen wird.

2. Gehörschäden, falls kein geeigneter Gehörschutz

getragen wird.

3. Gesundheitsschäden, die aus Hand-ArmSchwingungen resultieren, falls das Gerät über

einen längeren Zeitraum verwendet wird oder

nicht ordnungsgemäß geführt und gewartet wird.

5. Vor Inbetriebnahme

Montage (Abb. 3-6)

Transportrad in niedrigste Stellung (Abb. 3/Pos.

E) bringen. Dazu Sicherungsschraube (Abb. 3/

Pos. 13) lösen und entfernen. Anschließend

wieder einsetzen und sicher festziehen.

Untere Schubbügel (Abb. 4/Pos. 2) an den

Schubbügelhaltern mit je 2 Schrauben (Abb.

4/Pos. 9) und 2 Beilagscheiben (Abb. 4/Pos. 10),

2 Sprengringen (Abb. 4/Pos. 11) und 2 Muttern

(Abb. 4/Pos. 12) befestigen.

Kabelzugentlastung (Abb. 5/Pos. 5) auf oberen

Schubbügel (Abb. 5/Pos. 1) aufschieben. Oberen

Schubbügel (Abb. 5/Pos. 1) an den unteren

Schubbügeln (Abb. 5/Pos. 2) mit 2 Schrauben

(Abb. 5/Pos. 9) und 2 Sternmuttern (Abb. 5/Pos.

8) befestigen.

Kabel mit 2 Kabelbefestigungsclips (Abb. 6/Pos.

7) am unteren Schubbügel befestigen.

Stromanschluss

Das Gerät kann an jede Lichtsteckdose (mit 230 Volt

Wechselstrom) angeschlossen werden. Es ist jedoch

nur eine Schuko-Steckdose zulässig, zu deren Absicherung ein Leitungs-Schutzschalter für 16A vorzusehen ist. Außerdem muss ein Fehlerstrom-Schutzschalter (RCD) mit max. 30 mA vorgeschaltet sein!

Geräteanschlussleitung

Verwenden Sie bitte nur Geräteanschlussleitungen,

welche nicht beschädigt sind. Die Geräteanschlussleitung darf nicht beliebig lang sein (max. 50m), da

sonst die Leistung des Elektromotors vermindert

wird. Die Geräteanschlussleitung muss einen Querschnitt von 3 x 1,5mm

2

haben. An Geräteanschlussleitungen entstehen besonders häufig Isolationsschäden.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 6

Page 7

7

D

Ursachen hierfür sind u.a.:

Risse durch Alterung der Isolation

Knickstellen durch unsachgemäße Befestigung

oder Führung der Geräteanschlussleitung

Solche schadhaften Geräteanschlussleitungen werden verwendet, obwohl sie aufgrund der Isolationsschäden lebensgefährlich sind. Kabel, Stecker und

Kupplungsdosen sollen den nachfolgend aufgelisteten Bedingungen genügen.

Geräteanschlussleitungen zum Anschluss von Bodenhacken müssen Gummiisolierungen haben.

Die Geräteanschlussleitungen müssen mindestens

vom Typ H05RN-F und 3-adrig sein. Ein Aufdruck

der Typenbezeichnung auf der Geräteanschlussleitung ist vorgeschrieben. Kaufen Sie nur Geräteanschlussleitungen mit Kennzeichnung! Die Stecker

und Kupplungsdosen an Geräteanschlussleitungen

müssen aus Gummi bestehen und spritzwassergeschützt sein. Die Geräteanschlussleitungen dürfen

nicht beliebig lang sein. Längere Geräteanschlussleitungen erfordern größere Leiterquerschnitte.

Geräteanschlussleitungen und Verbindungsleitungen

müssen regelmäßig auf Schäden geprüft werden.

Achten Sie darauf, dass die Leitungen bei der Prüfung stromlos sind. Wickeln Sie die Geräteanschlussleitung ganz ab. Überprüfen Sie auch die

Geräteanschlussleitungseinführungen an Steckern

und Kupplungsdosen auf Knickstellen.

6. Bedienung

6.1. Inbetriebnahme

Schließen Sie die Geräteanschlussleitung (Bild 7/

Pos. B) an den Stecker (Bild 7 / Pos. A) an und sichern Sie die Anschlussleitung mit der Zugentlastung

(Bild 7/Pos. 5).

Achtung! Um ein ungewolltes Einschalten des Gerätes zu verhindern, ist der Schubbügel mit einem

Zweipunktschalter (Bild 8/Pos. A) ausgestattet, welcher gedrückt werden muss, bevor der Schalthebel

(Bild 8/Pos. B) gedrückt werden kann. Wird der

Schalthebel losgelassen schaltet sich das Gerät ab.

Führen Sie diesen Vorgang einige Male durch, damit

Sie sicher sind, dass Ihr Gerät korrekt funktioniert.

Bevor Sie Reparatur- oder Wartungsarbeiten am Gerät vornehmen, müssen Sie sich vergewissern, dass

sich die Hackmesser nicht drehen und das Gerät

vom Netz getrennt ist.

Die integrierte Höhenverstellung erlaubt die Anpassung des Führungsrades an die gewünschte Arbeitstiefe. Sicherungsschraube (Abb. 3/Pos. 13) lösen

und entfernen. Führungsrad in gewünschte Position

(Abb. 3/Pos. A-E) bringen. Sicherungsschraube wieder einsetzen und festziehen.

Der durch die Führungsholme gegebene Sicherheitsabstand zwischen Gerät und Benutzer ist stets einzuhalten.

Bei Fahrtrichtungsänderungen an Böschungen und

Hängen ist besondere Vorsicht geboten.

Achten Sie auf einen sicheren Stand, tragen Sie

Schuhe mit rutschfesten, griffigen Sohlen und lange

Hosen.

Arbeiten Sie immer quer zum Hang.

Üben Sie besondere Vorsicht beim Rückwärtsbewegen und beim Ziehen des Gerätes, Stolpergefahr!

6.2. Hinweise zum richtigen Arbeiten

Stellen Sie das Gerät vor die zu bearbeitende Fläche

und halten es am Schubbügel gut fest bevor Sie das

Gerät einschalten.

Führen Sie die Hackmesser über die zu bearbeitende Fläche.

Zur Erzielung von sauber bearbeitetem Boden das

Gerät in möglichst geraden Bahnen führen. Dabei

sollten sich diese Bahnen immer um einige Zentimeter überlappen, damit keine Streifen übrig bleiben.

Schalten Sie den Motor rechtzeitig ab wenn Sie am

Ende der zu bearbeitenden Fläche angekommen

sind. Wenn das Gerät angehoben wird (z.B. bei

Richtungsänderung) muss der Motor abgeschaltet

werden.

Die Unterseite des Gerätes sauber halten und Erdablagerungen unbedingt entfernen. Ablagerungen

erschweren den Startvorgang und beeinträchtigen

die Arbeitstiefe.

An Hängen die Arbeitsrichtung quer zum Hang legen. Bevor irgendwelche Kontrollen der Hackmesser

durchgeführt werden Motor abschalten und Netzkabel abziehen.

Achtung!

Die Hackmesser drehen nach dem Ausschalten des

Motors noch einige Sekunden weiter. Versuchen Sie

nie, diese zu stoppen. Falls die in Bewegung befindlichen Hackmesser auf einen Gegenstand schlagen,

das Gerät abschalten und warten bis die Hackmesser vollkommen still stehen. Kontrollieren Sie anschließend den Zustand der Hackmesser. Falls diese

beschädigt sind müssen sie ausgewechselt werden.

Legen Sie die verwendete Geräteanschlussleitung

schleifenförmig vor der verwendeten Steckdose auf

die Erde. Arbeiten Sie von der Steckdose bzw. vom

Kabel weg und achten Sie darauf, dass die Geräteanschlussleitung immer im bearbeiteten Boden liegt,

damit die Geräteanschlussleitung nicht von den

Hackmessern überfahren wird.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 7

Page 8

7. Austausch der

Netzanschlussleitung

Wenn die Netzanschlussleitung dieses Gerätes

beschädigt wird, muss sie durch den Hersteller oder

seinen Kundendienst oder eine ähnlich qualifizierte

Person ersetzt werden, um Gefährdungen zu

vermeiden.

8. Reinigung, Wartung und

Ersatzteilbestellung

Wartungs- und Reinigungsarbeiten am Gerät sowie

das Abnehmen von Schutzeinrichtungen darf nur bei

stehendem Motor und gezogener Netzleitung

vorgenommen werden.

8.1 Reinigung

Halten Sie Schutzvorrichtungen, Luftschlitze und

Motorengehäuse so staub- und schmutzfrei wie

möglich. Reiben Sie das Gerät mit einem

sauberen Tuch ab oder blasen Sie es mit

Druckluft bei niedrigem Druck aus.

Wir empfehlen, dass Sie das Gerät direkt nach

jeder Benutzung reinigen.

Reinigen Sie das Gerät regelmäßig mit einem

feuchten Tuch und etwas Schmierseife.

Verwenden Sie keine Reinigungs- oder

Lösungsmittel; diese könnten die Kunststoffteile

des Gerätes angreifen. Achten Sie darauf, dass

kein Wasser in das Geräteinnere gelangen kann.

8.2 Austausch der Hackmesser

Aus Sicherheitsgründen empfehlen wir, den

Austausch der Hackmesser von einem autorisierten

Fachmann vornehmen zu lassen (siehe Adresse auf

der Garantieurkunde).

Achtung!

Arbeitshandschuhe tragen! Verwenden Sie nur

Original-Ersatzteile, da andernfalls Funktion und

Sicherheit unter Umständen nicht gewährleistet sind.

8.3 Wartung

Sorgen Sie dafür, dass alle Befestigungselemente

(Schrauben, Mutter usw.) stets fest angezogen sind,

sodass Sie mit dem Gerät sicher arbeiten können.

Lagern Sie das Gerät in einem trockenen Raum. Für

eine lange Lebensdauer sollten alle Metallteile

gereinigt und anschließend geölt werden.

Säubern Sie die Kunststoffteile des Gerätes

möglichst mit Bürsten oder Lappen. Verwenden Sie

keine Lösungsmittel um den Schmutz zu beseitigen.

Zur Platz sparenden Lagerung lösen Sie die

Sternmuttern (Abb. 5/Pos. 8) und klappen Sie den

oberen Schubbügel (Abb. 5/Pos. 1) nach vorne.

Achten Sie dabei darauf, das Kabel nicht zu

beschädigen. Zum Saisonende führen Sie eine

allgemeine Kontrolle des Gerätes durch und

entfernen alle angesammelten Rückstände.

Vor jedem Saisonbeginn den Zustand des Gerätes

unbedingt überprüfen. Wenden Sie sich bei

Reparaturen an unsere Kundendienststelle (siehe

Adresse auf der Garantieurkunde).

8.4 Ersatzteilbestellung:

Bei der Ersatzteilbestellung sollten folgende

Angaben gemacht werden;

Typ des Gerätes

Artikelnummer des Gerätes

Ident-Nummer des Gerätes

Ersatzteilnummer des erforderlichen Ersatzteils

Aktuelle Preise und Infos finden Sie unter

www.isc-gmbh.info

9. Entsorgung und Wiederverwertung

Das Gerät befindet sich in einer Verpackung um

Transportschäden zu verhindern. Diese Verpackung

ist Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus

verschiedenen Materialien, wie z.B. Metall und

Kunststoffe. Führen Sie defekte Bauteile der

Sondermüllentsorgung zu. Fragen Sie im

Fachgeschäft oder in der Gemeindeverwaltung nach!

10. Lagerung

Lagern Sie das Gerät und dessen Zubehör an einem

dunklen, trockenen und frostfreiem sowie für Kinder

unzugänglichem Ort. Die optimale Lagertemperatur

liegt zwischen 5 und 30 ˚C. Bewahren Sie das

Elektrowerkzeug in der Originalverpackung auf.

8

D

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 8

Page 9

9

D

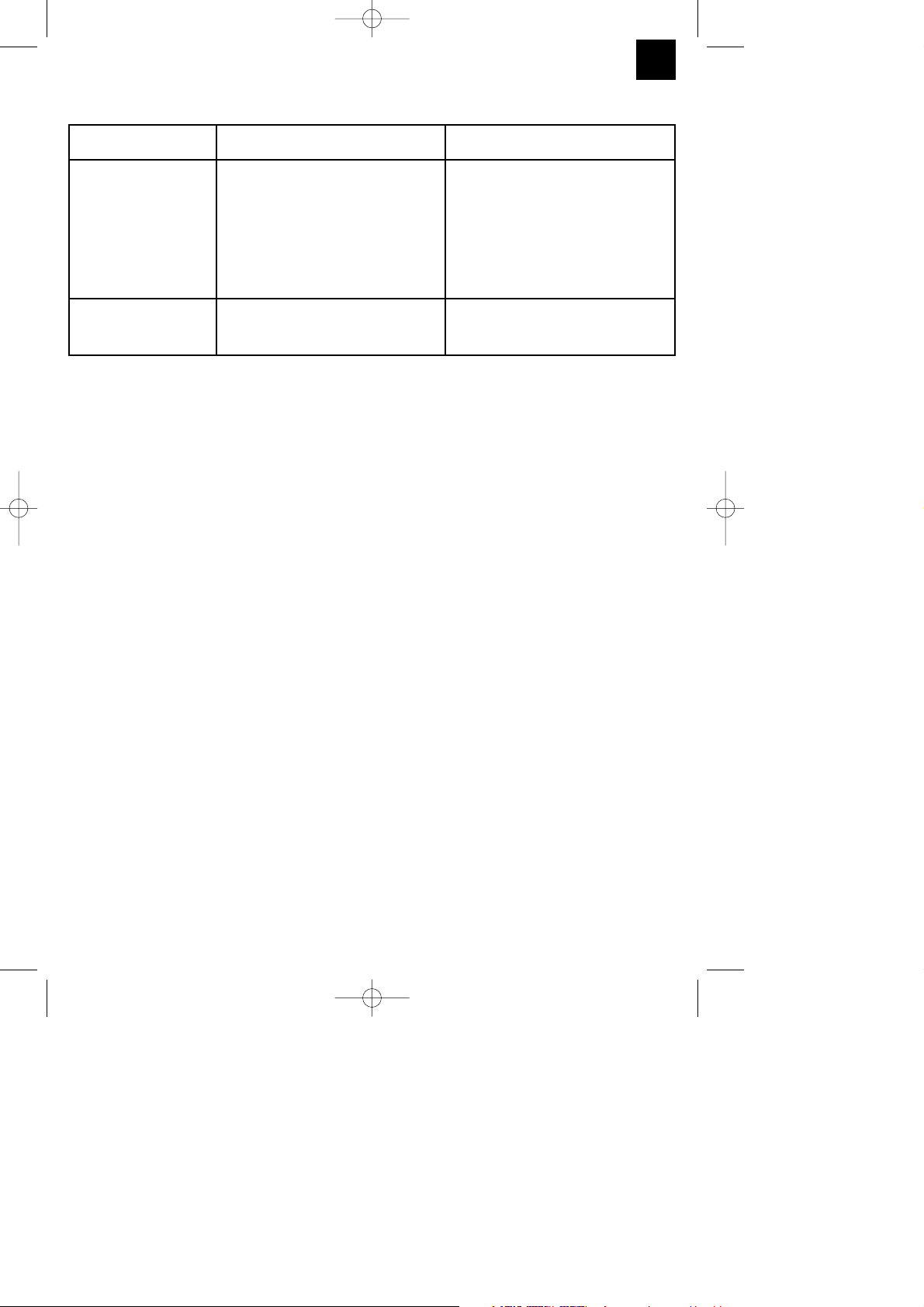

Fehler Mögliche Ursachen Beseitigung

Motor läuft nicht an a) Kein Strom im Stecker

b) Kabel defekt

c) Schalter Stecker Kombination

defekt

d) Anschlüsse am Motor oder

Kondensator gelöst

e) zu große Arbeitstiefe

a) Leitung und Sicherung

überprüfen

b) überprüfen

c) durch Kundendienstwerkstatt

d) durch Kundendienstwerkstatt

e) Arbeitstiefe verringern

Motorleistung lässt nach a) Zu harter Boden

b) Messer stark abgenutzt

a) Arbeitstiefe korrigieren

b) Hackmesser auswechseln

11. Fehlersuchplan

Wichtiger Hinweis!

Um den Motor zu schützen, ist dieser mit einem Thermoschalter ausgestattet, der bei Überlastung

abschaltet und nach einer kurzen Abkühlphase wieder automatisch einschaltet!

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 9

Page 10

10

GB

Important!

When using equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating manual with due

care. Keep this manual in a safe place, so that the

information is available at all times. If you give the

equipment to any other person, give them these

operating instructions as well.

We accept no liability for damage or accidents which

arise due to non-observance of these instructions

and the safety information.

1. Safety information

Please refer to the booklet included in delivery for the

safety instructions.

CAUTION!

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

2. Layout and items supplied

(Fig. 1)

2.1 Layout

1. Top push bar

2. Bottom push bar

3. Motor unit

4. Hoe blades

5. Cable strain-relief clamp

6. Two-hand safety switch

7. Cable securing clips

8. Two star nuts

9. Six screws

10. Four washers

11. Four circlips

12. Four nuts

2.2 Items supplied

Open the packaging and take out the equipment

with care.

Remove the packaging material and any

packaging and/or transportation braces (if

available).

Check to see if all items are supplied.

Inspect the equipment and accessories for

transport damage.

If possible, please keep the packaging until the

end of the guarantee period.

IMPORTANT

The equipment and packaging material are not

toys. Do not let children play with plastic bags,

foils or small parts. There is a danger of

swallowing or suffocating!

Motor unit with top push bar

Lower push bar (2x)

Cable strain-relief clamp

Cable securing clips (2x)

Star nut (2x)

Screw (6x)

Washer (4x)

Circlip (4x)

Nut (4x)

Original operating instructions

Safety instructions

3. Proper use

The machine is designed for digging soil (for

example garden beds). Be sure to observe the

restrictions in the safety instructions.

The machine is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the

manufacturer will be liable for any damage or injuries

of any kind caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial

businesses or for equivalent purposes.

The operating instructions as supplied by the

manufacturer must be kept and referred to in order to

ensure that the machine is properly used and

maintained. The instructions contain valuable

information on operating, maintenance and servicing

conditions.

For safety reasons, the machine may not be used as

a drive unit for other work tools or tool sets of any

kind.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 10

Page 11

11

GB

4. Technical data

Voltage 230V ~ 50Hz

Power input 1300 W

Working width 40 cm

Hoe diameter 23 cm

Idle speed 110 rpm

Number of blades 6 pieces

LpAnoise level 80 dB(A)

K uncertainty 2 dB(A)

LWApeak noise level 93 dB(A)

K uncertainty 2 dB(A)

Vibration at the handlebars a

hv

≤ 2.5 m/s

2

K uncertainty 1,5 m/s

2

Additional information for electric power tools

Warning!

The specified vibration value was established in

accordance with a standardized testing method. It

may change according to how the electric equipment

is used and may exceed the specified value in

exceptional circumstances.

The specified vibration value can be used to compare

the equipment with other electric power tools.

The specified vibration value can be used for initial

assessment of a harmful effect.

Keep the noise emissions and vibrations to a

minimum.

Only use appliances which are in perfect working

order.

Service and clean the appliance regularly.

Adapt your working style to suit the appliance.

Do not overload the appliance.

Have the appliance serviced whenever

necessary.

Switch the appliance off when it is not in use.

Wear protective gloves.

Residual risks

Even if you use this electric power tool in

accordance with instructions, certain residual

risks cannot be rules out. The following hazards

may arise in connection with the equipment’s

construction and layout:

1. Lung damage if no suitable protective dust mask

is used.

2. Damage to hearing if no suitable ear protection is

used.

3. Health damage caused by hand-arm vibrations if

the equipment is used over a prolonged period or

is not properly guided and maintained.

5. Before starting the equipment

Assembly (Fig. 3-6)

앬 Move the transport wheel into the lowest position

(Fig. 3/Item E). To do so, undo the retaining

screw (Fig. 3 / Item 13) and remove. Finally,

replace the screw and tighten.

앬 Attach the bottom push bar (Fig. 4/Item 2) to the

push bar brackets using two screws (Fig. 4/Item

9) and two washers (Fig. 4/Item 10), two spring

rings (Fig. 4/Item 11) and two nuts (Figure 4/Item

12) on each side.

앬 Slide the strain-relief clamp (Fig. 5/Item 5) onto

the top push bar (Fig. 5 / Item 1). Attach the top

push bar (Fig. 5/Item 1) to the bottom push bars

(Fig. 5/Item 2) with two screws (Fig. 5/Item 9)

and two star nuts (Fig. 5/Item 8).

앬 Fasten the two cable securing clamps (Fig.

6/Item 7) to the bottom push bar.

Power supply

The machine can be connected to any light socketoutlet (with 230 Volt alternating current). However,

the socket outlet must have an earthing contact

protected by a 16 A circuit breaker. Additionally, a

residual current device (RCD) circuit-breaker with

max. 30 mA must be used!

Power cable for the device

Please only use power cables that are not damaged.

The total length of the power cable should not

exceed 50 meters; going beyond this distance will

reduce the power output of the electric motor. The

power cable must have a cross-section of 3 x 1.5

mm

2

. The insulating sheath of such machines is

frequently damaged.

Some of the causes for this are:

Cracking due to old age of the insulation

Kinking caused by improper fastening or

guidance of the power cable

Even though power cables with damaged insulation

sheaths pose a lethal hazard, some people still use

them. Do not make this mistake! Cables, plugs and

socket couplers must meet the following

requirements listed below. Power cables used to

connect machines must have a rubber insulation

sheath.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 11

Page 12

GB

12

The power cables must, at the very minimum, be of

type HO5RN-F and 3-stranded. The cable type must

be printed somewhere on the power cable. Only

purchase power cables that are marked! Plugs and

socket couplers for the power cables must be made

from rubber and splash-proof. There is a limit to how

long power cables can be. Longer power cables

require larger conductor cross-sections. Power

cables and connecting lines must be regularly

checked for damage. Ensure that the lines are deenergized before checking them. Completely unwind

the power cable. Also check power cable entry

points, plugs and socket couplers for kinks.

6. Operation

6.1 Starting up

Connect the machineʼs power supply cable (Fig 7/

Item B) to the plug (Fig. 7/Item A) and secure the

power cable with the strain-relief clamp (Fig 7/Item

5).

Important! To prevent accidental start-up of the

machine, the push-bar is equipped with a two-point

switch (Fig. 8/Item A) which must be pressed before

the lever switch (Fig. 8/Item B) can be pressed. If the

lever switch is released, the machine switches off.

Repeat this process several times so that you are

sure that your machine functions properly. Before

you perform any repair or maintenance work on the

machine, ensure that the hoe blades are not rotating

and that the power supply is disconnected.

The integrated height adjustment system enables

you to adjust the guide wheel to the required working

depth. Undo the retaining screw (Fig. 3/Item 13) and

remove. Move the guide wheel into the required

position (Fig. 3/Item A-E). Replace the screw and

tighten.

Always ensure that a safe distance (provided by the

long handles) is maintained between the machine

and the user. Be especially careful when changing

direction on slopes and inclines. Maintain a solid

footing and wear sturdy, non-slip footwear and long

trousers. Always work along the incline (not up and

down).

Use special caution when backing up and pulling the

machine (tripping hazard).

6.2 Tips for proper working

Place the machine in front of the area you wish to

hoe and hold it securely on the push bar before you

switch on the machine. Guide the hoe blades over

the area.

To achieve cleanly hoed soil always ensure that you

guide the machine in straight lines wherever

possible. Insodoing, the aeration swaths should

always overlap each other by a few centimeters in

order to avoid bare strips.

Switch off the motor promptly when you arrive at the

end of the area you wished to hoe. The motor must

be switched off when you raise the machine (for

example to change direction).

Keep the underside of the machine clean and

remove soil deposits. Deposits make it more difficult

to start the machine and decrease the working depth.

Work perpendicular to the slop on inclined areas.

The machine must be switched off and the mains

cable disconnected before you make any checks on

the hoe blades.

Important!

The hoe blades will continue to rotate for a few

seconds after the motor is switched off. Never

attempt to manually stop them. In the event that the

rotating hoe blade strikes an object, immediately

switch off the machine and wait for the hoe blades to

come to a complete stop. Then inspect the condition

of the hoe blades. Replace any parts that are

damaged.

Lay the power cable on the ground in front of the

outlet in a figure 8. Work away from the outlet or

cable and ensure that the power cable always trails

in the hoed soil which will prevent the hoe blades

from traveling over the cable.

7. Replacing the power cable

If the power cable for this equipment is damaged, it

must be replaced by the manufacturer or its aftersales service or similarly trained personnel to avoid

danger.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 12

Page 13

GB

13

8. Cleaning, maintenance and ordering

of spare parts

Maintenance and cleaning work on the machine as

well as removal of the safety devices may only be

performed when the motor is switched off and the

power cable has been pulled.

8.1 Cleaning

Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

with compressed air at low pressure.

We recommend that you clean the device

immediately each time you have finished using it.

Clean the equipment regularly with a moist cloth

and some soft soap. Do not use cleaning agents

or solvents; these could attack the plastic parts of

the equipment. Ensure that no water can seep

into the device.

8.2 Replace the hoe blades

For safety reasons, we recommend having the hoe

blades replaced by an authorized professional (see

address on warranty certificate).

Important!

Wear working gloves. Use only genuine spare parts

since otherwise the function and safety of the

machine cannot be guaranteed.

8.3 Maintenance

Ensure that all mounting components (i.e. screws,

bolts, nuts etc.) are always tightened so that the

machine can be safely operated at all times.

Store the device in a dry room. All the metal parts

should be cleaned and then oil to ensure that they

provide a long life. For best results, clean the plastic

parts of the machine with a brush or rag. Do not use

any solvents to remove dirt.

For space saving storage undo the star nuts (Fig.

5/Item 8) and fold the bottom push bar (Fig. 5/Item 1)

forward. Ensure that you do not damage the cable.

At the end of the season, perform a general

inspection of the machine and remove any deposits

which may have accumulated. At the start of each

season, ensure that you check the condition of the

machine. If repairs are necessary, please contact

one of our customer service centers (see address on

warranty certificate).

8.4 Ordering replacement parts

Please quote the following data when ordering

replacement parts:

Type of machine

Article number of the machine

Identification number of the machine

Replacement part number of the part required

For our latest prices and information please go to

www.isc-gmbh.info

9. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

10. Storage

Store the equipment and accessories out of children’s

reach in a dark and dry place at above freezing

temperature. The ideal storage temperature is

between 5 and 30 °C. Store the electric tool in its

original packaging.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 13

Page 14

GB

14

11. Troubleshooting guide

Fault Possible causes Remedy

Motor does not start a) No power at the plug

b) Cable defective

c) Switch/plug block defective

d) Motor terminals or capacitor

disconnected

e) excessive working depth

a) Check the power cable and fuse

b) Check

c) By customer service workshop

d) By customer service workshop

e) Reduce working depth

Motor performance

drops

a) Soil too hard

b) Blades badly worn

a) Correct working depth

b) Replace hoe blades

Important note!

For protection, the motor is equipped with a thermal switch which cuts out when the motor is

overloaded and switches on again automatically after a short cooling period.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 14

Page 15

F

15

Attention !

Lors de lʼutilisation dʼappareils, il faut respecter

certaines mesures de sécurité afin dʼéviter des

blessures et dommages. Veuillez donc lire

attentivement ce mode dʼemploi. Conservez-le bien

de façon à pouvoir disposer à tout moment de ces

informations. Si lʼappareil doit être remis à dʼautres

personnes, remettez-leur aussi ce mode dʼemploi.

Nous déclinons toute responsabilité pour les

accidents et dommages dus au non-respect de ce

mode dʼemploi et des consignes de sécurité.

1. Consignes de sécurité

Vous trouverez les consignes de sécurité

correspondantes dans le petit manuel ci-joint.

AVERTISSEMENT !

Veuillez lire toutes les consignes de sécurité et

instructions.

Tout non-respect des consignes de sécurité et

instructions peut provoquer une décharge électrique,

un incendie et/ou des blessures graves.

Conservez toutes les consignes de sécurité et

instructions pour une consultation ultérieure.

2. Description de lʼappareil et étendue

de la livraison (figure 1)

2.1 Description de lʼappareil

1. Guidon supérieur

2. Guidon inférieur

3. Unité moteur

4. Couteau hacheur

5. Déchargeur pour câble

6. 2 interrupteurs de sécurité manuels

7. Clip de fixation du câble

8. 2x écrous-étoiles

9. 6x vis

10. 4x rondelles

11. 4x ciclips

12. 4x écrous

2.2 Volume de livraison

Ouvrez l’emballage et prenez l’appareil en le

sortant avec précaution de l’emballage.

Retirez le matériel d’emballage tout comme les

sécurités d’emballage et de transport (s’il y en a).

Vérifiez si la livraison est bien complète.

Contrôlez si l’appareil et ses accessoires ne sont

pas endommagés par le transport.

Conservez l’emballage autant que possible

jusqu’à la fin de la période de garantie.

ATTENTION

L’appareil et le matériel d’emballage ne sont pas

des jouets ! Il est interdit de laisser des enfants

jouer avec des sacs et des films en plastique et

avec des pièces de petite taille. Ils risquent de

les avaler et de s’étouffer !

Unité de moteur avec guidon supérieur

2x guidon inférieur

Décharge de traction du câble

2x clips attaches de câble

2x écrou en étoile

6x vis

4x rondelle

4x circlip

4x écrou

Mode d’emploi d’origine

Consignes de sécurité

3. Utilisation conforme à l’affectation

L’appareil est destiné à retourner la terre (par ex.

plates-bandes). Veuillez absolument respecter les

limites indiquées dans les consignes de sécurité

La machine doit exclusivement être employée

conformément à son affectation. Chaque utilisation

allant au-delà de cette affectation est considérée

comme non conforme. Pour les dommages en

résultant ou les blessures de tout genre, le

producteur décline toute responsabilité et

lʼopérateur/lʼexploitant est responsable.

Veillez au fait que nos appareils, conformément à

leur affectation, nʼont pas été construits, pour être

utilisés dans un environnement professionnel,

industriel ou artisanal. Nous déclinons toute

responsabilité si lʼappareil est utilisé

professionnellement, artisanalement ou dans des

sociétés industrielles, tout comme pour toute activité

équivalente.

Le respect du mode d’emploi joint par le producteur

est la condition primordiale prélable à une utilisation

conforme de l’appareil. Le mode d’emploi comprend

aussi les conditions de service, de maintenance et

d’entretien.

Pour des raisons de sécurité, l’appareil ne doit pas

être utilisé comme module d’entraînement pour

d’autres outils de travail et outillages de quelque

forme que ce soit.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 15

Page 16

4. Caractéristiques techniques

Tension du réseau : 230V ~ 50 Hz

Puissance absorbée : 1300 W

Largeur de travail : 40 cm

Ø du crochet : 23 cm

Vitesse de rotation de marche à vide : 110 tr/mn

Nombre de lames : 6 pièces

Niveau de pression acoustique LpA: 80 dB(A)

Imprécision K 2 dB(A)

Niveau acoustique L

WA

93 dB(A)

Imprécision K 2 dB(A)

Vibration du guidon a

hv

≤ 2,5 m/s

2

Imprécision K 1,5 m/s

2

Informations supplémentaires sur les outils

électriques

Avertissement !

La valeur d’émission de vibration a été mesurée selon

une méthode d’essai normée et peut être modifiée,

en fonction du type d’emploi de l’outil électrique ; elle

peut dans certains cas exceptionnels être supérieure

à la valeur indiquée.

La valeur d’émission de vibration indiquée peut être

utilisée pour comparer un outil électrique à un autre.

La valeur d’émission de vibration indiquée peut

également être utilisée pour estimer l’altération au

début.

Limitez le niveau sonore et les vibrations à un

minimum !

Utilisez exclusivement des appareils en excellent

état.

Entretenez et nettoyez l’appareil régulièrement.

Adaptez votre façon de travailler à l’appareil.

Ne surchargez pas l’appareil.

Faites contrôler l’appareil le cas échéant.

Mettez l’appareil hors circuit lorsque vous ne

l’utilisez pas.

Portez des gants.

Risques résiduels

Même en utilisant cet outil électrique

conformément aux prescriptions, il reste

toujours des risques résiduels. Les dangers

suivants peuvent apparaître en rapport avec la

construction et le modèle de cet outil électrique :

1. Lésions des poumons si aucun masque antipoussière adéquat n’est porté.

2. Déficience auditive si aucun casque anti-bruit

approprié n’est porté.

3. Atteintes à la santé issues des vibrations mainbras, si l’appareil est utilisé pendant une longue

période ou s’il n’a pas été employé ou entretenu

dans les règles de l’art.

5. Avant la mise en service

Montage (fig. 3-6)

앬 Placez la roue de transport dans la position la

plus basse (fig. 3/pos. E). Desserrez et retirez

pour ce faire la vis de blocage (fig. 3/pos. 13).

Réinsérez-la ensuite et serrez-la à fond.

앬 Fixez le guidon inférieur (fig. 4/pos. 2) sur les

supports de guidon avec respectivement 2 vis

(fig. 4/pos. 9) et 2 rondelles (fig. 4/pos. 10), 2

circlips (fig. 4/pos. 11) et 2 écrous (fig. 4/pos.

12).

앬 Faites glisser le déchargeur pour câble (fig.

5/pos. 5) sur le guidon supérieur (fig. 5/pos. 1).

Fixez le guidon supérieur (fig. 5/pos. 1) sur le

guidon inférieur (fig. 5/pos. 2) avec 2 vis (fig.

5/pos. 9) et 2 écrous-étoiles (fig. 5/pos. 8).

앬 Fixez le câble avec 2 clip de fixation du câble

(fig. 6/pos. 7) sur le guidon inférieur.

Branchement électrique

L’appareil peut être raccordé à chaque prise de

courant d’éclairage (de 230 Volt courant alternatif).

Seules cependant des prises à contact de protection

sont admises, il faut prévoir pour leur protection par

fusibles un disjoncteur automatique de protection

pour 16A. En outre, il faut coupler un interrupteur

différentiel (RCD) de 30 mA en amont !

Câble de raccordement de l’appareil

N’utilisez que des câbles de raccordement pour

l’appareil n’étant pas endommagés. Le câble de

raccordement de l’appareil ne doit pas être trop long

(max. 50 m), car autrement cela réduit la puissance

du moteur électrique. La section transversale du

câble de raccordement de l’appareil doit s’élever à 3

x 1,5mm

2

. Les câbles de raccordement souffrent

souvent d’endommagement de leur isolation.

Les causes en sont entre autres:

앬 des fissures par vieillissement de l’isolation

앬 des pliures dues à la fixation ou au guidage non

conforme du câble de raccordement

F

16

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 16

Page 17

F

17

Si de tels câbles de raccordement sont utilisés alors

que leur isolation est endommagée, ils représentent

un danger de mort. Les câbles, fiches et prises

d’accouplement doivent répondre aux conditions de

la liste suivante. Les câbles de raccordement des

appareils doivent avoir une isolation en caoutchouc.

Les câbles de raccordement doivent au moins être

de type H05RN-F et avoir 3 brins. Une impression de

la désignation de type sur le câble de raccordement

est obligatoire. N’achetez que des câbles de

raccordement dûment marqués ! Les fiches et prises

d’accouplement aux câbles de raccordement soivent

être en caoutchouc et être protégés contre les

éclaboussures d’eau. Les câbles de raccordement

des appareils ne doivent pas être trop longs. Des

câbles de raccordement longs doivent avoir une

section de conducteur plus importante.

Les câbles de raccordement et conduites de

raccordement doivent être contrôlées régulièrement

quant à d’éventuels dommages. Veillez à ce que les

câbles soient déconnectés pendant le contrôle.

Déroulez complètement le câble de raccordement de

l’appareil. Contrôlez aussi les introductions des

câbles de raccordement, au niveau des fiches et des

prises d’accouplement, quant à d’éventuels plis.

6. Commande

6.1 Mise en service

Raccordez le câble de l’appareil avec la fiche (fig. 7 /

pos.A) et assurez le câble avec la détente du collier

(fig. 7/pos. 5).

Attention ! Pour éviter une mise en marche

intempestive du scarificateur, le guidon est doté d’un

interrupteur à deux positions (fig. 8/pos. A) sur lequel

il faut appuyer avant de pouvoir actionner le levier de

commande (fig. 8 / pos. B). L’appareil se met hors

circuit dès qu’on lâche le levier de commande.

Répétez cette opération plusieurs fois afin de vous

assurer que l’appareil fonctionne correctement. Avant

d’entreprendre des réparations ou des travaux de

maintenance, vous devez vous assurer que les

couteaux hacheurs ne tournent pas et que l’appareil

n’est pas branché.

Le réglage en hauteur intégré permet dʼadapter la

roue de guidage à la profondeur de travail souhaitée.

Desserrez et retirez la vis de blocage (fig. 3/pos. 13).

Amenez la roue de guidage dans la position

souhaitée (fig. 3/pos. A-E) . Introduisez et serrez à

nouveau la vis de blocage.

L’espace de sécurité entre l’appareil et l’utilisateur,

qui correspond au guidon, doit toujours être respecté.

Montrez-vous particulièrement prudent en cas de

changement de direction devant un remblai ou un

talus. Veillez à vous tenir de façon sûre, portez des

chaussures à semelles anti-dérapantes et

agrippantes et des pantalons longs. Travaillez

toujours transversalement par rapport à la pente.

Faites particulièrement attention dans vos

mouvements en arrière et lorsque vous tirez le

scarificateur, risque de trébuchement !

6.2 Indications pour une bonne utilisation

Placez l’appareil devant la surface à travailler et

maintenez-le fermement par le guidon avant de le

mettre en marche.

Passez les couteaux hacheurs au-dessus de la

surface à travailler.

Essayez si possible de garder une trajectoire

constante afin d’arriver à traiter la surface

régulièrement. Les bords de ces pistes doivent alors

se chevaucher de quelques centimètres pour

qu’aucune bande ne reste sans aération.

Arrêtez le moteur à temps quand vous arrivez à la fin

d’une surface à travailler. Quand l’appareil est

soulevé (pour un changement de direction, par ex.), il

faut éteindre le moteur.

Veillez à toujours garder propre le dessous de

l’appareil et à retirer absolument tous les dépôts de

terre. Les dépôts de terre rendent le processus de

démarrage plus difficile et altèrent le travail en

profondeur.

Sur les talus, mettez-vous en position transversale à

la pente. Avant tout contrôle des couteaux, coupez le

moteur et débranchez le câble du réseau.

Attention !

Les couteaux continuent à tourner quelques

secondes encore après l’arrêt du moteur. Ne tentez

jamais de les arrêter. Au cas où les couteaux en

mouvement buttent contre un objet, mettez l’appareil

hors circuit et attendez que les couteaux

s’immobilisent complètement. Contrôlez ensuite l’état

des couteaux. Si ceux-ci sont endommagés, ils

doivent être changés.

Posez le câble de raccordement de l’appareil en

forme de boucle devant la prise utilisée, sur la terre.

Travaillez en vous éloignant de la prise et du câble et

en veillant à ce que le câble de raccordement se

trouve toujours sur le sol labouré afin d’être certain de

ne pas passer par-dessus avec les couteaux.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 17

Page 18

7. Remplacement de la ligne de

raccordement réseau

Si la ligne de raccordement réseau de cet appareil

est endommagée, il faut la faire remplacer par le

producteur ou son service après-vente ou par une

personne de qualification semblable afin dʼéviter tout

risque.

8. Nettoyage, maintenance et

commande de pièces de rechange

Ne procédez aux travaux de maintenance, au

nettoyage ou à l’enlèvement des dispositifs de

protection de l’appareil qu’après avoir arrêté le

moteur et l’avoir débranché.

8.1 Nettoyage

Maintenez les dispositifs de protection, les fentes

à air et le carter de moteur aussi propres (sans

poussière) que possible. Frottez lʼappareil avec

un chiffon propre ou soufflez dessus avec de lʼair

comprimé à basse pression.

Nous recommandons de nettoyer lʼappareil

directement après chaque utilisation.

Nettoyez lʼappareil régulièrement à lʼaide dʼun

chiffon humide et un peu de savon. Nʼutilisez

aucun produit de nettoyage ni détergeant ; ils

pourraient endommager les pièces en matières

plastiques de lʼappareil. Veillez à ce quʼaucune

eau nʼentre à lʼintérieur de lʼappareil.

8.2 Changement des couteaux hacheurs

Pour des raisons de sécurité, nous recommandons

de confier le remplacement des couteaux à un(e)

spécialiste dûment autorisé(e) (voir adresse sur le

certificat de garantie).

Attention !

Portez des gants de travail !

N’utilisez que des pièces détachées d’origine, faute

de quoi, le fonctionnement et la sécurité ne seraient

pas garantis.

8.3 Maintenance

Faites en sorte que les éléments de fixation (vis,

écrous etc.) restent toujours bien fixés afin de pouvoir

utiliser l’appareil en toute sécurité.

Stockez l’appareil dans une salle sèche. Pour leur

assurer une longue durée de vie, les pièces

métalliques doivent être nettoyées et huilées.

Nettoyez les parties en plastiques de l’appareil avec

des brosses ou des chiffons si possible. N’utilisez

aucun solvant pour éliminer les salissures.

Pour un stockage peu encombrant, desserrez les

écrous-étoiles (fig. 5/pos. 8) et rabattez le guidon

supérieur (fig. 5/pos. 1) en avant. Veillez ce faisant à

ne pas endommager le câble.

A la fin de la saison, effectuez un contrôle général de

l’appareil et retirez tous les dépôts accumulés.

En tout début de chaque saison, vérifier

impérativement l’état de l’appareil. Pour vos

réparations, adressez-vous à notre service aprèsvente (voir adresse sur le certificat de garantie).

8.4 Commande de pièces de rechange :

Pour les commandes de pièces de rechange,

veuillez indiquer les références suivantes:

Type de lʼappareil

No. dʼarticle de lʼappareil

No. dʼidentification de lʼappareil

No. de pièce de rechange de la pièce requise

Vous trouverez les prix et informations actuelles à

ʼadresse www.isc-gmbh.info

9. Mise au rebut et recyclage

Lʼappareil se trouve dans un emballage permettant

dʼéviter les dommages dus au transport. Cet

emballage est une matière première et peut donc

être réutilisé ultérieurement ou être réintroduit dans

le circuit des matières premières.

Lʼappareil et ses accessoires sont en matériaux

divers, comme par ex. des métaux et matières

plastiques. Eliminez les composants défectueux

dans les systèmes dʼélimination des déchets

spéciaux. Renseignez-vous dans un commerce

spécialisé ou auprès de lʼadministration de votre

commune !

10. Stockage

Entreposez l’appareil et ses accessoires dans un

endroit sombre, sec et à l’abri du gel tout comme

inaccessible aux enfants. La température de

stockage optimale est comprise entre 5 et 30 °C.

Conservez l’outil électrique dans l’emballage

d’origine.

18

F

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:23 Uhr Seite 18

Page 19

19

F

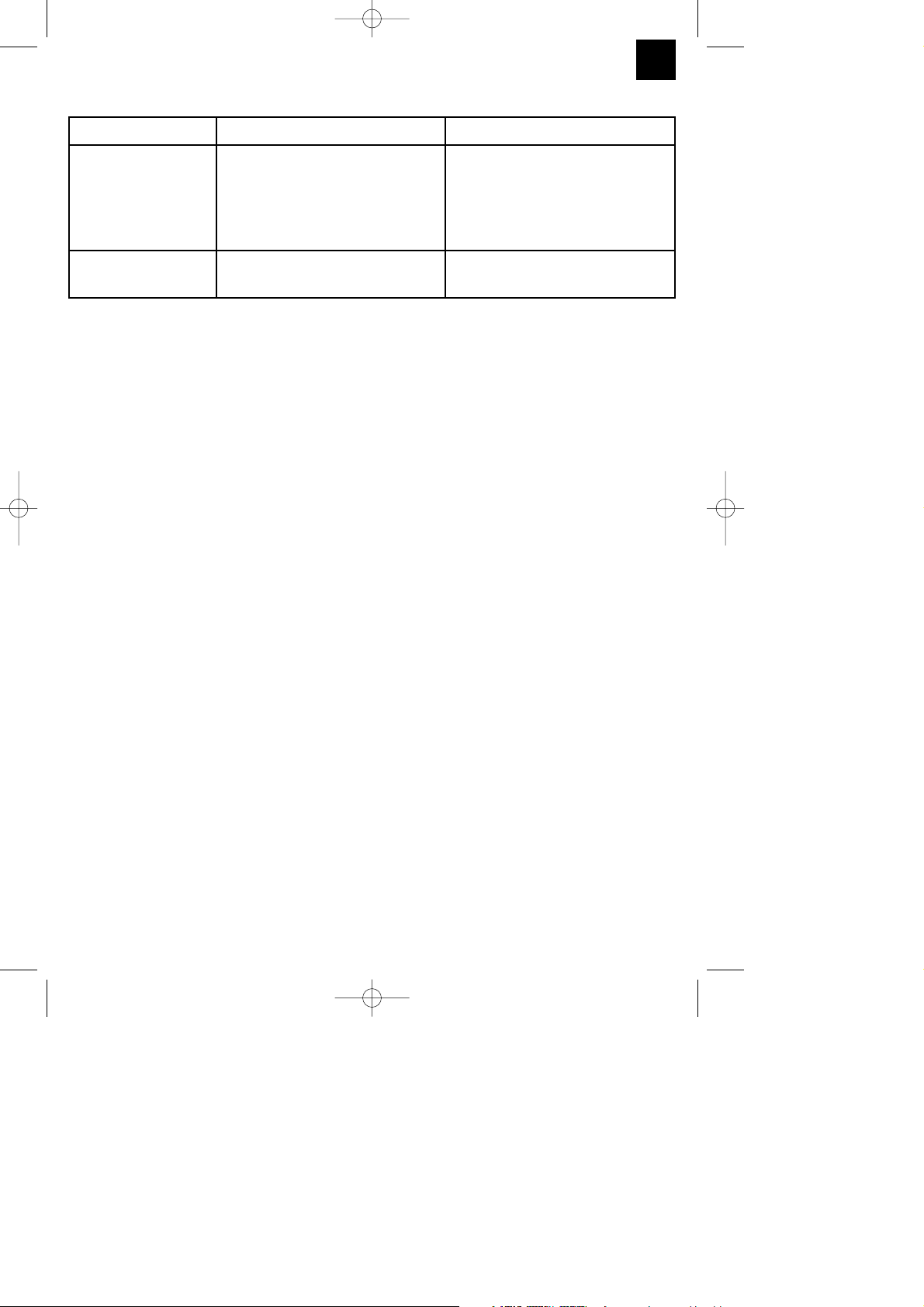

11. Plan de recherche des erreurs

Erreur Causes probables Suppression

Moteur ne démarre pas a) Pas de courant dans la fiche

b) Câble défectueux

c) Combinaison interrupteur-fiche

défectueuse

d) Raccordements sur le moteur ou

condensateur détachés

e) trop grande profondeur de travail

a) Contrôler le câble et le fusible

b) Contrôler

c) par atelier de service clientèle

d) par atelier de service clientèle

e) Diminuer la profondeur du travail

La puissance du moteur

diminue

a) sol trop dur

b) Couteau très usé

a) Corriger la profondeur du travail

b) Changer les couteaux hacheurs

Recommandation importante !

Le moteur est équipé d’un interrupteur thermique destiné à le ménager. Quand celui-ci est en

surchauffe, il s’arrête pour redémarrer automatiquement après une courte phase de refroidissement !

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 19

Page 20

I

20

Attenzione!

Nellʼusare gli apparecchi si devono rispettare diverse

avvertenze di sicurezza per evitare lesioni e danni.

Quindi leggete attentamente queste istruzioni per

lʼuso. Conservatele bene per avere a disposizione le

informazioni in qualsiasi momento. Se date

lʼapparecchio ad altre persone consegnate loro

queste istruzioni per lʼuso insieme allʼapparecchio!

Non ci assumiamo alcuna responsabilità per incidenti

o danni causati dal mancato rispetto di queste

istruzioni e delle avvertenze di sicurezza.

1. Avvertenze di sicurezza

Le relative avvertenze di sicurezza si trovano

nellʼopuscolo allegato.

AVVERTIMENTO!

Leggete tutte le avvertenze di sicurezza e le

istruzioni.

Dimenticanze nel rispetto delle avvertenze di

sicurezza e delle istruzioni possono causare scosse

elettriche, incendi e/o gravi lesioni.

Conservate tutte le avvertenze e le istruzioni per

eventuali necessità future.

2. Descrizione dellʼapparecchio ed

elementi forniti (Fig. 1)

2.1 Descrizione dellʼapparecchio

1. Impugnatura superiore

2. Impugnatura inferiore

3. Unità motore

4. Lame frangizolle

5. Dispositivo di eliminazione della trazione dal

cavo

6. Interruttore di sicurezza a 2 mani

7. Clip di fissaggio del cavo

8. 2x dadi a stella

9. 6x viti

10. 4x rosette

11. 4x anelli di sicurezza

12. 4x dadi

2.2 Elementi forniti

Aprite l’imballaggio e togliete con cautela

l’apparecchio dalla confezione.

Togliete il materiale d’imballaggio e anche i fermi

di trasporto / imballo (se presenti).

Controllate che siano presenti tutti gli elementi

forniti.

Verificate che l’apparecchio e gli accessori non

presentino danni dovuti al trasporto.

Se possibile, conservate l’imballaggio fino alla

scadenza della garanzia.

ATTENZIONE

L’apparecchio e il materiale d’imballaggio non

sono giocattoli! I bambini non devono giocare

con sacchetti di plastica, film e piccoli pezzi!

Sussiste pericolo di ingerimento e

soffocamento!

Unità motore con impugnatura superiore

2x impugnature inferiori

Dispositivo di eliminazione della trazione

2x clip di fissaggio per cavo

2x dadi a stella

6x viti

4x rosette

4x anelli di sicurezza

4x dadi

Istruzioni per l’uso originali

Avvertenze di sicurezza

3. Utilizzo proprio

L'apparecchio è adatto per zappare terriccio (per es.

orti, aiuole). Osservate assolutamente le limitazioni

nelle avvertenze di sicurezza.

Lʼapparecchio deve venire usato solamente per lo

scopo a cui è destinato. Ogni altro tipo di uso che

esuli da quello previsto non è un uso conforme.

Lʼutilizzatore/lʼoperatore, e non il costruttore, è

responsabile dei danni e delle lesioni di ogni tipo che

ne risultino.

Tenete presente che i nostri apparecchi non sono

stati costruiti per lʼimpiego professionale, artigianale

o industriale. Non ci assumiamo alcuna garanzia

quando lʼapparecchio viene usato in imprese

commerciali, artigianali o industriali, o in attività

equivalenti.

L'apparecchio è adatto all'uso privato nei giardini di

piccole dimensioni.

Il rispetto delle istruzioni per lʼuso fornite dal

produttore è una condizione per lʼuso corretto

dellʼapparecchio. Le istruzioni per l'uso contengono

anche condizioni per l'esercizio, la manutenzione e

la riparazione.

Per motivi di sicurezza l'apparecchio non deve venire

usato come gruppo motore per altri utensili o set di

utensili di qualsiasi tipo.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 20

Page 21

I

21

4. Dati tecnici

Tensione di rete: 230V ~ 50Hz

Potenza assorbita: 1300 W

Larghezza di lavoro: 40 cm

Lame frangizolle Ø: 23 cm

Numero di giri a vuoto: 110 min

-1

Numero delle lame: 6 pezzi

Livello di pressione acustica LpA: 80 dB(A)

Incertezza K 2 dB(A)

Livello di potenza acustica LWA: 93 dB (A)

Incertezza K 2 dB(A)

Vibrazioni sull'impugnatura a

hv

≤ 2,5 m/s

2

Incertezza K 1,5 m/s

2

Ulteriori informazioni per elettroutensili

Avvertimento!

Il valore di emissione di vibrazioni indicato è stato

misurato secondo un metodo di prova normalizzato e

può variare a seconda del modo in cui l’elettroutensile

viene utilizzato e, in casi eccezionali, può essere

superiore al valore riportato.

Il valore di emissione di vibrazioni indicato può essere

usato per il confronto tra elettroutensili di marchi

diversi.

Il valore di emissione di vibrazioni può essere

utilizzato anche per una valutazione preliminare dei

rischi.

Limitate al minimo lo sviluppo di rumore e le

vibrazioni!

Utilizzate soltanto apparecchi in perfetto stato.

Eseguite regolarmente la manutenzione e la

pulizia dell’apparecchio.

Adattate il vostro modo di lavorare

all’apparecchio.

Non sovraccaricate l’apparecchio.

Fate eventualmente controllare l’apparecchio.

Spegnete l’apparecchio se non lo utilizzate.

Indossate i guanti.

Rischi residui

Anche se questo elettroutensile viene utilizzato

secondo le norme, continuano a sussistere

rischi residui. In relazione alla struttura e al

funzionamento di questo elettroutensile

potrebbero presentarsi i seguenti pericoli:

1. Danni all’apparato respiratorio nel caso in cui non

venga indossata una maschera antipolvere

adeguata.

2. Danni all’udito nel caso in cui non vengano

indossate cuffie antirumore adeguate.

3. Danni alla salute derivanti da vibrazioni manobraccio se l’apparecchio viene utilizzato a lungo,

non viene tenuto in modo corretto o se la

manutenzione non è appropriata.

5. Prima della messa in esercizio

Montaggio (Fig. 3-6)

앬 Portare la ruota di avanzamento nella posizione

più bassa (Fig.3/Pos. E). Allentare la vite di

sicurezza (Fig. 3 / Pos. 13) e toglierla. Infine

reinserirla e serrarla bene.

앬 Fissare lʼimpugnatura inferiore (Fig.4/Pos. 2) ai

supporti dellʼimpugnatura con 2 viti (Fig. 4/Pos.

9) e due rosette (Fig.4/Pos.10), 2 anelli di

sicurezza (Fig. 4/Pos. 11) e due dadi

(Fig.4/Pos.12).

앬 Inserire il dispositivo di eliminazione della

trazione (Fig. 5/Pos. 5) nellʼimpugnatura

superiore (Fig. 5/Pos.1). Fissare lʼimpugnatura

superiore (Fig. 5/Pos.1) allʼimpugnatura inferiore

(Fig. 5/Pos. 2) con 2 viti (Fig. 5/Pos. 9) e due

dadi a stella (Fig. 5/Pos. 8).

앬 Fissare il cavo allʼimpugnatura inferiore con due

clip di fissaggio del cavo (Fig. 6/Pos. 7).

Collegamento di corrente

L'apparecchio può venire collegato ad ogni presa di

corrente (di 230 Volt di corrente alternata). È

consentita però solo una spina con contatto di terra,

dotata di un interruttore di sicurezza cavo da 16A.

Inoltre deve essere installato a monte un interruttore

di sicurezza per correnti di guasto (RCD) di max.

30mA.

Cavo di alimentazione dell'apparecchio

Usate solo cavi di alimentazione dell'apparecchio

che non siano danneggiati. Il cavo di alimentazione

dell'apparecchio non può essere lungo a piacimento

(max. 50 m), altrimenti si ridurrà la potenza del

motore elettrico. Il cavo di alimentazione

dell'apparecchio deve avere una sezione di 3 x 1,5

mm

2

. Sui cavi di alimentazione si verificano molto

spesso danni all'isolamento.

Eventuali cause per questo fenomeno sono:

앬 fessure dovute dell'invecchiamento

dell'isolamento;

앬 pieghe a causa di fissaggio o posizionamento

improprio del cavo di alimentazione

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 21

Page 22

I

22

Tali cavi di alimentazione danneggiati vengono

spesso usati nonostante rappresentino un pericolo

mortale a causa dei danni all'isolamento. Cavi, spine

e prese di accoppiamento devono soddisfare le

condizioni elencate qui di seguito. I cavi di

alimentazione per l'attacco di apparecchi devono

avere degli isolamenti in gomma.

I cavi di alimentazione per apparecchi devono essere

almeno del tipo H05RN-F a 3 fili. La denominazione

del tipo deve essere riportata sul cavo di

alimentazione. Comprate soltanto dei cavi di

alimentazione contrassegnati! Le spine e le prese di

accoppiamento sui cavi di alimentazione per

apparecchi devono essere di gomma e protette dagli

spruzzi d'acqua. I cavi di alimentazione non possono

essere di qualsiasi lunghezza. I cavi di alimentazione

più lunghi richiedono sezioni maggiori dei conduttori.

Si deve controllare regolarmente che i cavi di

alimentazione e di collegamento non presentino

danni. Fate attenzione che durante il controllo i cavi

non conducano corrente. Svolgete completamente il

cavo di alimentazione per apparecchi. Controllate

anche che le entrate dei cavi di alimentazione

dell'apparecchio su spine e su prese di

accoppiamento non presentino pieghe.

6. Uso

6.1 Messa in esercizio

Collegate il cavo di collegamento dell'apparecchio al

connettore (Fig. 7/Pos. A) e assicurate il cavo di

collegamento con il dispositivo di eliminazione della

trazione (Fig. 7/Pos. 5).

Attenzione! Per evitare un'accensione inavvertita

dell'apparecchio l'impugnatura è dotata di un

interruttore a due punti (Fig. 8/Pos. A) che deve

venire premuto prima di poter attivare la leva di

commutazione (Fig. 8 /Pos B). Mollando la leva di

commutazione l'apparecchio si spegne. Eseguite

questa operazione più volte per assicurarvi che

l'apparecchio funzioni correttamente. Prima di

eseguire riparazioni o lavori di manutenzione

sull'apparecchio dovete assicurarvi che le lame non

ruotino e che l'apparecchio sia scollegato dalla rete

elettrica.

Il dispositivo integrato di regolazione dellʼaltezza

permette lʼadeguamento della ruota di guida alla

profondità di lavoro desiderata. Allentare la vite di

sicurezza (Fig. 3 / Pos. 13) e toglierla. Portare la

ruota di avanzamento nella posizione più bassa

(Fig. 3/Pos. A-E). Reinserire la vite di sicurezza e

serrarla bene.

Deve venire sempre mantenuta la distanza di

sicurezza, data dalle impugnature di guida, tra

l'apparecchio e l'utilizzatore. Nel cambiare il senso di

direzione su scarpate e pendii si deve prestare

particolare attenzione. Accertatevi di essere in

posizione sicura, portate scarpe con suole

antisdrucciolevoli e pantaloni lunghi. Lavorate

sempre in senso trasversale rispetto al pendio.

Siate particolarmente attenti muovendovi all'indietro

e tirando l'apparecchio, pericolo di inciampare!

6.2 Avvertenze per lavorare in modo corretto

Prima di accendere l'apparecchio, posizionatelo

davanti la superficie da lavorare e tenetelo

saldamente per l'impugnatura. Fate passare le lame

sopra la superficie da lavorare.

Per ottenere un terreno ben lavorato si deve

muovere l'apparecchio in fasce possibilmente

parallele. Le corsie formate eseguendo l'operazione

si devono quindi sovrapporre sempre di alcuni

centimetri al fine di evitare strisce di prato non

lavorate.

Spegnete il motore tempestivamente quando avete

raggiunto il fine della superficie da lavorare. Il motore

deve essere spento quando l'apparecchio viene

sollevato (per es. in caso di un cambiamento di

direzione).

Tenete pulita la parte inferiore dell'apparecchio e

togliete assolutamente i depositi di terra. I depositi

rendono più difficile l'operazione di avvio e

influiscono negativamente sulla qualità della

profondità di lavoro. Sui pendii la direzione di lavoro

deve essere trasversale rispetto alla pendenza.

Prima di eseguire qualsiasi controllo delle lame

bisogna spegnere il motore e staccare il cavo dalla

presa.

Attenzione!

Dopo lo spegnimento del motore le lame continuano

a muoversi per qualche secondo. Non cercate mai di

fermare le lame. Se le lame in movimento vano a

battere contro un oggetto, fermate l'apparecchio e

attendete fino a quando le lame siano

completamente ferme. Controllate quindi lo stato

delle lame. Se sono danneggiate devono essere

sostituite.

Posate il cavo di alimentazione usato avvolto a spire

per terra davanti alla presa utilizzata. Lavorate

allontanandovi dalla presa o dal cavo e fate

attenzione che il cavo di alimentazione si trovi

sempre sul suolo lavorato affinché le lame non ci

passino sopra.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 22

Page 23

I

23

7. Sostituzione del cavo di

alimentazione

Se il cavo di alimentazione di questo apparecchio

viene danneggiato deve essere sostituito dal

produttore, dal suo servizio di assistenza clienti o da

una persona al pari qualificata al fine di evitare

pericoli.

8. Pulizia, manutenzione e ordinazione

dei pezzi di ricambio

I lavori di manutenzione e di pulizia dell'apparecchio

e lo smontaggio dei dispositivi di protezione devono

venire eseguiti solo con il motore fermo e con il cavo

di alimentazione staccato.

8.1 Pulizia

Tenete il più possibile i dispositivi di protezione,

le fessure di aerazione e la carcassa del motore

liberi da polvere e sporco. Strofinate

lʼapparecchio con un panno pulito o soffiatelo

con lʼaria compressa a pressione bassa.

Consigliamo di pulire lʼapparecchio subito dopo

averlo usato.

Pulite lʼapparecchio regolarmente con un panno

asciutto ed un poʼ di sapone. Non usate

detergenti o solventi perché questi ultimi

potrebbero danneggiare le parti in plastica

dellʼapparecchio. Fate attenzione che non possa

penetrare dellʼacqua nellʼinterno

dellʼapparecchio.

8.2 Sostituzione delle lame

Per motivi di sicurezza consigliamo di affidare la

sostituzione delle lame ad un tecnico autorizzato.

Attenzione!

Mettetevi guanti da lavoro! Usate solamente pezzi di

ricambio originali dato che altrimenti non sono

garantite eventualmente il funzionamento e la

sicurezza.

8.3 Manutenzione

Fate in modo che gli elementi di fissaggio (viti, bulloni

ecc.) siano sempre fissi e avvitati in modo da poter

lavorare con l'apparecchio in maniera sicura.

Conservate l'apparecchio in un luogo asciutto. Per

una lunga durata tutte le parti in metallo devono

venire pulite ed poi oliate. Se possibile pulite le parti

in plastica dell'apparecchio con spazzole o stracci.

Non usate solventi o acqua per togliere lo sporco.

Per una conservazione a risparmio di spazio

allentate i dadi a stella (Fig. 5/Pos. 8) e piegate

lʼimpugnatura superiore (Fig. 5/Pos. 1) in avanti. Nel

far questo fate attenzione a non danneggiare il cavo.

Alla fine della stagione eseguite un controllo generale

dell'apparecchio e togliete tutti i resti depositatisi.

All'inizio della stagione controllate sempre lo stato

dell'apparecchio. In caso di riparazioni rivolgetevi al

nostro servizio assistenza clienti (vedi indirizzo sul

certificato di garanzia).

8.4 Ordinazione di pezzi di ricambio:

Volendo commissionare dei pezzi di ricambio, si

dovrebbe dichiarare quanto segue:

modello dellʼapparecchio

numero dellʼarticolo dellʼapparecchio

numero dʼident. dellʼapparecchio

numero del pezzo di ricambio del ricambio

necessitato

Per i prezzi e le informazioni attuali si veda

www.isc-gmbh.info

9. Smaltimento e riciclaggio

Lʼapparecchio si trova in una confezione per evitare i

danni dovuti al trasporto. Questo imballaggio

rappresenta una materia prima e può perciò essere

utilizzato di nuovo o riciclato.

Lʼapparecchio e i suoi accessori sono fatti di materiali

diversi, per es. metallo e plastica. Consegnate i pezzi

difettosi allo smaltimento di rifiuti speciali. Per

informazioni rivolgetevi ad un negozio specializzato o

allʼamministrazione comunale!

10. Conservazione

Conservate l’apparecchio e i suoi accessori in un

luogo buio, asciutto, al riparo dal gelo e non

accessibile ai bambini. La temperatura ottimale per la

conservazione è compresa tra i 5 e i 30 °C.

Conservate l’elettroutensile nell’imballaggio originale.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 23

Page 24

I

24

11. Tabella per l'eliminazione delle anomalie

Anomalia Possible causes Eliminazione

Il motore non si avvia a) non c'è corrente sulla presa

b) cavo difettoso

c) gruppo interruttore connettore

difettoso

d) attacchi al motore o condensatore

allentati

e) profondità di lavoro troppo elevata

a) controllare il cavo ed il dispositivo di

protezione

b) fare controllare

c) da un'officina del servizio assistenza

clienti

d) da un'officina del servizio assistenza

clienti

e) ridurre la profondità di lavoro

La potenza del motore

diminuisce

a) suolo troppo duro

b) lame troppo consumate

a) correggere la profondità di lavoro

b) sostituire le lame

Avvertenza importante!

Il motore dispone come protezione di un interruttore termico che lo disinserisce in caso di

sovraccarico e lo reinserisce automaticamente dopo una breve fase di raffreddamento!

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 24

Page 25

S

25

Obs!

Innan produkten kan användas måste särskilda

säkerhetsanvisningar beaktas för att förhindra

olyckor och skador. Läs därför noggrant igenom

denna bruksanvisning. Förvara den på ett säkert

ställe så att du alltid kan hitta önskad information.

Om produkten ska överlåtas till andra personer

måste även denna bruksanvisning medfölja.

Vi övertar inget ansvar för olyckor eller skador som

har uppstått om denna bruksanvisning eller

säkerhetsanvisningarna åsidosätts.

1. Säkerhetsanvisningar

Gällande säkerhetsanvisningar finns i det bifogade

häftet.

VARNING!

Läs alla säkerhetsanvisningar och instruktioner.

Försummelser vid iakttagandet av

säkerhetsanvisningarna och instruktionerna kan

förorsaka elstöt, brand och/eller svåra skador.

Förvara alla säkerhetsanvisningar och

instruktioner för framtiden.

2. Beskrivning av maskinen /

Leveransomfattning (bild 1)

2.1 Beskrivning av maskinen

1. Övre skjutbygel

2. Undre skjutbygel

3. Motorenhet

4. Hackknivar

5. Kabeldragavlastning

6. Tvåhands-säkerhetsbrytare

7. Kabelklämmor

8. 2 st stjärnmuttrar

9. 6 st skruvar

10. 4 st distansbrickor

11. 4 st låsringar

12. 4 st muttrar

2.2 Leveransomfattning

Öppna förpackningen och ta försiktigt ut

produkten ur förpackningen.

Ta bort förpackningsmaterialet samt

förpacknings- och transportsäkringar (om

förhanden).

Kontrollera att leveransen är komplett.

Kontrollera om produkten eller tillbehörsdelarna

har skadats i transporten.

Spara om möjligt på förpackningen tills

garantitiden har gått ut.

VARNING!

Produkten och förpackningsmaterialet är ingen

leksak! Barn får inte leka med plastpåsar, folie

eller smådelar! Risk för att barn sväljer delar och

kvävs!

Motorenhet med övre skjutbygel

2 st undre skjutbygel

Kabeldragavlastning

2 st kabelklämmor

2 st stjärnmuttrar

6 st skruvar

4 st distansbrickor

4 st låsringar

4 st muttrar

Original-bruksanvisning

Säkerhetsanvisningar

3. Ändamålsenlig användning

Maskinen är avsedd för uppgrävning av jord (t ex

trädgårdsland). Beakta tvunget begränsningarna som

anges i säkerhetsanvisningarna.

Maskinen får endast användas till sitt avsedda

ändamål. Användningar som sträcker sig utöver detta

användningsområde är ej ändamålsenliga. För

materialskador eller personskador som resulterar av

sådan användning ansvarar användaren/operatören

själv. Tillverkaren påtar sig inget ansvar.

Tänk på att våra produkter endast får användas till

ändamålsenligt syfte och inte har konstruerats för

yrkesmässig, hantverksmässig eller industriell

användning. Vi ger därför ingen garanti om produkten

ska användas inom yrkesmässiga, hantverksmässiga

eller industriella verksamheter eller vid liknande

aktiviteter.

En förutsättning för ändamålsenlig användning av

maskinen är att tillverkarens bruksanvisning beaktas.

Bruksanvisningen innehåller även gällande drifts-,

underhålls- och reparationsvillkor.

Av säkerhetsskäl får maskinen inte användas som

drivaggregat för andra arbetsverktyg eller

verktygssatser av olika slag.

Anleitung_BG_RT_1340_M_SPK7:_ 22.07.2010 11:24 Uhr Seite 25

Page 26

S

26

4. Tekniska data

Nätspänning: 230 V ~ 50 Hz

Upptagen effekt: 1300 W

Arbetsbredd: 40 cm

Fräsningsdiameter: 23 cm

Tomgångsvarvtal: 110 min

-1

Antal knivar: 6 st.

Ljudtrycksnivå LpA: 80 dB(A)

Osäkerhet K : 2 dB(A)

Ljudeffektnivå LWA: 93 dB(A)

Osäkerhet K: 2 dB(A)

Vibrationahv vid stången: ≤ 2,5 m/s

2

Osäkerhet K : 1,5 m/s

2

Extra information för elverktyg

Varning!

Vibrationsemissionsvärdet som anges har mätts upp

med en standardiserad provningsmetod och kan

variera beroende på vilket sätt som elverktyget

används. I undantagsfall kan det faktiska värdet

avvika från det angivna värdet.

Vibrationsemissionsvärdet som anges kan användas

om man vill jämföra olika elverktyg.

Vibrationsemissionsvärdet som anges kan även

användas för en första bedömning av inverkan från

elverktyget.

Begränsa uppkomsten av buller och vibration till

ett minimum!

Använd endast intakta maskiner.

Underhåll och rengör maskinen regelbundet.

Anpassa ditt arbetssätt till maskinen.

Överbelasta inte maskinen.

Lämna in maskinen för översyn vid behov.

Slå ifrån maskinen om den inte används.

Bär handskar.

Kvarstående risker

Kvarstående risker föreligger alltid även om

detta elverktyg används enligt föreskrift.

Följande risker kan uppstå på grund av

elverktygets konstruktion och utförande:

1. Lungskador om ingen lämplig dammfiltermask

används.

2. Hörselskador om inget lämpligt hörselskydd

används.

3. Hälsoskador som uppstår av hand- och

armvibrationer om maskinen används under

längre tid eller om det inte hanteras och

underhålls enligt föreskrift.

5. Före användning

Montera maskinen (bild 3-6)

앬 Ställ transporthjulet på den lägsta inställningen

(bild 3/pos. E). Lossa först på säkringsskruven

(bild 3/pos. 13) och ta sedan bort den. Sätt

sedan in den igen och dra åt ordentligt.

앬 Montera den undre skjutbygeln (bild 4/pos. 2) på

bygelfästet med 2 st skruvar (bild 4/pos. 9), 2 st

distansbrickor (bild 4/pos. 10), 2 st låsringar (bild

4/pos. 11) samt 2 st muttrar (bild 4/pos. 12) på

vardera sida.

앬 Skjut kabeldragavlastningen (bild 5/pos. 5) på

den övre skjutbygeln (bild 5/pos. 1). Montera den

övre skjutbygeln (bild 5/pos. 1) på den undre

skjutbygeln (bild 5/pos. 2) med 2 st skruvar (bild

5/pos. 9) och 2 st stjärnmuttrar (bild 5/pos. 8).

앬 Fäst kabeln med 2 st kabelklämmor (bild 6/pos.

7) på den undre skjutbygeln.

Nätanslutning

Maskinen kan anslutas till ett valfritt nätuttag (med

230 V växelspänning). Tänk dock på att endast