Page 1

Art.-Nr.: 34.046.20 I.-Nr.: 11024

Originalbetriebsanleitung

Benzin-Motorsense

Original operating instructions

Petrol Power Scythe

Mode d’emploi d’origine

débroussailleuse à moteur à essence

Istruzioni per l’uso originali

Decespugliatore a motore a benzina

z

Πρωτότυπες Οδηγίες χρήσης

Bενζινοκίνητο θεριστήρι

Bf

Originalne upute za uporabu

Kosilica za travu s benzinskim motorom

j

Originální návod k obsluze

Benzínová motorová kosa

W

Originálny návod na obsluhu

Benzínová motorová kosa

Q

Instrucţiuni de utilizare originale

Motocoasă pe benzină

Z

Orijinal Kullanma Talimatı

Benzin Motorlu Tırpan

BBC 43

Anleitung_BBC_43_SPK7__ 29.08.14 07:48 Seite 1

Page 2

2

Vor Inbetriebnahme Bedienungsanleitung und Sicherheitshinweise

lesen und beachten.

Read and follow the operating instructions and safety information

before using for the first time.

Avant la mise en service, lisez le mode dʼemploi et les consignes

de sécurité et respectez-les.

Prima della messa in esercizio leggete e osservate le istruzioni per

l’uso e le avvertenze di sicurezza.

¶ЪИУ ЩЛ ı¤ЫЛ ЫВ ПВИЩФ˘ЪБ›· ‰И·‚¿ЫЩВ О·И ·ОФПФ˘ı‹ЫЩВ ЩЛУ √‰ЛБ›·

¯Ú‹Û˘ Î·È ÙȘ Àԉ›ÍÂȘ ·ÛÊ·Ï›·˜

Bf Prije puštanja u rad pročitajte upute za uporabu i sigurnosne

napomene i pridržavajte se istih.

j Před uvedením do provozu si přečíst a dodržovat návod k obsluze a

bezpečnostní pokyny.

W Pred uvedením do prevádzky si prečítajte a dodržiavajte návod na

obsluhu a bezpečnostné pokyny.

Q Înainte de punerea în funcţiune se vor citi şi respecta instrucţiunile de

folosire şi indicaţiile de siguranţă.

Z Aleti çalıştırmadan önce kullanma talimatı ve güvenlik uyarılarını

okuyun ve talimatlara riayet edin.

Anleitung_BBC_43_SPK7__ 29.08.14 07:48 Seite 2

Page 3

3

1

2

2a

17

16

18

19

21

14

13

15

27

26

31

30

2b

9

10

1

11

12

87

6

4

3

5

2b

2a

23

28

29

24

25

22

20

13

Anleitung_BBC_43_SPK7__ 29.08.14 07:48 Seite 3

Page 4

4

3 4a4

7a 7c7b

5 65a

1

18

1

26

30

33

34

15

32

35

1

14

2b

2a

2b

22

28

13

21

7d 7f7e

33

34

29

25

32

27

22

35

20

Anleitung_BBC_43_SPK7__ 29.08.14 07:48 Seite 4

Page 5

5

12b

1312a

8 9

31

10

16

32

22

11c

11d 11e 11f

11a 11b

38

39

37

36

17

24

17

24

26

Anleitung_BBC_43_SPK7__ 29.08.14 07:48 Seite 5

Page 6

6

14b

15c

15d

15e

15f

13a 14a

15b15a

E

D

1

2

C

39

6

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 6

Page 7

7

Inhaltsverzeichnis

1. Sicherheitshinweise

2. Gerätebeschreibung

3. Lieferumfang

4. Bestimmungsgemäße Verwendung

5. Technische Daten

6. Vor Inbetriebnahme

7. Bedienung

8. Reinigung, Wartung und Ersatzteilbestellung

9. Lagerung und Transport

10. Entsorgung und Wiederverwertung

11. Fehlerbehebung

D

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 7

Page 8

8

D

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut auf,

damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

Sicherheitsvorrichtungen

Beim Arbeiten mit dem Gerät muss die

entsprechende Kunststoffschutzhaube für Messeroder Fadenbetrieb montiert sein, um das

Wegschleudern von Gegenständen zu verhindern.

Das integrierte Messer in der SchnittfadenSchutzhaube schneidet den Faden automatisch auf

die optimale Länge ab.

Zusammenbau: Achten Sie beim Zusammenbau

darauf, dass keine Fremdkörper in das Gerät

gelangen oder die Funktion der Kupplung durch

Verschmutzung beeinträchtigt wird.

Nach dem Zusammenbau: Wenn das Gerät im

Standgas läuft darf sich das Werkzeug nicht

mitdrehen. Ist das nicht der Fall, wurde ein Fehler bei

der Montage gemacht.

2. Gerätebeschreibung (Abb. 1-15)

1. Führungsholm

2a. Führungshandgriff rechts

2b. Führungshandgriff links

3. Benzintank

4. Starterseil

5. Abdeckung Luftfiltergehäuse

6. Choke-Hebel

7. Kabelverbindung

8. Zündkerzenstecker

9. Ein-/Aus-Schalter

10. Arretierung Gashebel

11. Gashebel

12. Gashebelsperre

13. Baugruppe Motor

14. Baugruppe Führungsholm

15. Tragegurt

16. Fadenspule mit Schnittfaden

17. Fadenmesser

18. 2x Kabelbinder

19. Schlitzschraubenzieher

20. Zündkerzenschlüssel

21. Inbusschlüssel 5 mm

22. Inbusschlüssel 4 mm

23. Öl/Benzinmischflasche

24. Schnittfadenschutz

25. Oberteil Führungshandgriffhalterung

26. Schnittmesserschutzhaube

27. Schnittmesser

28. 4x Inbusschraube M6x30, Federring, U-Scheibe

29. 4x Inbusschraube M5x25, Federring, U-Scheibe

30. 2x Sechskantschraube M6x16

31. 3x Fadenmesserbefestigungsschraube

(L = 10mm)

3. Lieferumfang

n Öffnen Sie die Verpackung und nehmen Sie das

Gerät vorsichtig aus der Verpackung.

n Entfernen Sie das Verpackungsmaterial sowie

Verpackungs-/ und Transportsicherungen (falls

vorhanden).

n Überprüfen Sie, ob der Lieferumfang vollständig

ist.

n Kontrollieren Sie das Gerät und die Zubehörteile

auf Transportschäden.

n Bewahren Sie die Verpackung nach Möglichkeit

bis zum Ablauf der Garantiezeit auf.

ACHTUNG

Gerät und Verpackungsmaterial sind kein Kinderspielzeug! Kinder dürfen nicht mit Kunststoffbeuteln, Folien und Kleinteilen spielen! Es besteht

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 8

Page 9

9

D

Verschluckungs- und Erstickungsgefahr!

n Baugruppe Motor

n Baugruppe Führungsholm

n Führungshandgriff links

n Tragegurt

n Fadenspule mit Schnittfaden

n Fadenmesser

n 2x Kabelbinder

n Schlitzschraubenzieher

n Zündkerzenschlüssel

n Inbusschlüssel 5 mm

n Inbusschlüssel 4 mm

n Öl/Benzinmischflasche

n Schnittfadenschutz

n Oberteil Führungshandgriffhalterung

n Schnittmesserschutzhaube

n Schnittmesser

n 4x Inbusschraube M6x30, Federring, U-Scheibe

n 4x Inbusschraube M5x25, Federring, U-Scheibe

n 2x Sechskantschraube M6x16

n 3x Fadenmesserbefestigungsschraube

(L = 10mm)

n Originalbetriebsanweisung

n Sicherheitshinweise

4. Bestimmungsgemäße Verwendung

Die Motorsense (Verwendung des Schneidmessers)

eignet sich zum Schneiden von leichten Gehölz,

starken Unkraut und Unterholz.

Der Motortrimmer (Verwendung der Fadenspule mit

Schnittfaden) eignet sich zum Schneiden von Rasen,

Grasflächen und leichten Unkraut. Die Einhaltung der

vom Hersteller beigefügten Gebrauchsanweisung ist

Vorraussetzung für den ordnungsgemäßen

Gebrauch des Gerätes. Jede andere Verwendung,

die in dieser Anleitung nicht ausdrücklich zugelassen

wird, kann zu Schäden am Gerät führen und eine

ernsthafte Gefahr für den Benutzer darstellen.

Beachten Sie unbedingt die Einschränkungen in den

Sicherheitshinweisen.

Bitte beachten Sie, dass unsere Geräte

bestimmungsgemäß nicht für den gewerblichen,

handwerklichen oder industriellen Einsatz konstruiert

wurden. Wir übernehmen keine Gewährleistung,

wenn das Gerät in Gewerbe-, Handwerks- oder

Industriebetrieben sowie bei gleichzusetzenden

Tätigkeiten eingesetzt wird.

Achtung! Wegen körperlicher Gefährdung des

Benutzers darf die Benzinmotorsense nicht zu

folgenden Arbeiten eingesetzt werden: zum Reinigen

von Gehwegen und als Häcksler zum Zerkleinern

von Baum- und Heckenabschnitten. Ferner darf die

Benzinmotorsense nicht zum Einebnen von

Bodenerhebungen, wie z.B. Maulwurfshügel

verwendet werden. Aus Sicherheitsgründen darf die

Benzinmotorsense nicht als Antriebsaggregat für

andere Arbeitswerkzeuge und Werkzeugsätze

jeglicher Art verwendet werden.

Die Maschine darf nur nach ihrer Bestimmung

verwendet werden. Jede weitere darüber

hinausgehende Verwendung ist nicht

bestimmungsgemäß. Für daraus hervorgerufene

Schäden oder Verletzungen aller Art haftet der

Benutzer/Bediener und nicht der Hersteller.

5. Technische Daten

Motortyp 2-Takt-Motor, luftgekühlt

Motorleistung (max.) 1,25 kW/ 1,7 PS

Hubraum 43 ccm

Leerlaufdrehzahl Motor 3000 ± 300 min

-1

Max. Drehzahl Motor 7500 min

-1

Max. Schnittgeschwindigkeit 8300 min

-1

Zündung Elektronisch

Antrieb Zentrifugalkupplung

Gewicht (leerer Tank) 7,3 kg

Schnittkreis-Faden Ø 40 cm

Schnittkreis-Messer Ø 25,5 cm

Fadenlänge 2,5 m

Faden-Ø 2,4 mm

Tankinhalt 1,1 l

Zündkerze Torch L7T

Geräusch und Vibration

Die Geräusch- und Vibrationswerte wurden entsprechend EN ISO 11806-1, EN ISO 22868; EN ISO

22867 ermittelt.

Schalldruckpegel L

pA

100 dB(A)

Unsicherheit K

pA

1,5 dB

Schallleistungspegel L

WA

114 dB(A)

Unsicherheit K

WA

1,5 dB

Tragen Sie einen Gehörschutz.

Die Einwirkung von Lärm kann Gehörverlust bewirken.

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 9

Page 10

10

D

Betrieb

Linker Handgriff

Schwingungsemissionswert ah = 13,846 m/s

2

Unsicherheit K = 1,5 m/s

2

Rechter Handgriff

Schwingungsemissionswert ah = 10,602 m/s

2

Unsicherheit K = 1,5 m/s

2

Beschränken Sie die Geräuschentwicklung und

Vibration auf ein Minimum!

n Verwenden Sie nur einwandfreie Geräte.

n Warten und reinigen Sie das Gerät regelmäßig.

n Passen Sie Ihre Arbeitsweise dem Gerät an.

n Überlasten Sie das Gerät nicht.

n Lassen Sie das Gerät gegebenenfalls

überprüfen.

n Schalten Sie das Gerät aus, wenn es nicht

benutzt wird.

n Tragen Sie Handschuhe.

6. Vor Inbetriebnahme

6.1 Montage

6.1.1 Montage Führungsholm

(Abb. 3) Schrauben Sie die Baugruppe Führungsholm (14) mit den 4 Innensechskantschrauben

M6x30 (28) an der Baugruppe Motor (13) fest.

6.1.2 Montage Führungshandgriff

Montieren Sie den Führungshandgriff links (2b) bzw.

den Führungshandgriff rechts (2a) wie in den Abbildungen 4-4a dargestellt. Die Löcher in den Führungshandgriffen dienen als Schraubenaufnahme.

Ziehen Sie die Schrauben (29) am Oberteil der Führungshandgriffhalterung (25) fest.

6.1.3 Tragegurt und Kabel befestigen

Haken Sie wie in Abb. 5 dargestellt den Tragegurt (15)

in die Halterung ein. Anschließend befestigen Sie das

Kabel mittels der beigelegten Kabelbinder (18) am

Führungsholm und Führungshandgriff.

6.1.4 Montage Schnittmesserschutzhaube

Achtung: Beim Arbeiten mit dem Schnittmesser muss

die Schnittmesserschutzhaube (26) montiert sein.

Schrauben Sie wie in Abb. 6 dargestellt die Schnittmesserschutzhaube (26) mit den beiden Schrauben

M6x16 (30) an der dafür vorgesehenen Schelle an.

6.1.5 Montage/Ersetzen des Schnittmessers

Die Montage des Schnittmessers ist auf den Bildern

7a-7f zu sehen. Die Demontage erfolgt in umgekehrter Reihenfolge.

n Mitnehmerscheibe (32) auf die Zahnwelle

stecken (Abb. 7b)

n Schnittmesser (27) auf der Mitnehmerscheibe

arretieren (Abb. 7c)

n Druckplatte (33) über das Gewinde der

Zahnwelle stecken (Abb. 7d)

n Abdeckung Druckplatte (34) aufstecken (Abb. 7e)

n Die Bohrung der Mitnehmerscheibe suchen, mit

der darunter liegenden Kerbe überein bringen

und mit dem mitgelieferten Inbusschlüssel (22)

arretieren um nun die Mutter (35) anzuziehen

(Abb. 7f). Achtung: Linksgewinde

6.1.6 Montage Fadenmesser

Schrauben Sie das Fadenmesser (17) wie in Abb. 8

dargestellt mit drei Schrauben (31) am Schnittfadenschutz (24) fest. Verletzungsgefahr - Schutzhandschuhe tragen.

6.1.7 Montage Schnittfadenschutz an

Schnittmesserschutzhaube

Achtung: Beim Arbeiten mit dem Schnittfaden muss

zusätzlich die Schnittfadenschutzhaube montiert

werden.

Der Schnittfadenschutz (24) wird wie in Abb. 9 dargestellt in die Aufnahmen an der Messerschutzhaube (26) gedrückt. Achtung: Am Schnittfadenschutz befindet sich das Schnittfadenmesser – Verletzungsgefahr!

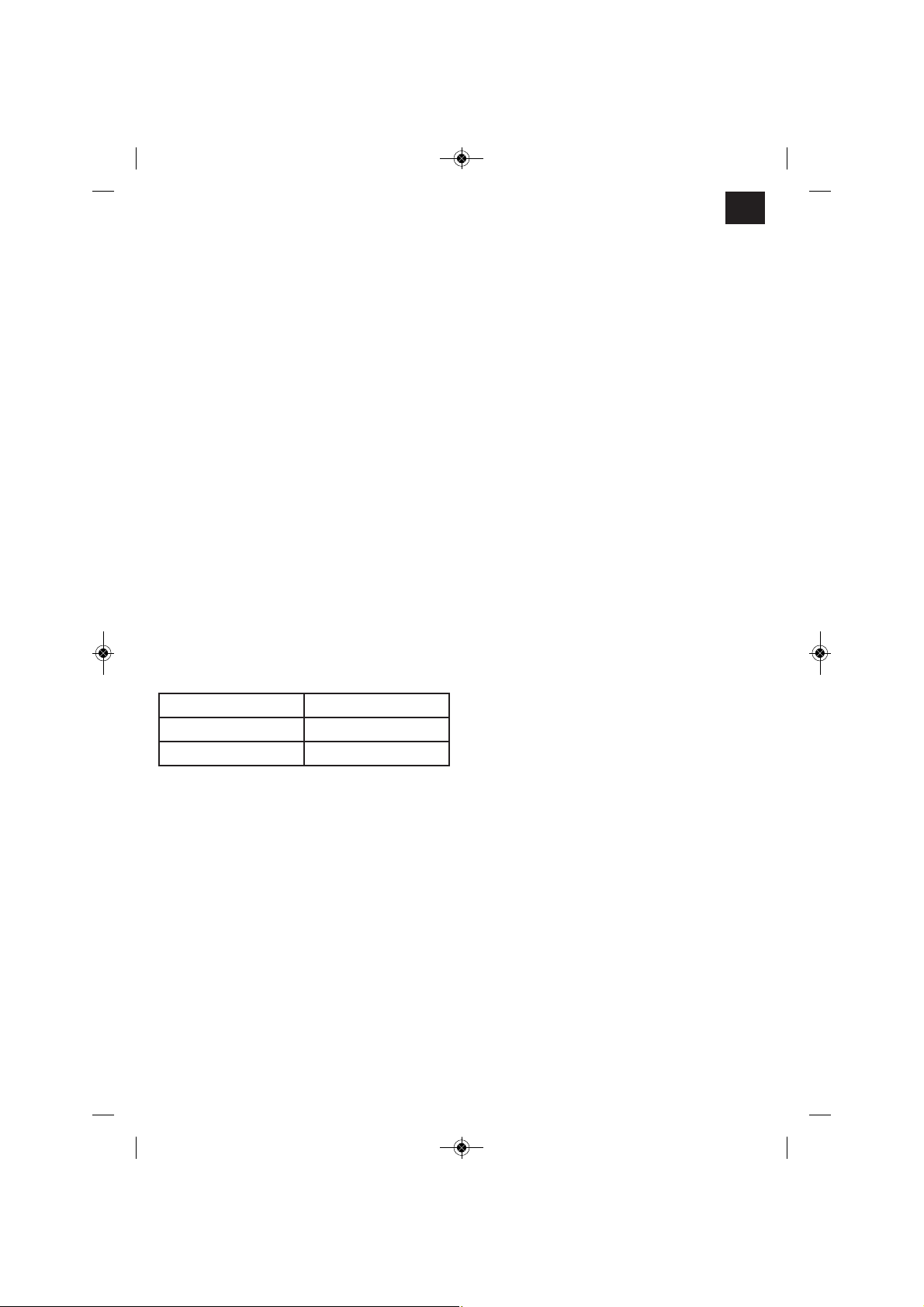

6.1.8 Montage/ Ersetzen der Fadenspule

Die Montage der Fadenspule ist auf dem Bild 10 zu

sehen. Die Demontage erfolgt umgekehrt.

Die Bohrung der Mitnehmerscheibe (32) suchen, mit

der darunter liegenden Kerbe überein bringen und mit

dem mitgelieferten Inbusschlüssel (22) arretieren um

nun die Fadenspule (16) auf das Gewinde zu

schrauben. Achtung: Linksgewinde

6.2 Einstellen der Schnitthöhe

n Streifen Sie den Schultergurt (15) über die linke

Schulter.

n Um die optimale Tragegurtlänge festzustellen

machen Sie anschließend einige

Schwingbewegungen ohne den Motor

anzulassen (Abb. 11a)

Achtung: Benutzen Sie den Gurt immer wenn Sie

mit dem Gerät arbeiten. Bringen Sie den Gurt an

sobald Sie den Motor gestartet haben und er im

Leerlauf läuft. Schalten Sie den Motor aus bevor Sie

den Tragegurt abnehmen.

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 10

Page 11

11

D

Prüfen Sie das Gerät vor jeder Inbetriebnahme auf:

n Dichtheit des Treibstoffsystems.

n Einwandfreien Zustand und Vollständigkeit der

Schutzeinrichtungen und der Schnittvorrichtung.

n Festen Sitz sämtlicher Verschraubungen.

n Leichtgängigkeit aller beweglichen Teile.

6.3 Treibstoff und Öl

Empfohlene Treibstoffe

Benutzen Sie nur ein Gemisch aus bleifreiem Benzin

und speziellem 2-Takt-Motoröl. Mischen Sie das

Treibstoffgemisch nach der Treibstoff-Mischtabelle

an.

Achtung: Verwenden Sie kein Treibstoffgemisch,

das mehr als 90 Tage lang gelagert wurde.

Achtung: Verwenden Sie kein 2-Takt-Öl das ein

Mischverhältnis von 100:1 empfiehlt. Bei

Motorenschäden auf Grund ungenügender

Schmierung entfällt die Motorgarantie des

Herstellers.

Achtung: Verwenden Sie zum Transport und zur

Lagerung von Kraftstoff nur dafür vorgesehene und

zugelassene Behälter.

Geben Sie jeweils die richtige Menge Benzin und 2Takt-Öl in die beiliegende Mischflasche (Siehe

aufgedruckte Skala). Schütteln Sie anschließend den

Behälter gut durch.

6.4 Treibstoff-Misch-Tabelle

Mischverfahren: 40 Teile Benzin auf 1 Teil Öl

7. Bedienung

Beachten Sie bitte die gesetzlichen Bestimmungen

zur Lärmschutzverordnung, die örtlich

unterschiedlich sein können.

7.1 Starten bei kaltem Motor

Füllen Sie den Tank mit einer angemessenen Menge

Benzin/Öl-Gemisch. Siehe auch Treibstoff und Öl.

1. Gerät auf eine harte, ebene Fläche stellen.

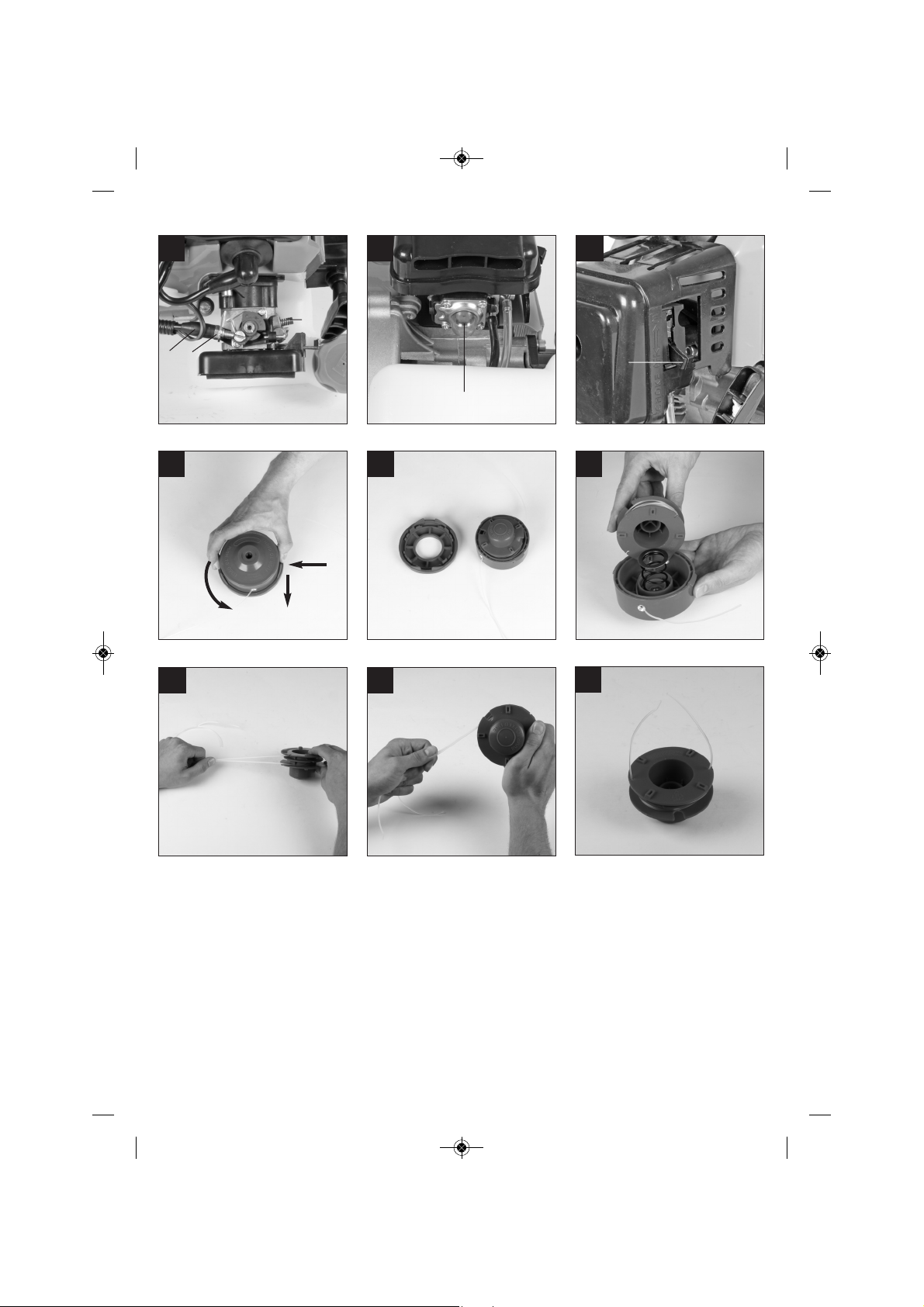

2. Kraftstoffpumpe (Primer) (Abb. 14a/Pos. 39) 10x

drücken.

3. Ein-/ Aus-Schalter (Abb. 1/Pos. 9) auf „I“

schalten.

4. Gashebel feststellen. Hierzu Gashebelsperre

(Abb. 1/Pos. 12) und anschließend Gashebel

(Abb. 1/Pos. 11) betätigen und durch

gleichzeitiges Drücken der Arretierung (Abb.

1/Pos. 10) den Gashebel feststellen.

5. Choke-Hebel (Abb. 14b/Pos. 6) auf „ON“ stellen.

6. Das Gerät gut festhalten und die Starterleine

(Abb. 1/Pos. 4) bis zum ersten Widerstand

herausziehen. Jetzt den Startseilzug 4x rasch

anziehen. Das Gerät sollte starten.

Achtung: Die Starterleine nicht

zurückschleudern lassen. Dies kann zu

Beschädigungen führen.

Achtung: Durch den festgestellten Gashebel

beginnt das Schnittwerkzeug bei startendem

Motor zu arbeiten.

Ist der Motor gestartet, den Choke-Hebel sofort

auf „OFF “ stellen und das Gerät ca. 3 Sek.

warmlaufen lassen.

Achtung: Durch den festgestellten Gashebel beginnt das Schnittwerkzeug bei startendem

Motor zu arbeiten. Anschließend Gashebel durch

einfaches Betätigen entriegeln (Der Motor kehrt

in den Leerlauf zurück).

7. Sollte der Motor nicht starten wiederholen Sie die

Schritte 4-6.

Zur Beachtung: Springt der Motor auch nach

mehreren Versuchen nicht an, lesen Sie den

Abschnitt „Fehlerbehebung am Motor“.

Zur Beachtung: Ziehen Sie den Startseilzug stets

gerade heraus. Wird sie in einem Winkel

herausgezogen, entsteht Reibung an der Öse. Durch

diese Reibung wird die Schnur durchgescheuert und

nutzt sich schneller ab. Halten Sie stets den

Anlassergriff, wenn sich die Schnur wieder einzieht.

Lassen Sie die Schnur nie aus dem ausgezogenen

Zustand zurückschnellen.

7.2 Starten bei warmem Motor

(Das Gerät stand für weniger als 15-20min still)

1. Gerät auf harte, ebene Fläche stellen.

2. Ein-/Aus-Schalter auf „I“ schalten.

3. Gashebel feststellen (analog „Starten bei kaltem

Motor“).

4. Gerät gut festhalten und die Starterleine bis zum

ersten Widerstand herausziehen. Jetzt die

Starterleine rasch anziehen. Das Gerät sollte

nach 1-2 Zügen starten. Falls die Maschine nach

6 Zügen immer noch nicht startet wiederholen

Sie die Schritte 1-7 unter kalten Motor starten.

7.3 Motor abstellen

Not-Aus Schrittfolge:

Falls es notwendig ist, die Maschine sofort

anzuhalten, stellen Sie hierzu den Ein-/Aus-Schalter

auf „Stop“ bzw. „0“

Benzin 2-Takt-Öl

1 Liter 25 ml

5 Liter 125 ml

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 11

Page 12

12

D

Normale Schrittfolge:

Lassen Sie den Gashebel los und warten Sie bis der

Motor in Leerlaufgeschwindigkeit übergegangen ist.

Stellen Sie dann den Ein-/ Aus-Schalter auf „Stop“

bzw. „0“.

7.4 Arbeitshinweise

Trainieren Sie vor Einsatz des Gerätes sämtliche

Arbeitstechniken bei abgestelltem Motor.

Verlängerung des Schnittfadens

Warnung! Benutzen Sie keinen Metalldraht oder

kunststoffumhüllten Metalldraht irgendeiner Art in der

Fadenspule. Dies kann zu schweren Verletzungen

beim Benutzer führen.

Zur Verlängerung des Schnittfadens, lassen Sie den

Motor auf Vollgas laufen und tippen Sie die

Fadenspule auf den Boden. Der Faden wird

automatisch verlängert. Das Messer am Schutzschild

kürzt den Faden auf die zulässige Länge.

Vorsicht: Entfernen Sie regelmäßig alle Rasen- und

Unkrautreste um ein Überhitzen des Schaftrohrs zu

vermeiden. Rasen-/ Gras-/Unkrautreste verfangen

sich unterhalb des Schutzschilds (Abb. 11c), dies

verhindert eine ausreichende Kühlung des

Schaftrohrs. Entfernen Sie die Reste vorsichtig mit

einem Schraubenzieher oder dergleichen.

Verschiedene Schnittverfahren

Ist das Gerät richtig montiert, schneidet es Unkraut

und hohes Gras an schwer zugänglichen Stellen, wie

z.B. entlang von Zäunen, Mauern und Fundamenten

sowie um Bäume herum. Es lässt sich auch für

„Abmäharbeiten“ einsetzen, um Vegetation zur

besseren Vorbereitung eines Gartens oder zum

Ausputzen eines bestimmten Bereiches bodennah

zu entfernen.

Zur Beachtung: Auch bei sorgfältiger Anwendung

hat das Schneiden an Fundamenten, Stein- oder

Betonmauern usw. eine über dem Normalen

liegende Abnutzung des Fadens zur Folge.

Trimmen/ Mähen

Schwingen Sie den Trimmer in sichelartiger

Bewegung von Seite zu Seite. Halten Sie die

Fadenspule stets parallel zum Boden. Überprüfen

Sie das Gelände und legen Sie die gewünschte

Schnitthöhe fest. Führen und halten Sie die

Fadenspule in der gewünschten Höhe, zwecks

gleichmässigem Schnitt (Abb. 11d).

Niedriges Trimmen

Halten Sie den Trimmer mit einer leichten Neigung

genau vor sich, so dass sich die Unterseite der

Fadenspule über dem Boden befindet und der Faden

die richtige Schnittstelle trifft. Schneiden Sie immer

von sich weg. Ziehen Sie den Trimmer nicht zu sich

hin.

Schneiden an Zaun/ Fundament

Nähern Sie sich beim Schneiden langsam

Maschendrahtzäunen, Lattenzäunen,

Natursteinmauern und Fundamenten um nah daran

zu schneiden, ohne jedoch mit dem Faden gegen

das Hindernis zu schlagen. Kommt der Faden z.B.

mit Steinen, Steinmauern oder Fundamenten in

Berührung, nutzt er sich ab oder franst aus. Schlägt

der Faden gegen Zaungeflecht, bricht er ab.

Trimmen um Bäume

Trimmen Sie um Baumstämme, nähern Sie sich

langsam, damit der Faden die Rinde nicht berührt.

Gehen Sie um den Baum herum, und schneiden Sie

dabei von links nach rechts. Nähern Sie sich Gras

oder Unkraut mit der Spitze des Fadens, und kippen

Sie die Fadenspule leicht nach vorn.

Warnung: Seien Sie überaus vorsichtig bei

Abmäharbeiten. Halten Sie bei solchen Arbeiten

einen Abstand von 30 Metern zwischen sich und

anderen Personen oder Tieren ein.

Abmähen

Beim Abmähen erfassen Sie die gesamte Vegetation

bis zum Grund. Dazu neigen Sie die Fadenspule im

30 Grad Winkel nach rechts. Stellen Sie den

Handgriff in die gewünschte Position. Beachten Sie

die erhöhte Verletzungsgefahr des Benutzers,

Zuschauer und Tiere, sowie die Gefahr der

Sachbeschädigung durch weggeschleuderte Objekte

(z.B. Steine) (Abb. 11e).

Warnung: Entfernen Sie mit dem Gerät keine

Gegenstände von Fußwegen usw.!

Das Gerät ist ein kraftvolles Werkzeug, und kleine

Steine oder andere Gegenstände können 15 Meter

und mehr weggeschleudert werden und zu

Verletzungen oder Beschädigungen an Autos,

Häusern und Fenstern führen.

Sägen

Das Gerät ist nicht zum Sägen geeignet.

Verklemmen

Sollte das Schnittmesser wegen zu dichter

Vegetation blockieren stellen Sie unverzüglich den

Motor ab. Befreien Sie das Gerät von Gras und

Gestrüpp bevor Sie es erneut in Betrieb nehmen.

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 12

Page 13

13

D

Vermeiden von Rückschlag

Beim Arbeiten mit dem Schnittmesser besteht die

Gefahr des Rückschlages wenn dieses auf feste

Hindernisse (Baumstamm, Ast, Baumstumpf, Stein

oder dergleichen) trifft. Das Gerät wird dabei gegen

die Drehrichtung des Werkzeugs zurückgeschleudert. Dies kann zum Verlust der Kontrolle über das

Gerät führen. Benutzen Sie das Schnittmesser nicht

in der Nähe von Zäunen, Metallpfosten,

Grenzsteinen oder Fundamenten.

Zum Schneiden von dichten Stängeln positionieren

Sie diese wie in Abb. 11f dargestellt um Rückschläge

zu vermeiden.

8. Reinigung, Wartung und

Ersatzteilbestellung

Schalten Sie das Gerät vor Wartungsarbeiten immer

aus und ziehen Sie den Zündkerzenstecker ab.

8.1 Ersetzen von Fadenspule/Schnittfaden

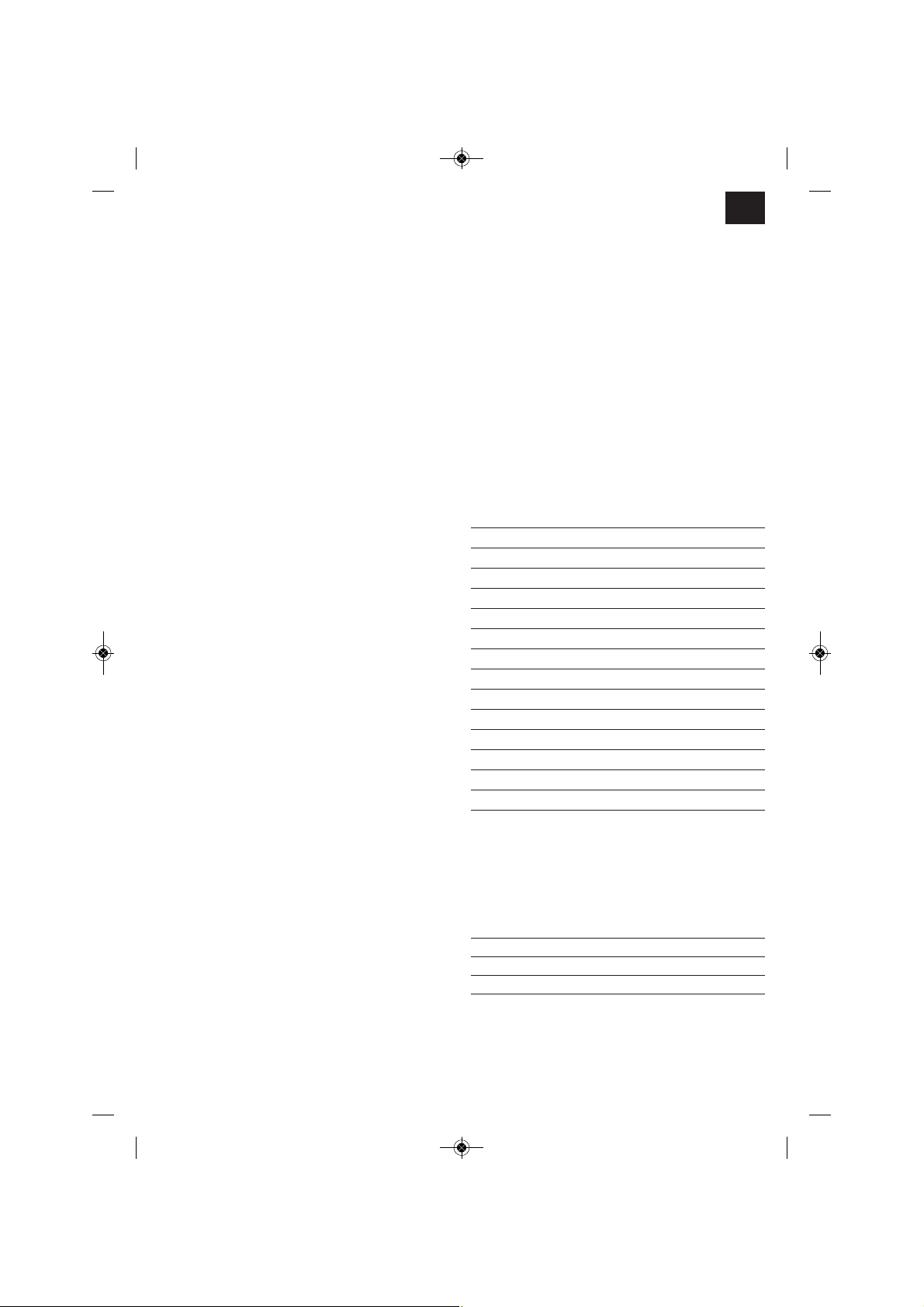

1. Die Fadenspule (16) wie in Abs 6.1.8. beschrieben demontieren. Die seitliche Rastnase leicht

eindrücken, gleichzeitig die Spule nach unten

drücken und im Uhrzeigersinn drehen (Abb. 15a).

Eine Gehäusehälfte abnehmen.

2. Fadenspule aus dem Fadenspulen-Gehäuse

entnehmen (Abb. 15c).

3. Evtl. noch vorhandenen Schnittfaden entfernen.

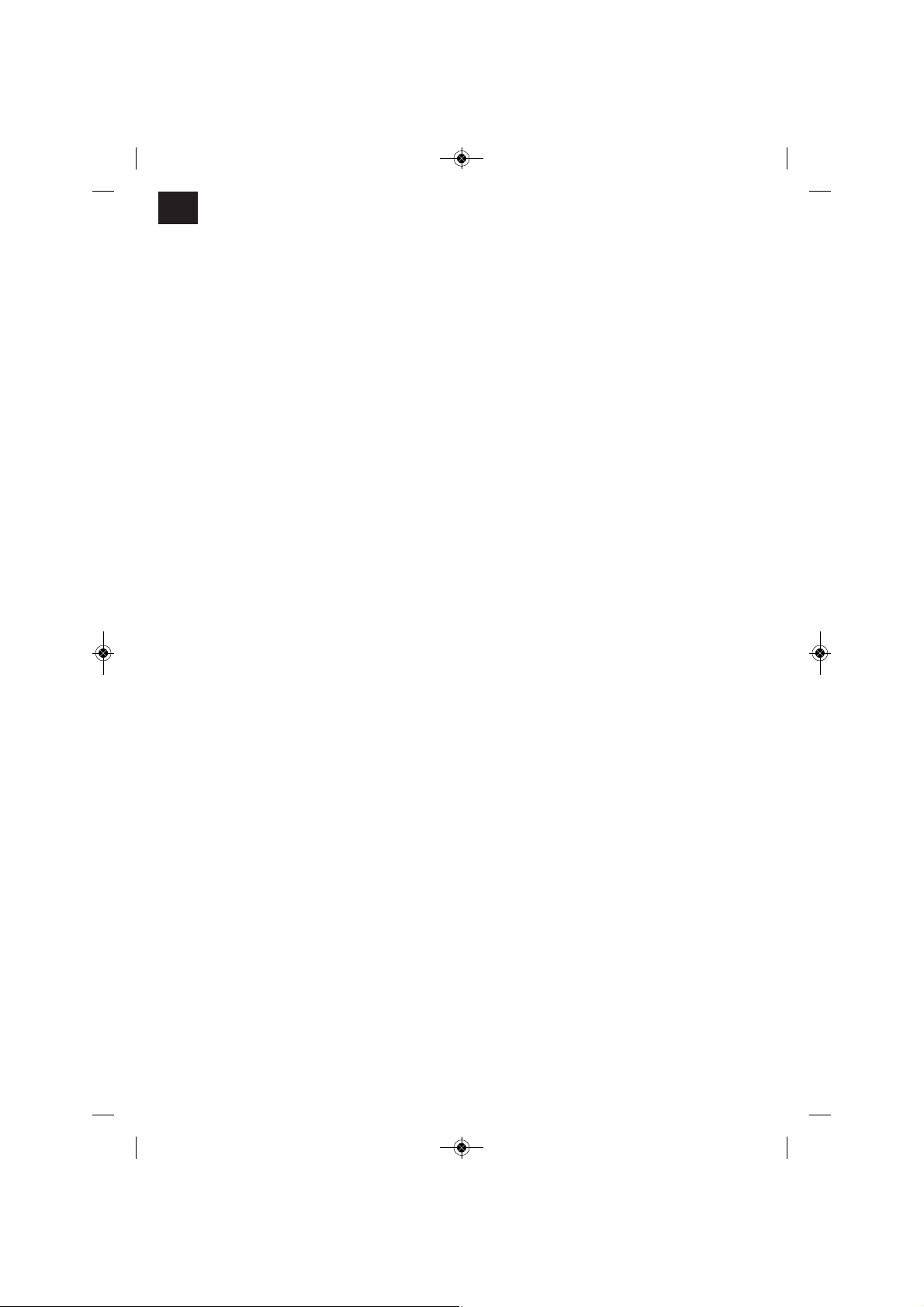

4. Neuen Schnittfaden in der Mitte zusammenlegen

und die entstandene Schlaufe in die Aussparung

des Spulenteilers einhängen. (Abb. 15d)

5. Faden unter Spannung gegen den Uhrzeigersinn

aufwickeln. Der Spulenteiler trennt dabei die

beiden Hälften des Nylonfadens. (Abb. 15e)

6. Die letzten 15cm der beiden Fadenenden in die

gegenüberliegenden Fadenhalter der Fadenspule einhaken. (Abb. 15f)

7. Die beiden Fadenenden durch die Metallösen im

Fadenspulen-Gehäuse führen (Abb. 15c).

8. Fadenspule in das Fadenspulen-Gehäuse

drücken.

9. Kurz und kräftig an beiden Fadenenden ziehen

um diese aus den Fadenhaltern der Fadenspule

zu lösen.

10. Überschüssigen Faden auf etwa 13 cm zurückschneiden. Das verringert die Belastung auf den

Motor während des Startens und Aufwärmens.

11. Fadenspule wieder montieren Siehe Punkt 6.1.8

Wird die komplette Fadenspule erneuert sind die

Punkte 3-6 zu überspringen.

8.2 Wartung des Luftfilters

Verschmutzte Luftfilter verringern die Motorleistung

durch zu geringe Luftzufuhr zum Vergaser.

Regelmäßige Kontrolle ist daher unerlässlich. Der

Luftfilter (37) sollte alle 25 Betriebsstunden

kontrolliert werden und bei Bedarf gereinigt werden.

Bei sehr staubiger Luft ist der Luftfilter häufiger zu

überprüfen.

1. Entfernen Sie den Luftfilterdeckel (Abb.12a/

Pos. 36)

2. Entnehmen Sie den Luftfilter (Abb.12b/ Pos. 37)

3. Reinigen Sie den Luftfilter durch ausklopfen oder

ausblasen.

4. Der Zusammenbau erfolgt in umgekehrter

Reihenfolge.

Achtung: Luftfilter nie mit Benzin oder brennbaren

Lösungsmitteln reinigen.

8.3 Wartung der Zündkerze (Abb. 13)

Zündkerzenfunkenstrecke = 0,6mm. Ziehen Sie die

Zündkerze mit 12 bis 15 Nm an. Überprüfen Sie die

Zündkerze erstmals nach 10 Betriebsstunden auf

Verschmutzung und reinigen Sie diese gegebenenfalls mit einer Kupferdrahtbürste.

Danach die Zündkerze alle 50 Betriebsstunden

warten.

1. Ziehen Sie den Zündkerzenstecker (38) ab.

2. Entfernen Sie die Zündkerze (39) mit dem beiliegenden Zündkerzenschlüssel (20).

3. Der Zusammenbau erfolgt in umgekehrter

Reihenfolge.

8.4 Schleifen des Schutzhaubenmessers

Das Schutzhaubenmesser kann mit der Zeit stumpf

werden. Sollten Sie dies feststellen, lösen Sie die 3

Schrauben mit denen das Schutzhaubenmesser an

der Schutzhaube befestigt ist. Befestigen Sie das

Messer in einem Schraubstock. Schleifen Sie das

Messer mit einer Flachfeile und achten Sie darauf,

den Winkel der Schnittkante beizubehalten. Feilen

Sie nur in eine Richtung.

8.5 Vergaser Einstellungen

Achtung! Einstellungen am Vergaser dürfen nur

durch autorisierten Kundendienst vorgenommen

werden.

Zu allen Arbeiten am Vergaser muss zuerst die

Luftfilterabdeckung wie in Abbildung 12a und 12b

gezeigt demontiert werden.

Einstellen des Gasseilzuges:

Sollte die Maximaldrehzahl des Geräts mit der Zeit

nicht mehr erreicht werden und sämtliche anderen

Ursachen nach Abschnitt 11 Fehlerbehebung ausgeschlossen sein, könnte eine Einstellung des Gasseilzuges erforderlich sein.

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 13

Page 14

Überprüfen Sie hierfür zunächst ob der Vergaser bei

voll durchgedrücktem Gasgriff ganz öffnet. Dies ist

der Fall wenn der Vergaserschieber (Abb. 13a) bei

voll betätigtem Gas vollständig geöffnet ist.

Abbildung 13a zeigt die korrekte Einstellung. Sollte

der Vergaserschieber nicht vollständig geöffnet sein,

ist eine Nachjustierung notwendig.

Um den Gasseilzug nachzustellen sind folgende

Schritte erforderlich:

n Lösen Sie die Kontermutter (Abb. 13a/Pos. C)

einige Umdrehungen.

n Drehen Sie die Verstellschraube (Abb. 13a/Pos.

D) heraus, bis der Vergaserschieber bei voll

betätigtem Gas, wie in Abbildung 13a gezeigt,

vollständig geöffnet ist.

n Ziehen Sie die Kontermutter wieder fest.

Einstellen des Standgases:

Achtung! Standgas bei warmen Betriebszustand

einstellen.

Sollte das Gerät bei nicht betätigtem Gashebel ausgehen und sämtliche anderen Ursachen nach Abschnitt 11 Fehlerbehebung ausgeschlossen sein, ist

ein Nachjustieren des Standgases notwendig.

Drehen Sie hierzu die Standgasschraube (Abb. 13a/

Pos. E) im Uhrzeigersinn bis das Gerät im Leerlauf

sicher läuft. Sollte das Standgas so hoch sein, dass

sich das Schnittwerkzeug mitdreht, muss dies durch

Linksdrehen der Standgasschraube soweit verringert

werden bis sich das Schnittwerkzeug nicht mehr

mitdreht.

8.6 Umweltschutz

Verschmutztes Wartungsmaterial und Betriebsstoffe

in einer dafür vorgesehenen Sammelstelle abgeben.

Verpackungsmaterial, Metall und Kunststoffe dem

Recycling zuführen.

8.7 Ersatzteilbestellung

Bei der Ersatzteilbestellung sollten folgende

Angaben gemacht werden;

n Typ des Gerätes

n Artikelnummer des Gerätes

n Ident-Nummer des Gerätes

n Ersatzteilnummer des erforderlichen Ersatzteils

Aktuelle Preise und Infos finden Sie unter

www.isc-gmbh.info

9. Lagerung und Transport

9.1 Lagerung

Vorsicht: Verstauen Sie das Gerät nie länger als 30

Tage, ohne folgende Schritte zu durchlaufen.

Verstauen des Gerätes

Wenn Sie das Gerät länger als 30 Tage verstauen,

muss sie hierfür hergerichtet werden. Andernfalls

verdunstet der im Vergaser befindliche, restliche

Treibstoff und lässt einen gummiartigen Bodensatz

zurück. Dies könnte den Start erschweren und teure

Reparaturarbeiten zur Folge haben.

1. Nehmen Sie die Treibstofftankkappe langsam

ab, um eventuellen Druck im Tank abzulassen.

Entleeren Sie vorsichtig den Tank.

2. Starten Sie den Motor und lassen Sie ihn laufen,

bis die Säge anhält, um den Treibstoff aus dem

Vergaser zu entfernen.

3. Lassen Sie den Motor abkühlen (ca. 5 Minuten).

4. Entfernen Sie die Zündkerze (siehe 8.3)

5. Geben Sie 1 Teelöffel sauberes 2-Takt-Öl in die

Verbrennungskammer. Ziehen Sie mehrere Male

langsam an der Starterleine, um die internen

Komponenten zu beschichten. Setzen Sie die

Zündkerze wieder ein.

Hinweis: Verstauen Sie das Gerät an einem

trockenen Ort und weit entfernt von möglichen Entzündungsquellen, z.B. Ofen, Heißwasserboiler mit

Gas, Gastrockner, etc.

Erneutes Inbetriebnehmen

1. Entfernen Sie die Zündkerze (siehe 8.3).

2. Ziehen Sie rasch an der Starterleine, um überschüssiges Öl aus der Verbrennungskammer zu

entfernen.

3. Reinigen Sie die Zündkerze und achten Sie auf

den richtigen Elektrodenabstand an der Zündkerze; oder setzen Sie eine neue Zündkerze mit

richtigem Elektrodenabstand ein.

4. Bereiten Sie das Gerät für den Betrieb vor

5. Füllen Sie den Tank mit der richtigen Treibstoff-/

Ölmischung auf. Siehe Abschnitt Treibstoff und

Öl.

9.2 Transport

Wenn Sie das Gerät transportieren möchten entleeren Sie den Benzintank wie im Kapitel „Lagerung“

erklärt. Reinigen Sie das Gerät mit einer Bürste oder

einem Handfeger von grobem Schmutz.

Demontieren Sie den Führungshandgriff wie unter

Punkt 6.1.2 erklärt.

14

D

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 14

Page 15

15

D

10. Entsorgung und Wiederverwertung

Das Gerät befindet sich in einer Verpackung um

Transportschäden zu verhindern. Diese Verpackung

ist Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus

verschiedenen Materialien, wie z.B. Metall und

Kunststoffe. Führen Sie defekte Bauteile der

Sondermüllentsorgung zu. Fragen Sie im

Fachgeschäft oder in der Gemeindeverwaltung nach!

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 15

Page 16

16

D

11. Fehlerbehebung

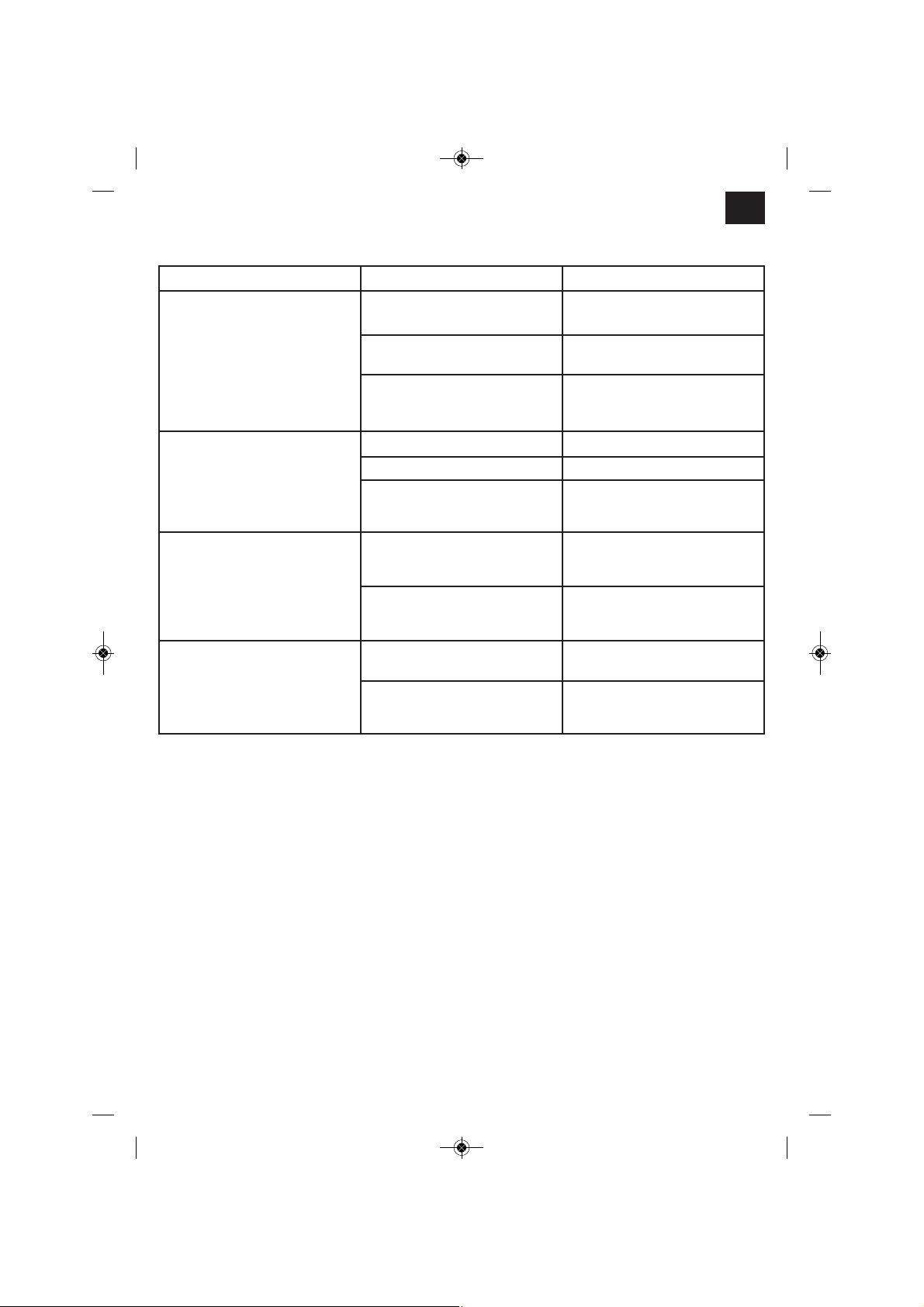

Störung Mögliche Ursache Störungsbehebung

Das Gerät springt nicht an. Fehlerhaftes Vorgehen beim

Starten.

Verrußte oder feuchte Zündkerze

Falsche Vergasereinstellung

Folgen Sie den Anweisungen zum

Starten

Zündkerze reinigen oder durch

neue ersetzen.

Autorisierten Kundendienst

aufsuchen, oder das Gerät an die

ISC-GmbH senden.

Das Gerät springt an, hat aber nicht

die volle Leistung.

Falsche Einstellung des

Chokehebels

Verschmutzter Luftfilter

Falsche Vergasereinstellung

Chokehebel auf „OFF“ stellen.

Luffilter reinigen

Autorisierten Kundendienst

aufsuchen, oder das Gerät an die

ISC-GmbH senden.

Der Motor läuft unregelmäßig Falscher Elektrodenabstand der

Zündkerze

Falsche Vergasereinstellung

Zündkerze reinigen und

Elektrodenabstand einstellen oder

neue Zündkerze einsetzen.

Autorisierten Kundendienst

aufsuchen, oder das Gerät an die

ISC-GmbH senden.

Motor raucht übermäßig Falsche Treibstoffmischung

Falsche Vergasereinstellung

Richtige Treibstoffmischung

verwenden (siehe TreibstoffMischtabelle)

Autorisierten Kundendienst

aufsuchen, oder das Gerät an die

ISC-GmbH senden.

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 16

Page 17

17

GB

Table of contents

1. Safety information

2. Layout

3. Items supplied

4. Intended use

5. Technical data

6. Before starting the equipment

7. Operation

8. Cleaning, maintenance and ordering of spare parts

9. Storage and transport

10. Disposal and recycling

11. Troubleshooting

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 17

Page 18

Important.

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety information with due care. Keep these

operating instructions in a safe place so that the

information is available at all times. If you give the

equipment to any other person, hand over these

operating instructions and the safety information as

well. We cannot accept any liability for damage or

accidents which arise due to a failure to follow these

instructions and the safety information.

1. Safety information

Please refer to the booklet included in delivery for the

safety information.

CAUTION

Read all the safety regulations and instructions.

Any errors made in following the safety information

and instructions set out below may result in an electric

shock, fire and/or serious injury.

Keep all safety information and instructions in a

safe place for future use.

Safety devices

When working with the equipment, the appropriate

plastic guard hood for cutting blade mode or cutting

line mode must be fitted to prevent objects being

thrown out by the equipment. The integrated blade in

the cutting line guard hood automatically cuts the line

to the optimum length.

Assembly: During assembly, take care not to let any

foreign bodies get inside the equipment or the

operation of the coupling will be impaired by dirt.

After assembly: When the equipment is running in

idling mode, the tool is not allowed to rotate. If this is

not the case, an error was made during the assembly

work.

2. Layout (Fig. 1-15)

1. Long handle

2a. Right steady grip

2b. Left steady grip

3. Petrol tank

4. Starter cable

5. Air filter housing cover

6. Choke lever

7. Cable connection

8. Spark plug connector

9. On/Off switch

10. Throttle lever lock

11. Throttle lever

12. Throttle lever block

13. Engine assembly

14. Long handle assembly

15. Harness

16. Line spool with cutting line

17. Line cutter

18. 2x cable tie

19. Slotted screwdriver

20. Spark plug wrench

21. Allen key 5 mm

22. Allen key 4 mm

23. Oil/petrol mixing bottle

24. Cutting line guard

25. Top part of the steady grip holder

26. Cutting blade guard hood

27. Cutting blade

28. 4x Allen screw M6x30, spring washer, washer

29. 4x Allen screw M5x25, spring washer, washer

30. 2x hex screw M6x16

31. 3x line cutter fastening screw (L = 10mm)

3. Items supplied

n Open the packaging and take out the equipment

with care.

n Remove the packaging material and any

packaging and/or transportation braces (if

available).

n Check to see if all items are supplied.

n Inspect the equipment and accessories for

transport damage.

n If possible, please keep the packaging until the

end of the guarantee period.

IMPORTANT

The equipment and packaging material are not

toys. Do not let children play with plastic bags,

foils or small parts.

There is a danger of swallowing or suffocating!

n Engine assembly

n Long handle assembly

n Steady grip on the left

n Harness

n Line spool with cutting line

n Thread cutter

n 2x cable tie

n Slotted screwdriver

n Spark plug wrench

n Allen key size 5 mm

n Allen key size 4 mm

18

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 18

Page 19

n Oil/petrol mixing bottle

n Cutting line guard

n Top part of steady grip holder

n Cutting blade guard hood

n Cutting blade

n 4x Allen screw M6x30, spring washer, washer

n 4x Allen screw M5x25, spring washer, washer

n 2x hex screw M6x16

n 3x line cutter fastening screw (L = 10mm)

n Original operating instructions

n Safety information

4. Intended use

The power scythe (using the cutting blade) is

designed for cutting young trees, strong weeds and

undergrowth.

The power trimmer (using the line spool with cutting

line) is designed for cutting lawns, grassed areas and

small weeds. The operating instructions as supplied

by the manufacturer must be kept and referred to in

order to ensure that the equipment is properly used

and maintained. Any use which is not expressly

permitted in the manual may result in damage to the

equipment and place the user in serious danger. Be

sure to observe the restrictions in the safety

instructions.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

Important. Due to the high risk of bodily injury to the

user, the petrol power scythe must not be used to

carry out the following work: to clean dirt and debris

off walkways, or to chop up tree or hedge clippings.

Moreover, the petrol power scythe may not be used to

level out high areas such as molehills. For safety

reasons, the petrol power scythe may not be used as

a drive unit for other work tools or toolkits of any kind.

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user/operator and not the manufacturer

will be liable for any damage or injuries of any kind

caused as a result of this.

5. Technical data

Engine type 2-stroke engine, air-cooled

Engine power (max.) 1.25 kW (1.7 HP)

Displacement 43 ccm

Idle speed of engine 3.000 ± 300 min

-1

Max. engine speed 7.500 min

-1

Max. cutting speed 8.300 min

-1

Ignition Electronic

Drive Centrifugal clutch

Weight (with empty tank) 7.3 kg

Cutting line diameter 40 cm

Cutting circle diameter of blade 25.5 cm

Cutting line length 2.5 m

Cutting line diameter: 2.4 mm

Tank capacity 1.1 l

Spark plug Torch L7T

Sound and vibration

Sound and vibration values were measured in

accordance with EN ISO 11806-1; EN ISO 22868;

EN ISO 22867.

Sound pressure level L

pA

100 dB(A)

Uncertainty K

pA

1.5 dB

Sound power level L

WA

114 dB(A)

Uncertainty K

WA

1.5 dB

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Functions Right steady grip

Vibration emission value ah= 13.846 m/s

2

K uncertainty = 1.5 m/s

2

Functions Left steady grip

Vibration emission value ah= 10.602 m/s

2

K uncertainty = 1.5 m/s

2

19

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 19

Page 20

Reduce noise generation and vibration to a

minimum!

n Use only equipment that is in perfect condition.

n Maintain and clean the equipment regularly.

n Adopt your way of working to the equipment.

n Do not overload the equipment.

n Have the equipment checked if necessary.

n Switch off the equipment when not in use.

n Wear gloves.

6. Before starting

6.1 Assembly

6.1.1 Fitting the long handle

(Fig. 3) Using the 4 Allen screws M6x30 (28), fasten

the long handle assembly (14) to the engine

assembly (13).

6.1.2 Fitting the steady grip

Fit the left steady grip (2b) or the right steady grip (2a)

as shown in Figs. 4-4a. The holes in the steady grips

are for receiving the screws. Tighten the screws (29)

securely at the top part of the steady grip holder (25).

6.1.3 Fastening the harness and cable

Hook the harness (15) into the holder as shown in Fig.

5. Then use the supplied cable ties (18) to fasten the

cable to the long handle and the steady grip.

6.1.4 Fitting the cutting blade guard hood

Important: The cutting blade guard hood must be

fitted if you want to work with the cutting blade. Using

the two screws M6x16 (30), secure the cutting blade

guard hood (26) to the clip provided as shown in Fig.

6.

6.1.5 Fitting/Replacing the cutting blade

The procedure for fitting the cutting blade is shown in

Figs. 7a-7f. To dismantle, proceed in reverse order.

n Plug the carrier plate (32) onto the spline shaft

(Fig. 7b)

n Lock the cutting blade (27) on the carrier plate

(Fig. 7c)

n Plug the pressure plate (33) over the thread of the

spline shaft (Fig. 7d).

n Plug on the cover of the pressure plate (34) (Fig.

7e).

n Look for the hole in the carrier plate, line up with

the notch underneath and lock with the supplied

Allen key (22) in order to now tighten the nut (35)

(Fig. 7f). Important: Left-hand thread

6.1.6 Fitting the line cutter

Using the three screws (31), secure the line cutter

(17) to the cutting line guard (24) as shown in Fig. 8.

Risk of injury – wear safety gloves.

6.1.7 Fitting the cutting line guard to the cutting

blade guard hood

Important: The cutting line guard hood must be fitted

in addition when working with the cutting line.

The cutting line guard (24) is pressed into the mounts

on the blade guard hood (26) as shown in Fig. 9.

Important: The cutting line cutter is on the cutting line

guard – risk of injury!

6.1.8 Fitting/Replacing the line spool

The procedure for fitting the line spool is shown in Fig.

10. To dismantle, proceed in reverse order.

Look for the hole in the carrier plate (32), line up with

the notch underneath and lock with the supplied Allen

key (22) in order to now screw the line spool (16) onto

the thread. Important: Left-hand thread

6.2. Adjusting the cutting height

n Slip the shoulder strap (15) over your left

shoulder.

n To establish the optimum length of the carrying

strap, make a few swinging movements without

starting the engine (Fig. 11a).

Important: Always use the strap when working with

the equipment. Attach the strap as soon as you have

started the engine and it is running in idle mode.

Switch off the engine before you take off the carrying

strap.

Check the equipment for the following each time

before use:

n That there are no leaks in the fuel system.

n That the equipment is in perfect condition and

that the safety devices and cutting devices are

complete.

n That all screws are securely fastened.

n That all moving parts move smoothly.

6.3 Fuel and oil

Recommended fuels

Use only a mixture of unleaded petrol and special 2stroke engine oil. Mix the fuel mixture as indicated on

the fuel mixing table.

Important: Do not use a fuel mixture which has been

stored for longer than 90 days.

Important: Never use 2-stroke oil with a

recommended mixing ratio of 100:1. The

manufacturer’s warranty will be voided in case of

engine damage due to inadequate lubrication.

20

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 20

Page 21

Important: Only use containers designed and

approved for the purpose to transport and store fuel.

Pour the correct quantities of petrol and 2-stroke oil

into the mixing bottle (see scale printed on the bottle).

Then shake the bottle well.

6.4 Fuel mixture table

Mixing procedure: 40 parts petrol to 1 part oil

7. Using the home waterworks

Please note that the statutory regulations governing

noise abatement may differ from town to town.

7.1 Starting the engine when cold

Fill the tank with the required amount of oil/petrol mix.

See “Fuel and oil”.

1. Set the equipment down on a hard, level surface.

2. Press the fuel pump (primer) (Fig. 14a/Item 39) 10

times.

3. Move the ON/OFF switch (Fig. 1/Item 9) to “I”

4. Secure the throttle lever. To do this, press the

throttle lever lock (Fig. 1/Item 12) and then press

the throttle lever (Fig. 1/Item 11) and lock the

throttle lever by pressing the lock (Fig. 1/Item 10)

at the same time.

5. Set the choke lever (Fig. 14b/Item 6) to „ON“.

6. Hold the equipment firmly and pull out the starter

cable (Fig. 1/Item 4) until you feel it begin to resist.

Then tug sharply on the starter cable 4 times. The

equipment should start.

Caution: Never allow the starter line to snap

back. This may result in damage.

Caution: Since the throttle lever is secured, the

cutting tool will start to operate when the engine is

started.

Once the engine has started, move the choke

lever immediately to „OFF“ and allow the

equipment to warm up for approx. 3 seconds.

Caution: Since the throttle lever is secured, the

cutting tool starts to operate when the engine is

started. Then release the throttle lever by simply

actuating it (the engine will return to running in

idle mode).

7. If the engine does not start up, repeat steps 4-6

above.

Please note: If the engine does not start up even after

several attempts, read the section “Engine

Troubleshooting”. Please note: Always pull the starter

cord out in a straight line. If it is pulled out at an angle,

then friction will occur on the eyelet. As a result of this

friction, the cable will become frayed and will wear

away faster. Always hold the starter handle when the

cable retracts. Never allow the cable to snap back

when it has been pulled out.

7.2 Starting the engine when warm

(The equipment has been idle for less than 15-20 min.)

1. Set the equipment down on a hard, level surface.

2. Switch the ON/OFF switch to “I”.

3. Secure the throttle lever (in the same way as

described in “Starting the engine when cold”).

4. Hold the equipment firmly and pull out the starter

cable until you feel it start to resist. Then tug

sharply on the starter cable. The equipment

should start after 1-2 tugs. If the equipment does

not start after 6 pulls, repeat steps 1 – 7 of the

procedure for starting the engine from cold.

7.3 Switching off the engine

Emergency Stop procedure:

If it becomes necessary to stop the equipment

immediately, set the ON/OFF switch to “Stop” or “0”

Normal procedure:

Let go of the throttle lever and wait until the engine

has changed to idling speed. Then set the ON/OFF

switch to “Stop” or “0”.

7.4 Practical tips

Practice all operating techniques with the engine

switched off before you start to use the equipment.

Extending the cutting line

Warning! Do not use any kind of metal wire or metal

wire encased in plastic in the line spool. This may

cause serious injuries to the user.

To extend the cutting line run the engine at full speed

and tap the line spool on the ground. This will

automatically extend the line. The blade on the safety

shield will cut the line to the appropriate length.

Important: Remove all grass and weed remains at

regular intervals to prevent the shaft tube overheating.

Grass and weed remains become trapped under the

safety shield (Fig. 11c) and they prevent the shaft

tube receiving adequate ventilation. Remove the

remains carefully using a screwdriver or the like.

21

GB

Petrol 2-stroke oil

1 liters 25 ml

5 liters 125 ml

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 21

Page 22

Different cutting methods

If the equipment is correctly assembled it will cut

weeds and long grass in places with difficult access,

for example along fences, walls and foundations and

also around trees. It can also be used for mowing

work to remove vegetation to allow the better

preparation of a garden or to clear a certain area

down to the soil.

Please note: Even if it is used carefully, cutting

around foundations, stone or concrete walls, etc. will

result in the line suffering above normal wear.

Trimming/mowing

Swing the trimmer from side to side in a scything

motion. Always keep the line spool parallel to the

ground. Check the site and decide what cutting height

you require. Guide and hold the line spool at the

required height to ensure that you cut evenly (Fig.

11d).

Low trimming

Hold the trimmer right in front of you at a slight angle

so that the underside of the line spool is above the

ground and the line strikes the correct target. Always

cut away from yourself. Never draw the trimmer

towards yourself.

Cutting along fences/foundations

When cutting approach wire mesh fences, lath

fences, natural stone walls and foundations slowly so

that you can cut close to them without striking the

obstacle with the line. If, for example, the line strikes

stones, stone walls or foundations, it will wear or fray.

If the line strikes wire fencing it will break.

Trimming around trees

When trimming around tree trunks, approach slowly

so that the line does not strike the bark. Walk around

the tree, cutting from left to right. Approach grass or

weeds with the tip of the line and tilt the line spool

forwards slightly.

Warning: Take extreme care during mowing work.

When doing such work keep a distance of 30 meters

between yourself and other people or animals.

Mowing

For mowing you want to cut all the vegetation down to

the ground. To do this, set the line spool at an angle of

30° to the right. Place the handle in the required

position. Remember the increased risk of injury to the

user, watchers and animals and the danger of

damaging other items due to objects (for example

stones) being thrown out (Fig. 11e).

Warning: Do not remove any objects from footpaths,

etc. using the equipment.

The equipment is a powerful tool and can throw small

stones and other objects a distance of 15 meters or

more, causing injuries and damage to cars, houses

and windows.

Sawing

The equipment is not suitable for sawing.

Jamming

If the cutting blade jams as a result of attempting to

cut vegetation that is too dense, switch off the engine

immediately. Remove the grass and scrub from the

equipment before you restart it.

Preventing recoil

When you work with the blade there is a risk of recoil

if it strikes solid objects such as tree trunks, branches,

tree stumps, stones or the like. This will throw the

equipment backwards in the direction opposite to the

rotation of the tool. This can cause you to lose control

of the equipment. Do not use the blade near fences,

metal posts, boundary stones or foundations.

For cutting dense stalks, position it as shown in Figure

9f to prevent recoil.

8. Cleaning, maintenance and ordering

of spare parts

Always switch off the equipment and pull out the

spark boot plug before carrying out any maintenance

work.

8.1 Replacing the line spool/cutting line

1. Dismantle the line spool (16) as described in

section 6.1.8. Press in the side lugs slightly while

simultaneously pressing the spool down and

turning it clockwise (Fig. 15a). Remove one half of

the housing.

2. Take the line spool out of the line spool housing

(Fig. 15c).

3. Remove any remaining cutting line.

4. Place the new cutting line in the center and attach

the resulting loop to the recess in the spool splitter

(Fig. 15d).

5. Wind the line on to the spool counter-clockwise

with tension. The spool splitter will separate the

two halves of the nylon line (Fig. 15e).

6. Hook the last 15 cm of the two ends of the line to

the line holders opposite the line spool (Fig. 15f).

7. Thread the two ends of the line through the metal

eyelets in the line spool housing (Fig. 15c).

8. Press the line spool into the line spool housing.

22

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 22

Page 23

9. Pull the two line ends briefly and powerfully to

release them from the line holders in the line spool.

10. Cut the excess line to a length of around 13 cm.

This will reduce the load on the engine when

starting up and warming up.

11. Fit the line spool again. See section 6.1.8. If you

are replacing the complete line spool, ignore

points 3-6.

8.2 Servicing the air filter

Soiled air filters reduce the engine output by supply

too little air to the carburetor. Regular checks are

therefore essential. The air filter (37) should be

checked after every 25 hours of use and cleaned if

necessary. If the air contains a lot of dust, the air filter

should be checked more frequently.

1. Remove the air filter cover (Fig. 12a/Pos. 36).

2. Remove the filter element (Fig. 12b/Pos. 37).

3. Clean the filter element by tapping it or blowing it.

4. Assemble in reverse order.

Important: Never clean the air filter with petrol or

inflammable solvents.

8.3 Maintenance of the spark plug (Fig. 13)

Spark plug sparking gap = 0.6mm. Tighten the spark

plug with a torque of 12 to 15 Nm. Check the spark

plug for dirt and grime after 10 hours of operation and

if necessary clean it with a copper wire brush.

Thereafter service the spark plug after every 50 hours

of operation.

1. Pull out the spark plug connector (38).

2. Remove the spark plug (39) with the supplied

spark plug wrench (20).

3. Assemble in reverse order.

8.4 Grinding the safety hood blade

The safety hood blade can become blunt over time.

When you notice this, undo the two screws holding

the safety hood blade to the safety hood. Clamp the

blade in a vise. Sharpen the blade with a flat file and

make sure that the angle of the cutting edge is not

altered in the process. File in one direction only.

8.5 Carburetor settings

Important. Settings on the carburetor may only be

made by authorized customer service personnel.

The air filter cover must be removed before any work

on the carburetor, as shown in Figures 12a and 12b.

Setting the throttle cable

If the maximum speed of the equipment falls over

time and you have ruled out all the other causes listed

in section 11 Troubleshooting, it may be necessary to

adjust the throttle cable.

First of all check whether the carburetor opens fully

when the throttle handle is pressed fully. This is the

case if the carburetor slide (Fig. 13a) is completely

opened when the throttle is fully activated.

Figure 13a shows the correct setting. If the carburetor

slide is not completely open, it must be adjusted.

The following work is required to adjust the throttle

cable:

n Undo the lock nut (Fig. 13a/Item C) a few turns.

n Undo the adjusting screw (Fig. 13a/Item D) until

the carburetor slide is completely open when the

throttle is fully activated, as shown in Figure 13a.

n Retighten the lock nut.

Setting the idling speed

Important. Set the idling speed when the equipment

is warm.

If the engine stalls when the throttle is not pressed

and you have ruled out all the other causes listed in

section 11 Troubleshooting, the idling speed must be

adjusted. To do this turn the idling speed screw (Fig.

13a/Item E) clockwise until the equipment runs

smoothly at idling speed. If the idling speed is so fast

that the cutting tool turns as well, it has to be reduced

by turning the idling speed screw for as long as is

required for the cutting tool to stop turning as well.

8.6 Environmental protection

Dispose of soiled maintenance material and

operating materials at the appropriate collection point.

Recycle packaging material, metal and plastics.

8.7 Ordering replacement parts

Please provide the following information on all orders

for spare parts:

n Model/type of the equipment

n Article number of the equipment

n ID number of the equipment

n Spare part number of the required spare part

For our latest prices and information please go to

www.isc-gmbh.info

9. Storage and transport

9.1 Storage

Important: Never put the equipment into storage for

longer than 30 days without carrying out the following

steps.

Storing the equipment

If you intend to store the equipment for longer than 30

days, the equipment must be prepared accordingly.

Otherwise the fuel still remaining in the carburetor will

evaporate and leave a rubbery sediment. This can

cause problems when starting up the equipment and

may require expensive repairs.

1. Slowly remove the fuel tank cap to release any

23

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 23

Page 24

pressure that may have formed in the tank.

Carefully empty the tank.

2. Start the engine and let it run until the equipment

stops in order to remove any fuel from the

carburetor.

3. Leave the engine to cool (approx. 5 minutes).

4. Remove the spark plug (8.3).

5. Add one teaspoon of 2-stroke engine oil into the

combustion chamber. Slowly pull the starter cord

several times to apply a layer of oil to all internal

components. Fit the spark plug again.

Note: Store the equipment in a dry place and far

away from possible ignition sources such as an oven,

a gas-fired hot water boiler, a gas-fired dryer, etc.

Putting the equipment back into operation

1. Remove the spark plug (8.3).

2. Quickly tug on the starter cord to remove excess

oil from the combustion chamber.

3. Clean the spark plug and check that the electrode

gap is correct.

4. Prepare the equipment for operation.

5. Fill the tank with the relevant mixture of fuel and

oil. See the section entitled “Fuel and oil”.

9.2 Transport

To transport the equipment, empty the petrol tank as

described in the section entitled “Storage”. Clean

coarse dirt off the equipment with a brush or hand

brush. Dismantle the steady grip as described in

section 6.1.2.

10. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The

equipment and its accessories are made of various

types of material, such as metal and plastic. Defective

components must be disposed of as special waste.

Ask your dealer or your local council.

24

GB

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 24

Page 25

25

GB

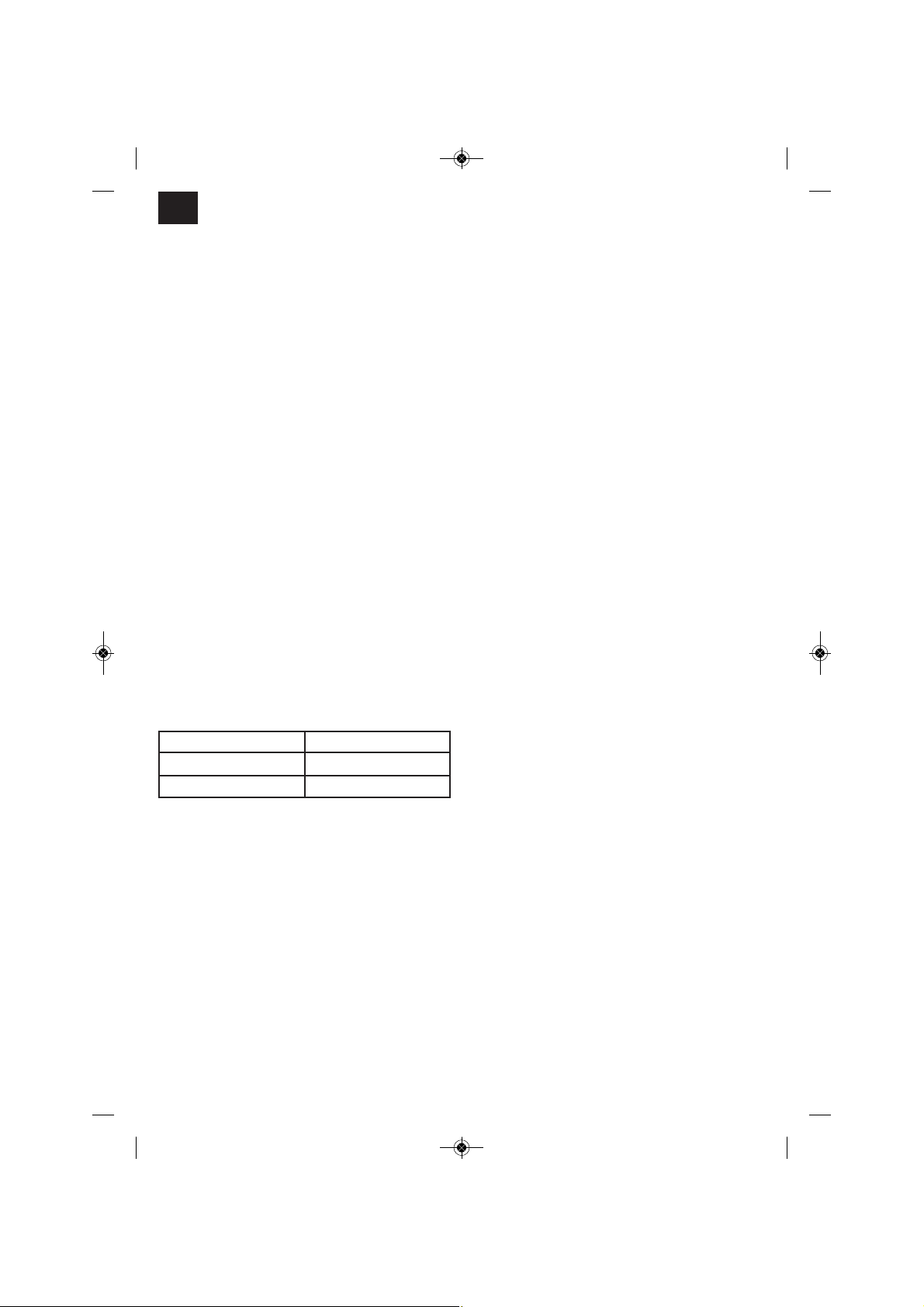

Fault Possible cause Troubleshooting

The machine does not start. Correct starting procedure not

followed.

Follow the instructions for starting.

Sooted or damp spark plug Clean the spark plug or replace it

with a new one.

Incorrect carburetor setting Contact an authorized customer

service outlet or send the machine

to ISC-GmbH.

The machine starts but does not

develop its full output.

Incorrect choke lever setting Set choke lever to “OFF”

Soiled air filter Clean the air filter

Incorrect carburetor setting Contact an authorized customer

service outlet or send the machine

to ISC-GmbH.

The engine does not run smoothly Incorrect electrode gap on the

spark plug

Clean the spark plug and adjust

the electrode gap or fit a new spark

plug.

Incorrect carburetor setting Contact an authorized customer

service outlet or send the machine

to ISC-GmbH.

Engine smokes excessively Incorrect fuel mix Use the correct fuel mix (see fuel

mixing table)

Incorrect carburetor setting Contact an authorized customer

service outlet or send the machine

to ISC-GmbH.

11. Troubleshooting

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 25

Page 26

Sommaire

1. Consignes de sécurité

2. Description de l’appareil

3. Volume de livraison

4. Utilisation conforme à l’affectation prévue

5. Caractéristiques techniques

6. Avant la mise en service

7. Utilisation

8. Nettoyage, maintenance et commande de pièces de rechange

9. Stockage et transport

10. Traitement des déchets et recyclage

11. Élimination des erreurs

26

F

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 26

Page 27

Attention !

Lors de l’utilisation d’appareils, il faut respecter

certaines mesures de sécurité afin d’éviter des

blessures et dommages. Lisez attentivement ce mode

d’emploi/consignes de sécurité. Veillez à le conserver

en bon état pour pouvoir accéder aux informations à

tout moment. Si l’appareil doit être remis à d’autres

personnes, veillez à leur remettre aussi ce mode

d’emploi/ces consignes de sécurité. Nous déclinons

toute responsabilité pour les accidents et dommages

dus au non-respect de ce mode d’emploi et des

consignes de sécurité.

1. Consignes de sécurité

Vous trouverez les consignes de sécurité

correspondantes dans le petit manuel ci-joint !

AVERTISSEMENT

Veuillez lire toutes les consignes de sécurité et

instructions. Toute omission lors du respect des

consignes de sécurité indiquées plus loin peut

entraîner des décharges électriques, un incendie

et/ou de graves blessures.

Conservez toutes les consignes de sécurité et

instructions pour une consultation ultérieure.

Dispositifs de sécurité

Pendant que vous travaillez sur l’appareil, le capot de

protection en plastique correspondant (pour

fonctionnement à lames ou à fil) doit être monté pour

éviter de catapulter des objets. La lame intégrée dans

le capot de protection du fil coupe le fil

automatiquement à la longueur optimale.

Assemblage : veillez à ce qu’aucun corps étranger

ne pénètre dans l’appareil ou à ce qu’aucune saleté

n’altère le fonctionnement de l’accouplement.

Après l’assemblage : lorsque l’appareil fonctionne

au ralenti, l’outil ne doit pas tourner en même temps.

Si ce n’est pas le cas, c’est qu’une erreur a été

commise lors du montage.

2. Description de l’appareil (fig. 1 à 15)

1. Guidon

2a. Poignée de guidage droite

2b. Poignée de guidage gauche

3. Réservoir d’essence

4. Cordon du démarreur

5. Recouvrement du boîtier du filtre à air

6. Levier étrangleur

7. Raccordement de câble

8. Cosse de bougie d’allumage

9. Interrupteur marche/arrêt

10. Dispositif d’arrêt de l’accélérateur

11. Accélérateur

12. Blocage de l’accélérateur

13. Module moteur

14. Module guidon

15. Ceinture de port

16. Bobine de fil avec fil de coupe

17. Couteau de fil

18. 2x serre-câble

19. Tournevis pour vis à fente

20. Clé à bougie

21. Clé à six pans creux 5 mm

22. Clé à six pans creux 4 mm

23. Flacon d’essence/d’huile

24. Protection du fil de coupe

25. Partie supérieure fixation de poignée de guidage

26. Capot de protection de la lame de coupe

27. Lame

28. 4x vis à six pans creux M6x30, rondelle élastique,

rondelle en U

29. 4x vis à six pans creux M5x25, rondelle élastique,

rondelle en U

30. 2x vis à six pans M6x16

31. 3x vis de fixation pour le couteau de fil

(L = 10 mm)

3. Volume de livraison

n Ouvrez l’emballage et prenez l’appareil en le

sortant avec précaution de l’emballage.

n Retirez le matériel de l’emballage tout comme les

sécurités d’emballage et de transport (s’il y en a).

n Vérifiez si la livraison est bien complète.

n Contrôlez si l’appareil et ses accessoires ne sont

pas endommagés par le transport.

n Conservez l’emballage autant que possible

jusqu’à la fin de la période de garantie.

ATTENTION

L’appareil et le matériel d’emballage ne sont pas

des jouets ! Il est interdit de laisser des enfants

jouer avec des sacs et des films en plastique et

avec des pièces de petite taille !

Ils risquent de les avaler et de s’étouffer !

n Module moteur

n Module guidon

n Poignée de guidage gauche

n Ceinture de port

n Bobine de fil avec fil de coupe

n Couteau de fil

27

F

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 27

Page 28

n 2x serre-câbles

n Tournevis pour vis à fente

n Clé à bougie

n Clé à six pans creux 5 mm

n Clé à six pans creux 4 mm

n Flacon d’essence/d’huile

n Protection du fil de coupe

n Partie supérieure fixation de poignée de guidage

n Capot de protection de la lame de coupe

n Lame

n 4x vis à six pans creux M6x30, rondelle élastique,

rondelle en U

n 4x vis à six pans creux M5x25, rondelle élastique,

rondelle en U

n 2x vis à six pans M6x16

n 3x vis de fixation du couteau de fil (L = 10mm)

n Mode d’emploi d’origine

n Consignes de sécurité

4. Utilisation conforme à l’affectation

prévue

La débroussailleuse à moteur (utilisation de la lame

de coupe) convient à la coupe de bois léger, de

mauvaises herbes épaisses et de broussailles.

La débroussailleuse à moteur (utilisation de la bobine

de fil avec fil de coupe) convient à la coupe du gazon,

de surfaces enherbées et de mauvaises herbes. Le

respect du mode d’emploi joint par le producteur est

la condition préalable à une utilisation conforme de

l’appareil. Tout autre emploi non autorisé

expressément dans ce mode d’emploi peut entraîner

des dommages de l’appareil et représenter un risque

grave pour l’opérateur. Respectez absolument les

limites indiquées dans les consignes de sécurité.

Veillez au fait que nos appareils, conformément au

règlement, n’ont pas été conçus pour être utilisés

dans un environnement professionnel, industriel ou

artisanal. Nous déclinons toute responsabilité si

l’appareil venait à être utilisé professionnellement,

artisanalement ou par des sociétés industrielles, ou

par toutes activités équivalentes.

Attention ! En raison de l’exposition à des risques

corporels de l’utilisateur/utilisatrice, la

débroussailleuse à essence ne doit pas servir aux

travaux suivants : pour nettoyer des chemins, ni

comme hacheuse pour broyer des tronçons d’arbres

et de haie. En outre, la débroussailleuse à essence

ne doit pas être utilisée pour égaliser des bosses du

sol, comme par exemple des taupinières. Pour des

raisons de sécurité, la débroussailleuse à essence ne

doit pas être utilisée comme groupe d‘entraînement

pour d’autres outils et jeux d’outils en tous genres.

La machine doit exclusivement être employée

conformément à son affectation. Chaque utilisation

allant au-delà de cette affectation est considérée

comme non conforme. Pour les dommages en

résultant ou les blessures de tout genre, le producteur

décline toute responsabilité et l’opérateur/l’exploitant

est responsable.

5. Caractéristiques techniques

Type de moteur Moteur 2 temps, refroidi par air

Puissance du moteur (maximum) 1,25 kW (1,7 PS)

Cylindré 43 ccm

Vitesse de rotation à vide

du moteur : 3000 ± 300 min

-1

Vitesse maximale Vitesse de rotation

du moteur: 7500 t/min

-1

Vitesse de coupe maximale 8300 t/min

-1

Allumage électronique

Entraînement accouplement centrifuge

Poids (réservoir vide) 7,3 kg

Fil du cercle de coupe Ø 40 cm

Lame de cercle de coupe Ø 25,5 cm

Longueur du fil 2,5 m

Ø du fil 2,4 mm

Contenance du réservoir 1,1 l

Bougie d’allumage Torch L7T

Bruit et vibrations

Les valeurs de bruit et de vibration ont été

déterminées conformément à la norme EN ISO

11806-1; EN ISO 22868; EN ISO 22867.

Niveau de pression acoustique L

pA

100 dB(A)

Imprécision K

pA

1,5 dB

Niveau acoustique L

WA

114 db(A)

Imprécision K

WA

1,5 db

Portez un casque anti-bruit.

L’exposition au bruit peut entraîner une perte de

l’ouïe.

28

F

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 28

Page 29

Fonctionnement Poignée de guidage droite

Valeur d’émission de vibration ah = 13,846 m/s

2

Insécurité K = 1,5 m/s

2

Fonctionnement Poignée de guidage gauche

Valeur d’émission de vibration ah = 10,602 m/s

2

Insécurité K = 1,5 m/s

2

Limitez le niveau sonore et les vibrations à un

minimum !

n Utilisez exclusivement des appareils en excellent

état.

n Entretenez et nettoyez l’appareil régulièrement.

n Adaptez votre façon de travailler à l’appareil.

n Ne surchargez pas l’appareil.

n Faites contrôler l’appareil le cas échéant.

n Mettez l’appareil hors circuit lorsque vous ne

l’utilisez pas.

n Portez des gants.

6. Avant la mise en service

6.1 Montage

6.1.1 Montage guidon

(fig. 3) Vissez le module du guidon (14) à l’aide des 4

vis à six pans creux M6x30 (28) au module du moteur

(13).

6.1.2 Montage poignée de guidage

Montez la poignée de guidage gauche (2b) ou la

poignée de guidage droite (2a) comme illustré sur les

figures 4-4a. Les trous dans les poignées de guidage

servent de logement pour les vis. Serrez les vis (29)

sur la partie sur la partie supérieure de la fixation de

la poignée de guidage (25).

6.1.3 Fixer la ceinture de port et le câble

Accrochez la ceinture de port (15) dans la fixation

comme illustré sur la figure 5. Ensuite, fixez le câble à

l’aide des serre-câbles joints à la livraison (18) sur le

guidon et la poignée de guidage.

6.1.4 Montage capot de protection de la lame de

coupe

Attention : lors du travail avec la lame, le capot de

protection de la lame (26) doit être monté. Vissez le

capot de protection de la lame (26) à l’aide des deux

vis M6x16 (30) au collier de serrage prévu à cet effet

illustré sur la figure 6.

6.1.5 Montage/Remplacement de la lame

Le montage de la lame est illustré sur les figures 7a7f. Le démontage doit être effectué dans l’ordre

inverse.

n Enfichez le disque entraîneur (32) sur l’arbre

cannelé (fig. 7b)

n Bloquez la lame (27) sur le disque entraîneur (fig.

7c)

n Enfichez la plaque de compression (33) sur le

filetage de l’arbre cannelé (fig. 7d)

n Montez le recouvrement de la plaque de

compression (34) (fig. 7e)

n Cherchez le trou du disque entraîneur, faites-le

correspondre à l’encoche qui se trouve dessous

et bloquez-le à l’aide de la clé à six pans creux

(22) fournie pour ensuite serrer l’écrou (35) (fig.

7f). Attention : filet à gauche

6.1.6 Montage couteau de fil

Vissez le couteau de fil (17) comme illustré sur la fig.

8 à l’aide de trois vis (31) sur la protection du fil de

coupe (24). Risque de blessure – Portez des gants de

protection.

6.1.7 Montage protection de fil de coupe sur le

capot de protection de la lame

Attention : lors de travaux avec le fil de coupe, il faut

monter également le capot de protection du fil de

coupe.

La protection du fil de coupe (24) s’enfonce comme

illustré sur la fig. 9 dans les logements situés sur le

capot de protection de la lame (26). Attention : sur la

protection de fil de coupe se trouve le couteau de fil Risque de blessure !

6.1.8 Montage/ remplacement de la bobine de fil

Le montage de la bobine de fil est visible sur la figure

10. Le démontage s’effectue dans le sens inverse.

Cherchez le trou du disque entraîneur (32), faites-le

correspondre à l’encoche qui se trouve dessous et

bloquez-le avec la clé à six pans creux (22) fournie

pour ensuite visser la bobine de fil (16) sur le filetage.

Attention : filet à gauche

6.2 Réglage de la hauteur de coupe

n Passez la ceinture de port (15) par-dessus

l’épaule gauche.

n Afin de vérifier si la longueur de ceinture de port

convient, faites ensuite quelques mouvements de

balancier sans allumer le moteur (fig. 11a)

Attention: Utilisez toujours la ceinture pour travailler

avec l’appareil. Mettez la bandoulière dès que le

moteur est démarré et qu’il fonctionne à vide. Mettez

le moteur hors circuit avant de retirer la bandoulière.

29

F

Anleitung_BBC_43_SPK7__ 29.08.14 07:49 Seite 29

Page 30

Vérifiez l’appareil avant chaque mise en service quant

à :

n l’étanchéité du système à carburant.

n l’excellent état et l’intégralité des dispositifs de

protection et du dispositif de coupe.

n la bonne fixation des raccords vissés.

n la souplesse de toutes les pièces amovibles.

6.3 Carburant et huile

Carburants recommandés

Utilisez uniquement un mélange fait d’essence

normale sans plomb et d’une huile spéciale moteur à

2 temps. Mélangez le carburant comme indiqué dans

le tableau de mélange de carburant.

Attention : n’utilisez jamais de mélange de carburant

ayant été stocké plus de 90 jours.

Attention : n’utilisez jamais d’huile à deux temps qui

a besoin d’un mélange de 100:1. En cas de

dommages sur le moteur en raison d’un graissage

insuffisant, la garantie moteur du fabricant est

annulée.

Attention : pour le transport et le stockage de

carburant, utilisez exclusivement les réservoirs

prévus et homologués à cet effet.

Remplacez respectivement de la bonne quantité