Page 1

BWS 115/85

Operating Instructions

Right-angle Grinder

Istruzioni per l’uso

della smerigliatrice angolare

Käyttöohje

Kulmahiomakone

Art.-Nr.: 44.302.32 I.-Nr.: 015r.:

®

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 1

Page 2

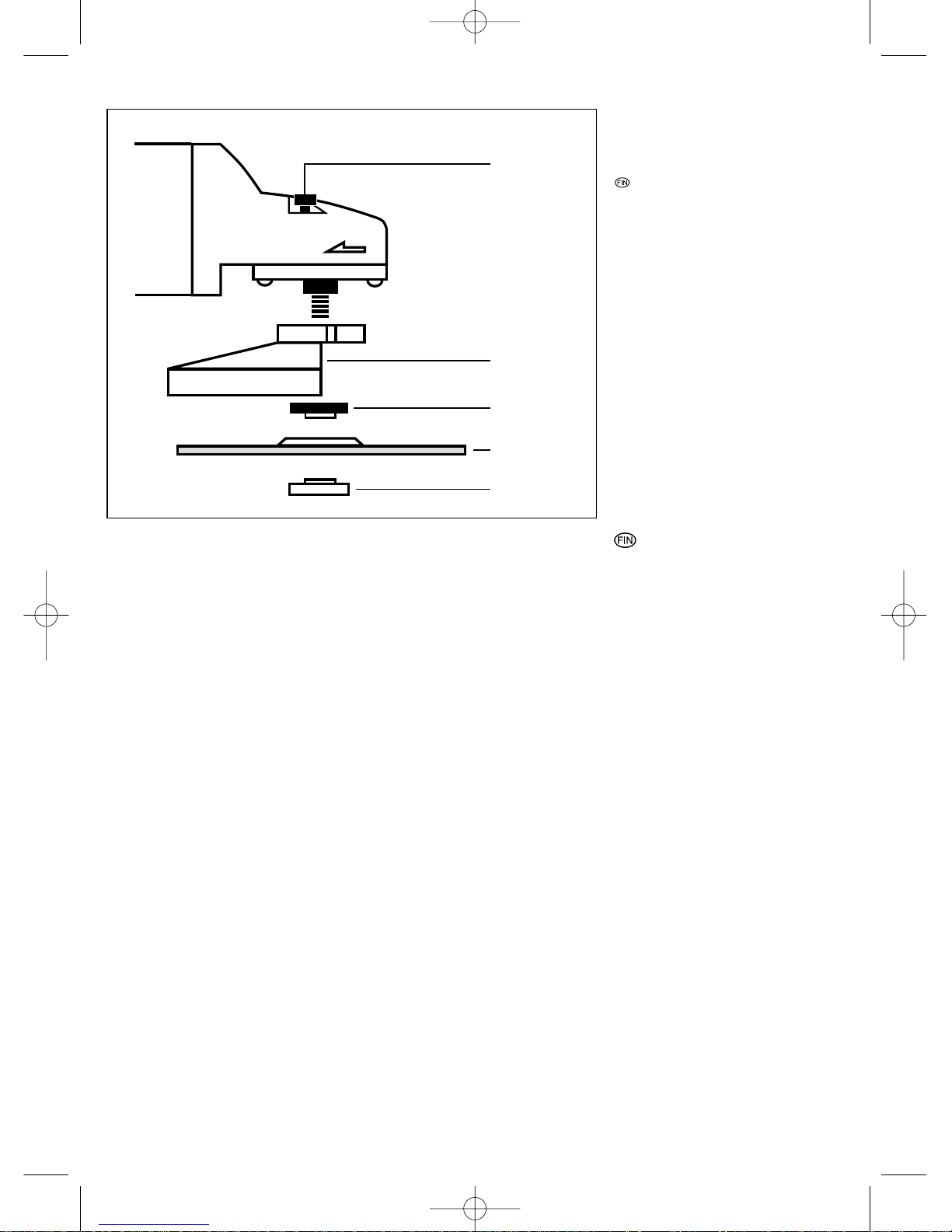

1 Spindle catch

2 Guard

3 Clamping flange *

4 Grinding wheel

5 Flange nut *

1 Arresto del mandrino

2 Carter di protezione

3 Flangia fissaggio *

4 Disco

5 Dado fissaggio *

1 Karanlukitus

2 Suojus

3 Kiinnityslaippa *

4 Hiomalaikka

5 Laippamutteri *

1

2

3

4

5

2

* Flange arrangement see page 5

* Per la disposizione della flangia vedi

pag. 8

* Laipan sijoitus, katso sivu 11

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 2

Page 3

3

General safety and accident prevention

regulations

To work safely with this machine and to prevent

accidents it is imperative to read the following safety

regulations and operating instructions in full and to

put all the information into practice.

Always check the machine, the power cable and

the plug before use. Only ever use the machine if

it is in perfect, undamaged condition. Damaged

parts are to be repaired or replaced immediately

by a qualified electrician.

Always pull the plug out of the power socket

before carrying out any work on the machine,

before changing the grinding tool and in periods of

non-use.

Always run the power cable away from the back of

the machine to guard it from damage.

For outdoors work use only suitably approved

extension cables with a minimum conductor cross

section of 1.5 mm2. The plug connectors must

have earthing contacts and be rain-water-proof.

Keep the machine in a safe place and out of the

reach of children.

Always wear goggles, safety gloves and ear muffs

when using the machine for grinding, brushing

and cutting purposes. Wear a breathing mask on

dusty jobs.

For safety reasons the right-angle grinder is only

to be used with the guard hood and the additional

handle fitted in place.

Secure the workpiece (with a clamp) so that it

cannot slip.

It is imperative to use a dust extractor when

working on stone (cutting or grinding). Make sure

the dust extractor is approved for stone dust.

It is prohibited to use the machine on

asbestos materials.

Please note the accident prevention regulations in

force in your country.

Caution! Risk of fire! Make sure there are no

combustible materials within the maximum radius

of flying sparks when you are cutting and grinding

materials.

Use only original spare parts.

Repairs are to be carried out by qualified

electricians only.

The level of noise at the workplace may exceed

85 dB(A). In this case you will need to introduce

noise protection measures for the user. The noise

produced by this electric tool is measured in

accordance with IEC 59 CO 11, IEC 704,

DIN 45635 Part 21, NFS 31-031 (84/537/EEC).

Make sure of your footing. Avoid abnormal

working positions.

Keep your electric tool out of the rain. Never use

electric tools in wet or damp conditions, and never

use them near inflammable liquids.

Never carry the machine by its power cable. Keep

the power cable safe from damage. Oil, solvent

and sharp edges can damage cables.

Keep your workplace tidy.

Make sure the power switch is off before inserting

the plug in the socket.

Wear suitable clothing. Never wear loose-fitting

clothes or jewelry. Use a hair-net on long hair.

For your own safety, use only the manufacturer´s

accessories and attachments.

Vibration measured according ISO 5349.

GB

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 3

Page 4

4

Operating instructions for

right-angle grinders

The machine is light, handy, totally insulated and

designed in compliance with the international

specifications CEE 20. Provided it is serviced as

described in these instructions, the machine will

serve you for a long time.

VOLTAGE

Before you use the machine for the first time, check

that the voltage marked on the rating plate is the

same as your mains voltage. Under no

circumstances is the mains voltage to differ from the

rated voltage by more than 10%.

SWITCH

To help prevent accidents, the right-angle grinder is

equipped with a safety switch. To turn on the

machine, push the switch forward and push down

until it latches in place. To turn the right-angle grinder

off, push the switch down. It will then jump back to its

original position.

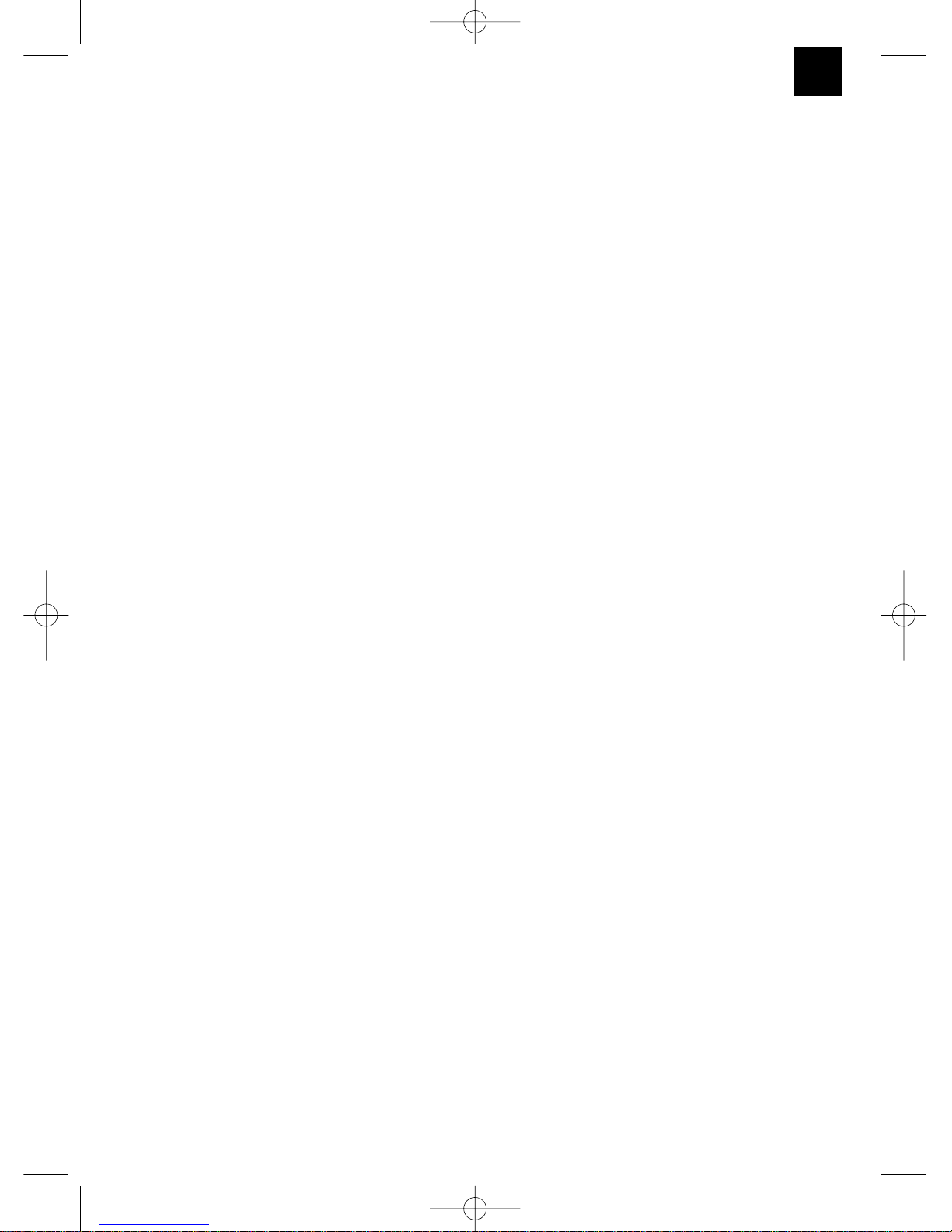

REPLACING THE GRINDING WHEEL

Pull out the power plug.

Simple wheel change by spindle

lock: Press the spindle lock and

allow the grinding wheel to latch

in place.Open the flange nut with

the face spanner.

Change the grinding or cutting

wheel and tighten the flange nut

with the face spanner.

Important! Only ever press the spindle lock

when the motor and grinding

spindle are at a standstill!

You must keep the spindle lock pressed while

you change the wheel!

For grinding or cutting wheels up to approx. 3 mm

thick, screw on the flange nut with the flat side facing

the grinding or cutting wheel.

TEST RUN FOR NEW GRINDING WHEELS

Allow the right-angle grinder to run in idle for at least

1 minute with the grinding or cutting wheel fitted in

place. Vibrating wheels are to be replaced

immediately.

MOTOR

It is vital for the motor to be well ventilated during

operation. Be sure, therefore, to keep the ventilation

holes clean at all times.

CARBON BRUSHES

Carbon brushes that are burned, broken or shorter

than 5 mm are to be replaced by original

replacement brushes. Always replace the carbon

brushes in pairs.

GRINDING WHEELS

Never use a grinding or cutting wheel bigger than the

specified diameter.

Before using a grinding or cutting wheel, check its

rated speed. The wheel´s rated speed must be

higher than the idle speed of the right-angle grinder.

Use only grinding and cutting wheels that are

approved for a maximum speed of 11,000 rpm and a

peripheral speed of 80 m/sec.

OPERATING MODES

Rough grinding:

For the best rough grinding results, hold the grinding

wheel at an angle of between 30° and 40° to the

workpiece surface and guide back and forth over the

workpiece in steady movements.

Cutting:

When you use the right-angle grinder for cutting

purposes, avoid tilting it in the cutting plane. The

cutting wheel must have a clean cutting edge.

A diamond cutting wheel is best used to cut hard

stone.

It is prohibited to use the machine on asbestos

materials!

Never use a cutting wheel for rough grinding.

TECHNICAL DATA

Nominal voltage: 230 V ~ 50 Hz

Power consumption: 850 W

Idle speed: 11.000 rpm

Max. wheel diameter: 115 mm

Drive spindle thread: M 14

Sound pressure level LPA: 89 dB(A)

Sound power level LWA: 99,6 dB(A)

Vibration

a

–

w

< 2,5 m/s

2

Weight 2,2 kg

Totally insulated

GB

STOP

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 4

Page 5

5

GB

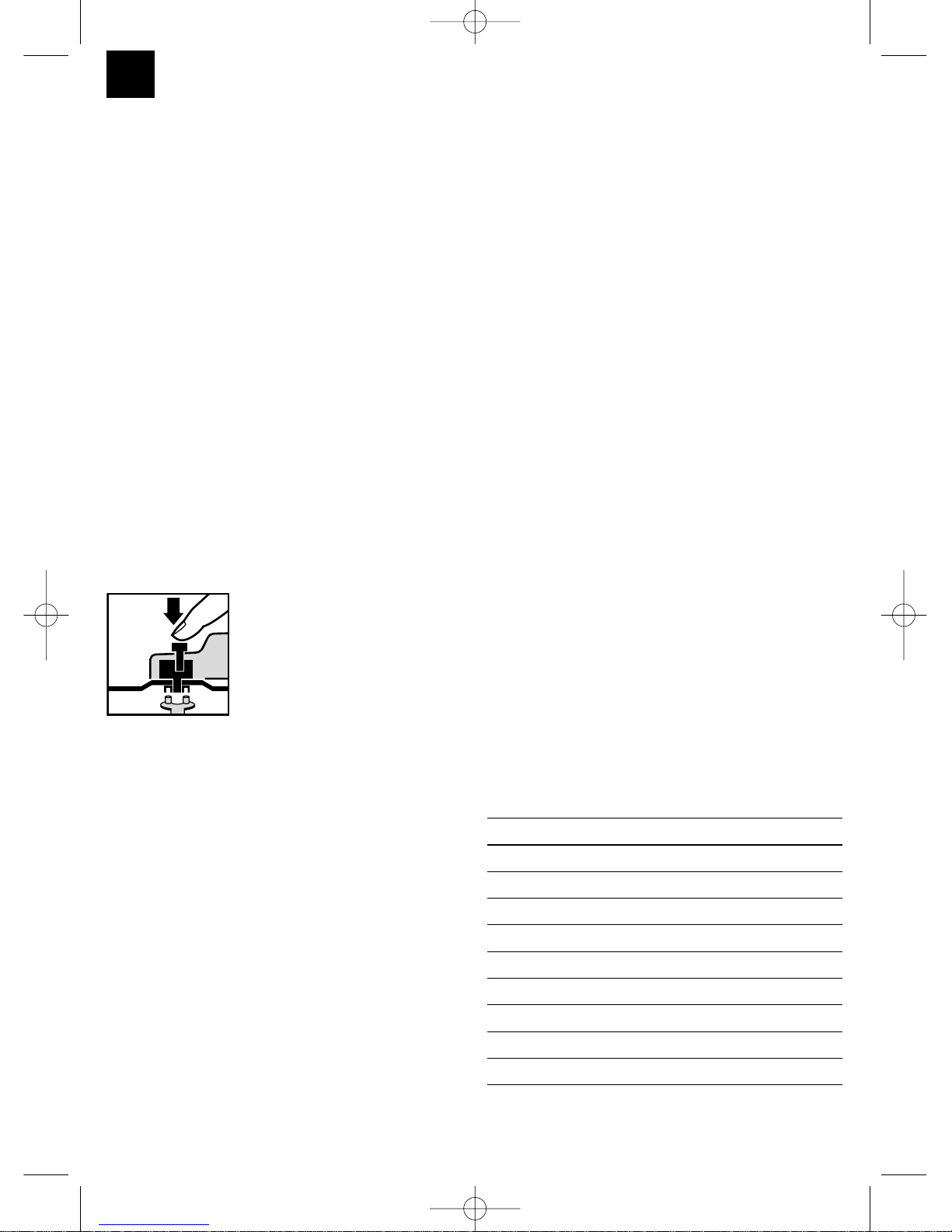

Flange arrangements when using grinding

wheels and cutting wheels

1

Clamping flange

Flange nut

Flange arrangement when using a depressed-centre or straight grinding wheel

2

Clamping flange

Flange nut

Flange arrangement when using a depressed-centre cutting wheel

3

Clamping flange

Flange nut

Flange arrangement when using a straight cutting wheel

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 5

Page 6

6

Avvertenze generali di sicurezza e di

prevenzione degli infortuni

Si assicura un funzionamento dell´apparecchio

sicuro e senza infortuni solo se le avvertenze di

sicurezza e le istruzioni per l´uso vengono lette

completamente e se le avvertenze in esse contenute

vengono seguite.

Controllare ogni volta prima dell´uso

l´apparecchio, il cavo di alimentazione e la spina.

Lavorare solo se l´apparecchio è in perfetto stato

e non presenta danni. Le parti danneggiate

devono venire sostituite subito da un elettricista.

Togliere sempre la spina dalla presa di corrente

per tutti i lavori alla macchina, prima di sostituire

gli utensili e quando l´apparecchio non viene

usato.

Per evitare danni al cavo di alimentazione, esso

deve sempre trovarsi sul retro della macchina.

Per lavori all´aperto è permesso solo l´uso di cavi

di prolunga omologati. I cavi di prolunga usati

devono avere una sezione minima di 1,5 mm2.

I collegamenti a spina devono avere contatti di

terra ed essere protetti dagli spruzzi d´acqua.

Conservare gli utensili in un posto sicuro e

inaccessibile per i bambini.

Portare sempre gli occhiali protettivi, i guanti di

sicurezza e le cuffie durante i lavori di

smerigliatura, spazzolatura e troncatura nonchè

una mascherina di protezione delle vie respiratorie

se si sviluppa anche polvere.

Per motivi di sicurezza la smerigliatrice angolare

può venire usata solo con la calotta di protezione

montata e con l´impugnatura ausiliaria.

Accertarsi che il pezzo da lavorare sia ben fissato

e non si sposti (serrarlo).

Nel lavorare (troncare e smerigliare) la pietra si

deve usare un dispositivo di aspirazione della

polvere che sia omologato per l´aspirazione di

polvere minerale.

Non devono essere lavorati materiali

contenenti amianto.

Rispettare le corrispondenti disposizioni per la

prevenzione degli infortuni (VBG 119)

dell´associazione di categoria.

Attenzione: pericolo d´incendio!

Durante le operazioni di troncatura e smerigliatura

accertarsi che non ci siano materiali infiammabili

che possano venir raggiunti dalle scintille.

Impiegare solo ricambi originali.

Le riparazioni devono essere eseguite solo da un

elettricista.

Il livello di emissioni sonore sul posto di lavoro

può superare gli 85 dB (A). In questo caso è

necessario che l´operatore prenda delle misure di

protezione contro i rumori. Il livello sonoro di

questo elettroutensile viene misurato secondo le

norme IEC 59 CO 11, IEC 704, DIN 45635 parte

21, NFS 31-031 (84/537/CEE).

Assicurarsi di essere bene in equilibrio, evitare di

assumere posizioni insolite.

Non esporre l´elettroutensile alla pioggia. Non

usarlo in ambiente bagnato o umido e nelle

vicinanze di liquidi infiammabili.

Non usare il cavo di alimentazione per trasportare

l´utensile. Evitare danni al cavo di alimentazione:

oli, solventi e spigoli vivi lo possono rovinare.

Tenere in ordine il posto di lavoro.

Accertarsi che l´interruttore sia spento quando

viene inserita la spina di alimentazione.

Portare indumenti da lavoro adatti. Non portare

indumenti ampi e gioielli. Portare una retina nel

caso di capelli lunghi.

Per la propria sicurezza usare solo accessori e

utensili ausiliari del produttore dell´elettroutensile.

Valore di vibrazione secondo la ISO 5349, rilevato

pugnatura, sorrisponde a < 2,5 m/s2.

I

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 6

Page 7

7

Istruzioni per il funzionamento della

smerigliatrice angolare

La macchina è leggera, facile da maneggiare,

provvista di isolamento protettivo e concepita

secondo le disposizioni internazionali CEE 20. Si

assicura una lunga durata se la manutenzione viene

eseguita secondo queste avvertenze.

TENSIONE

Prima della messa in esercizio controllare che la

tensione di rete corrisponda a quella indicata sulla

targhetta. La tensione di rete non deve

assolutamente differire di più del 10% dalla tensione

nominale indicata.

INTERRUTTORE

La smerigliatrice angolare è provvista di un

interruttore di sicurezza per la prevenzione degli

infortuni. Per accenderla, spingere in avanti il tasto e

premerlo perchè scatti in posizione. Per spegnere la

smerigliatrice premere il tasto che ritorna

automaticamente nella posizione di partenza.

SOSTITUZIONE DELLA MOLA

Togliere la spina dalla presa di

alimentazione.

Facile sostituzione della mola

grazie all´arresto del mandrino.

Premere l´arresto del mandrino e

far scattare in posizione la mola.

Aprire il dado flangiato con la

chiave a pioli.

Sostituire la mola di smerigliatura o di troncatura e

serrare il dado flangiato con la chiave a pioli.

Attenzione:

Premere l´arresto del mandrino solo se il

motore ed il mandrino di smerigliatura sono

fermi! Durante la sostituzione della mola l´arresto

del mandrino deve rimanere premuto!

Nel caso di mole di smerigliatura o di troncatura fino

a 3 mm di spessore, avvitare il dado flangiato con il

lato piatto verso la mola.

FUNZIONAMENTO DI PROVA DI UNA MOLA

NUOVA

Far funzionare a vuoto per almeno 1 minuto la

smeriglitrice angolare con la mola di smerigliatura o

di troncatura montata. Se la mola vibra, sostituirla

subito.

MOTORE

Il motore deve essere ben ventilato durante il

funzionamento, per questo motivo le aperture di

areazione devono sempre essere tenute pulite.

SPAZZOLE DI CARBONE

Se le spazzole di carbone sono bruciate, rotte o più

piccole di 5 mm, devono essere sostituite con

spazzole di ricambio originali. Sostituire le spazzole

sempre a coppie.

MOLE DI SMERIGLIATURA

La mola di smerigliatura o di troncatura non deve

superare il diametro prescritto. Prima di usare la

mola controllarne il numero giri indicato. Il numero di

giri della mola di smerigliatura o di troncatura deve

essere maggiore del numero di giri a vuoto della

smerigliatrice angolare.

Usare solamente mole di smerigliatura o di

troncatura che siano omologate per un numero

massimo di giri di 11.000 min-1e per una velocità

periferica di 80 m/sec.

AVVERTIMENTI PER L´USO

Smerigliatura di sgrossatura

I risultati migliori nella sgrossatura si ottengono

ponendo la mola in un angolo che va dai 30° ai 40°

rispetto alla supericie da smerigliare e spostandola

sul pezzo da lavorare con movimenti regolari da

destra a sinistra e viceversa.

Smerigliatura di troncatura

Per la troncatura non inclinare la smerigliatrice sul

piano di taglio. La mola di troncatura deve

presentare uno spigolo di taglio netto.

Per troncare pietre dure si consiglia di unsare una

mola diamantata.

Non devono venir lavorati materiali contenenti

amianto!

Per la sgrossatura non usare mai mole per troncare.

DATI TECNICI

Tensione nominale: 230 V ~ 50 Hz

potenza assorbita: 850 W

numero giri a vuoto: 11.000 min

-1

ø max. mola: 115 mm

filetto del mandrino motore: M 14

livello di pressione acustica LPA: 89 dB (A)

livello di potenza sonora LWA: 99,6 dB (A)

Vibrazione

a

–

w

< 2,5 m/s

2

Peso 2,2 kg

Con isolamento protettivo

I

STOP

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 7

Page 8

8

I

Posizione della flangia se si impiegano

mole per smerigliatura e troncatura

1

flangia di serraggio

dado flangiato

Posizione della flangia se si impiega una mola per smerigliatura piegata a gomito o diritta

2

flangia di serraggio

dado flangiato

Posizione della flangia se si impiega una mola per troncatura piegata a gomito

3

flangia di serraggio

dado flangiato

Posizione della flangia se si impiega una mola per troncatura diritta

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 8

Page 9

9

Yleiset turvallisuusohjeet ja

tapaturmantorjunta

Onnettomuuksilta vältytään ja vaaratta voidaan

työskennellä vain silloin, kun turvallisuus- ja

käyttöohjeet luetaan kokonaan ja ohjeita

noudatetaan.

Tarkastakaa kone, liitäntäjohto ja pistoke ennen

jokaista käyttöä. Käyttäkää vain moitteettomassa

kunnossa olevaa, vaurioitumatonta konetta.

Sähkömiehen on vaihdettava vioittuneet osat

välittömästi uusiin.

Ennen kaikkia koneelle tehtäviä töitä ja

laikanvaihtoa sekä koneen ollessa

käyttämättömänä on verkkopistoke irrotettava

pistorasiasta.

Verkkojohdon vahingoittumisen välttämiseksi

viekää johto aina taakse koneesta poispäin.

Ulkona työskenneltäessä saa käyttää vain tähän

tarkoitukseen hyväksyttyjä jatkojohtoja.

Käytettävien jatkojohtojen halkaisijan tulee olla

vähintään 1,5 mm2. Pistoliittimissä tulee olla

suojamaadoitus ja roiskevesisuojaus.

Säilyttäkää laikat turvallisessa paikassa lasten

ulottumattomissa.

Käyttäkää hiomisen, harjauksen ja katkaisun

yhteydessä aina suojalaseja, turvakäsineitä ja

kuulosuojaimia.

Jos työssä syntyy pölyä, on käytettävä

hengityssuojaa.

Kulmahiomakonetta saa turvallisuussyistä käyttää

vain silloin, kun suojus ja lisäkahva ovat

paikoillaan.

Varmistakaa, että käsiteltävä kappale ei pääse

luistamaan (kiinnitettävä).

Kiveä käsiteltäessä (katkaistaessa ja hiottaessa)

on käytettävä pölynpoistoimua. Poistoimun tulee

olla hyväksytty kivipölyn poistoimuun.

Asbestia sisältäviä materiaaleja ei

saa käsitellä.

On noudatettava vastaavaa tapaturmantorjunnan

määräystä (VBG 119).

Huomio! Tulipalon vaara! Varmistakaa, että

katkaisun tai hionnan yhteydessä ei ole syttyviä

materiaaleja alueella, jonne kipinät voivat kantaa.

Käyttäkää ainoastaan alkuperäisvaraosia.

Korjaukset saa suorittaa vain sähkömies.

Työpaikan melu saattaa ylittää 85 dB (A). Tällöin

on työntekijän osalta suoritettava meluntorjunta- ja

kuulonsuojelutoimenpiteet. Kulmahiomakoneen

melu mitataan IEC 59 CO 11, IEO 704, DIN

45635, osa 21, NFS 31-031 (84/537/EWG)

mukaisesti.

Kiinnittäkää huomiota varmaan asentoon.

Välttäkää luonnottomia asentoja.

Älkää jättäkö konetta sateelle alttiiksi. Älkää

käyttäkö sitä märässä tai kosteassa ympäristössä

älkääkä syttyvien nesteiden läheisyydessä.

Älkää kantako konetta verkkojohdosta. Suojatkaa

verkkojohto öljyltä, liuottimilta ja teräviltä kulmilta.

Pitäkää työskentelyalueenne järjestyksessä.

Varmistakaa, että kytkin on katkaisuasennossa,

kun kone kytketään verkkovirtaan.

Käyttäkää sopivaa työvaatetusta. Älkää käyttäkö

väljiä vaatteita tai koruja. Pitkähiuksisten on

käytettävä hiusverkkoa.

Käyttäkää oman turvallisuutenne vuoksi vain

valmistajan varusteita ja lisälaitteita.

ISO 5349 mukainen kahvasta mitattu tärinä < 2,5

m/s2.

FIN

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 9

Page 10

10

Kulmahiomakoneen käyttöohjeet

Kulmahiomakone on kevyt ja kätevä. Se on

suojaeristetty ja valmistettu kansainvälisten

CEE 20 -määräysten mukaisesti. Se käyttöikä on

pitkä, jos sitä huolletaan käyttöohjeiden mukaisesti.

JÄNNITE

Tarkastakaa ennen käyttöönottoa, vastaako

tyyppikilpeen merkitty jännite verkkojännitettä.

Verkkojännite ei saisi missään tapauksessa poiketa

10 % enemmän tyyppikilven nimellisjännitteestä.

KYTKIN

Kulmahiomakoneessa on turvakytkin

onnettomuuksien välttämiseksi. Käynnistys tapahtuu

työntämällä painike eteen, painike lukittuu

painamalla. Kone sammutetaan painamalla painike

alas. Painike siirtyy takaisin alkuasentoon.

HIOMALAIKKOJEN VAIHTO

Irrota virtapistoke!

Laikanvaihto käy helposti

karanlukituksen avulla.

Karanlukitusta painetaan ja

hiomalaikan annetaan lukittua

paikalleen. Laippamutteri avataan

laippamutteriavaimella. Hioma-

tai katkaisulaikka vaihdetaan ja

laippamutteri kiristetään

laippamutteriavaimella.

Huomio:

Karanlukitusta saa painaa vain silloin, kun

moottori ja kara eivät ole käynnissä!

Karanlukitus on pidettävä alaspainettuna

laikanvaihdon aikana!

Kun hioma- tai katkaisulaikat ovat korkeintaan n. 3

mm paksuisia, laippamutteri on avattava sileä puoli

laikkaa kohti.

UUSIEN HIOMALAIKKOJEN KOEKÄYTTÖ

Kun hioma- tai katkaisulaikka on kiinnitetty

kulmahiomakoneeseen, koneen annetaan käydä

vähintään minuutin ajan joutokäyntiä. Tärisevät

laikat on heti vaihdettava.

MOOTTORI

Moottorin tuuletuksen tulee olla hyvä työn aikana, ja

sen vuoksi tuuletusaukot on aina pidettävä puhtaina.

HIILIHARJAT

Jos hiiliharjat ovat palaneet tai murtuneet tai mikäli

ne ovat lyhempiä kuin 6 mm, ne on vaihdettava

valmistajan alkuperäisiin hiiliharjoihin. Vaihtakaa

hiiliharjat aina pareittain.

HIOMALAIKAT

Hioma- tai katkaisulaikka ei saa koskaan olla

ohjeenmukaista halkaisijaa suuurempi. Tarkastakaa

laikan käyntinopeus ennen laikan kiinnitystä. Laikan

käyntinopeuden tulee olla suurempi kuin

kulmahiomakoneen joutokäyntinopeus.

Käyttäkää ainoastaan sellaisia hioma- ja

katkaisulaikkoja, jotka ovat sallittuja 11.000 min

-1

maksimikäyntinopeudelle ja 80 m/s kehänopeudelle.

TYÖTÄ KOSKEVIA OHJEITA

Pinnan hionta

Pinnan hionta onnistuu parhaiten, kun hiomalaikka

asetetaan 30 - 40 asteen kulmaan hiomapintaan

nähden ja liikutetaan tasaisesti edestakaisin

hiottavan kappaleen yli.

Katkaisuhionta

Katkaisutöissä hiomakonetta ei saa kääntää niin, että

laikan leikkuutaso muuttuu. Katkaisulaikan

leikkuusärmän tulee olla puhdas. Kovien

kivimateriaalien katkaisuun on parasta käyttää

timanttilaikkaa.

Asbestia sisältäviä materiaaleja ei saa käsitellä!

Älkää koskaan käyttäkö katkaisulaikkoja pinnan

hiontaan.

TEKNISIÄ TIETOJA

Nimellisjännite 230 V ~ 50 Hz

Tehonkäyttö 850 W

Joutokäyntinopeus 11.000 min

-1

Laikan halkaisija kork. 115 mm

Käyttökaran kierteitys M14

Äänen painetaso 89 dB (A)

Äänen tehotaso 99,6 dB (A)

Tärinä

a

–

w

< 2,5 m/s

2

Paino 2,2 kg

Soujaeristetty

FIN

STOP

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 10

Page 11

11

FIN

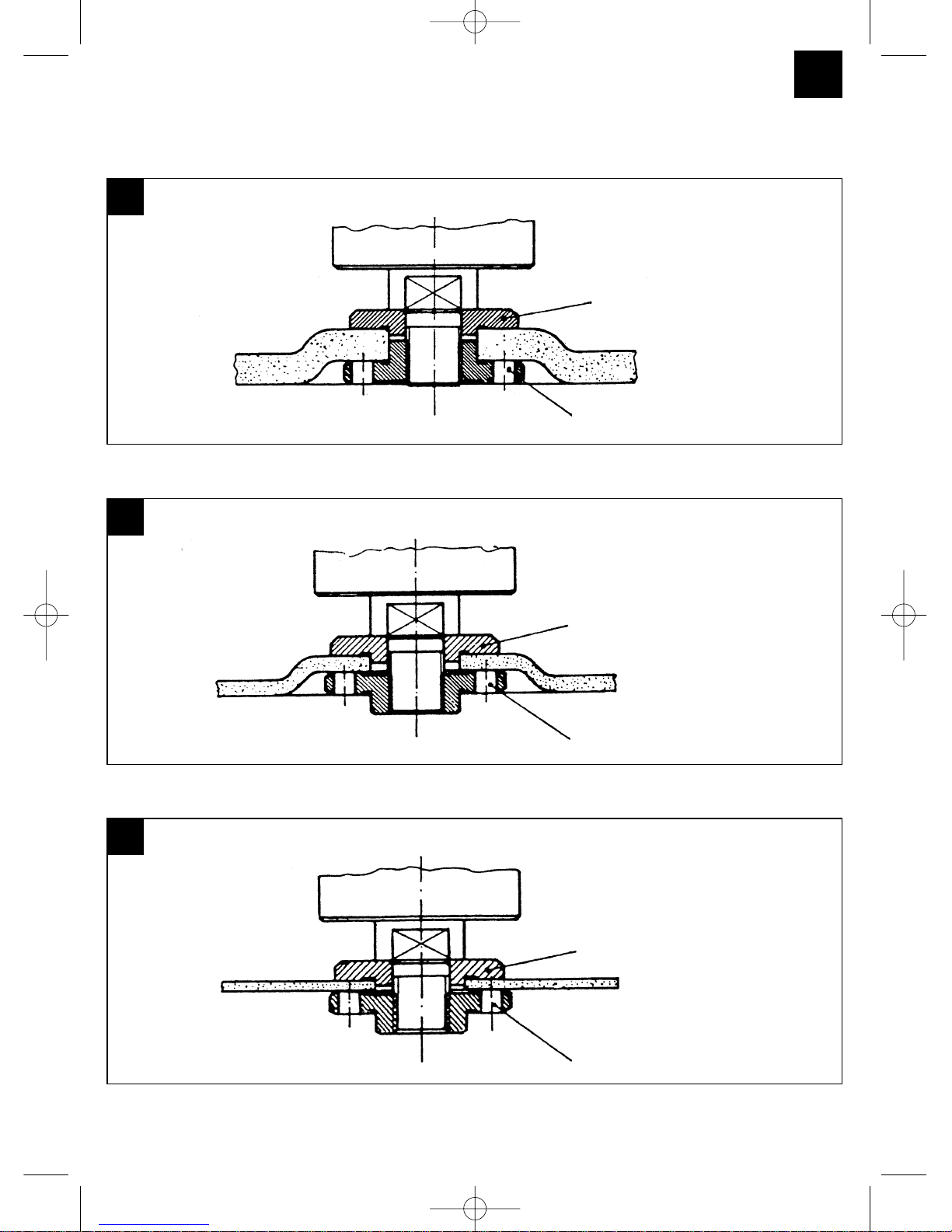

Laippojen sijoitus käytettäessä

hiomalaikkoja ja katkaisulaikkoja

1

Kiinnityslaippa

Laippamutteri

Laippojen sijoitus käytettäessä syvennyksellä varustettua tai suoraa hiomalaikkaa

2

Kiinnityslaippa

Laippamutteri

Laippojen sijoitus käytettäessä syvennyksellä varustettua katkaisulaikkaa

3

Kiinnityslaippa

Laippamutteri

Laippojen sijoitus käytettäessä suoraa katkaisulaikkaa

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 11

Page 12

EG Konformitätserklärung

Der Unterzeichnende erklärt im

Namen der

Firma

Achivierung / For archives: BWS-0633-25-4147145-E

BWS 115/85

– Seriennummer auf

dem Produkt –

der

EG Maschinenrichtlinie

89/392/EWG mit

Änderungen

EG Niederspannungs-

richtlinie 73/23 EWG

EG Richtlinie Elektro-

magnetische Verträglichkeit

89/336 EWG mit

Änderungen entspricht.

Landau/Isar, den

24.05.2000

Pflaum

Produkt-Management

Typ

Marke

daß die

Maschine/Produkt

EC Declaration of Conformity

The Undersigned declares, on

behalf of

– Serial number specified on

the product -

is in accordance with the

EC Directive regarding

machinery 89/392 EEC, as

amended;

EC Directive regarding

low-voltage equipment

73/23 EEC;

EC Directive regarding

electromagnetic compatibility

89/336 EEC, as amended.

Landau/Isar, (date)

24.05.2000

Pflaum

Produkt-Management

Landau/Isar, (date)

24.05.2000

Pflaum

Produkt-Management

Landau/Isar, datum

24.05.2000

Pflaum

Produkt-Management

Landau/Isar

24.05.2000

Pflaum

Produkt-Management

Landau/Isar

24.05.2000

Pflaum

Produkt-Management

Type

produced by:

that the

Machine / Product

Déclaration de Conformité CE

Le soussigné déclare, au nom

de

– no. série indiqué sur le

produit -

correspond(ent) à la

Directive CE relative aux

machines 89/392 CEE avec

les modifications y

apportées;

Directive CE relative aux

basses tensions 73/23 CEE;

Directive CE relative à la

compatibilité électro-

magnétique 89/336 CEE

avec les modifications y

apportées.

– serienummer op het produkt-

conform de volgende

richtlijnen is:

EG machinerichtlijn

89/392/EWG met wijzigingen

EG laagspanningsrichtlijn

73/23 EWG

EG richtlijn Elektro-

magnetische compatibiliteit

89/336 EWG met wijzigingen

Type

du fabricant

que

la machine / le produit

EC Conformiteitsverklaring

De ondertekenaar verklaart in

naam van de

firma

type

merk

dat de

machine/produkt

Declaracion CE de

Conformidad

Por la presente, el abajo

firmante declara en nombre de

la empresa

– No. de serie en el producto:

satisface las disposiciones

pertinentes siguientes:

Disposición de maquinaria

de la CE 89/392/CEE con

modificaciones

Disposición de baja tensión

de la CE 73/23 CEE

Disposición de la

compatibilidad electro-

magnética de la CE 89/336

CEE con modificaciones.

tipo

marca

que el/la

máquina/producto

Declaração de conformidade

CE

O abaixo assinado declara em

nome da

empresa

– cujo número de série

encontra-se no produto -

corresponde à

Directiva da CE de

máquinas 89/392/CEE, com

alterações

Directiva da CE de baixa

tensão 73/23 CEE

Directiva da CE de

compatibilidade electro-

magnética 89/336 CEE, com

alterações

tipo

marca

que

a máquina/o produto

ISC GmbH · Eschenstraße 6 · D-94405 Landau/Isar

Winkelschleifer

Right-angle Grinder Meuleuse d'angle Haakse slijper Lijadora angular Rectificadora angular

EN 50144-1; HD 400.2; EN 55014-1; EN 55014-2; EN 61000-3-2; EN 61000-3-3

12

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 12

Page 13

13

EC Konformitetsförklaring

Undertecknad förklarar i

firmans

Achivierung / For archives: BWS-0633-25-4147145-E

BWS 115/85

– serienummer på produkten -

motsvarar

EU riktlinje för maskiner

89/392/EWG med ändringar

EU riktlinje för lågspänning

73/23 EWG

EU riktlinje för elektro-

magnetisk kompatibilitet

89/336 med ändringar

Landau/Isar, den

24.05.2000

Pflaum

Produkt-Management

typ

märke

namn, att

maskinen/produkten

EC Yhdenmukaisuusilmoitus

Allekirjoittanut ilmoittaa

yhtiön

– tuotteen valmistusnumero -

vastaa

EU-konedirektiivik (johon on

tehty muutoksia)

89/392/EWG

EU-pienjänitedirektiiviä

73/23 EWG

EU-direktiiviä 89/336 EWG

(johon on tehty muutoksia) ja

joka koskee sähkömagn-

eettista mukautuvuutta (EMI)

Landau/Isar

24.05.2000

Pflaum

Produkt-Management

Landau/Isar, den

24.05.2000

Pflaum

Produkt-Management

Landau/Isar,

στις

24.05.2000

Pflaum

Produkt-Management

Landau/Isar,l”

24.05.2000

Pflaum

Produkt-Management

Landau/Isar, den

24.05.2000

Pflaum

Produkt-Management

tyyppi

merkki

nimissä että

kone/tuote

EC Konfirmitetserklæring

Undertegnede erklærer på

vegne av firma

– Serienumer på produktet –

tilfredsstiller følgende

retningslinjer:

EU Maskinretningslinje 89/

392/ EWG med endringer

EU Lavspennings-

retningslinje 73 / 23 EWG

EU Ratningslinje for

elektromagnetisk

kompatibilitet 89/336 EWG

med endringer.

– Αριθµς σειρς πνω στο

προιν –

ανταποκρνεται στην

κατευθυντρια γραµµ της

Ευρωπαικς Κοιντητας 89/

392/ ΕΟΚ µε αλλαγ

κατευθυντρια γραµµ

χαµηλς τσεως της

Ευρωπαικς Κοιντητας

73/ 23/ ΕΟΚ

κατευθυντρια γραµµ

ηλεκτροναγνητικς

ανεκτικτητας της

Ευρωπαικς Κοιντητας

89/ 336/ ΕΟΚ µε αλλαγς.

Type

Merke

at

Maskin/produkt

EC ∆λωση περι της

ανταπκρισης

Ο υπγρφων δηλ!νει εν

ονµατι της εταιρας

τπος

υρκα

τι η

µηχαν / το προιν

Dichiarazione di

conformità CE

Il sottoscritto dichiara in nome

della ditta

– numero di serie sul prodotto -

corrisponde

alla Direttiva CE sulle

macchine 89/392/CEE con

modifiche

alla Direttiva CE sulla bassa

tensione 73/23 CEE

alla Direttiva CE sulla

compatibilità elettro-

magnetica 89/336 CEE con

modifiche

tipo

marca

che la

macchina/prodotto

EC Overensstemmelses-

erklæring

Undertegnede erklærer på

vegne af firmaet

– Serienummer på produktet -

opfylder

EU-maskindirektiv

89/392/EØF med ændringer

EU-lavspændingsdirektiv

73/23/EØF

EU-direktiv vedr.

elektromagnetisk støj (EMC)

89/336/EØF med ændringer.

type

mærke

at

maskine/produkt

ISC GmbH · Eschenstraße 6 · D-94405 Landau/Isar

Vinkelslipverk Kulmahiomakone Vinkelslipemaskin

ÁÈ· ÙÔÓ ÁˆÓÈ·Îfi ÙÚÔxfi

Smerigliatrice angolare Vinkelsliber

EN 50144-1; HD 400.2; EN 55014-1; EN 55014-2; EN 61000-3-2; EN 61000-3-3

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 13

Page 14

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 14

Page 15

ISC GmbH

Eschenstraße 6

D-94405 Landau/Isar

Tel. (09951) 942 357, Fax (09951) 2610 u. 5250

Hans Einhell AG, UK Branch

32, Craven Court Winwick Quay

Warrington, Cheshire, WA2 8QU

Tel. 01925 419400, Fax 01925 419292

V.B.P. Distribution Service Après Vente

5, allée Joseph Cugnot, Z.I. du Phare

F-33700 Merignac

Tel. 05 56479483, Fax 05 56479525

Einhell Benelux

Weberstraat 3

NL-7903 BD Hoogeveeen

Tel. 0528 232977, Fax 0528 232978

Einhell Benelux

Abtsdreef 10

B-2940 Stadbroek

Tel/Fax 03 5699539

Comercial Einhell S.A.

Carretera Sanguesa

E-31310 Carcastillo/Navarra

Tel. 948 725025, Fax 948 715714

Einhell Iberica

Rua da Aldeia , 225 Apartado 2100

P-4405-017 Arcozelo VNG

Tel. 02 75336100, Fax 02 7536109

Antzoulatos E. E.

Paralia Patron-Panayitsa

GR-26517 Patras

Tel. 061 525448, Fax 061 525491

Einhell Italia s.r.l.

Via Marconi, 16

I-22077 Beregazzo (Co)

Tel. 031 992080, Fax 031 992084

Einhell Skandinavia

Rodelundvej 11 - Rodelund

DK-8653 Them

Tel.+ 45 86 849511, Fax+ 45 86 849522

Suomen Einhell OY

Hepolamminkatu 20

FIN 33720 Tampere

Tel. 03 3587800, Fax 03 3587828

Einhell Polska sp. z.o.o.

Al.Niepodleglosci 36

PL 65·950 Zielona Gora

Tel. 0683 242055, Fax 0683 272914

Einhell Hungaria Ltd.

Vjda Peter u. 12

H 1089 Budapest

Tel. 01 3039401, Fax 01 2101179

Star AS

Ahmet Cavus Sokak No: 17

TR 81630 Beykoz - Istanbul

Tel. 0216 4250840, Fax 0216 4250841

Novatech S.R.L.

Bd.Lasar Catargiu 24-26

S.C. A Ap. 9 Sector 1

RO 75 121 Bucharest

Tel. 01 4104800, Fax 01 4103568

DAT spol s.r.o

Hrubeho 3

CZ 61200 Brno

Tel. 05 49211107, Fax 05 41214831

CZ

Technische Änderungen vorbehalten

Technical changes subject to change

Sous réserve de modifications

Technische wijzigingen voorbehouden

Salvo modificaciones técnicas

Salvaguardem-se alterações técnicas

Förbehåll för tekniska förändringar

Oikeus teknisiin muutoksiin pidätetään

Der tages forbehold för tekniske ændringer

Ο κατασκεναστς διατηρε το δικαωµα

τεχνικ!ν αλλαγ!ν

Con riserva di apportare modifiche tecniche

Tekniske endringer forbeholdes

Technické změny vyhrazeny

Technikai változások jogát fenntartva

Tehnične spremembe pridržane.

Zastrzega się wprowadzanie zmian technicznych

Se rezervå dreptul la modificåri tehnice.

Teknik de©iµiklikler olabilir

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 15

Page 16

BWS 115/85 GB,I,FIN 29.10.2001 10:06 Uhr Seite 16

Loading...

Loading...