Page 1

Showstopper Precision

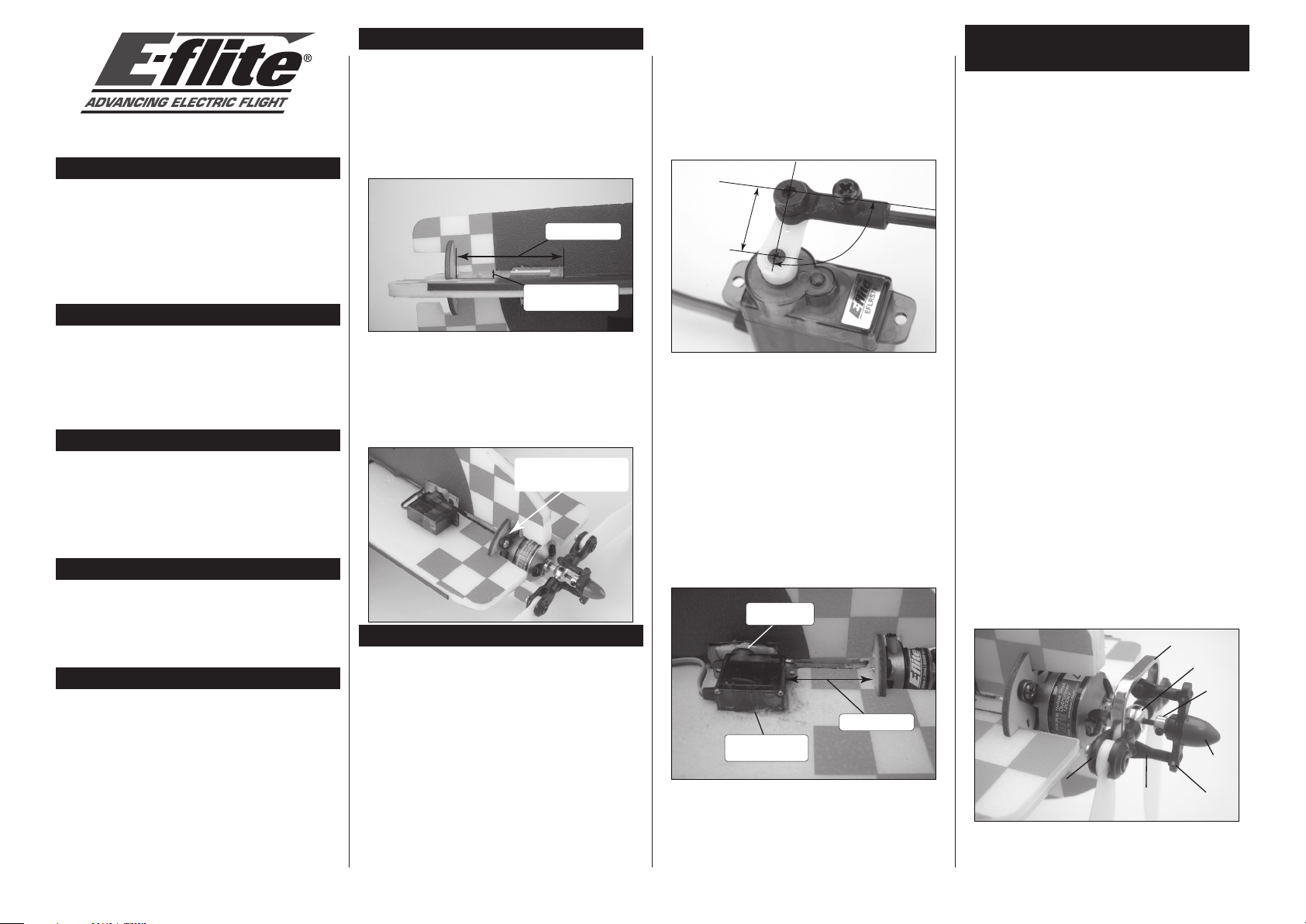

Approximately 60mm

Widen slot 3–4mm above

the horizontal fuselage

Install washers between the two

lower holes of the X mount and

the firewall to remove downthrust

9mm or less

Approximately

90 degrees

Approximately 33mm

Remove section of first

layer of foam doubler

Output shaft faces

rear and Inside

Pitch Bridge

Ball Link

Pitch Bridge

Spinner

Securing

Collar

Center Hub

Zero Pitch Tool

Blade Grip

Variable Pitch Prop System

Specifications and Items Needed to Complete

Diameter: 10

System Weight: 0.7 oz (20 g)

Motor: 300- to 370-size, 1080–1360Kv brushless outrunner w/hollow shaft

Speed Control: 10A to 20A brushless (depending on motor)

Battery: 3S 11.1V 480–910mAh Li-Po (depending on motor)

Servo: Sub-micro with 17 oz/in (minimum) of torque

Radio: 6+ channel with helicopter and 5-point (minimum) pitch and throttle

curve programming

For models weighing up to 12 ounces (340 g) ready to fly (including the

SSVPP system):

Motor: E-flite Park 370 Brushless Outrunner, 1200Kv w/4mm Hollow Shaft

(EFLM1210HS)

Speed Control: E-flite 10-Amp Pro Brushless (EFLA1010)

Battery: Thunder Power 730mAh 3S 11.1V Li-Po (THP7303SJPL)

Pitch Servo: E-flite 7.5 Gram S75 Sub-Micro (EFLRS75)

EFLPVPP101 101/4" Diameter Blade Set

EFLPVPP103 Blade Grip and Center Hub Set

EFLPVPP104 Blade Grip Bearing, 3x6x2.5mm (2)

EFLPVPP105 Pitch Bridge and Link Set

EFLPVPP106 Pitch Bridge Bearing, 2x6x3mm (2)

EFLPVPP107 Carbon Fiber Pushrod and Nut

EFLPVPP108 Spinner and Hardware Set

This manual will guide you through installation and setup of the Showstopper

Variable Pitch Prop (SSVPP) System on the E-flite® Extra 260 3D Profile

model (EFL2300). And although only the Extra 260 is shown, the SSVPP will

also work very well on the E-flite Byp Yak 3D (EFL2325, if measures are taken

to keep the airframe as light as possible) or any other model that weighs

12 ounces (340 g) or less when ready to fly with the SSVPP and battery

installed.

Before beginning assembly and installation of the SSVPP, it will be necessary

for you to take a few minutes to complete the initial setup and programming

of your transmitter.

Note: You will need to use a transmitter with 6 or more channels, equipped

with helicopter and 5-point (minimum) pitch and throttle curve programming

for proper setup and the best performance. You will also need to use a 6 or

more channel receiver that is compatible with your chosen transmitter.

After selecting a new “helicopter” model, be sure that the

Next, connect the rudder, aileron and elevator servos to the receiver as

1

/4 in (260mm)

Recommended Setup

Included and Replacement Parts

Introduction

Radio Requirements and Initial Setup

programming is set for Standard swashplate mixing and NOT 90- or

120-degree CCPM.

you would for a typical airplane setup. Connect the ESC to the throttle

channel and the “Pitch” servo (used for changing pitch of the SSVPP)

to the “Pitch” or “Aux 1” channel (usually channel 6).

Model Preparation and Motor Mounting

The following steps outline installation of the SSVPP on an Extra 260

airframe that has already been assembled. However, many of the steps can

also be completed for an airframe that is not yet assembled.

Note: The Extra 260 comes from the factory with a slot in the vertical

fuselage that serves as a starting point for installation of the SSVPP.

All of the measurements shown are based on this slot, though they are

approximate and may need to be fine-tuned for your particular installation.

Start by widening the slot in the vertical fuselage by 3–4mm above the

horizontal fuselage. Overall, the widened slot needs to be approximately

60mm long.

Next, mount the E-flite Park 370 1200Kv brushless outrunner motor

(EFLM1210HS) to the plywood motor mount. If your mount has any

left/right or up/down thrust built in, we suggest shimming the motor

so that the thrust angle is zero in all directions. In the case of the Extra

260, you will need to shim the motor upward to eliminate the down

thrust that is built into the firewall. Do this by installing a #2 washer

between each of the two lower holes of the X mount and the firewall.

It may take 1–2 washers to eliminate the down thrust,

depending on the thickness of the washers used.

Servo and Servo Arm Setup and Mounting

For the best possible performance, we recommend that you use a servo that

has at least 17 ounce inches (oz/in) of torque, like the E-flite S75 Sub-Micro

Servo (EFLRS75). You must also keep the distance between the center of

the servo output shaft and the pushrod linkage to 9mm or less. DO NOT

exceed 9mm as it will require you to further reduce the pitch servo

travel for proper pitch range, in turn, lowering the effective torque

the servo is actually offering. Reduced torque can result in a lack of pitch

control in flight.

Once you have selected your servo and servo arm, mount the pushrod

linkage to the arm using the supplied socket head shoulder screw and

hex nut. You will likely have to enlarge the hole in the arm to fit the

screw. Then, be sure to use blue threadlock to secure the nut on the

screw, making sure that the pushrod linkage is able to move side to

side on the slot and rotate around the screw freely.

After installing the pushrod linkage on the servo arm, power your radio

system on and center the pitch servo at what should be the “zero pitch”

setting. This is usually easiest to accomplish by using the default pitch

curve programming of the transmitter with the throttle/collective stick

set to exactly the middle position. If your transmitter features a graphic

display of pitch curves, it may also be helpful to select this menu to

better determine the exact mid-stick position.

With the pitch servo centered, we suggest installing the servo

arm on the servo so that it will be as close to perpendicular

(90 degrees) to the pitch control pushrod as possible.

With the servo arm installed on the servo, it will now be necessary to choose

where to install the servo on the model. In the case of the Extra 260, the front

edge of the servo should be about 33mm back from the firewall, with the

output shaft of the servo facing toward the rear and inside of the model.

Note: When choosing the proper mounting position for the

servo, the pitch control pushrod will need to be approximately

centered in the hollow motor shaft when the servo arm is

perpendicular to the pushrod. To check this, temporarily install

the pushrod through the motor shaft and into the pushrod

linkage on the servo arm (do not worry about cutting the

pushrod to proper length at this time). If the servo cannot be

positioned so that the pushrod is centered in the motor shaft,

remove foam and/or add shims as necessary until it can be.

Once you have determined the servo mounting location, mark the

outline of the servo on the foam. In the case of the Extra 260, carefully

cut the first/bottom layer of foam around the outline that you made,

making sure not to cut in to the second/top layer. Removing this

section of the foam doubler will allow the servo to be positioned so that

the pushrod is very close to centered in the motor shaft.

Center Hub, Pitch Bridge and Pitch Control

Pushrod Installation

Note: All parts MUST be assembled with blue threadlock for maximum

security and reliability.

Position the center hub and blade grip assembly on the motor shaft,

making sure that the blade grips are positioned so that the recess

for the nut is facing toward the motor and the rear of the model. The

rounded side of the center hub goes toward the motor, and the flat side

should be positioned flush with the end of the motor shaft. Use the

included setscrews (and threadlock) to mount the hub on the shaft,

making sure that at least one of the setscrews engages the flat spot on

the end of the E-flite Park 370 (EFLM1210HS) motor’s shaft.

Next, install the pitch bridge assembly by snapping the ball links in

place on the ball ends of the blade grips. Then, slide the pitch control

pushrod through the bearings in the pitch bridge until the end of the

pushrod just exits past the rear bearing.

Before sliding the pushrod into the motor shaft, it will be necessary to

slide the pitch bridge securing collar onto the end of the pushrod that

extends past the rear bearing of the pitch bridge. This collar must be

installed with the “cone” side toward the bearing in the pitch bridge,

and by using the included setscrews (and threadlock). However, do not

tighten the setscrews all the way down at this time.

Slide the pushrod through the securing collar and motor shaft, then

past the servo arm and pushrod linkage as the pushrod will likely

need to be shortened in the next step. Once the nut on the end of the

pushrod is pressing against the front bearing of the pitch bridge, slide

the securing collar up against the rear bearing. Sandwich the pitch

bridge bearings between the securing collar and nut, noting that the

pitch bridge should spin freely, but with no play, between them. Then,

fully tighten the setscrews on the securing collar.

During the following steps you will need to determine the final length of

the pitch control pushrod.

Note: Determining the final length of the pitch control

pushrod is a critical step and we strongly suggest that you

take your time to read through the following steps first. If you

do happen to cut the pushrod to a length that is too short,

replacement pushrods are available (EFLPVPP107).

In the case of the Extra 260, the pushrod will need to be shortened

to a length of approximately 105mm from end to end. However, be

sure to double check this required length after reviewing the following

steps first, as it may vary slightly depending on your particular setup.

With the radio system powered on and the Pitch servo centered (at

what should be the “zero pitch” setting), slide the U-shaped “zero

pitch” tool into the blade grips. This tool will set the blade grips to

exactly zero pitch, and with the servo set to the zero pitch setting,

you will now be able to determine the correct length required for the

pushrod.

Once you have determined the correct length required for the pushrod,

making sure to allow as much length of the pushrod as possible to

pass by the securing screw location, cut the pushrod to length. Then,

insert the pushrod into the pushrod linkage.

Page 2

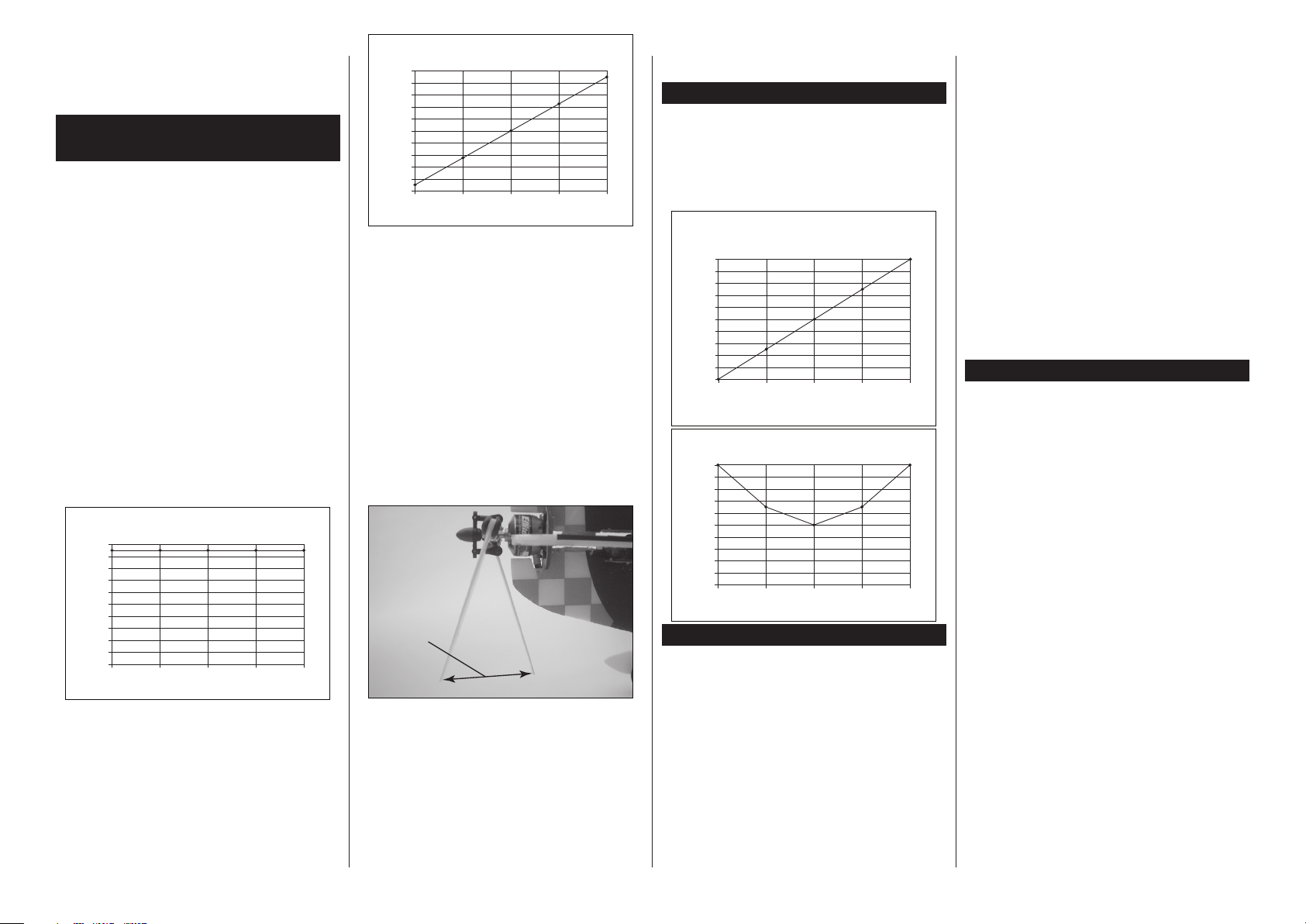

After ensuring that the servo arm and blade grips are in the zero pitch

0

10

20

30

40

50

60

70

80

90

100

L 1 2 3 H

Stick Position

Pitch Curve

Normal Flight Mode

Values

0

10

20

30

40

50

60

70

80

90

100

L 1 2 3 H

Stick Position

Pitch Curve

Idle Up Flight Mode

Values

Approximately 55mm

0

10

20

30

40

50

60

70

80

90

100

L 1 2 3 H

Stick Position

Throttle Curve

Normal Flight Mode

Values

0

10

20

30

40

50

60

70

80

90

100

L 1 2 3 H

Stick Position

Throttle Curve

Idle Up Flight Mode

Values

positions, secure the pushrod in the pushrod linkage by using the

included self-tapping screw. However, be sure that you do not use too

much force to tighten the screw as it could strip the plastic.

Install the included rubber spinner over the front “lip” of the pitch

bridge to complete installation.

Main Blade Installation and Initial Pitch Curve/

Travel Settings

Now that you have completed installation of the SSVPP system, you will

need to install the main blades and complete initial setup and adjustment of

the pitch curves and pitch servo travel value in the various flight modes that

will be used.

Install one main blade in each blade grip using the included

socket head shoulder screws and nylon insert locknuts. Be sure

that the blades are installed so that the leading edges will rotate

counterclockwise.

Tighten the main blade mounting screws until some moderate force is

required to rotate the main blades in the blade grips. Be sure that you

do not leave the blades loose in the grips.

Note: It may be necessary for you to further tighten the

main blade mounting screws after the first few flights to

prevent the blades from moving too freely in the grips.

Before proceeding, be sure that your transmitter and onboard electronics are

powered on. Also, be sure that the motor is left unplugged from the

ESC for safety.

Set the Travel Adjustment/End Point Adjustment values for the “Pitch”

channel to approximately 50% each way. This is generally a good

starting point for adjusting the overall pitch range/travel of your

system.

Next, program the following pitch curves for the “Normal” and “Idle

Up” flight modes:

Note: The values shown are approximate and may need

to be adjusted depending on your particular setup and/

or preferred performance. However, these values are

similar to those used during most of our testing.

With the pitch curves programmed, use the corresponding switch on your

transmitter to enter the Idle Up flight mode. In this mode you will be able to

check the maximum travel/pitch range of the blades. You will also be able to

confirm proper operating direction of the pitch servo.

When in the Idle Up flight mode, and with the motor still

disconnected from the ESC, advance the throttle/pitch stick to the

full position. With the blades extended outward, the leading edge of

the blades should now be positioned away from the model and motor,

indicating that they are providing “positive” pitch for forward thrust.

With the throttle/pitch stick in the lowest position, the leading edge

of the blades should now be positioned toward the model and motor,

indicating that they are providing “negative” pitch for reverse thrust.

If you find that the pitch response is opposite to the stick movements

indicated, simply use the servo reversing function of your

transmitter to reverse the operating direction of the pitch servo.

After confirming proper control response of main blade pitch, you can

now make initial adjustments to the overall travel/pitch range. In the

case of the Extra 260, when using the recommended setup, we find

that there should be approximately 55mm between the ends of the

blades when they are folded parallel (when viewed from the front) to

one another and viewed from the side (when in the Idle Up flight mode,

with the throttle/pitch stick in the highest and lowest positions).

If you find that the distance between the ends of the blades is more

or less than 55mm, use the travel/end point adjustment function

of your transmitter to adjust the overall pitch servo travel in both

the highest and lowest stick positions. Typically we find that a

travel/endpoint adjustment value of approximately 70% in both

directions provides the correct pitch servo travel for the Extra 260.

Note: The actual amount of overall travel/pitch range of the blades

you need to set will depend on your chosen power system’s

performance and maximum power output capability, as well

as the size and weight of your model. In general it is best to

adjust the maximum travel/pitch values by using a Power Meter

(EFLA110) to measure the current and power of your power

system when full positive or negative pitch is applied. Typically

you will want to be sure that you are not pulling too much current

for the motor, ESC or battery pack you have chosen to use, based

on the maximum recommendations from the manufacturer.

In the case of the recommended setup for the Extra

260, you should be sure not to exceed approximately

12 amps of current consumption when full positive or

negative pitch is applied in the Idle Up flight mode.

Throttle Curve Settings

With the pitch curves and travel values set, you can now program the throttle

curves for the various flight modes that will be used.

Program the following throttle curves for the “Normal” and “Idle Up”

flight modes:

Note: The values shown are approximate and may need

to be adjusted depending on your particular setup and/

or preferred performance. However, these values are

similar to those used during most of our testing

Flying Tips

We have found that the use of white lithium grease on the pushrod

where it slides through the motor shaft helps to smooth out the

operation of the Showstopper Variable Pitch Prop System. You may

purchase this at any local hardware store, however, be sure to keep

the grease away from the foam parts of the airplane as it can cause

damage to the foam.

The “Normal” flight mode is typically used for flying like you

would when using a standard, fixed-pitch propeller. This is why

the recommended pitch curve for this mode keeps the blades at a

consistent pitch setting through the entire throttle/pitch range, and why

the recommended throttle curve allows the power to be adjusted from

zero to full power.

In general, it is best to begin and end each flight in the Normal

flight mode. Also, you will need to be in the Normal flight mode for

the ESC to arm properly, and in order to power down the motor.

The “Idle Up” flight mode is typically used when you would like to

utilize forward and reverse thrust during flight. In this flight mode,

placing the throttle/pitch stick in the highest position will offer

maximum forward thrust by providing full power and full positive

pitch. Placing the throttle/pitch stick in the lowest position will offer

maximum reverse thrust by providing full power and full negative

pitch. When the throttle/collective stick is in the middle position, the

thrust will be approximately zero in either direction when using the

recommended curve.

In general, it is best to enter and exit the Idle Up flight mode during

level forward flight at cruise speed. This will help to minimize any

pitch and thrust changes during the transition. Also, it is usually best

to keep abrupt positive to negative (and vice versa) pitch changes

to a minimum as it can place a significant amount of stress on the

airframe and system. With some practice, you will find that smooth

and deliberate applications of positive to negative (and vice versa)

pitch can result in controlled flight, opening the door to many

maneuvers never before possible with a fixed-pitch propeller.

Take your time when learning to fly the model in the Idle Up flight

mode, and be sure to remember that any time you lower the stick

below approximately the middle position, the power system will offer

reverse thrust. For this reason, most of the flight will be spent with

the stick in the 3/4 to 2/3 position (for typical forward flight), with

lower stick positions typically reserved for reverse thrust maneuvers.

After you have gained some flight experience and confidence using the

SSVPP system, you may choose to adjust the pitch and throttle curves

(especially in the Idle Up flight mode) to better suit your preferred

performance and flying style. You can also visit www.E-fliteRC.com for

more pitch and throttle curve setups, including those used by Quique

Somenzini for his competition Byp Yak 3D model.

Precautions, Warnings and Support

Please read these safety precautions and warnings before use. Failure

to comply with these warnings and/or improper use of the Showstopper

Variable Pitch Prop System may result in serious injury.

Please make sure the Showstopper Variable Pitch Prop System is properly

balanced before use for proper performance. You must also make sure that

the blades and all other components are secure before use. Keep fingers and

hands, hair, face, body parts, or clothing away from the moving propeller

or risk serious injury. Keep all spectators twenty feet from the path of this

propeller. Do not start the motor/propeller near any loose gravel or dirt to

prevent particles from flying and injuring individuals. Do not throw anything

into the moving propeller to stop it from running. Please discard and replace

any blades that appear damaged, showing signs of wear, nicks or cracks.

Please do not attempt to repair parts of the SSVPP system or modify it from

its intended use.

For additional information concerning the Showstopper Variable Pitch Prop

System, please refer to our web page for this item or contact your E-flite

distributor. You can also direct emails to productsupport@horizonhobby.com,

or in the U.S. call 877.504.0233 toll-free to speak to a support technician.

© 2006 Horizon Hobby, Inc.

www.horizonhobby.com

E-flite® is an exclusive brand of Horizon Hobby, Inc.

www.E-fliteRC.com

10002

Loading...

Loading...