E-flite Nieuport 17 250 ARF User Manual

Nieuport 17 250 Slow Flyer

Specifications

Wingspan: 34.5 in (875mm)

Wing Area: 295 sq in (19.03 sq dm)

Length: 24 in (610mm)

Weight w/o Battery: 8–8.5 oz (227–240 g)

Weight w/Battery: 6.75–7.25 oz (190–205 g)

Assembly Manual

Table of Contents

Introduction

Using the Manual

Specifications ......................................................... 1

Introduction ........................................................... 2

Important Information Regarding

Warranty Information ........................................ 2

Using the Manual ................................................... 2

Contents of Kit/Parts Layout .................................... 2

Recommended Radio Equipment ............................. 3

Required Tools and Adhesives ................................. 3

Brushless Outrunner Setup ...................................... 3

Optional Accessories .............................................. 3

Note on Lithium Polymer Batteries ........................... 3

Warning ................................................................ 3

Servo Installation .................................................... 3

Stabilizer Installation .............................................. 6

Rudder Installation ................................................. 8

Connecting the Linkages ....................................... 11

Motor and Speed Control Installation .................... 12

Bottom Wing and Landing Gear Installation ........... 16

Top Wing and Outer Strut Installation .................... 17

Rigging Installation ............................................... 18

Scale Accessory Installation .................................. 21

Control Throws..................................................... 22

Center of Gravity ................................................. 22

Preflight ............................................................... 23

Range Test Your Radio .......................................... 23

Flying Your Nieuport 17 Slow Flyer ....................... 23

Safety, Precautions and Warnings ......................... 24

Safety Do’s and Don’ts for Pilots ............................ 24

Warranty Information ........................................... 24

Instructions for Disposal of WEEE by

Users in the European Union ............................ 26

2008 Official Academy of

Model Aeronautics Safety Code ....................... 26

The Nieuport 17 was designed by the French as a

single-seat fighter biplane in World War I. It was a

very maneuverable aircraft and many British and

French pilots began their careers with a Nieuport 17.

E-flite’s Nieuport 17 Slow Flyer is an electric indoor

version of the French biplane fighter. It’s the third in

a line of E-flite slow flyers and boasts a low weight

and a more majestic type of slow flight thanks to the

biplane design and reduced wing loading. So you

can get to flying faster, the Nieuport 17 comes with

many prefinished details including wood interplane

and cabane struts, molded cowling, a dummy motor,

a prepainted trim scheme and decals that are already

applied.

The E-flite Nieuport 17 Slow Flyer 250 ARF is a

fantastic flying foamie with outstanding slow speed

characteristics—making it perfect for indoor flight.

Important Information

Regarding Warranty Information

Please read our Warranty and Liability Limitations

section on Page 24 before building this product. If you

as the Purchaser or user are not prepared to accept the

liability associated with the use of this Product, you are

advised to return this Product immediately in new and

unused condition to the place of purchase.

This manual is divided into sections to help make

assembly easier to understand, and to provide breaks

between each major section. In addition, check boxes

have been placed next to each step to keep track

of its completion. Steps with a single circle () are

performed once, while steps with two circles ( )

indicate that the step will require repeating, such as for

a right or left wing panel, two servos, etc.

Remember to take your time and follow the directions.

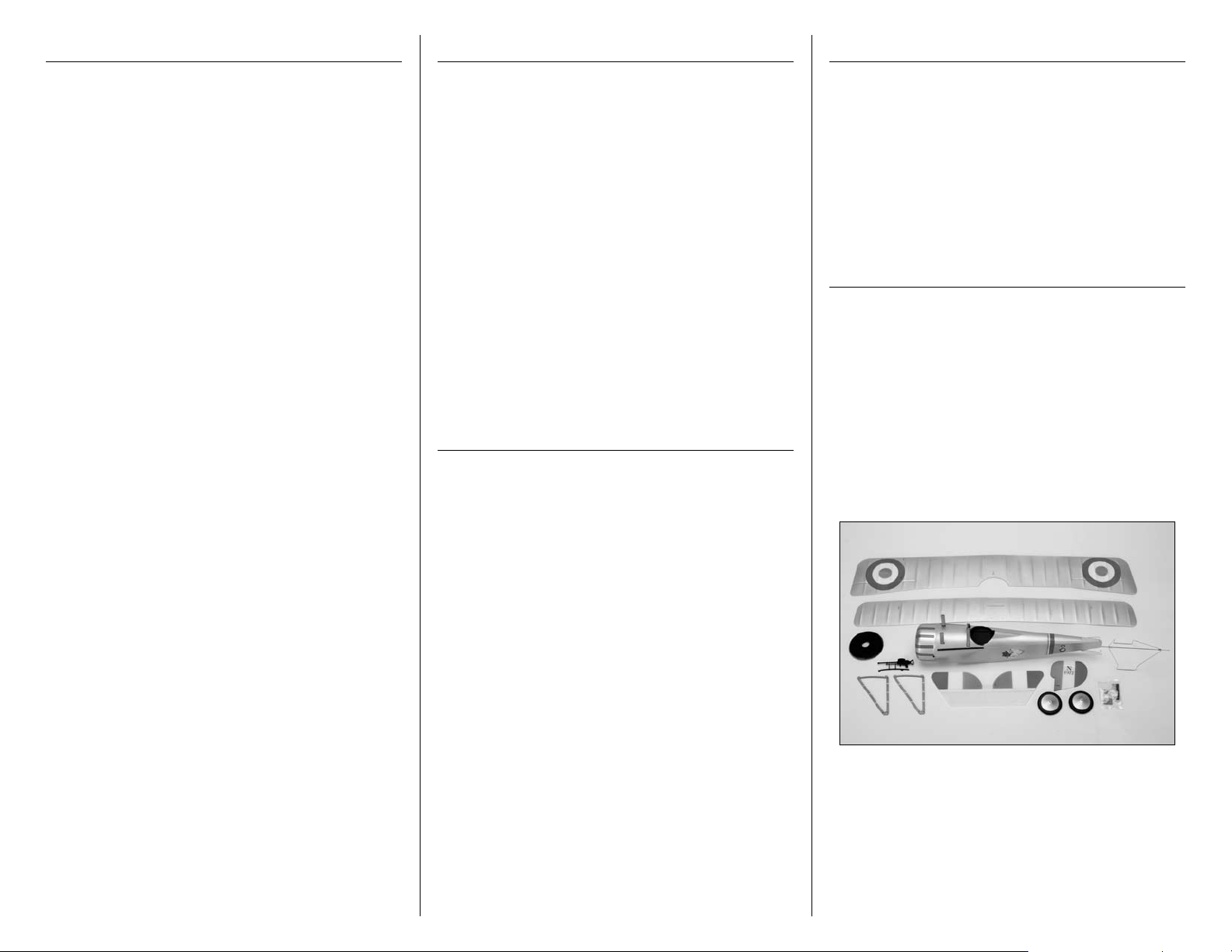

Contents of Kit/Parts Layout

Replacement Parts

EFL1951 Wing Set

EFL1952 Fuselage Set

EFL1953 Tail Set

EFL1954 Cowling

EFL1955 Wheel Set

EFL1956 Landing Gear

EFL1957 Wing Struts

EFL1958 Hardware Pack

EFL1959 Machine Gun

EFL1960 Dummy Motor

2 E-flite Nieuport 17 Slow Flyer Assembly Manual

Recommended Radio Equipment

Brushless Outrunner Setup

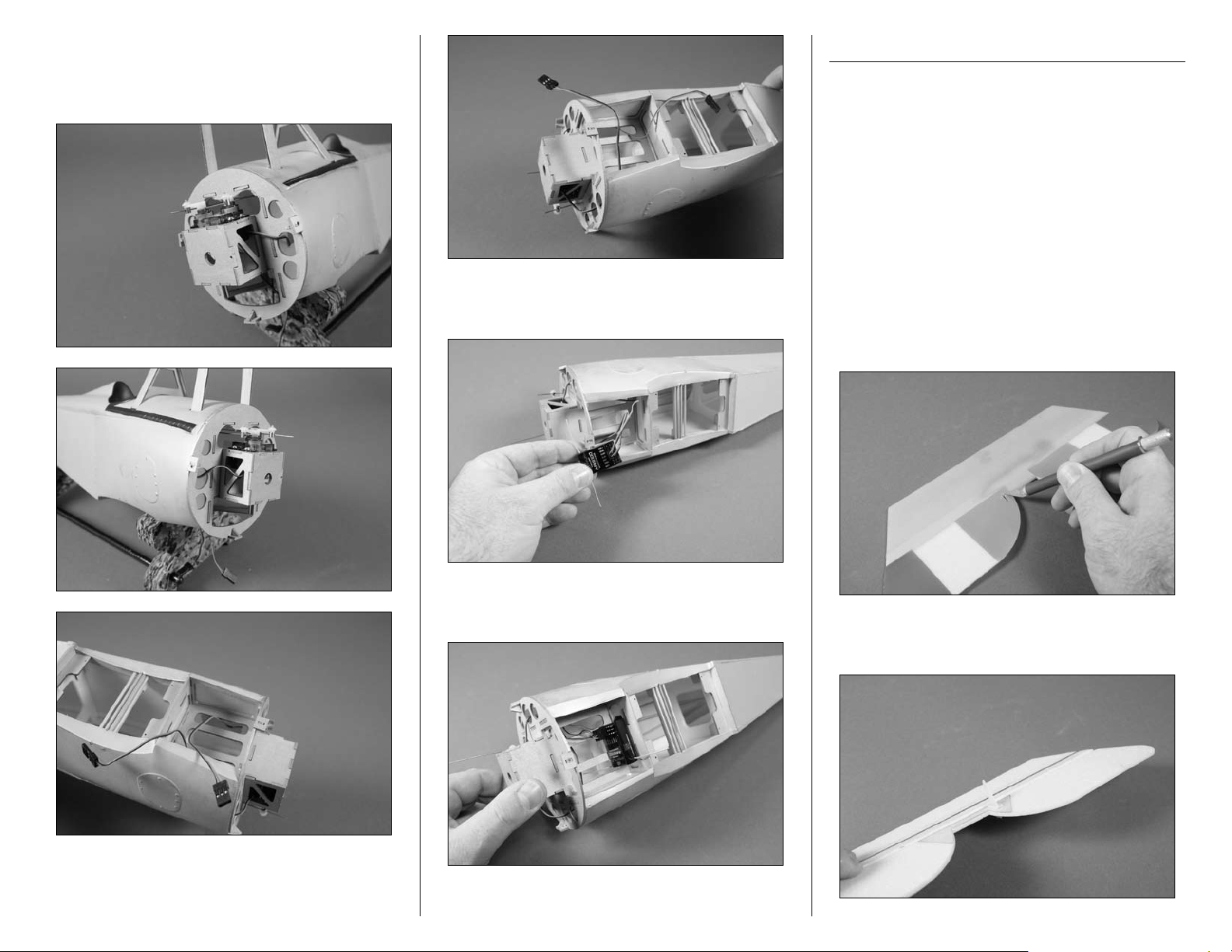

Servo Installation

You will need a minimum 4-channel transmitter,

receiver and two servos. You can choose to purchase

a complete radio system. If you are using an

existing transmitter, just purchase the other required

equipment separately. We recommend the crystalfree, interference-free Spektrum™ DX5e 2.4GHz DSM®

5-channel system. If using your own transmitter, we

recommend the E-flite® S60 Sub-Micro servos.

If you own a Spektrum radio, just add a DSM2

receiver and two E-flite S60 Sub-Micro servos. We

show the installation of the AR6100 receiver in the

manual.

Complete Radio System

SPM5500 DX5e DSM2 5CH system

Or Purchase Separately

SPMAR6100 AR6100 DSM2 6-Channel Park

Flyer Receiver (for DX5e, DX6i,

or DX7)

And

EFLRS60 6.0-gram Sub-Micro

Servo (2)

™

Required Tools and Adhesives

Tools & Equipment

Paper towels Pencil

Pin drill Pliers

Ruler Hobby scissors

T-pins Medium grit sandpaper

Felt-tipped pen Phillips screwdriver: #0, #1

Diagonal Cutters Low-tack Tape

Lead weight

Hobby knife (#11 blade)

Drill bit: 1/16-inch (1.5mm)

5 5/8-inch (143mm) block of foam (2 required)

Adhesives

Threadlock Thin CA

RTV Silicone

Foam-safe CA (EFLA209)

The Spektrum trademark is used with permission

of Bachmann Industries, Inc.

EFLM1130 Park 250 Brushless Outrunner

Motor, 2200Kv

GWSEP7035 7x3.5 Direct Drive Prop

EFLA1010 10-Amp Pro Brushless ESC

EFLB0990 7.4V 800mAh 2-Cell LiPo,

JST/Balance

Optional Accessories

EFLA110 Power Meter

EFLC3005 Celectra™ 1- to 3-Cell

Li-Po Charger

EFLC505 Intelligent 1- to 5-Cell

Balancing Charger

Note on Lithium Polymer Batteries

Lithium Polymer batteries are significantly

more volatile than alkaline or Ni-Cd/

Ni-MH batteries used in RC applications.

All manufacturer’s instructions and warnings

must be followed closely. Mishandling of

Li-po batteries can result in fire. Always

follow the manufacturer’s instructions when

disposing of Lithium Polymer batteries.

Warning

An RC aircraft is not a toy! If misused, it can cause

serious bodily harm and damage to property. Fly

only in open areas, preferably at AMA (Academy of

Model Aeronautics) approved flying sites, following all

instructions included with your radio.

Keep loose items that can get entangled in the

propeller away from the prop, including loose clothing,

or other objects such as pencils and screwdrivers.

Especially keep your hands away from the propeller.

During the course of building your Nieuport 17

250 Slow Flyer we suggest that you use a soft

base for the building surface. Such things as a

foam stand, large piece of bedding foam or a

thick bath towel will work well and help protect

the model from damage during assembly.

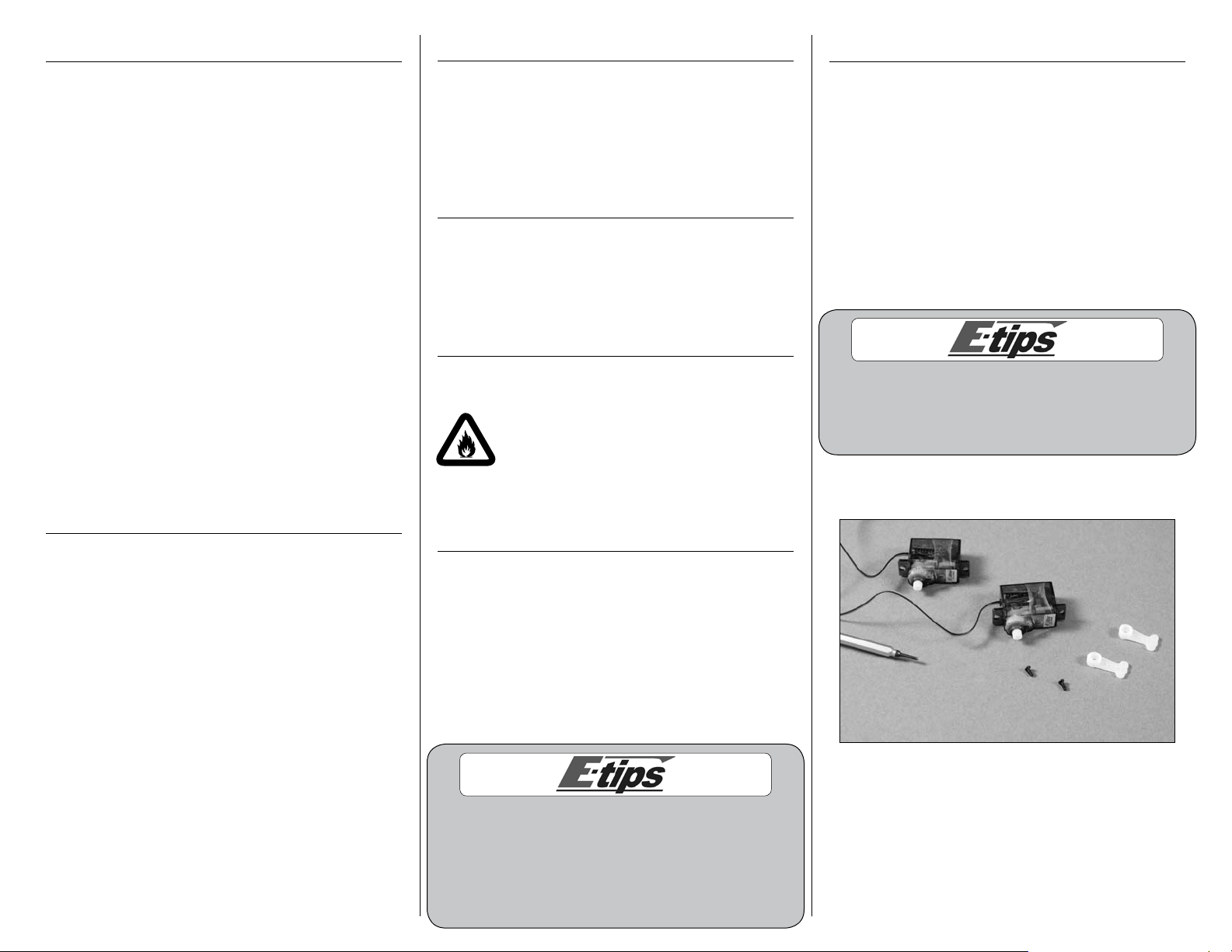

Required Parts

Fuselage Servo w/hardware (2)

Receiver Double-sided tape

Micro pushrod connector (2)

Micro pushrod connector backplate (2)

Required Tools and Adhesives

Pin drill Diagonal cutter

Thin CA Medium grit sandpaper

Pliers Pencil

Phillips screwdriver: #0, #1

Drill bit: 1/16-inch (1.5mm)

The pushrods are pre-installed from the factory. You

will also need to use a #0 Phillips screwdriver to

remove the three screws from the cowling and remove

the cowl from the fuselage to install the servos.

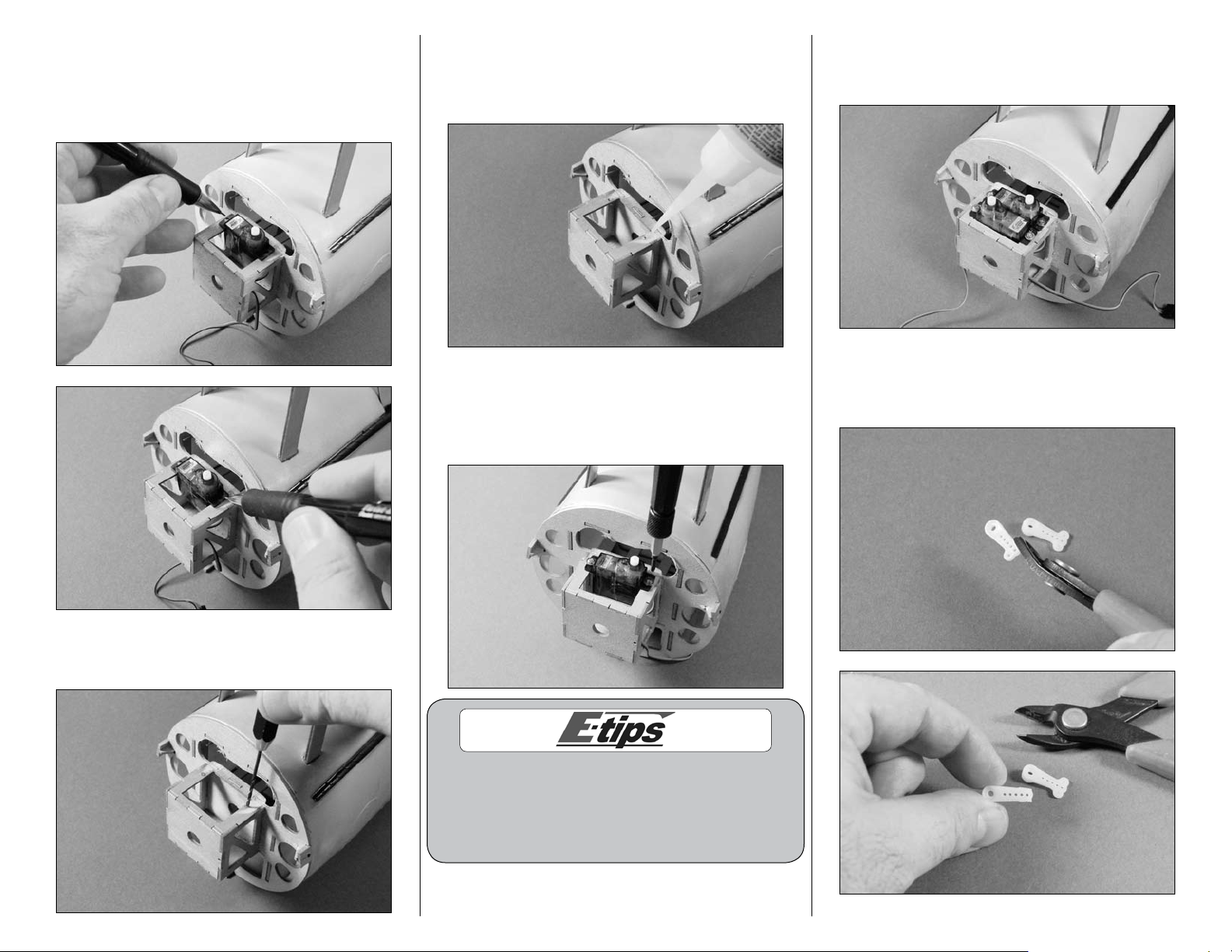

1. Use a #0 Phillips screwdriver to remove the

servo arms from the rudder and elevator servos.

3E-flite Nieuport 17 Slow Flyer Assembly Manual

2. Position the rudder servo in the opening at the

front of the fuselage as shown. Slide the servo as

far back in the opening as possible. Use a pencil to

mark the position for the screws that will be used to

secure the rudder servo.

4. Apply 2–3 drops of thin CA into each of the

holes to harden the surrounding wood. This is done

to strengthen the wood and provide a stronger

surface for the servo mounting screws.

5. Position the rudder servo back in the opening

in the front of the fuselage. Use a #1 Phillips

screwdriver and the screws provided with the servo

to secure the rudder servo.

6. Repeat Steps 2 through 5 to install the elevator

servo. Note the direction of the output of the

elevator servo.

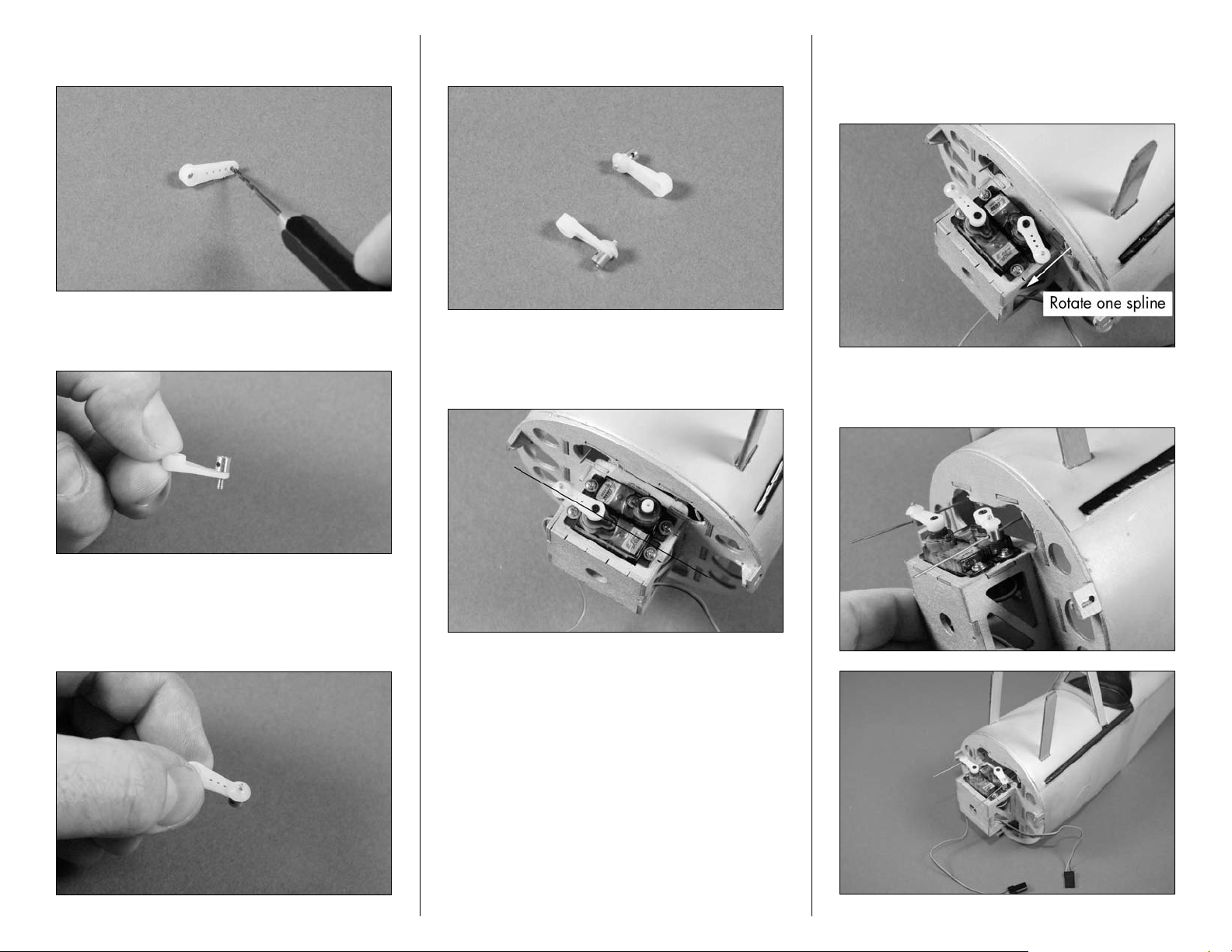

7. Use diagonal cutters to remove the ears of the

servo arm as shown. Use medium grit sandpaper

to smooth the servo arm for a finished look.

3. Use a pin drill and 1/16-inch (1.5mm) drill bit

to drill the holes for the two servo mounting screws.

It is best to support the fuselage with the palm of your

hand while installing the servo screws. The plywood

structure is strong enough for the model and flight

loads but could fail if extreme downward pressure is

placed on it during the servo mount screw installation.

4 E-flite Nieuport 17 Slow Flyer Assembly Manual

8. Use a pin drill and 1/16-inch (1.5mm) drill bit

to enlarge the outermost hole in the servo arm.

9. Insert the micro pushrod connector into the servo

arm from the bottom of the horn as shown.

11. Repeat Steps 7 through 10 so two servo arms

have been prepared for your servos.

12. Install the servo arm on the elevator servo. The

arm will be parallel to the center line of the servo

as shown.

13. Install the servo arm on the rudder servo. The

arm on the rudder servo is installed one spline off

from center so it will not interfere with the fuselage

during operation.

14. Slide the pushrod wires through the pushrod

connectors at this time.

10. Use a micro pushrod connector backplate to

secure the pushrod connector to the servo arm.

Use pliers to fully push the backplate tight on the

connector.

5E-flite Nieuport 17 Slow Flyer Assembly Manual

15. Pass the leads from the servos through the

center hole in the sub firewall and into the battery

compartment. Holes have been made inside the

fuselage for the servo leads to pass through.

16. Plug the rudder and elevator servo leads into

the appropriate ports of the receiver.

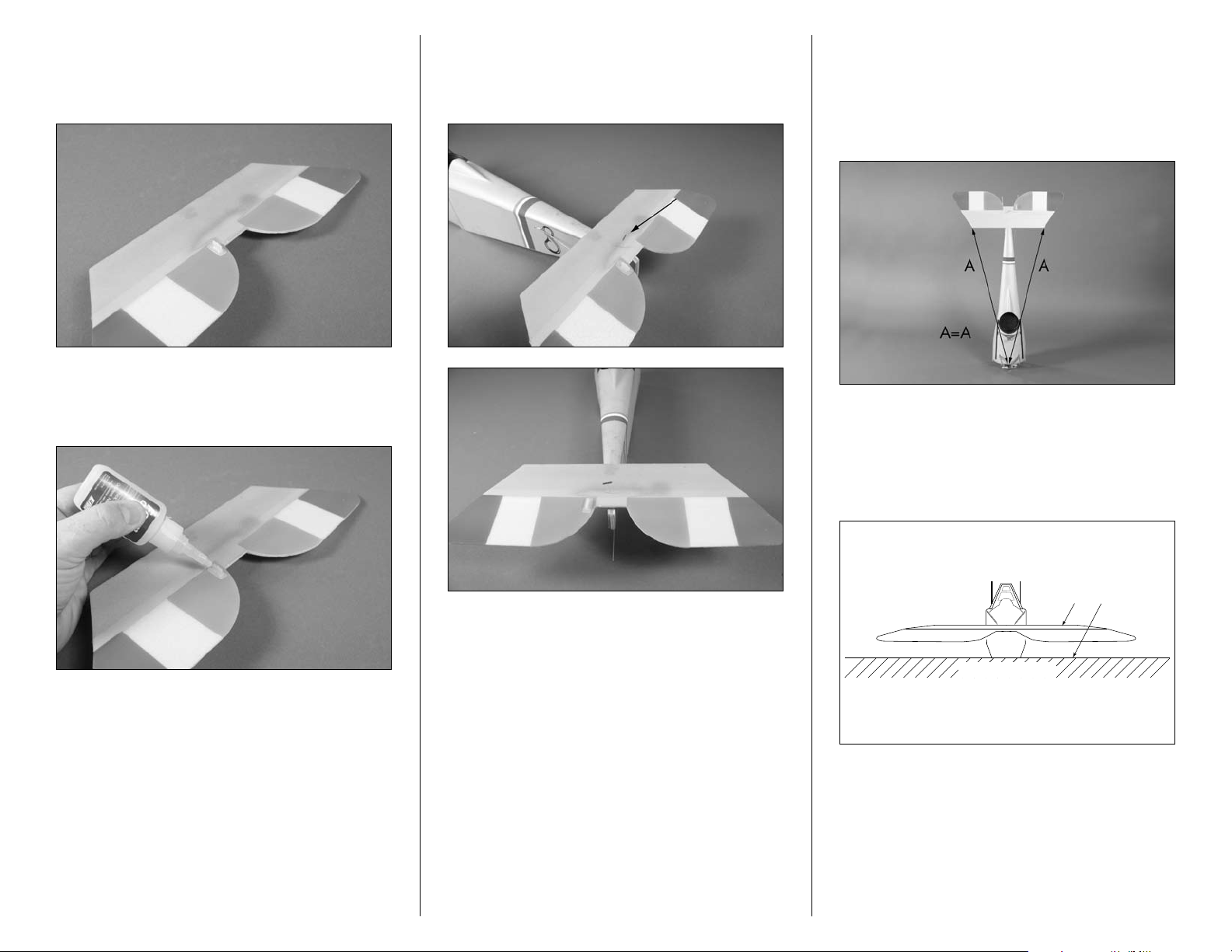

Stabilizer Installation

Required Parts

Fuselage Stabilizer/elevator

Micro control horn Micro control horn backplate

Required Tools and Adhesives

Foam-safe CA Hobby knife w/#11 blade

Felt-tipped pen Ruler

T-pins Pencil

1. Use a hobby knife with a #11 blade to remove

the hinge tape to fully expose the slot for the

elevator control horn. You may also need to

enlarge the plastic support piece slightly for the

control horn to fit. You want this slot to have a snug

fit, not a loose fit.

17. Use two-sided tape to secure the receiver in the

fuselage as shown.

6 E-flite Nieuport 17 Slow Flyer Assembly Manual

2. Slide the tab on the micro control horn through

the elevator from the bottom side as shown.

3. Slide the micro control horn backplate on the tab

Parallel

Work Surface

from the control horn. It will ratchet down and lock

into position. Slide the backplate so it holds the

control horn tightly in position.

4. Apply 2–3 drops of foam-safe CA to the joint

between the backplate and control horn to keep it

secure for the life of your model.

5. Position the stabilizer on the fuselage as shown.

Make sure to center the stabilizer left-to-right on the

fuselage. Use a T-pin at the back of the stabilizer to

hold it in position for the following step.

6. Use a ruler to measure from a point center at

the front of the fuselage to each of the tips of the

stabilizer. The measurements must be equal for the

best performance from your model. Use a second

T-pin to keep the stabilizer in position for the

following step.

7. With the fuselage resting flat on your work

surface, check to verify the stabilizer is parallel

to the work surface. Lightly sand the area of the

fuselage where the stabilizer rests to correct any

alignment problems.

7E-flite Nieuport 17 Slow Flyer Assembly Manual

8. Use a pencil to trace the outline of the fuselage

on the bottom of the stabilizer. You will only need

to mark one side of the stabilizer in this step so you

can return the stabilizer to the correct alignment on

the fuselage.

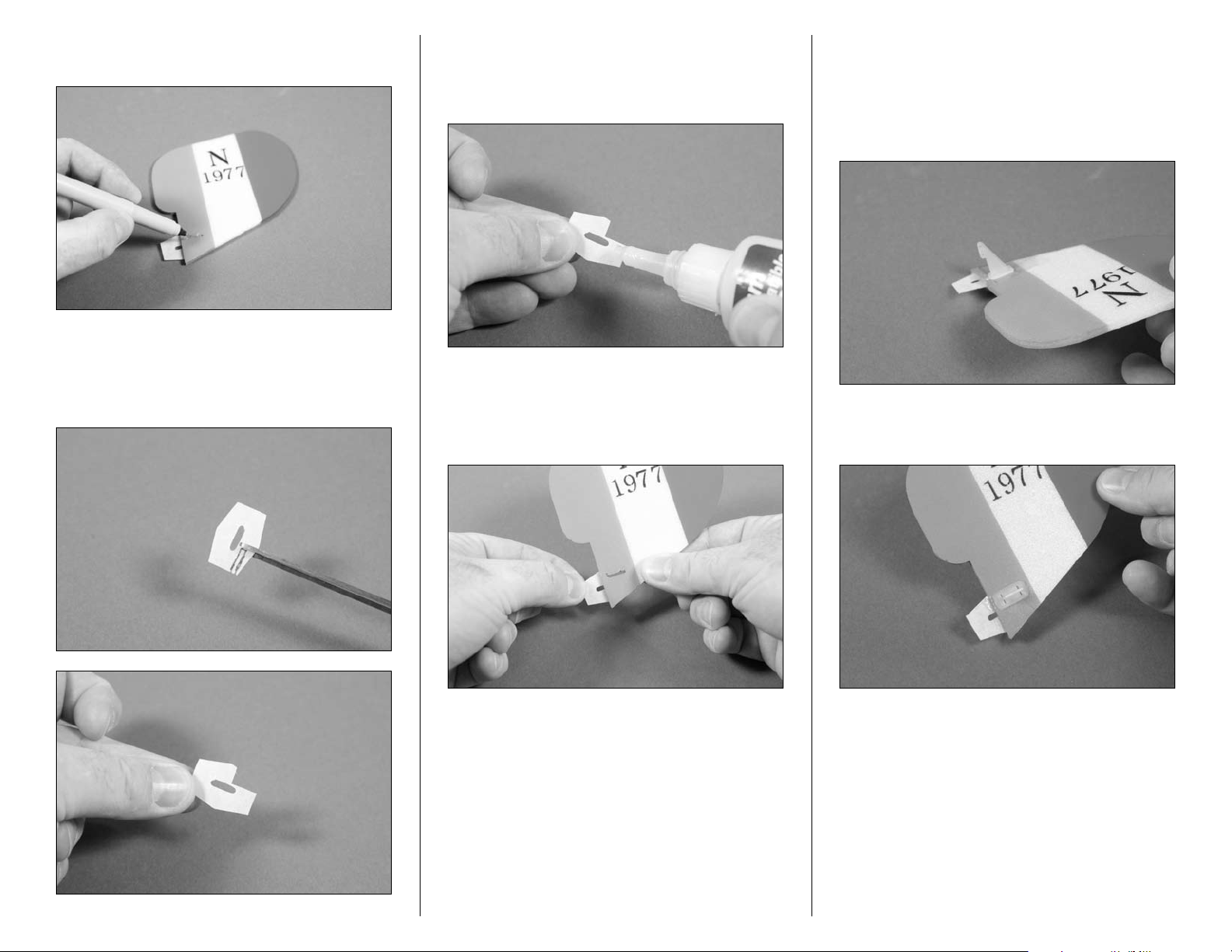

Rudder Installation

Required Parts

Fuselage assembly CA hinge

Rudder

Micro control horn Micro control horn backplate

Required Tools and Adhesives

Felt-tipped pen Hobby scissors

Foam-safe CA Hobby knife w/#11 blade

Please follow the procedure as illustrated for

hinging the rudder. Trying to trim the hinge for

the control horn after it has been glued in the

rudder can cause damage to the rudder.

9. Remove the stabilizer from the fuselage. Apply

foam-safe CA to the fuselage where the stabilizer

fits. Using the line drawn on the bottom of the

stabilizer, reposition it on the fuselage. If the stab

saddle is flat you will still need to sand the paint off

this area before gluing the stab in place. Hold the

stabilizer tightly against the fuselage until the CA

fully cures.

1. Insert the CA hinge in the slot in the rudder.

8 E-flite Nieuport 17 Slow Flyer Assembly Manual

2. Use a felt-tipped pen to trace the outline of the

slot for the micro control horn onto the hinge.

3. Use scissors to notch the hinge based on

the position traced in the previous step. This is

necessary to provide clearance for the rudder

control horn.

4. Apply a small amount of foam-safe CA on the

side of the hinge that will be inserted in the rudder.

Make sure to apply CA to both sides of the hinge

to glue it securely in the rudder.

5. Insert the hinge half-way into the rudder. Allow

the CA to fully cure before proceeding. Do not use

CA accelerators as it will reduce the bond between

the hinge and rudder.

6. Insert the tab from the micro control horn

through the hole in the rudder. Note the side of

the rudder the control horn is installed in. You may

need to open the slot slightly with a hobby knife

and #11 blade. Ensure the control horn has a snug

fit, not a loose fit.

7. Use a micro control horn backplate to secure the

control horn in the rudder.

9E-flite Nieuport 17 Slow Flyer Assembly Manual

Loading...

Loading...