Page 1

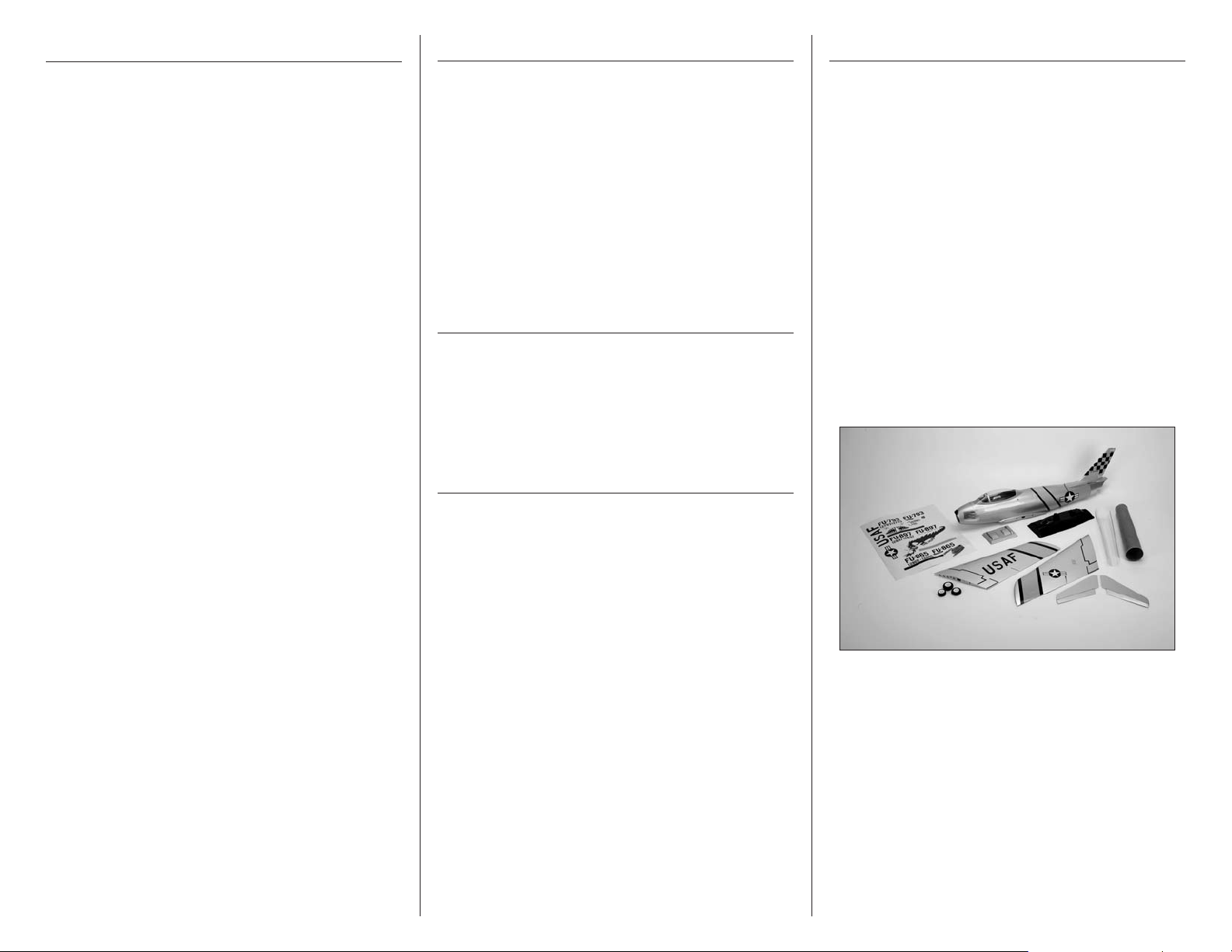

F-86 Sabre 15 DF

Assembly Manual

Pilot not included (PKZ7003)

Specifications

Wingspan: 33.8 in (860mm)

Length: 35.4 in (900mm)

Wing Area: 256 sq in (16.5 sq dm)

Weight w/o Battery: 40–42 oz (1135–1190 g)

Weight w/Battery: 53–55 oz (1500–1560 g)

Page 2

Table of Contents

Introduction

Contents of Kit/Parts Layout

Introduction ........................................................... 2

Important Information Regarding

Warranty Information ........................................ 2

Using the Manual ................................................... 2

Contents of Kit/Parts Layout .................................... 2

Recommended Radio Equipment ............................. 3

Required Brushless Ducted Fan Setup ....................... 3

Required Tools and Adhesives ................................. 3

Optional Accessories .............................................. 3

Warnings .............................................................. 3

Aileron Servo Installation ........................................ 4

Aileron Linkage Installation ..................................... 6

Mounting the Main Wing Panels ............................. 9

Stabilizer Installation ............................................ 12

Elevator Installation .............................................. 15

Rudder Installation ............................................... 16

Elevator Servo and Linkage Installation .................. 18

Rudder Servo and Linkage Installation ................... 22

Landing Gear Installation ...................................... 24

Steering Servo and Linkage Installation .................. 26

Speed Control and Receiver Installation ................. 27

Intake Tube Installation.......................................... 29

Fan Installation..................................................... 30

Exhaust Tube Installation ....................................... 32

Securing the Intake Tube ....................................... 34

Canopy Assembly ................................................ 35

Motor Battery Installation ...................................... 35

Decal Placement ................................................... 36

Center of Gravity ................................................. 36

Control Throws..................................................... 37

Preflight ............................................................... 38

Flying Your F-86 Sabre 15 DF............................... 38

Range Test Your Radio .......................................... 38

Safety Do’s and Don’ts for Pilots ............................ 39

Daily Flight Checks ............................................... 39

Warranty and Repair Policy .................................. 39

Warranty Services ................................................ 40

Compliance Information for the European Union .... 41

2010 Official Academy of

Model Aeronautics Safety Code ....................... 41

This performance model was designed around E-flite’s

Delta-V 15 (69mm) fan unit and matched 15 DF

3200Kv brushless motor. Pilots can use a 4-cell Li-Po

battery pack for great performance. The built-in fan

mounts make installing the fan easy—just drop in

the fan unit and tighten four screws. The removable

magnetic front hatch also allows easy access to the

radio equipment and battery. The entire trim scheme

is prepainted, pre-trimmed; the wings are covered in

UltraCote®. Just add your favorite nose art decals and

enjoy.

Important Information

Regarding Warranty Information

Please read our Warranty and Liability Limitations

section on Page 39 before building this product. If you

as the Purchaser or user are not prepared to accept the

liability associated with the use of this Product, you are

advised to return this Product immediately in new and

unused condition to the place of purchase.

Using the Manual

This manual is divided into sections to help make

assembly easier to understand, and to provide breaks

between each major section. In addition, check boxes

have been placed next to each step to keep track

of its completion. Steps with a single circle () are

performed once, while steps with two circles ( )

indicate the step will require repeating, such as for a

right or left wing panel, two servos, etc.

Remember to take your time and follow the directions.

Replacement Parts

EFL8101 Fuselage with Upper and

Lower Hatch

EFL8102 Canopy Hatch

EFL8103 Left Wing Panel with

Hinged Aileron

EFL8104 Right Wing Panel with

Hinged Aileron

EFL8105 Horizontal Stabilizer with

Elevator (left and right)

EFL8106 Pushrods and Carbon

Wing Tubes

EFL8107 Plastic Accessories

EFL8108 Landing Gear and Wheels

with Hardware

EFL8109 Control Hardware

EFL8110 Intake and Thrust Tube

EFL8111 Consumer Decal Sheet

2 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 3

Recommended Radio Equipment

You will need a minimum 4-channel transmitter,

receiver and five servos. You can choose to purchase

a complete radio system. If you are using an

existing transmitter, just purchase the other required

equipment separately. We recommend the crystalfree, interference-free Spektrum™ DX6i 2.4GHz DSM®

6-channel system. If using your own transmitter, we

recommend the following radio equipment.

If you own the Spektrum DX6i radio, or you are using

a different DSM2 radio, just add the AR6200 DSM2

6-channel receiver, four E-flite S75 Sub-Micro servos

and one JR SPORT™ MC35 servo

Complete Radio System

SPM6600 DX6i DSM2 6CH system

Or Purchase Separately

SPMAR6200 AR6200 DSM2 6-Channel Full-

Range Receiver (for DX6i or

DX7)

EFLRS75 7.5-Gram Sub-Micro S75

Servo (4)

JSP20030 MC35 Micro Servo

And

EFLREX9L 9-inch Extension, Lightweight (2)

Note: A Y-harness can be used for the for nose

gear steering if a computer radio with mixing

is not being used.

Tools & Equipment

Epoxy brushes Felt-tipped pen

Hobby scissors Hobby knife (#11 blade)

Low-tack tape Hex wrench: 1.5mm

Mixing cups Sanding bar

Mixing sticks Needle-nose pliers

Paper towels Pencil

Petroleum jelly Phillips screwdriver: #0, #1

™

Pin vise Rubbing alcohol

Ruler Scissors

Side cutters Square

String/dental floss Toothpicks

T-pins Waxed paper

Sandpaper

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Adhesives

Threadlock 6-Minute Epoxy (HAN8000)

Thin CA 12-Minute Epoxy (HAN8001)

Medium CA

PKZ7003 Pilot: Habu

EFLA110 Power Meter

EFLC505 Intelligent 1- to 5-Cell

EFLAEC312 Charge Lead with 12-inch

Required Tools and Adhesives

Optional Accessories

Balancing Charger

wire and Jacks, 16AWG

Warnings

Read and follow all instructions and safety precautions

before use. Improper use can result in fire, serious

injury and damage to property.

COMPONENTS

Use only with compatible components. Should any

compatibility questions exist please refer to the product

instructions, the component instructions or contact

Horizon Hobby, Inc.

FLIGHT

Fly only in open areas to ensure safety. It is

recommended flying be done at AMA (Academy of

Model Aeronautics) approved flying sites.

PROPELLER

Keep loose items that can get entangled in the

propeller away from the prop, including loose clothing,

or other objects such as pencils and screwdrivers.

Especially keep your hands away from the propeller as

injury can occur.

BATTERIES

Notes on Lithium Polymer Batteries

EFLRYH3 3-inch Y-Harness, Lightweight

Required Brushless Ducted Fan Setup

EFLM3215DF 15 DF Brushless Motor, 3200Kv

EFLDF15 Delta-V 15 (69mmm) Ducted

Fan Unit

EFLA1060 60-Amp Pro Switch-Mode

BEC Brushless ESC

EFLB32004S30 3200mAh 4S 14.8V 30C Li-Po,

13AWG EC3

The Spektrum trademark is used with permission

of Bachmann Industries, Inc.

Lithium Polymer batteries are significantly more

volatile than alkaline or Ni-Cd/Ni-MH batteries used

in RC applications. Always follow the manufacturer’s

instructions when using and disposing of any batteries.

Mishandling of Li-Po batteries can result in fire and

explosion causing serious injury and damage.

3E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 4

SMALL PARTS

This kit includes small parts and should not be left

unattended near children as choking and serious injury

could result.

SAFETY PRECAUTIONS

This is a sophisticated hobby Product and not a toy.

It must be operated with caution and common sense

and requires some basic mechanical ability. Failure to

operate this Product in a safe and responsible manner

could result in injury or damage to the Product or

other property. This Product is not intended for use by

children without direct adult supervision. The Product

manual contains instructions for safety, operation and

maintenance. It is essential to read and follow all

the instructions and warnings in the manual, prior to

assembly, setup or use, in order to operate correctly

and avoid damage or injury.

During the course of building your F-86 Sabre we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of bedding

foam or a thick bath towel will work well and help

protect the model from damage during assembly.

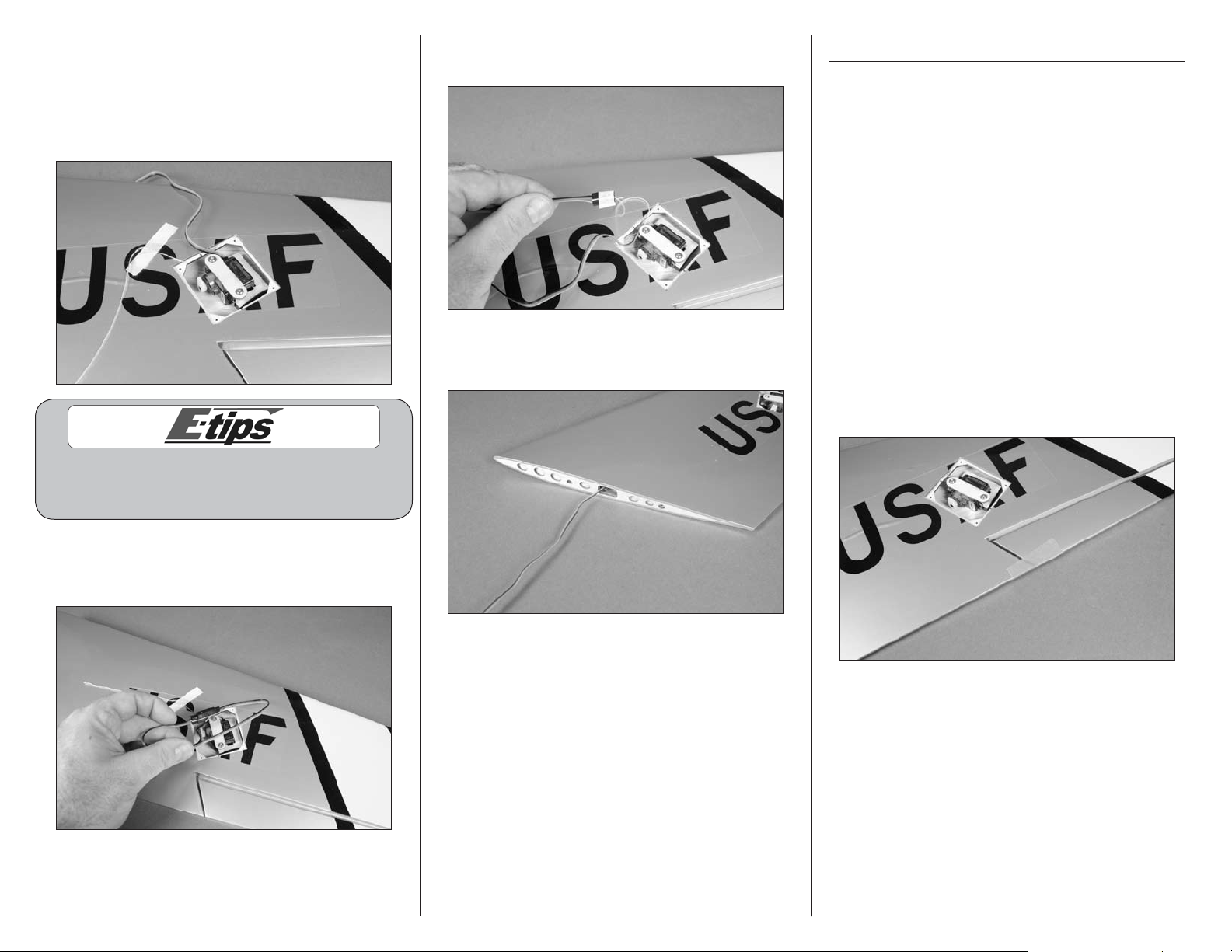

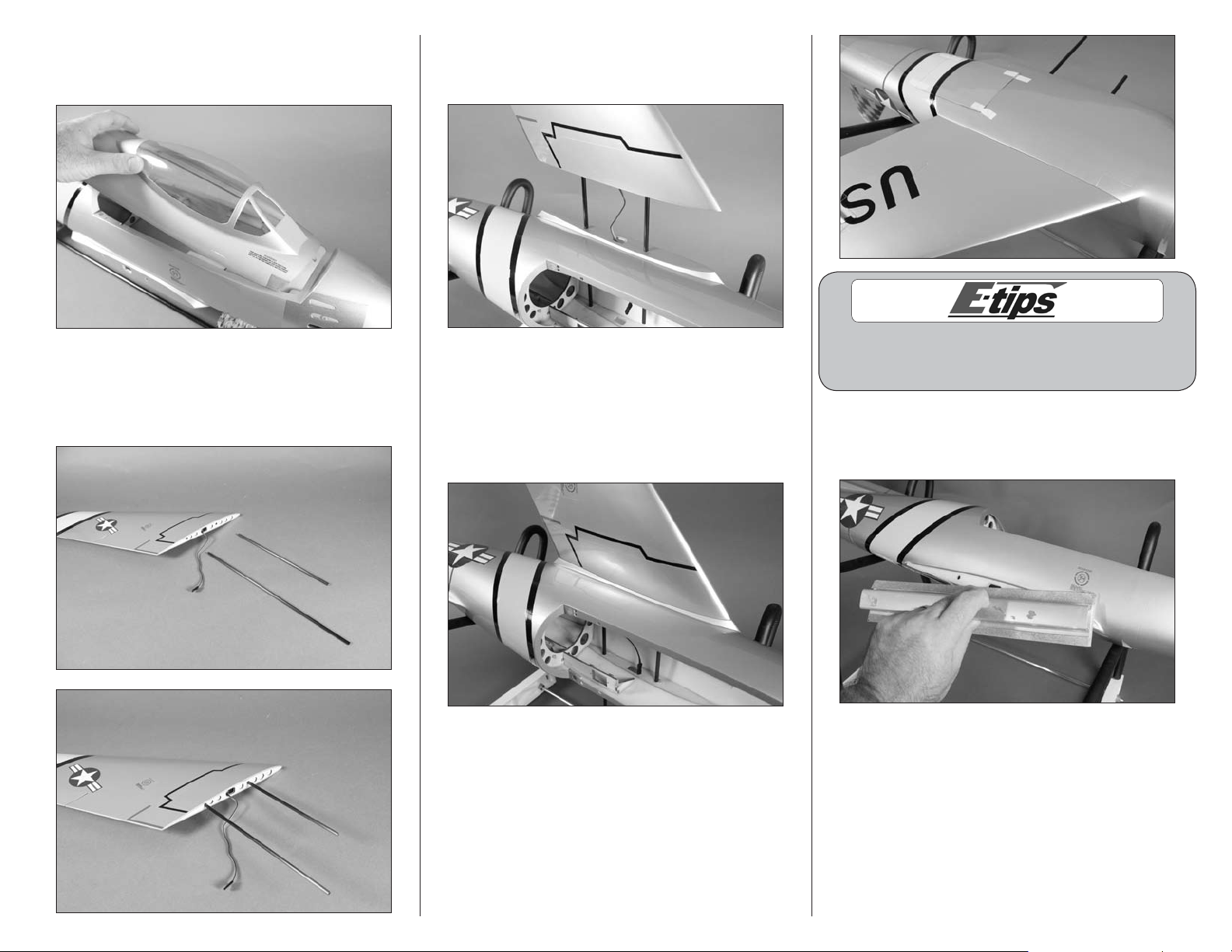

Aileron Servo Installation

Required Parts

Left wing panel Right wing panel

Transmitter Receiver

Servo (2)

2.5 x 12mm sheet metal screw (4)

9-inch (228mm) extension (2)

Aileron servo mount (2)

Servo mounting strap (2)

Required Tools and Adhesives

Medium grit sandpaper

6-minute epoxy Phillips screwdriver: #1

Dental floss/string Hobby knife with #11 blade

Side cutter Ruler

Pen Mixing cups

Mixing sticks Paper towels

The wood servo cover will not be used when installing

the recommended E-flite S75 servo for the ailerons. If

you install a smaller servo, you may choose to use the

plywood cover rather than the molded plastic cover.

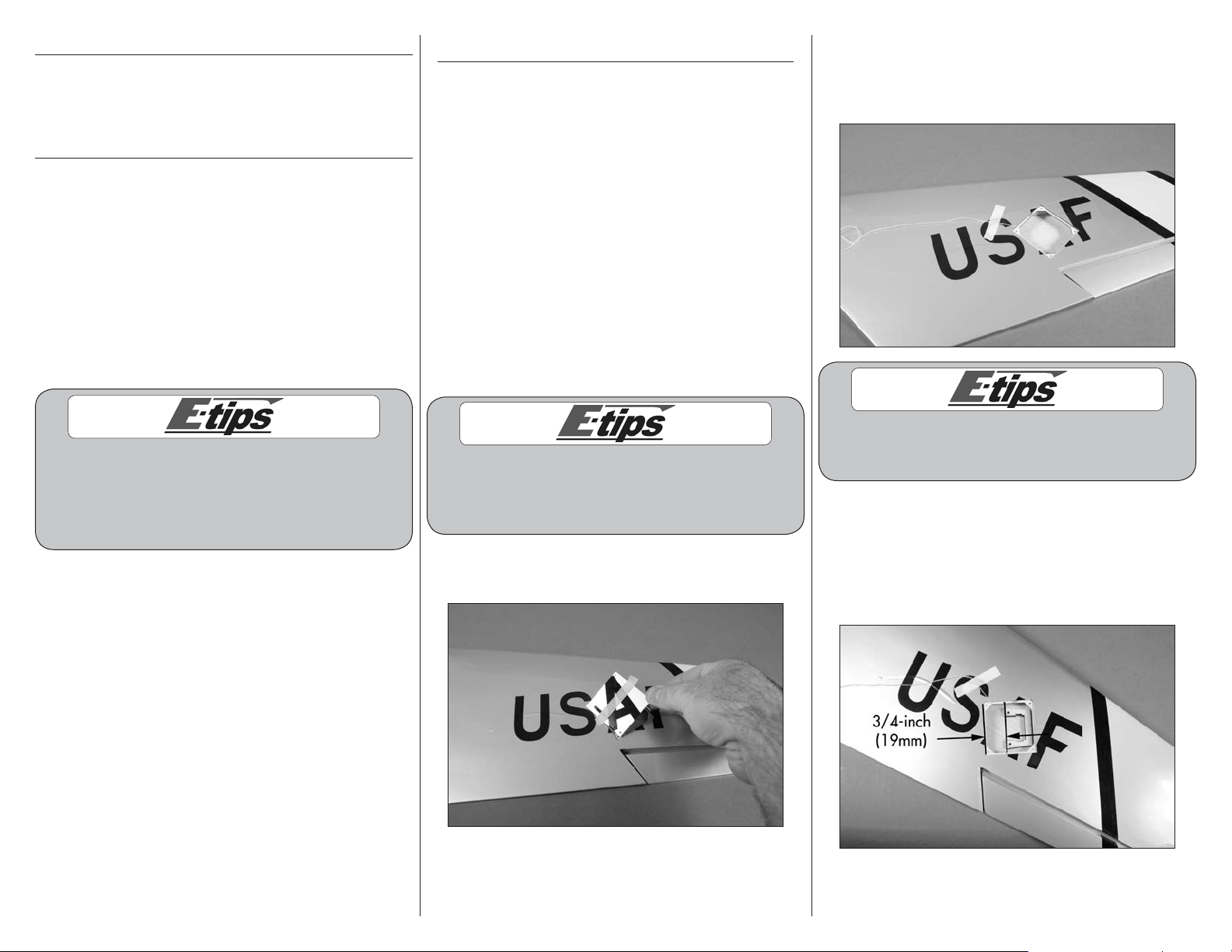

1. Remove the wood servo cover from the wing. Set

the cover aside.

2. Relocate the string from the aileron opening so

it is near one of the corners. This allows full access

to the opening and prevents accidentally gluing the

string into the wing.

DO NOT remove the string from the wing. The

string will be used to pull the aileron servo

lead through the wing later in this section.

3. Measure and mark the opening for the aileron

servo 3/4-inch (19mm) from the edge closest to

the wing root as shown. The edge of the aileron

servo mount will align with these marks when it is

installed. Center the mount fore/aft in the opening

for the aileron servo.

4 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 5

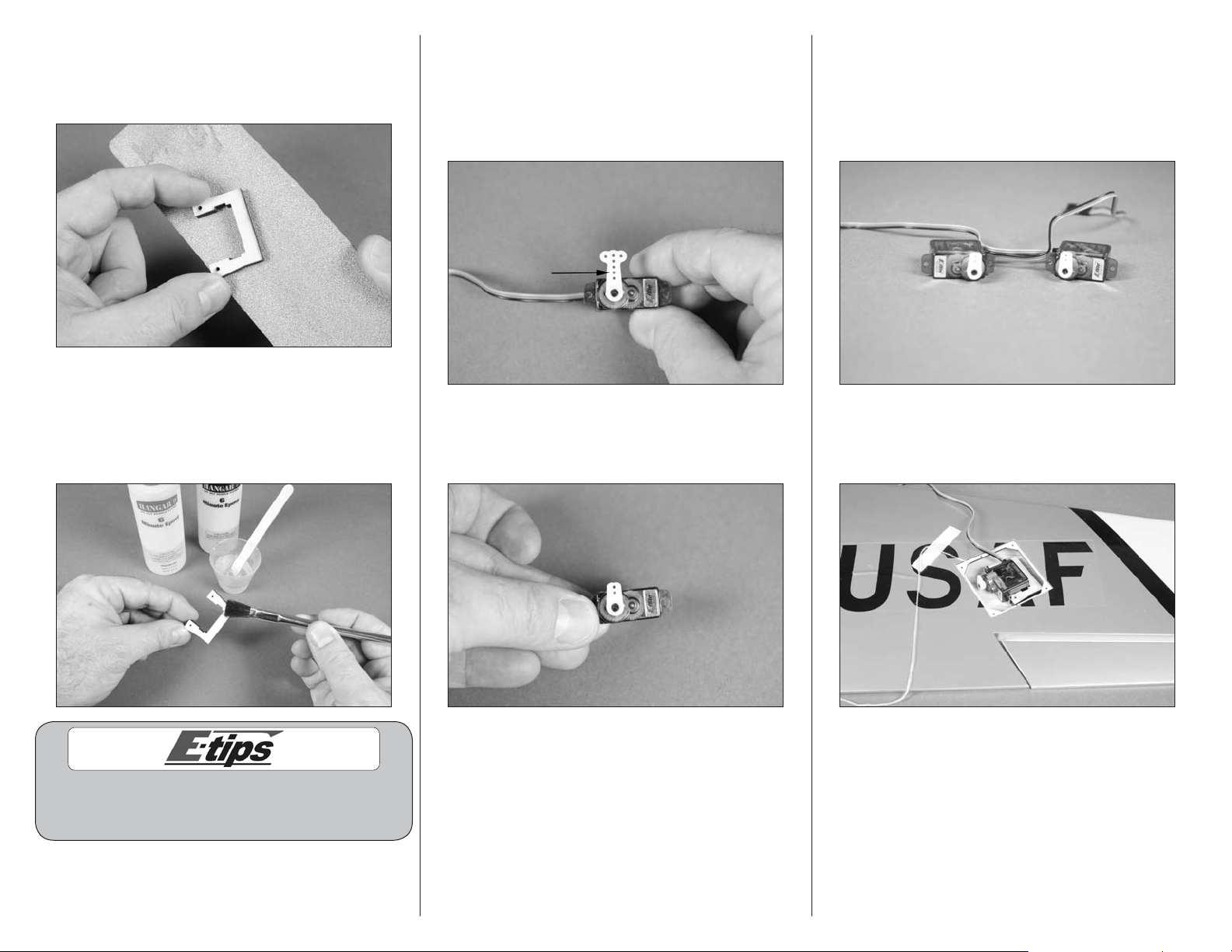

4. Lightly sand the aileron servo mount using

medium grit sandpaper. This allows the glue to

penetrate into the mount and provides a better

bond between the mount and wing.

5. Mix a small amount of 6-minute epoxy and

brush it onto the side of the aileron servo mount

that was sanded in the previous step. Position the

mount in the wing as shown in Step 3 and allow

the epoxy to fully cure before proceeding.

6. Use a hobby knife with a #11 blade to enlarge

the hole in the servo arm indicated in the photo.

Only open the hole in the servo arm enough for the

aileron linkage to fit in. Making it larger will only

create a poor fit between the linkage and servo

arm and make it difficult to trim your aircraft.

7. Use a hobby knife and #11 blade or side cutters

to remove the excess servo arm so it does not

interfere with the servo cover when it is installed.

8. Prepare a second aileron servo as shown in

Steps 6 and 7. Note the servos will be a mirror

image of each other. Plug the aileron servos into

the receiver and use the transmitter to center the

servos. Also check that they are operating correctly

at this time.

9. Position the aileron servo in the servo mount as

shown in the image with the horn facing the front

of the wing.

While waiting for the epoxy to dry on one wing

panel, you can repeat the previous steps to glue the

remaining servo mount into the opposite wing panel.

5E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 6

10. Use a #1 Phillips screwdriver and two 2.5mm

x 12 sheet metal screws to secure the servo in the

servo mount using the servo mounting strap. Install

one screw and only turn it one or two turns, then

install the second screw. Tighten the strap with even

pressure at both the front and back of the servo.

12. Tie the string around the end of the servo lead

as shown.

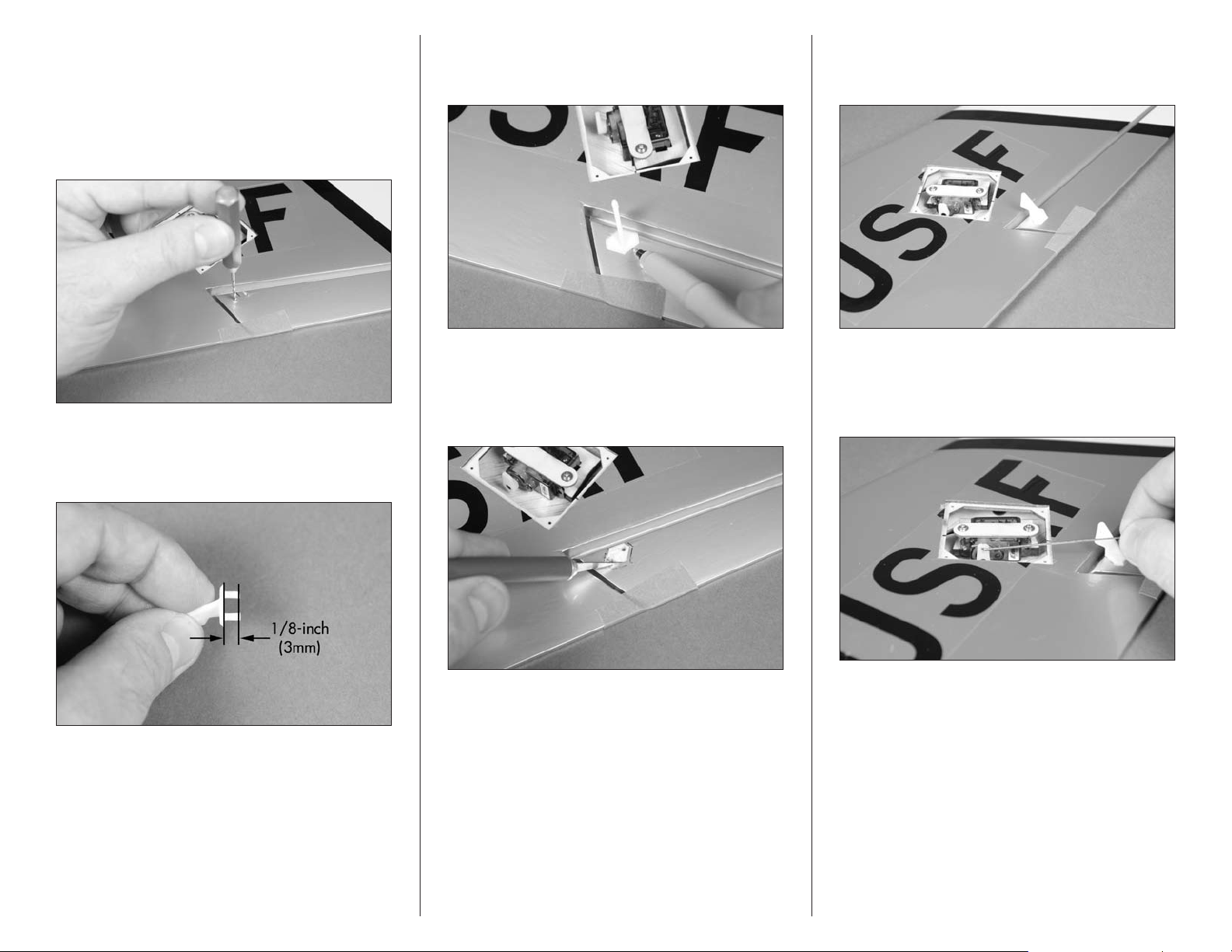

Aileron Linkage Installation

Required Parts

Transmitter Receiver

Aileron pushrod keeper (2)

Aileron pushrod wire, 2 9/16-inch (65mm) (2)

Servo cover (2)

Aileron control horn (2) Clear tape

Required Tools and Adhesives

Side cutters Medium CA

Pin vise Low-tack tape

Felt-tipped pen Hobby knife with #11 blade

Needle-nose pliers Hobby scissors

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Use care when installing the servo mounting strap.

Over-tightening the strap could stress the wing sheeting

and even push the servo through the top of the wing.

11. Use string or dental floss to secure a 9-inch

(228mm) servo extension to the lead from the

aileron servo.

13. Carefully pull the aileron servo lead through the

wing using the string tied to it in the previous step.

14. Repeat Steps 1 through 13 to install the

remaining aileron servo.

1. Use a small piece of low-tack tape to keep

the aileron centered with the trailing edge of the

wing. This will make the installation of the linkage

much easier.

6 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 7

2. Locate the two holes for the aileron control horn

in the aileron. The holes should be located directly

behind the servo arm. Use a hobby knife with a

#11 blade or pin vise with a 1/16-inch (1.5mm)

drill bit to remove the covering for the aileron

control horn. Use care not to accidentally make

holes through to the top of the aileron.

4. Insert the pins of the control horn into the holes

in the aileron. Use a felt-tipped pen to trace the

outline of the control horn onto the aileron.

6. Use medium CA to glue the control horn to the

aileron. Allow the CA to cure before proceeding to

the next step.

3. Use side cutters to trim the pins on the control

horn to a length of 1/8-inch (3mm) so they don’t

extend through the top of the aileron.

5. Remove the control horn. Use a hobby knife with

a #11 blade to trim the covering 1/32-inch (1mm)

inside the lines drawn. Don’t cut into the underlying

wood as you could possibly weaken the structure.

7. Connect the Z-bend of the 2 9/16-inch (65mm)

aileron pushrod wire to the hole in the servo horn

as shown.

7E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 8

8. Slide the pushrod connector onto the pushrod

wire at this time. The connector can’t be installed

after the wire has been bent to fit into the control

horn so it must be positioned at this time.

10. Use pliers to make a 90-degree bend in the

pushrod wire. The bend must be angled to fit into

the control horn.

12. Insert the pushrod wire into the hole of the

control horn that is two holes up from the control

surface as shown.

9. With the aileron servo centered and the radio

system on, use a felt-tipped pen to mark the wire

where it crosses the hole of the control horn as shown.

11. Use side cutters to trim the wire 1/4-inch

(6mm) from the bend as shown.

13. Use pliers to open the pushrod keeper just

enough to slip it over the bend of the pushrod

wire so it secures the pushrod wire to the control

horn. Don’t open the connector too far as it could

possibly break the connector.

8 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 9

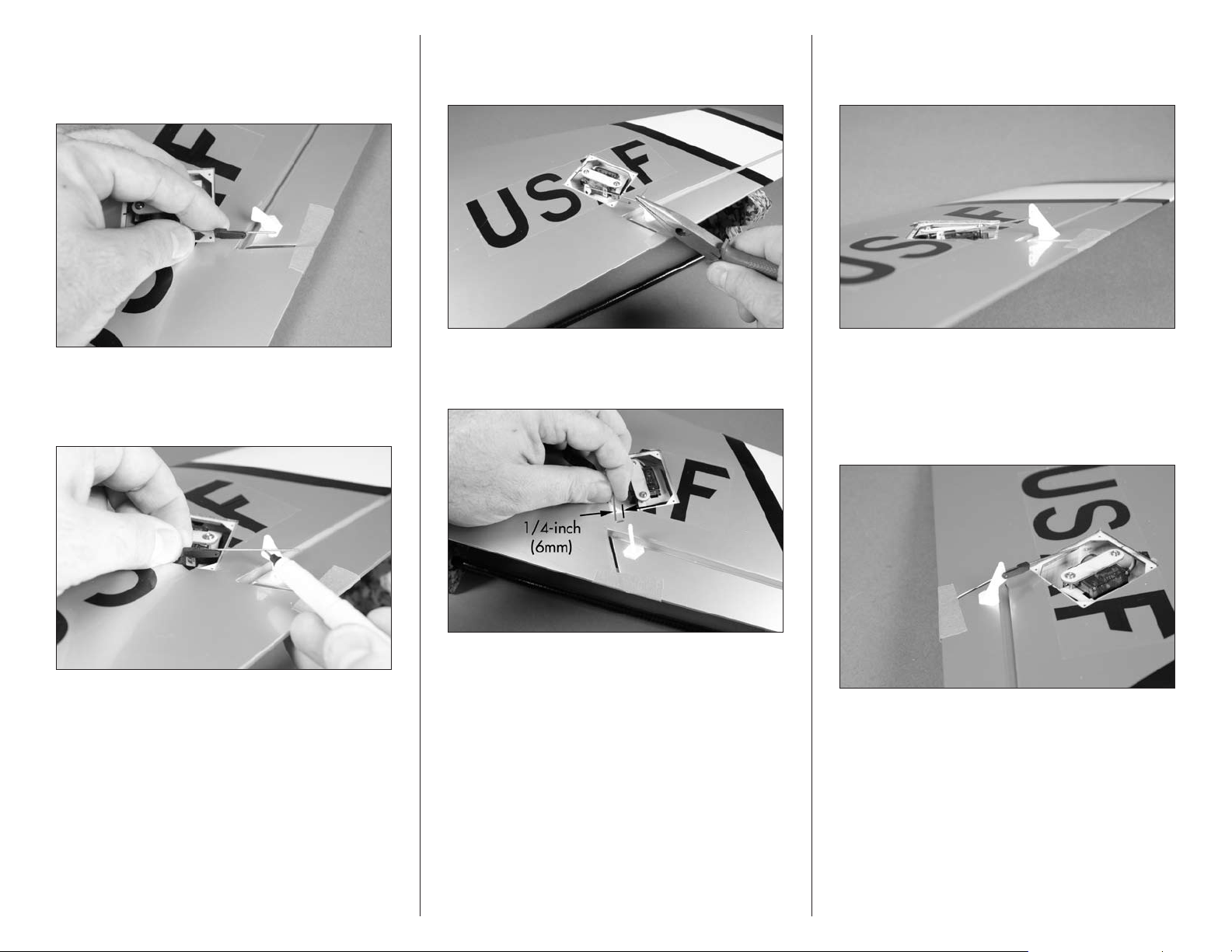

14. Use a hobby knife and #11 blade or hobby

scissors to trim the aileron servo cover. Lines have

been embossed on the cover to be used as a guide.

Make sure the opening for the linkage is angled

slightly so the linkage doesn’t bind on the cover.

15. Use the tape provided with the model to attach

the cover to the wing. Make sure the aileron servo

can operate without having the linkage binding on

the cover.

16. Apply the decal to the servo cover. Take your

time to fit the decal to the contours of the cover.

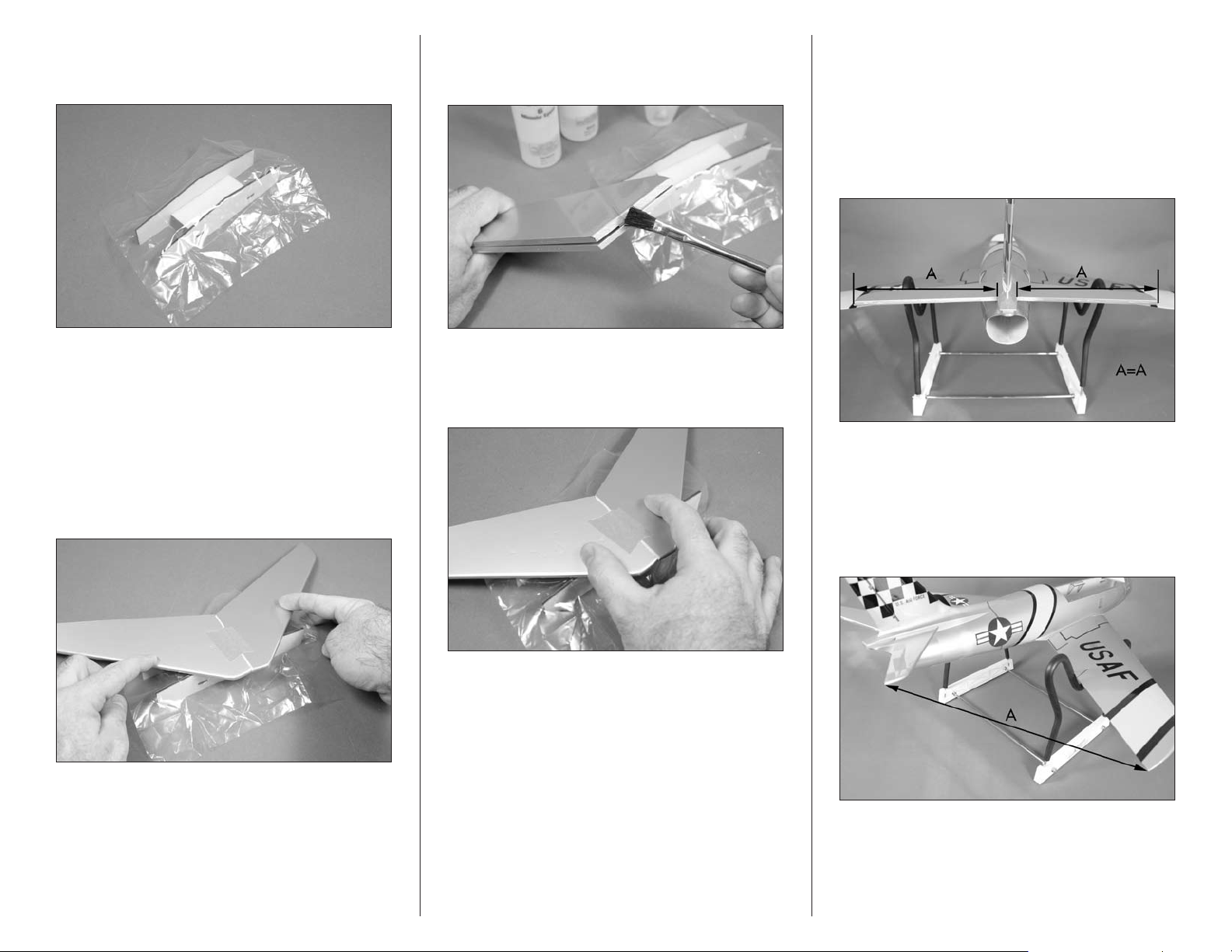

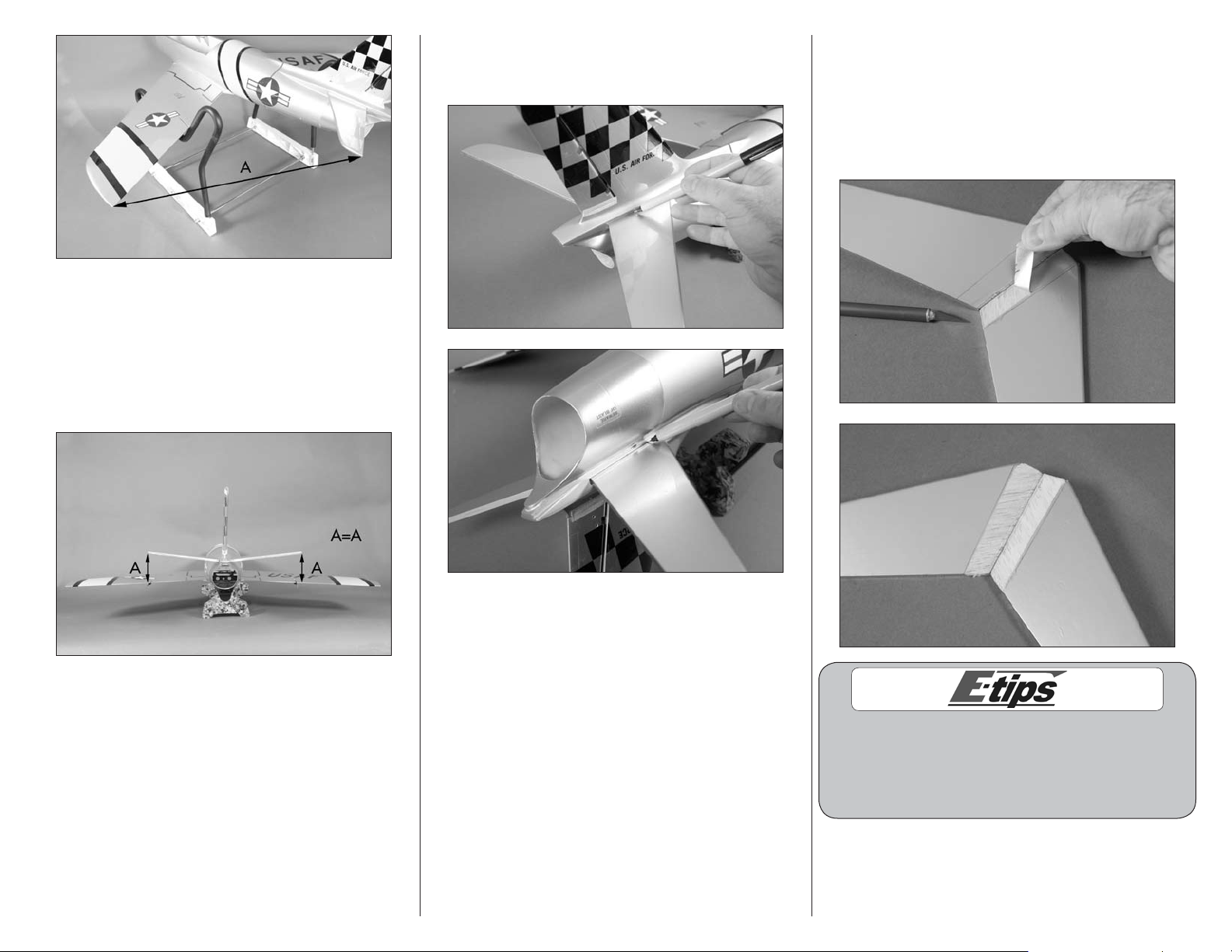

Mounting the Main Wing Panels

Required Parts

Left wing assembly Right wing assembly

Carbon wing rod, 9-inch (230mm)

Carbon wing rod, 13-inch (330mm)

Fuselage assembly

Required Tools and Adhesives

12-minute epoxy Mixing cup

Mixing stick Epoxy brush

Paper towel Rubbing alcohol

Low-tack tape Sandpaper

Sanding Bar

1. Remove the shipping tape that holds the canopy

to the fuselage.

17. Repeat Steps 1 through 16 to install the

remaining aileron linkage and servo cover.

Cut the portions of the letters from the decal

sheet to apply to the cover to complete

the form of the covered letters.

9E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 10

2. Carefully lift the canopy hatch from the fuselage.

The canopy is held in position by magnets and

alignment pegs at the rear and a peg at the front.

3. Slide the short and long wing rods into one

of the wing panels. The longer wing rod will be

inserted near the trailing edge of the wing, and the

shorter rod toward the leading edge of the wing.

4. Slide the wing tubes into the fuselage. Make sure

to guide the aileron servo extension into the fuselage

so the wing can fit tight against the fuselage.

5. Look at the fit of the wing to the fuselage on both

the top and bottom. You will need to use sandpaper

to remove the paint from the fuselage where the

wing fits or the epoxy won’t hold the wing securely

to the fuselage. You also don’t want to sand too

much and ruin the paint on the fuselage.

You can use low-tack tape to make an outline about

a 1/16-inch (1.5mm) inside the wing outline on the

fuselage to prevent it from scratching the paint.

6. Remove the wing from the fuselage. Use medium

grit sandpaper to remove the paint from the

fuselage where the wing fits.

10 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 11

7. Repeat Steps 1 through 6 to prepare the

opposite side of the fuselage for the wing.

10. Apply a thin coat of 15-minute epoxy on the

end of the wing that will butt against the fuselage.

12. Repeat Steps 8 through 11 to install the

remaining wing panel to the fuselage.

8. Apply a thin layer of 15-minute epoxy to the

fuselage where it was sanded previously.

9. Apply a thin layer of 15-minute epoxy to the

short and long wing rods before you insert them

into the wing.

11. Slide the wing into position against the

fuselage. Use low-tack tape to keep the wing tight

against the fuselage until the epoxy fully cures.

13. Before the epoxy cures, use a paper towel

and rubbing alcohol to remove any excess epoxy

that may have oozed out from the joint between

the wing and fuselage.

11E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 12

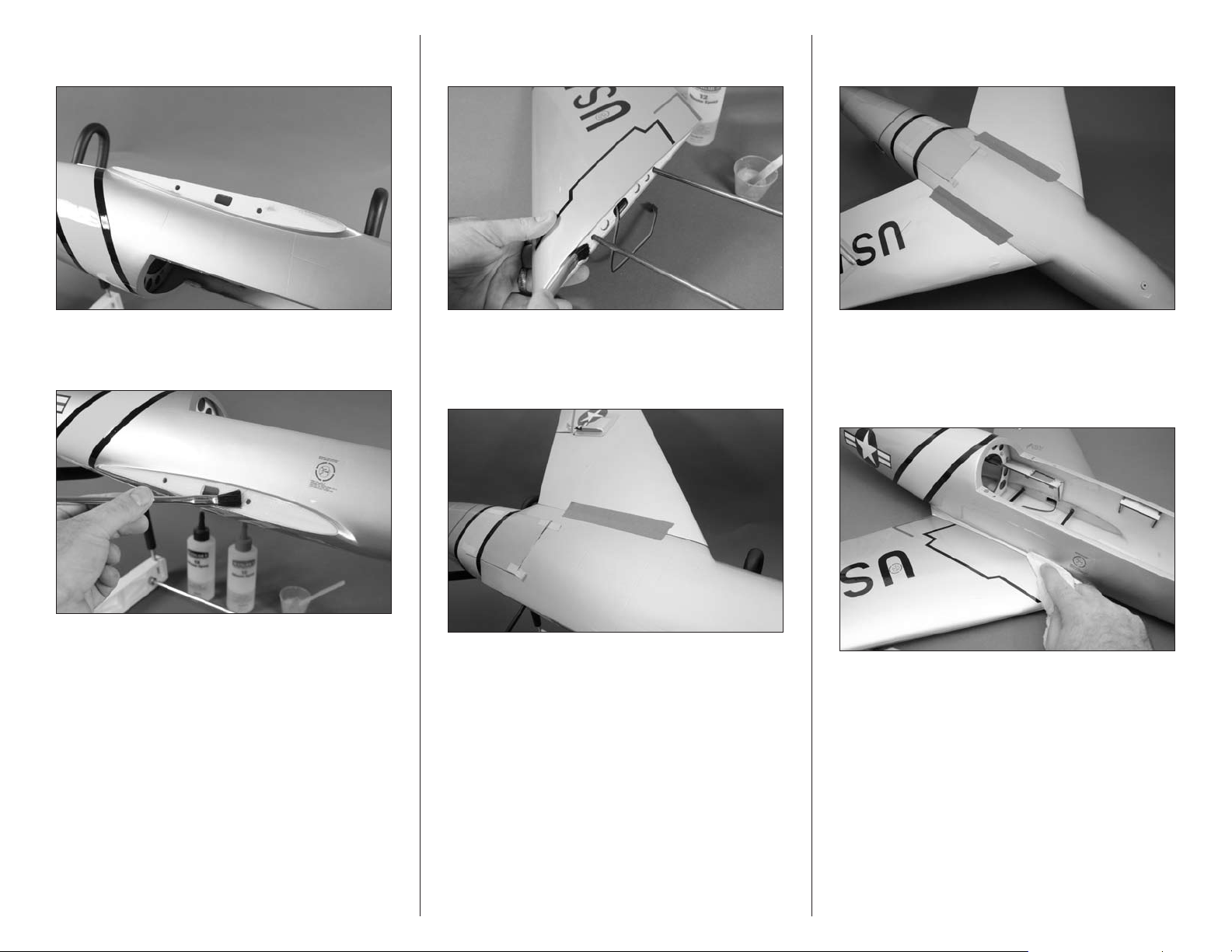

Stabilizer Installation

Required Parts

Stabilizer jig center Stabilizer jig side (2)

Right stabilizer Left stabilizer

Airframe assembly

Required Tools and Adhesives

Medium CA Square

6-minute epoxy Mixing cup

Mixing stick Epoxy brush

Paper towel Rubbing alcohol

Low-tack tape Waxed paper

Ruler Felt-tipped pen

Hobby knife with #11 blade

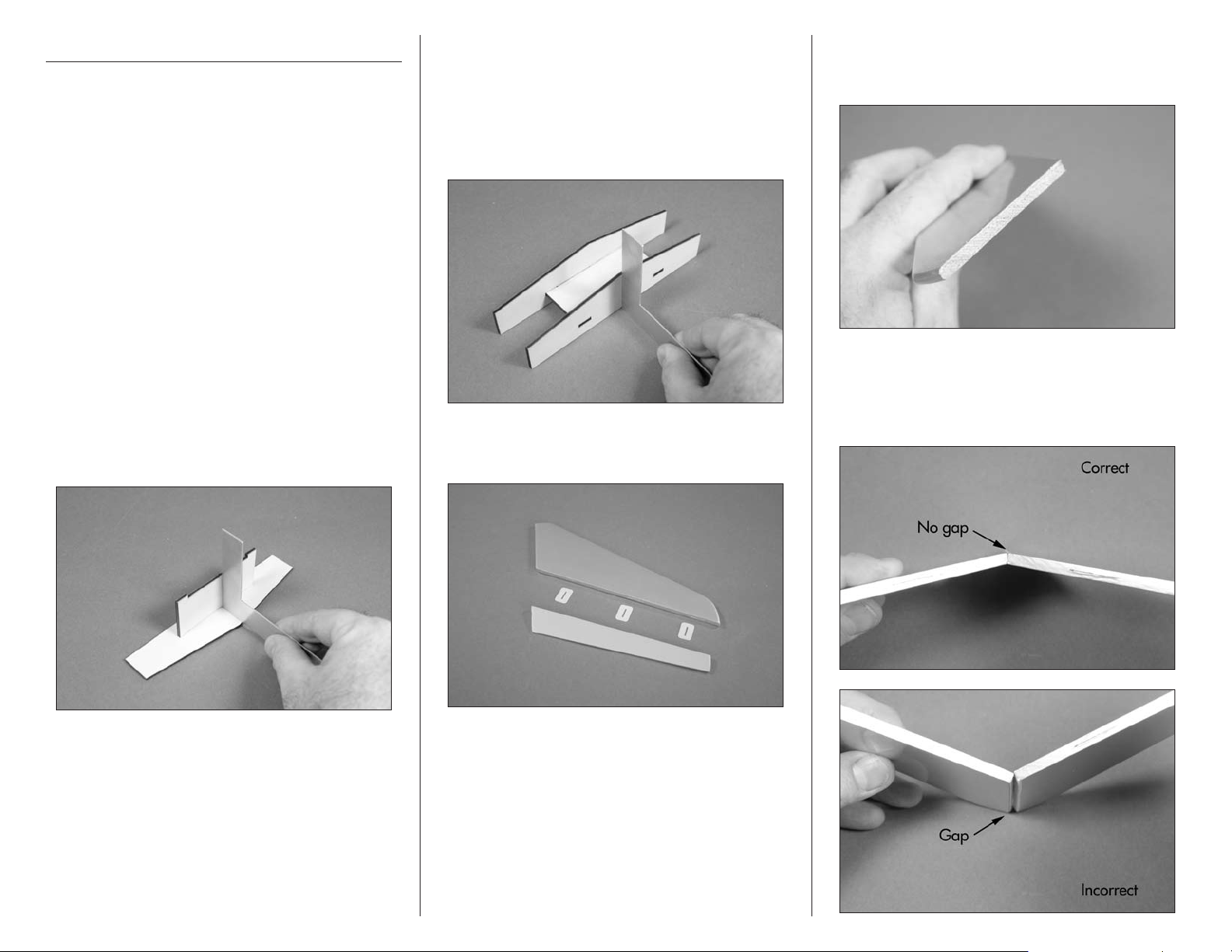

1. Use a square and medium CA to glue the

stabilizer jig center to the stabilizer jig side. The

square will keep the center perpendicular to the

side and result in a straight jig. Not doing so

may result in the jig being crooked and could

produce the wrong angle when gluing the

stabilizer halves together.

2. Use a square and medium CA to glue the

stabilizer jig side to the structure assembled

in Step 1. Using a square will keep the side

perpendicular to the stabilizer jig center. Not

doing so may result in the jig being crooked and

could produce the wrong angle when gluing the

stabilizer halves together.

3. Separate the elevator from the stabilizer. Set the

elevator and hinges aside at this time.

4. Use a hobby knife and a #11 blade to remove

the covering from the end of both the left and

right stabilizers.

5. The stabilizer halves have been prepared at the

factory with an angle so they fit tightly together

when joined. If the fit is incorrect, the two halves

will not fit tightly together.

12 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 13

6. Place a piece of clear plastic or waxed paper

over the stabilizer jig to prevent gluing the

stabilizer directly to the jig.

8. Mix a small amount of 6-minute epoxy and use

an epoxy brush to apply a thin layer of epoxy on

the edges of each stabilizer half.

10. Slide the stabilizer into the slot in the fuselage.

Make sure that they are installed in the fuselage

with dihedral as shown in Step 12. Measure the

distance from the fuselage to the tip of the stabilizer

on both sides of the fuselage. Both measurements

must be equal. If they are not, reposition the

stabilizer and re-measure until both measurements

are equal on both sides of the fuselage.

7. Position the two stabilizer halves together

(remember the angle) and align the front edges

of the stabilizer halves. Use a small piece of lowtack tape to act as a hinge and keep the halves

aligned. Position the stabilizer assembly on the

jig to make sure the halves can rest against the

jig without forcing them. If not, you will need to

make a small gap between the two halves before

taping them together.

9. Position the stabilizer on the jig and either hold

it or use weights to keep the halves tight against the

jig until the epoxy fully cures.

11. Measure the distance from the wing tip to

the stabilizer tip on both the right and left of the

aircraft. Both measurements must be equal. If not,

readjust the stabilizer and re-measure until the

measurement is the same on both the left and right

of the aircraft.

13E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 14

12. Step back about 4–5 feet (1.2–1.5 meters)

and view the fuselage from the rear. Check that the

stabilizer is in alignment with the wing by checking

the stabilizer tips against the wing. Both stabilizer

tips should align with the wing trailing edge. Adjust

the position of the stabilizer if necessary for correct

stabilizer alignment.

13. Use a felt-tipped pen to trace the outline of

the fuselage onto the top, bottom, left and right

of the stabilizer.

14. Remove the stabilizer from the fuselage.

Carefully use a hobby knife to remove the covering

1/16-inch (1.5mm) from inside the lines. Use light

pressure with a new #11 blade to avoid cutting

into the underlying wood. You will need to trim the

covering from the top and bottom of the stabilizer

at this time.

Other options other than a hobby knife are to

use a hot knife (with a new blade) or a soldering

iron for cutting the covering. These will melt

the covering and lower the chances of cutting

into the wood structure of the stabilizer.

14 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 15

15. Reinstall the stabilizer and check all of the

alignments from steps 10–12. Use medium CA to

glue the stabilizer to the fuselage. Apply a bead

of CA to the joint inside the fuselage, both right

and left. Wick thin CA on the top of the stabilizer/

fuselage joint by holding the nose down. Use care

not to let the CA wick out on the outside of the

fuselage or stabilizer.

Elevator Installation

Required Parts

Elevator (left and right)

CA hinge (6)

Required Tools and Adhesives

Thin CA T-pins

1. Place a T-pin in the center of three of the elevator

hinges. This will help center them equally in the

stabilizer and elevator when they are installed.

3. Place the elevator into position. The hinges will

fit into the pre-cut slots in the stabilizer.

4. Position the elevator tight against the stabilizer.

There should be just a slight gap between the

elevator and the stabilizer. Check that the tips of

the elevator and stabilizer align with each other.

Use a paper towel and rubbing alcohol to

remove the lines from the stabilizer and fuselage

before gluing the stabilizer in position.

2. Slide the three hinges into the slots that have

been pre-cut into the elevator.

15E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 16

5. Use thin CA to glue the three hinges. Apply CA

to the top and bottom of each hinge, enough that it

fully soaks into the hinge.

DO NOT use CA accelerator on the hinges.

The CA must be allowed to soak into the hinge

to fully penetrate the hinge and surrounding

wood. Accelerator will not allow the CA to soak

into the hinge and will result in a poor bond

between the hinge and surrounding wood.

7. Break in the elevator hinges by moving the

elevator through its range of motion a few times.

This will help in reducing the initial load on the

servo and make the control surfaces easier to

move initially.

Rudder Installation

Required Parts

Fuselage assembly Pin hinge (3)

Required Tools and Adhesives

Side cutter 6-minute epoxy

Petroleum jelly Toothpick

Paper towel Rubbing alcohol

Mixing cup Mixing stick

1. Remove the shipping tape from the rudder and

fuselage. Separate the rudder from the fuselage.

6. Once the CA has fully cured, lightly pull on the

elevator and stabilizer to make sure the hinges are

secure. If not, apply additional CA to the hinges

that are not secure.

8. Repeat Steps 1 through 7 to install the

remaining elevator.

16 E-flite F-86 Sabre 15 DF ARF Assembly Manual

2. Apply a small amount of petroleum jelly to the

knuckle of each of the rudder hinges. Use care not

to get any petroleum jelly on the main parts of the

hinge. Use side cutters to trim down the hinges that

fit at the top and center of the rudder as shown.

Page 17

3. Test fit the hinges into the rudder. Each of the

Hinge point

of rudder

Hinge point recessed in control surface

hinges will fit with the pin in the knuckle recessed

in the hinge line as shown. The hinge line of the

rudder is set back from the edge of the rudder as

illustrated in the second photo.

4. Check the fit of all three hinges. The top two

may require adjustments if not trimmed properly

in Step 2.

5. Mix a small amount of 6-minute epoxy. Apply

the epoxy in each hinge pocket using a toothpick.

Also apply a small amount of epoxy to each hinge

where it fits into the pockets of the rudder.

6. Insert the hinges in the rudder. Make sure each

hinge can operate 90-degrees to the hinge line

as shown before the epoxy begins to cure. Use

rubbing alcohol and a paper towel to remove any

excess epoxy from the hinges or rudder.

7. After the epoxy has fully cured, work each hinge

through its range of motion check that the hinges

have no epoxy in the knuckle.

17E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 18

8. Check the fit of the rudder to the fin. Start by

setting the hinges for about 45-degrees of throw.

Insert the bottom hinge, then work upward inserting

the middle then top hinge.

9. Once the fit has been checked, use 6-minute

epoxy to glue the hinges in place. You will need to

remove the rudder so you can use a toothpick to

apply epoxy in the hinge pockets of the fuselage

and to the hinges. Use rubbing alcohol and a

paper towel to remove any excess epoxy from the

hinges or rudder.

Elevator Servo and

Linkage Installation

Required Parts

Transmitter Servo with hardware

Receiver Assembled airframe

2mm nut 3mm x 4mm machine screw

2mm washer Elevator control horn (2)

Pushrod connector (large)

Elevator pushrod keeper (2)

Elevator pushrod wire, 19 11/16-inch (500mm) (2)

Required Tools and Adhesives

Side cutter Hobby knife with #11 blade

Needle-nose pliers Medium CA

Pin vise Drill bit: 5/64-inch (2mm)

Threadlock Felt-tipped pen

Thin CA Phillips screwdriver: #1

10. Once the epoxy has fully cured, work the

rudder through its range of motion a number of

times to make sure there is no epoxy in the knuckle.

1. Remove the screw holding the servo horn to the

servo using a #1 Phillips screwdriver. Use the radio

system to center the elevator servo so the shorter

arm is positioned as shown. The pushrod connector

will attach to this arm.

18 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 19

2. Remove the arm from the servo. Use side cutters

to remove any arms that will not be used.

5. Slide a 2mm washer on the threaded end of the

pushrod connector.

7. Install the servo horn on the servo using the screw

provided with the servo and a #1 Phillips screwdriver.

3. Use a pin vise and 5/64-inch (2mm) drill bit to

enlarge the hole in the servo arm.

4. Insert the pushrod connector in the hole. It

should move freely in the hole but not have

excessive slop.

8. Install the servo grommets and brass eyelets

in the servo.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

6. Install the 2mm nut on the pushrod connector.

Don’t over-tighten the nut causing the pushrod

connector not to move. The nut should be just tight

enough, so the connector can rotate freely. Make

sure to secure this nut with threadlock or CA.

19E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 20

Do not enlarge the holes in the fuselage rails

as some are used for the hatch alignment.

9. Use a #1 Phillips screwdriver to thread the servo

mounting screw into the four holes for mounting the

elevator servo.

11. Secure the elevator servo in the fuselage using

the screws provided with the servo and a #1

Phillips screwdriver.

13. Use side cutters to trim the pins on the control

horn to a length of 3/32-inch (2mm) so they don’t

extend through the top of the elevator.

10. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This will harden the

wood, making the screws more secure.

12. Use a hobby knife and #11 blade to remove

the covering to expose the holes to mount the

elevator control horn. Use care not to poke through

the hole to the top of the elevator.

14. Position the horn on the elevator. Use a felt-tipped

pen to trace the outline of the horn on the elevator.

20 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 21

15. Use a hobby knife with a #11 blade to

1/16-inch

(1.5mm)

1-inch

(25mm)

remove the covering 1/32-inch (1mm) inside

the line drawn.

16.Use medium CA to glue the control horn to the

elevator. Allow the CA to cure before proceeding to

the next step.

17. Slide a pushrod connector on the 19 11/16-inch

(500mm) pushrod wire.

18. Bend the pushrod wire as shown so it does not

bind when operating the elevator. You will need to

make a left and right pushrod.

19. Slide the pushrod wire into the pushrod tube in

the fuselage closest to the elevator. Guide it into the

connector on the servo at this time also.

20. Insert the pushrod wire into the hole of the

control horn that is two away from the control

surface as shown. Use pliers to open the pushrod

keeper just enough to slip it over the bend of the

pushrod wire so it secures the pushrod wire to the

control horn. Don’t open the connector too far as it

could possibly break the connector.

21E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 22

21. Repeat Steps 12 through 19 to install the

remaining control horn and pushrod wire.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

22. Center both elevator halves and the elevator

servo. Use a 3mm x 4mm machine screw to secure

the pushrod wires in the pushrod connector. Use

a #1 Phillips screwdriver to tighten the screw.

Use side cutters to trim the excess pushrod wire

extending past the pushrod connector.

Rudder Servo and

Linkage Installation

Required Parts

Transmitter Servo with hardware

Receiver Assembled airframe

Nylon pushrod backplate

Micro pushrod connector

2mm x 4mm machine screw

Pushrod connector (large)

Rudder pushrod keeper

Rudder pushrod wire, 19 11/16-inch (500mm) (2)

Required Tools and Adhesives

Side cutter Hobby knife with #11 blade

Medium CA Threadlock

Pin vise Drill bit: 1/16-inch (1.5mm)

6-minute epoxy Mixing cup

Mixing stick Paper towels

Rubbing alcohol Thin CA

Phillips screwdriver: #1

1. Use 6-minute epoxy to glue the control

horn to the rudder. Allow the epoxy to fully

cure before proceeding.

2. Use the radio system to center the rudder servo.

Note the direction of the servo arm in relationship

to the servo.

3. Use a pin vise and 1/16-inch (1.5mm) drill bit

to enlarge the hole in the servo arm as shown.

22 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 23

4. Use a hobby knife and #11 blade or side cutters

to remove the excess servo arm so it does not

interfere with the intake tube when it is installed.

5. Insert the micro pushrod connector in the hole. It

should move freely in the hole.

6. Install the nylon backplate on the pushrod

connector to secure the connector to the servo horn.

7. Use a #1 Phillips screwdriver to thread the servo

mounting screw into the two holes for mounting the

elevator servo.

8. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This will harden the

wood, making the screws more secure.

9. Secure the rudder servo in the fuselage using

the screws provided with the servo and a #1

Phillips screwdriver.

23E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 24

10. Slide a pushrod connector on the 19 11/16-inch

(500mm) pushrod wire.

11. Insert the pushrod wire into the outside hole of

the control horn. Slide the rudder pushrod in the

hole of the pushrod connector. Use pliers to open

the pushrod keeper just enough to slip it over the

bend of the pushrod wire so it secures the pushrod

wire to the control horn. Don’t open the connector

too far as it could possibly break the connector.

12. Center the rudder and the rudder servo. Use a

2mm x 4mm machine screw to secure the pushrod

wires in the pushrod connector. Use a #1 Phillips

screwdriver to tighten the screw. Use side cutters

to trim the excess length of the pushrod wire so it

does not interfere with the operation of the servo.

Landing Gear Installation

Required Parts

Nose gear wire Wheel collar (7)

Main gear wire, left

Main gear wire, right

3mm x 3mm setscrew

Landing gear strap (2)

Nose gear steering arm

2mm x 8mm machine screw (7)

Nose wheel, 1 3/16-inch (30mm)

Main wheel, 1 5/8-inch (41mm) (2)

2mm x 8mm sheet metal screw (4)

Required Tools and Adhesives

Phillips screwdriver: #1

Hex wrench: 1.5mm Threadlock

1. Insert the main landing gear into the notch in

the wing. The wire will fit flush with the wing when

installed. There is a left and right main gear wire.

When positioned correctly the spring coil will face

the rear as shown in the photos.

24 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 25

2. Use a #1 Phillips screwdriver to tighten the two

2mm x 8mm sheet metal screws that secure the

landing gear strap to the bottom of the wing. The

holes for the straps are pre located in the wing.

3. Slide a wheel collar on the main landing gear

and use a #1 Phillips screwdriver and 2mm x 8mm

machine screw to secure the wheel collar to the

wire. The wheel collars have a slight flange which

faces toward the wheel. Make sure to install the

wheel collars in the correct direction.

4. Slide a main wheel and wheel collar onto the

landing gear wire. Use a #1 Phillips screwdriver

and 2mm x 8mm machine screw to secure the

wheel. Remember to use threadlock on the screw to

prevent it from vibrating loose.

Leave a very small gap between the wheels and

each collar to allow the wheel to roll freely.

7. Install the nose wheel on the nose gear

wire using two wheel collars and a #1 Phillips

screwdriver to tighten the two 2mm x 8mm

machine screws.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

5. Repeat Steps 1 through 4 to install the remaining

main gear wire and wheel.

6. Position a wheel collar on the nose gear wire as

shown and thread a 2mm x 8mm machine screw in

the wheel collar. Note that the flange on the collar

faces away from the spring on the nose gear wire.

Do not tighten the screw at this time.

8. Slide the nose gear wire into the bushing in the

front of the fuselage. The gear will angle forward

as shown in the photo.

25E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 26

During manufacturing the end of the nose gear wire

may be slightly enlarged due to cutting. If this happens

use a file to reduce the diameter of the end of the

wire so that it slides smoothly through the bushings.

9. Slide the steering bellcrank on the nose gear

wire from inside the fuselage. Use a 1.5mm hex

wrench and 3mm x 3mm setscrew to secure the

steering arm to the nose gear wire. The nose gear

wire will fit flush at the top of the steering arm. The

setscrew will tighten onto the flat spot of the nose

gear that can be seen in the photo in Step 6. Make

sure to use threadlock on the setscrew to prevent

it from vibrating loose. Tighten the collar on the

bottom so the nose gear turns freely but will not

slide up and down on the bushing.

Steering Servo and

Linkage Installation

Required Parts

Assembled airframe Steering linkage

Transmitter Receiver

Steering servo Servo mount

Servo mounting strap

Nose gear pushrod wire, 7 7/8-inch (200mm)

2.5mm x 10mm sheet metal screw (4)

Required Tools and Adhesives

Pin vise Drill bit: 5/64-inch (2mm)

6-minute epoxy Mixing stick

Sandpaper Felt-tipped pen

Mixing cup Phillips screwdriver: #1

1. Insert the Z-bend for the nose gear pushrod wire

into the steering bellcrank.

2. Use the radio system to center the steering servo.

Note the direction of the servo arm in relationship

to the servo.

3. Use a pin vise and 5/64-inch (2mm) drill bit to

enlarge the hole in the servo arm that is four holes

away from the center of the servo arm as shown.

Check to make sure the nose gear wire

can move freely so the steering servo is not

overloaded when trying to steer your aircraft.

26 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 27

4. Insert the steering pushrod in the hole of the

servo arm. Position the servo so the nose gear is

aligned with the fuselage centerline so it will taxi

straight down the runway. Use a felt-tipped pen to

mark the fuselage where the servo rests.

5. Lightly sand the seam in the fuselage where the

steering servo rests. This provides a flat area for the

mount to be glued.

6. Use 6-minute epoxy to glue the servo mount in

the fuselage. Once the epoxy fully cures, secure

the servo using the servo mounting strap and two

2.5mm x 10mm sheet metal screws. Tighten the

screws using a #1 Phillips screwdriver.

Check to make sure the nose gear wire

can move freely so the steering servo is not

overloaded when trying to steer your aircraft.

Speed Control and

Receiver Installation

Required Parts

Assembled airframe

Speed control Receiver

Hook and loop tape

Required Tools and Adhesives

Hobby scissors

1. Cut a piece of hook and loop tape and apply it

to the bottom of the speed control as shown. Leave

the adhesive backing on the mating hook and loop

until instructed to do so.

2. Remove the backing from the hook and loop

tape on the speed control. Secure the speed control

inside the fuselage as shown.

27E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 28

Note: When flying your model in locations

High-Temperature ESC Location

Cut hole for ESC cooling

where the air temperature is very high, you will

need to mount the ESC between the wing rods.

Cut a hole in the bottom of the fuselage so the

fins of the ESC can be exposed to the air flow

outside of the fuselage. This keeps the ESC cool

and prevents over-heating.

3. Insert the leads from the speed control through

the hole in the former in the fuselage as shown.

4. Use a small amount of hook and loop tape to

mount the switch from the speed control to the side

of the fuselage. Make sure to position it where it

can be easily accessed.

5. Cut two pieces of hook and loop tape and apply

it to the bottom of the main and remote receivers as

shown. Leave the adhesive backing on the mating

hook and loop until instructed to do so.

4. Plug the leads from the aileron servos, elevator

servo, steering servo and speed control into the

appropriate ports of the receiver. Use hook and

loop tape to attach the receiver inside the fuselage

as shown in the photo.

28 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 29

5. When installing a remote receiver, attach it as

shown in the fuselage using hook and loop tape.

Intake Tube Installation

Required Parts

Assembled airframe

Intake tube Hook and loop strap

1. Remove the cover from the bottom of the

fuselage and set it aside in a safe location.

2. Prepare the hook and loop strap by attaching

the pieces together using a 2-inch (52mm)

overlap as shown.

3. Locate the intake tube. The circular end will fit to

the rear of the fuselage. The front is egg-shaped to

match the intake of the fuselage and the flatter side

will face to the bottom of the fuselage.

4. Place the hook and loop tape on the intake tube

at this time. This will prevent you from accidentally

looping the tape around the steering linkage wire.

29E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 30

5. Insert the intake tube into the fuselage. Slide it

Fan bottom (fuselage top)

Fan centerline

Mounting lug

Mounting lug

forward so it keys to the intake of the fuselage. The

tube will be secured after the fan has been installed.

Fan Installation

Required Parts

Fan assembly Assembled airframe

Exhaust tube Fan fairing

2mm x 6mm machine screw (2)

2mm x 8mm sheet metal screw (4)

Required Tools and Adhesives

Felt-tipped pen Hobby scissors

Thin CA Phillips screwdriver: #1

Paper Low-tack tape

1. Locate the fan unit. View the fan unit and use

the drawing provided to determine the top and

bottom of the fan. Place a piece of low-tack tape

on the bottom of the fan so the bottom can easily

be determined during assembly.

2. Pass the wires through the fan fairing.

3. Use two 2mm x 6mm machine screws and a #1

Phillips screwdriver to attach the fan fairing to the

motor. Note that the fairing faces to the bottom of

the fan unit.

30 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 31

4. Cut a paper template to locate where the fan fairing

will exit the exhaust tube. Make sure the template fits

tightly against the mounting lugs as the overall width of

the template will be used for positioning.

5. Use a felt-tipped pen to mark the edge of the fan

unit on the template. Make a mark for both of the

mounting lugs.

6. Align the template on the exhaust tube. The

marks made in the previous step will align with

the notches in the tube for the mounting lugs.

Make sure the template is on the side of the

exhaust tube with the seam (bottom). Use a felttipped pen to trace the outline for the fan fairing

on the exhaust tube.

7. Remove the template from the exhaust tube. Use

hobby scissors to trim the exhaust tube for the fan

fairing. Slot the exhaust tube so it can be slid over

the fan fairing.

8. Check the fit of the exhaust tube on the fan unit.

It may be necessary to trim the opening slightly

using hobby scissors.

Matching the colors between the ESC and motor

when they are connected results in the correct

motor direction if using all E-flite components.

9. Use a #1 Phillips screwdriver to thread a

mounting screw into the four holes for mounting the

fan unit.

31E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 32

10. Place 2–3 drops of thin CA in each hole to

harden the surrounding wood. This hardens the

wood, making the screws more secure.

11. Connect the wires from the motor to those

coming from the speed control.

12. Fit the fan unit into the fuselage with the fan

fairing facing to the bottom of the fuselage. Make

sure to fit the fan into the intake tube and that all the

screw holes for mounting the fan are visible through

the mounting lugs. Secure the fan unit in the fuselage

using four 2mm x 8mm sheet metal screws. Tighten

the screws using a #1 Phillips screwdriver.

Exhaust Tube Installation

Required Parts

Assembled airframe

Exhaust tube Clear tape

Fan access hatch

Required Tools and Adhesives

Hobby scissors Felt-tipped pen

1. Carefully roll or fold the exhaust tube into the

shape shown below. It is made of a durable clear

plastic and will not be harmed by doing so.

2. Slide the exhaust tube into the fuselage, with

the wider end of the tube entering the fuselage

from the rear. It will “pop” open when it has been

inserted fully into the fuselage.

32 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 33

3. Position the exhaust tube so it overlaps onto the

fan assembly.

4. Use a felt-tipped pen to trace the outline of the

fuselage on the exhaust tube.

5. Remove the exhaust tube and use hobby scissors

to trim the exhaust tube at the line drawn in the

previous step to match the outline of the fuselage.

6. Insert the exhaust tube back into the fuselage.

Use the clear tape supplied with your aircraft to

tape the thrust tube to the fan housing.

7. Use clear tape at the bottom and both sides

of the thrust tube to secure the tube at the rear

of the fuselage.

8. Cut four pieces of clear tape using scissors and

tape the fan access hatch to the fuselage.

33E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 34

Securing the Intake Tube

Required Parts

Assembled airframe

Plywood intake mounting plate (2)

Plywood intake mounting gusset (4)

2mm x 6mm sheet metal screw (4)

Required Tools and Adhesives

Medium CA 6-minute epoxy

Mixing stick Thin CA

Pin vise Drill bit: 1/16-inch (1.5mm)

Mixing cup Sandpaper

1. Use medium CA to glue the two plywood intake

mounting gussets to the plywood plate. Note the

position of the pieces in the photo.

2. Place the assembly on the rest in the fuselage.

The gussets should rest lightly on the intake tube. If

they are deforming the intake tube, you may need

to sand the plywood plate or stop as necessary.

Use a pencil to mark the location for the two screws

that secure the plywood plate to the stop.

4. Use 2–3 drops of thin CA to harden the

surrounding wood for the screws. This makes the

screws more secure when they are installed.

5. Repeat Steps 1 through 4 to assemble and fit the

remaining plywood plate and gussets.

3. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill the two holes for the mounting screws.

6. Apply a small amount of 6-minute epoxy to the

plywood gussets where they contact the intake tube.

Insert the assembly into the fuselage and secure it

to the rest in the fuselage using two 2mm x 6mm

sheet metal screws and a #1 Phillips screwdriver.

Install both assemblies at this time.

34 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 35

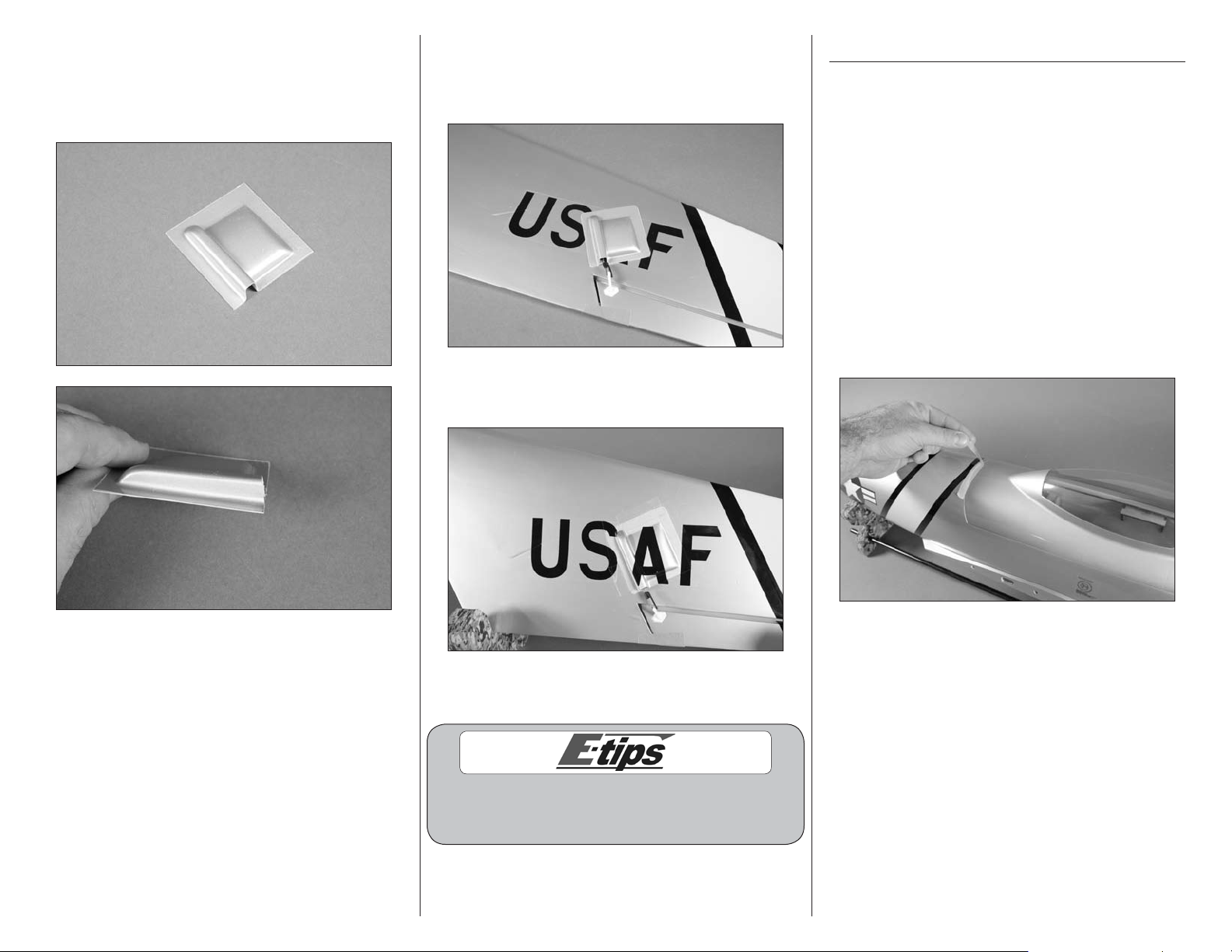

Canopy Assembly

Required Parts

Canopy hatch Cockpit

Clear tape Pilot figure (optional)

Required Tools and Adhesives

Hobby scissors

1. Use hobby scissors to trim the cockpit along the

molded lines.

3. Use clear tape to hold the cockpit in the

canopy hatch.

Optional Pilot

You may notice a pilot shown in the F-86 Sabre. A

pilot is not included with the kit. It can be purchased

separately under part number (PKZ7003). The pilot

was cut down to fit and was glued in with canopy

glue as shown before the cockpit was installed in the

canopy hatch.

Motor Battery Installation

Required Parts

Motor battery Hook and loop tape

Assembled airframe

Canopy hatch assembly

Required Tools and Adhesives

Hobby scissors

1. Cut a piece of hook and loop tape that is

41/2 inches (115mm) long. Apply the tape to the

intake tube so it is centered on the top of the tube

and positioned equally forward and backward of

the intake mounting plates.

2. Insert the cockpit in the canopy hatch. It is best

to insert the front first, then the rear will fit right in.

2. Apply the mating portion of the tape to the

bottom of the motor battery as shown.

35E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 36

3. Position the motor battery in the fuselage and

use the hook and loop strap to secure it inside

the fuselage.

4. Place the canopy hatch on the fuselage.

Decal Placement

Required Parts

Decal sheet Assembled airframe

Required Tools and Adhesives

Hobby scissors Hobby knife with #11 blade

1. Use hobby scissors and a hobby knife with a

#11 blade to cut the decals from the decal sheet.

Apply the decals to the airfame following one of

the schemes shown. Drawings for decal placement

are located on Page 43 of this manual.

Center of Gravity

An important part of preparing the aircraft for flight is

properly balancing the model.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location

for your model is 5

back from the leading edge of the wing as shown with

the battery pack installed. Mark the location of the CG

on the top of the wing with a felt-tipped pen.

When balancing your model, support the plane

inverted at the marks made on the wing with your

fingers or a commercially available balancing stand.

This is the correct balance point for your model. Make

sure your model is assembled and ready for flight

before balancing.

Adjust the motor battery as necessary so the model is

level or slightly nose down. This is the correct balance

point for your model. You should find the CG to be

very close with the battery installed as shown in this

manual. Mark the location of the battery on the intake

tube using a felt-tipped pen so it can be returned to

this position if it is removed from your model.

3

/4 to 61/8 inches (145 to 155mm)

36 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 37

After the first flights, the CG position can be adjusted

for your personal preference.

Control Throws

1. Turn on the transmitter and receiver of your

model. Check the movement of the rudder using

the transmitter. When the stick is moved right,

the rudder should also move right. Reverse the

direction of the servo at the transmitter if necessary.

2. Check the movement of the elevator with the

radio system. Moving the elevator stick toward

the bottom of the transmitter makes the airplane

elevator move up.

3. Check the movement of the ailerons with the

radio system. Moving the aileron stick right makes

the right aileron move up and the left aileron move

down.

4. Use a ruler to adjust the throw of the elevator,

ailerons and rudder. Adjust the position of

the pushrod at the control horn to achieve the

following measurements when moving the sticks to

their endpoints.

Elevator High Rate (100%)

Up 1/2-inch (12mm) +10% Exponential

Down 1/2-inch (12mm) +10% Exponential

Rudder High Rate (100%)

Right 3/8-inch (10mm) +10% Exponential

Left 3/8-inch (10mm) +10% Exponential

Rudder Low Rate (40%)

Right 3/16-inch (5mm) +5% Exponential

Left 3/16-inch (5mm) +5% Exponential

Adding spoilerons to the F-86 Sabre during landing

approach and landing will add washout affect and

decrease the floating affect. Set both ailerons so they

raise up 1/8-inch (3mm) above the trailing edge of

the wing from center. Follow your computer radio

instructions for the correct setup.

The rudder low rate is used for takeoff and landing

as the F-86 Sabre has a narrow stance gear. If

using a computer radio it is also possible to use

a mix and separate channel for the nose gear

steering to create a low rate for just the nose gear.

Elevator Low Rate (70%)

Up 5/16-inch (9mm) +5% Exponential

Down 5/16-inch (9mm) +5% Exponential

Aileron High Rate (100%)

Up 3/8-inch (10mm) +10% Exponential

Down 3/8-inch (10mm) +10% Exponential

Aileron Low Rate (80%)

Up 9/32-inch (7mm) Linear Exponential

Down 9/32-inch (7mm) Linear Exponential

Measurements are taken at the inner or

widest point on the control surface.

These are general guidelines measured from our own

flight tests. You can experiment with higher rates to

match your preferred style of flying.

Travel Adjust and Sub-Trims are not listed

and should be adjusted according to each

individual model and preference.

37E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 38

Preflight

Flying Your F-86 Sabre 15 DF

Range Test Your Radio

Check Your Radio

Before going to the field, be sure your batteries are

fully charged per the instructions included with your

radio. Charge the transmitter and motor battery

for your airplane. Use the recommended charger

supplied with your particular radio system, following

the instructions provided with the radio. In most

cases, the radio should be charged the night before

going out flying.

Before each flying session, be sure to range check your

radio. See your radio manual for the recommended

range and instructions for your radio system. Each

radio manufacturer specifies different procedures for

their radio systems. Next, run the motor. With the

model securely anchored, check the range again.

The range test should not be significantly affected. If

it is, don’t attempt to fly! Have your radio equipment

checked out by the manufacturer.

Double-check that all controls (aileron, elevator, rudder

and throttle) move in the correct direction.

Check the radio installation and make sure all the

control surfaces are moving correctly (i.e., the correct

direction and with the recommended throws).

Check all the control horns, servo horns, and clevises

to make sure they are secure and in good condition.

You will find the agile F-86 is very capable in the air

yet predictable on approach and landings.

As with all performance scale aircraft takeoff and

landings must be performed smoothly with small

control inputs. Take off using low rate steering and

full power. Hold a small amount of up elevator during

the takeoff roll and let the model fly off of the ground.

After rotation, ease off of the up elevator and climb to

altitude. Do not try to pull the model off of the ground

too soon before it has a good amount of airspeed.

Landings are best made by flying the model to the

ground with a slight positive angle of attack. Use the

throttle to control your descent and rudder to keep the

model on heading.

The F-86 Sabre tracks very well in the air and is

capable of many basic aerobatic maneuvers like

loops, slow rolls, point rolls and inverted flight. We

recommend you use throttle management during the

whole flight. Using full power throughout the duration

of the flight will result in shorter flight times and could

result in a shorter life span for the electronics and

batteries.

Happy Landings!

Before each flying session, and especially with a new

model, it is important to perform a range check. It

is helpful to have another person available to assist

during the range check. If you are using a Spektrum

transmitter, please refer to your transmitter’s manual for

detailed instructions on the range check process.

1. With the model resting on the ground, stand 30

paces (approximately 90 feet) away from the model.

2. Face the model with the transmitter in your

normal flying position. Be sure the throttle is in the

full down position and plug the flight battery into

the speed control.

3. As you move the controls, watch to be sure the

airplane’s motor and controls operate smoothly.

You should have total control of the model at 30

paces (90 feet).

4. If control issues exist, call the appropriate

Horizon Product Support office (see page 40–41)

or go to horizonhobby.com to find a local

Spektrum distributor in your country for service if

using a Spektrum radio system.

38 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 39

Safety Do’s and Don’ts for Pilots

Daily Flight Checks

Warranty and Repair Policy

• Checkallcontrolsurfacespriortoeachtakeoff.

• Donotflyyourmodelnearspectators,parking

areas or any other area that could result in injury to

people or damage of property.

• Donotflyduringadverseweatherconditions.Poor

visibility can cause disorientation and loss of control

of your aircraft. Strong winds can cause similar

problems.

• Donottakechances.Ifatanytimeduringflightyou

observe any erratic or abnormal operation, land

immediately and do not resume flight until the cause

of the problem has been ascertained and corrected.

Safety can never be taken lightly.

• Donotflynearpowerlines.

1. Check the battery voltage of the transmitter

battery. Do not fly below the manufacturer’s

recommended voltage. To do so can crash

your aircraft.

When you check these batteries, ensure you have the

polarities correct on your expanded scale voltmeter.

2. Check all hardware (linkages, screws, nuts,

and bolts) prior to each day’s flight. Be sure that

binding does not occur and that all parts are

properly secured.

3. Ensure all surfaces are moving in the

proper manner.

4. Perform a ground range check before each

day’s flying session.

5. Prior to starting your aircraft, turn off your

transmitter, then turn it back on. Do this each time

you start your aircraft. If any critical switches are

on without your knowledge, the transmitter alarm

will sound a warning at this time.

6. Check that all trim levers are in the

proper location.

7. All servo pigtails and switch harness plugs

should be secured in the receiver. Make sure the

switch harness moves freely in both directions.

WARRANTY PERIOD

Exclusive Warranty- Horizon Hobby, Inc., (Horizon)

warranties that the Products purchased (the “Product”)

will be free from defects in materials and workmanship

at the date of purchase by the Purchaser.

LIMITED WARRANTY

Horizon reserves the right to change or modify this

warranty without notice and disclaims all other

warranties, express or implied.

(a) This warranty is limited to the original Purchaser

(“Purchaser”) and is not transferable. REPAIR OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY

IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This

warranty covers only those Products purchased from an

authorized Horizon dealer. Third party transactions are not

covered by this warranty. Proof of purchase is required for

warranty claims.

(b) Limitations- HORIZON MAKES NO WARRANTY

OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE

PURCHASER ACKNOWLEDGES THAT THEY ALONE

HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY

MEET THE REQUIREMENTS OF THE PURCHASER’S

INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder

shall be that Horizon will, at its option, (i) repair or

(ii) replace, any Product determined by Horizon to be

defective. In the event of a defect, these are the Purchaser’s

exclusive remedies. Horizon reserves the right to inspect

any and all equipment involved in a warranty claim.

Repair or replacement decisions are at the sole discretion

of Horizon. This warranty does not cover cosmetic damage

or damage due to acts of God, accident, misuse, abuse,

negligence, commercial use, or modification of or to any

part of the Product. This warranty does not cover damage

due to improper installation, operation, maintenance, or

attempted repair by anyone other than Horizon. Return of

any goods by Purchaser must be approved in writing by

Horizon before shipment.

39E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 40

DAMAGE LIMITS

Warranty Services

NON-WARRANTY REPAIRS

HORIZON SHALL NOT BE LIABLE FOR SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS

OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE

PRODUCT, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY. Further, in no event shall the liability of

Horizon exceed the individual price of the Product on

which liability is asserted. As Horizon has no control

over use, setup, final assembly, modification or misuse,

no liability shall be assumed nor accepted for any

resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared

to accept the liability associated with the use of

this Product, you are advised to return this Product

immediately in new and unused condition to the place

of purchase.

Law: These Terms are governed by Illinois law (without

regard to conflict of law principals).

QUESTIONS, ASSISTANCE, AND REPAIRS

Your local hobby store and/or place of purchase

cannot provide warranty support or repair. Once

assembly, setup or use of the Product has been

started, you must contact Horizon directly. This will

enable Horizon to better answer your questions

and service you in the event that you may need any

assistance. For questions or assistance, please direct

your email to productsupport@horizonhobby.com,

or call 877.504.0233 toll free to speak to a service

technician.

INSPECTION OR REPAIRS

If this Product needs to be inspected or repaired,

please call for a Return Merchandise Authorization

(RMA). Pack the Product securely using a shipping

carton. Please note that original boxes may be

included, but are not designed to withstand the rigors

of shipping without additional protection. Ship via a

carrier that provides tracking and insurance for lost

or damaged parcels, as Horizon is not responsible

for merchandise until it arrives and is accepted at our

facility. A Service Repair Request is available at www.

horizonhobby.com on the “Support” tab. If you do

not have internet access, please include a letter with

your complete name, street address, email address

and phone number where you can be reached during

business days, your RMA number, a list of the included

items, method of payment for any non-warranty

expenses and a brief summary of the problem.

Your original sales receipt must also be included for

warranty consideration. Be sure your name, address,

and RMA number are clearly written on the outside of

the shipping carton.

WARRANTY INSPECTION AND REPAIRS

Should your repair not be covered by warranty the

repair will be completed and payment will be required

without notification or estimate of the expense unless

the expense exceeds 50% of the retail purchase cost.

By submitting the item for repair you are agreeing

to payment of the repair without notification. Repair

estimates are available upon request. You must include

this request with your repair. Non-warranty repair

estimates will be billed a minimum of 1/2 hour of

labor. In addition you will be billed for return freight.

Please advise us of your preferred method of payment.

Horizon accepts money orders and cashiers checks,

as well as Visa, MasterCard, American Express, and

Discover cards. If you choose to pay by credit card,

please include your credit card number and expiration

date. Any repair left unpaid or unclaimed after 90

days will be considered abandoned and will be

disposed of accordingly. Please note: non-warranty

repair is only available on electronics and model

engines.

United States:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

USA

All other Products requiring warranty inspection or

repair should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

USA

To receive warranty service, you must include your

original sales receipt verifying the proof-of-purchase

date. Provided warranty conditions have been met,

your Product will be repaired or replaced free of

charge. Repair or replacement decisions are at the sole

discretion of Horizon Hobby.

40 E-flite F-86 Sabre 15 DF ARF Assembly Manual

Please call 877-504-0233 or e-mail us at

productsupport@horizonhobby.com with any questions

or concerns regarding this product or warranty.

Page 41

United Kingdom:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Hobby UK

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Please call +44 (0) 1279 641 097 or e-mail us at

sales@horizonhobby.co.uk with any questions or

concerns regarding this product or warranty.

Germany:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Technischer Service

Hamburger Strasse 10

25335 Elmshorn

Germany

Please call +49 4121 46199 66 or e-mail us at

service@horizonhobby.de with any questions or

concerns regarding this product or warranty.

France:

Horizon Hobby SAS

14 Rue Gustave Eiffel

Zone d’Activité du

Réveil Matin

91230 Montgeron

Please call +33 (0) 1 60 47 44 70 with any questions

or concerns regarding this product or warranty.

Compliance Information for the

European Union

INSTRUCTIONS FOR DISPOSAL OF WEEE BY USERS IN

THE EUROPEAN UNION

This product must not be disposed of with other waste.

Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated

collection point for the recycling of waste electrical

and electronic equipment. The separate collection

and recycling of your waste equipment at the time

of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that

protects human health and the environment. For more

information about where you can drop off your waste

equipment for recycling, please contact your local city

office, your household waste disposal service or where

you purchased the product.

Age Recommendation: 14 years or over. Not a toy.

Not intended for use by children without direct adult

supervision.

2010 Official Academy of Model

Aeronautics Safety Code

GENERAL

1. A model aircraft shall be defined as a non-humancarrying device capable of sustained flight in

the atmosphere. It shall not exceed limitations

established in this code and is intended to be used

exclusively for recreational or competition activity.

2. The maximum takeoff weight of a model aircraft,

including fuel, is 55 pounds, except for those flown

under the AMA Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules

established for the flying site I use. I will not

willfully fly my model aircraft in a reckless and/or

dangerous manner.

4. I will not fly my model aircraft in sanctioned events,

air shows, or model demonstrations until it has

been proven airworthy.

5. I will not fly my model aircraft higher than

approximately 400 feet above ground level, when

within three (3) miles of an airport without notifying

the airport operator. I will yield the right-of-way

and avoid flying in the proximity of full-scale

aircraft, utilizing a spotter when appropriate.

6. I will not fly my model aircraft unless it is identified

with my name and address, or AMA number,

inside or affixed to the outside of the model

aircraft. This does not apply to model aircraft flown

indoors.

7. I will not operate model aircraft with metal-blade

propellers or with gaseous boosts (other than

air), nor will I operate model aircraft with fuels

containing tetranitromethane or hydrazine.

41E-flite F-86 Sabre 15 DF ARF Assembly Manual

Page 42

8. I will not operate model aircraft carrying

pyrotechnic devices which explode burn, or propel

a projectile of any kind. Exceptions include Free

Flight fuses or devices that burn producing smoke

and are securely attached to the model aircraft

during flight. Rocket motors up to a G-series

size may be used, provided they remain firmly

attached to the model aircraft during flight. Model

rockets may be flown in accordance with the

National Model Rocketry Safety Code; however,

they may not be launched from model aircraft.

Officially designated AMA Air Show Teams (AST)

are authorized to use devices and practices as

defined within the Air Show Advisory Committee

Document.

9. I will not operate my model aircraft while under

the influence of alcohol or within eight (8) hours of

having consumed alcohol.

3. I will not fly my model aircraft in the presence of

spectators until I become a proficient flier, unless I

am assisted by an experienced pilot.

4. At all flying sites a line must be established,

in front of which all flying takes place. Only

personnel associated with flying the model aircraft

are allowed at or in front of the line. In the case

of airshows demonstrations straight line must be

established. An area away from the line must be

maintained for spectators. Intentional flying behind

the line is prohibited.

5. I will operate my model aircraft using only

radio-control frequencies currently allowed by

the Federal Communications Commission (FCC).

Only individuals properly licensed by the FCC are

authorized to operate equipment on Amateur Band

frequencies.

8. Under no circumstances may a pilot or other

person touch a model aircraft in flight while it is

still under power, except to divert it from striking an

individual.

9. Radio-controlled night flying is limited to lowperformance model aircraft (less than 100 mph).

The model aircraft must be equipped with a lighting

system which clearly defines the aircraft’s attitude

and direction at all times.

10. The operator of a radio-controlled model aircraft

shall control it during the entire flight, maintaining

visual contact without enhancement other than by

corrective lenses that are prescribed for the pilot.

No model aircraft shall be equipped with devices

which allow it to be flown to a selected location

which is beyond the visual range of the pilot.

F-86 Sabre 15 DF Safe Operating Recommendations

10. I will not operate my model aircraft while using

any drug which could adversely affect my ability to

safely control my model aircraft.

11. Children under six (6) years old are only allowed

on a flightline or in a flight area as a pilot or while

under flight instruction.

12. When and where required by rule, helmets must be

properly worn and fastened. They must be OSHA,

DOT, ANSI, SNELL or NOCSAE approved or

comply with comparable standards.

RADIO CONTROL

1. All model flying shall be conducted in a manner to

avoid over flight of unprotected people.

2. I will have completed a successful radio equipment

ground-range check before the first flight of a new

or repaired model aircraft.

6. I will not knowingly operate my model aircraft

within three (3) miles of any preexisting flying site

without a frequency-management agreement. A

frequency management agreement may be an

allocation of frequencies for each site, a dayuse agreement between sites, or testing which

determines that no interference exists. A frequencymanagement agreement may exist between two

or more AMA chartered clubs, AMA clubs and

individual AMA members, or individual AMA

members. Frequency-management agreements,

including an interference test report if the

agreement indicates no interference exists, will be

signed by all parties and copies provided to AMA

Headquarters.