Page 1

Main Rotor Diameter ........................................................................................... 28.2 in (718mm)

Tail Rotor Diameter ................................................................................................ 5.3 in (135mm)

Height ................................................................................................................. 9.0 in (230mm)

Length ................................................................................................................ 25.6 in (650mm)

Weight with Battery ...............................................................................................23.5 oz (665 g)

Motor ....................................................................... 420H brushless outrunner, 3800Kv (installed)

ESC ................................................................................................... 25-amp brushless (installed)

Battery ...........................................................................3S 11.1V 1800mAh 20C Li-Po (included)

Charger ............................................................................. DC Li-Po Balancing Charger (included)

Transmitter............................... Spektrum DX6i 2.4GHz DSM2 6-channel Computer Radio (included)

Receiver .........................................Spektrum AR6100e 2.4GHz DSM2 Microlite Receiver (installed)

Servos .................................................................................. DS75H Digital Sub-Micro (4 installed)

Gyro ..................................................................................... G110 Micro Heading Lock (installed)

Specifications

Page 2

2

3

Introduction

The Blade™ 400 3D RTF is designed to offer intermediate to advanced heli pilots a ready-to-fly

experience like no other. It comes 100% factory built and tested so you can get flying right away,

and is equipped with state-of-the-art features like brushless and Li-Po power, a heading lock gyro,

digital servos and CCPM control. From smooth hovering to 3D flying, the Blade 400 3D’s size and

performance allow it to be flown outdoors in breezier conditions that would typically ground smaller

micro-class helicopters.

In addition to its impressive features and performance, the Blade 400 3D is the first ready-to-fly miniheli to come equipped with Spektrum’s advanced DX6i 2.4GHz DSM2™ 6-channel programmable

computer transmitter. Besides providing freedom from frequency restrictions and interference, the

DX6i’s DSM2 technology offers other unique advantages like faster control response and innovative

features such as ServoSync™. ServoSync automatically resequences transmitted data so mixed servos

receive their pulses at the same time so you can fly extreme 3D aerobatics with absolute precision. The

system also includes the feather light, 4.4-gram Spektrum™ AR6100e Microlite Receiver.

Other DX6i features include:

• Full-range capability • Servo monitor

• 10-model memory • Two 5-point throttle curves

• Heli and airplane programming • Three 5-point pitch curves

• Standard or 120º CCPM swashplate mixing • Revo mixing

• 3-axis dual rates and exponential • Gyro sensitivity programming

• Travel adjust • Two programmable mixes

• Sub trim

The DX6i is not only perfectly suited for the Blade 400––it can also be used to y just about any size

and type of model due to its full-range and programming capabilities.

And although the Blade 400 3D is nearly ready-to-fly right from the box, please take the time to read

through this manual for tips on battery safety and charging, control checks, adjustments and more

before making your first flight.

Warning

An RC helicopter is not a toy! If misused, it can cause serious bodily harm and damage to property.

Fly only in open areas, preferably at AMA (Academy of Model Aeronautics) approved flying sites,

following all instructions.

Keep loose items that can get entangled in the rotor blades away for the main and tail blades,

including loose clothing, or other objects such as pencils and screwdrivers. Especially keep your hands

away from the rotor blades.

Note on Lithium Polymer Batteries

Lithium Polymer batteries are significantly more volatile than alkaline or Ni-Cd/Ni-MH batteries

used in RC applications. All manufacturer’s instructions and warnings must be followed closely.

Mishandling of Li-Po batteries can result in fire. Always follow the manufacturer’s instructions

when disposing of Lithium Polymer batteries.

Warranty Period

Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the “Product”) will be free from

defects in materials and workmanship at the date of purchase by the Purchaser.

Table of Contents

Specifications .......................................................................................................................... 1

Introduction ............................................................................................................................. 3

Warning ................................................................................................................................. 3

Note on Lithium Polymer Batteries ............................................................................................. 3

Warranty Period ...................................................................................................................... 3

Limited Warranty ..................................................................................................................... 4

Damage Limits ......................................................................................................................... 4

Safety Precautions .................................................................................................................... 4

Questions, Assistance and Repairs ............................................................................................4

Inspections or Repairs .............................................................................................................. 5

Warranty Inspection and Repairs .............................................................................................. 5

Non-Warranty Repairs .............................................................................................................5

Additional Safety Precautions and Warnings .............................................................................. 6

Additional Required Equipment ................................................................................................. 6

Blade 400 3D Contents ............................................................................................................7

Preparing for the First Flight Checklist ........................................................................................ 8

Flying Checklist ........................................................................................................................ 8

Battery Warnings and Guidelines ..............................................................................................9

Battery Charging ................................................................................................................... 11

Charge Errors and Indications ................................................................................................ 14

Installing the Transmitter Batteries ............................................................................................ 15

Installing the Flight Battery ......................................................................................................16

Control Test ...........................................................................................................................17

Electronic Speed Control (ESC) Features, Arming and Motor Control Test ...................................20

Gyro Initialization, Response Test and Adjustment ..................................................................... 23

Understanding the Primary Flight Controls ............................................................................... 27

Normal and Stunt Flight Modes ............................................................................................... 30

Throttle Hold .......................................................................................................................... 32

Before the First Flight .............................................................................................................. 34

Choosing a Flying Area ..........................................................................................................35

Flying the Blade 400 3D ......................................................................................................... 35

Main Rotor Blade Tracking Adjustment.....................................................................................37

Flybar Paddle Tracking Adjustment ..........................................................................................39

Head Dampening Shims and Tuning Cyclic Response ................................................................ 40

Recommended Maintenance ................................................................................................... 40

2007 Official AMA National Model Aircraft Safety Code .........................................................41

Exploded View Parts Listing ....................................................................................................42

Exploded View ......................................................................................................................43

Replacement Parts List ............................................................................................................ 44

Optional Parts List .................................................................................................................. 44

NOTES ................................................................................................................................. 45

NOTES ................................................................................................................................. 46

NOTES ................................................................................................................................. 47

Page 3

4

5

Inspections or Repairs

If this Product needs to be inspected or repaired, please call for a Return Merchandise Authorization

(RMA). Pack the Product securely using a shipping carton. Please note that original boxes may be

included, but are not designed to withstand the rigors of shipping without additional protection. Ship

via a carrier that provides tracking and insurance for lost or damaged parcels, as Horizon is not

responsible for merchandise until it arrives and is accepted at our facility. A Service Repair Request is

available at www.horizonhobby.com on the “Support” tab. If you do not have internet access, please

include a letter with your complete name, street address, email address and phone number where

you can be reached during business days, your RMA number, a list of the included items, method of

payment for any non-warranty expenses and a brief summary of the problem. Your original sales

receipt must also be included for warranty consideration. Be sure your name, address, and RMA

number are clearly written on the outside of the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-ofpurchase date. Provided warranty conditions have been met, your Product will be repaired or replaced

free of charge. Repair or replacement decisions are at the sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will be completed and payment will be

required without notification or estimate of the expense unless the expense exceeds 50% of the retail

purchase cost. By submitting the item for repair you are agreeing to payment of the repair without

notification. Repair estimates are available upon request. You must include this request with your

repair. Non-warranty repair estimates will be billed a minimum of ½ hour of labor. In addition you

will be billed for return freight. Please advise us of your preferred method of payment. Horizon accepts

money orders and cashiers checks, as well as Visa, MasterCard, American Express, and Discover

cards. If you choose to pay by credit card, please include your credit card number and expiration

date. Any repair left unpaid or unclaimed after 90 days will be considered abandoned and will be

disposed of accordingly. Please note: non-warranty repair is only available on electronics and model

engines.

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other Products requiring warranty inspection or repair should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

Please call 877-504-0233 with any questions or concerns regarding this Product or warranty.

Limited Warranty

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is not transferable. REPAIR

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

PURCHASER. This warranty covers only those Products purchased from an authorized Horizon dealer.

Third party transactions are not covered by this warranty. Proof of purchase is required for warranty

claims. Further, Horizon reserves the right to change or modify this warranty without notice and

disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT

THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon will, at its option, (i)

repair or (ii) replace, any Product determined by Horizon to be defective. In the event of a defect, these

are the Purchaser’s exclusive remedies. Horizon reserves the right to inspect any and all equipment

involved in a warranty claim. Repair or replacement decisions are at the sole discretion of Horizon.

This warranty does not cover cosmetic damage or damage due to acts of God, accident, misuse,

abuse, negligence, commercial use, or modification of or to any part of the Product. This warranty

does not cover damage due to improper installation, operation, maintenance, or attempted repair by

anyone other than Horizon. Return of any goods by Purchaser must be approved by Horizon before

shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCT, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE,

OR STRICT LIABILITY. Further, in no event shall the liability of Horizon exceed the individual price of

the Product on which liability is asserted. As Horizon has no control over use, setup, final assembly,

modication or misuse, no liability shall be assumed nor accepted for any resulting damage or injury.

By the act of use, setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this

Product, you are advised to return this Product immediately in new and unused condition to the place

of purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be operated with caution and common

sense and requires some basic mechanical ability. Failure to operate this Product in a safe and

responsible manner could result in injury or damage to the Product or other property. This Product

is not intended for use by children without direct adult supervision. The Product manual contains

instructions for safety, operation and maintenance. It is essential to read and follow all the instructions

and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid

damage or injury.

Questions, Assistance and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once

assembly, setup or use of the Product has been started, you must contact Horizon directly. This will

enable Horizon to better answer your questions and service you in the event that you may need any

assistance. For questions or assistance, please direct your email to productsupport@horizonhobby.

com, or call 877.504.0233 toll free to speak to a service technician.

Page 4

6

7

Additional Safety Precautions and Warnings

As the user of this product, you are solely responsible for operating it in a manner that does not

endanger yourself and others or result in damage to the product or the property of others.

This model is controlled by a radio signal that is subject to interference from many sources outside your

control. This interference can cause momentary loss of control so it is advisable to always keep a safe

distance in all directions around your model, as this margin will help to avoid collisions or injury.

• Never operate your model with low transmitter batteries.

• Always operate your model in an open area away from cars, trafc, or people.

• Avoid operating your model in the street where injury or damage can occur.

• Never operate the model out into the street or populated areas for any reason.

• Carefully follow the directions and warnings for this and any optional support equipment

(chargers, rechargeable battery packs, etc.) that you use.

• Keep all chemicals, small parts and anything electrical out of the reach of children

• Moisture causes damage to electronics. Avoid water exposure to all equipment not specically

designed and protected for this purpose.

• Never lick or place any portion of your model in your mouth as it could cause serious injury

or even death.

Additional Required Equipment

No additional equipment is required to complete your Blade 400 3D.

Blade 400 3D Contents

Item Description

Not Available Separately Blade 400 3D RTF Airframe

SPM6600 Spektrum DX6i 2.4GHz DSM2 6-channel computer radio

EFLB18003S 3S 11.1V 1800mAh 20C Li-Po, 13GA EC3

EFLC3115 3S 11.1V Li-Po Balancing Charger, 1.8A

EFLH1001 Mini Helicopter Main Blade Holder

EFLH1474 Mounting Accessories, Screwdriver & Wrench Set

Not Available Separately Hook and Loop Material

Not Available Separately 4 AA Batteries

Page 5

8

9

Preparing for the First Flight Checklist

Please note this checklist is not intended to be a replacement for the content included in this instruction

manual. Although it can be used as a quick start guide, we strongly suggest reading through this

manual completely before proceeding.

r Remove and inspect contents

r Begin charging the flight battery

r Install the 4 included AA batteries in the transmitter

r Install the flight battery in the helicopter (once it has been fully charged)

q Test the controls

q Familiarize yourself with the controls

q Find a suitable area for flying

Flying Checklist

Please note this checklist is not intended to be a replacement for the content included in this instruction

manual. Although it can be used as a quick start guide, we strongly suggest reading through this

manual completely before proceeding.

q Always turn the transmitter on first

q Plug the flight battery into the electronic speed control (ESC)

q Allow the ESC and gyro to arm and initialize properly

q Fly the model

q Land the model

q Unplug the flight battery from the ESC

q Always turn the transmitter off last

Battery Warnings and Guidelines

While the 3S 11.1V 1800mAh Lithium Polymer Battery (EFLB18003S) included with your Blade 400

3D features Charge Protection Circuitry and Balance Charging via the included 3S 11.1V 1.8-Amp

Lithium Polymer Balancing Charger (EFLC3115) to help ensure a safe charge every time, you MUST

read the following safety instructions and warnings before handling, charging or using the Li-Po

battery.

Note: Lithium Polymer batteries are significantly more volatile than the alkaline, Ni-Cd or

Ni-MH batteries used in RC applications. All instructions and warnings must be followed

exactly. Mishandling of Li-Po batteries can result in fire.

By handling, charging or using the included Li-Po battery you assume all risks associated with

lithium batteries. If you do not agree with these conditions, return your complete Blade 400 3D

model in new, unused condition to the place of purchase immediately.

• You must charge the included 3S 11.1V 1800mAh Li-Po battery in a safe area away from

flammable materials.

• Do not charge the battery when installed in the helicopter.

• Never charge the battery unattended. When charging the battery you should always remain in

constant observation to monitor the charging process and react to potential problems that may

occur.

• After ight, the battery must be cooled to ambient temperature before charging.

• You MUST use the included 3S 11.1V 1.8-Amp Li-Po Balancing Charger ONLY. Failure to do so

may result in a re causing personal injury and/or property damage. DO NOT use a Ni-Cd or

Ni-MH charger.

• If at any time during the charge or discharge process the battery begins to balloon or swell,

discontinue charging or discharging immediately. Quickly and safely disconnect the battery,

then place it in a safe, open area away from flammable materials to observe it for at least 15

minutes. Continuing to charge or discharge a battery that has begun to balloon or swell can

result in a fire. A battery that has ballooned or swollen even a small amount must be removed

from service completely.

Page 6

10

11

• In the event of a crash, you must quickly and safely disconnect and remove the battery from the

model, then place it in a safe, open area away from flammable materials to observe it for at least

15 minutes.

• Store the battery at room temperature and approximately ½ charge (3.8V per cell; 11.4V for a

3S battery pack) for best results.

• When transporting or temporarily storing the battery, the temperature range should be from

40–120 degrees Fahrenheit. Do not store the battery or model in a car or direct sunlight

whenever possible. If stored in a hot car, the battery can be damaged or even catch fire.

• Do not over-discharge the battery. Discharging the battery too low can cause damage to the

battery resulting in reduced performance and duration.

Li-Po cells should not be discharged to below 3V each under load. In the case of the 3S 11.1V

Li-Po battery used for the Blade 400 3D, you will not want the voltage of the battery to fall

below 9V during flight.

The 25-amp brushless ESC installed on your Blade 400 model features a “soft” low voltage cutoff

(LVC) that occurs when the battery reaches 9V under load. When the soft cut-off occurs, the ESC

will automatically reduce power to the motor (regardless of the power level you have set with the

throttle stick/curve) in order to prevent the voltage of the battery from dropping to below 9V. After

the power is reduced and the voltage “rebounds” (rises) to above 9V, the ESC will automatically

return power to the motor until the battery reaches 9V again. This process will continue to repeat,

sometimes causing the motor/power to “pulse” rapidly, helping to provide a visual and/or audible

indication of the low battery voltage. However, in some cases it may be difficult to detect pulsing

of the motor/power, so we suggest that you be extremely aware of the power level of the Li-Po

battery during flight. If at any time the helicopter begins to require more throttle than typical to

maintain hover or flight, or has lost significant power, you must land the helicopter IMMEDIATELY

to prevent a sudden loss in power that could result in a crash.

Although the soft LVC of the ESC will help to prevent “deep” (below 9V; 3V per cell) over-

discharge of the battery, it is not recommended that you continue to run the motor for an extended

length of time after landing and/or noticing a loss of power. Routinely discharging the battery

to 9V can still cause permanent damage to the battery, resulting in shortened flight times, loss of

power output or failure of the battery entirely. It is recommended that you use the timer function of

the DX6i transmitter to keep the duration of each flight consistent and to prevent reaching the soft

LVC each time you fly.

Note: The timer of the DX6i transmitter included with your Blade 400 3D model has been

set for 4 minutes and 30 seconds. Although it is possible to achieve longer flight durations

safely depending on the performance of the battery, flying style of the pilot and other

factors, we suggest using this timer setting for the rst few ights. You can keep track of the

flight duration on subsequent flights and adjust the setting of the timer, as you prefer. Please

see the manual for the DX6i transmitter for more information regarding the timer function.

If you have any further questions or concerns regarding the handling, charging and/or use of the

included Li-Po battery pack, please contact Horizon Hobby’s Product Support staff

at 877-504-0233.

Battery Charging

It is important that you only charge the included 3S 11.1V 1800mAh Li-Po Battery (EFLB18003S)

with the included 3S 11.1V 1.8-Amp Li-Po Balancing Charger (EFLC3115). Your battery is equipped

with special Charge Protection Circuitry and Balance Charge Leads with connector that are only

compatible with this charger. Attempting to charge the battery using another Li-Po charger or non

Li-Po compatible charger could result in serious damage. Please familiarize yourself thoroughly with

the Battery Warnings and Guidelines section before continuing.

The included 3S 11.1V 1.8-Amp Li-Po Balancing Charger will charge a near fully discharged (not

over-discharged) 3S 11.1V 1800mAh Li-Po battery in approximately 1.2–1.5 hours. In some cases

the charge time may be shorter depending on the actual amount of capacity left in the battery after a

flight. NEVER charge the battery unattended.

Note: The Li-Po battery included with your Blade 400 3D will arrive partially charged. For this

reason the initial charge may only take approximately 30–50 minutes.

The charger requires up to 3-Amps of 11.5–15 Volt DC input power that can be supplied by the

optional AC to 12V DC, 3-Amp Power Supply (EFLC4030) for convenient charging anywhere an

AC outlet is available. NEVER attempt to power the charger from an AC outlet without the use of a

proper AC to DC adapter/power supply.

Page 7

12

13

Input power for the charger can also be supplied by a small 12V gel cell or car battery using the

included wire harness with alligator clips.

The charger is equipped with four LED indicators marked as CELL 1, CELL 2, CELL 3 and CHARGE

STATUS on the label. These LEDs indicate the following (also found on the label of the charger):

• Red Solid CELL STATUS LEDs and Red Flashing CHARGE STATUS LED: Input power connected,

battery to charge not connected

• Green Solid CELL Status LEDs and Red Solid CHARGE STATUS LED: Battery to charge connected

and charging, balance between cells OK

• Yellow Solid CELL STATUS LED and Red Solid CHARGE STATUS LED: Charging and balancing cell

with yellow LED

• Red Solid CELL STATUS LEDs and Red Solid CHARGE STATUS LED: Charge complete

• Red and Green Flashing CELL STATUS LEDs and Red Solid (or ashing) CHARGE STATUS LED:

Charge error

Use care to ensure proper polarity (as marked on the bottom of the charger case) when connecting

the charger to a power source. Once you have connected the charger to the power source, its CELL

STATUS LEDs will glow solid red and the CHARGE STATUS LED will flash to indicate the charger has

power and is ready to begin charging. Connect the Li-Po battery to the charger using the specially

marked Balance Charge Lead exiting the battery and the mating connector on the side of the charger

labeled with 11.1V. The balance connector is keyed to prevent reverse polarity connection.

Note: Be sure to place the battery and charger on a smooth, heat-resistant surface during charging.

When the battery is properly connected and charging normally, the CHARGE STATUS LED will glow

solid red and the CELL STATUS LED indicators will glow solid green when the voltage balance between

the cells is OK. If the CELL STATUS LED for any cell is glowing yellow while the CHARGE STATUS LED is

solid red, the indicated cell will be balanced (charged) so its voltage closely matches that of the other

two cells and the “full” charge voltage. Once the battery has been fully charged, the CELL STATUS and

CHARGE STATUS LEDs will glow solid red. The battery can now be removed from the charger and

installed in the Blade 400 3D for flight.

Page 8

14

15

Charge Errors and Indications

In the event that any CELL STATUS LED flashes red and green while the CHARGE STATUS LED glows

solid or flashes red, a charge error has occurred. Some examples of charge errors include:

• If any CELL STATUS LED ashes red and green while the CHARGE STATUS LED ashes red, the

voltage of the indicated cell(s) is below 2.5V. In this case the voltage of the indicated cell(s) is too low

to allow the charge process to begin.

If only one or two CELL STATUS LEDs flash red and green (while the CHARGE STATUS LED flashes

red), the balance connector connections for the indicated cell(s) may not be making good contact

with the charger’s mating connector. Be sure to double-check the connections to ensure they are

making good contact. If the connections are making good contact, the indicated cell(s) may have

failed or dropped to a voltage that no longer allows the battery to be charged safely.

In the event that all three CELL STATUS LEDs flash red and green (while the CHARGE STATUS LED

flashes red), the battery was likely overdischarged. Although the Electronic Speed Control (ESC)

installed on your Blade 400 3D model is programmed to help prevent deep overdischarge of the

Li-Po battery, you must exercise proper care of the battery if it is used in another application. You

must also be sure that the battery is never left plugged into the ESC for an extended period of time

after flying in order to prevent overdischarge.

Anytime one or more CELL STATUS LEDs flash red and green while the CHARGE STATUS LED

flashes red, you should remove the Li-Po battery from service and replace it with a new one.

• If any CELL STATUS LED ashes red and green while the CHARGE STATUS LED glows solid red, the

charge process for the indicated cell(s) has been interrupted. In this case, the balance connector

connections for the indicated cell(s) may not be making good contact with the charger’s mating

connector. Double-check the connections to ensure they are making good contact, and then begin

the charge process again.

If you have any further questions or concerns regarding charge error indications, please contact

Horizon Hobby’s Product Support staff at 877-504-0233

Installing the Transmitter Batteries

Install the 4 included AA batteries in the Spektrum DX6i transmitter. Check the power level of the

batteries and operation of the transmitter by switching the power switch on (to the right). The voltage

display on the LCD screen at the bottom of the transmitter will indicate the power level of the batteries.

If at any time the voltage of the batteries falls to 4.3V or less, an alarm will sound, and it will be

necessary to replace the batteries with new ones.

Page 9

16

17

Installing the Flight Battery

Use the included hook and loop material for mounting the Li-Po battery. We suggest installing the

“loop” (fuzzy) material on the battery and the “hook” material on the battery support located at the

front of the main frame. Install the hook and loop material on the battery so the main power wire

leads with the blue EC3 connector are oriented to the right side of the helicopter (when viewing the

helicopter from behind). This will help to keep the wire leads from interfering with the elevator servo on

the left side of the model.

Also, be sure that the battery is positioned so that it will not come into contact with the elevator servo

arm and the motor case. If the battery comes into contact with either of these components during flight,

it can result in damage to the battery, motor and/or servo, potentially resulting in a crash.

Once the battery has been properly positioned, fasten the hook and look strap around the battery for

added security.

Control Test

Although each Blade 400 3D model is control tested at the factory, it is a good idea to test the controls

prior to the first flight to ensure none of the servos, linkages or other parts were damaged during

shipping and handling. Before proceeding, disconnect the three bullet connectors between the motor

and ESC. It is not safe to perform the control test with the motor connected to the ESC.

Turn the transmitter on first and lower the throttle/collective (left-hand) stick completely.

Page 10

18

19

Then, plug the battery into the battery lead of the ESC.

Position the helicopter to view it from the left or right side. Move the left-hand stick up and down to

check the collective pitch control. When the stick is pushed up, the swashplate should lower, increasing

the pitch of the main blades.

With the stick pulled back down, the swashplate should raise, decreasing the pitch of the main blades.

Again viewing the helicopter from the left or right side, move the right-hand stick forward and aft to

check elevator pitch control. When the stick is pushed forward, the swashplate should also tilt forward.

With the stick pulled back, the swashplate will tilt toward the rear.

While viewing the helicopter from the rear (tail boom toward you), move the right-hand stick left and

right to check aileron roll control. When the stick is pushed to the left, the swashplate should also tilt

left.

With the stick pushed right, the swashplate will tilt to the right.

While viewing the helicopter from the rear (tail boom toward you), move the left-hand stick left and

right to check rudder/tail rotor pitch control. When the stick is pushed to the left, the tail pitch slider

should move to the right.

With the stick pushed right, the tail pitch slider should move to the left.

Page 11

20

21

If at any time during the test the swashplate controls do not respond properly, double-check the

swashplate mixing (SWASH MIX) settings in the transmitter (see the manual for the DX6i for more

information). The values should be set as follows:

AILE -75%

ELEV -75%

PITCH +85%

If the swashplate controls still do not respond properly after ensuring that the swashplate mixing values

are correct, or if the rudder/tail rotor pitch control is not responding properly, double-check the servo

reversing (REVERSE) settings in the transmitter (see the manual for the DX6i for more information).

They should be set as follows:

THRO – N (Normal)

AILE – R (Reverse)

ELEV – N (Normal)

RUDD – R (Reverse)

PITC – N (Normal)

If the controls still do not respond properly after ensuring the servo reversing switch positions are

correct, you may also check the servo connections to the receiver. The connection for each servo (when

viewing the helicopter from behind) should be connected to the receiver as follows:

AILE – Lower rear-mounted swashplate control “aileron” servo

ELEV – Forward-mounted swashplate control “elevator” servo

RUDD – Rear-mounted tail rotor pitch control “rudder” servo

AUX1 – Upper rear-mounted swashplate control “pitch” servo

Once you have confirmed proper swashplate mixing values, servo reversing settings and servo

connection locations, all controls should be functioning properly. However, if you continue to encounter

any problems relating to your Blade 400 3D responding properly to the transmitter, do not fly. Call

Horizon’s Product Support staff at 1-877-504-0233 before proceeding.

If you have confirmed proper control operation of your Blade 400 3D, unplug the flight battery from

the ESC and reconnect the three bullet connectors between the motor and ESC, taking care to connect

the like-color leads to one another (black to black, blue to blue and red to red) to ensure proper

operation of the motor.

Electronic Speed Control (ESC) Features, Arming and Motor Control Test

Your Blade 400 3D model is equipped with a 25-amp brushless ESC that is specifically designed for

use in helicopter models.

The ESC is not programmable for use in other applications, however, it is equipped with features and

functions that optimize its performance for the Blade 400. These features and functions include:

• “Soft” Low Voltage Cutoff

The ESC features a “soft” low voltage cutoff (LVC) that occurs when the battery reaches

approximately 9V under load. This helps to prevent “deep” overdischarge of the Li-Po battery

during use. Please see the Battery Warnings and Guidelines section for more information

regarding the soft LVC feature and how to prevent overdischarge of the Li-Po battery.

• Soft (Slow) Start

The soft (slow) start function of the ESC is intended to help prevent potential damage of the

geartrain, motor and ESC by softly (slowly) “ramping up” (increasing) power to the motor

(particularly when the rotor blades are not already spinning). The first time you “power up” the

ESC after it has been powered on and armed, it will take approximately 15 seconds for the ESC/

motor to reach the power level you initially set with the throttle stick/curve. This means you will

need to wait approximately 15 seconds before attempting any aggressive maneuvering as you

should allow the power system to reach the set level of power first.

Any time (after the initial soft startup occurs) the ESC/motor have been powered down

completely (to 0% power) for approximately 15 seconds or more, the soft start will occur again.

This is particularly helpful if you land the helicopter to make an adjustment as you will not need

to re-arm the ESC in order to perform a soft startup. It is simply best to wait approximately 15

seconds before powering up the ESC/motor again for flight.

• Fast Start

The fast start function of the ESC is intended to allow any level of power to be applied almost

immediately after ESC/motor have been powered down completely (to 0% power) for any

amount of time less than approximately 15 seconds. This is particularly helpful if you accidentally

bump the Throttle Hold switch or when aborting an auto-rotation attempt as it will allow the

ESC/motor to reach any power level you have set with the throttle stick/curve almost immediately

when the Throttle Hold switch is set back to the OFF (0) position.

The following checklist includes the steps you must follow to ensure proper arming and operation of the

ESC (as well as proper operating direction of the motor and rotor blades):

q Each time before you fly you must ALWAYS turn on the transmitter power first before connecting

the flight battery to the ESC. Never connect the flight battery to the ESC before powering on

the transmitter first. After each flight, be sure that you never turn off the transmitter before

disconnecting the flight battery from the ESC first.

Note: The antennas exiting the Spektrum AR6100e receiver should extend outward (to the

left and right of the helicopter) as much as possible for the best overall performance. Be sure

to double-check the position and orientation of both antennas before each flying session,

especially if the helicopter was taken out of a box or carrying case.

q The throttle (left-hand) stick MUST be in the lowest possible position, with the throttle trim set in

approximately the middle position, in order for the ESC to arm. Also, the Flight Mode (F MODE)

switch must be in the “Normal” (0) position with the switch toggled toward the back of the

transmitter. The Throttle Hold (TH HOLD) switch should be set in the “Off” (0) position, however,

the ESC will still arm if the switch is set in the “On” (1) position and the “Hold” throttle curve

values are all set to 0%.

Note: In some cases it may be possible to arm the ESC with the throttle stick set to a position

that is higher than the lowest possible position. While the ESC may still function in this

situation, it is best to re-arm the ESC with the throttle stick in the lowest possible position in

order to ensure the best performance of the ESC overall.

Page 12

22

23

q After confirming that the transmitter has been turned on and has an adequate level of battery

power (as displayed on the LCD screen at the bottom of the transmitter), and that the throttle stick

is in the lowest possible position, it is now safe to connect the flight battery to the ESC.

q With battery power applied, you will hear two “beeps” once the ESC has armed properly. Use

caution as the motor, main rotor and tail rotor blades will now run with throttle stick input. For

safety, we suggest setting the Throttle Hold (TH HOLD) switch in the “On” (1) position once the

ESC has armed. This will keep the motor and rotor blades from running while you handle the

helicopter and transmitter (as long as the throttle curve values for the “Hold” flight mode are all

set to 0%, as they are from the factory).

If you have not set the Throttle Hold switch to the “On” position, or after you set the switch to the

“Off” (0) position, DO NOT advance the throttle stick until you are clear of the rotor blades.

Note: If you do not hear two beeps after battery power is applied, the ESC has not armed properly.

Please review the following:

q Confirm that the throttle stick is in the lowest possible position and that the throttle trim is set in

approximately the middle position.

q Confirm that the Flight Mode (F MODE) switch is set to the “Normal” (0) position.

q Confirm that the low (L) position (POS) value for the normal (NORM) throttle curve (THRO CUR)

is set to 0%.

q Conrm that the travel adjustment (TRAVEL ADJ) value for the throttle (THRO) channel is set to

100% in the low position.

If the ESC will not arm after confirming the details listed above, contact Horizon Hobby’s Product

Support staff at 1-877-504-0233 before proceeding.

q Once you have placed the helicopter in a safe area, free of obstructions, and are clear of the

rotor blades, you can safely begin to power up the model to confirm proper operation and

operating direction of the motor and rotor blades.

q Advance the throttle stick slowly, just until the motor and rotor blades begin to spin. Note the

direction that the main and tail rotor blades spin. The main rotor blades should spin clockwise

when viewed from the top, and the tail rotor blades should spin counterclockwise when viewed

from the right-hand side of the helicopter. If both sets of rotor blades are operating in the wrong

direction, power down the helicopter, unplug the flight battery, then simply reverse the position of

any two motor wire lead connections to the ESC.

Note: If the main rotor blades are operating in the correct direction but the tail rotor blades

are not, the belt driving the tail rotor may be “twisted” in the wrong direction. To correct this,

remove the tail rotor case and parts from the tail boom and pull the belt “straight” (so it is

horizontal and has no twists). Then, rotate the belt 90 degrees clockwise when viewing the

helicopter from behind.

Reinstall the tail rotor case and other parts, then, double check proper operating direction of the

tail rotor blades by spinning the main rotor blades in the clockwise direction (when viewed from the

top) by hand. The tail rotor blades should now spin counterclockwise (when viewed from the righthand side of the helicopter).

q After confirming that both sets of rotor blades are operating in the correct directions, please be

sure to review the following sections of the manual BEFORE proceeding with the first flight.

Gyro Initialization, Response Test and Adjustment

Your Blade 400 3D model is equipped with an E-flite G110 Micro Heading Lock Gyro. This gyro offers

an excellent blend of size, weight, features and performance.

Set throttle stick in

lowest position

Page 13

24

25

Initialization and Response Test

The following checklist includes the steps you must follow to ensure proper initialization and

operation of the gyro:

q After connecting the flight batter y to the ESC, be sure that you do not move or sway the

helicopter. Allow it to remain motionless until the red LED on the gyro illuminates solidly,

indicating that the gyro has initialized properly and is ready for use.

Note: It is extremely important that you do not move or sway the helicopter

after powering it on and before the gyro initializes. The gyro must be allowed

adequate time to record the neutral position in order to initialize for proper

operation. If you accidentally move the helicopter after powering it on and before

the gyro initializes, power the helicopter off (by disconnecting the flight battery

from the ESC) then repeat the process to power the helicopter on and to initialize

the gyro properly.

q Once the gyro has initialized properly, we suggest setting the Throttle Hold (TH HOLD) switch

to the “On” (1) position for added safety during the response test.

q Before making your first flight, it will be necessary to confirm that the gyro is responding

properly to the movements of the helicopter and providing proper inputs to the tail servo in

order to counteract any unwanted changes in yaw. To do this, view the servo arm (from the

top of the servo) and note the direction the arm rotates when you give a right rudder input on

the transmitter (while the model remains motionless). In the case of the DS75H servo installed

on your Blade 400 model, the servo arm should rotate toward the front of the helicopter.

Then, yaw the nose of the helicopter quickly to the left, while again noting the direction

the tail servo arm rotates. The arm should rotate in the same direction as it did for a right

rudder command (toward the front of the helicopter). If the servo arm rotates in the opposite

direction, switch the position of the Reverse switch located on the side of the gyro. The switch

should be set to the Normal (NOR) position. Then, repeat the steps above to confirm that the

gyro is now providing proper inputs to the tail servo.

q After confirming that the gyro is providing proper inputs to the tail servo, power off the helicopter

and be sure to review the following sections of the manual BEFORE proceeding with the first

flight.

Gyro Mode and Gain Adjustments:

• The G110 offers a Dual Remote Gain Adjustment feature. This, along with the DX6i’s Gyro

Sensitivity feature, allows the gyro mode (Standard Rate or Heading Lock) and gain values to

be set remotely in the transmitter. This means that the Gain Setting Adjustment Pot located on the

gyro itself will not be active and will not be used for adjusting gain values.

• The gain values for the gyro are adjusted in the Gyro Sensitivity (GYRO) menu of the transmitter.

And because the switch (SW) selection choice has been set to the Gyro (GYRO) switch, the two

available gain values can be selected using this switch during flight. When the Gyro switch is

toggled in the upward (0) position, the gain value will be equivalent to the Rate (RATE) set on the

first (0:) line. When the Gyro switch is toggled in the downward (1) position, the gain value will

be equivalent to the Rate (RATE) set on the second (1:) line. Please see the manual for the DX6i for

any additional information you may require.

• When the Rate for either Gyro switch position is set to 0%, it is equivalent to an approximately

100% gain value in the Standard Rate (non-Heading Lock) mode.

When the Rate for either Gyro switch position is set to 25%, it is equivalent to an approximately

50% gain value in the Standard Rate (non-Heading Lock) mode.

When the Rate for either Gyro switch position is set to 50%, it is equivalent to an approximately

0% gain value in the Standard Rate (non-Heading Lock) mode.

• When the Rate for either Gyro switch position is set to 75%, it is equivalent to an approximately

50% gain value in the Heading Lock mode.

When the Rate for either Gyro switch position is set to 100%, it is equivalent to an approximately

100% gain value in the Heading Lock mode.

In the case of the Blade 400 3D, it is generally preferred to fly with the gyro set to the Heading

Lock mode. This means that the Rate for either Gyro switch position should not typically be set to

below approximately 60% (an approximately 20% gain value in the Heading Lock mode).

• While you can set and select between two different Modes and Rates using the Gyro switch,

two slightly different Rates have been set for the same Mode (Heading Lock) from the factory.

The Rate/value is slightly higher when the Gyro switch is set in the upward (0) position than it

is in the downward (1) position. After your first few flights you can experiment with different

values in each position to find the values that work best depending on your flying style and

flying conditions. For example, it may be desirable to use a higher gain value when flying in the

Normal flight mode, and/or a lower gain value when flying in windy conditions. The DX6i also

allows you the option to set gain values for each specific flight mode. This can be accomplished

by setting the gyro switch (SW) selection to Flight Mode (F. MODE) (please see the manual for the

DX6i for more information.)

• During your rst ight, establish a stable hover and apply some short and quick rudder inputs

while observing the reaction of the tail when the control stick is returned to its neutral position. If

there is any tendency for the tail to twitch quickly (oscillate) from side to side, it will be necessary

to lower the Rate used for the selected Gyro switch position.

The goal when adjusting the Rate for one or both of the Gyro switch positions is to nd the highest

gyro gain value (Rate) at which the tail of the helicopter will not oscillate in nearly all areas of

flight, including fast forward flight and descents. In some cases it may not be possible to use

the same Rate for hovering (in the Normal flight mode for example) and fast forward flight/

aerobatics (in the Stunt flight mode for example). By setting two different Rates for each Gyro

switch position, it will allow you to select the best Rate (using the Gyro switch) depending on the

flight mode you are using and the type of flying you are doing at any given time. This can be

particularly helpful when flying in windy conditions, as it may sometimes be necessary to switch to

a lower Rate in flight to prevent significant tail oscillation when performing certain maneuvers.

Trim Adjustments

• During ight, it may be necessary to make some small adjustments to the rudder trim in order to

prevent the nose/tail of the model from “drifting” to the left or right when the rudder stick is in the

neutral position. Typically, only a small amount of adjustment may be necessary.

Note: It is always best to avoid sudden temperature and environmental condition changes

when using a gyro. For example, it is best to not fly a model on a very hot (or cold) day

immediately after removing it from an air-conditioned (or heated) vehicle. It is also best to keep

the gyro out of direct sunlight and away from any heat-generating sources on the model.

To help the gyro better acclimate to temperature and environmental conditions at the flying field,

it is best to let your Blade 400 3D model stand for approximately 10–15 minutes before flying,

allowing the temperature of the gyro sensor to stabilize. If you do not allow the temperature to

stabilize, you may experience radical trim changes that require signicant adjustments of the

rudder trim during flight.

Page 14

26

27

Servo Mode Setting

• The G110 is equipped with a switch and software that allows its performance to be optimized for

use with most analog and some digital servos. The Servo Mode selection switch can be found on

the side of the gyro.

• When the Servo Mode selection switch is set in the Standard (STD) position, the gyro is optimized

for use with most analog servos. It is also optimized for use with digital servos that are not

designed to accept a pulse rate of 275Hz or higher. And although the DS75H rudder/tail servo

installed on your Blade 400 3D model is a digital servo, it is not designed to accept a pulse

rate of 275Hz. As a result, you must be certain that the Servo Mode selection switch is set to

the Standard position when the DS75H servo is being used.

Note: Do not use analog or digital servos that are not designed to accept a pulse rate of 275Hz

with the Servo Mode selection switch set to the Digital Servo (DS) position. If either type of ser vo

is used with the gyro set to the Digital Servo mode, it will reduce the operating life of the servo,

typically causing the servo to fail within a few minutes of use or after a few flights.

• When the Servo Mode selection switch is set in the Digital Servo (DS) position, the gyro is

optimized for use with digital servos that are designed to accept a pulse rate of 275Hz. Some

such servos include the Spektrum DSP60 and DSP75, as well as the JR 3400G. Again, although

the DS75H tail servo installed on your model is a digital servo, it is not designed to accept a pulse

rate of 275Hz. Be certain that the Servo Mode selection switch is set to the Standard position

when the DS75H servo is being used.

Understanding the Primary Flight Controls

If you are not familiar with the primary flight controls of your Blade 400 3D, please take a few minutes

to familiarize yourself with them before proceeding and before attempting your first flight.

The left-hand stick on the transmitter controls both throttle/collective pitch (climb/descend) and

rudder (yaw left/right). When the left-hand stick is in the lowest position and the throttle trim is set to

approximately the middle position, the motor and rotor blades will not spin (when in the Normal or

Throttle Hold flight mode). Advancing the stick upward will increase the speed and pitch of the main

rotor blades. Increasing the speed and pitch of the main rotor blades will cause the model to climb.

Decreasing the speed and pitch of the main rotor blades by lowering the left-hand stick will cause the

model to descend.

Note: When you are in the Stunt/Idle Up flight mode, lowering the left-hand stick will actually

cause the speed of the main rotor blades to increase while also increasing the amount of negative

pitch the main rotor blades can offer. This allows the model to be flown inverted and to perform

aerobatics like loops, rolls and 3D flying.

After lifting the model off the ground you can balance the throttle/collective pitch by carefully moving

the left-hand stick up and down so that the model will hold a stationary hover without climbing or

descending.

Also, in most cases it will not be necessary to adjust the throttle trim from the middle position for any

reason.

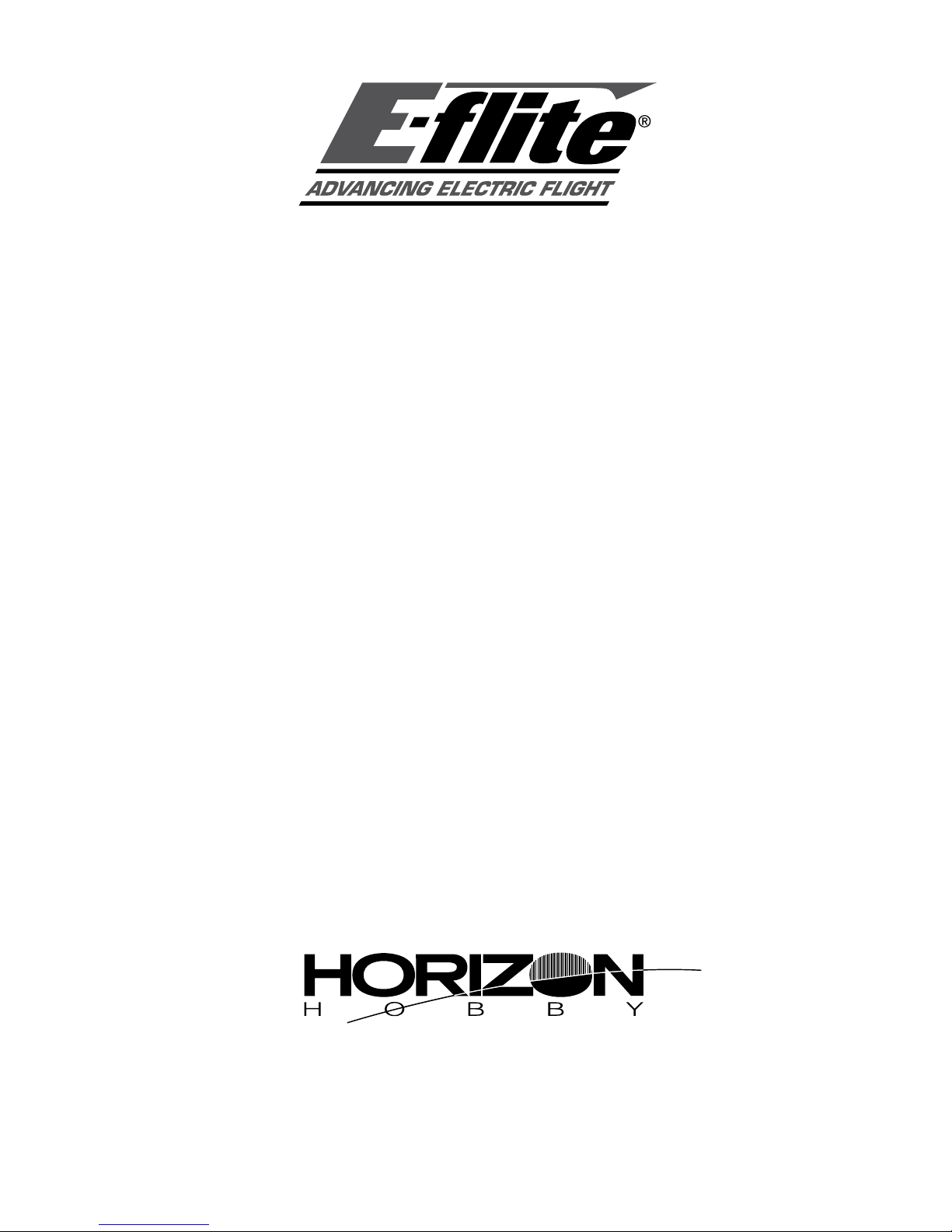

Climb

Throttle

Trim

Decend

Page 15

28

29

Moving the left-hand stick to the left will turn (yaw) the nose of the helicopter to the left about the axis

of the main shaft. This is accomplished by changing the pitch of the tail rotor blades.

Moving the stick to the right will turn (yaw) the nose of the helicopter to the to the right about the axis

of the main shaft.

The rudder trim can be used to help keep the nose of the helicopter from rotating to the left or right

when in hover with no rudder stick input. For example, if the nose of the helicopter drifts to the right

when in hover, click the rudder trim lever to the left until the nose stays as close to straight as possible.

The right-hand stick controls both elevator (pitch fore/aft) and aileron (roll). Pushing the stick forward

will pitch the nose of the helicopter downward, allowing the helicopter to be flown forward and to

perform forward flips.

Pulling the stick backward will pitch the tail of the helicopter downward, allowing the helicopter to be

flown backward and to perform backward flips.

The elevator trim can be used to help keep the helicopter from drifting forward or backward when in

hover with no elevator stick input. For example, if the helicopter drifts forward when in hover, click the

elevator trim lever downward until the helicopter hovers as level as possible with no forward drifting.

Moving the stick to the left will roll the helicopter to the left, allowing the helicopter to be flown to the

left and to perform left-hand rolls.

Moving the stick to the right will roll the helicopter to the right, allowing the helicopter to be flown to

the right and to perform right-hand rolls.

The aileron trim can be used to help keep the helicopter from drifting left or right when in hover with

no aileron stick input. For example, if the helicopter drifts to the right when in hover, click the aileron

trim lever to the left until the helicopter hovers as level as possible with no drifting to the right.

Once you have become familiar with the primary controls of the helicopter, you are almost

ready to fly.

Elevator

Trim

Helicopter moves

forward

Nose Yaws

Right

Rudder

Trim

Nose Yaws

Left

Helicopter moves

backward

Aileron

Trim

Helicopter Moves

Left

Helicopter Moves

Right

Page 16

30

31

Normal and Stunt Flight Modes

The Spektrum DX6i transmitter included with your Blade 400 3D features a Flight Mode (F. MODE)

switch. This switch allows the pilot to toggle between the “Normal” (0) and “Stunt/Idle Up” (1) flight

modes during flight.

When the Flight Mode switch is toggled toward the rear of the transmitter (position 0), the Blade 400

3D will be in the Normal (NORM) flight mode. In this flight mode, the throttle curve is linear from 0%

to 100%, with a pitch range of approximately -3 degrees (35%) to +10 degrees (100%). This is the

preferred flight mode for general hovering and basic (non-aerobatic) flight.

When the Flight Mode switch is toggled toward the front of the transmitter (position 1), the Blade 400

3D will be in the Stunt/Idle Up (STUNT) flight mode. In this flight mode, the throttle curve is “V” shaped

from 100% to 100% with 85% throttle at mid-stick, with a pitch range of -10 (0%) to +10 degrees

(100%). This is the preferred flight mode for most forward/backward, aerobatic and 3D flying.

Note: When in the Stunt flight mode, even with the throttle stick pulled all the way down to its

lowest possible position, the motor and rotor blades will continue to spin aggressively. You must

use the Normal flight mode (or Throttle Hold) to safely power down the motor and rotor blades. For

added safety, the ESC will not arm if the flight battery is plugged in and the flight mode switch is set

to the Stunt position.

When switching between the Normal and Stunt flight modes, it is typically best to do so in the air while

hovering. The throttle and pitch curves of each flight mode have been optimized to transition smoothly

around hover.

Note: Although the midpoint (point 3) of the throttle curve in the Stunt flight mode has been factoryset to 85% to provide good overall sport and 3D aerobatic performance, this value (as well as the

values for points 2 and 4) can easily be adjusted to better suit the pilot’s preference. Pilots new to

this class of model, or those that may not require the most aggressive performance, may prefer to

reduce the value of the midpoint to approximately 70%. This will reduce the headspeed in upright

and inverted hover, as well as at mid-stick, often times helping to make it easier (smoother) and less

intimidating to fly the model. However, if you reduce the value of the midpoint (point 3), it will also

be necessary to adjust the values of points 2 and 4 in order to achieve the best performance. In

F. MODE Switch

THROTTLE CURVE

STICK POSITION

Low Half High

100%

50%

85%

0%

108&3

065165

PITCH CURVE

STICK POSITION

Low Half High

+10°

0°

-10°

-3°

1*5$)

3"/(&

THROTTLE CURVE

STICK POSITION

Low Half High

100%

50%

0%

108&3

065165

PITCH CURVE

STICK POSITION

Low Half High

+10°

0°

-10°

1*5$)

3"/(&

Page 17

32

33

general, it is usually preferred to simply “split the difference” between the values of the lowest point

(point L) and the midpoint (point 3), as well as the highest point (point H) and the midpoint. For

example, if the lowest and highest points are set to 100%, and the midpoint is set to 70%, points 2

and 4 should be set to 85%.

Pilots interested in the most aggressive performance for added cyclic and collective pitch response

may prefer to increase the value of the midpoint (as well as the values for points 2 and 4 as

necessary). Please see the manual for the DX6i for more information on throttle curve settings

and adjustments.

Throttle Hold

The Spektrum DX6i transmitter also features a Throttle Hold (TH HOLD) switch. This switch allows the

pilot to toggle between the Throttle Hold “Off” (0) and Throttle Hold “On” (1).

When the Throttle Hold switch is toggled toward the rear of the transmitter (position 0), Throttle Hold

will be “Off.” When Throttle Hold is off, the transmitter will be in the Normal or Stunt flight mode

(depending on the position in which the F MODE switch is set).

When the Throttle Hold switch is toggled toward the front of the transmitter (position 1), Throttle Hold

will be “On” (activated). When Throttle Hold is on, the helicopter will be in the Throttle Hold (HOLD)

flight mode. In this flight mode, the throttle curve is linear from 0% to 0%. In the case of an electricpowered model like the Blade 400, this will power down the ESC/motor completely. And, because

the pitch range in this flight mode is approximately -3 degrees (35%) to +10 degrees (100%), it also

allows you to perform auto-rotations during flight if you choose.

Toggling the Throttle Hold switch to the on position also allows you to safely power down the ESC/

motor any time the helicopter is not flying. This is particularly helpful as it allows you to safely handle

the helicopter, while the ESC is still armed, regardless of the throttle/collective stick and Flight Mode

switch positions.

Note: If the Throttle Hold switch is in the on position, and the throttle/collective stick set to anything

above the lowest possible position with the Flight Mode switch set to the Normal position, the ESC/

motor will power up as soon as the Throttle Hold switch is set to the off position. This is also the

case regardless of the throttle/collective stick position when the Flight Mode switch is set to the Stunt

position. You must exercise extreme care and caution when switching the Throttle Hold switch to the

off position. You should always be in the Normal ight mode and have the throttle/collective stick

set to the lowest possible position BEFORE switching Throttle Hold off.

TH HOLD Switch

THROTTLE CURVE

STICK POSITION

Low Half High

100%

50%

0%

108&3

065165

PITCH CURVE

STICK POSITION

Low Half High

+10°

0°

-10°

-3°

1*5$)

3"/(&

Page 18

34

35

Before the First Flight

Although each Blade 400 3D model is factory assembled and tested, you should check the following

before making your first flight:

q Check the security of all screws and control/linkage balls on your model. Tighten any screws and

control/linkage balls that may be loose and replace any screws, control/linkage balls or other

parts that may be stripped.

q Check to be sure that the screws securing the main and tail rotor blades in the blade grips are

tightened so that the blades can pivot in the grips when moderate pressure is applied.

q Check the security of all the plastic ball link ends on your model. The links should stay attached

to the control/linkage balls even when moderate force is applied. Any link that does not stay

attached to the control/linkage ball should be replaced before flight.

q Check to be sure that all electronic equipment and wire leads are secure and will not come into

contact with any moving parts.

q Check for proper tail rotor drive belt tension. Proper belt tension plays a critical role in achieving

maximum performance and reliability of your model.

If the belt tension is set too tight, it can result in a loss of power while also causing the belt and/

or pulleys to wear more quickly.

If the belt tension is set too loose, the belt can skip and strip teeth from the belt and/or pulleys. It

can also result in a loss of tail rotor performance and control in flight.

You can check the tension of the tail rotor drive belt by using an Allen/hex wrench (or any other

suitable tool/device) to compress the belt through the opening in the main frame and tail boom located

on the right side of the model. Apply light pressure to the exposed side of the belt, compressing it

toward the other side of the belt. The belt tension is set properly if the compressed side of the belt

reaches approximately ½ of the way to the other side of the belt.

If the compressed side of the belt reaches more than ½ of the way to the other side of the belt, the

tension is set too loose. If it is difficult to compress the exposed side of the belt, or if it does not reach

approximately ½ of the way to the other side of the belt, the tension is set too tight.

You can adjust the belt tension by loosening the two screws that mount the horizontal stabilizer and the

four screws that hold the rear section of the main frame together around the tail boom. After loosening

these six screws, slide the boom further into the frame (to loosen belt tension) or farther out of the

frame (to tighten belt tension). After properly adjusting the tail drive belt tension, be sure to retighten

all six screws while also confirming proper alignment of the horizontal stabilizer and tail rotor shaft

(both should be level/horizontal and perpendicular to the main shaft when viewed from behind the

model).

q If this is the first test flight, or a test flight following repairs, you will also want to center the rudder,

aileron and elevator trims.

Your Blade 400 3D is now ready for flight.

Choosing a Flying Area

When you are ready for your first flight, you will want to select a large, open area that is free of

people and obstructions. Until you have properly trimmed, adjusted and become familiar with the

handling of the Blade 400 3D, we suggest that your first and subsequent test flights be made outdoors

in low-wind conditions only.

While it is possible for the Blade 400 3D to be flown indoors, we suggest that it only be in a very large

indoor facility such as a gym (with proper approval) that is also free of people and obstructions. The

Blade 400 3D is not intended to be flown in small indoor areas or facilities where it may be possible to

fly a micro coaxial helicopter like the Blade CX or Blade CX2, or a micro collective pitch helicopter like

the Blade CP+ or Blade CP Pro.

Flying the Blade 400 3D

Having followed the proper ESC and gyro arming and initialization procedures, confirmed proper

control of the servos and motor, and found a suitable flying area, your Blade 400 3D is ready for

flight.

• Slowly raise the throttle/collective pitch (left-hand) stick, increasing the speed of the main rotor

blades until the model begins to lift off. Do not raise the throttle stick too quickly as the model could

climb too fast causing you to lose control or make contact with objects above.

• Lift the model off the ground just a few inches and concentrate on balancing the throttle stick position

so that the model holds a steady hover altitude. In some cases it may be best to make a few short

“hops” to an altitude of just a few inches until you become familiar with the control inputs and trim

settings required to maintain a steady hover and altitude.

Page 19

36

37

As you will nd, the Blade 400 3D requires minor throttle/collective pitch adjustments to maintain its

altitude in hover. Remember to keep these adjustments as minimal as possible as large adjustments

could result in a loss of control and/or a possible crash.

• While attempting to establish a low-level hover, you can also check to see if any trim adjustments

are required to help keep the Blade 400 3D from constantly drifting in various directions. If you find

the helicopter constantly drifts without any directional control input, it will be best to land the model

before making any adjustments to the trim levers. Additional details regarding the location and

function of the trim levers can be found in the “Understanding the Primary Flight Controls” section of

this manual.

If the nose of the helicopter is drifting to the left or right, you will need to adjust the rudder trim.

If the helicopter is drifting forward or backward, you will need to adjust the elevator trim.

If the helicopter is drifting to the left or right, you will need to adjust the aileron trim.

Continue to make trim adjustments until the helicopter can hover at a low altitude with very little

drifting and directional control input.

• Once you have the Blade 400 3D properly trimmed and maintaining a stable low-level hover,

practice using the rudder, elevator and aileron controls to get a feel for how the helicopter responds

to control inputs. Remember to keep the control inputs as minimal as possible to prevent overcontrolling the helicopter, especially when in hover.

• After becoming comfortable with hovering the Blade 400 3D at low-levels of altitude just a few

inches off the ground, you can transition to hovering and flying the helicopter at higher altitudes of

approximately three to four feet. At these higher altitudes you will be able to get a feel for the flight

characteristics of the Blade 400 3D when it is flying out of “ground effect.”

• If at any time during ight you feel like the helicopter is driting out of control, it is best to return all

controls to neutral and to lower the throttle stick completely or activate Throttle Hold. This will help

reduce the amount of damage that may be caused in the event of a crash.

Failure to lower the throttle stick to the lowest possible position (in the Normal Flight mode only) or to

activate Throttle Hold (in any flight mode) in the event of a crash could result in damage to the ESC.

While the ESC is readily capable of handling all in-flight power loads, and even brief momentary

bursts beyond these typical loads, it can be damaged if an excessive amount of current is pulled

through it for an extended period of time. This period of time may vary depending on conditions, so it

is best to keep any momentary overloads as short as possible in order to prevent damage to the ESC.

Note: Crash damage is not covered under warranty.

• It is extremely important when hovering and ying the Blade 400 3D to be aware of the power level

of the Li-Po battery pack. If at any time the helicopter begins to require more throttle than typical to

maintain hover or flight or has lost significant power, you must land the helicopter IMMEDIATELY to

prevent a sudden loss in power that could result in a crash.

Main Rotor Blade Tracking Adjustment

Caution: Be sure to maintain a safe distance from the helicopter (10–15 feet) when tracking the

main rotor blades.

Blade tracking is a critical element to the ight performance of just about any helicopter, including

the Blade 400 3D. Main rotor blades that are out of track may cause vibration, instability, and loss

of power due to increased drag. Although the main rotor blades of each Blade 400 3D model are

tracked at the factory, minor adjustments to blade tracking may be required after blade changes,

linkage adjustments or repairs.

To check main rotor blade tracking and make any required adjustments, please note the following tips:

• Before proceeding with the test ight of a new model, or any model to which changes or repairs

have been made, be certain that the main rotor blades have been properly installed and secured.

The main rotor blade mounting bolts should be tightened so the blades can pivot in the blade grip

when moderate pressure is applied. Never allow the main rotor blades to swing freely in their grips.

• After powering the model on and allowing the ESC and gyro to properly arm and initialize, bring

the main rotor blades of your Blade 400 3D up to speed. You can check the blade tracking either on

the ground or in the air at approximately eye level. It might be a good idea to have an assistant on

hand to help sight the blades. Again, be certain to maintain a safe distance of 10–15 feet from the

helicopter when checking the tracking of the main rotor blades.

• Once the main rotor blades have been brought up to speed, note which blade is running low and

which blade is running high (by the colored tracking tape).

Blades Out of

Track —Adjustment

Necessary

Page 20

38

39

• After conrming which blade is running low and which blade is running high, power down the

helicopter in order to make any necessary adjustments to the linkages. You can increase the pitch of

the low blade by shortening the “mixing arm to inner swashplate linkage.” This is accomplished by

turning one of the Ball Link ends in by one-half to one full turn at a time. Or, you can decrease the

pitch of the high blade by lengthening the same linkage.

Note: The blade you choose to raise or lower when making tracking adjustments will depend on

the pitch of each blade. Because both rotor blades should be as close to 0 degrees as possible

when Throttle Hold is activated (DO NOT attempt to check for 0 pitch in the Normal or Stunt/Idle

Up flight modes) and the throttle/collective stick is in the middle position, you can easily identify

which rotor blade to adjust. If one blade is “lower” than 0 degrees, raise it to match the other

blade. If one blade is “higher” than 0 degrees, lower it to match the other blade.

Typically, not much adjustment should be necessary to properly track the main rotor blades. If

signicant adjustments are required, be sure to double-check the length of both mixing arm to inner