EFCO Sliding Glass Door User Manual

Sliding glass door Series 3000, 3001, 3014, 3015, 3005

Installation Instructions

Part NO. YW41

February 2013

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Page

I.Sliding Glass Door General Overview

A. |

General Notes |

3 |

B. |

Construction Notes |

4 |

C. |

Building Codes |

5 |

D. |

General Sliding Glass Door Frame Installation |

5 |

E. |

Perimeter Anchorage |

7 |

F. |

General Sliding Panel Inspection |

8 |

II.Basic Sliding Glass Door Installation

A. |

Installation Without Subframe |

9 |

B. |

Installation With Subframe |

12 |

III.Series Specific Assembly Instructions

A. |

S-2000/3000 |

17 |

B. |

S-3001/3000 Modified |

25 |

C. |

S-3015 |

33 |

D. |

S-3014 |

42 |

E. |

S-3005 |

51 |

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and relative humidity and exterior temperature) are present. When the formation of excessive condensation is a concern, it is highly recommended that a design professional is utilized to perform an analysis of the shop drawings to recommend the best possible installation methods. Please contact your EFCO representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of condensation. Though not all inclusive, the list of examples below illustrates conditions under which condensation is likely to occur:

1.Bridging system thermal break with non-thermally broken metal flashing or lintels that are exposed to the exterior

2.System exposure to cold air cavities

3.Interior relative humidity levels not maintained at recommended levels, see EFCO’s “Understanding Condensation” brochure

4.Inadequate separation between system and surrounding condition at perimeter

5.Product combinations during the shop drawing stage that result in bridging thermal breaks

of one or all products involved

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 2 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

These recommendations are for general erection procedures only. For actual job conditions, see the details on the shop drawings. For perimeter anchor type and spacing, refer to the approved shop drawings or consult the project design professional.

SECTION I: Sliding Glass Door General Overview

Sliding Glass Doors are disassembled products and must be protected against damage. The following procedures and precautions are recommended:

A.General Notes

1.Protection and Storage

a.Handle the material carefully.

b.To avoid racking or damage to glazed panels and all Sliding Glass Door components and accessories, do not drop or drag from the truck.

c.Stack the Sliding Glass Door panels with the directional arrows in the proper position to allow adequate separation so the door panels will not rub together.

d.Store the Sliding Glass Door panels and accessories off the ground (i.e., pallets, planks, etc.).

e.Protect against the elements and other construction trades by using a well ventilated covering.

f.Remove material from packaging if it becomes wet. Then repack materials and move to dry location.

g.Sliding Glass Doors are not to be used as ladders, scaffolds, or scaffold supports.

2.Check Materials

a.Check all the material upon arrival for quantity and damage. Any visibly damaged material must be noted on the freight bill at the time of receipt. If a claim is required, the receiving party must process a claim with the freight carrier. If the delivery is by an EFCO truck, any damage or variance in the quantity of window units or boxes must be reported to the EFCO driver during the unloading process.

3.Cleaning Door Units

a.Cement, plaster, terrazzo, alkaline, and acid based materials used to clean masonry are very harmful to finishes and should be removed with water and mild soap immediately; otherwise, permanent staining will occur. A spot test is recommended before any cleaning agent is used.

b.For cleaning of anodized aluminum surfaces, refer to AAMA 609-93 Voluntary Guide Specification for Cleaning and Maintenance of Architectural Anodized Aluminum.

c.For cleaning of painted aluminum surfaces, refer to AAMA 610.1-1979 Voluntary Guide Specification for Cleaning and Maintenance of Painted Aluminum Extrusions and Curtain Wall Panels.

Please note: The prolonged application of masking tape, duct tape, and similar products to painted aluminum surfaces will induce permanent bonding of the tape to the paint. This will cause adhesion failure between the paint and the aluminum surface when the tape is removed.

d.If a protective coating is specified, remove it in areas that require field-applied sealant prior to installation.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 3 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

B.Construction Notes

1.Reference Shop Drawings

a.Check the shop drawings and installation instructions to become thoroughly familiar with the project. The shop drawings take precedence and include specific details for the project. The installation instructions are general in nature and cover most common conditions.

2.Check Openings

a.Make certain that construction, which will receive the material, is in accordance with the contract documents. If not, notify the general contractor in writing and resolve differences before proceeding with your work.

3.Benchmark Layout

a.All work should start from benchmarks and/or column center lines as established by the architectural drawings and the general contractor.

4.Plumb/Level/True

a.All materials are to be installed plumb, level, true, and in proper alignment and relation to established lines and grades. Products are to be installed maintaining tolerances of 1/8” in 12’-0” of length.

5.Isolate Aluminum

a.Isolate aluminum that directly contacts masonry or incompatible materials with a heavy coat of zinc chromate, plastic isolators, or bituminous paint.

6.Poured and Debridged and Thermal Strut Sections

a.Do not drill, punch, penetrate, or alter the poured and debridged thermal break or extruded thermal strut in any manner.

7.Fastening

a.Fastening means any method of securing one part to another or to adjacent materials. Due to varying opening conditions, window configurations, design pressures, and methods of anchorage (subframe, “F” anchors, etc.), perimeter fasteners are not specified in these instructions. For anchor fastening, refer to the shop drawings or consult the project design professional.

8.Blocking

a.All blocking and shims will be high strength plastic or non-corrosive materials, Not by EFCO. Blocking must be of sufficient size and shape to support the frame at all anchorage locations. The blocking must prevent the anchorage fasteners from bowing, racking, twisting, or distorting the window frames and accessories in any manner.

9.Sealant

a.Sealants must be compatible with all materials they contact, including other sealant surfaces. Any sealant details shown herein, unless specifically called out to by EFCO, are by others.

It is not EFCO Corporation’s position to select or recommend sealant or caulking types and will not assume liability or responsibility thereof. Consult the sealant supplier for recommendations relative to compatibility, adhesion, priming, tooling, shelf life, and joint design. It is the sole responsibility of the customer to perform all sealant adhesion and compatibility testing that is required by the sealant manufacturer of choice.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 4 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

C.Building Codes

1.Glass and glazing codes governing the design and use of products vary widely. EFCO does not control the selection of product configurations, operating hardware, or glazing materials; therefore, we assume no responsibility in these areas. It is the responsibility of the owner, architect, and the installer to make these selections in strict conformity to all applicable codes.

D.General Sliding Glass Door Frame Installation

1.The rough opening should be checked for the correct size as determined by tolerances listed in the architectural specifications and the shop drawings. (FIG. “A”)

2.Establish the face of the Sliding Glass Door line at the head, sill, and jambs. This reference is to be arrived at by using the architectural plans, general contractor’s reference lines, and shop drawings.

3.Determine the high point of the masonry sill using string line or transit and shim the balance of the opening to match. (Fig. “B”)

High

Fig. “A” |

Fig. “B” |

|

Shim at Anchor

Locations

Plumb |

Note: For proper Sliding Glass Door operation |

|

and drainage it must be installed PLUMB and |

||

Frame |

||

LEVEL. |

||

|

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 5 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

4.Do not fasten drapery tracks, ceiling supports, or convector covers to Sliding Glass Doors. The Sliding Glass Door must be free to contract and expand.

5.Install blocking in the Sliding Glass Door frame at anchor locations. All blocking and shims will be high strength plastic or non-corrosive materials, Not by EFCO. (Fig. “C”)

Fig. “C”

6.Seal all exposed perimeter joints between structure and door frame perimeters with a skinning, non-hardening type of sealant. Refer to the approved shop drawings for joint design.

Seal all frame to frame and frame to accessory (subframe, panning, mullions) joints with compatible silicone sealant. Refer to the approved shop drawings for joint design.

7.Seal all anchor heads along the sill and 6” up the jambs.

Sealant on anchor heads

Sealant on anchor heads

Fig. “D”

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 6 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

E.Perimeter Anchorage

1.From the approved shop drawings, determine the size, type, and quantity of perimeter fasteners required. EFCO will provide fasteners for EFCO material to EFCO material only. All perimeter fasteners are not by EFCO and should be purchased prior to arriving at the job site. (If subframe is used, please refer to the Subframe Installation sheets.)

Due to varying opening conditions, window configurations, design pressures, and methods of anchorage (subframe, “F” anchors, etc.), perimeter fasteners are not specified in these instructions. For perimeter anchor type and spacing, refer to the approved shop drawings or consult the project design professional. The design professional should analyze the anchorage system, and take into account the following information.

a.Frame dimensions and configuration of the as installed door.

b.Material properties of the door frame.

c.Allowable tension, shear, and bending properties of the perimeter fastener.

d.Design pressure.

e.Details of the surrounding condition for the head, sill, and jambs.

f.Relative building movements and expected thermal movement of the door system.

Substrate

Edge

Distance

Bearing

Surface

Edge

Distance

Perimeter

Fastener

Frame

Edge

Distance

Substrate

Edge

Distance

Bearing |

Substrate |

Surface |

Thickness |

Edge |

|

|

|

Distance |

|

Shim

Height

Note: This sketch is a typical representation, other anchorage systems will require similar information.

Frame

Edge

Distance

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 7 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

2.Perimeter anchors should never penetrate a tank or tubular shape at a window sill. Any penetration of the frame must be visible for sealing purposes.

3.Blocking must be of sufficient size and shape to support the frame at all anchorage locations. The blocking must prevent the anchorage fasteners from bowing, racking, twisting, or distorting the window frames and accessories in any manner. Excessive shim heights could increase the prying tension and/or bending forces on the perimeter fastener. Refer to the approved shop drawings and/or design professional for project specific applications.

F.General Sliding Panel Inspection

1.Upon completion of the Sliding Glass Door installation, all operating panels must be checked for proper alignment and operation. If the sliding panels are removed, care must be taken to ensure that sliding panels are reinstalled into the same frames they were removed from. It may be necessary to adjust the rollers and locking hardware to ensure proper sealing and locking. All hardware must be cleaned as necessary to provide smooth operation.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 8 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

SECTION II: Basic Sliding Glass Door Installation

A.Installation Without Subframe

1.Assemble the Sliding Glass Door frame per the assembly instructions for the appropriate Sliding Glass Door series.

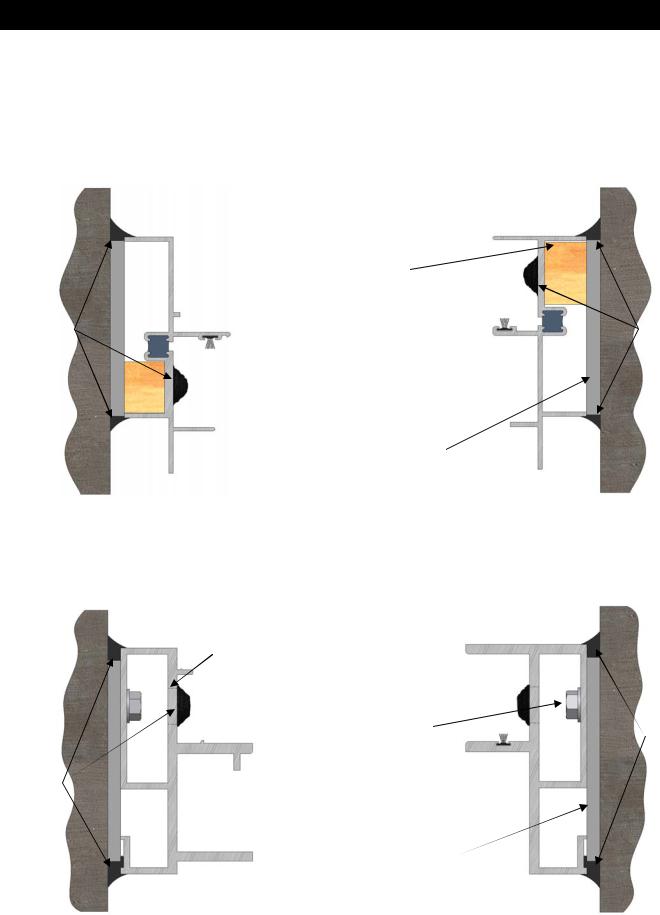

EFCO Sliding Glass Doors, without a tank at the sill, may be anchored without the use of a starter sill. This is because sealant can be applied over the head of the anchor. (A tankdesigned sill will not allow this option.) The sliding door sill may be anchored in the exterior track or the interior track. Locating the anchor in the exterior or interior track would need the consideration of minimum edge distance, the substrate to which the sills are being anchored, or anything that would govern the best location for the anchor. (Fig. E & F)

Fig. “E” |

S-2000 |

Erector to Field |

|

|

Drill for Anchors |

|

Blocking by Erector |

|

High Impact Shim by |

|

Erector |

|

Sealant |

S-3000

Erector to Field

Drill for Anchors

Fig. “F”

Blocking by Erector

High Impact Shim by

High Impact Shim by

Erector

Sealant

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 9 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

2.Seal sliding door head to the building substrate. The seal joint along the head is to marry in with the seal joint down the jamb as shown. (Fig. G & H)

Fig. “G”

Sealant

High Impact Shim

by Erector

Access Hole |

Blocking by |

|

Erector |

||

|

S-3014 Shown

S-3005 & S-3015 Similar

The S-3014, S-3015, & S-3005 require an access hole to be drilled prior to fastening the anchor (by the Erector).

Sealant

Sealant |

Erector to Field |

|

Drill for Anchors |

||

|

S-3001 Shown

S-2000/3000 Similar

Marry sealant at

head and jamb.

head and jamb.

Fig. “H”

Building Substrate

Sealant

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 10 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

3.Seal sliding door jambs to the building substrate. The seal joint along the jamb is to marry in with the seal joint across the head.

4.Stuff access holes, fixed jamb side, with backer rod and seal over the access holes before snapping on the cover (S-3005, S-3014 & S-3015).

S-3001 Shown

S-2000/3000 Similar

Blocking by

Erector

Sealant

Erector to Field Drill

for Anchors and

Cover Anchors With

Sealant

High Impact Shim

by Erector

Fig. “H”

S-3005 Shown

S-3014 & 3015 Similar

Access Hole

Erector to Field

Drill for Anchors

Sealant

Sealant

Sealant

Sealant

High Impact Shim

by Erector

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 11 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

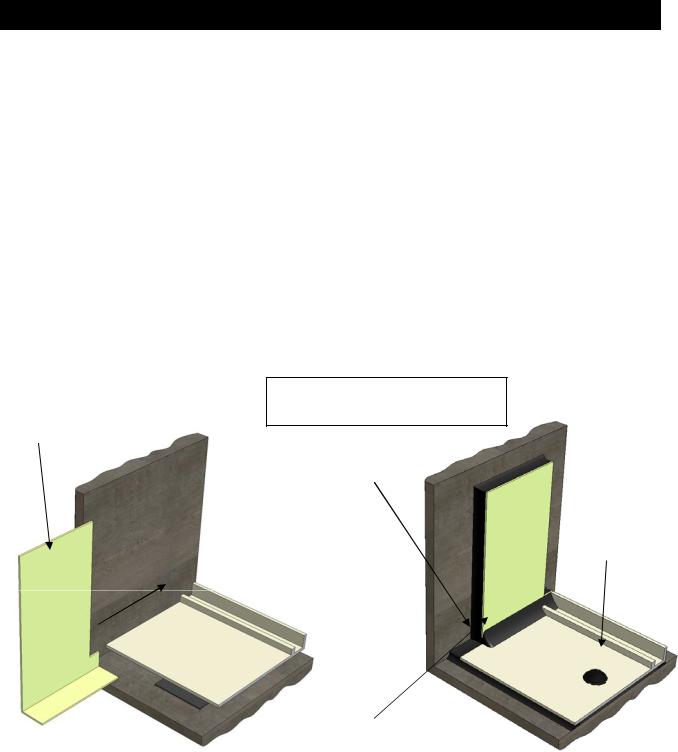

B. Installation With Subframe

All subframe material shipped long for field cut to fit and field drilling.

1.Measure the opening for the horizontal opening dimension.

2.Apply the end dams and install the subsill with erector-supplied fasteners, and apply sealant to the head of the fasteners. Also seal the end dam to the subsill and the end dam to the building substrate. (Fig I)

ERECTOR NOTE: When drilling and locating the fasteners, care must be taken to ensure that the head of the fasteners does not interfere with the door sill.

.062” aluminum angle with chromate or anodized finish. End dam to be placed under the subsill before anchoring the subsill.

Typical Starter Sill Application for all Sliding Glass Doors Series.

Fig. “I”

Sealant

Erector to field drill for anchors and cover anchors with sealant

Silicone sealant by others to be continuous from the subsill to the end dam. Silicone should have a minimum contact on each surface of ½”. Erector Note:

This sealant could interfere with end of jambs.

Seal end dam to the subsill and end dam to the building substrate as shown.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 12 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

3.Subheads to be field cut to length and installed.

ERECTOR NOTE: Two-piece and one-piece subheads will seal the same. (Fig. J)

|

Fig. “J” |

Sealant |

Sealant |

Erector to Field Drill for Anchors

Backbed the Sliding Glass Door to subhead contact area with silicone sealant before installing the door or cap seal after the door is installed.

When preparing subframe for anchorage into the building opening please make note of plumb line alignment of subhead to subsill as shown in examples below.

Example for: |

Example for: |

Series 3014, 3015, 3005 |

Series 5XP sliding glass |

sliding glass doors and |

doors and 5XF fixed windows. |

2900, 3016, 3017 fixed windows.

Plumb Line

Plumb Line

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 13 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

The opening is now ready to install the Sliding Glass Door frame.

(See assembly instructions for appropriate series on project)

4.Load the field assembled door frame into the anchored subframe. Snap-in the interior subhead closure for all two-piece subhead applications. (Fig. K) Drive-in the continuous silicone wedge between the doorframe and the interior subsill leg and cover wedge with silicone. (Fig. L)

S-3001 Shown All Other Series are Similar

Snap-in

Closure

Erector to Field

Drill for Anchors

Fig. “K”

Sealant

Compatible Silicone

Sealant by Others

Fig. “L”

To ensure a watertight seal, silicone over the continuous drivein wedge.

Note:

All sealant, interior and exterior, to marry one with another.

Fig. “M”

S-3001 Shown

S-2000 & S-3000 Similar

Sealant Over

Drive-In Dart

Compatible Silicone

Sealant by Others

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 14 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

Fig. “N”

Backer Rod by

Others

Compatible  Silicone Sealant by

Silicone Sealant by

Others

Compatible

Silicone Sealant by

Others

S-3005 Shown

S-3014 & S-3015

Similar

Sealant

A bead of sealant to be applied in this cavity before door frame is interlocked in place.

Note:

All sealant, interior and exterior, to marry one with another.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 15 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

Fig. “O”

Compatible Silicone |

Backer Rod |

Sealant by Others |

by Others |

Backbed or Cap Seal

Silicone Compatible

Sealant by Others

S-3014 Shown

S-3005 & S-3015 Similar

Two-Piece Subheads

Similar

Drive-in

Wedge

Silicone Compatible

Cap Seal by Others

Foam Backer Rod for non Three Sided Adhesion

Erector Note:

Not all Sliding Door subheads will be equipped with a drive-in wedge in the interior side of the subhead. When bulb vinyl is used, a silicone cap will not be required.

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 16 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

These recommendations are for general erection procedures only. For actual job conditions, see the details on the shop drawings. For perimeter anchor type and spacing, refer to the approved shop drawings or consult the project design professional.

SECTION III: Series Specific Assembly Installation

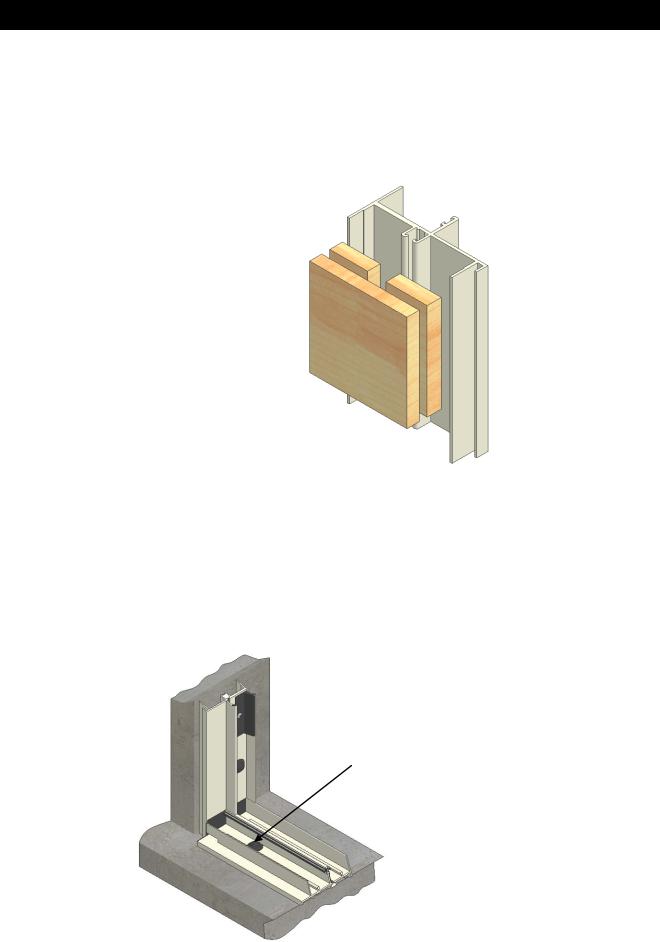

S-2000 or S-3000 Door Assembly Instructions

3492 Head

Closure

EW65 Threshold

3237 Screen

Sill Guide

3491 Head

3390 Head

Closure

HV04 Sash Stop

3234 Sill (S-3000)

3320 Sill (S-2000)

3190 Closure

3483 OXO |

3247 |

3236 |

|

Meeting Rail |

|||

Fixed Jamb |

Operable Jamb |

||

|

|||

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 17 of 59 |

SLIDING GLASS DOOR INSTALLATION INSTRUCTIONS

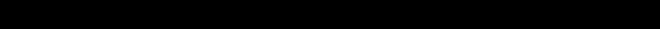

H075 Gasket (adhere to the jamb)

Interior

3492

Jamb

Head

3390

EW65

Threshold

H017 Gasket (S-2000) |

Jamb |

|

H073 Gasket (S-3000) |

||

|

||

(adhere to the jamb) |

Sill |

|

|

Exterior

Locate 3236 and 3247 jambs. Adhere H075 head gaskets and H017 (S-2000) or H073 (S-3000) sill gaskets to the jambs. Gaskets have pressure sensitive adhesive on one side of the gasket. Match up the holes in the gasket with the holes in the jambs and adhere to the jamb.

Locate 3491 head and 3320 (S-2000) or 3234 (S-3000) sill. Fasten the head and the sill to the jambs with SLQ6 screws (#8 x 1 ¼” PL-PH-SMS 410 B-LP MG).

For proper door operation, position the doorframe in the opening by using shims as needed to ensure that the frame is plumb, square, and level without warp, twist, or bow.

Lay the setting channels (F132 S-2000 or FD28 S-3000) in the outside sill track at approximate quarter points of the fixed panel.

Setting Channel

F132 Shown

EFCO CORPORATION 6/8/2012 |

PART NO. YW41 |

Page 18 of 59 |

Loading...

Loading...