Page 1

Chain Saw

Instruction Manual

MODELS : CS-301

CS-341

CS-346

X7503202807

WARNING DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Instruction Manual and a Safety Manual. Both must be read and understood for proper and

safe operation.

X750001597

11/06

Page 2

Rules foR safe opeRation

A. Kickback Safety Precaution for Chain Saw Users

WARNING!

B. Other Safety Precautions

KICKBACK may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning

fast reverse REACTION, Kicking the guide bar up

and back towards the operator. Pinching the saw

chain along the top of the guide bar may push

the guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury.

®

The Kick Guard

guide bar when you purchase your ECHO chain

saw. The Kick Guard ® can be used in a majority

of cutting operations, and is especially recommended for beginners, homeowners, or chain

saw novices. Most cutting operations can be accomplished with the Kick Guard® in place.

device is not installed on the

1. With a basic understanding of kickback,

you can reduce or eliminate the element of

surprise. Sudden surprise contributes to accidents.

2. Keep a good rm grip on the saw with both

hands, the right hand on the rear handle, and

the left hand on the front handle, when the

engine is running. Use a rm grip with thumbs

and ngers encircling the chain saw handles.

A rm grip will help you reduce kickback and

maintain control of the saw. Don’t’ let go.

3. Make sure that the area in which you are cutting is free from obstructions. Do not let the

nose of the guide bar contact a log, branch,

or any other obstruction which could be hit

while you are operating the saw.

4. Cut at high engine speeds.

Do not rely exclusively upon the safety devices

built into your saw. As a chain saw user, you

5. Do not overreach or cut above shoulder

height.

should take several steps to keep your cutting

jobs free from accident or injury.

6. Follow manufacturer’s sharpening and maintenance instructions for the saw chain.

7. Only use replacement bars and chains speci-

ed by the manufacturer or the equivalent.

1. Do not operate a chain saw with one hand! Serious injury to the operator, helpers, bystanders, or

any combination of these persons may result from one-handed operation. A chain saw is intended

for two-handed use.

2. Do not operate a chain saw when you are

fatigued.

3. Use safety footwear; snug-tting clothing;

protective gloves; and eye, hearing and head

protection devices. Wear protective hair covering to contain long hair.

4. Use caution when handling fuel. Move the

chain saw at least 3 m (10 feet) from the fueling point before starting the engine.

5. Do not allow other persons to be near the

chain saw when starting or cutting with the

chain saw. Keep bystanders and animals out

of the work area.

6. Do not start cutting until you have a clear work

area, secure footing, and a planned retreat

path from the falling tree.

7. Keep all parts of your body away from the saw

chain when the engine is running.

Copyright© 2006 By Echo, Incorporated

All Rights Reserved.

8. Before you start the engine, make sure that

the saw chain is not contacting anything.

2

Page 3

9. Carry the chain saw with the engine stopped,

the guide bar and saw chain to the rear, and

the mufer away from your body.

10. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Be sure that the saw

chain stops moving when the throttle control

trigger is released.

11. Shut off the engine before setting the chain

saw down.

12. Use extreme caution when cutting small size

brush and saplings because slender material

may catch the saw chain and be whipped

toward you or pull you off balance.

13. When cutting a limb that is under tension, be

alert for spring back so that you will not be

struck when the tension in the wood bers is

released.

14. Keep the handles dry, clean, and free of oil

or fuel mixture.

16. Do not operate a chain saw in a tree unless

you have been specically trained to do so.

17. All chain saw service, other than the items

listed in the Instruction Manual maintenance instructions, should be performed

by competent chain saw service personnel.

(For example, if improper tools are used to

remove the ywheel or if an improper tool is

used to hold the ywheel in order to remove

the clutch, structural damage to the ywheel

could occur and could subsequently cause

the ywheel to burst.)

18. When transporting your chain saw, use the

appropriate guide bar scabbard.

19. Spark arrestor mufers approved to SAE

Standard J335b are Standard on ECHO

Chain saws to reduce the possibility of for-

est res. Do not operate the chain saw with

a loose or defective mufer. Do not remove

the spark arrestor screen.

15. Operate the chain saw only in well-ventilated

areas.

WARNING DANGER

• During operation, the mufer or catalytic mufer and surrounding cover become hot.

• Never suspend the saw on a lanyard with the engine running.

• Always use the saw from the right-hand side of your body – NEVER from the left side.

• Always wear proper safety clothing to protect your lower body from sharp saw chain and

hot mufer.

• Always keep exhaust area clear of ammable debris during transportation or when storing,

otherwise serious property damage or personal injury may result.

WARNING DANGER

Using improper replacement components or removing safety devices may result in serious or fatal injury.

3

Page 4

Contents

C

ONTENTS

Page

Rules for Safe Operation .................................................................................................. 2

Technical Data ................................................................................................................. 5

Emission Data ................................................................................................................. 6

Description ...................................................................................................................... 6

Nomenclature of Parts ...................................................................................................... 7

Preparation for Use .......................................................................................................... 8

Fuel and Lubricant............................................................................................................ 9

Operation ....................................................................................................................... 11

Cutting Instructions ......................................................................................................... 13

Maintenance and Care ................................................................................................... 16

Chain and Guide Bar Combinations ............................................................................... 21

Troubleshooting.............................................................................................................. 23

Storage .......................................................................................................................... 24

Correct Use of Chain Brake ........................................................................................... 26

Servicing Information ...................................................................................................... 28

Carburetor adjustment

- Idle speed

Carburetor adjustment

- High speed mixture

Wear eyes, ears and head

protection

Carburetor adjustment

- Low speed mixture

Gasoline and oil mixture

Symbol form/shape Symbol description/application Symbol form/shape Symbol description/application

Chain oiler adjustmentChain brake operation

Chain oil pump

Chain oil fill

Emergency stop

Choke control “Cold Start”

position (choke closed)

STOP

I

NTERNATIONAL SYMBOLS

Read and understand

Operator's Manual.

Page

Rules for Safe Operation .................................................................................................. 2

Technical Data .................................................................................................................. 5

Emission Data ..................................................................................................................6

Description........................................................................................................................6

Nomenclature of Parts ...................................................................................................... 7

Preparation for Use ..........................................................................................................9

Fuel and Lubricant .......................................................................................................... 10

Operation ........................................................................................................................ 12

Cutting Instructions ......................................................................................................... 14

Maintenance and Care ...................................................................................................17

Chain and Guide Bar Combinations ............................................................................... 22

Troubleshooting ..............................................................................................................24

Storage ........................................................................................................................... 25

Correct Use of Chain Brake............................................................................................26

Servicing Information ...................................................................................................... 28

inteRnational symbols

4

Page 5

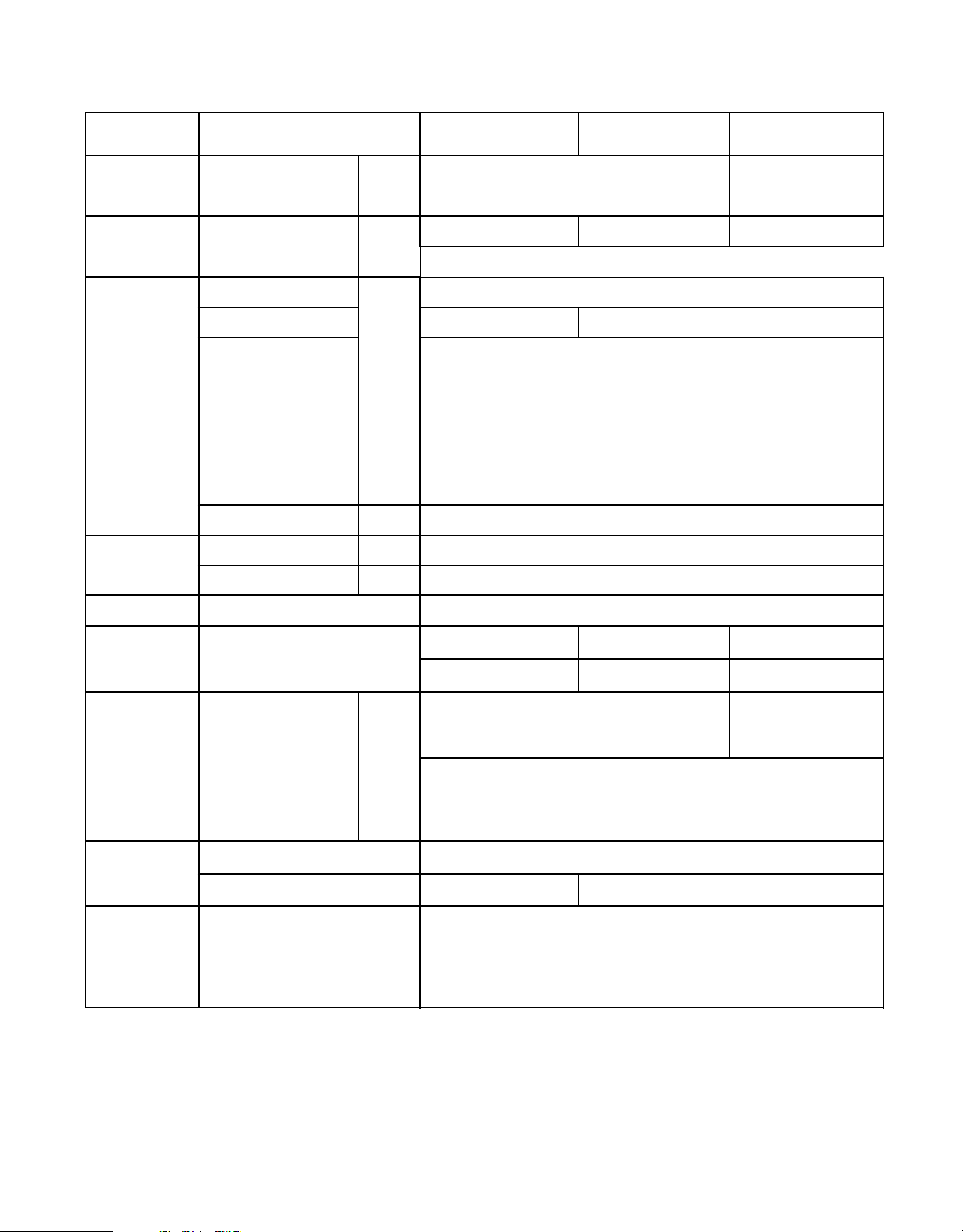

teChniCal Data

ledoM

103-SC143-SC643-SC

noisnemiDHxWxL

mm022x532x062022x532x083

hcni7.8x2.9x2.017.8x2.9x0.51

thgieWyrd,daehrewoPgk)bl1.7(2.3)bl3.7(3.3)bl5.7(4.3

rabediugdnaniahctuohtiW

enignEepyT

lm

rednilycelgnis,ekorts-owt,delooc-riA

tnemecalpsiD).ni.uc38.1(1.03).ni.uc30.2(4.33

roterubraC

otengaM

gulPkrapS

retratS

noissimsnartrewoP

epytmgarhpaiD

metsysIDC:otengamleehwylF

Y8-MPBKGN

retratslioceR

hctulclagufirtneccitamotuA

leuFoitarerutxiMdnelBrewoP

ohcEhtiwoitar1:05

MT

.lioekorts-2

,lohoclalyhtemgniniatnocleufesutonoD.dedaelnuenatco98

.EBTM%51rolohoclalyhte%01nahterom

yticapaCknaTL ).S.Uzolf0.9(62.0

liOniahcdnaraB)liorotomro(lioniahcdnarabOHCE

yticapaCknaTL ).S.U.zo.lf5(51.0

noitacirbuLpmupliocitamotuaelbatsujdA

rabediuG

niahcwaS

dradnatS.ni21dradnatS.ni41dradnatS.ni61

lanoitpO.ni61,41lanoitpO.ni61,21lanoitpO.ni41,21

dradnatS

serutaef

eldnaHpoTeldnahlanoitnevnoC

draugd

nahraeR

,draugdnahtnorF

,ecivednoitarbiv-itnA

,ekarbniahC,tuokcollortnocelttorhT

relffumcitylatacrotserrakrapS,rehctacniahC

MPRenignE

eldI

003,3-007,2

)TOW(elttorhTnepOediW

005,21-000,21000,21-005,11

kcabkciK

ytefaS

serutaeF

raBediuGkciKwoLdrauGelbuoD

niahCwaSkniLdrauGkciKwoL

reveLekarBniahC/drauGdnaHtnorF

ekarBniahC

drauGkciK

* Technical data subject to change without notice.

5

Page 6

emission Data

emission ContRol

EPA Phase 2/California Tier II

The emission control system for these engines are

EM/TWC (Engine Modication and Catalyst).

An Emission Control Label is located on the

engine. (This is an EXAMPLE ONLY, information

on label varies by engine FAMILY).

PRODUCT EMISSION DURABILITY

The 300 hour emission durability compliance period is the time span selected by the manufacturer certifying the engine emissions output meets applicable California and/or U.S. EPA emissions regulations,

provided that approved maintenance procedures are followed as listed in the Maintenance Section of

this manual.

impoRtant enGine infoRmation

enGine family: 6eXhs.0334Ca DisplaCement: 30.1 CC

emission ComplianCe peRioD: 300 houRs

THIS ENGINE MEETS U.S. EPA PH2 AND 2005 - 2006

CALIFORNIA EMISSION REGULATIONS FOR SOREs.

REFER TO OWNER’S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS.

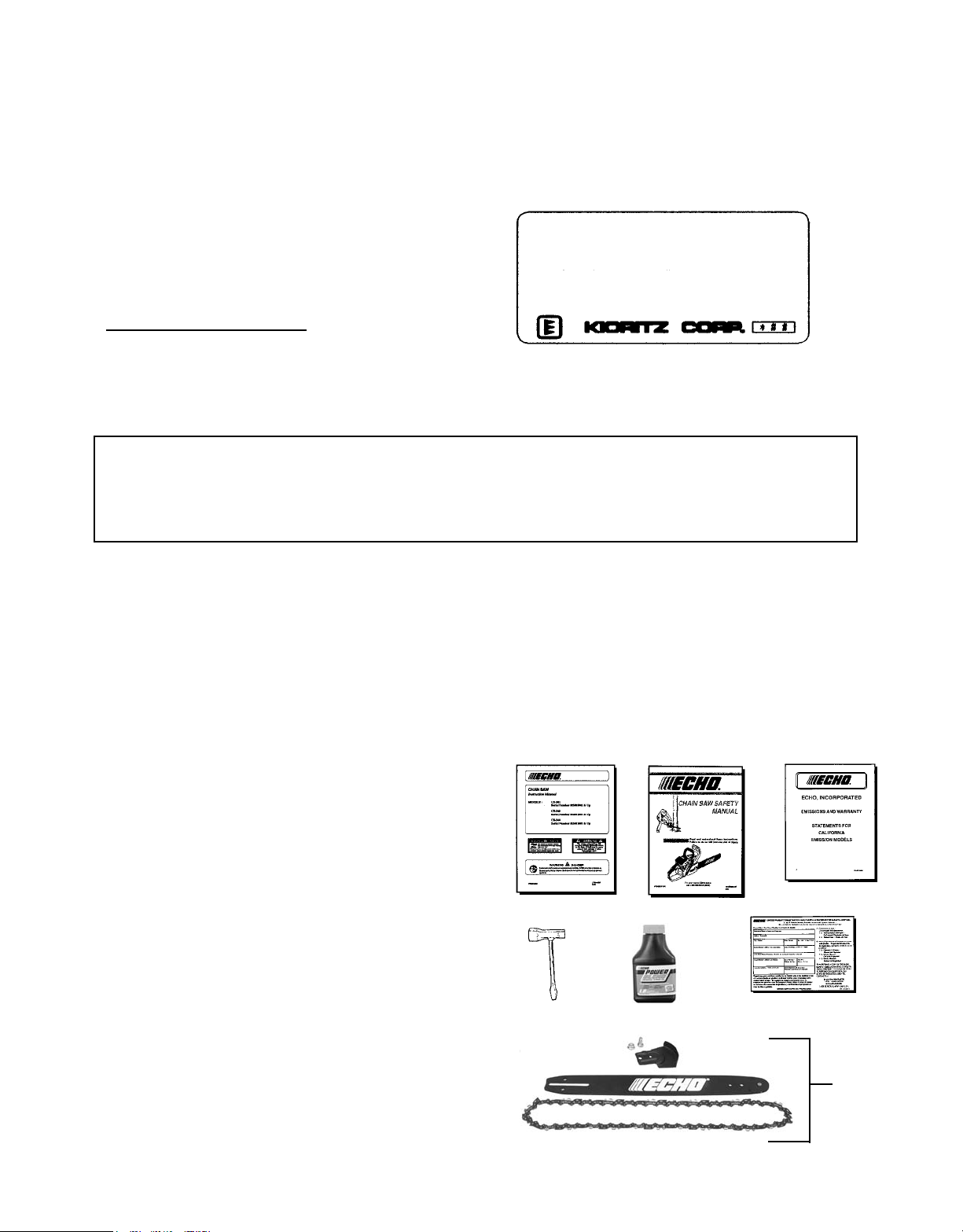

DesCRiption

The ECHO product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, guide bar and saw chain installation and other assembly may be necessary.

After opening the carton, check for damage. Immediately notify your retailer or ECHO Dealer of damaged or missing

parts. Use the contents list to check for missing parts.

Contents

1 - Power Head

1 - Guide Bar

*1 - Kick Guard

1 - Hex Head Bolt

1 - Hex Nut

*1 - Saw Chain

1 - Instruction Manual

1 - Safety Manual

1 - Warranty Registration Card

1 - Limited Warranty Statement

1 - T-Wrench

1 - Echo Power Blend TM 2-stroke oil sample

* The machine may be delivered with guide bar and saw chain

assembled.

*

6

Page 7

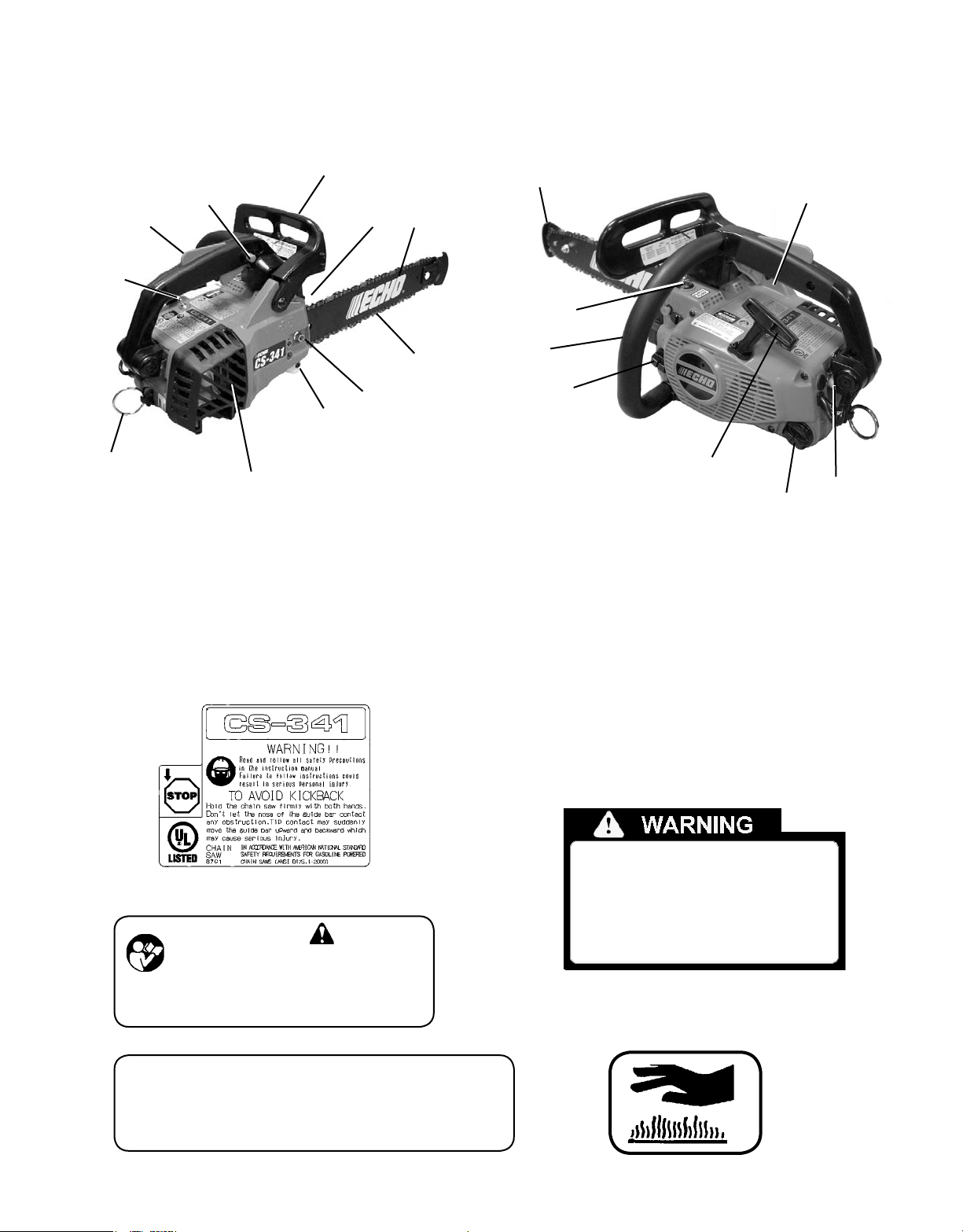

CS-301, CS-341

opeRation

15

2

11

18

17

1. Hand guard

(Chain brake locking lever)

2. Throttle control lockout

3. Throttle control trigger

4. Sprocket guard

5. Chain catcher

1

16

6

8

3

7

9

4

10

12

5

13

19

14

6. Air cleaner cover

7. Purge bulb

8. Guide bar

9. Saw chain

10. Front handle

11. On / Off switch

12. Fuel tank cap

13. Pull starter

14. Oil tank cap

15. Throttle control latch

16. Tip guard

17. Catalytic mufer

18. Lanyard ring

19. Spark Plug

CS-301 P/N X524000313

CS-341 P/N X524000333

P/N 89022839131

ADVERTENCIA PELIGRO

Esta unidad puede ser peligrosa y producir lesiones personales graves si no se usa en forma adecuada.

ayudantes y los espectadores deben leer y comprender el Manual Del

Operador y los Manuales De Seguridad que se entregan escritos en

español.

Para reducir el riesgo de lesioarse, los operadores, los

P/N X524000792

GUIDE BAR* CHAIN*

PART NO. TYPE LINKS

12” 12A0CD3745 OREGON 91VG 45

14” 14A0CD3752 OREGON 91VG 52

16” 16A0CD3757 OREGON 91VG 57

REPLACEMENT BAR AND CHAIN

Note:There may be other replace-

ment components for achieving

kickback protection. For details,

please refer to the chain and

bar combination sheet shown in

the instruction manual.

Chain brake must be unlocked before removing or

installing clutch cover. Improper cover installation can

result in serious injury and cause severe damage to

saw.

El freno de la cadena debe ser desbloqueado antes

de remover o de instalar la cubierta del embrague. La

instalación incorrecta de la cubierta puede dar lugar a

lesión seria y causar daño severo a la sierra.

P/N 89016006361

7

Page 8

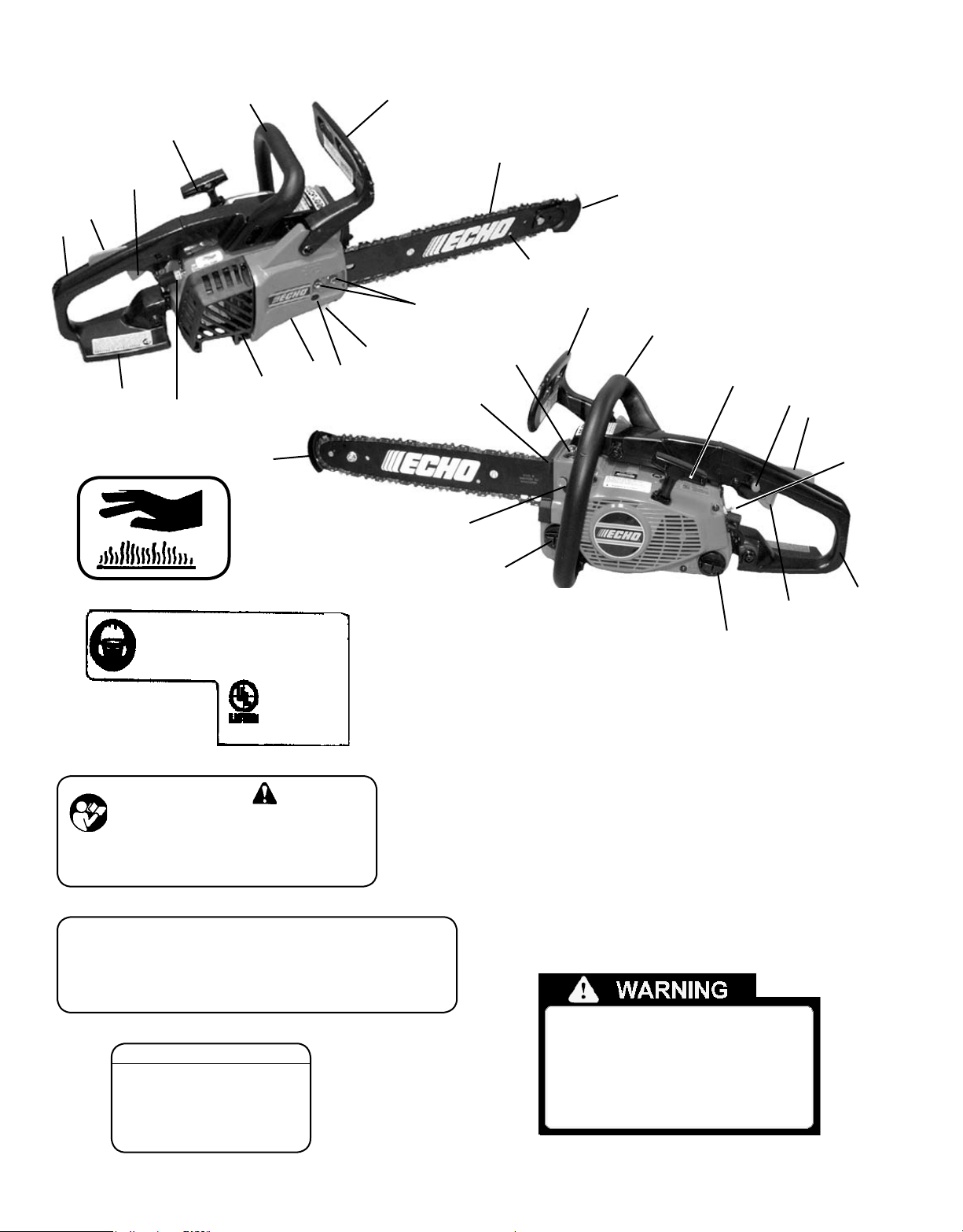

CS-346

13

1

2

3

10

9

22

CS-306

6

8

20

P/N 89016006361

7

19

P/N 89011439134

Read and follow all safety precautions in the

Instruction manual. Failure to follow instruc-tions

could result in serious personal injury.

WARNING ! !

CHAIN SAW 87G1

IN ACCORDANCE WITH

AMERICAN NATIONAL

STANDARD SAFETY

REQUIREMENTS FOR

GASOLINE POWERED CHAIN SAWS

(ANSI B175.1-2000)

P/N 89022839131

ADVERTENCIA

Esta unidad puede ser peligrosa y producir lesiones personales graves si no se usa en forma adecuada.

Para reducir el riesgo de lesioarse, los operadores, los ayudantes y los

espectadores deben leer y comprender el Manual Del Operador y los

Manuales De Seguridad que se entregan escritos en español.

PELIGRO

P/N X524000792

GUIDE BAR* CHAIN*

PART NO. TYPE LINKS

12” 12A0CD3745 OREGON 91VG 45

14” 14A0CD3752 OREGON 91VG 52

16” 16A0CD3757 OREGON 91VG 57

REPLACEMENT BAR AND CHAIN

Note:There may be other replacement

components for achieving kickback

protection. For details, please refer to

the chain and bar combination sheet

shown in the instruction manual.

4

21

5

18

11

12

23

17

1. Front handle

2. Hand guard

(Chain brake actuating lever)

3. Saw chain

4. Guide bar

5. Chain catcher

6. Sprocket guard

7. Mufer

8. Rear hand guard

9. Throttle control lockout

10. Throttle control trigger

19

1

2

13

14

9

15

22

10

16

11. Air cleaner cover

12. Chain tension adjustment screw

13. Pull starter

14. Throttle control latch

15. On / Off switch

16. Oil tank cap

17. Fuel tank cap

18. Purge bulb

19. Kick guard

20. Spark Plug

21. Guide Bar Nuts

22. Rear Handle

23. Choke

P/N 90019130131

TO AVOID KICKBACK

1.Holdthechainsawrmlywithboth

hands.

2. Don’t let the nose of the guide bar

contact any obstruction.

3. Tip contact may suddenly move the

guide bar upward and backward,

which may cause serious injury.

Chain brake must be unlocked before removing or

installing clutch cover. Improper cover installation can

result in serious injury and cause severe damage to

saw.

El freno de la cadena debe ser desbloqueado antes

de remover o de instalar la cubierta del embrague. La

instalación incorrecta de la cubierta puede dar lugar a

lesión seria y causar daño severo a la sierra.

8

Page 9

pRepaRation foR use

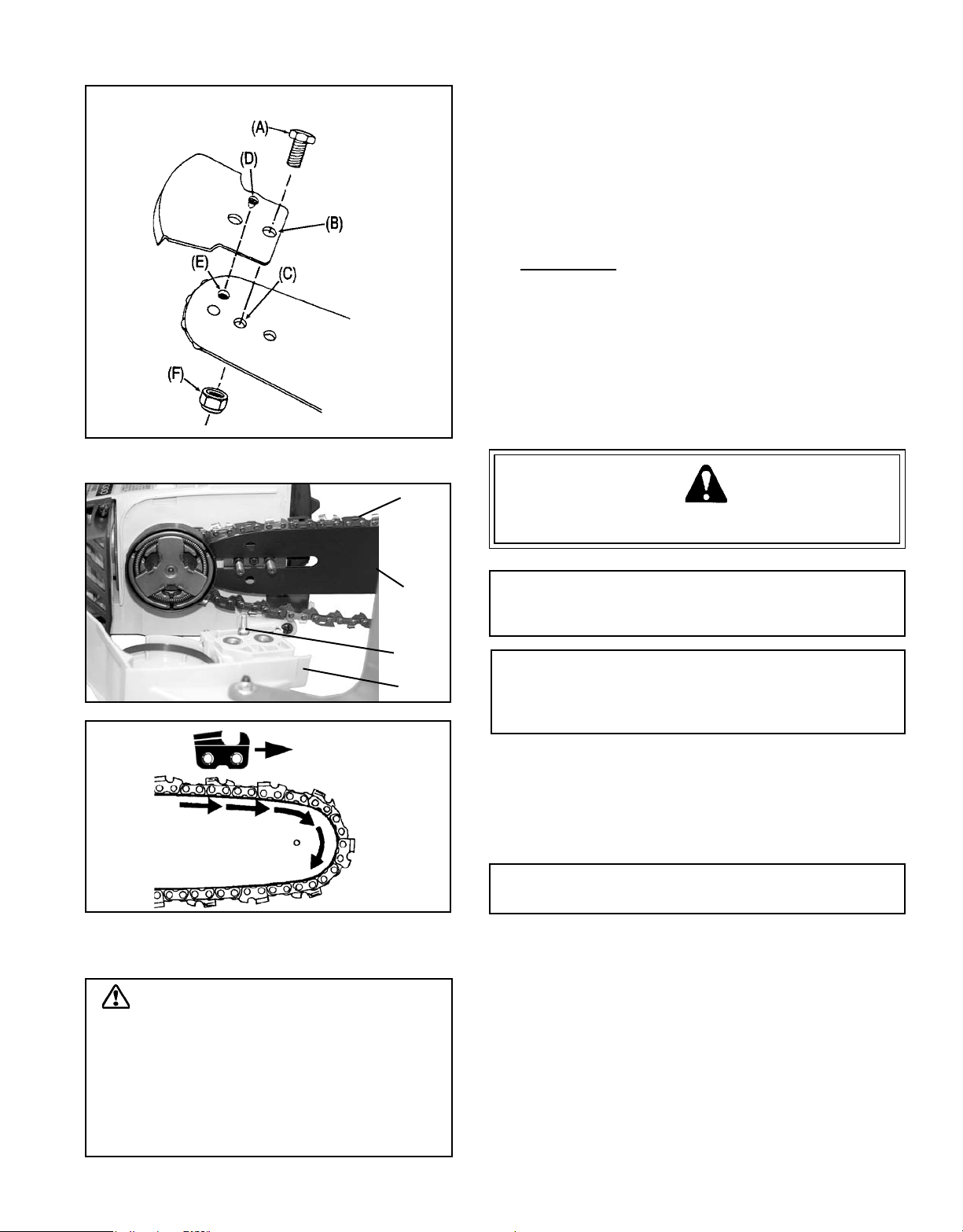

kiCk GuaRD® to baR instRuCtions

For saws with Kick Guard® P/N 2894901 and symmetrical or asymmetrical low-kick type guide bars.

1. Install bolt (A) in rear hole (B) of Kick Guard® and

through front hole (C) in guide bar.

2. IMPORTANT: Dimple in Kick Guard® (D) must engage

recess in guide bar (E).

3. Tighten nut (F) and bolt (A) until snug. Make certain

Kick Guard® is ush against guide bar.

GuiDe baR anD saw Chain-install/

Remove

H

I

J

WARNING

IMPROPER CLUTCH COVER ASSEMBLY CAN RESULT IN SERIOUS INJURY, AND WILL CAUSE SEVERE SAW DAMAGE IF UNIT IS STARTED. NEVER

START OR OPERATE SAW IF BRAKE BAND IS NOT

IN PLACE ON CLUTCH DRUM. ALWAYS CHECK

CHAIN BRAKE OPERATION AFTER REPLACING

COVER. DO NOT USE SAW IF CHAIN BRAKE DOES

NOT FUNCTION PROPERLY.

WARNING DANGER

Saw Chain is sharp! Always wear gloves when handling

assembly, otherwise serious personal injury may result.

NOTE

Move chain brake lever fully rearward to remove or install

clutch cover to saw.

IMPORTANT

Always loosen guide bar nuts before turning chain

tension adjuster, otherwise clutch cover and tensioner

will be damaged.

1. Remove spark plug lead.

2. Remove two guide bar nuts and remove guide bar cover.

Turn tension adjustment screw counterclockwise 2 to 3

turns if bar and chain are installed.

3. Remove guide bar and saw chain if necessary.

NOTE: See “MAINTENANCE AND CARE” instructions

for guide bar, sprocket, and saw chain maintenance.

4. Mount guide bar (G) on studs, and slide toward sprocket

to make saw chain installation easier.

5. Install saw chain (H) as shown, with cutters on top of

guide bar facing forward.

6. Align holes of clutch cover (J) with guide bar studs,

and tensioner pin (I) with lower guide bar adjuster hole.

7. Turn saw over and check brake band for correct position around clutch drum. If brake band is not in place

around drum, remove clutch cover, make sure brake is

released, and reinstall.

9

Page 10

aDjustment, Chain tension

IMPORTANT

Always loosen guide bar nuts before turning chain

tension adjuster, otherwise clutch cover and tensioner

will be damaged.

1. Remove spark plug lead.

2. Loosen two guide bar nuts, if necessary.

3. Hold the bar nose up, and turn the adjuster screw (L)

L

clockwise until chain ts snugly against underside of

bar.

4. Tighten both guide bar nuts with bar nose held up.

5. Pull the saw chain around the guide bar by hand.

Reduce chain tension, if you feel tight spots.

6. When chain is properly tensioned, tighten guide bar

nuts securely - 90 – 110 kgf/cm (80 – 95 in. lbs.).

7. Keep chain properly tensioned at all times.

NOTE

All chains require frequent adjustments.

fuel anD lubRiCant

NOTICE: Use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor

performance, or severe engine damage and void the product warranty. Read and follow instructions in the Storage

section of this manual.

fuel statement

WARNING DANGER

Alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting ECHO requirements

are NOT approved for use in ECHO 2-stroke gasoline engines. Use of alternative fuels may cause performance

problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including, but not limited

to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel lines, gaskets,

carburetors and other engine components.

GASOLINE - Use 89 Octane [R+M/2] (mid grade or higher) gasoline or gasohol known to be good quality. Gasohol

may contain up to 10% Ethyl (grain) alcohol or 15% MTBE (methyl tertiary-butyl ether). Gasohol containing methyl

(wood) alcohol is NOT approved.

Two Stroke Oil - A two-stroke engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O. FC Standards must be

used. Echo brand premium Power Blend TM Universal 2-Stroke Oil meets these standards. Engine problems due to

inadequate lubrication caused by failure to use an ISO-L-EGD and J.A.S.O. FC certied oil, such as Echo premium

Power BlendTM, will void the two-stroke engine warranty. (Emission related parts only are covered for two years, regardless of two-stroke oil used, per the statement listed in the Emission Defect Warranty Explanation.)

IMPORTANT

Echo premium Power BlendTM Universal 2-Stroke Oil may be mixed at 50:1 ratio for application in all Echo engines

sold in the past regardless of ratio specied in those manuals.

10

Page 11

Handling Fuel

WARNING DANGER

Fuel is VERY ammable. Use extreme care when mixing,

storing or handling or serious personal injury may result.

• Use an approved fuel container.

• DO NOT smoke near fuel.

• DO NOT allow ames or sparks near fuel.

• Fuel tanks/cans may be under pressure. Always loosen

fuel caps slowly allowing pressure to equalize.

• NEVER refuel a unit when the engine is HOT or RUN-

NING!

• DO NOT ll fuel tanks indoors. ALWAYS ll fuel tanks

outdoors over bare ground.

• DO NOT overll fuel tank. Wipe up spills immediately.

• Securely tighten fuel tank cap and close fuel container

after refueling.

• Inspect for fuel leakage. If fuel leakage is found, do not

start or operate unit until leakage is repaired.

• Move at least 3m (10 ft.) from refueling location before

starting the engine.

Mixing Instructions

1. Fill an approved fuel container with half of the required

amount of gasoline.

2. Add the proper amount of 2-stroke oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and remix.

IMPORTANT

Spilled fuel is a leading cause of hydrocarbon emissions.

Some states may require the use of automatic fuel shut-

off containers to reduce fuel spillage.

Fuel Mix Chart

50:1

After use

• DO NOT store a unit with fuel in its tank. Leaks

can occur. Return unused fuel to an approved

fuel storage container.

Storage - Fuel storage laws vary by locality.

Contact your local government for the laws

affecting your area. As a precaution, store fuel

in an approved, airtight container. Store in a

well-ventilated, unoccupied building, away from

sparks and ames.

IMPORTANT

Stored fuel ages. Do not mix more fuel

than you expect to use in thirty (30) days,

ninety (90) days when a fuel stabilizer is

added.

IMPORTANT

Stored two-stroke fuel may separate.

ALWAYS shake fuel container thoroughly

before each use.

Chain lubRiCant

Proper lubrication of the chain while in operation reduces friction between the chain and the guide bar to a minimum and

assures a longer service life.

• use bar and chain oil of high quality for this purpose.

• Do not use used or reclaimed oil to avoid various oiler

problems.

• Use ECHO bar and chain oil.

• When ECHO bar and chain oil is not available:

Use motor oil, etc.

• Use bar and chain oil of the following grades:

SAE NO. 30 ..... in summer

SAE NO. 10 ..... in winter or when cutting resinous trees.

• When refueling, also rell chain oil.

11

TANK INDICATION

FUEL TANK OIL TANK

Page 12

staRtinG ColD enGine

WARNING DANGER

Make sure bar and chain are not touching anything when

starting the saw.

1. Move chain brake lever fully forward to lock chain brake

before starting.

2. Fill the fuel tank with fuel. Do not over ll.

3. Fill the chain oil tank with lubricant. Do not over ll.

4. Lay unit on a at, clear area and keep bar and chain

clear of all obstacles.

5. Turn switch (A) to “RUN” position (I).

6. Pull choke (B) all the way out (closed position).

7. Push purge bulb (C) 10 times.

8. Pull starter handle several times until rst ring sound is

heard. (Secure unit on ground with your knee or foot.)

(5 - 6 pulls maximum.)

9. Push choke (B) all the way in. (open position)

10. Pull starter handle again.

NOTE

If engine does not start after 5 pulls, repeat instructions.

CS-346

A

A

CS-301

CS-341

C

when enGine is haRD to staRt

WARNING DANGER

Clutch engages and chain may rotate when engine is started

with throttle control latch engaged. Never use the throttle

control latch for cutting. Use only when starting the engine.

1. Ensure that there is fuel and chain oil in the tanks.

2. Move chain brake lever fully forward to lock chain brake

before starting.

3. Lay unit on a at, clear area and keep bar and chain clear

of all obstacles.

4. Press throttle control lockout down, squeeze throttle trig-

ger, and push in throttle control latch.

5. Turn switch (A) to “RUN” position (I).

6. Pull starter handle.

7. When engine starts, immediately squeeze throttle trig-

ger to release the latch otherwise damage to clutch may

result.

NOTE

Do not pull starter rope out to the maximum possible

position.

Do not allow recoil handle to snap back against the casing.

12

B

Securely hold the saw.

Page 13

staRtinG waRm enGine

1. Ensure that there is fuel and chain oil in the tanks. (If fuel tank

was emptied during previous operation, rell tank and push

purge bulb 10 times.)

2. Move chain brake lever fully forward to lock chain brake be-

fore starting.

3. Lay unit on a at, clear area and keep bar and chain clear of

all obstacles.

4. Turn switch (A) to “RUN” position (I).

5. Pull starter handle.

6. Choke may be used if necessary, but be sure to push it back

on rst ring sound.

CS-346

A

A

NOTE

If engine does not start after 5 pulls, use cold start procedure.

RunninG

WARNING DANGER

The saw chain should not move at idle, otherwise serious personal injury may result.

NOTE

If saw chain moves adjust carburetor according to “Carburetor

Adjustment” instructions in this manual, or see your dealer.

• After engine starts, allow it to return to idle.

• Move chain brake lever fully rearward to unlock chain brake.

• Press throttle control lockout then gradually squeeze throttle

trigger to increase engine speed.

• Saw chain starts moving when the engine reaches approxi-

mately 4200 rpm.

• Ensure proper acceleration and lubrication of chain and bar.

• Do not run the engine at high speed unnecessarily.

• Be sure that saw chain stops moving when throttle trigger is

released.

CS-301

CS-341

stoppinG

1. Release throttle trigger and turn switch (A) to STOP (O) posi-

tion.

2. Move chain brake lever fully forward to lock chain brake.

NOTE

If engine does not stop, pull choke out fully to stop engine.

Return the unit to your authorized ECHO dealer to check and

repair stop switch before starting the engine again.

13

CS-346

CS-301

CS-341

A

A

Page 14

GENERAL

CuttinG instRuCtions

WARNING DANGER

Read the ECHO “CHAIN SAW SAFETY MANUAL” included

with your chain saw for additional cutting and safety instructions. Failure to obey all instructions may result in serious

or fatal injuries.

In all circumstances the operation of the chain saw is a

one-man job. It is difcult at times to take care for your own

safety, so don’t assume the responsibility for a helper as

well. After you have learned the basic techniques of using the saw, your best aid will be your own good common

sense...

The accepted way to hold the saw is to stand to the left of

the saw with your left hand on the front handlebar and your

right hand on the rear handle so you can operate the throttle

trigger with your right index nger.

Before attempting to fell a tree, cut some small logs or limbs.

Become thoroughly familiar with the controls and the responses of the saw.

Kickback

Start the engine, see that it is running properly. Squeeze the

trigger to open the throttle wide open and start the cut. If the

chain is properly sharpened, the cutting should be relatively

effortless. It is not necessary to press down hard to make the

saw cut. Pushing the saw too hard will slow the engine and

cutting will actually be more difcult.

NOTE

Some material may adversely affect the housings of your

ECHO chain saw.

(Example: Palm Tree Acid, fertilizer, etc.) To avoid housing

deterioration, carefully remove all packed saw dust around

clutch and guide bar area and wash with water. Coat

metal parts with light oil.

WARNING DANGER

Do not let the tip of the bar touch anything while the engine

is running. At cutting speed the chain is moving at a high rate

of speed. Should the tip contact a limb or log while the chain

is moving, the tip will be pushed upward with considerable

force. This is known as kickback. Avoid it!

14

Page 15

FELLING A TREE

DIRECTION

OF FALL

Direction of fall

First cut

Notch

Second cut

One-third tree

diameter

2”

45°

Hinge

Felling cut

2”

WARNING DANGER

A falling tree can seriously damage anything it may hit

- a car, a house, a fence, a power line, or another tree.

There are ways to make a tree fall where you want it,

so rst decide where that is!

Before cutting, clear the area around the tree. You will

need good footing while working and you should be able

to work the saw without hitting any obstacles. Next, select

a path of retreat. When the tree begins to fall you should

retreat away from the direction of fall at a 45 degree angle

to avoid the trunk kicking back over the stump.

Begin the cut on the side to which the tree is to fall. Cut

a notch about 1/3 of the way into the tree as shown. The

position of this notch is important since the tree will try to

fall “into” the notch. The felling cut is made on the side opposite the notch and at a level about 2” above the bottom

of the notch. Do not try to cut through to the notch with the

felling cut. The remaining wood between the notch cut and

felling cut (about 2”) will act as a hinge when the tree falls,

guiding it in the desired direction. When the tree starts to

fall, kill the engine, place the saw on the ground and make

your retreat quickly.

LIMBING

To fell big trees with a diameter exceeding twice the bar

length, start the notching cuts from one side and draw the

saw through to the other side of the notch. Start the back

cut on one side of the tree, pivoting the saw through to

form the desired hinge on that side.

Then remove the saw for the second cut. Insert the saw

in the rst cut, very carefully so as not to cause kickback.

The nal cut is made by drawing the saw forward in the

cut to reach the hinge.

Limbing a fallen tree is much the same as bucking. Never

stand on the tree that you are limbing. When limbing, caution is the word. Be careful of the tip touching other limbs.

Always use both hands.

15

Page 16

BUCKING

Don’t cut with the saw overhead or the bar in a vertical position. If the saw should kick back you may not have good

enough control to prevent possible injury.

Bucking is the sawing of a log or fallen tree into smaller

pieces. There are a few basic rules which apply to all

bucking operations.

Keep both hands on the handles at all times.

Uphill position

FIRST CUT

KICKBACK

FINISH CUT

Board or at stones

Support logs if possible.

When cutting on a slope or hillside, always stand uphill.

Keep in mind that the wood is heavy and that it will bend

and pinch the saw if improperly supported.

The trunk will weaken at the point where you make the cut

unless the tree is lying on perfectly at ground or supported

as shown.

If you make the cut with the tree on the ground, don’t let the

saw’s chain dig into the earth; it is harmful for the saw, and

you stand a good chance of being struck by ying debris.

To cut the trunk, use the bucking and two-cut sequence

shown. The rst cut should be no deeper than one-third the

trunk diameter.

WARNING DANGER

• Improper thrust cutting.

• When the bar nose hits another tree, etc.

KICKBACK IS DANGEROUS

Kickback is generated when the rotation of the chain is

arrested for some reason. The most dangerous effect

of this action occurs when the nose of the bar contacts

another object, the chain is momentarily stopped and

all the energy of the engine throws the bar upwards and

backwards towards the operator.

The chain saw industry and government agencies have

attempted to prescribe various safety devices, but the

best protection is to avoid kickback.

Comply with the Safety Precautions as listed in this

manual.

16

Page 17

COMPONENT/

SYSTEM

MAINTENANCE

PROCEDURE

REQ'D

SKILL

LEVEL

DAILY OR

BEFORE

USE

EVERY

REFUEL

3

MONTHS

OR 90

HOURS

6

MONTHS

OR 270

HOURS

YEAR LY

600

HOURS

Recommended Echo Dealer Maintenance Procedures

Cylinder Exhaust Port Inspect/Clean/Decarbon 3 I / C

Do-It-Yourself Maintenance Procedures

Air Filter Inspect/Clean/Replace 1 I / C R *

Automatic Oiler Inspect/Adjust 1 I

Oil Strainer Inspect/Replace 1 I / R *

Fuel Strainer Inspect/Replace 1 I R *

Guide Bar & Oil Holes Inspect/Clean 1 I / C

Sprocket Inspect/Replace 2 I / R *

Spark Plug Inspect/Clean/Replace 2 I / C R *

Cooling System Inspect/Clean 2 I / C

Muffler Spark Arrestor Inspect/Clean/Replace 2 I / R *

Recoil Starter Rope Inspect/Replace 1 I / R *

Screws/Nuts/Bolts Inspect/Tighten/Replace 1 I / R *

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT N OTE - Time intervals shown are maximum. Actual use and your experience will determine the frequency of required

maintenance.

MAINTENANCE PROCEDURE NOTES:

* All recommendations to replace are based on the finding of damage or wear during inspection..

maintenanCe anD CaRe

Your ECHO unit is designed to provide many hours of trouble free service. Regular scheduled maintenance will help

your unitr achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take

your unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or

have the ECHO Dealer do it, each maintenance task has been graded. If the task is not listed see your Echo dealer

for repairs.

skill levels

Level 1 = Easy to do. Most required tools come with unit.

Level 2 = Moderate difculty. Some specialized tools may be required.

Level 3 = Experience required. Specialized tools are required. ECHO recommends

that the unit be returned to your ECHO dealer for servicing.

ECHO offers REPOWERTM Maintenance Kits and Parts to make your maintenance job easier. Just below each task

heading are listed the various part numbers required for

that task. See your ECHO dealer for these parts.

maintenanCe inteRvals

17

Page 18

aiR filteR

1. Close choke (A) (Cold Start Position [ ]). This prevents

C

A

B

dirt from entering the carburetor throat when the air lter

is removed. Brush accumulated dirt from air cleaner area.

2. Remove air lter cover (B). Brush dirt from inside cover.

3. Remove air lter (C) and lightly brush debris from lter.

Replace lter if it is damaged, fuel soaked, very dirty, or

the rubber sealing edges are deformed.

4. If lter can be reused, be certain it:

• Fits tightly in the air lter cavity.

• Is installed with the original side out.

5. Install air lter cover.

automatiC oileR

• The discharge volume of the automatic oiler is adjusted to

3 to 4 cc/min. (@ 7000 rpm) prior to shipment from the

D

factory.

• Always check oil discharge when in use.

• Turn adjusting screw (D) counter-clockwise to increase oil

volume, clockwise to decrease oil volume.

oil stRaineR

• Check periodically.

- Do not allow dust to enter into oil tank.

E

- Clogged oil strainer will affect the normal

lubricating system.

- Pick it up through oil port.

- If the strainer (E) is dirty, wash it in gasoline.

- When the inside of the tank gets dirty, rinsing the

tank out with gasoline will clean it.

fuel stRaineR

• Check periodically.

- Do not allow dust to enter fuel tank.

- Clogged strainer will cause difculty in starting engine

or abnormalities in engine performance.

- Pick up the fuel strainer (F) through fuel inlet port

with a piece of steel wire, or the like.

- When the strainer is dirty, wash it in suitable

cleaning uid.

- When the inside of the fuel tank is dirty, rinsing the

tank out with suitable cleaning uid will clean it.

F

18

Page 19

GuiDe baR anD oil holes

H

• Clean after each use

G

J

- Clean the grooves (G) of the guide bar with a small

screwdriver.

- Clean oil holes (H) with a wire.

• Reverse guide bar periodically.

Worn : 0.5 mm

spRoCket

• A damaged sprocket (J) will cause premature damage

J

or wear of saw chain.

- When the sprocket has worn out 0.5mm (.020”) or

more, replace it.

• Check sprocket when you install new chain. Replace it

if worn.

• Clean sprocket, clutch and bar mount area before installation of bar.

IMPORTANT

Some tree sap and resins are corrosive. Thoroughly wash

the guide bar and sprocket areas after each use, then

coat metal parts with light oil.

spaRk pluG

• Check periodically

• Gap = 0.65mm (.026 in.)

• Replace if either electrode is worn, or if the insulator is

fouled by oil or other deposits.

• Torque = 150 – 170 kg*cm (130 – 150 in. lb.)

IMPORTANT

Do not over-torque

19

Page 20

CoolinG system CleaninG

• Remove spark plug lead.

• Remove two (2) mufer cover screws and mufer cover.

• Remove four (4) recoil starter housing screws and starter

housing.

• Use a stiff bristle cleaning brush (do not us a metal

brush) to remove dirt from cylinder ns in mufer and

ignition coil areas.

muffleR spaRk aRRestoR

IMPORTANT

Carbon deposits in mufer will cause a drop in engine

output and overheating. Spark arrestor screen must be

checked periodically.

1. Remove mufer cover.

2. Remove spark arrestor screen cover, gaskets, and

screen from mufer body.

3. Clean carbon deposits from mufer components.

NOTE

When cleaning carbon deposit, be careful not to damage

the catalytic element inside mufer.

4. Replace screen if it is cracked, plugged, or has holes

burned through.

5. Assemble components in reverse order.

Cylinder Exhaust Port

IMPORTANT

The cylinder exhaust port must be inspected and cleaned

of excess carbon every 3 months or 90 hours of operation in order to maintain this engine within the emissions

durability period. ECHO strongly recommends that you

return your unit to your ECHO dealer for this important

maintenance service.

20

Page 21

CaRbuRetoR aDjustment

Engine Break-In

New engines must be operated a minimum duration

of two tanks of fuel break-in before carburetor adjustments can be made. During the break-in period

your engine performance will increase and exhaust

emissions will stabilize. Idle speed can be adjusted

as required.

BEFORE MAKING ADJUSTMENTS:

• The correct spark plug must be clean and properly gapped.

• The air lter element must be clean and properly

installed.

• The mufer spark arrestor screen and exhaust

port must be clear of carbon.

• The standard bar and chain combination must be

installed to the power head, and properly tensioned.

LOW ALTITUDE ADJUSTMENT

Engines that have been adjusted to operate at high

altitudes must be readjusted to operate properly at

altitudes below 2000 feet.

1. Start engine and run for several minutes to reach operating temperature.

2. Stop engine. Remove grommet cover (A) over “H” and “L”

limiter needles.

3. Start engine and turn the high-speed needle rich (CCW)

until the engine runs between 11,500 and 12,000 RPM.

Then turn the low-speed needle rich (CCW) until the engine does not hesitate when accelerated.

DO NOT REMOVE LIMITER CAPS!

4. Idle Speed Adjustment.

• Turn “idle” speed adjustment screw (B) CW until the saw

chain begins to move, then turn the screw CCW until saw

chain stops moving. Turn screw CCW an additional 1/4

turn.

5. Accelerate to full throttle for 2-3 seconds to clear excess

fuel from engine then return to idle. Accelerate to full

throttle to check for smooth transition from idle to full

throttle. If engine stops or stalls after full warm up return

the unit to your authorized ECHO dealer for adjustment.

6. Install grommet cover (A) over “H” and “L” limiter needles.

HIGH ALTITUDE ADJUSTMENT

High altitude adjustment may be required for proper operation of this engine above 2000 feet.

1. Start engine and run for several minutes to reach operat-

A

B

ing temperature.

2. Stop engine. Remove grommet cover (A) over “H” and “L”

limiter needles.

3. Start engine and turn the HI speed needle lean (CW) until

the engine runs between 11,500 and 12,000 RPM. Then

turn the LO speed needle lean (CW) until the engine does

not hesitate when accelerated.

DO NOT REMOVE LIMITER CAPS!

4. Idle Speed Adjustment.

• Turn “idle” speed adjustment screw (B) CW until the saw

chain begins to move, then turn the screw CCW until saw

chain stops moving. Turn screw CCW an additional 1/4

turn.

5. Accelerate to full throttle for 2-3 seconds to clear excess

fuel from engine then return to idle. Accelerate to full

throttle to check for smooth transition from idle to full

throttle. If engine stops or stalls after full warm up return

the unit to your authorized ECHO dealer for adjustment.

6. Install grommet cover (A) over “H” and “L” limiter needles.

21

Page 22

Chain anD GuiDe baR Combinations

LEDOM

RAB

HTGNEL

KCABKCIKWOL

RABDRAUG

NIAHCWASKCABKCIKWOL

KCIK

DRAUG

N/PRAB

NIAHC

.ONTRAP

SKNILEPYTHCTIPEGUAG

N/POHCE

)N/PMEO(

103-SC

143-SC

643-SC

"21

"41

"61

znetnI"21

MT

znetnI"41

MT

"61znetnI

MT

5473DC0A21

2573DC0A41

7573DC0A61

5473DZ0A21

2573DZ0A41

7573DZ0A61

E54-GV19

E25-GV19

E75-GV19

E54-GV19

E25-GV19

E75-GV19

54

25

75

54

25

75

GV19"8/3"050.

1094982

94982

The following combinations may be used on CS-301, CS-341 or CS-346.

*Reduced nose radius symmetrical bars (OREGON name — Double Guard)

WARNING DANGER

Use of replacement saw chain and/or guide bar other than that specied, or operation without the “tip guard” in place,

may cause severe kickback resulting in serious injury.

Only use saw chain designated as, “LOW-KICKBACK,” that meets the ANSI B175.1-2000 Standard when tested on

the representative sample of chain saws below 3.8 C.I.D., and the Echo guide bar specied.

IMPORTANT

Chain and guide bar gauge size must be identical. Use Bar/Chain combinations shown in table

above.

IMPORTANT

If your kick guard is damaged or lost, contact your Echo dealer for a replacement. For the name

of the Echo dealer nearest you, Call: 1-800-432-ECHO (3246) or on the web at www.echo-usa.

com.

Refer to your Chain Saw Safety Manual for kick guard application information.

22

Page 23

SETTING THE SAW CHAIN

For setting saw chains, round le (4 mm: 5/32”) and at le are used.

• To keep correct position and correct angle, use the le holder.

- Round le and at le are available from your Echo Dealer.

• File cutters as below.

To sharpen other type chain, follow chain manufacturer’s instructions

Type : 91VG

Keep this angle

PUSH FILE AS SHOWN

30°

HOLD FILE HOLDER

LEVEL

1/5

ONE FIFTH OF FILE DIAMETER

REMAINS ABOVE CUTTER EDGE

Depth

gauge

• Place the depth gauge tool rmly on guide bar so that depth gauge protrudes. Then le top of depth gauge with at

le until at with top of the gauge tool.

- Be sure to round off the front edge of the depth gauge.

Depth gauge

tool

Remove

until at

with tool

Round

off the

edge

• Properly led cutters are shown below.

(Top plate angle) (Side plate angle) (Top plate cutting angle) (Depth gauge)

0.64 mm (0.025”)

Parallel

30°

80°

60°

• When setting of the chain is nished, soak it in oil and wash away lings completely before using.

• When chain has been led on the bar, supply sufcient oil to it, rotate the chain slowly to wash away the lings

before using again.

• If the chain saw is operated with lings clogged in the groove, the saw chain and the guide bar will be damaged

prematurely

• If the saw chain becomes soiled with resin, for instance, clean it with kerosene and soak it in oil.

CHAIN TYPE AND SPROCKET PITCH

Saw chain should be used with corresponding pitched

sprocket. To identify chain type and pitch of sprocket,

check as follows.

• Chain type number (A) is stamped on drive link.

• Sprocket pitch (B) is stamped on clutch drum.

Number indi-

cates Chain

type

(DRIVE LINK)

91

(SPROCKET)

91S

Number

indicates

Chain type

23

A

B

Page 24

tRoubleshootinG

TRAHCGNITOOHSELBUORTMELBORPENIGNE

melborPkcehCsutatSesuaCydemeR

enignE

-sknarc

/drahstrats

t'nseod

trats

roterubractaleuFroterubractaleufoNdeggolcreniartsleuF

deggolcenilleuF

roterubraC

ecalperronaelC

ecalperronaelC

relaedohcEruoyeeS

rednilyctaleuFrednilyctaleufoNroterubraCrelaedohcEruoyeeS

leufhtiwtewrelffuMhcirooterutxiMleuFekohcnepO

retlifriaecalper/naelC

roterubractsujdA

relaedohcEruoyeeS

dnetakrapS

eriwgulpfo

krapsoNffohcti

wspotS

melborplacirtcelE

hctiwskcolretnI

NOothctiwsnruT

relaedohcEruoyeeS

relaedohcEruoyeeS

gulptakrapSkrapsoNtcerrocnipagkrapS

nobrachtiwderevoC

leufhtiwdeluoF

evitcefedgulP

).ni620.0(mm56.ottsujdA

ecalperronaelC

ecalperronaelC

gulpecalpeR

,snurenignE

roseidtub

tonseod

etarelecca

ylreporp

retlifriAytridretlifriAraewlamroNecalperronaelC

retlifleuFytridretlifleuFseudiser/stnanimatnoCni

leuf

ecalpeR

tnevleuFdeggulptnevleuFniseudise

r/stnanimatnoC

leuf

ecalperronaelC

gulPkrapSnrow/ytridgulPraewlamroNecalperrotsujdadnanaelC

roterubraCtnemtsujdareporpmInoitarbiVtsujdA

metsySgnilooCmetsysgnilooC

deggulp/ytrid

ninoitarepodednetxE

snoitacolytsud/ytrid

naelC

rotserrAkrapS

neercS

rotserrakrapS

deggulpneercs

raewlamroNecalpeR

seodenignE

knarcton

A/NA/NmelborpenignelanretnIrelaedohcEruoyeeS

Poor performance of the engine and/or cutting mechanism can normally be prevented by carefully following these

instructions.

Poor performance can easily be corrected even by a beginner.

When the engine does not function properly check the following three (3) points rst.

• Istheenginecompressionadequate?

• Isfuelsystemingoodconditionandisenoughfuelbeingsupplied?

• Iselectricalsystemingoodconditionandissparkplugoperatingnormally?

When there is serious trouble with the unit, do not try to repair it yourself but have your distributor or dealer do it for

you. For detailed TROUBLESHOOTING refer to tables 1 and 2. Locate the problem on the following charts and repair

as necessary.

Table 1

reaching carburetor

Fuel is not

Engine cranks

There is fuel in the tank

Engine does not start (or, is difcult to start)

Fuel is reaching cylinder

Fuel is reaching carburetor

There is spark at high

tension cord end

Fuel is not reaching

cylinder

No spark at high

tension cord end.

No spark at plug

Fuel does not keep

running

Acceleration and low

speed function defective

There is spark at plug

Carburetor

overow

Engine does

not crank

correct

Fuel strainer

clogged ..........

Clean.

Fuel pipe

clogged ............

Clean.

Starting procedures

Make sufcient.

Strainer clogged ..........................................Clean.

Carburetor out of order ................................Disassemble and check.

C.D.I. module defective ...............................Remove and replace.

Ignition coil defective ...................................Remove and replace.

Wire connection defective ..........................Reconnect.

High-tension cord connection defective.......Repair as necessary.

Switch is grounded ......................................Switch on.

Insulator cracked .........................................Replace plug.

Spark gap incorrect .....................................Adjust.

Covered with carbon....................................Clean or replace.

Fouled with fuel ...........................................Clean or replace.

Starting procedures incorrect ......................Start correctly.

Low and high speed needle.........................Readjust.

setting too lean

Metering lever spring too strong ..................Readjust.

Fuel pump diaphragm defective ..................Replace.

Fuel passage clogged with dust ..................Disassemble and clean.

Fuel leaking from xing surfaces ................Retighten all screws.

of carburetor

Air valve, fuel tank cap does not

work normally ..............................................Replace or Clean.

Fuel pump does not operate........................Check

impulse drilling.

Fuel inlet needle valve clogged with dust ....Clean.

Metering lever spring not placed

in dent of lever .............................................Correct.

Mufer sticky with fuel .................................Fuel mixture is too rich

Start the engine several

times

with choke rod fully open

and

run at fast idle until engine

does not smoke.

Bearing damaged ........................................Disassemble and

replace.

Piston and/or cylinder seized.......................Disassemble and replace.

Crankshaft worn ..........................................Disassemble and replace.

Crankshaft contacting crankcase ................Disassemble and replace.

Suction insuf-

cient ................

24

Page 25

Table 2

Improper fuel used.......................................Use fuel with correct mixing ratio. Never use

gasoline of poor quality.

WARNING DANGER

Engine over-

Fuel vapors are extremely ammable and may cause re and/or explosion. Never test for ignition spark by

heated

grounding spark plug near cylinder plug hole, otherwise serious personal injury may result.

Spark plug defective (worn) .........................Replace.

As cooling ns clogged, air

does not pass well .......................................Clean ns.

Excessive deposits in

combustion chamber ...................................Disassemble and remove carbon.

stoRaGe afteR use

• Inspect and adjust every part of the chain saw.

- Completely clean every part, and repair, if necessary.

Firing function

defective

- Apply thin coating of oil on metal parts to prevent rust.

• Drain fuel tank, pull starter slowly a few times to drain fuel from carburetor.

• Pour a small amount of clean two-stroke oil into spark plug hole, pull starter and crank engine until the piston is at TOP DEAD

CENTER.

• Store in a dry area, free from dust.

Ouput (engine speed) insufcient

Carburetor

defective

Plug damaged or fouled ..............................Replace or clean.

Comubstion poor due to

defective wiring ............................................Check wiring.

High-speed needle setting incorrect ............Readjust.

Carburetor overow .....................................Refer to Table 1.

Air cleaner clogged ......................................Clean as necessary.

CoRReCt use of Chain bRake

The installation of a chain brake may be mandatory by law or as stipulated by insurance regulations in your area of

operation. You should inquire through local government ofces, your employer or your local dealer to ensure that your

chain saw conforms to the required safety standard. Echo chain brakes have been designed and tested to comply

with international safety standards as follows.

USA: ANSI Standard B175.1-2000 Safety Requirement for chain saws

Other

troubles

Canada: CSA Standard Z 62.1 CHAIN SAWS

ANSI Standard B175.1-2000 stipulates that the brake shall stop the chain in 0.15 seconds maximum (.12 sec avg)

at full throttle. It is the responsibility of the Owner/Operator to ensure that the brake is serviced, adjusted and

tested strictly in accordance with the instructions as detailed herein in order to ensure that the brake performance

is maintained in compliance with the Standard B175.1-2000.

Kickback Motion:

Engine keeps running, but chain does not cut clean

Output (engine speed) sufcient

Chain does not cut

clean

Chain stops

(Clutch slips)

Chain poorly

lubricated

Compression insufcient

(piston ring stuck or worn out) .....................Disassemble, check and replace if necessary.

Cylinder chromium plating peeled ...............Replace cylinder

or worn out

Exhaust port clogged with carbon ...............Clean as necessary.

Throttle is not fully open ..............................Readjust.

WARNING DANGER

Chain tension incorrect ................................Adjust.

Chain wrongly set ........................................Set correctly.

Depth incorrect ............................................Readjust.

Chain saw pressed against

tree to rmly .................................................Press lightly.

Clutch shoe worn out ...................................Replace.

No oil in tank ................................................Rell.

Oil delivery incorrect ....................................Adjust.

Oil contaminated with dust ..........................Rinse tank and ll with new oil..

Oil viscosity inappropriate............................Use oil with correct viscosity for summer or winter.

Function:

• When the bar nose hits another tree, etc.

• When the lever is pushed forward, chain brake instantly

works to stop the chain.

Release:

• When the lever is fully pulled toward the operator, brake is

released.

25

Page 26

INSTALLATION

• Echo recommends that the chain brake should be serviced

by an authorized Echo servicing dealer.

OPERATION

• Set the lever in the unlocked position before starting to cut.

• If the brake is tripped by kick back reaction, the chain will

stop. Immediately release the throttle to avoid possible

damage to the engine or clutch.

• Do not attempt to operate the engine with the brake locked.

• When the lever is fully pulled toward the operator, brake is

unlocked.

TESTING THE BRAKE

• Start the engine on a solid level surface and run at a fast

idle until warm.

• Hold the saw rmly by the handles and accelerate the engine to a fast idle.

• Slowly operate the chain brake lever while holding the saw

rmly on the ground. When the brake lever trips, the chain

should stop. Immediately release the throttle trigger.

IMPORTANT

Do not allow the saw to tip forward in order to

avoid damage to the chain.

If the chain does not stop, immediately return the saw to your

authorized Echo dealer for repair.

26

Page 27

notes

27

Page 28

seRviCinG infoRmation

paRts

Genuine ECHO Parts and ECHO REPOWERTM Parts and Assemblies for your ECHO products are available only from an Authorized

ECHO Dealer. When you do need to buy parts always have the Model

NumberandSerialNumberoftheunitwithyou.Youcanndthese

numbers on the engine housing. For future reference, write them in the

space provided below.

Model No. _____________ SN. __________

/seRial numbeR

seRviCe

Service of this product during the warranty period must be performed

by an Authorized ECHO Service Dealer. For the name and address

oftheAuthorizedECHOServiceDealernearestyou,askyourretailer

or call: 1-800-432-ECHO. When presenting your unit for Warranty

service/repairs, proof of purchase is required.

eCho ConsumeR pRoDuCt suppoRt

If you require assistance or have questions concerning the application, operation or maintenance of this product you may call the ECHO

Consumer Product Support Department at 1-800-673-1558 from 8:30

am to 4:30 pm (Central Standard Time) Monday through Friday. Before

calling,pleaseknowthemodelandserialnumberofyourunittohelp

your Consumer Product Support Representative.

waRRanty CaRD

This card is our means of registering all original owners of ECHO

equipment. The card plus proof of purchase provides you the assurance

thatauthorizedwarrantyworkwillbedone.Italsoprovidesadirect

linkbetweenyouandECHOifwenditnecessarytocontactyou.

DEALER?

Call

1-800-432-ECHO

or

www.echo-usa.com

CONSUMER PRODUCT

SUPPORT

1-800-673-1558

8:30 - 4:30 Mon - Fri C.S.T.

aDDitional oR ReplaCement manuals

Safety Manuals in English/Spanish or English/French are available, free of charge, from your ECHO dealer or at www.

echo-usa.com.

Instruction and Parts Manuals are available by:

• Downloadingfreefromwww.echo-usa.com

• PurchasingfromyourEchoDealer.

• ManualsareavailablebysendingawrittenrequeststatingthemodelnumberandserialnumberofyourEchounit,part

number of the manual, your name and address, and mail to the address below.

Safety Videos are available from your Echo dealer. A $5.00 shipping charge will be required for each video.

ECHO, INCORPORATED

400 OakwOOd ROad

Lake ZuRich, iL 60047-1564

www.echo-usa.com

02001001/02999999

Loading...

Loading...