Page 1

Chain Saw

Operator’ s Manual

MODELS : CS-3000 TYPE 1E

Serial Number 001001 - 630329

CS-3400 TYPE 1E

Serial Number 001001 - 580667

CS-3450 TYPE 1E

Serial Number 001001 - 594521

X7503200005

WARNING

Read rules for safe operation and instructions carefully . ECHO provides

an Operator’s Manual and an Engine Operator’s Manual. Both must be

read and understood for proper and safe operation.

DANGER

99922202726

05/02

Page 2

RULES FOR SAFE OPERATION

A. Kickback Safety Precaution for Chain Saw Users

WARNING!

KICKBACK may occur when the nose or tip of the guide bar

touches an object, or when the wood closes in and pinches

the saw chain in the cut.

Tip contact in some cases may cause a lightning fast reverse

REACTION, Kicking the guide bar up and back towards the

operator, pinching the saw chain along the top of the guide

bar rapidly back towards the operator. Either of these reactions may cause you to lose control of the saw which could

result in serious personal injury .

Do not rely exclusively upon the safety devices built into your

saw. As a chain saw user, you should take several steps to

keep your cutting jobs free from accident or injury .

1. With a basic understanding of kickback, you can reduce

or eliminate the element of surprise. Sudden surprise

contributes to accidents.

B. Other Safety Precautions

1. Do not operate a chain saw with one hand! Serious injury

to the operator, helpers, bystanders, or any combination

of these persons may result from one-handed operation.

A chain saw is intended for two-handed use.

2. Do not operate a chain saw when you are fatigued.

3. Use safety footwear; snug-fitting clothing; protective gloves;

and eye, hearing and head protection devices.

2. Keep a good firm grip on the saw with both hands, the

right hand on the rear handle, and the left hand on the

front handle, when the engine is running. Use a firm grip

with thumbs and fingers encircling the chain saw handles.

A firm grip will help you reduce kickback and maintain

control of the saw. Dont’ let go.

3. Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of th guide bar

contact a log, branch, or any other obstruction which

could be hit while you are operating the saw.

4. Cut at high engine speeds.

5. Do not overreach or cut above shoulder height.

6. Follow manufacturer’s sharpening and maintenance instructions for the saw chain.

7. Only use replacement bars and chains specified by the

manufacturer or the equivalent.

1 1. Shut off the engine before setting the chain saw down.

12. Use extreme caution when cutting small size brush and

saplings because slender material may catch the saw

chain and be whipped toward you or pull you off balance.

13. When cutting a limb that is under tension, be alert for

springback so that you will not be struck when the tension in the wood fibers is released.

4. Use caution when handling fuel. Move the chain saw at

least 10 feet (3 m) from the fueling point before starting

the engine.

5. Do not allow other persons to be near the chain saw

when starting or cutting with the chain saw. Keep bystanders and animals out of the work area.

6. Do not start cutting until you have a clear work area,

secure footing, and a planned retreat path from the falling

tree.

7. Keep all parts of your body away from the saw chain

when the engine is running.

8. Before you start the engine, make sure that the saw chain

is not contacting anything.

9. Carry the chain saw with the engine stopped, the guide

bar and saw chain to the rear, and the muf fler away from

your body .

10. Do not operate a chain saw that is damaged, improperly

adjusted, or not completely and securely assembled. Be

sure that the saw chain stops moving when the throttle

control trigger is released.

14. Keep th handles dry, clean, and free of oil or fuel mixture.

15. Operate the chain saw only in well-ventilated areas.

16. Do not operate a chain saw in a tree unless you have

been specifcally trained to do so.

17. All chain saw service, other than the items listed in the

operator’s manual maintenance instructions, should be

performed by competent chain saw service personnel.

(For example, if improper tools are used to remove the

flywheel or if an improper tool is used to hold the flywheel

in order to remove the clutch, structural damage to the

flywheel could occur and could subsequently cause the

flywheel to burst.)

18. When transporting your chain saw , use the appropriate

gude bar scabbard.

19. Spark arrester mufflers approved to SAE Standard J335b

are Standard on ECHO Chain saws to reduce the possibility of forest fires. Do not operate the chain saw with a

loose or defective muffler. Do not remove the spark arrester screen.

2

Page 3

CONTENTS

Page

Rules for Safe Operation.................................................................................................................. 2

T echnical Data .................................................................................................................................4

Nomenclature of Parts......................................................................................................................5

Preparation for Use..........................................................................................................................6

Operation.........................................................................................................................................7

Cutting Instructions ........................................................................................................................... 9

Maintenance and Care...................................................................................................................13

Chain and Guide Bar Combinations...............................................................................................14

Setting the Saw Chain....................................................................................................................15

Troubleshooting.............................................................................................................................. 16

Storage........................................................................................................................ .................. 17

Correct Use of Chain Brake ........................................................................................................... 18

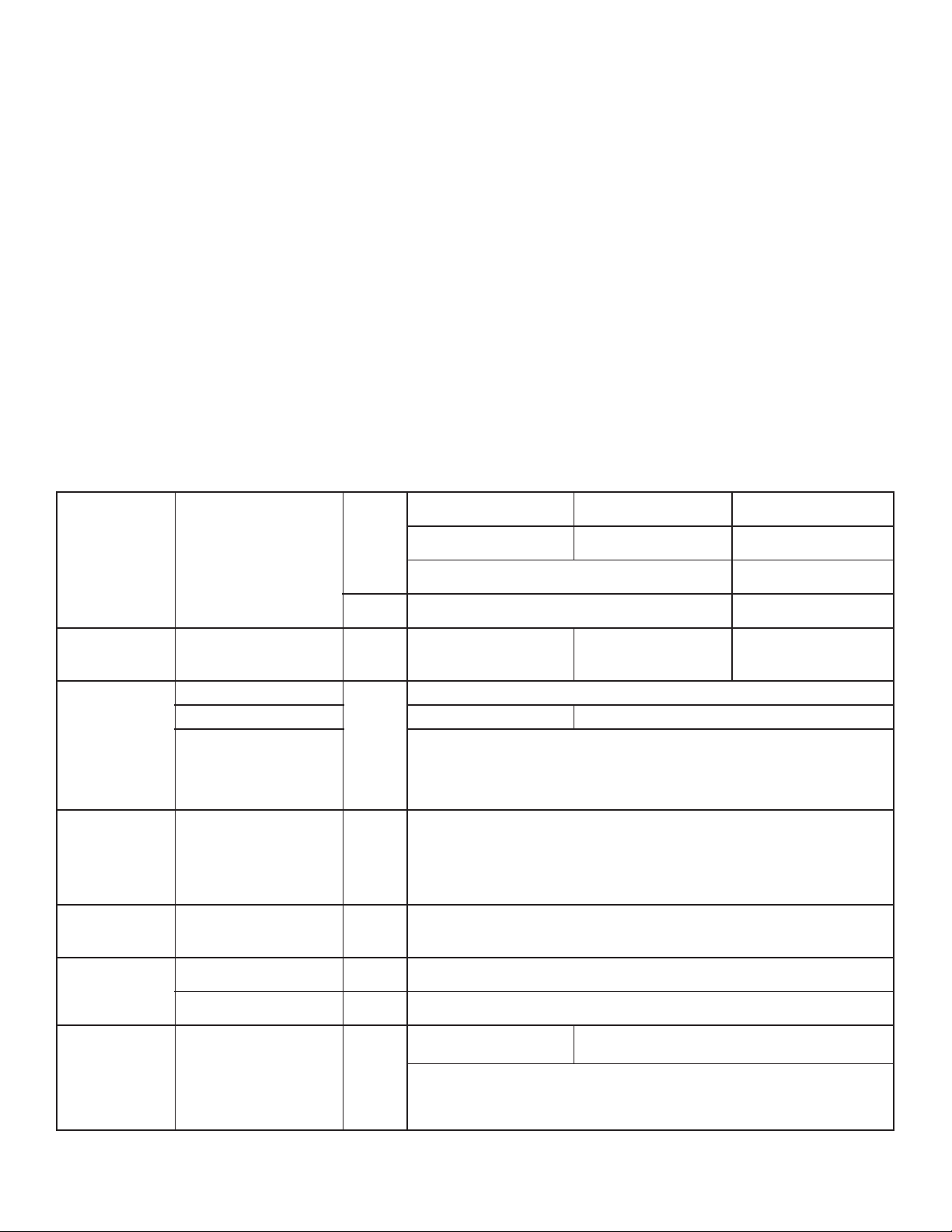

TECHNICAL DATA

E-1EPYT0003-SCE-1EPYT0043-SCE-1EPYT0543-SC

noisnemiDHxWxL

mm

hcni

thgieWyrd,daehrewoPgk)bl1.7(2.3

enignEepyT

tnemecalpsiD).ni.uc38.1(1.03).ni.uc30.2(4.33

leuFoitarerutxiM

liOniahcdnaraB

rabediuG

wasdna

niahc

roterubraC

otengaM

gulPkrapS

retratS

yticapaCknaTretil

yticapaCknaTretil

noitacirbuLpmupliocitamotuaelbatsujdA

cc

noissimsnartrewoP

0003-SC0043-SC0543-SC

022x032x062542x032x083

7.8x1.9x2.016.9x1.9x0.51

dnaniahctuohtiW

rabediug

epytmgarhpaiD

metsysIDC:otengamleehwylF

retratslioceR

hctulclagufirtneccitamotuA

).S.Uzolf6.8(52.0

).S.U.zo.lf5(51.0

)bl3.7(3.3

dnaniahctuohtiW

rabediug

rednilycelgnis,ekorts-owt,delooc-riA

A7MPBKGNroY7-JCNOIPMAHC

.lioekorts-owtdnarbOHCEhtiwoitar1:05

.EBTM%51rolohoclalyhte%01nahterom

)liorotomro(lioniahcdnarabOHCE

.atadlacinhcetniahCdnaraBrof41egapeeS

)bl5.7(4.3

dnaniahctuohtiW

rabediug

,lohoclalyhtemgniniatnocleufesutonoD.dedaelnuenatco98

dradnatS

serutaef

* Technical data subject to change without notice.

eldnaHpoTeldnahlanoitevnoC

draugdnahraeR

,draugdnahtnorF

,ecivednoitarbiv-itnA

,ekarbniahC,tuokcollortnocelttorhT

relffumretserratrapS,rehctacniahC

3

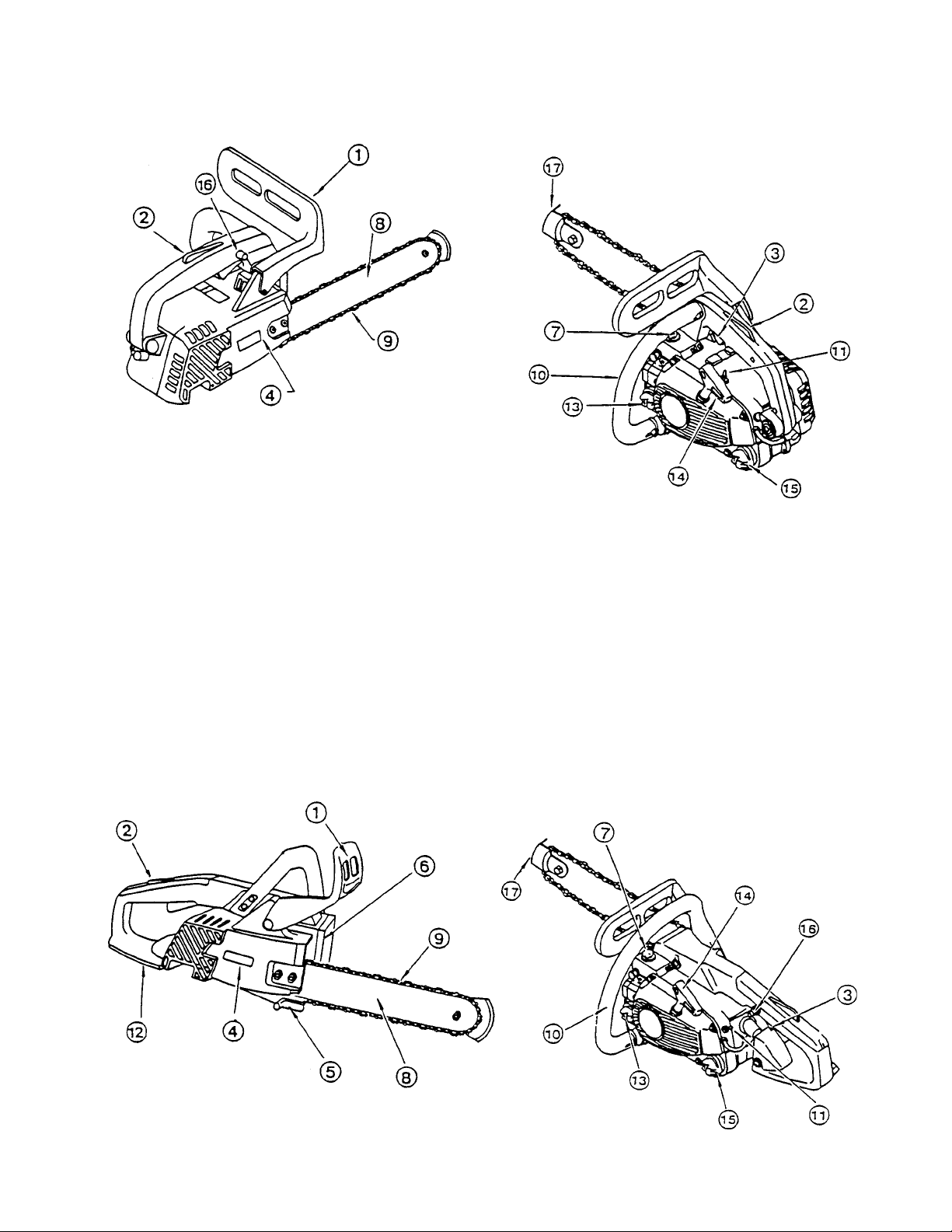

Page 4

CS-3000, CS-3400

NOMENCLATURE OF PARTS

1. Hand guard

(Chain brake actuating lever)

2. Throttle control lockout

3. Throttle control trigger

4. Sprocket guard

5. Chain catcher

CS-3450

6. Air cleaner cover

7. Purge bulb

8. Guide bar

9. Saw chain

10. Front handle

11. On / Off switch

12. Rear handle guard

13. Fuel tank cap

14. Pull starter

15. Oil tank cap

16. Throttle control latch

17. Tip guard

4

Page 5

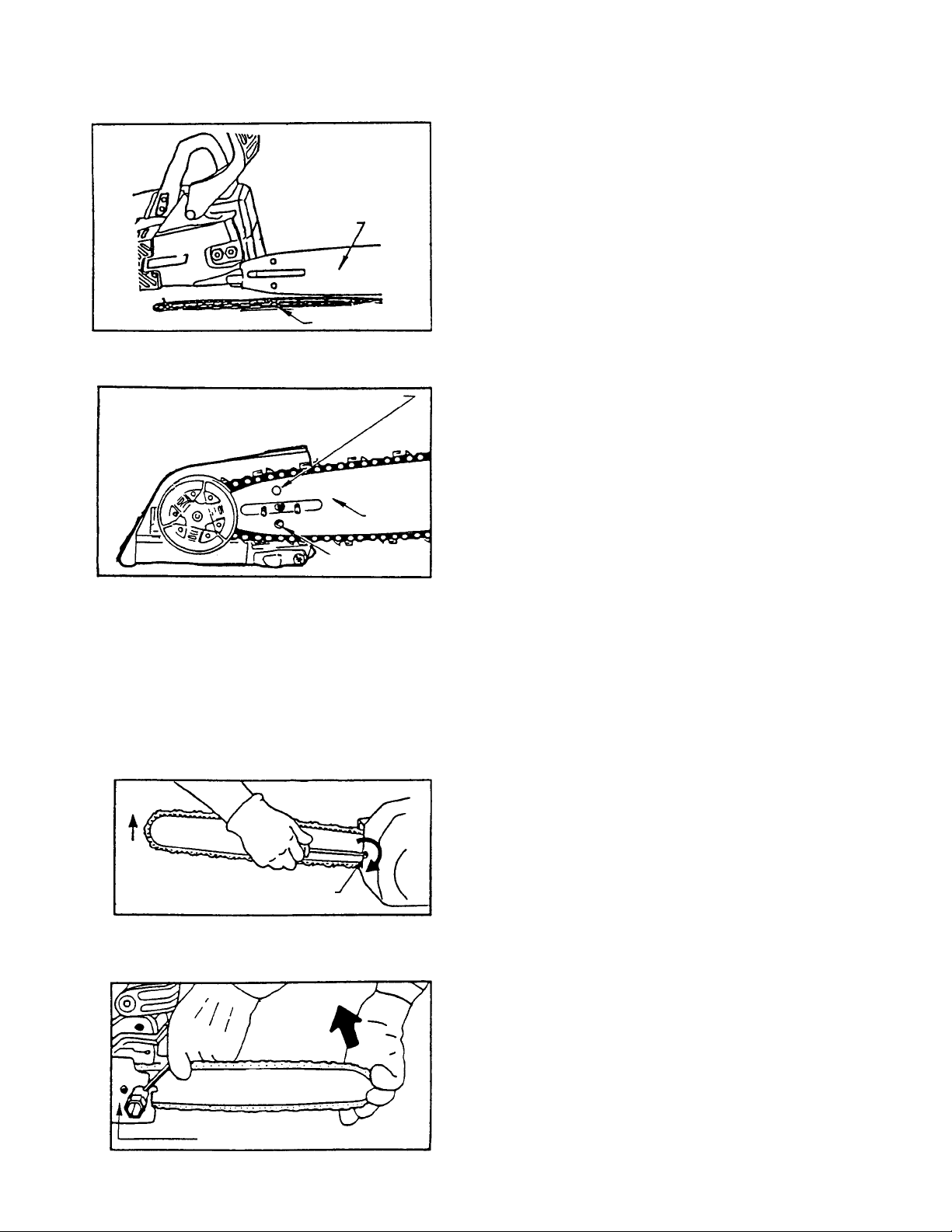

Guide bar

Saw chain

PREPARATION FOR USE

The machine is delivered with guide bar and saw chain

separated. Install guide bar and chain as follows.

Direction to tension

T ensioner adjusting screw

Holes

Guide

bar

Chain tensioner

the chain

UP

GUIDE BAR AND SA W CHAIN

• Unscrew two nuts and remove sprocket guard.

• Mount bar and slide toward sprocket to make saw chain

installation easier.

• Install chain as shown with cutters facing forward.

• Ensure that tensioner fits into bar hole.

• Install sprocket guard tighten nuts finger tight.

ADJUSTMENT, CHAIN TENSION

• Turn the adjuster screw clockwise until the chain

touches the bottom of the bar.

• Hold the bar nose up and tighten the chain until there is

no clearance between the bar and chain tie straps.

• Tighten both nuts with the bar nose held up to eliminate

clearance.

• Pull the chain around the bar by hand. Loosen the

adjustment if you feel tight spots.

• Start the engine and run at low speed. Stop and readjust

if necessary .

Sprocket guard

CAUTION

1. All adjustments should be made cold.

2. Always wear gloves when working on chain.

3. Do not operate with a loose chain.

5

Page 6

FUEL AND LUBRICANT

).S.U()CIRTEM(

SAGLIOSAGLIO

.laG.zo.lFretiL.cc

1

2

5

6.2

1.5

8.21

4

8

02

08

061

004

FUEL STATEMENT

GASOLINE - Use 89 Octane (R+M/2) gasoline or gasohol

known to be good quality . Gasohol may contain maximum 10%

ethyl (grain) alcohol or 15% MTBE (methyl tertiary-butyl ether).

Gasohol containing methy (wood) alcohol is not approved.

Oil

OIL - ECHO brand premium two-stroke 50:1 oil is preferred. Mix

oil and gasoline/gasohol according to instructions on the oil

container label.

MIXING - Follow directions on the oil container.

IMPORTANT

Stored fuel ages. Do not mix more fuel than you expect to use

in thirty (30) days, ninety (90) days when a fuel stabilizer is

added.

Stored two-stroke fuel may separate. AL WAYS shake fuel

container thoroughly before each use.

CHAIN LUBRICANT

• Proper lubrication of the chain while in operation reduces

friction between the chain and the guide bar to a minimum

and assures a longer service life.

• use bar and chain oil of high quality for this purpose.

• Do not use used or reclaimed oil to avoid various oiler

problems.

• Use ECHO bar and chain oil.

• When ECHO bar and chain oil is not available:

Use motor oil, etc.

• Use bar and chain oil of the following grades:

SAE NO. 30 ..... in summer

SAE NO. 10 ..... in winter or when cutting resinous trees.

• When refueling, also refill chain oil.

50

Gasoline

Fuel Mix Chart

50:1

TANK INDICA TION

Fuel/oil tanks are indicated by the following illustrations on

the tanks.

FUEL TANK OIL TANK

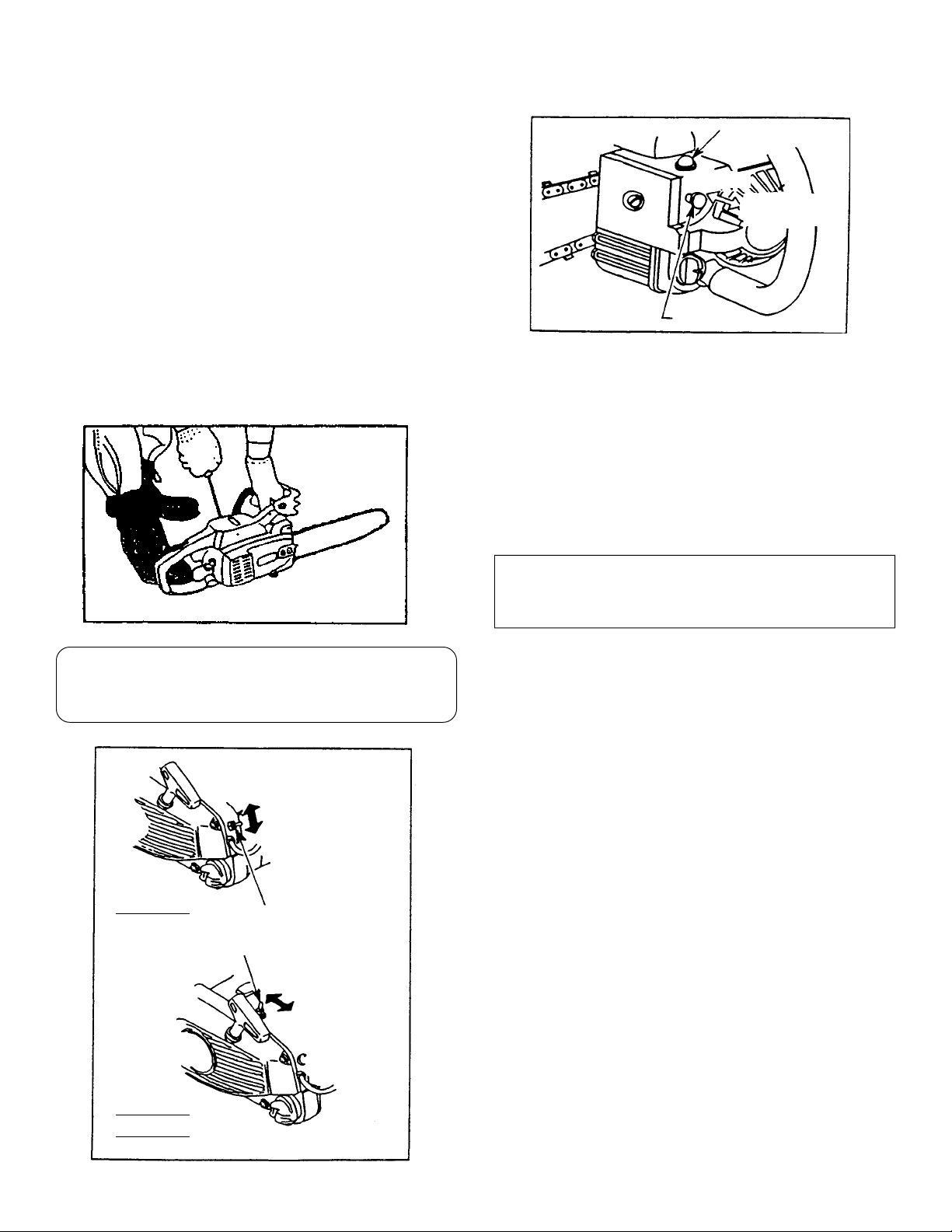

OPERATION

WHEN THE ENGINE IS COLD

• Fill the fuel tank with fuel.

• Fill the chain oil tank with lubricant.

• Turn switch to “RUN” position.

• Pull choke all the way out. (Close position)

• Push purge bulb 3 to 4 times

• Pull starter handle several times until first firing sound. (Hold

machine with your knee.)

• Push choke all the way in. (Open position)

• Pull starter handle again.

START / RUN

STOP

CS-3450

On / Off switch

On / Off switch

START / RUN

STOP

CS-3000

CS-3400

6

Page 7

WHEN THE ENGINE IS HARD TO

START

• Press throttle control lockout down while holding throttle

trigger and push in latch.

• Pull starter handle.

• When engine starts, immediately push throttle trigger

up, to release the latch.

CAUTION

Clutch engages and chain will rotate when engine is started

with throttle latch engaged.

After engine starts, release throttle trigger to idle engine.

Never use the latch for cutting.

Use it only when starting the engine.

Purge bulb

RUN

START

(PULL)

Choke knob

Do not pull starter rope out to the maximum possible position.

Do not allow recoil handle to snap back against the casing.

STARTING WARM ENGINE

• Ensure that there is fuel and chain oil in the tanks.

(If fuel tank was emptied during previous operation, refill

tank and push purge bulb 3 or 4 times.)

• Turn switch to “RUN” position.

• Pull starter handle.

• Choke may be used if necessary but be sure to push it

back on first firing sound.

Securely hold the saw.

Make sure bar and chain are not touching anything when starting

the saw.

START / RUN

STOP

CS-3450

On / Off switch

On / Off switch

START / RUN

STOP

NOTE

If engine does not start after 4 pulls, use cold start procedure.

RUNNING

• After engine starts, allow it to idle for a few minutes.

• Squeeze throttle trigger with throttle control lockout

gradually to increase engine speed.

• Saw chain starts running when the engine reaches

approximately 4200 rpm.

• Ensure proper acceleration and lubrication of chain and

bar.

• Do not run the engine at high speed unnecessarily.

• Be sure that saw chain stops moving when throttle

trigger is released.

STOPPING

• Release throttle trigger and turn switch to STOP position.

(NOTE)

When engine does not stop, pull choke out fully to stop

engine.

Check and repair stop switch before starting the engine

again.

CS-3000

CS-3400

7

Page 8

GENERAL

CUTTING INSTRUCTIONS

[NOTE]

Read the ECHO “CHAIN SAW SAFETY MANUAL” included

with your chain saw for additional cutting and safety instructions.

In all circumstances the operation of the chain saw is a

one-man job. It is difficult at times to take care for your own

safety , so don’t assume the responsibility for a helper as

well. After you have learned the basic techniques of using

the saw, your best aid will be your own good common

sense...

The accepted way to hold the saw is to stand to the left of

the saw with your left hand on the front handlebar and your

right hand on the rear handle so you can operate the

throttle trigger with your right index finger.

Before attempting to fell a tree, cut some small logs or

limbs. Become thoroughly familiar with the controls and the

responses of the saw.

Start the engine, see that it is running properly . Squeeze

the trigger to open the throttle wide open and start the cut.

If the chain is properly sharpened, the cutting should be

relatively effortless. It is not necessary to press down hard

to make the saw cut. Pushing the saw too hard will slow

the engine and cutting will actually be more difficult.

Kickback

Some material may adversely affect the housings of your

ECHO chain saw.

(Example: Palm Tree Acid, fertilizer , etc.) T o avoid housing

deterioration, carefully remove all packed saw dust around

clutch and guide bar area and wash with water.)

CAUTION

Do not let the tip of the bar touch anything while the

engine is running. At cutting speed the chain is moving,

at a high rate of speed. Should the tip contact a limb or

log while the chain is moving, the tip will be pushed

upward with considerable force. This is known as kickback. Avoid it!

CAUTION

Wear suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

8

Page 9

FELLING A TREE

A falling tree can seriously damage anything it may hit - a

car, a house, a fence, a powerline, or another tree. There are

ways to make a tree fall where you want it, so first decide

where that is!

DIRECTION

OF FALL

Direction of fall

First cut

Second cut

One-third tree

diameter

Notch

Before cutting, clear the area around the tree. Y ou will need

good footing while working and you should be able to work

the saw without hitting any obstacles. Next, select a path of

retreat. When the tree begins to fall you should retreat away

from the direction of fall at a 45 degree angle to avoid the

45°

Hinge

trunk kicking back over the stump.

Begin the cut on the side to which the tree is to fall. Cut a

notch about 1/3 of the way into the tree as shown. The position of this notch is important since the tree will try to fall

2”

Felling cut

“into” the notch. The felling out is made on the side opposite

the notch and at a level about 2” above the bottom of the

notch. Do not try to cut through to the notch with the felling

cut. The remaining wood between the notch cut and felling

2”

cut (about 2”) will act as a hinge when the tree falls, guiding it

in the desired direction. When the tree starts to fall, kill the

engine, place the saw on the ground and make your retreat

quickly.

LIMBING

To fell big trees with a diameter exceeding twice the bar

length, start the notching cuts from one side and draw the

saw through to the other side of the notch. Start the back cut

on one side of the tree, pivoting the saw through to form the

desired hinge on that side.

Then remove the saw for the second cut. Insert the saw in the

first cut, very carefully so as not to cause kickback. The final

cut is made by drawing the saw forward in the cut to reach

the hinge.

Limbing a fallen tree is much the same as bucking. Never

limb on the tree that you are standing. When limbing, caution

is the word. Be careful of the tip touching other limbs. Always

use both hands.

9

Page 10

BUCKING

Uphill position

Don’t cut with the saw overhead or the bar in a verticle position. If the saw should kick back you may no have good enough

control to prevent possible injury .

Bucking is the sawing of a log or fallen tree into smaller

pieces. There are a few basic rules which apply to all

bucking operations.

Keep both hands on the handles at all times.

Support logs if possible.

When cutting on a slope or hillside, always stand uphill.

FINISH CUT

FIRST CUT

KICKBACK

• Improper thrust cutting.

Board or flat stones

Keep in mind that the wood is heavy and that it will bend and

pinch the saw if improperly supported.

The trunk will weaken at the point where you make the cut

unless the tree is lying on perfectly flat ground or supported

as shown.

If you make the cut with the tree on the ground, don’t let the

saw’s chain dig into the earth; it is harmful for the saw , and

you stand a good chance of being struck by flying debris. T o

cut the trunk, use the bucking and two-cut sequence shown.

The first cut should be no deeper than one-third the trunk

diameter.

WARNING: KICKBACK IS DANGEROUS

Kickback is generated when the rotation of the chain is arrested for some reason. The most dangerous effect of this

action occurs when the nose of the bar contacts another object, the chain is momentarily stopped and all the energy of

the engine throws the bar upwards and backwards towards

the operator.

The chain saw industry and government agencies have attempted to presecribe various safety devices, but the best

protection is to avoid kickback.

• When the bar nose hits another tree, etc.

Comply with the Safety Precautions as listed on page 2 of

this manual.

10

Page 11

INFORMATION

Kickback Safety Features

The following features are recommended for this model as Kickback Safety Features.

• Double Guard Low Kick Type Guide Bar or Asymmetrical Low Kick T ype Guide Bar

Note: Y ou saw chain can be equipped with either of these bars.

Guide à Double Guard

Reduced nose radius

NOTE:

Replacement Guide Bars

The following guide bars may be considered to have equivalent kickback energy .

• Sprocket nose guide bars o fthe same length and nose radius, same pitch and having the same number of teeth.

• A hard nose guide bar having the same length and nose radius as a sprocket nose bar.

• Low Kick Guard Link Type Saw Chain

The low kick guard link chain must be maintained correctly . Follow instruction “SETTING THE CHAIN” in operator’s

manual.

• Front Handle Guard

The front handle guard must be installed correctly and kept in good condition.

• Chain Brake

The chain brake is available as a standard feature on the P-type model.

Chain brak must be maintained correctly . Follow instruction “CORRECT USE OF CHAIN BRAKE” in operator’s manual.

CAUTION !!

The consequences of using improper replacement components and of removing safety devices may result in serious or

fatal injury

11

Page 12

MAINTENANCE AND CARE

Air filter

Air cleaner cover

Oil discharge

adjusting screw

AIR FILTER

• Check before every use.

• Pull choke all the way out (Close position).

• Loosen bolt, and remove air cleaner cover and filter.

• Brush off dust lightly, or wash it in water and detergent if

necessary . Dry it completely before installation.

AUTOMA TIC OILER

• The discharge volume of the automatic oiler is adjusted

to 3 to 4 cc/min (at 7000 rpm), prior to shipment from

factory.

• Always check oil discharge when in use.

OIL STRAINER

• Check periodically.

• Do not allow dust to enter into oil tank.

• Clogged oil strainer will affect the normal lubricating

system.

• Pick it up through oil port.

• If the strainer is dirty, wash it in gasoline.

• When the inside of the tank gets dirty, it can be cleaned

by rinsing the tank out with gasoline.

Sprocket

Fuel strainer

Oil port

Oil strainer

Oil holes

Groove

FUEL STRAINER

• Check periodically.

• Do not allow dust to enter fuel tank.

• Clogged strainer will cause difficulty in starting engine or

abnormalities in engine perfomance.

• Pick up the fuel strainer through fuel inlet port with a

piece of steel wire or the like.

• When the strainer is dirty, wash it in suitable cleaning

fluid.

• When the inside of the fuel tank is dirty, it can be

cleaned by rinsing the tank out with suitable cleaning

fluid.

GUIDE BAR AND OIL HOLES

• Clean before starting work.

• Clean the groove of the guide bar with, for example, a

small screw driver.

• Clean oil holes with a wire.

• Reverse guide bar periodically.

SPROCKET

• The damaged sprocket will cause premature damage or

wear of saw chain.

• When the sprocket has worn out 0.5 mm (.020 in.) or

more, replace it.

• Check sprocket when you install new chain. Replace it if

worn.

• Clean sprocket, clutch and bar mount area before

installation of bar.

12

Page 13

SPARK PLUG

• Check periodically.

• Gap = 0.65 mm (.026”)

• Replace if either electrode is worn or if the insulator is fouled

by oil or other deposits.

• TORQUE = 145 ~ 155 kg•cm (125 ~ 135 in. lb.)

0.65 mm

(.026”)

Idle adjustment screw

Choke button

Grommet

cover

CAUTION Do not over torque.

CARBURETOR ADJUSTMENT

Non Emission Models

T ools Required: Tachometer P/N 99051 130010

GENERAL ADJUSTMENTS

• Idle adjustment screw is adjusted not to rotate the saw chain

at idling speed, prior to shipment from factory .

• Remove grommet cover over “H” and “L” limiter needles.

1. Turn H i and Lo speed mixture needles iclockwise (CW) until

lightly seated.

IMPORT ANT: Do not over tighten mixture needles, otherwise

needle tip and carburetor body seat damage may occur.

2. Back Lo speed mixture needle out counter-clockwise (CCW)

1-1/4 turns for CS-3400/3450, and 1-5/16 for CS-3000. Back

Hi speed mixture needle out counter-clockwise (CCW) out 11/2 turns out for the CS-3400/3450 and 1-3/8 turns out for CS-

3000.

FIG. 3

Locating slots

FIG. 4

for cap slots

Hi Lo

3. Turn Idle Speed screw in or out until the tip of the screw

contacts the throttle plate. Then turn it in clockwise (CW) 3

additional turns.

4. Start the engine and conduct initial warm-up at idle for one

minute.

5. Using a tachometer, confirm WOT (Wide Open Throttle)

engine speed. If the WOT (wide open throttle) RPM is above

11,500, enrich the mixture by turning Hi Speed mixture needle

counter-clockwise (CCW) until engine runs between 10,500

and 11,500 RPM.

IMPORT ANT: After one minute idle warm-up, to assure

accurate carburetor adjustments, the engine temperature must

be fully and completely stabilized, using the following procedure.

Operate the choke twice during the first minute of WOT (Wide

Open Throttle) warm-up to clear air from the carburetor

chambers. T o completely stabilize engine temperature, run the

unit for 5 minutes at a cycle of 15 seconds WOT (Wide Open

Throttle) and 5 seconds idle down period.

IMPORT ANT: T o avoid engine damage during engine warm-up,

do not run the engine at WOT (Wide Open Throttle) for longer

than 15 seconds at a time, without the 5 second idle down

period.

13

Page 14

LO SPEED MIXTURE ADJUSTMENT

1. Adjust the Lo speed mixture needle in clockwise (CW) until

maximum idle RPM (just before lean drop off) is achieved.

NOTE: Engine RPM must be allowed to stabilize a minimum of

20 seconds after each adjustment .

2. Turn the Idle speed adjusting screw to achieve idle of 4,000

RPM.

3. Using tachometer, rich down by adjusting Lo speed mixture

needle out counter-clockwise (CCW) until engine reaches

3,000 RPM at idle.

HI SPEED MIXTURE ADJUSTMENT

1. Turn the Hi speed mixture needle or counter-clockwise (CCW)

out (richer) until the RPM is between 10,500

and 11,500.

2. Turn limiter caps counter-clockwise (CCW), so that the limiter

cap stops, align with locating slots in the carb body. Place

limiter caps over respective mixture needles. (See Fig. 3)

3. With a flat end tool, push both limiter caps down gently and

completely on to their respective needles. (See Fig. 4) Push,

do not hit the limiter caps. Make sure the mixture needles do

not move while the caps are being installed.

4. Install needle access cover to prevent dirt entry into carb

airbox.

(CAUTION)

When starting, idling adjustment speed should be adjusted not

to rotate the saw chain.

Correct idle speed is adjusted 2900 to 3100 rpm. Or 1/4 turn

counter clockwise from the point the chain stops moving.

When there is some trouble with the carburetor, refer to your

distributor or dealer.

CARBURETOR ADJUSTMENT

Emission Models

Before starting the unit for adjustment, check the following items:

• The correct spark plug must be clean and properly gapped.

• The air filter element must be clean and properly installed.

• The muffler spark arrestor screen and exhaust port must be

clear of carbon.

A

B

• The standard bar and chain combination (see page 4) must be

installed to the power head, and properly tensioned.

1. Start engine and run for several minutes to reach operating

temperature.

2. Stop engine. Remove grommet cover (A) over “H” and “L” limiter

needles.

3. Turn HI speed needle (H) CCW (counter clockwise) to stop.

Turn LO speed needle (L) CCW (counter clockwise) to stop.

14

Page 15

4. Idle Speed Adjustment.

• Start engine and turn “idle” speed adjustment screw (B) CW

until the saw chain begins to move, then turn the screw CCW

until saw chain stops moving. Turn screw CCW an additional

1/4 turn.

5. Accelerate to full throttle for 2-3 seconds to clear excess fuel

from engine then return to idle. Accelerate to full throttle to

check for smooth transition from idle to full throttle. If engine

stops or stalls after full warm up return the unit to your authorized ECHO dealer for repair.

6. Check HI speed RPM at W.O.T. (Wide Open Throttle). HI

speed RPM should be set between 10,500 and 11,500 RPM’s.

7. Check idle speed and reset if necessary. If a tachometer is

available, idle speed should be set between 2,700 and 3,300

RPM’s.

(CAUTION)

• When starting, idling adjustment speed should be adjusted not to

rotate the saw chain.

• When there is trouble with the carburetor, refer to your distributor

or dealer.

CHAIN AND GUIDE BAR COMBINATION

The following combinations may be use on CS-3000, CS-3400 or CS-3450

RABEDIUG

ledoM

htgneLN/POHCEN/PNOGERO

0003-SC

0043-SC

0543-SC

.ni21

.ni41

.ni61

105473021*

102573041*

107573061*

5473DCOA21

2573DCOA41

7573DCOA61

hctiP

ediuG

050.8/3

050.8/3

050.8/3

niahC

rebmuN

X54-GV19

X25-GV19

X75-GV19

drauGkciK

rebmuN

94982

94982

94982

* Reduced nose radius symmetrical bars.

(OREGON name ----- Double Guard)

WARNING DANGER

Use of replacement saw chain and/or guide bar other than that specified, or operation without the “tip guard” in place may

cause severe kickback resulting in serious injury .

Only use saw chain designated as, “LOW-KICKBACK”, that meets the ANSI B175. 1-2000 standard and the ECHO guide

bar specified.

SETTING THE SAW CHAIN

For setting saw chains, round file (4 mmø: 5/32”) and flat file are used.

• T o keep correct position and correct angle, use the file holder (Sure Sharp).

- Round file (P-No. 897510-03930) and flat file (P-No. 89751 1-00230) are optional.

- Please inquire about the file holder, if desired.

• File cutters as below.

T o sharpen other type chain, follow chain manufacturer’s instructions

Keep this angle

PUSH FILE AS SHOWN

30°

Type : 91SG

HOLD FILE HOLDER LEVEL

15

1/5

ONE FIFTH OF FILE DIAMETER REMAINS

ABOVE CUTTER EDGE

Depth gauge

Page 16

• Place the depth gauge tool firmly on guide bar so that depth gauge protrudes. Then file top of depth gauge with flat file

until flat with top o the gauge tool.

- Be sure to round off the front edge of the depth gauge.

Depth gauge tool

Remove until

flat with tool

Sharpen bottom edge

Round off

the edge

• Properly filed cutters are shown below.

(Top plate angle) (Side plate angle) (Top plate cutting angle) (Depth gauge)

0.64 mm (0.025”)

Parallel

30°

85°

60°

• When setting of the chain is finished, soak it in oil and wash away filings completely before using.

• When chain has been filed on the bar, supply sufficient oil to it, rotate the chain slowly to wash away the filings before

using again.

• If the chain saw is operated with filings clogged in the groove, the saw chain and the guide bar will be damaged prema-

turely

• If the saw chain becomes soiled with resin, for instance, clean it with kerosene and soak it in oil.

CHAIN TYPE AND SPROCKET PITCH

Saw chain should be used with corresponding pitched

sprocket. To identify chain type and pitch of sprocket,

check as follows.

• Chain type number is stamped on drive link.

• Sprocket pitch is stamped on clutch drum.

Number indicates

Chain type

16

(DRIVE LINK)

91

(SPROCKET)

91S

Number

indicates

Chain type

Page 17

TROUBLESHOOTING

Poor performance of the engine and/or cutting mechanism can normally be prevented by carefully following the above instructions.

Poor performance can easily be corrected even by a beginner.

When the engine does not function properly check the following three (3) points first.

• Is the engine compression adequate?

• Is fuel system in good condition and is enough fuel being supplied?

• Is electrical system in good condition and is spark plug operating normally?

When there is serious trouble with the unit, do not try to repair it yourself but have your distributor or dealer do it for you. For

detailed TROUBLESHOOTING refer to tables 1 and 2. Locate the problem on the following charts and repair as necessary .

Table 1

Engine cranks

Engine does not start (or, is difficult to start)

There is fuel in the tank

Fuel is reaching cylinder

Fuel is reaching carburetor

Fuel is not reaching

carburetor

Fuel is not reaching

cylinder

There is spark at high

tension cord end

○○○○○

○○○○○○

No spark at high tension

cord end.

No spark at plug

Fuel does not

keep running

○○○

○○

○○○

Fuel strainer clogged ................................... Clean.

Fuel pipe clogged ......................................... Clean.

Suction insufficient .......................................Make sufficient.

Strainer clogged ........................................... Clean.

Carburetor out of order ................................. Disassemble and check.

C.D.I. module defective ................................ Remove and replace.

Ignition coil defective .................................... Remove and replace.

Wire connection defective .............................Reconnect.

High-tension cord connection defective .........Repair as necessary.

Switch is grounded .......................................Switch on.

Insulator cracked.......................................... Replace plug.

Spark gap incorrect ...................................... Adjust.

Covered with carbon .................................... Clean or replace.

Fouled with fuel ............................................Clean or replace.

Starting procedures incorrect ....................... Start correctly.

Low and high speed needle ........................... Readjust.

setting too lean

Metering lever spring too strong .................. Readjust.

Fuel pump diaphragm defective .................... Replace.

There is spark at plug

Starting procedures

correct

Engine does

not crank

Acceleration

and low speed

function

defective

Carburetor

overflow

○○○○○

17

○○○

○○○

Fuel passage clogged with dust .................... Disassemble and clean.

Fuel leaking from fixing surfaces .................. Retighten all screws.

of carburetor

Air valve, fuel tank cap does not

work normally ............................................... Replace or Clean.

Fuel pump does not operate .......................... Check impulse drilling.

Fuel inlet needle valve clogged with dust....... Clean.

Metering lever spring not placed

in dent of lever .............................................. Correct.

Muffler sticky with fuel .................................Fuel mixture is too rich

Bearing damaged ......................................... Disassemble and replace.

Piston and/or cylinder seized ........................Disassemble and replace.

Crankshaft worn ........................................... Disassemble and replace.

Crankshaft contacting crankcase .................. Disassemble and replace.

Start the engine several times

with choke rod fully open and

run at fast idle until engine does

not smoke.

Page 18

Table 2

Engine

overheated

Improper fuel used ..................................... Use fuel with correct mixing ratio. Never use

gasoline of poor quality.

Spark plug defective (burnt) ....................... Replace.

As cooling fins clogged, air

does not pass well .....................................Clean fins.

Excessive deposits in

combustion chamber ................................. Disassemble and remove carbon.

Firing function

defective

Carburetor

Ouput (engine speed) insufficient

Engine keeps running, but chain does not cut clean

defective

Other

troubles

Chain does not cut

clean

Chain stops

(Clutch slips)

Plug damaged or fouled............................. Replace or clean.

Comubstion poor due to

defective wiring .......................................... Check wiring.

High-speed needle setting incorrect .......... Readjust.

Carburetor overflow .................................... Refer to Table 1.

Air cleaner clogged ....................................Clean as necessary.

Compression insufficient

(piston ring stuck or worn out)....................Disassemble, check and replace if necessary.

Cylinder chromium plating peeled ............. Replace cylinder

or worn out

Exhaust port clogged with carbon.............. Clean as necessary.

Throttle is not fully open .............................Readjust.

Chain tension incorrect .............................. Adjust.

Chain wrongly set....................................... Set correctly.

Depth incorrect ........................................... Readjust.

Chain saw pressed against

tree to firmly ............................................... Press lightly.

Clutch shoe worn out .................................Replace.

No oil in tank .............................................. Refill.

Output (engine speed) sufficient

Chain poorly

lubricated

Oil delivery incorrect................................... Adjust.

Oil contaminated with dust ........................ Rinse tank and fill with new oil..

Oil viscosity inappropriate ..........................Use oil with correct viscosity for summer or winter.

STORAGE AFTER USE

• Inspect and adjust every part of the chain saw.

- Completely clean every part, and repair, if necessary.

- Apply thin coating of oil on metal parts to prevent rust.

- Remove chain and guide bar, apply sufficient oil coating and wrap them up in plastic.

• Drain fuel tank, pull starter slowly a few times to drain fuel from carburetor.

• Pour a small amount of clean motor oil into spark plug hole, pull starter and crank engine until the TOP DEAD CENTER.

• Store in a dry area, free from dust.

18

Page 19

CORRECT USE OF CHAIN BRAKE

The installation of a chain brake may be mandatory by law or as stipulated by insurance regulations in your area of

operation. Y ou should enquire through local government offices, your employer or your local dealer to ensure that your

chain saw conforms to the required safety standard. Echo chain brakes have been designed and tested to comply with

international safety standards as follows.

USA: ANSI Standard B175.1-2000 Safety Requirement for chain saws

Canada: CSA Standard Z 62.1 CHAIN SAWS

WARNING :

• ANSI Standard B175.1-2000 stipulates that the brake shall stop the chain in 0.10 seconds (one tenth) at an engine

speed of 8000 RPM. It is the responsibility of the Owner/Operator to ensure that the brake is serviced, adjusted and

tested strictly in accordance with the instructions as detailed herein in order to ensure that the brake performance is

maintained in compliance with the Standard B175.1-2000.

Kickback Motion:

• When the bar nose hits another tree, etc.

• Improper thrust cutting.

Function:

• When the lever is pushed forward, chain brake instantly

works to stop the chain.

Release:

• When the lever is fully pulled toward the operator, brake is

released.

INSTALLATION

• Echo recommends that the chain brake should be

serviced by an authorized Echo servicing dealer.

OPERATION

• Set the lever in the released position before starting to cut.

• If the brake is tripped by kick back reaction, the chain will

stop. Immediately release the throttle to avoid possible

damage to the engine or clutch.

• Do not attempt to start or operate the engine with the

brake engaged.

TESTING THE BRAKE

• Start the engine on a solid level surface and run at a fast

idle until warm.

• Hold the saw firmly by the handles and accelerate the

engine to a fast idle.

• Slowly operate the chain brake lever while holding the saw

firmly on the ground. When the brake lever trips, the chain

should stop. Immediately release the throttle trigger.

CAUTION

DO NOT ALLOW THE SAW TO TIP FOR WARD IN ORDER TO

A VOID DAMAGE TO THE CHAIN.

If the chain does not stop, immediately return the saw to your

authorized Echo dealer for repair.

19

Page 20

SERVICING INFORMATION

P ARTS

Genuine ECHO Parts and ECHO Re Power Parts and Assemblies for

your ECHO products are available only from an Authorized ECHO

Dealer. When you do need to buy parts always have the Model

Number, Type number and Serial Number of the unit with you. You can

find all three numbers on the engine housing. For future reference, write

them in the space provided below.

Model No. _____________Type No. ____________ SN. __________

SERVICE

Service of this product during the warranty period must be performed

by an Authorized ECHO Service Dealer. For the name and address of

the Authorized ECHO Service Dealer nearest you, ask your retailer or

call: 1-800-432-ECHO. When presenting your unit for Warranty

service/repairs, proof of purchase is required.

www.echo-usa.com

DEALER?

CALL

1-800-432-ECHO

OR

ECHO CUSTOMER ASSISTANCE

If you require assistance or have questions concerning the application,

operation or maintenance of this product you may call the ECHO

Customer Assistance Department at 1-800-673-1558 from 8:30 am to

4:30 pm (Central Standard Time) Monday through Friday. Before calling,

please know the model and serial number of your unit to help your

Customer Assistance Representative.

8:30 - 4:30 Mon - Fri C.S.T.

CUSTOMER

ASSISTANCE

1-800-673-1558

W ARRANTY CARD

This card is our means of registering all original owners of ECHO

equipment. The card plus proof of purchase provides you the assurance that authorized warranty work will be done. It also provides a

direct link between you and ECHO if we find it necessary to contact

you.

ADDITIONAL OR REPLACEMENT MANUALS

Safety Manuals in English/Spanish or English/French are available, free of charge, from your ECHO dealer or at www.echousa.com.

Operator's and Parts Manuals are available by:

• Downloading free from www.echo-usa.com

• Purchasing from your Echo Dealer.

• Sending a check or money order for $2.00 per Parts Catalog or $1.50 per Operator's Manual made payable to ECHO, INCORPORATED. State on a sheet of paper the model number and serial number of the ECHO unit you have, part number of the

manual (if known), your name and address and mail to address below.

Safety Videos are available from your Echo dealer. A $5.00 shipping charge will be required for each video.

Available Parts Catalog Parts Lists

CS-3000 TYPE 1E S/N 001001 & UP,

CS-3400 TYPE 1E S/N 001001 & UP,

CS-3000 TYPE 1E S/N 001001 & UP, PART NUMBER 99922202830

ECHO, INCORPORATED

400 OAKWOOD ROAD

LAKE ZURICH, IL 60047-1564

www.echo-usa.com

Page 21

SUPPLEMENT TO OPERATOR'S MANUALS

FOR MODELS: CS-3000/3400/3450

FOR MODELS: CS-300/340/345

FOR MODELS: CS-301/341/346

FOR MODELS: CS-305/306

This Supplement contains important information. Please keep with your Instruction Manual.

Please use this information when installing or adjusting guide bar/saw chain.

PREPARATION FOR USE

ADJUSTMENT, CHAIN TENSION

IMPORTANT!

Tighten guide bar nuts to 90 – 110 kgf/cm (80 – 95 in. lbs.)

DO NOT over-tighten nuts. Damage to saw may result.

Este suplemento contiene la información importante. Guarde por favor con el manual de su operador.

Use esta información al instalar o ajuste de la barra y la cadena.

ANTES DE LA OPERACIÓN

AJUSTE DE LA TENSIÓN LA CADENA

IMPORTANTE!

Apriete las tuercas de la barra de la guía 90 a 110 kgf/cm (80 a 95 pulg. libras.)

No apriete las tuercas demasiado. El daños a la unidad pueden resultar.

Ce supplément contient l’information importante. Veuillez le garder avec le manuel de votre opérateur.

Utiliser ces instructions pour l’installation et adjustment du le barre ainsi que la chaîne.

PRÉPARATION POUR L’UTILISATION

RÉGLAGE DE LA TENSION DE LA CHAÎNE DE SCIE

IMPORTANT!

Serrez des écrous de barre de guide 90 à 110 kgf/cm (80 à 95 po livres.)

Ne serrez pas les écrous trop. Les dommages avec l’unité peuvent résulter.

SUP22203717

99922203717

01/04

Loading...

Loading...