ebm-papst Kickstart User Manual

Kickstart

Setup and control software for motors with integrated drive electronics

Kickstart User Manual

Status: Kickstart V1.9.40

Doc Rev 1.0.12 – 31.01.2014

Copyright 2013 ebm-papst

All rights reserved. No parts of this work may be reproduced in any form or by any means – graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems – without the written permission of the publisher.

Trademarks

Products that are referred to in this document may be either trademarks and/or registered trademarks of the respective owners. The publisher and the author make no claim to these trademarks.

Disclaimer

While every precaution has been taken in the preparation of this document, the publisher and the author assume no responsibility for errors or omissions, or for damages resulting from the use of information contained in this document or from the use of programs and source code that may accompany it. In no event shall the publisher and the author be liable for any loss of profit or any other commercial damage caused or alleged to have been caused directly or indirectly by this document.

Subject to change without notice.

The respective current version of this operating manual is available on the ebm-papst internet site: www.ebmpapst.com

2

Table of Contents

1 |

About This Manual |

4 |

||

|

1.1 |

Symbols Used |

4 |

|

|

1.2 |

Terms Used |

4 |

|

2 |

Safety |

|

6 |

|

|

2.1 |

Intended Use |

6 |

|

|

2.2 |

Safety Notices |

6 |

|

3 |

Overview |

|

7 |

|

4 |

Installation |

|

9 |

|

5 |

Using Kickstart |

10 |

||

|

5.1 |

Getting started |

10 |

|

|

5.2 |

Main Screen and Toolbar |

11 |

|

|

5.3 |

User Level |

12 |

|

|

5.4 |

Projects and Templates |

13 |

|

|

5.5 |

Editing the Module Tree |

14 |

|

6 |

Kickstart Modules |

15 |

||

|

6.1 |

CAN Interface |

15 |

|

|

|

6.1.1 |

CAN Monitor |

15 |

|

|

6.1.2 |

CAN Sender |

16 |

|

6.2 |

Drive01 / CANopen Drive |

17 |

|

|

|

6.2.1 |

Setup |

18 |

|

|

6.2.2 |

Object Editor |

18 |

|

|

6.2.3 |

Script |

19 |

|

|

6.2.4 |

Firmware |

19 |

6.3Motor Access / CANopen Node 20

|

6.3.1 CANopen Node – Edit Mode |

21 |

|

|

6.3.2 |

CANopen Node - UI Format |

21 |

6.4 |

Network Manager |

22 |

|

6.5 |

Scope |

|

23 |

|

6.5.1 The Scope – Getting Started |

23 |

|

|

6.5.2 |

Configuration |

24 |

|

6.5.3 |

Recording Data |

25 |

|

6.5.4 |

Plot |

25 |

|

6.5.5 |

Trigger |

26 |

6.6 UI Panel |

|

27 |

6.6.1 |

UI Panel - Getting Started |

27 |

6.6.2 |

UI Format Definition |

27 |

6.6.3 Node IDs and Multi-Node Panels |

30 |

|

6.6.4 Project and UI Files / |

|

|

|

Advanced User Interfaces |

31 |

3

1 About This Manual

1.1 Symbols Used

The following symbols are used in this document:

As defined by these operating instructions and the danger notices on the products, death, severe bodily injury or

considerable damage to property could result if the appropriate safety measures are not taken.

WARNiNG

Important information about the product or part of the operating instructions.

Notice

1.2 Terms Used

Qualified personnel

Personnel who are familiar with the installation, assembly, commissioning and operation of the product and are qualified to carry out the respective activities.

CAN (CAN-Bus)

Controller Area Network. Field bus design according to ISO 11898-1.

CANopen

CAN-based higher layer protocol designed for use in motion-oriented machine control networks, as maintained by www.can-cia.org.

CAN Interface

Accessory to connect the PC with the CAN bus network. Usually this is a CAN-USB interface, but other options (e.g. CAN-NET via Ethernet TCP) can be available.

Node

CANopen device, identified by a Node ID in the range of 1..127.

CANopen Drive

EC position drive that can be configured and operated using Kickstart, e.g. ebm-papst ECI series.

Python

A programming and scripting language under OSI Open Source License, maintained by www.python.org. Kickstart currently uses the Python 2.6.7 implementation.

Data Object

A device parameter or value that can be read out and / or modified using Kickstart. For CANopen devices a data object is referenced by the Node ID, and the object index and subindex. Kickstart uses the following standard format for a Data Object ID:

127.1000h.00h (here: Node ID = 127, object index 1000h and subindex 0h)

CANopen object data values are obtained using SDO or PDO transfer.

4

1 About This Manual

SDO Service Data Object

CANopen SDO transfers are used for low priority reading and writing of device parameters and objects. SDO Upload (read from device) and SDO Download (write to device) specifications define different standard methods of reading and writing different types of data, including optimized transfers for large blocks of data.

PDO Process Data Object

CANopen devices produce or consume PDO CAN frames. They are used for fast data transfer of critical process data. Before using PDO transfer, the CANopen device must be configured, i.e. the content of the PDO object must be defined (PDO Mapping). Two types of PDOs are defined for CANopen:

Transmit PDO (TPDO) - process data produced by the device node, e.g. status and position information. Receive PDO (RPDO) - process data consumed by the device node, e.g. control command.

XDD / XDC

XXML Device Description File (.xdd) / XML Device Configuration File (.xdc).

XDD files contain a dictionary of device functions and parameters and supersede the classic .eds files (Electronic DataSheet).

XDC file in addition contain parameter values for device configuration and supersede the .dcf file format (Device Configuration File).

Qt Quick / QML

Qt Quick is a new user interface (UI) technology and development kit for creating rich, attractive user interfaces in minimum time. QML is a declarative user interface language based on Javascript. It describes how user interface elements look and how they behave. Kickstart projects can make use of Qt Quick technology to build custom designed screens and attractive end user applications.

RS485-interface

The RS485 interface is a wired bus system for serial data transmissions. The transmission takes place via 2 wires. The digital signal is transmitted via these wires in differential form. In this way common-mode interference is suppressed effectively.

RS485-Communication

Communication between users and the drive software takes place via so-called telegrams. Each program contains specified data, which has to be received or sent. The drive software ignores telegrams that are not addressed to it.

5

2 Safety

2.1 Intended Use

This software is intended for the commissioning and service of position drives and other motionoriented machine control units. This software accesses the devices via a multi-layer application protocol, such as the CANopen application or the RS485 protocol.

2.2 Safety Notices

For all commissioning and service tasks, please refer to the technical documentation of your drive unit or automation

device controlled by this software. All works must be performed by Qualified Personnel familiar with the drive units or WARNiNG devices.

6

3 Overview

|

K4 motor |

|

|

|

|

|

|

Kickstart software |

|

|

|

|

|

K5 motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Start screen |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RS485 |

CAN-Bus |

Kickstart K4 |

|

|

|

Kickstart K5 |

|

|

|

|

|

Start interface |

|

|

|

Start interface |

|

|

|

|

|

|

|

|

|

|

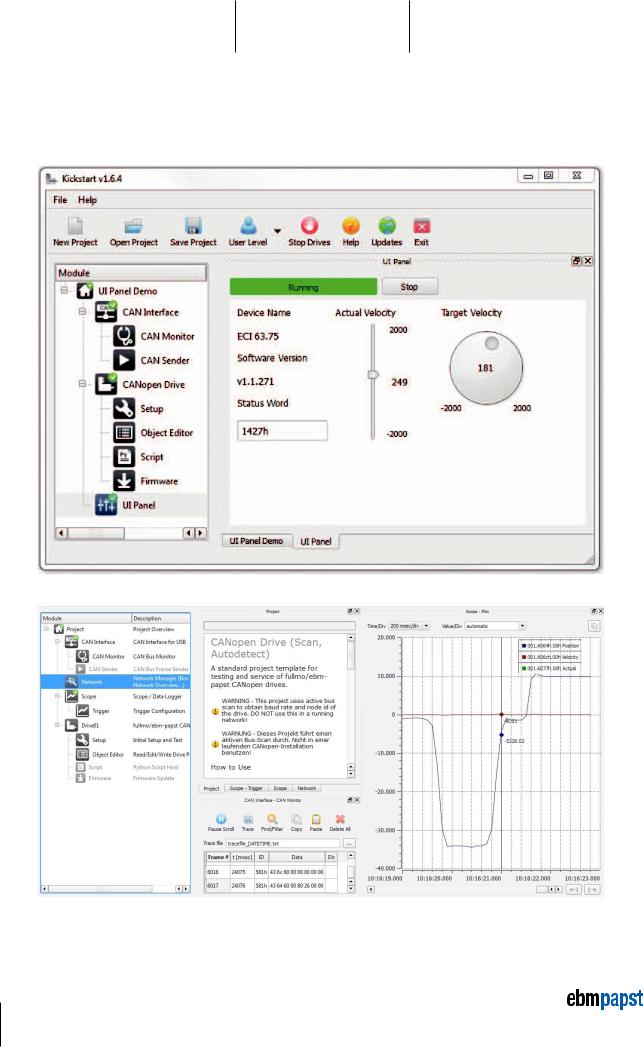

Kickstart is a modular PC software platform that can be used for a variety of configuration, commissioning and service tasks.

It is highly flexible and uses application-specific project and template files to present the user with exactly the functions and controls needed for a specific task. For example, a field engineer could work with a Kickstart project that performs exclusively application-specific service tasks, e.g. a drive firmware update. Meanwhile, developers and application engineers could work with a scalable, fully flexible interface, making use of the full range of Kickstart’s functionality. For example:

•Commissioning and configuring field bus nodes, like drive units or controllers.

•Field bus monitoring (e.g. generating a CAN Bus trace file, CAN BUS monitor with Find and Filter functions).

•Communication via the RS485 takes place in the background. The user only has to concentrate on the defined objects. The protocol is implemented in the external converter box, the USB-CAN-RS485 adapter, as described in the manual.

•Scope data display: Live display of data from one or several drive parameters, logging to a file, trigger on specific events.

•Custom UI Panels: create, display and control elements for a specific application, e.g. machine control. Build a simple panel from predefined sliders and dials using simple drag and drop.

7

3 Overview

Kickstart projects are made up of standard modules which are used as blocks. For example, the "CAN (USB) Interface" or "Drive01 / CANopen Drive" modules. Additional project templates containing other modules are available for specialised applications (scope, UI panels, etc.).

8

4 Installation

The Kickstart application software is usually distributed in a .exe self extracting archive file.

Double-click the .exe file to copy the application to a directory on your computer, or a removable media, e.g. a disk-on-key USB memory stick.

Then start the Kickstart software by double-clicking on Kickstart.exe.

No installation (setup) is required, but please make sure you extracted all files and folders from the original .zip archive

to a location on your PC or removable media.

Notice

|

Additional device driver installation can be required for hardware accessories like the CAN Interface (USB-CAN). Driver |

Notice |

installation on Windows Vista, Windows 7 and other recent Windows versions is fully automatic when connecting the |

device for the first time. Please follow the Windows instructions. |

The respective most up-to-date version of the Kickstart.exe file is available to download from the ebm-papst website

(www.ebmpapst.com).

Notice

Compressed files must be decompressed using appropriate software. Information on this is available on www.winzip.de.

Notice

9

5 Using Kickstart

5.1 Getting started

Do not operate Kickstart within an automation network where any of the Kickstart CAN or CANopen communication could

possibly disrupt the normal operation.

WARNiNG

Incorrect wiring or wrong cabling can damage electronic components, including the USB-CAN-RS485 adapter, the

CAN-RS485 interface and the PC connected with the CAN Interface.

WARNiNG

The USB-CAN-RS485 adapter is required as an accessory for the ebm-papst "Kickstart" software, in order to connect the

PC with the K4 drive. The adapter can be ordered under Material No. 914 0000 400.

Notice

•Connect the USB-CAN-RS485-Interface to your equipment first, before connecting it to the PC.

•Switch on power supply for the CAN nodes.

•Connect the CAN Interface to your PC using the USB cable supplied.

•Start the Kickstart software application.

Kickstart presents a home screen that allows you to pick your specific application or project.

Kickstart Main Screen and Project Selector

•Pick a project or an application from the Project Selector list on the right.

•Alternatively, use  Open Project to load a Kickstart Project File (.kickzip or .kickpro) that you received for your specific application.

Open Project to load a Kickstart Project File (.kickzip or .kickpro) that you received for your specific application.

10

Loading...

Loading...