ebm-papst G3G250-MW50-01 User Manual

Translation of the original operating instructions

G3G250-MW50-01

ebm-papst Mulfingen GmbH & Co. KG

Bachmühle 2 D-74673 Mulfingen

Phone +49 (0) 7938 81-0

Fax +49 (0) 7938 81-110 info1@de.ebmpapst.com www.ebmpapst.com

CONTENTS

1.SAFETY REGULATIONS AND NOTES

1.1 Levels of hazard warnings

1.2 Staff qualification

1.3 Basic safety rules

1.4 Electrical voltage

1.5 Safety and protective functions

1.6 Electromagnetic radiation

1.7 Mechanical movement

1.8 Deflagration

1.9 Emission

1.10 Hot surface

1.11 Transport

1.12 Storage

1.13 Disposal

2.PROPER USE

3.TECHNICAL DATA

3.1Product drawing

3.2Nominal data

3.3Data according to ErP directive

3.4Technical features

3.5Mounting data

3.6Transport and storage conditions

3.7Electromagnetic compatibility

4.CONNECTION AND START-UP

4.1 Connecting the mechanical system

4.2 Connecting the electrical system

4.3 Connection in terminal box

4.4 Factory settings

4.5 Connection screen

4.6 Checking the connections

4.7 Switch on device

4.8 Switching off the device

5.INTEGRATED PROTECTIVE FUNCTIONS

6.MAINTENANCE, MALFUNCTIONS, POSSIBLE CAUSES AND REMEDIES

6.1Cleaning

6.2Safety test

Operating instructions

1. SAFETY REGULATIONS AND NOTES

Please read these operating instructions carefully before starting to work with the device. Observe the following warnings to prevent malfunctions or physical damage to both property and people.

These operating instructions are to be regarded as part of this device. If the device is sold or transferred, the operating instructions must accompany it.

These operating instructions may be duplicated and forwarded for information about potential dangers and their prevention.

1 |

1.1 Levels of hazard warnings |

|

1 |

||

These operating instructions use the following hazard levels to indicate |

||

1 |

||

potentially hazardous situations and important safety regulations: |

||

|

||

1 |

DANGER |

|

1 |

||

Indicates an imminently hazardous situation which, if not |

||

2 |

avoided, will result in death or serious injury. Compliance with |

|

2 |

the measures is mandatory. |

|

|

||

2 |

WARNING |

|

Indicates a potentially hazardous situation which, if not avoided, |

||

2 |

||

could result in death or serious injury. Exercise extreme |

||

2 |

||

caution while working. |

||

3 |

CAUTION |

|

|

||

3 |

Indicates a potentially hazardous situation which, if not avoided, |

|

3 |

may result in minor or moderate injury or damage of property. |

|

|

||

3 |

NOTE |

|

3 |

A potentially harmful situation can occur and, if not avoided, can |

|

lead to property damage. |

||

5 |

1.2 Staff qualification |

|

|

5The device may only be transported, unpacked, installed, operated,

6maintained and otherwise used by qualified, trained and authorised

6 |

technical staff. |

6Only authorised specialists are permitted to install the device, to carry out a test run and to perform work on the electrical installation.

6 |

|

|

6 |

1.3 Basic safety rules |

|

7 |

Any safety hazards stemming from the device must be re-evaluated |

|

7 |

once it is installed in the end device. |

|

Observe the following when working on the unit: |

||

|

||

7 |

; Do not make any modifications, additions or conversions to the |

7device without the approval of ebm-papst.

81.4 Electrical voltage

10 |

; Check the electrical equipment of the device at regular intervals, refer |

|

11 |

||

to chapter 6.2 Safety test. |

||

|

||

12 |

; Replace loose connections and defective cables immediately. |

|

12 |

DANGER |

|

12 |

||

Electrical load on the device |

||

12 |

Risk of electric shock |

|

→ Stand on a rubber mat if you are working on an electrically |

||

13 |

||

charged device. |

||

14 |

WARNING |

|

Terminals and connections have voltage even with a |

||

|

||

14 |

unit that is shut off |

|

|

Electric shock |

→ Wait five minutes after disconnecting the voltage at all poles before opening the device.

Item no. 50734-5-9970 · Revision 82547 · Release 2014-05-08 · Page 1 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com

G3G250-MW50-01 |

Operating instructions |

|

|

|

|

Translation of the original operating instructions

CAUTION

In the event of failure, there is electric voltage at the rotor and impeller

The rotor and impeller are base insulated.

→ Do not touch the rotor and impeller once they are installed.

CAUTION

If control voltage is applied or a speed setpoint is stored, the motor automatically restarts, e.g. after a power failure.

Danger of injury

→Keep out of the danger zone of the device.

→When working on the device, switch off the mains

supply voltage and secure the latter from being switched on again.

→Wait until the device stops.

→After working on the device, remove any used tools or other objects from the device.

1.5Safety and protective functions

DANGER

Missing safety device and non-functioning safety device

If there is no safety device, you could be seriously injured, for example if you reach into the running device or your hands are sucked into it.

→Operate the device only with a fixed and isolating safety protection and a fixed guard grille.

The guard must withstand the kinetic energy of a fan blade detaching at maximum speed.

→The device is a built-in component. You, the owner/

operator, are responsible for providing adequate protection for the device.

→Shut down the device immediately if you detect a missing or ineffective protective feature.

1.6Electromagnetic radiation

Interference from electromagnetic radiation is possible, e.g. in conjunction with open and closed-loop control devices.

If unacceptable emission intensities occur when the fan is installed, appropriate shielding measures have to be taken by the user.

NOTE

Electrical or electromagnetic interferences after integrating the device in installations on the customer's side.

→Verify that the entire setup is EMC compliant.

1.7Mechanical movement

DANGER

Danger of injury from open blower

Gas escapes. When the blower is open, you come into contact with rotating and electrically live parts. Escaping gas may also cause explosions.

→ Never open the blower.

DANGER Flying parts

Missing safety devices may cause balancing weights or broken fan blades to be ejected at high speeds, causing bodily harm.

→ Take appropriate safety measures.

WARNING Rotating device

Long hair, loose items of clothing and jewellery could become entangled and pulled into the device. You could be injured.

→Do not wear any loose clothing or jewellery while working on rotating parts.

→Protect long hair by wearing a cap.

WARNING Flying parts

Missing safety devices may cause fan blades to be ejected at high speeds, causing bodily harm.

→Take appropriate safety measures.

The safety devices must prevent contact with rotating parts and the printed circuit board.

1.8Deflagration

DANGER

Gas escapes through leaky housing after deflagration

Danger of injury

→After a deflagration, check that the housing of the gas blower is tightly sealed.

→Replace any gas blower with a leaky housing.

DANGER

Fire and deflagration hazard

The gas blower is not approved according to Ex protection guidelines. Rotating parts can scrape against stationary parts. This may cause sparks and chips. The surface temperature may rise, resulting in a fire.

→Check which hazards arise from installing, operating, servicing or disposing the gas blower in conjunction with your device.

Prevent these hazards.

Carry out all appropriate measures to this purpose.

1.9Emission

WARNING

Depending on the installation and operating conditions, a sound pressure level greater than 70 dB(A) may arise.

Danger of noise-induced hearing loss

→Take appropriate technical safety measures.

→Protect operating personnel with appropriate safety equipment, e.g. hearing protection.

→Also observe the requirements of local agencies.

Item no. 50734-5-9970 · Revision 82547 · Release 2014-05-08 · Page 2 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com

G3G250-MW50-01 |

Operating instructions |

|

|

|

|

Translation of the original operating instructions

1.10 Hot surface

CAUTION

High temperature at the electronics enclosure

Danger of burn injuries

→Ensure that sufficient protection against accidental contact is provided.

1.11Transport

NOTE

Transport of blower

→Transport the blower in its original packaging only.

→Secure the blower so that it does not slip, e.g. by using a clamping strap.

1.12Storage

;Store the device, partially or fully assembled, in a dry and weatherproof manner in the original packing in a clean environment.

;Protect the device from environmental impacts and dirt until the final installation.

;We recommend storing the device for a maximum up to one year to guarantee proper operation and longest possible service life.

;Even devices explicitly suited for outdoor use are to be stored as described prior to being commissioned.

;Maintain the storage temperature, see chapter 3.6 Transport and storage conditions.

;Please make sure that all screwed cable glands are fitted with dummy plugs.

1.13 Disposal

When disposing of the device, please comply with all relevant requirements and regulations applicable in your country.

Item no. 50734-5-9970 · Revision 82547 · Release 2014-05-08 · Page 3 / 14

2. PROPER USE

The device is exclusively designed as a built-in device for moving air and gases according to its technical data.

Any other or secondary use is deemed improper and constitutes a misuse of the device.

Installations on the customer's side must meet the mechanical, thermal and service life-related stresses that can occur.

Proper use also includes:

●Use the device in power systems with earthed neutral (TN/TT power systems) only.

●Moving air in gas burners.

●Moving air with a density ranging from 0.9 to 1.2 kg/m³.

●Minding the operating instructions.

●Using the device within the permitted ambient temperature range; see chapter 3.6 Transport and storage conditions and

chapter 3.2 Nominal data.

●Only using the device in stationary systems.

●Installing the device into an overall system for moving air.

●Commissioning the built-in component only after installation in the customer unit.

●Operating the device with all protective features in place.

●Only using the device in stationary systems.

●Carrying out all maintenance.

Improper use

Using the device in the following ways is particularly prohibited and may cause hazards:

●Operating the device with an imbalance, e.g. caused by dirt deposits or icing.

●Moving a medium that contains abrasive particles.

●Moving a highly corrosive medium.

●Moving a medium that contains dust pollution, e.g. suctioning off saw dust.

●Operating the gas blower in an environment that contains flammable gases or dust or combustible solids or fluids.

●Moving an air/gas mixture outside an overall system that fulfils the requirements described above.

●Using the blower as a safety component or for taking on safety-related functions.

●Operation in medical equipment with a life-sustaining or lifesaving function.

●Contact with materials that could damage blower parts, e.g. liquids during cleaning.

●Operation with completely or partially disassembled or modified protective features.

●Exposure to radiation which could damage blower parts, e.g. strong UV radiation.

●Operation with external vibrations.

●Operating the device in an explosive atmosphere.

●Operation with completely or partially disassembled or modified protective features.

●In addition, all application options that are not listed under proper use.

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com

G3G250-MW50-01 |

Operating instructions |

|

|

|

|

●Operation in medical equipment with a life-sustaining or lifesaving function.

●Operation with external vibrations.

●Moving solids content in flow medium.

●Painting the device

●Connections (e.g. screws) coming loose during operation.

●Opening the terminal box during operation.

Translation of the original operating instructions

Item no. 50734-5-9970 · Revision 82547 · Release 2014-05-08 · Page 4 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com

G3G250-MW50-01

3. TECHNICAL DATA

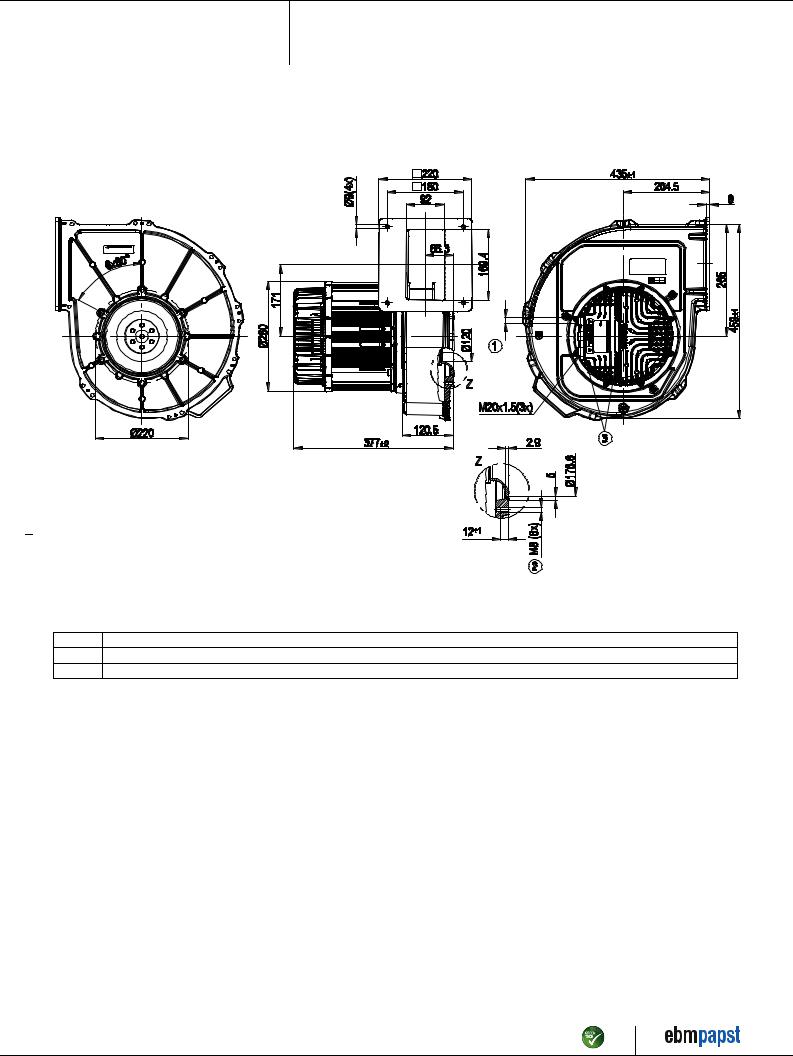

3.1 Product drawing

Operating instructions

All measures have the unit mm.

1Cable diameter min. 4 mm, max. 10 mm, tightening torque 4±0.6 Nm

2Depth of screw 10-12 mm, tightening torque 20±3 Nm

3Tightening torque 3.5±0.5 Nm

Translation of the original operating instructions

Item no. 50734-5-9970 · Revision 82547 · Release 2014-05-08 · Page 5 / 14

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · info1@de.ebmpapst.com · www.ebmpapst.com

Loading...

Loading...