Ebara A70W, A30W, A25S, A10S, A07V User Manual

INSTRUCTION MANUAL

MULTI-STAGE DRY VACUUM PUMP

A70W (A70W-S,A70W-C)

A30W (A30W-S, A30W-C)

A25S (A25S-S)

A10S (A10S-S)

A07V (A07V-S)

idealvac.com

(505)872-0037 idealvac.com

Do not reproduce or reprint any portion of this manual without permission.

Manufacturer reserves the right to discontinue or change any specifications or designs without notice and without incurring obligations.

All rights reserved, copyright EBARA Corporation.

(i)

Record of Changes

Rev. |

Date |

Page |

Position |

Contents |

Reason |

0 |

2-Jun-94 |

|

|

Newly issued |

|

1 |

13-Jul-94 |

5 |

A07V Spec. |

Pumping Speed |

Correction |

|

|

6-10 |

Outline Drawing |

Water Sup./Rtn |

Add NPT |

|

|

14 |

Fig. 3.4 |

Sys. Flow |

Add Note |

|

|

17 |

Fig. 4.2 |

Coupler |

Add Drawing |

|

|

21 |

Fig. 4.6 |

Ctrl. Wiring |

Correction |

|

|

22 |

Table 4.5 |

Pin Assign. |

Add note |

2 |

14-Nov-96 |

, |

Fig. 1,2,3,4,5 |

Safety warning |

Add |

|

|

|

|

labels |

|

|

|

, , |

Drawing |

Warning label |

Add |

|

|

|

Location |

|

|

|

|

4 |

3.3 List |

Detailed |

Add List |

|

|

|

specifications |

|

|

|

|

21 |

Dig. 4.4 |

Power Sup. Rec |

Correction |

|

|

Table 4.6 |

Dipswitch |

Design Change |

|

|

|

25 |

Fig. 4.7 |

S.W setting |

Design Change |

|

|

26 |

Table 6.1 |

Typical check |

Add Table |

|

|

33 |

|

items |

|

|

|

35,36 |

6.3 |

Spare Parts |

Add List |

|

|

7 (8) |

Pump Lifting |

Add Note |

|

|

|

37 |

9 |

Service Net. |

Add List |

|

|

44,45 |

|

|

|

A |

12-Dec-97 |

|

|

|

New release |

|

|

|

|

|

per ECO 2905 |

3 |

20-May-99 |

21 |

Tab. 4.2 |

Suitable wire |

Correction |

|

|

44,45 |

9. Service Network |

Japan, Taiwan |

Change |

|

|

|

|

(Add., Phone, Fax) |

|

|

|

5,6,18, |

----- |

The Unit was |

----- |

|

|

27,28, |

|

changed in terms |

|

|

|

32 |

|

of Domestic |

|

|

|

|

|

regulation for |

|

|

|

|

|

Measurement low. |

|

3A |

27-Apr-01 |

|

|

|

ETI release of |

|

|

|

|

|

EC Rev 3 per |

|

|

|

|

|

ECO 5394. |

3B |

June 2002 |

20 |

|

Add UL grounding |

Third-party |

|

|

|

|

note |

marking |

|

|

iv |

|

Add LCD “hot |

Third-party |

|

|

|

|

surface” note |

marking |

|

|

|

|

Add appendices |

SEMI S2 |

|

|

Thruout |

|

Language Edit |

ECO 5771 |

|

|

|

|

|

|

EBARA Corporation

(ii)

Safety Information

Anyone operating this pump must have the knowledge to identify and avoid hazardous conditions associated with the pump.

Rash actions or improper operation may cause dangerous accidents and serious injuries.

Before installation and operation, the operator first should have a thorough knowledge of the pump’s construction, operating procedures, and hazards.

The operator should read this instruction manual and other documents issued by EBARA.

If you have any questions on pump operation, safety, or maintenance, please do not hesitate to contact EBARA directly.

Three terms in this manual designate different levels of hazard:

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

indicates an imminently hazardous situation that, if not avoided, may result in minor or moderate injury.

This term may also indicate situations that might damage equipment.

EBARA Corporation

(iii)

Important Precautions

DANGER |

Keep out from under the pump when it is elevated. |

|

Only qualified personnel should unload and lift the pump. |

||

|

WARNING |

Be careful not to overturn the pump when pushing or pulling it |

|

sideways. The pump is narrow in comparison to its height. |

||

|

WARNING |

Only a qualified electrician, observing all national and local |

|

regulations, should perform electrical work. |

||

|

WARNING |

Cut and lock out electrical power before beginning wiring or |

|

maintenance work. |

||

|

||

|

Do not switch on the power supply to the pump until work is |

|

|

completed and pump and piping are back in safe operating |

|

|

condition. |

|

WARNING |

Supply N2 gas to the exhaust piping when necessary to dilute |

|

flammable or toxic gases down to a safe concentration. |

||

|

||

WARNING |

Purge system with sufficient N2 gas before removing and cleaning |

|

the vacuum lines and exhaust piping. |

||

|

||

|

Prevent dispersal of flammable, toxic or dangerous materials and |

|

|

guard against their contact with the human body. |

|

|

Work only in locations with an emergency escape route. |

|

WARNING |

Do not convert the pump from one process to another without an |

|

intervening overhaul. Gases or reaction products remaining in |

||

|

||

|

the pump may react and lead to accidents or to the formation of |

|

|

large amounts of byproduct. |

|

WARNING |

Check Safety Interlock functions periodically (every 6 months) to |

|

confirm correct operation. See Appendix 2 for a description of |

||

|

||

|

these interlocks. |

|

WARNING |

Connect exhaust from pumps handling process gases to an |

|

appropriate exhaust abatement system that is equipped with |

||

|

||

|

discharge quality monitors to provide warnings and to shut down |

|

|

the process gas flow if concentrations exceed allowable limits. |

|

WARNING |

Check for gas leaks after initial installation of the piping and after |

|

reassembly following maintenance or, at least, annually. Gas |

||

|

||

|

leaks can result in the discharge of harmful and dangerous |

|

|

substances and in abnormal reactions due to the admission of air |

|

|

into the pump. Replace o-rings as required to correct leaks. |

|

|

See Appendix 4. |

|

WARNING |

Do not modify the pump or any of its parts without EBARA's |

|

approval. |

||

|

EBARA Corporation

(iv)

WARNING |

Do not place the LCD controller on or near a surface with a |

|

temperature exceeding 65ºC. |

||

|

WARNING |

The pump casing and exhaust piping become extremely hot |

|

during operation and remain hot for some time after stopping. |

||

|

||

|

Keep pump and exhaust piping away from contact with personnel |

|

|

and flammable substances. |

|

|

Do not remove pump enclosure panels during operation. |

CAUTION |

Disposal of process byproducts must be in strict accord with all |

|

local and national environmental and safety regulations. |

||

|

CAUTION |

Dispose of printed circuit boards containing lithium batteries in |

|

strict accord with all applicable local and national environmental |

||

|

||

|

regulations. |

CAUTION |

The height of EBARA dry pumps may place the EMO button and |

|

the LCD controller below the heights recommended in SEMI |

||

|

||

|

S8-95. See Appendix 3. |

The following safety warning labels appear on the pump covers:

High temperature warning

Hazardous voltage warning

Hazardous materials warning

Electric charge mark

Hazardous weight danger

High temperature warning

Hot surface may burn or cause injury.

Allow the piping and casing to cool before servicing.

EBARA Corporation

(v)

Hazardous voltage warning

Hazardous Voltage may shock, burn, or cause death.

Turn power off and lockout before servicing.

Hazardous materials warning

(Applies only when pumping hazardous materials) Run the pump only with N2 gas purge before servicing.

Take adequate measures against dangerous reaction and contact with human body.

Electric charge mark

EBARA Corporation

(vi)

Hazardous weight danger

Heavy weight may cause severe injury or death due to overturning or falling pump. Keep out from under the lifted pump.

Raise all adjuster feet fully when moving.

EBARA Corporation

(vii)

EBARA Corporation

(viii)

EBARA Corporation

(ix)

EBARA Corporation

(x)

|

|

|

Contents |

|

Record of Changes......................................................................................................... |

i |

|||

Safety Information ......................................................................................................... |

ii |

|||

Important Precautions.................................................................................................. |

iii |

|||

Contents |

......................................................................................................................... |

|

x |

|

1 |

Foreword.................................................................................................................. |

|

1 |

|

2 |

Introduction ............................................................................................................. |

|

1 |

|

3 |

Product ................................................................................................Description |

2 |

||

|

3.1 ........................................................................................................ |

Summary |

2 |

|

|

.................................................................................... |

3.1.1 |

Pump Module |

2 |

|

............................................................................................... |

3.1.2 |

N2 Gas |

2 |

|

................................................................................... |

3.1.3 |

Cooling Water |

2 |

|

............................................................................................. |

3.1.4 |

Exhaust |

2 |

|

3.2 .............................................................................................. |

Control System |

2 |

|

|

............................................................................................. |

3.2.1 |

Warning |

3 |

|

................................................................. |

3.2.2 |

Operation Status Control |

3 |

|

3.3 ........................................................................................... |

Moving the Pump |

3 |

|

|

....................................................................................... |

3.3.1 |

Preparation |

3 |

|

................................................................................. |

3.3.2 |

Moving Method |

4 |

|

3.4 ................................................................................. |

Detailed Specifications |

4 |

|

4 |

Installation ............................................................................................................. |

|

16 |

|

|

4.1 ....................................................................................................... |

Location |

16 |

|

|

4.2 ........................................................................................................... |

Piping |

|

17 |

|

......................................................... |

4.2.1 |

Vacuum and Exhaust Piping |

17 |

|

..................................................................... |

4.2.2 |

Cooling Water Piping |

17 |

|

.................................................................................. |

4.2.3 |

N2 Gas Piping |

19 |

|

.............................................................................. |

4.2.4 |

Ventilation Duct |

19 |

|

4.3 .......................................................................................... |

Electrical Wiring |

20 |

|

|

..................................................................... |

4.3.1 |

Power Supply Wiring |

20 |

|

..................................................................... |

4.3.2 |

Control Signal Wiring |

21 |

|

4.4 ........................................................................................... |

Operation Mode |

24 |

|

5 |

Operation ............................................................................................................... |

|

26 |

|

|

5.1 ............................................................................................. |

Before Starting |

26 |

|

|

5.2 ..................................................................................................... |

Operation |

30 |

|

|

........................................................ |

5.2.1 |

Local (Pump side) Operation |

31 |

|

........................................................... |

5.2.2 |

Remote (Distant) Operation |

31 |

6 |

Maintenance ...................................................................................and Overhaul |

32 |

||

|

6.1 ...................................................................................... |

Routine Inspection |

32 |

|

|

6.2 ..................................................................................... |

Piping Maintenance |

33 |

|

|

6.3 ................................................................................................ |

Lubricant Oil |

33 |

|

|

6.4 .................................................................. |

Spare (Maintenance) Parts List |

34 |

|

|

6.5 ....................................................................................................... |

Overhaul |

35 |

|

EBARA Corporation

(xi)

7 |

Removal and Transportation................................................................................ |

36 |

|

8 |

Troubleshooting .................................................................................................... |

38 |

|

|

8.1 |

Troubleshooting (1) Basic Trouble ............................................................ |

38 |

|

8.2 |

Troubleshooting (2) ALARM ....................................................................... |

39 |

|

8.3 |

Troubleshooting (3) TRIP............................................................................ |

41 |

|

8.4 |

Troubleshooting (4) TRIP [Options] ........................................................... |

42 |

9 |

Inquiries ................................................................................................................. |

43 |

|

|

9.1 |

North America .............................................................................................. |

43 |

|

9.2 |

Asia ............................................................................................................... |

44 |

|

9.3 |

Europe .......................................................................................................... |

45 |

Appendices |

|

|

1. |

Material Safety Data Sheet – Vacuum Pump Oil |

.................................................I |

2. |

Safety Interlocks .............................................................................................. |

III |

3. |

Ebara Dry Pumps and SEMI S2-93A (S2-0200)................................................ |

V |

4. |

Leak Check Procedure ..................................................................................... |

VI |

5. |

Returning pumps for Rebuild in U.S. ............................................................... |

VII |

EBARA Corporation

(xii)

[Blank page]

EBARA Corporation

(1)

1 Foreword

We appreciate your selection of an EBARA A Series dry vacuum pump. EBARA has manufactured this pump with much care and attention to permit safe and satisfactory operation.

Incorrect operation will result in lack of performance and may cause accidents and injuries to personnel.

[NOTE] This instruction manual contains necessary information on operation and maintenance of the pump.

Operate the pump correctly in accordance with these instructions to ensure a long service life.

Keep this instruction manual in a suitable place for immediate reference whenever needed.

2 Introduction

Check the following items on receipt of the pump package.

Check the nameplate affixed to the outer cover of the pump to confirm that the pump supplied agrees with your order.

Check the accessories against the packing list and the previously submitted drawings and documents to confirm that the all ordered accessories have arrived.

Check for damage and for screws/bolts that have worked loose in transit.

CAUTION |

Notify EBARA without delay when there is damage or when |

|

components are missing. |

||

|

||

|

Do not use when a leak is present as this may result in an accident. |

Store the pump in a dry and clean place until installation.

Temperature |

: |

5 – 40 °C |

Humidity |

: |

80 % or less |

Do not stack the pump. Place it in an upright position.

EBARA Corporation

(2)

3 Product Description

3.1Summary

The A Series dry vacuum pump has a compact design and includes various sensors and controls to enhance reliability and operation.

3.1.1 Pump Module

The pump is a roots-type vacuum pump that rotates a pair of non-contact, multi-stage rotors synchronized by timing gears. High-capacity units have a Booster Pump (BP) connected in series with the Main Pump (MP).

A compartment, isolated from the pump casing, encloses the timing gears and bearings, which require lubrication with Perfluoro-Polyether (PFPE) oil and grease.

The pumps of this series are factory-filled with lubricating oil. Replenish or replace only with the recommended oil grades shown in Specification Tables 3.1 and 3.2.

3.1.2 N2 Gas

Pressurized nitrogen, supplied to the labyrinth seal section, isolates the vapor stream from the lubricated components, enabling the pump to draw a clean vacuum without admitting lubricant oil to the pump casing.

Additional N2 gas, injected in various pump stages, reduces corrosion due to process gas and retards the accumulation of reaction byproducts. For processes that do not produce corrosion or reaction byproducts, the selector valve can stop completely the dilution N2 flow. Adjusting the regulation pressure to the specified value supplies the correct amount of N2 gas for these two types of purge operation.

The pumps of this series are equipped with a dilution N2 gas control valve. Consult EBARA before adjusting the N2 gas supply to the appropriate level for specific conditions of use. (Maximum dilution N2 flow rate: 76 Pam3/s.)

3.1.3 Cooling Water

Compressing gas from vacuum to atmospheric pressure generates heat. Therefore, cool motors and casings with cooling water.

Quick-connect cooling water couplers make connection and disconnection easy.

3.1.4 Exhaust

The exhaust check valve, a standard accessory, prevents reverse flow of gas from the exhaust back through the pump to the vacuum chamber when pump stops. A silencer (optional) reduces exhaust noise.

3.2Control System

A Series dry vacuum pumps have a built-in sensing unit consisting of an Earth Leakage Breaker (ELB), an electro-magnetic switch and a control circuit or an overcurrent circuit breaker (CB). To improve reliability and safety, sensors monitor the condition of each utility

EBARA Corporation

(3)

and pump section.

During pump operation the central processing unit monitors all operating conditions, including power supply, cooling water flow, N2 gas flow, lubrication oil level, casing and motor coil temperature, motor current and suction pressure.

Pump operation “rides through” a transient power outage up to 500 milliseconds long. (Two-second ride through is available as an option.)

3.2.1 Warning

To improve the reliability of the vacuum exhaust system, the pump control scheme generates two levels of trouble warning: ALARM and TRIP.

An ALARM signal draws attention to an operating parameter value that has exceeded the normal operating range; it does not signify that danger is imminent. The pump will continue to operate in this condition, which enables the operator to complete the wafer cycle before checking the pump.

The pump will stop automatically and generate a TRIP signal output if a parameter approaches a mechanical safety limit.

Contact EBARA Corporation for details on checking the ALARM and TRIP setting conditions.

3.2.2 Operation Status Control

To facilitate operation status control and daily inspection, the LCD controller displays the sensor data.

The LCD controller displays all ALARM and TRIP signals. For remote operation and monitoring, the signals are available individually and as collective outputs.

3.3Moving the Pump

3.3.1 Preparation

Raise all four adjuster feet fully before moving the pump; otherwise, an obstacle on the floor may cause the moving pump to tip over.

Caster

fully raised

Adjuster f

EBARA Corporation

(4)

3.3.2 Moving Method

Move pump slowly by pushing eyebolt along the long axis of the pump (Direction A). Keep toes and fingers away from moving wheels. If placing the pump in a corner or narrow space requires moving it along the short axis (Direction B), two persons should “walk” the pump over by alternately pushing the ends as shown below.

B

A

To move the pump across cracks or joints in the floor, spread a steel plate or similar device, which can sustain the pump’s weight, over the discontinuity. At least two persons, using great caution, should move the pump.

Steel Plate

DANGER |

If, when moving a pump, it loses balance and starts to tip over, do |

|

not attempt to stop it. Get away from the pump immediately and |

||

|

||

|

let it fall. |

3.4Detailed Specifications

Refer to the following tables and figures for detailed specifications, size, and pump performance.

List of Tables and Figures

Category |

Contents |

Page |

Table 3.1, 3.2 |

Specification |

5,6 |

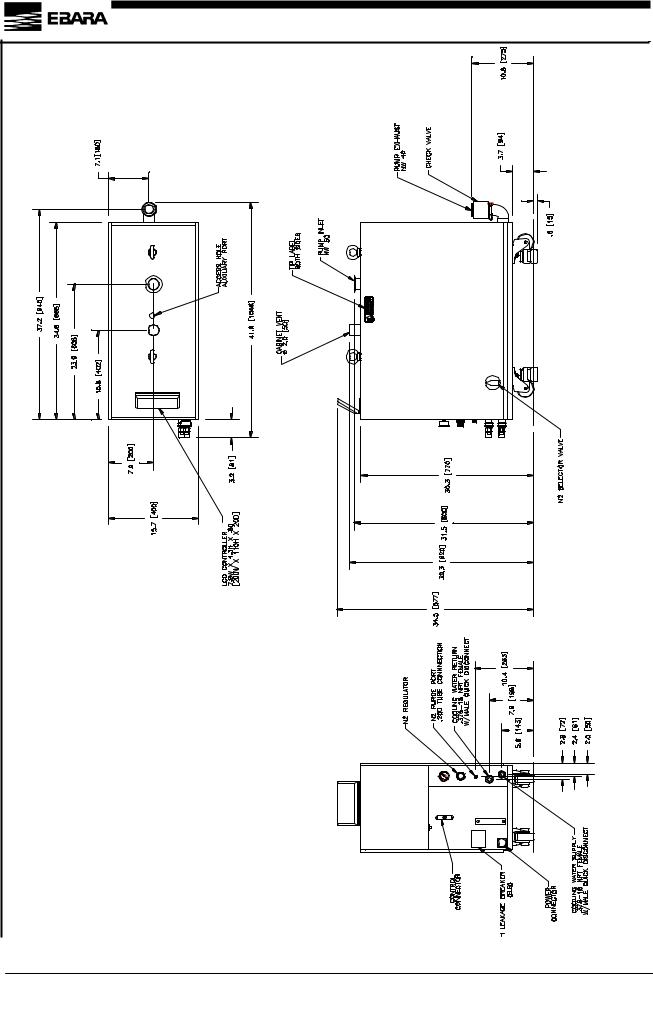

Outline Drawing 1 |

A70W |

7 |

Outline Drawing 2 |

A30W |

8 |

Outline Drawing 3 |

A25S |

9 |

Outline Drawing 4 |

A10S |

10 |

Outline Drawing 5 |

A07V |

11 |

Figure 3.1 |

Performance Curve (A70W, A30W) |

12 |

Figure 3.2 |

Performance Curve (A25S, A10S) |

13 |

Figure 3.3 |

Performance Curve (A07V) |

14 |

Figure 3.4 |

System Flow |

15 |

EBARA Corporation

(5)

Table 3.1 Specification (A70W, A30W)

|

Model |

A70W |

|

A30W |

|

Pumping Speed (50 / 60Hz) |

7000 / 8400 L/min |

|

3000 / 3600 L/min |

||

Ultimate Pressure (50 / 60Hz) |

0.27 / 0.13 Pa |

|

0.4 / 0.27 Pa |

||

Connection |

Gas Inlet |

|

NW50 |

||

Gas Outlet |

|

NW40 |

|||

|

|

||||

|

Motor |

2P 2.2 kW + 3.7 kW |

|

2P 1.5 kW + 2.2 kW |

|

|

Connection |

Coupler ( c 3/8) |

|||

|

|

|

|||

Cooling |

Pressure |

Supply Max 0.4 MPa |

|||

[Gauge Press.] |

|

|

|

||

Water |

Differential Press. 0.1 MPa |

||||

|

|

|

|||

|

Flow Rate |

Min. 3.5 L/min |

|||

|

Temperature |

Max. 30 deg C |

|||

|

Connection |

1/4” Tube Fitting (Same as Swagelok®) |

|||

|

Pressure |

Supply 0.1-0.7 MPa |

|||

N2 Gas |

[Gauge Press.] |

Setting 0.04-0.07 MPa |

|||

|

|||||

|

Approx. Flow |

24-27 Pa m3/s |

|

17-22 Pa m3/s |

|

|

Rate |

[3.4 Pa m3/s] |

|

[3.4 Pa m3/s] |

|

|

[Dilution 0 Mode] |

|

|||

|

|

|

|

||

|

Connection |

d50 mm×L50 mm |

|||

Duct |

|

|

|

|

|

Pressure |

|

-196 Pa |

|||

Ventilation |

|

||||

Approx. Flow |

|

0.5 m3/min |

|||

|

|

||||

|

Rate |

|

|

|

|

|

|

FOMBLIN Y-L VAC 25/6 |

|||

Lubrication |

Brand |

BARRIERTA J100 |

|||

DEMNUM S-65 |

|||||

Oil |

|

||||

|

KRYTOX VPF 1525 |

||||

|

|

||||

|

Quantity |

|

0.8 L |

||

Approximate Weight |

380 kg |

|

330 kg |

||

|

Phase/Volt/Freq. |

3 Phase, 200V (50 Hz), 200-220 V (60Hz) |

|||

Power |

Current Rating |

29.5 / 28.1 A |

|

19.7 / 18.5 A |

|

(50 / 60 Hz) |

|

||||

Supply |

|

|

|

||

Connection |

MS Series 22-22 |

||||

|

|||||

|

(Japan Aviation Electronics Industry) |

||||

|

|

||||

|

|

|

|||

Control Signal |

57 Series 50 (DDK. Ltd) |

||||

[Note] Approximate flow rate of N2 gas shows a necessary total amount for seal N2 and dilution N2.

LCD controller displays only the flow rate of dilution N2.

EBARA Corporation

(6)

Table 3.2 Specification (A25S, A10S, A07V)

|

Model |

A25S |

|

|

A10S |

|

A07V |

Pumping Speed (50 / 60 Hz) |

2500 / 3000 L/min |

|

1000 / 1200 L/min |

|

700 / 840 L/min |

||

Ultimate Pressure (50 / 60 Hz) |

5.3 / 4.0Pa |

|

|

5.3 / 4.0Pa |

|

1.1 / 1.0 Pa |

|

Connection |

Gas Inlet |

NW50 |

|

|

NW40 |

|

NW40 |

Gas Outlet |

|

|

|

NW40 |

|

||

|

|

|

|

|

|||

|

Motor |

2P 3.7 kW |

|

|

2P 2.2 kW |

|

2P 1.5 kW |

|

Connection |

|

|

Coupler ( c 3/8) |

|

||

|

|

|

|

|

|

|

|

Cooling |

Pressure |

|

Supply |

ax 0.4MPa |

|||

[Gauge Press.] |

|

|

|

|

|

|

|

Water |

|

Differential Press. Min 0.1MPa |

|||||

|

|

|

|

|

|

|

|

|

Flow Rate |

|

|

Min. 3.5 L/min |

|

||

|

Temperature |

|

|

Max. 30 deg C |

|

||

|

Connection |

1/4” Tube Fitting (Same as Swagelok®) |

|||||

|

Pressure |

|

|

Supply 0.1-0.7 MPa |

|

||

N2 Gas |

[Gauge Press.] |

|

Setting 0.04-0.07 MPa |

||||

|

|

||||||

|

|

|

|

|

|

|

|

|

Approx. |

17-20 Pa m3/s |

|

17-20 Pa m3/s |

|

15-19 Pa m3/s |

|

|

Flow Rate** |

[3.4 Pa m3/s] |

|

[3.4 Pa m3/s] |

|

[3.4 Pa m3/s] |

|

|

Connection |

d50 mm×L50 mm |

|

d50 mm×L60 mm |

|||

Duct |

|

|

|

|

|

|

|

Pressure |

|

|

|

-196 Pa |

|

||

Ventilation |

|

|

|

|

|||

Approx. Flow |

|

|

|

0.5 m3/min |

|

||

|

|

|

|

|

|||

|

Rate |

|

|

|

|

|

|

|

|

|

FOMBLIN Y-L VAC 25/6 |

|

|||

Lubrication |

Brand |

|

|

BARRIERTA J100 |

|

||

|

|

DEMNUM S-65 |

|

||||

Oil |

|

|

|

|

|||

|

|

|

KRYTOX VPF 1525 |

|

|||

|

|

|

|

|

|||

|

Quantity |

0.4 L |

|

|

0.4 L |

|

0.5 L |

Approx. Weight |

240 kg |

|

|

220 kg |

|

150 kg |

|

|

Phase/Volt/Freq. |

3 Phase, |

200V (50 Hz), 200-220 |

V (60Hz) |

|||

Power |

Current Rating |

18.3 / 17.5 A |

|

11.7 / 11.1 A |

|

8.4 / 8.6 A |

|

(50 / 60 Hz) |

|

|

|||||

Supply |

|

|

|

|

|

|

|

Connection |

MS Series 22-22 |

|

|

MS Series 20-4 |

|||

|

|

|

|||||

|

(Japan Aviation Electronics Industry) |

||||||

|

|

||||||

Control Signal |

|

57 Series 50 (DDK. Ltd) |

|

||||

** Numerals in brackets [ ] are flow rate in dilution-0 mode.

[Note] Approximate flow rate of N2 gas shows a necessary total amount for seal N2 and dilution N2.

LCD controller displays only the flow rate of dilution N2.

EBARA Corporation

(7) |

Outline Drawing A70W |

EBARA Corporation

Loading...

Loading...