Page 1

WT-3600

TON CONTAINER

WEIGH TRUNNION

OPERATION INSTALLATION AND SERVICE MANUAL

366 CIRCLE OF PROGRESS POTTSTOWN, PA 19464

(610)323-2250 FAX: (610)323-0114

Page 2

TABLE OF CONTENTS

CONTENTS

SECTION1 . 0 DESCRIPTION.

SECTION2 . 0 PREPARATION FOR USE

2.1 RECEIVING INSPECTION

2.2 SHIPMENT

2.3 SITE SELECTION

2.4 INSTALLATION

2.5 CONNECTION TO DISPLAY/TRANSMITTER

SECTION3 . 0 TROUBLE SHOOTING

SECTION4 . 0 SERVICING

4.1 CHECKING THE SUMMING BOX CONNECTIONS

4.2 CHECKING FOR TRUNNION DAMAGE/INTERFERENCE

4.3 CHECKING THE LOAD CELL

SECTION5 . 0 SPECIFICATIONS

SECTION6 . 0 SPARE PARTS LIST

LIST OF ILLUSTRATIONS

FIGURE 1: Anchor Bolt Spacing

FIGURE 2: System Wiring

FIGURE 2a: Wiring Color Code

FIGURE 3 : Summing Junction Board

Page 3

SECTION 1.0 DESCRIPTION

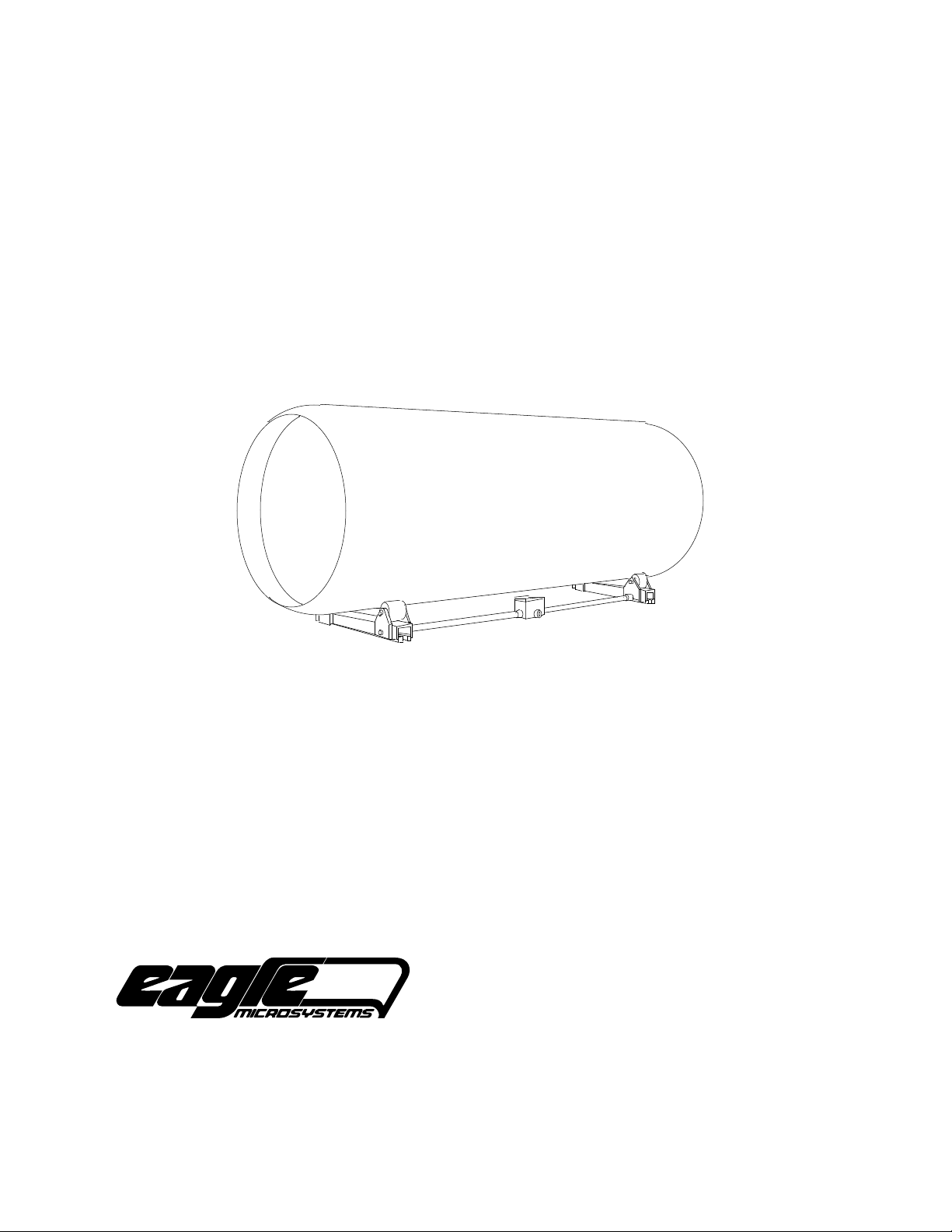

EAGLE MICROSYSTEMS WT3600 Weigh Trunnion was designed specifically for weighing standard t on

containers for Chlorine and Sodium Dioxide. Rollers made of UHMW plastic on stainless steel axles allow

easy ton rotation and require no greasing or other preventive maintenance. Two sealed stainless steel,

electronic load cells provide an accurate weight reading. Each WT3600 weighs less than 50 pounds so it

is shipped via parcel service and can be handled and installed by one person. Several WT3600’s can be

daisy chained to create a multiple container scale. This modularity allows easy reconfiguration to

accommodate growth or downsizing without waste of resources.

SECTION 2.0 PREPARATION FOR USE

2.1 RECEIVING INSPECTION

1. Upon receiving the WT3600, carefully inspect the condition of the shipping container including

the banding and any protective covering used for shipping. Report any damage to the shipper and to

Eagle Microsystems.

2. Remove the WT3600 from the box and inspect for damage. Report any damage to the shipper

and to Eagle Microsystems.

2.2 SHIPMENT

Should re-shipment of your WT3600 become necessary.

1. Use a strong, well-built shipping container. The shipping container must be larger than the outer

dimensions of the WT3600 to protect it in shipping.

2. Make sure the hook-up cable is protected and secured in crate.

3. Use strong banding to secure WT3600 in shipment.

2.3 SITE SELECTION

1. Line power devices causing large inductive currents should not run off the same circuit as

the weigh system. Fluctuations in line voltage caused by such devices may result in display instability.

2. The hook-up cable to the read-out should not run close to other unshielded cables. Display

instability may result.

3. For best accuracy, a flat, level, and rigid surface is recommended to support the WT3600.

4. The area should be accessible for periodic cleaning.

Page 4

2.4 INSTALLATION

1. The WT3600 is “rolled up” prior to packaging and shipment. Prior to installation, the scale assembly

must be “unrolled” so that the flexible conduit is straight on either side of the junction box. Rollers

should face upward.

57"

19"

17"

19"

FIGURE 1: Anchor Bolt Spacing

2. Figure 1. shows the mounting pattern for four 7/16” diameter mounting studs (by others) as well as

the minimum spacing between weigh trunnions for multiple trunnion applications.

3. Mounting tab on the base of each trunnion assembly is 3/4” high. 7/16” mounting studs should

extend no more than 1 3/8” above the floor.

4. For good scale performance and easy roller operation, care should be taken to ensure that

the two ends of the WT3600 are parallel, concentric and level with each other. If

necessary, use grout to achieve this.

Page 5

2.5 CONNECTION TO DISPLAY/TRANSMITTER

Refer to FIGURE 2 and 2a. Several configurations are possible. Note that the “Channel 2 Input” option

allows the cables for two scales or “banks” of scales to share a single conduit back to a dual channel

instrument. This option must be specified when ordering.

TO

DISPLAY

+E+S-S-E +E+S-S-E

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

CHAN#1 OUT

SUMMING

INPUT

CHAN#2 OUT

CHANNEL

#2 INPUT

WT #1

+E+S-S-E +E+S-S-E

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

CHAN#1 OUT

SUMMING

INPUT

CHAN#2 OUT

CHANNEL

#2 INPUT

WT #2

SINGLE CYLINDER OR SUMMED

BANK OF CYLINDERS

FIGURE 2: System Wiring

+E+S-S-E +E+S-S-E

CHAN#2 OUT

CHANNEL

#2 INPUT

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

WT #1-1

+E+S-S-E +E+S-S-E

CHAN#2 OUT

CHANNEL

#2 INPUT

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

WT #1-2

BANK #1

CHAN#1 OUT

CHAN#1 OUT

SUMMING

INPUT

SUMMING

INPUT

TO

DISPLAY

+E+S-S-E +E+S-S-E

CHAN#2 OUT

CHANNEL

#2 INPUT

WT #2-1

+E+S-S-E +E+S-S-E

CHAN#2 OUT

CHANNEL

#2 INPUT

WT #2-2

BANK #2

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

TO

DISPLAY

CHAN#1 OUT

CHAN#1 OUT

SUMMING

INPUT

SUMMING

INPUT

TWO SEPARATELY WEIGHED CYLINDERS

OR SEPARATE BANKS OF CYLINDERS.

OPTION ALLOWS TWO CHANNELS TO SHARE A SINGLE CONDUIT.

COLOR FUNCTION

RED +Excitation

GREEN +Signal

WHITE - Signal

BLACK - Excitation

YELLOW Shield

FIGURE 2a : Wiring Color Code

Page 6

SECTION 3.0 TROUBLE SHOOTING

The following is a list of potential problems and likely cures.

1. Inaccurate but repeatable weight readings:

a. Recalibrate the system (see instrument manual)

2. Inaccurate, non-repeatable weight readings.

3. Check the WT3600 trunnions for damage or interference (Sect. 4.2).

4. Check for bad load cell (Sect. 4.3).

5. Blank or drifting display:

a. Consult the instrument manual.

b. Look for loose connection in hook-up cable at the instrument or in the Summing Box(Sect.

4.1).

c. Look for moisture in the Summing Box (Sect. 4.1).

6. Check for bad load cell ( Sect. 4.3).

SECTION 4.0 SERVICING

4.1 CHECKING THE SUMMING BOX CONNECTIONS.

1. Locate the Summing Junction Box between the two trunnions and remove the lid.

2. Gently lift the summing board out of the box. Check for any signs of moisture or corrosion.

3. Check all connections by lightly pulling on each lead. Tighten terminal connections as

needed.

4. If problem persists, press lightly on the circuit board itself and check meter response.

Replace board if required.

Note: Make sure, when replacing the cover, that the box is dry and the cover is tight.

+E+S-S-E +E+S-S-E

CHAN#2 OUT

CHANNEL

#2 INPUT

+EXCIT.

+SIGNAL

-SIGNAL

+EXCIT

SHIELD

TOP

CHAN#1 OUT

SUMMING

INPUT

+E

+S

-S

-E

LOAD CELL #1 LOAD CELL #2

WTSJB4

BOTTOM

+E

+S

-S

-E

FIGURE 3: Summing Junction Board

Page 7

4.2 CHECKING FOR TRUNNION DAMAGE / INTERFERENCE.

1. Remove the ton container.

2. The 2 trunnions that support the ton container are hinged at the end where the pipe enters. Lift the

top casting at the opposite end to expose the load cell. The load cell has a small button that faces up.

This contacts a shock pad that is installed in the top casting directly above the load cell. This pad

consists of a metal plate attached to a rubber backing that is glued or taped in place. Check to be sure

that neither the plate nor the entire pad has fallen out on both trunnions. The pad and plate can be

glued back together and put in place with contact cement or double sided tape if they have come

apart.

3. Check for any objects that may have gotten stuck between the top and bottom castings.

4. Lower the top casting. It should not rub against the sides of the bottom casting or anything else as it is

lowered. If grouting was used when the scale was installed check that it is not under or against the top

casting.

CHECKING THE LOAD CELLS.

1. Disconnect the scale cable at the display instrument.

2. Measure the resistance between the green and white wires. This should be approximately 1502

ohms.

3. Measure the resistance between the black and red wires. This should be approximately 600 ohms.

Page 8

SECTION 5.0 SPECIFICATIONS

CONSTRUCTION: Load Cell: Stainless Steel

Trunnion Castings: Aluminum

Axles & Hardware: Stainless Steel

Rollers: UHMW Plastic

Shock Pads: Fabcel 300 ®

Conduit & Fittings: PVC

Junction Box: Cast Iron

FINISH: Trunnion Castings: Acrylic Paint

Junction Box: Clear Acrylic Paint

CAPACITY: 4000 Lb

SAFE OVERLOAD: 200% of Rated Capacity.

ULTIMATE OVERLOAD: 300% of Rated Capacity.

NOMINAL OUTPUT: 0.5 mV/V at full scale

EXCITATION VOLTAGE: 5 to 15 VDC

OPERATING ACCURACY: 0.5% of Capacity.

REPEATABILITY: 0.2% of Capacity.

LOAD CELL: Stainless Steel strain gage, hermetically sealed,1000 Ω.

TEMPERATURE: 0 to 150 Degr. F.

HOOK-UP CABLE: 15' of 4 conductor, color coded,shielded cable. PVC jacket.

SECTION 6.0 SPARE PARTS LIST

PART DESCRIPTION MODEL/CAPACITY

Load Cell TH-CM / 4,000 lbs F.S.

Roller M10246

Roller Retaining Ring WST-75

Shock Plate M10250

Shock Pad M10249

Shock Disk M10131

Load cell Summing Board WTSJB

Loading...

Loading...