Page 1

Vector Flight Controller + OSD User Guide

USER GUIDE

March, 2015

Version 2.2

Software Ve r s i on 11. 70+

1

Page 2

Table of Contents

1 Safety ............................................................................................................................................................................. 6

1.1 .... Read the Manual!................................................................................................................................................................6

1.2 .... Special Symbols used in the Manual ..........................................................................................................................6

1.3 .... General Safety Precautions ............................................................................................................................................6

2 Overview ...................................................................................................................................................................... 7

2.1 .... Introduction ..........................................................................................................................................................................7

2.2 .... Packing List ...........................................................................................................................................................................8

2.3 .... Specifications ........................................................................................................................................................................8

2.4 .... How to Get Help and Request New Features .........................................................................................................9

2.5 .... Installing the Software, and Updating the Firmware .......................................................................................9

2.5.1 Software Compatibility ............................................................................................................................................................. 9

2.5.2 Downloading the Latest Software ....................................................................................................................................... 9

2.5.3 Updating your Vector Firmware ....................................................................................................................................... 10

USER GUIDE

2.6 .... Getting Notified about Important Vector Updates .......................................................................................... 10

2.7 .... Glossary of Terms used in the Manual ................................................................................................................... 11

3 Connecting the Vector.......................................................................................................................................... 13

3.1 .... Vector Controller Connections .................................................................................................................................. 13

3.1.1 Backup Power ............................................................................................................................................................................ 13

3.2 .... Vector GPS/Mag and Current Sensor/PSU Connections ............................................................................... 14

3.3 .... Vector Current Sensor/PSU Power Output .......................................................................................................... 15

3.4 .... Current Sensor Maximum Continuous Current, and Load Testing .......................................................... 15

3.5 .... Vector Wiring .................................................................................................................................................................... 16

3.5.1 Vector Video Harness + Connecting your Video Camera and Transmitter .................................................... 16

3.5.2 Providing power to your Video Transmitter and Camera ..................................................................................... 17

3.5.3 Vector Audio Harness and Audio Connections ........................................................................................................... 18

3.5.4 Vector Receiver Harness....................................................................................................................................................... 19

3.5.5 Receiver Connection Harness Load Capacity (Fixed Wing Only) ....................................................................... 20

3.5.6 Powering your Receiver on Multirotors ........................................................................................................................ 20

3.5.7 Connecting Receiver and Servos/ESCs to the Vector .............................................................................................. 22

3.5.8 Connecting you Receiver’s RSSI Output (if available) ............................................................................................. 25

3.5.9 Configuring SPPM Based RSSI and Link Quality ........................................................................................................ 25

4 Mounting the Vector and Accessories ........................................................................................................... 26

4.1 .... Mounting the Vector ...................................................................................................................................................... 26

4.1.1 Mounting Location and Orientation ................................................................................................................................ 26

4.1.2 Mounting Technique............................................................................................................................................................... 26

2

Page 3

4.2 .... Mounting the GPS/MAG Sensor ................................................................................................................................ 27

4.2.1 GPS Signal Interference ......................................................................................................................................................... 27

4.2.2 Magnetometer Interference ................................................................................................................................................ 27

4.2.3 GPS/MAG Mounting Orientation ....................................................................................................................................... 27

4.2.4 The GPS Stand and Clip ......................................................................................................................................................... 28

4.3 .... Mounting the Current Sensor/PSU .......................................................................................................................... 28

4.4 .... Mounting the Optional Pitot Tube ........................................................................................................................... 28

4.5 .... Controlling the Vector ................................................................................................................................................... 29

4.5.1 The Mode Switch ...................................................................................................................................................................... 29

4.5.2 The Submode Switch .............................................................................................................................................................. 29

4.5.3 The Gain Knob ........................................................................................................................................................................... 29

4.5.4 The Kill Switch (for Multirotors Only) ............................................................................................................................ 30

5 Configuring the Vector ........................................................................................................................................ 30

5.1 .... Configuration Overview ................................................................................................................................................ 30

5.2 .... Transmitter Channel Mixing ...................................................................................................................................... 30

USER GUIDE

5.3 .... Configuring with the Windows Software ............................................................................................................. 31

5.4 .... Configuring the Vector via Stick Menus ................................................................................................................ 32

5.4.1 Teaching the Vector about SPPM or S.BUS™ Channel Mappings ........................................................................ 32

5.4.2 Navigating the Stick Menus ................................................................................................................................................. 33

5.4.3 Exiting Menu Mode ................................................................................................................................................................. 34

5.4.4 Accessing Menus during Flight .......................................................................................................................................... 34

5.5 .... Selecting the Airframe type ........................................................................................................................................ 34

5.6 .... Accepting the Airframe Type ..................................................................................................................................... 35

5.7 .... Telling the Vector about Transmitter Dual Surface Mixing ........................................................................ 35

5.8 .... Running the Receiver Analysis Wizard .................................................................................................................. 35

5.9 .... Configuring Auxiliary Receiver Inputs and Servo Outputs ........................................................................... 37

5.9.1 Configuring the Auxiliary Input Channel (for non-serial Rx inputs) ................................................................ 37

5.9.2 Configuring the Vector Auxiliary Output Channels (Fixed wing only) ............................................................ 37

5.10 . Flight Modes, and Configuring the Mode/Submode Switches .................................................................... 38

5.10.1 Flight Mode Description ................................................................................................................................................ 38

5.10.2 Control Stick Function in Multirotor Modes ......................................................................................................... 40

5.10.3 2D Hold Flight Mode Information for Fixed Wing ............................................................................................. 40

5.10.4 Programming the Mode Switch .................................................................................................................................. 40

5.10.5 Programming the Optional Submode Switch ....................................................................................................... 41

5.11 . Configuring the Flight Controller/Stabilizer ...................................................................................................... 42

5.11.1 Setting Controller Gains ................................................................................................................................................. 42

5.11.2 Verifying Correct Control Surfaces Movement (Fixed Wing) ....................................................................... 46

3

Page 4

5.11.3 Confirming ESC Endpoints are set Correctly (Multirotor only) ................................................................... 46

5.11.4 Arming and Disarming your Multirotor (Multirotor only) ............................................................................ 47

5.11.5 Setting Idle Throttle (Multirotor only) ................................................................................................................... 48

5.11.6 Confirming Correct Motor Order and Direction (Multirotor only) ............................................................ 48

5.11.7 Configuring Low Battery Autoland (Multirotor only) ...................................................................................... 49

5.11.8 Setting Flat Level Mounting ......................................................................................................................................... 49

5.11.9 Rezeroing Gyros ................................................................................................................................................................ 49

5.12 . Configuring Return to Home and other Safety Modes ................................................................................... 50

5.12.1 Configuring Failsafe Detection ................................................................................................................................... 50

5.12.2 Configuring RTH/Safety Mode ................................................................................................................................... 52

5.12.3 Configuring Maximum Altitude and Maximum Distance ................................................................................ 53

5.13 . The Vector’s LED Indicator ......................................................................................................................................... 53

5.14 . Configuring the OSD ....................................................................................................................................................... 54

5.14.1 Adjusting the Display ...................................................................................................................................................... 54

5.14.2 Setting Display Units (English or Metric) .............................................................................................................. 55

USER GUIDE

5.14.3 Choosing what to Display on the OSD Screen ...................................................................................................... 55

5.14.4 Basic Numeric Readouts ................................................................................................................................................ 55

5.14.5 Advanced Numeric Readouts ...................................................................................................................................... 57

5.14.6 Graphics and Indicator Readouts .............................................................................................................................. 57

5.14.7 Setting OSD Alarms .......................................................................................................................................................... 59

5.15 . Configuring and Calibrating the Magnetic Compass ...................................................................................... 60

5.15.1 Using the Compass with Fixed Wing Airframes .................................................................................................. 60

5.15.2 Calibrating the Compass ................................................................................................................................................ 61

5.15.3 Testing the Compass ....................................................................................................................................................... 62

5.16 . Configuring the EagleEyes™ FPV Station ............................................................................................................. 62

6 First Flights .............................................................................................................................................................. 63

6.1 .... Preflight Checklist ........................................................................................................................................................... 63

6.1.1 Resetting Home Position ...................................................................................................................................................... 63

6.2 .... First Flight Recommendations .................................................................................................................................. 64

6.2.1 Ground Tests before First Flight ....................................................................................................................................... 64

6.2.2 Flight Mode for Takeoffs ....................................................................................................................................................... 64

6.3 .... In-air Leveling ................................................................................................................................................................... 64

6.3.1 Multirotor in-air leveling ...................................................................................................................................................... 65

6.3.2 Fixed Wing in-air leveling .................................................................................................................................................... 65

6.3.3 Optimal Fixed Wing leveling ............................................................................................................................................... 65

6.4 .... Return to Home Testing and Operation ................................................................................................................ 65

6.4.1 RTH Limitations........................................................................................................................................................................ 65

4

Page 5

6.4.2 RTH Ground Testing ............................................................................................................................................................... 66

6.4.3 In-air RTH Testing ................................................................................................................................................................... 66

7 Advanced Vector Setup and Calibration....................................................................................................... 66

7.1 .... Advanced OSD Setup ...................................................................................................................................................... 66

7.1.1 The Advanced Numeric Readouts Menu ....................................................................................................................... 66

7.1.2 Gauges and Swatches ............................................................................................................................................................. 68

7.1.3 The Advanced Graphics/Indicators Menu .................................................................................................................... 69

7.2 .... Using Optional RPM and Temperature Sensors ................................................................................................ 69

7.2.1 Temperature Sensor ............................................................................................................................................................... 69

7.2.2 Brushless RPM Sensor ........................................................................................................................................................... 70

7.3 .... Waypoints ........................................................................................................................................................................... 71

7.3.1 Configuring Waypoints .......................................................................................................................................................... 71

7.3.2 Showing Waypoints on the OSD ........................................................................................................................................ 71

7.4 .... Data Logging ..................................................................................................................................................................... 72

7.4.1 Configuring Data Logging ..................................................................................................................................................... 72

USER GUIDE

7.4.2 Downloading, Viewing and Saving Logged Flight Information ........................................................................... 72

7.4.3 Additional Data Logging and Telemetry Features .................................................................................................... 73

7.5 .... Advanced RTH Setup ...................................................................................................................................................... 74

7.5.1 Home Altitude Mode ............................................................................................................................................................... 74

7.5.2 Other Advanced RTH Settings ............................................................................................................................................ 75

7.6 .... Acoustic Variometer ....................................................................................................................................................... 75

7.7 .... Vector Calibration ........................................................................................................................................................... 76

7.7.1 Electrical Calibration .............................................................................................................................................................. 76

7.7.2 Altimeter Calibration.............................................................................................................................................................. 77

7.8 .... GPS Configuration ........................................................................................................................................................... 77

7.8.1 Choosing the GPS Position Display Format .................................................................................................................. 77

7.8.2 Changing the GPS Fix Quality Settings ............................................................................................................................ 77

8 Troubleshooting ..................................................................................................................................................... 79

9 Notification Messages .......................................................................................................................................... 83

10 Description of Numeric Readouts ................................................................................................................... 88

11 Regulatory ................................................................................................................................................................ 90

12 Limited Warranty .................................................................................................................................................. 91

5

Page 6

USER GUIDE

1 Safety

The Vector is intended to be used exclusively for recreational purposes in model planes, boats and cars. Using

the Vector for other purposes is not supported. Further, using the Vector in situations where its use or failure

could result in loss of life, bodily injury or property damage is expressly prohibited.

Eagle Tree Systems, LLC, is not responsible for your use of this product, or for any damages or injuries

you may cause or sustain as a result of its usage.

1.1 Read the Manual!

This manual contains important instructions related to safety. Read the entire manual before proceeding, to

become familiar with the features and operation of the Vector. Failure to correctly configure or operate the

Vector could cause damage to personal property or serious injury!

The latest version of this manual is available in the Product Manuals section of the Support tab on

http://www.eagletreesystems.com.

If, after you read the manual, you have further questions or problems, see the “How to Get Help” section below.

Reading this manual is probably more enjoyable, and will probably take less time, than rebuilding your

model!

1.2 Special Symbols used in the Manual

Warning that could affect safety or result in injury, a crash, property damage or Vector hardware

damage if not heeded.

Under construction. This feature is experimental, incomplete, or under active development.

Information applicable only for fixed wing models

Information applicable only for multirotor models

Helpful Note or Tip

1.3 General Safety Precautions

In addition to other warnings and other precautions in this manual, the following should always be

observed:

The Vector is intended for recreational use only, in model aircraft. Any other use is not supported.

Never connect ESCs or servos to the Vector until you have verified the airframe type is correctly

selected! Doing so can cause multirotor propellers to spin at high speed, or can destroy fixed wing

servos.

Always remove propeller(s) or otherwise disable motor(s) when configuring the Vector!

Always move a safe distance away from the model before starting the motor(s), and never approach the

model with the propeller(s) spinning! Never approach a multirotor when it is armed!

Always wear eye protection when operating models with propellers!

6

Page 7

RC models and accessories are not toys! The Vector should not be used by children.

You should always use a spotter if your eyes are not on your model. For USA customers, please refer

to the Academy of Model Aeronautics Safety Code at http://www.modelaircraft.org/files/105.PDF and

FPV related code at http://www.modelaircraft.org/files/550.pdf

Always obey the law when flying. Most video transmitters used for FPV flying require an amateur

radio license to operate legally.

If you have never set up or operated an RC model before, you will need help from an experienced

modeler. Local RC clubs are great ways to meet experienced modelers, and receive the required

training. This requirement is especially true for FPV flying, which can be more challenging.

Never operate your model aircraft near or over buildings, power/telephone lines, or other obstacles.

Never operate your model aircraft near or over people or animals! Never operate your model after

consuming drugs or alcohol!

Never operate the Vector in a situation where it may get wet, such as on a rainy day.

Do not change wiring in your model when any power is applied.

2 Overview

2.1 Introduction

USER GUIDE

Thank you for your purchase! Based on Eagle Tree's proven inertial stabilization and video technology, the

Vector Flight Controller + OSD has everything we’ve dreamed about, in one small, lightweight, easy to use

product:

Straightforward to set up and operate "out of the

box" with no PC required

FIXED WING and MULTIROTOR Flight Controller

with GPS modes and RTH

Built-in OSD with COLOR GRAPHICS

OSD display is fully configurable, so you can make

the screen as simple or detailed as you want it

OSD still displays even if your camera fails!

COMPATIBLE: PCM, SPPM and S.BUS™ receiver

support, with several types of RSSI

EXPANDABLE with additional sensors,

accessories, and internet firmware updates

FLEXIBLE: fly with or without your FPV equipment

Built in FLIGHT DATA RECORDER helps take the guesswork out if something goes wrong

REDUCED WIRING: innovative wire harness with power distribution simplifies hookup

Built-in altimeter, IMU, and magnetic compass sensors

Current sensor with quiet and efficient Power Supply Unit supports up to 6S packs

7

Page 8

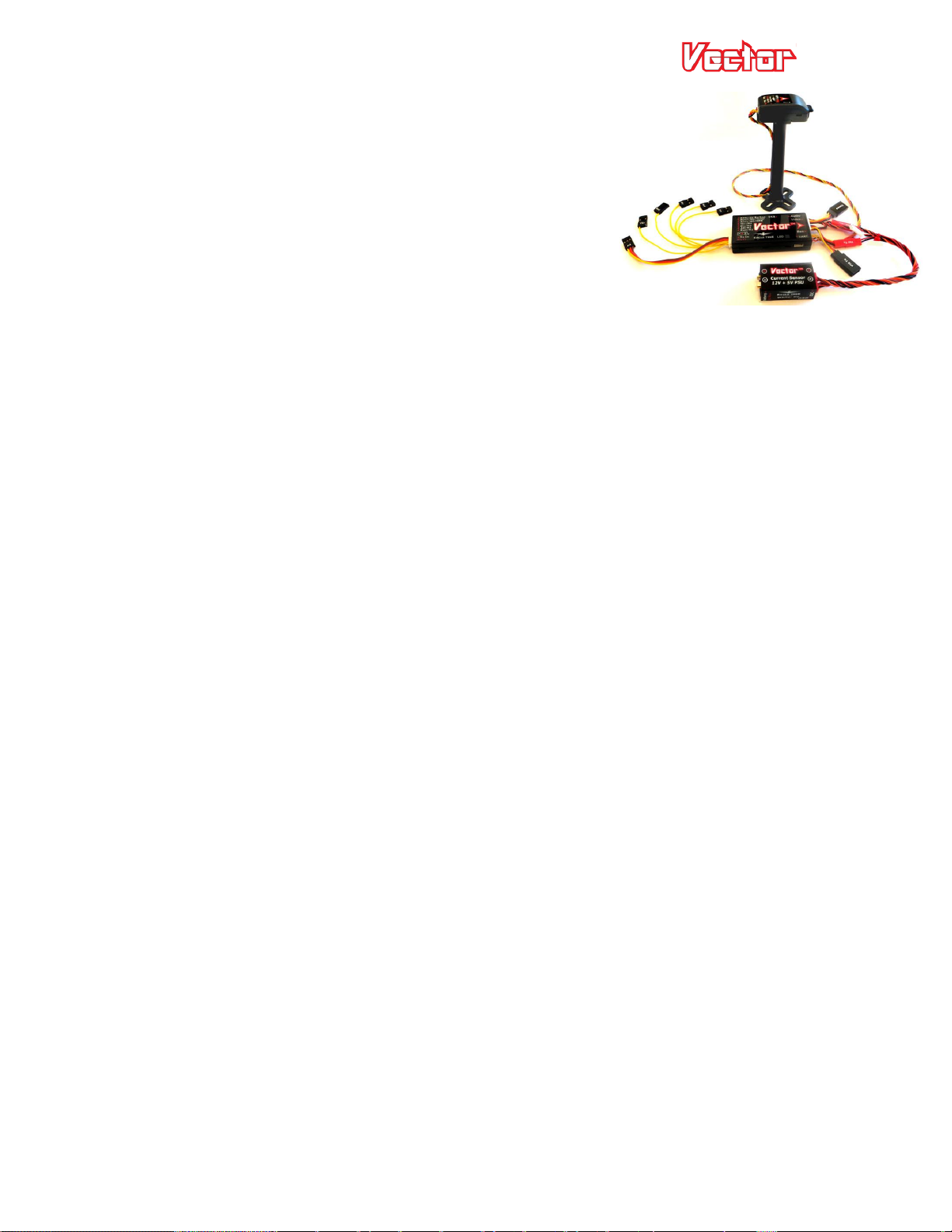

2.2 Packing List

Your package should include the following:

Vector Controller

Current Sensor/PSU (Deans

GPS/Magnetometer (GPS/Mag), with GPS stand, clip and screw

Video, Audio (not shown), GPS, and Receiver Harnesses

TM

, XT60TM or wire leads version),

2.3 Specifications

Supported Airframes:

o Traditional fixed wing, Elevon, and V-tail planes

o Tricopter, Quadcopter, and Hexacopter multirotors

Recommended Airframes: the Vector is not recommended for large or heavy airframes, due to no or

limited testing on these types of models at this time. Examples: giant scale fixed wing models, gas or

nitro models, turbines, or multirotors larger than 650mm are not recommended.

Video formats: composite NTSC and PAL (autodetect)

Servo/ESC Output framerate:

o Fixed wing: adjustable up to 400Hz

o Multirotor (including tricopter yaw servo): 400Hz

USER GUIDE

Dimensions (L x W x H, approximate):

o Controller: 65mm x 33mm x 14mm

o GPS/Mag: 35mm x 24mm x 15mm

o Current Sensor/PSU (with Deans™): 42mm x 19mm x 18mm

Mass (approximate):

o Controller: 21g

o GPS/Mag: 13g

o Current Sensor/PSU (with Deans™): 15g

Current Sensor/PSU

o Peak measured current: 140 amps (see section 3.4)

o Max pack voltage: 6s/25.2V

o Maximum 12V PSU current: 1A

o Maximum 5V PSU current: 1A

8

Page 9

USER GUIDE

2.4 How to Get Help and Request New Features

Eagle Tree is committed to providing great customer service. Once you’ve read the manual, if something is not

clear, just ask. We’d much prefer to take the time to answer your questions, rather than having you waste your

valuable time struggling with an issue.

To get help 24/7, visit the Eagle Tree Vector support thread on RCGroups:

http://www.rcgroups.com/forums/showthread.php?t=2032857

Or, visit the thread on FPVLab:

http://fpvlab.com/forums/showthread.php?22260

Chances are someone has posted a solution to your problem already. If not, posting your problem on the forum

will get a very quick response from the Eagle Tree community.

If you prefer to not post on the forum, or you feel there is a problem with your Eagle Tree hardware, please

open a support ticket with us at http://ticket.eagletreesystems.com and we will respond to your support ticket

as soon as we can – normally within a few business hours. Note that when you create a support ticket, you

will be emailed a link that will let you check the status of the ticket. If you do not receive the email, most likely a

spam filter is intercepting emails from Eagle Tree.

Also, Eagle Tree greatly values your feedback on how we can improve our products. To leave us feedback for a

new feature request or improvement, post the feedback on our support threads above, create a support ticket

with your feedback, or just email us at support@eagletreesystems.com.

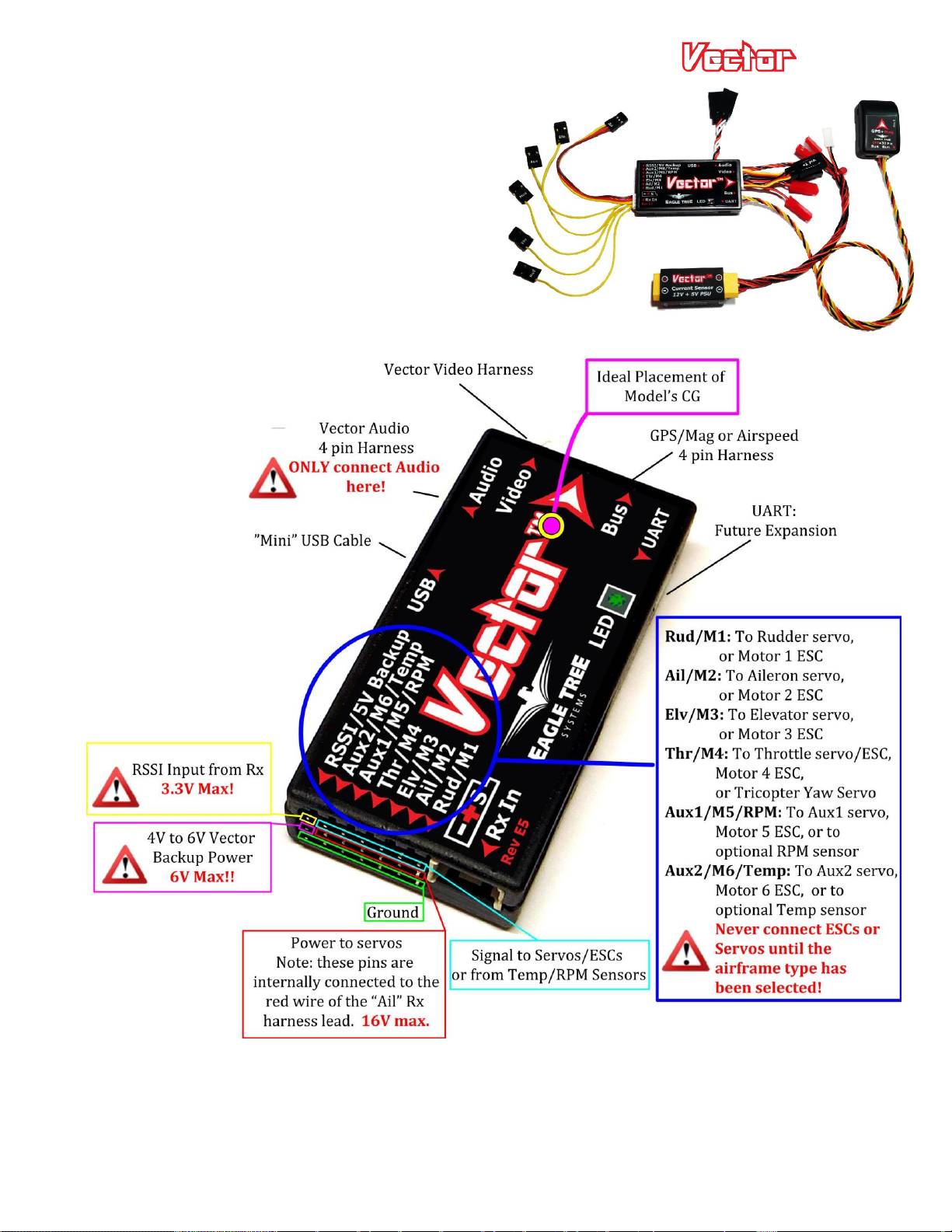

2.5 Installing the Software, and Updating the Firmware

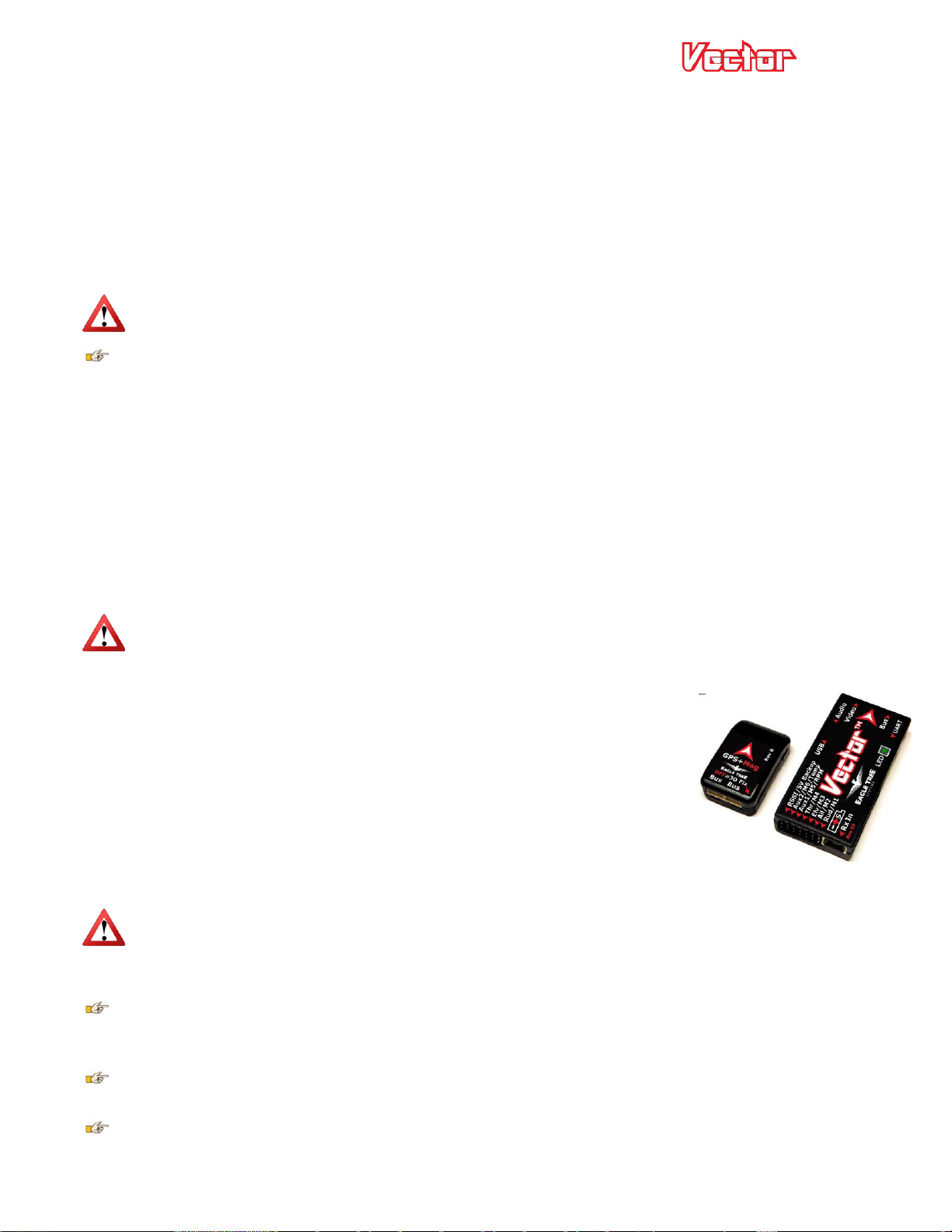

To configure your Vector with the software, or to update the Vector firmware, you

will need to install our software on a compatible device.

Additionally, you will need a standard “mini” USB cable. You probably have one of

these cables already, but if not, you can order one online from us, or elsewhere.

Our p/n is USB-CAB-MINIB.

2.5.1 Software Compatibility

The software is compatible with Windows XP, Vista, Windows 7, and Windows 8/8.1. Most Windows based

PCs, laptops, notebooks, and tablets (including the Surface™ Pro™) are compatible with the software.

A minimum screen resolution of 1024x768 is required.

If you have a Mac™, you can run our software by using a correctly configured Windows emulator such as

VMWare™.

2.5.2 Downloading the Latest Software

The latest software for the Vector is available online at no

additional charge, by selecting “Download Latest Software”

from the Support tab at http://www.eagletreesystems.com

and selecting the Vector software.

The software version you are presently running is shown in

the lower left hand corner of the software. If that version

is lower than the version presently on our website,

consider upgrading.

9

Page 10

USER GUIDE

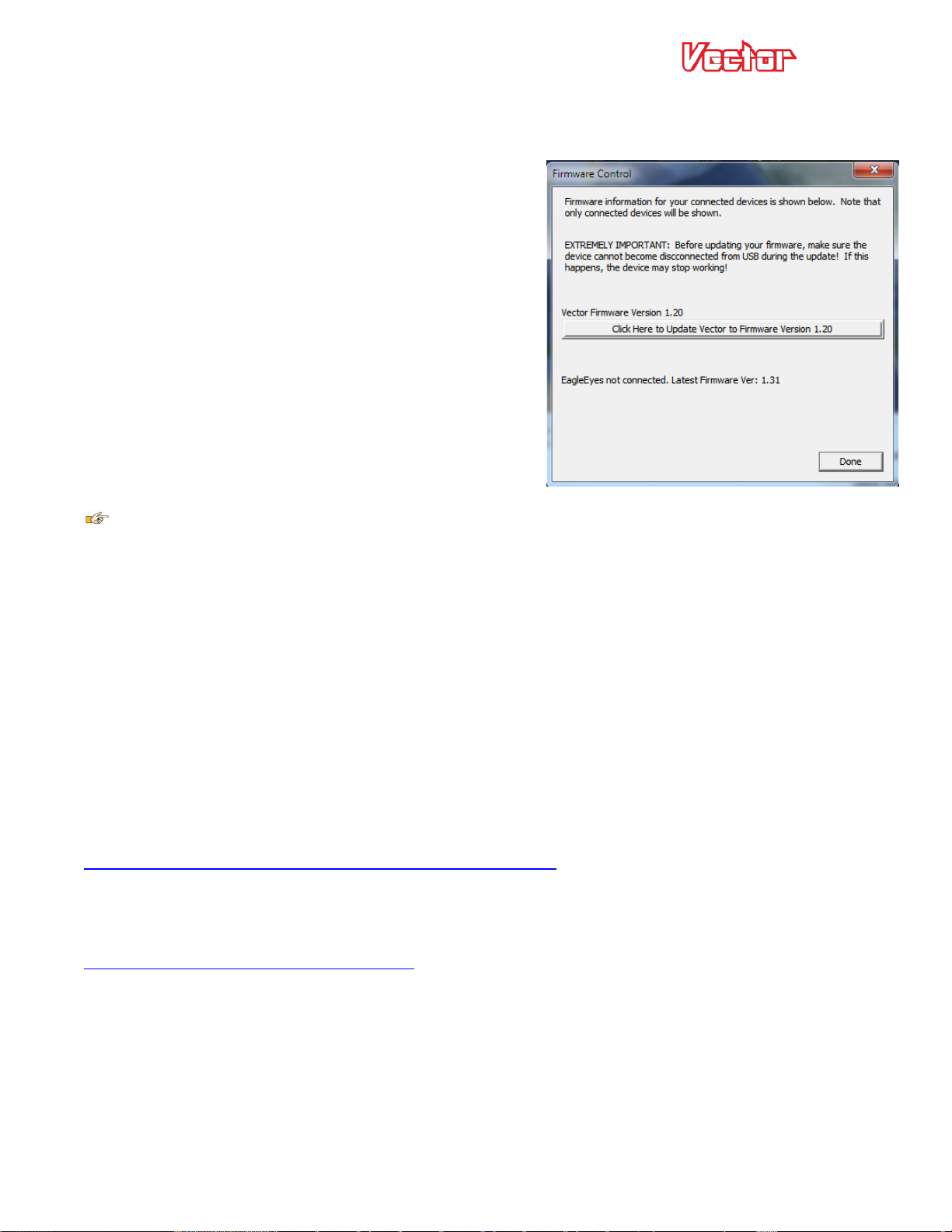

2.5.3 Updating your Vector Firmware

Even if you will be configuring the Vector using the stick menus, it’s a good idea to keep your Vector firmware

updated, in case we add a feature or resolve an issue that is relevant to your airframe. Our latest software

always has the latest Vector firmware included with it.

To check to see if you have the latest firmware, first check

what firmware version is installed on your Vector, which is

displayed at the bottom of the Vector boot-up OSD screen.

Or, you can check the version by using the firmware update

utility described below. Then, compare your version

number with the latest Vector firmware version we have

released (listed on the software download page on our

website).

To update the Vector firmware, install the latest software,

connect the Vector to USB, click the “Firmware Update”

button in the software (in the bottom row of buttons), and

follow the instructions.

Make sure that your GPS/Mag is connected to your Vector before updating firmware. The firmware on

the GPS/Mag will also be updated automatically, if needed.

Also, note that if you install new software and it detects that the Vector’s firmware needs an update, it will

automatically run the firmware update utility.

2.6 Getting Notified about Important Vector Updates

Eagle Tree updates the Vector firmware and software periodically to add new features or to address issues that

may arise, and will issue important hardware information bulletins as needed. There are two ways to get

notified about these:

1) Subscribe to the Vector update notification thread on RCGroups. Whenever we update the software or

release a hardware bulletin, we will post a note to this thread, and subscribing to it should result in you

receiving an email. Note that this thread will normally be closed, so only we can post to it, reducing the

number of emails you will receive.

http://www.rcgroups.com/forums/showthread.php?t=2159747

2) Follow us or like us on Facebook™. We will post a note on Facebook indicating that new software or

important hardware information has been posted, and you should see that on your Facebook page.

http://www.facebook.com/eagletreesystems

10

Page 11

USER GUIDE

2.7 Glossary of Terms used in the Manual

Here are definitions for some of the terms used throughout the manual.

FPV – FPV stands for First Person View. If you are not familiar with FPV, there are many websites devoted to

it. Our FPV overview web page at http://www.eagletreesystems.com/OSD has a brief tutorial on FPV, which is

a good place to start.

OSD – OSD stands for On Screen Display. The OSD shows flight information, overlaid on the video camera

image.

RTH – Return to Home. The Vector can optionally return your model to the home point if R/C link is lost.

Software – the term “software” in the manual refers to our Windows PC software application.

Firmware – the firmware is the code that runs on the Vector itself. The latest Vector firmware is included

with the software.

Flight Controller or Stabilizer – the aspect of the Vector that stabilizes your model during flight

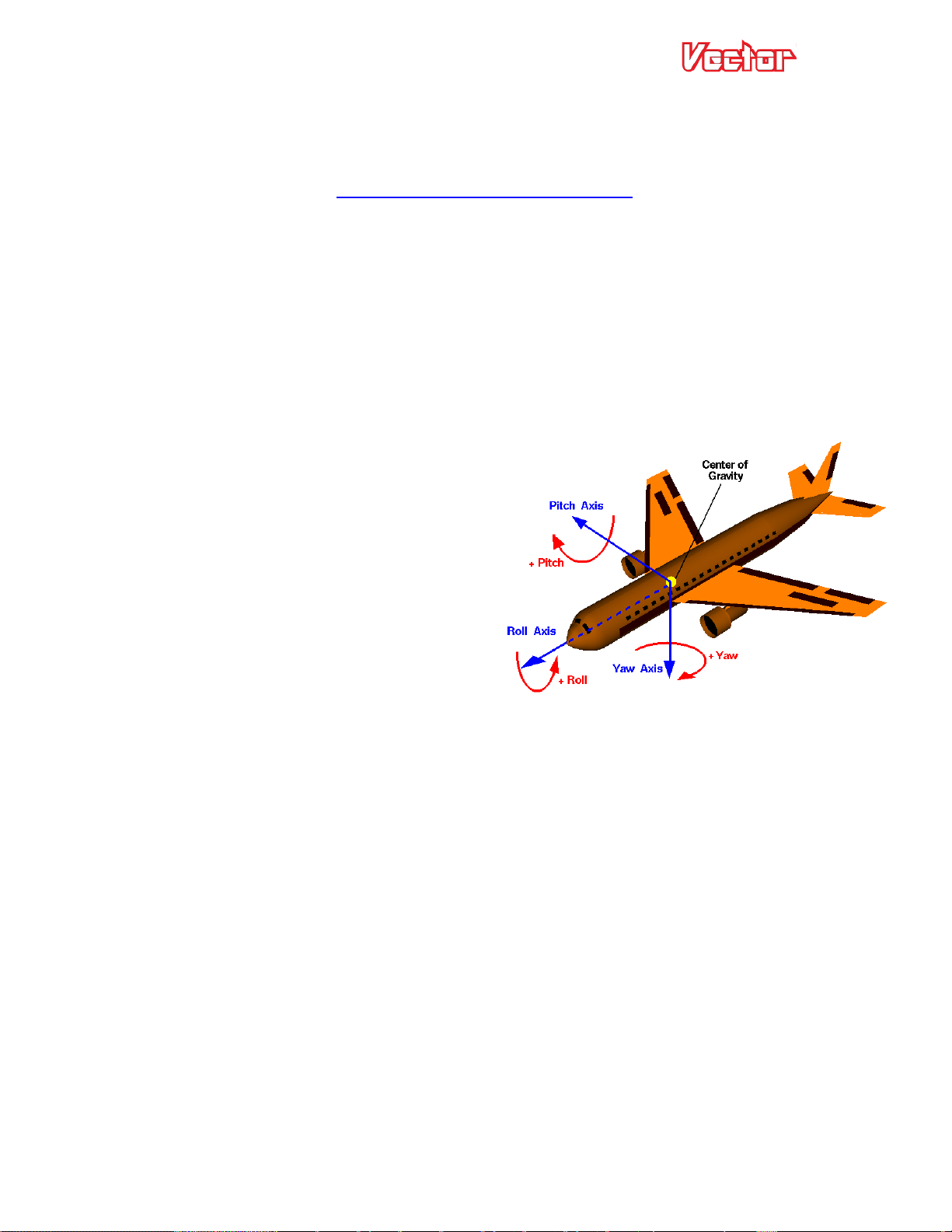

Pitch – Lift or descent of the nose and tail of the

model (front to back tilt on multirotors). Normally

controlled by the elevator, or movement of elevons in

same direction.

Roll – Rocking movement of the wings, side to side

(side to side tilt on multirotors). Normally controlled

by ailerons, or movement of elevons in opposite

directions.

Yaw – Turning of the airplane without banking

(rotation on multirotors). Normally controlled by

the rudder.

Axis – an imaginary line drawn horizontally through

your model’s wing (for Pitch), horizontally through your fuselage (for roll), or vertically through the center of

your fuselage (for yaw).

Gain – a setting that controls how hard the stabilizer works to hold the orientation of the model around a

certain axis.

Oscillations – rapid swings of your model around one of its axes, due to a gain setting being too high.

Mode 2 Radio: Transmitters with rudder and throttle on the left stick, and aileron and elevator on the right

stick.

Control Stick – The stick on Mode 2 radios that controls elevator and aileron functions (pitch and roll).

Attitude – The orientation of the model with respect to the horizon.

2D Mode – A mode where the model is brought to a level attitude (level flight and level wings) by the Vector

when the control stick is centered.

3D Mode – A mode where the Vector attempts to hold the model’s present attitude when the control stick is

centered, by moving the model’s control surfaces automatically.

Gyro Mode – A mode where the stabilizer responds similarly to having gyros installed on the control surface

outputs.

Heading – The present direction of travel of the model with respect to North.

Control Surfaces – Your model’s elevator, ailerons (or elevons), flaperons, and/or rudder (if equipped).

11

Page 12

USER GUIDE

Mode Switch – A two or three position switch on your radio transmitter which you have configured to control

the “Mod” input on the Vector’s Receiver Connection Harness.

Toggle – One fairly rapid movement the Mode Switch between its extents. (UP/DOWN or DOWN/UP)

Configuration Gestures – A series of toggles of the Mode Switch. The number of times you toggle the switch

determines which configuration step is performed.

PSU - Power Supply Unit. This refers to the 5V and 12V switching regulators built into the Vector current

sensor.

Toilet Bowl – When a multirotor is hovering, the condition of orbiting around the desired hover point,

sometimes in an ever increasing diameter, due to compass error or other issues.

12

Page 13

3 Connecting the Vector

This section describes the Vector’s cabling and

connections, and how to connect the Vector to your

RC receiver, your servos or ESCs, and your FPV video

transmitter and camera.

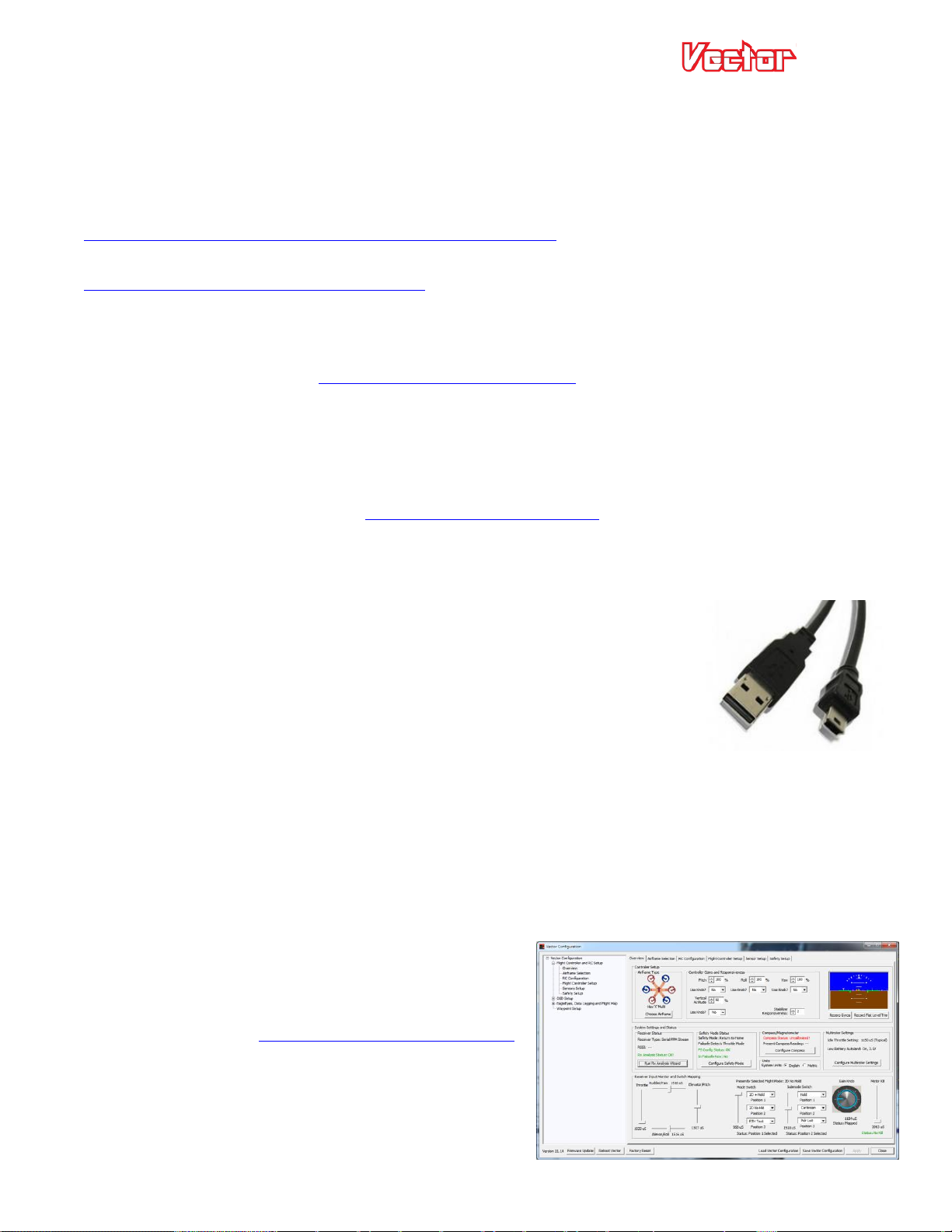

3.1 Vector Controller Connections

The figure below shows the function of each of the

Vector’s ports, and other Vector information.

USER GUIDE

3.1.1 Backup Power

If you want the Vector to use a redundant power supply for safety, the middle pin of the RSSI/5V Backup

connection can be used to supply backup power to the Vector. Normally the Vector is powered by 5V from the

Current Sensor/PSU, but the Vector will take power from the backup connection whenever the voltage at this

pin is approximately 0.5V higher than the voltage coming from the Current Sensor/PSU.

13

Page 14

USER GUIDE

For example, if the backup power is connected to the BEC of your ESC (via your receiver), and that is supplying

5.0V, the Vector will use the PSU power unless the PSU voltage drops below 4.5V. Likewise, if your BEC is

providing 6.0V to the backup power port, the backup power port will always be powering the Vector unless the

BEC output fails.

Note that the backup power input will NOT power your camera or video transmitter. Only the Vector

and accessories connected to the “Bus” port will be powered.

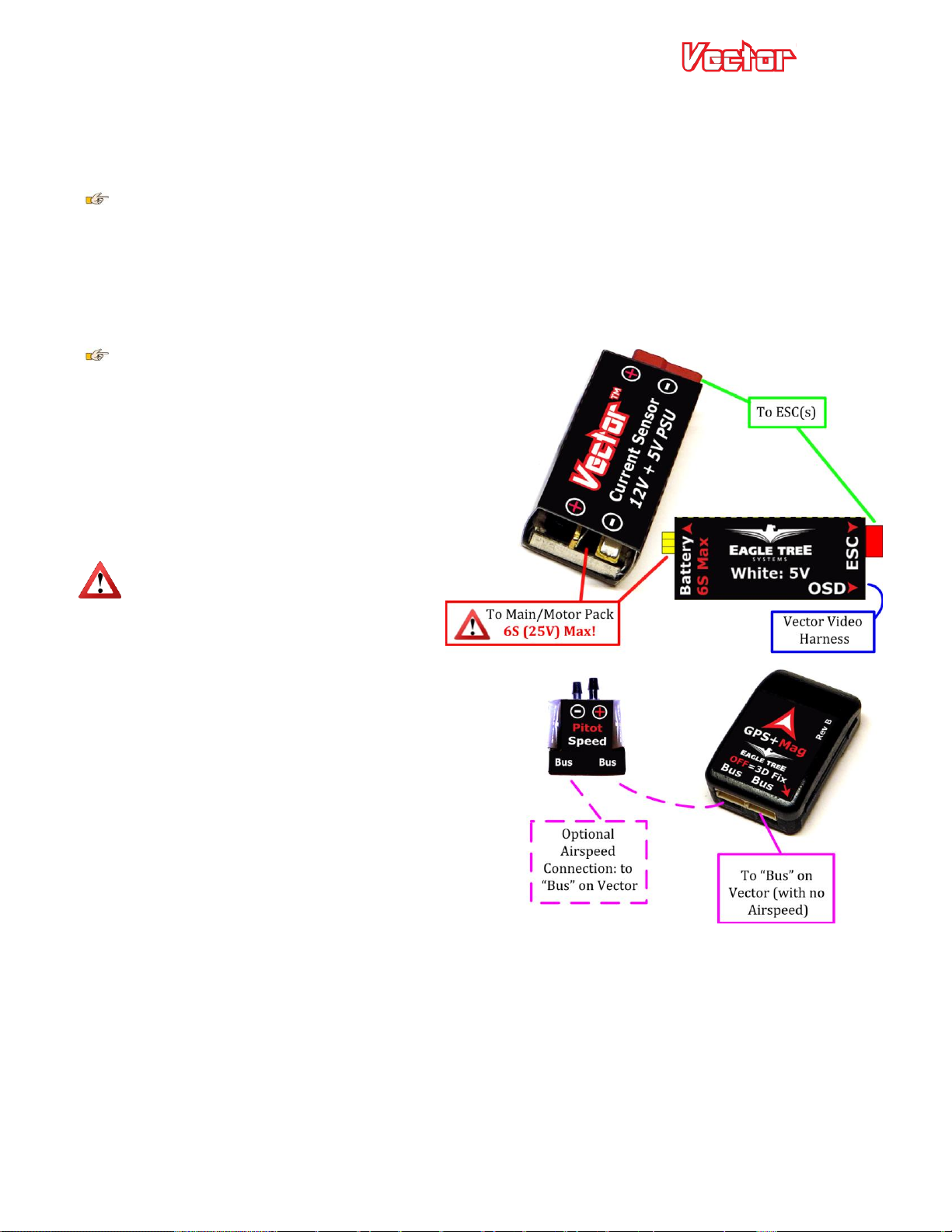

3.2 Vector GPS/Mag and Current Sensor/PSU Connections

Connections to the Current Sensor/PSU (DeansTM version shown), the GPS/Mag, and the optional Pitot Airspeed

sensor are shown in the figure below.

The “Bus” connectors on the GPS/Mag

and Airspeed sensors are internally connected

together. Wiring order, or which of the two

connectors on each sensor is used, does not

matter.

In other words, you can plug into either “Bus”

connector, and if you “daisy-chain” the

Airspeed with the GPS/Mag, either unit can be

at the head of the chain.

Never connect the GPS/Mag or pitot

sensor to the Vector’s AUDIO

connection. Doing so will destroy the sensor!

14

Page 15

USER GUIDE

3.3 Vector Current Sensor/PSU Power Output

The Vector’s high efficiency and low noise PSU accepts up to 6S voltage input, and provides filtered 5V and up

to 12V output at 1A max per channel. It's perfect for powering most FPV gear, and can also power your receiver

on multirotors (when NO servos are being powered by the RX!), eliminating the need for an external BEC.

Never use the PSU to power any servos on your model! The PSU can shut off due to excessive power

draw, causing a crash! Servos MUST be powered by a stand alone BEC, a BEC built into your ESC, or a

separate radio flight pack!

Note that the 12V regulator does NOT boost the voltage, like a SEPIC. However, the Vector's 12V PSU has a

unique Low Voltage Loss feature that drops the regulator’s output by only about 0.5V if you are using a 3S

pack operating below 12.5V. For example, if your 3S pack is at 11.5V, the regulator outputs about 11V. Other

non-boost switching regulators typically drop the output voltage by 1.3V or more.

SEPIC and other voltage boost regulators are generally much less efficient and generate much more UHF band

noise, and in many cases you don’t need one. You never need one if your pack is 4s or above, and all known

cameras and many transmitters will operate well across the 3S pack voltage range. Typically, 1.3GHz

transmitters may provide reduced power output with less than 12V voltage, and 5.8GHz transmitters work fine

at less than 12V. Be sure to check your transmitter manual’s specs to determine this. If your transmitter does

need a boost when operating at the lower end of 3S, a JST equipped boost regulator can easily be connected

into the Vector's video harness (between connections “A” and “E” in the video harness drawing below).

3.4 Current Sensor Maximum Continuous Current, and Load Testing

The current sensor’s continuous current capability depends on the type of connectors/wires you are using, and

other factors.

If your model draws a large amount of current (greater than approximately 60 amps continuous) make sure

you verify that your power system, including the current sensor, can handle your worst case continuous

current load.

In high current applications it is recommended (if you can do so safely) that you run your model in an extended

stationary “bench” test, similar in duration and power usage to your most aggressive modeling, to ensure there

are no problems with any connections, wiring doesn’t get too hot, etc. DO NOT OPERATE YOUR MODEL IF

YOU HAVE PROBLEMS DURING THIS EXTENDED STATIONARY TEST!

It is also recommended that the current sensor be mounted so that airflow is directed through one of the

openings of the sensor.

Never exceed the manufacturer’s continuous current rating for the types of connectors installed on your

current sensor! If the current sensor or wiring becomes too hot during flight due to too much current,

the connectors can fail, or the PSU can shut off, causing a crash!

Make sure that the connector contacts on your current sensor and mating connectors are not damaged or

weakened. A damaged or weakened contact can potentially fold over and short when connected, or cause

intermittent in-flight failures!

15

Page 16

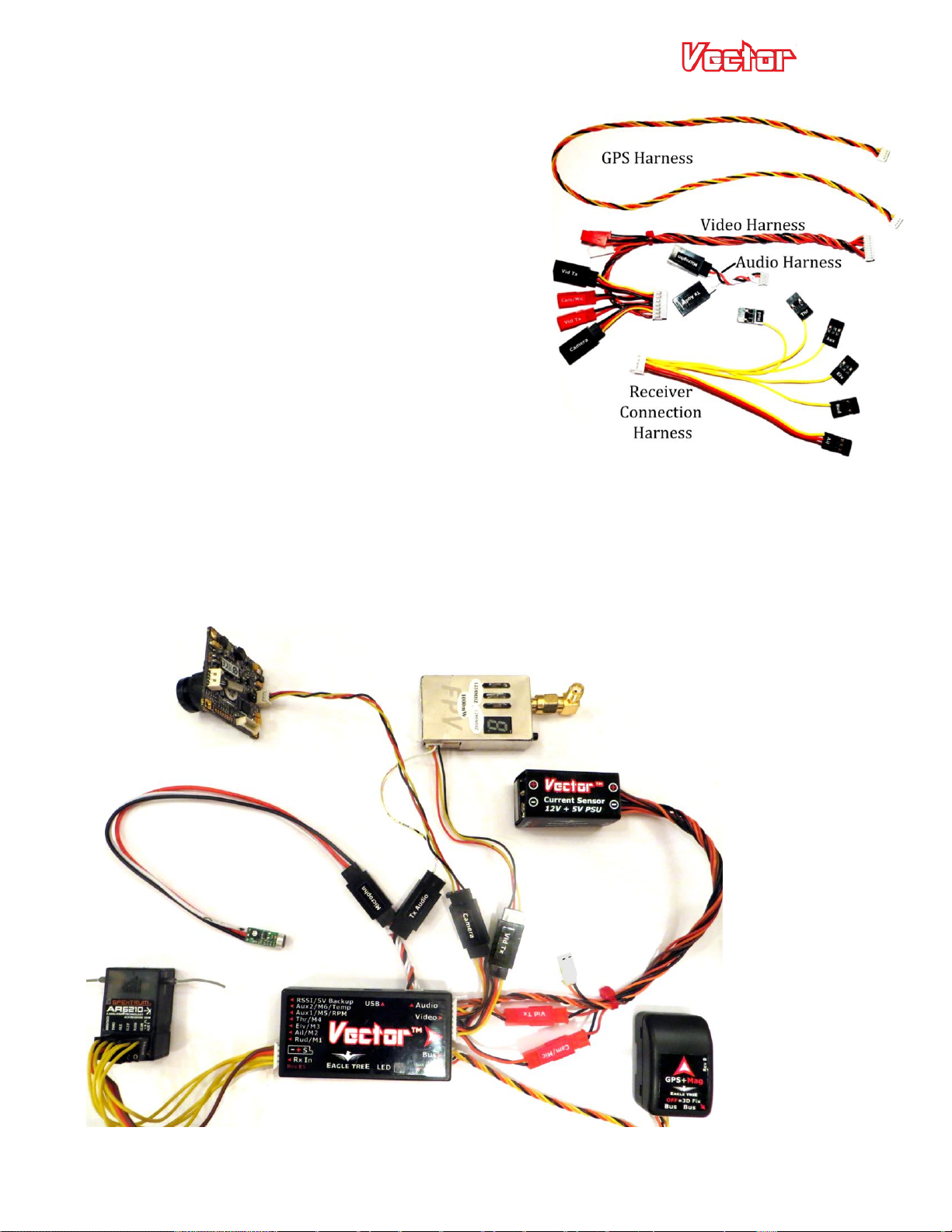

3.5 Vector Wiring

The Vector’s wire harnesses are shown below. Note that

a set of replacement wire harnesses is available (p/n VECCAB-SET). Having additional sets make it easier to move

your Vector from model to model.

Video Harness – routes video signals, and provides

power from the Current Sensor/PSU to the Vector, and

optionally to your video transmitter, camera, and

microphone.

Audio Harness – this cable connects to your microphone,

and also to the audio output of your video transmitter.

Receiver Connection Harness – this cable connects

between the Vector and your RC receiver/LRS.

GPS Harness – this cable connects between the Vector and the GPS/Mag.

USER GUIDE

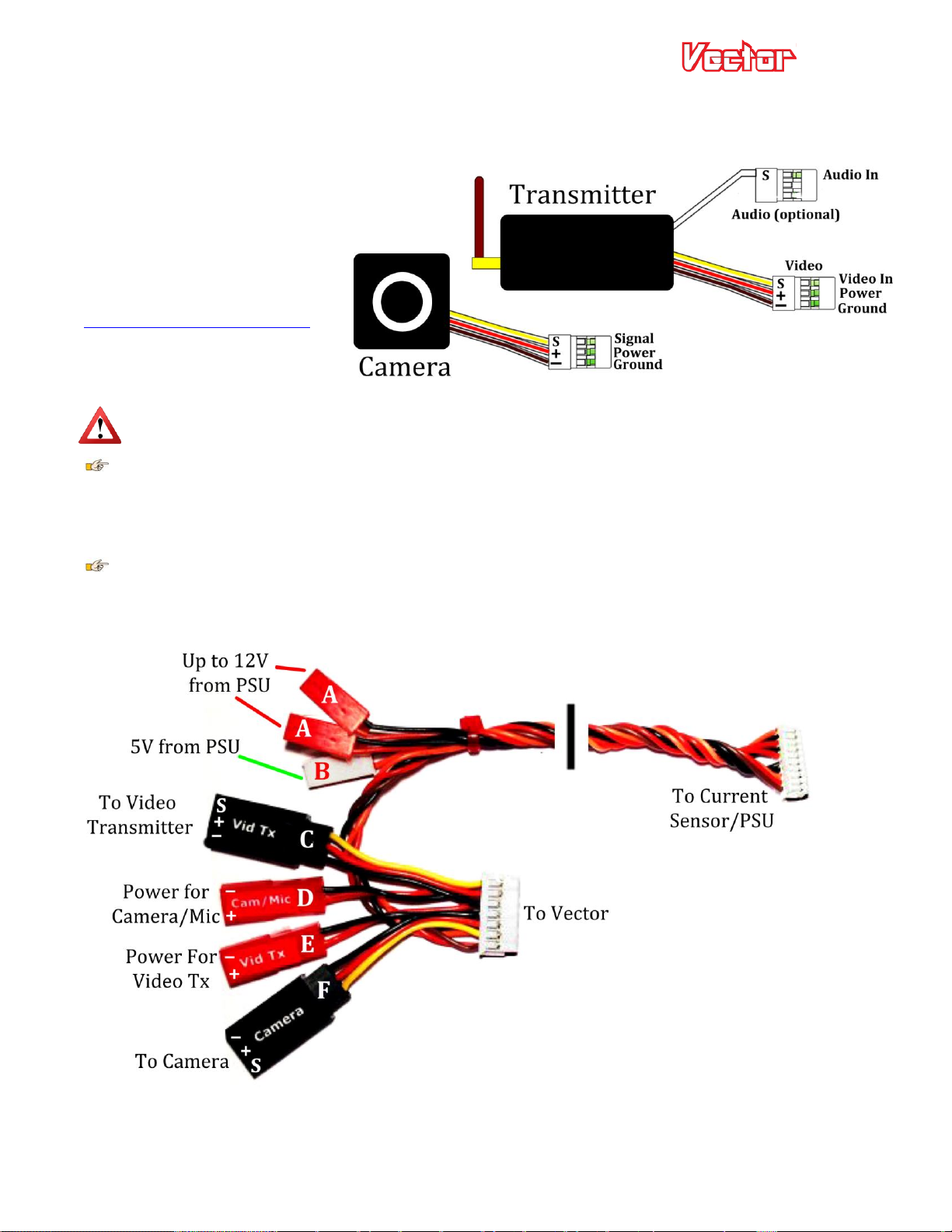

3.5.1 Vector Video Harness + Connecting your Video Camera and Transmitter

The Vector's innovative video harness makes it easy to connect your 5V or 12V cameras and transmitters

without keeping an electrician on standby. The figure below shows a typical hookup, with a 12V camera, 12V

transmitter, and a microphone.

16

Page 17

USER GUIDE

The first step to wiring your camera and transmitter is to install servo connectors on the wire harnesses that

came with these components, if they don’t have them already. Servo connectors and crimpers are available

online or at your local hobby store. Either Futaba™ or JR™ style connectors will work.

Refer to the figure at right.

Consult the manuals for your

camera and video transmitter,

identify the signal, power and

ground wires, and install the servo

connectors on these wires.

Alternatively, FPV shops like

http://www.readymaderc.com

supply Vector compatible servo

adapter cables for most cameras

and video transmitters.

Make sure the polarity of the servo connector is correct, so that the “S, + and –” pins of the connector

align correctly the “S, + and –” pins of the mating female connector on the video harness!

If you are using a camera with a built-in battery, such as a GoPro™, the power servo lead does not need

to be connected.

Referring to the video harness diagram below, connect the camera’s servo connector to camera connector “F”,

and the video transmitter’s servo connector to transmitter connector “C” on the video harness.

Inside the Vector, the red wire of the camera power connector “D” is internally connected to the red

wire of the camera connector “F”, and the red wire of transmitter power connector “E” is internally connected

to the red wire of transmitter connector “C”. Also, all ground (black) wires are internally connected in the

Vector.

3.5.2 Providing power to your Video Transmitter and Camera

Powering your video equipment is typically very easy with the Vector.

17

Page 18

USER GUIDE

Video Setup

Wiring Method

Single Battery, 12V

camera, 12V transmitter

Connect both red PSU power taps “A” to camera and transmitter power inputs “D”

and “E”

Single Battery, 5V

camera, 12V transmitter

Connect the white PSU power tap “B” to camera power input “D”. Connect a red

PSU power tap “A” to transmitter power input “E”.

Single Battery, 12V

camera, 5V transmitter

Connect the white PSU power tap “B” to transmitter power input “E”. Connect a

red PSU power tap “A” to camera power input “D”.

Single Battery, 5V

camera, 5V transmitter

Construct or purchase a JST Y cable. Connect the female end of the Y cable to the

white PSU power tap “B”, and connect the two male ends of the Y cable to

transmitter power input “E” and camera power input “D”.

Separate Video

battery(s)

Connect video battery(s) of appropriate voltage(s) to camera power input “D”

and/or transmitter power input “E”. Note that if you want to use one video

battery for both camera and transmitter, a JST Y cable will be needed.

Here are typical wiring strategies, depending on the number of batteries desired, transmitter and camera

voltages, etc.

Make sure that you do not make a mistake in the wiring that causes 12V power to be used with a 5V

camera or transmitter! This will likely destroy the camera or transmitter.

Remember that if you use a 3s or lower pack, the 12V power taps will provide a voltage that is about

0.5V less than the present pack voltage. If your video transmitter reduces output power with voltages less

than 12V, and you need maximum range, you will need to insert a “boost” or “SEPIC” regulator between the

power tap “A” and the transmitter power input “E”, or use a separate video battery.

Never exceed the 1 amp current limit for either the 5V tap or the 12V taps. The affected voltage

regulator may shut off if this is exceeded, which can cause the Vector to turn off during flight if the 5V

regulator is affected, as well as shutting off the affected video equipment! Never use the taps for powering

equipment other than your video equipment!

Normally, only extremely high power video transmitters would exceed 1 amp, but check your video equipment

manual.

It is ok if you draw up to 1 amp from the 5V regulator and up to 1 amp from the 12V regulator

simultaneously.

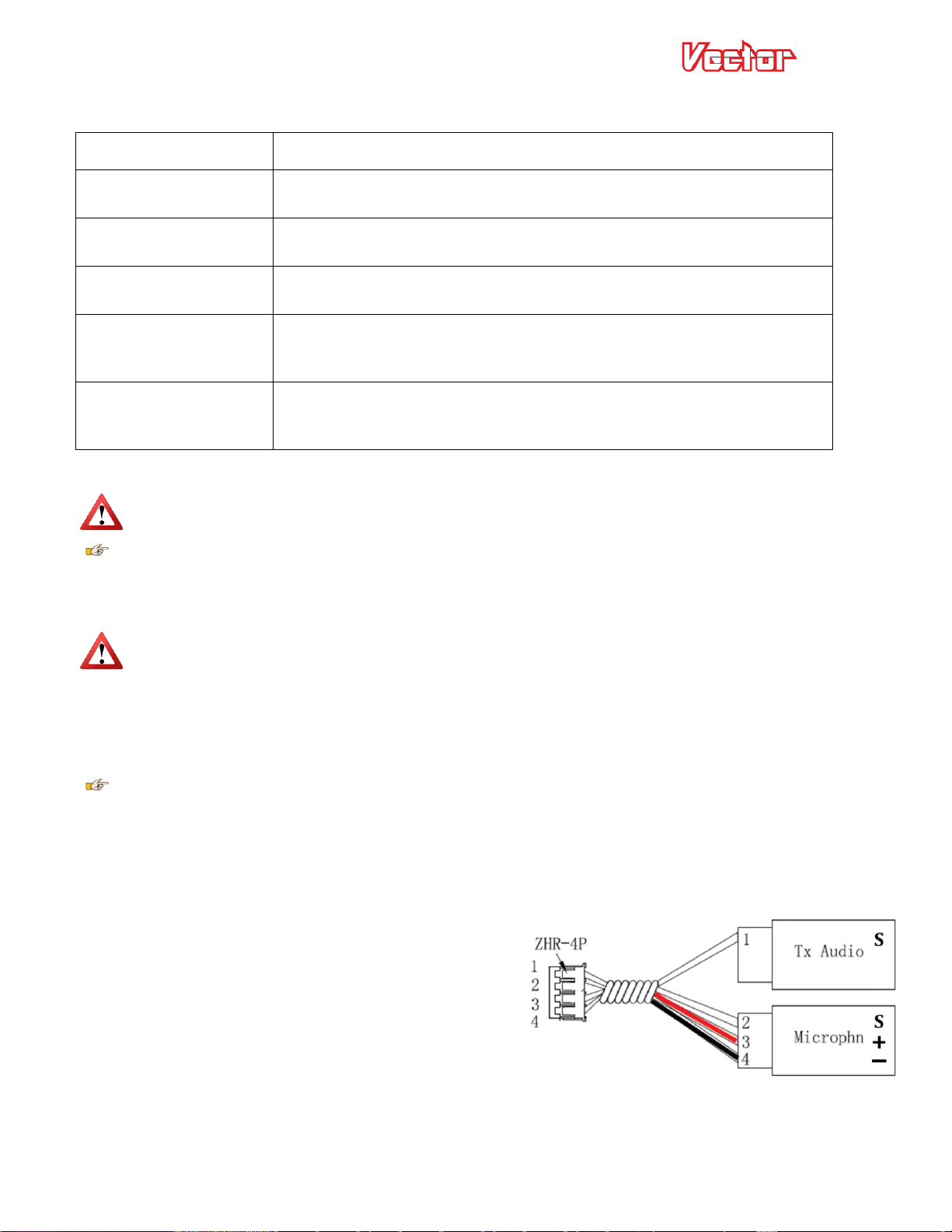

3.5.3 Vector Audio Harness and Audio Connections

If you do not want to hear Vector voice alerts or the acoustic variometer, it is not necessary to use the audio

harness, so this step can be skipped.

Refer to the figure:

To hear voice alerts or the acoustic variometer from the

Vector, connect the audio harness to the Vector’s Audio

connector, and connect your video transmitter’s audio

in servo connector (described above) to the “Tx Audio”

connector on the audio harness.

To use an external microphone in this configuration, connect the microphone to the audio harness “Microphn”

connector, paying attention to the correct pinout.

18

Page 19

USER GUIDE

Note that the voltage supplied to the red wire of the “Camera/Mic” power input connector “D” on the

video harness will be supplied to the red wire on the “Microphn” audio harness connector.

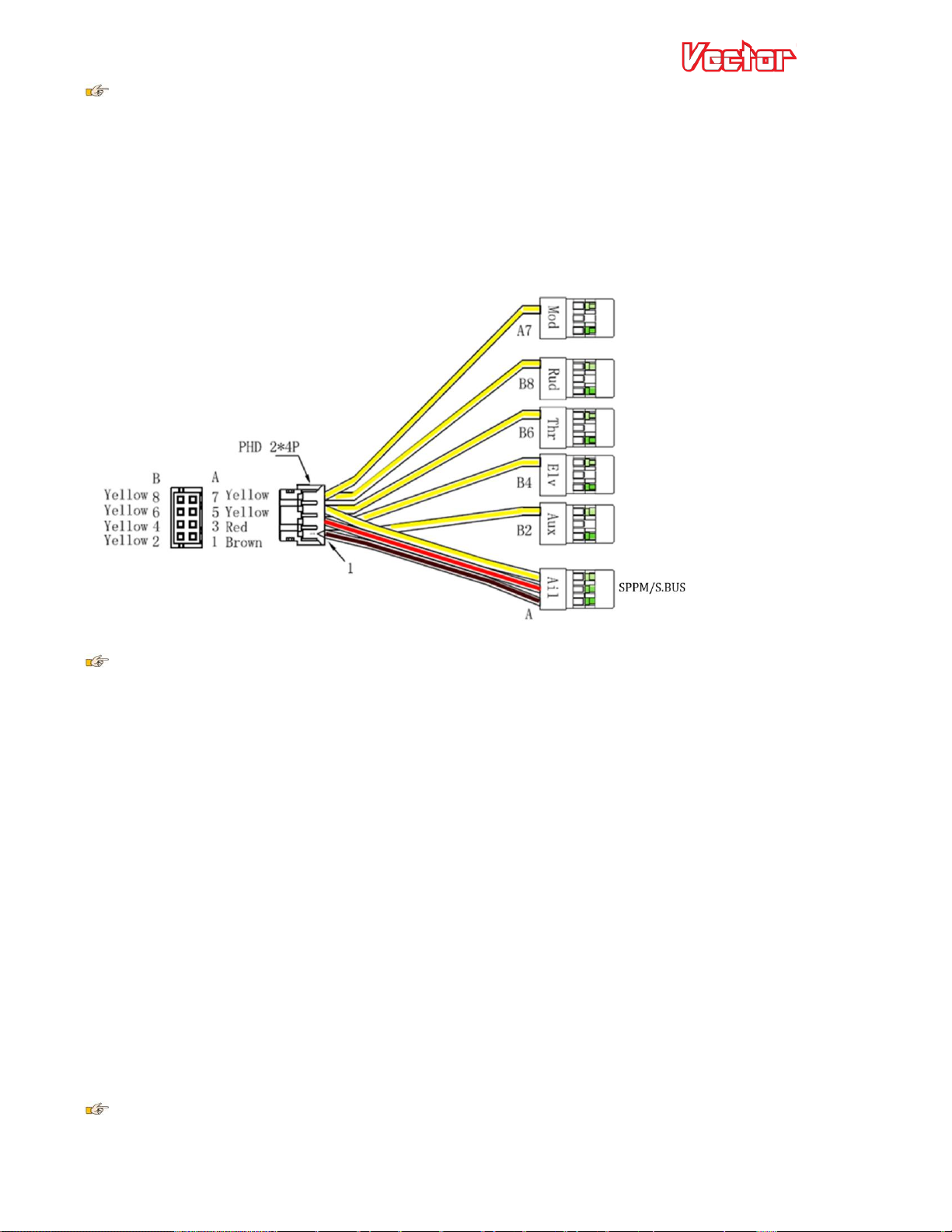

3.5.4 Vector Receiver Harness

The Receiver Harness is used to connect the Vector to the outputs of your receiver. The pin-out for the

Receiver Harness is shown below.

Do not power your receiver with a voltage higher than 16V.

The Vector does not power your receiver or servos. You will need to power your receiver and servos

as you would in a non-Vector model, such as with a stand-alone BEC, a BEC built into your ESC, or a separate

battery pack.

Whatever power is provided to your receiver will be routed through the Vector to your servos. Whatever

power is provided by an ESC’s BEC will be routed through the Vector to your receiver and servos.

You can alternatively use the 5 volt tap from the PSU (if not being used to power a 5 volt camera or video TX) to

power your receiver on multirotors. Please see section 3.5.6, “Powering your Receiver on Multirotors" for

additional info.

Three types of receiver inputs are supported with the Vector:

Traditional (parallel): each of the relevant harness connections needs to be connected to the appropriate

output port on the receiver. See section 3.5.7 below for information on connecting the receiver harness inputs

to your receiver.

Serial PPM (SPPM) and S.BUS™ (serial modes): only the “Ail” connector of the receiver harness should be

connected to the SPPM or S.BUS™ output of your receiver. Your receiver’s outputs are programmed in the

Vector, as described later.

Note: Connect only the “Ail” wire to your receiver when using a serial mode. Never connect other wires from

the receiver harness to your receiver if you are using a serial mode!

To reduce wiring, if you use a serial mode you can use a needle or small probe to carefully pry up the

tabs of the other connections of the receiver harness, remove the unused wires, and save them for later use. Or,

just trim off the extra wires.

19

Page 20

USER GUIDE

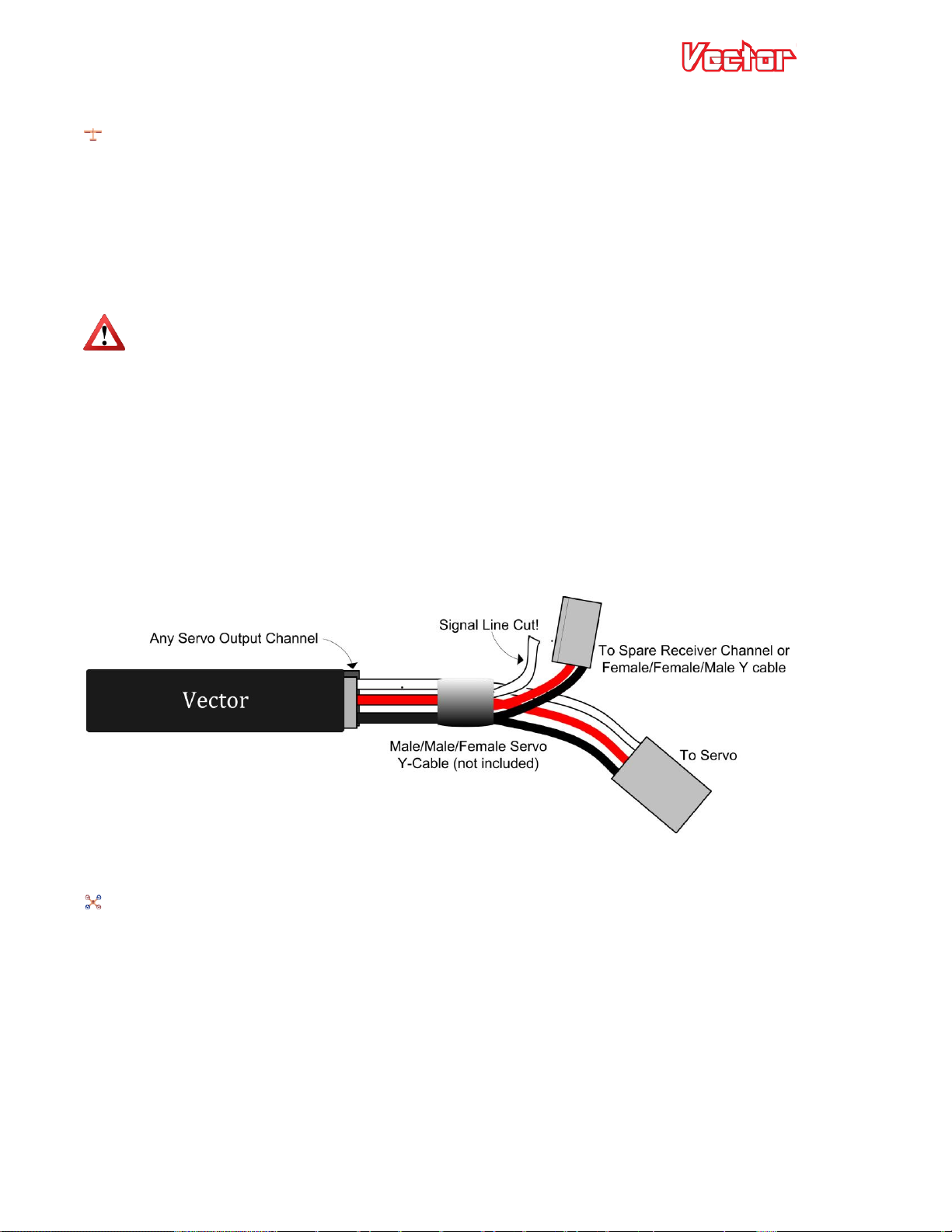

3.5.5 Receiver Connection Harness Load Capacity (Fixed Wing Only)

With typical fixed wing electric model wiring, the ESC’s BEC is connected to the Vector’s throttle output

channel. This BEC powers the servos, and all servos are connected to the Vector’s servo outputs. If you

have this configuration, please skip this section.

Also, skip this section if you do not have large servos, or if the BEC or battery powering your servos is rated at 6

amps continuous or less (the vast majority are).

If, however, the AIL lead of the Vector’s receiver connection harness takes power from your receiver, and this

powers large servos you have connected to the Vector, OR, you have large servos connected to both your

receiver and the Vector, please read the following:

You should not allow more than 6 amps continuous current to flow through the AIL wire.

Note also that the AIL lead of the harness should not be excessively warm after flying, which could indicate that

too much current is passing through it.

If your configuration could result in more than 6 amps continuous current flowing through the AIL wire, there

are two ways to supply additional power to your servos:

If you are not using all the servo output connections on your Vector, a male to male servo wire (with

the signal line cut!) can be connected between a free servo channel on the Vector, and a free channel on

your receiver.

If all the servo connections on the Vector are being used, a male/male/female Y cable (ET p/n CAB-Y-1

or similar) with the signal line cut can be used to provide additional power to the servos, as shown in

Figure 3.

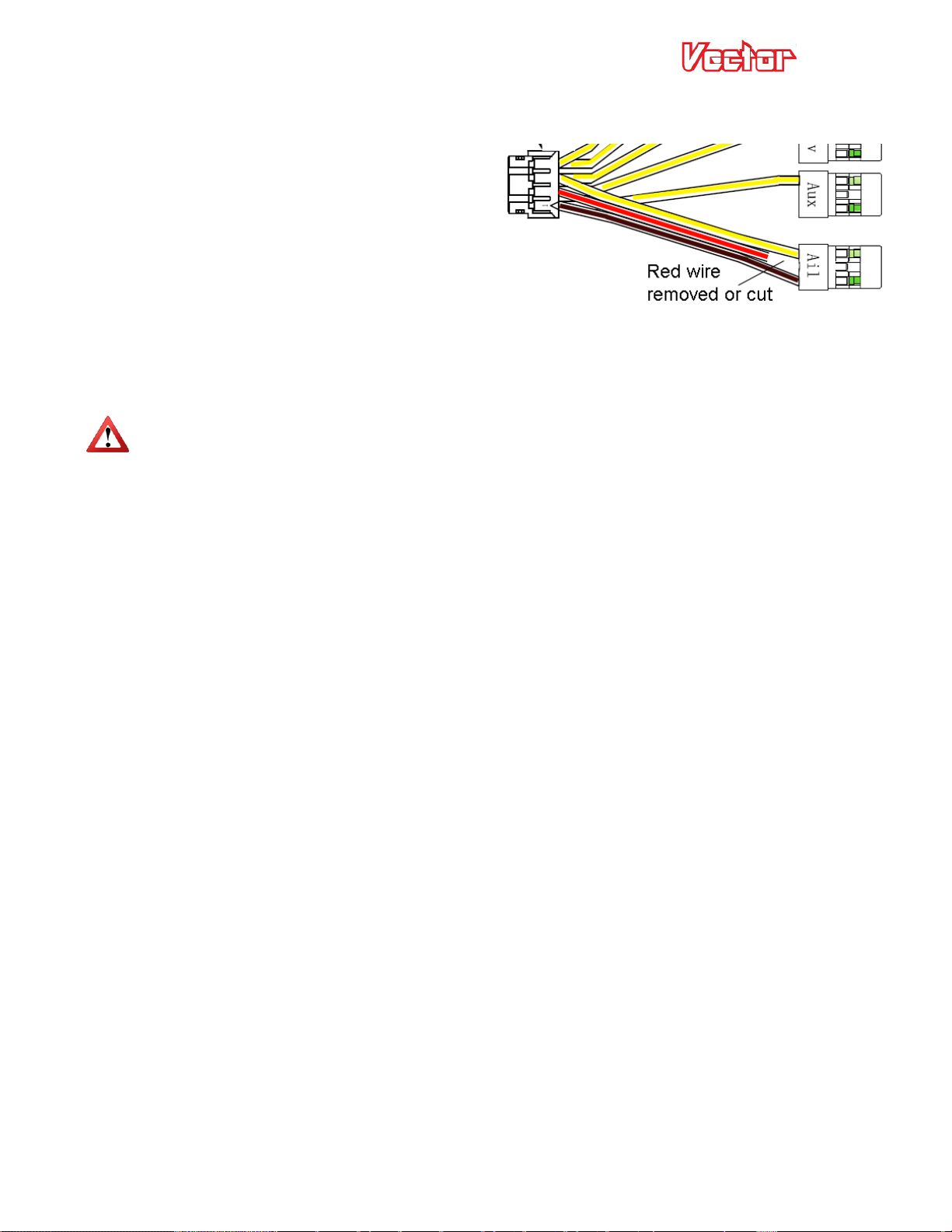

3.5.6 Powering your Receiver on Multirotors

Voltage from the 5V tap “B” can normally be used to power your receiver on multirotors, eliminating

the need to have an additional BEC. One way to do this, assuming the 5V tap is not being used for your camera

or transmitter, is to connect a female JST to male servo adapter cable from the 5V tap to a spare receiver

channel. If the 5V tap is already being used, you will need a Y cable to do this.

However, remember that power will go from your receiver to the Vector’s servo outputs, via the red wire of the

“Ail” connector on the Vector receiver harness. If your ESCs are not optoisolated from their receiver inputs,

this voltage will power the ESCs even if the ESC main power connector is not plugged into the Current

Sensor/PSU. If your ESCs produce startup tones when the receiver is powered from the Vector, but the ESC

main power connector is not plugged into the Current Sensor/PSU, the ESCs are not optoisolated.

20

Page 21

USER GUIDE

In this case, it’s important that you make sure you never arm your multirotor when the main ESC power

connector is disconnected from the Current Sensor/PSU. Or, you can address this issue in some other ways:

a) remove/disconnect the red wire from the “Ail”

connector, so that power will not pass from

your receiver to the ESCs when using the 5V

tap to power your receiver.

b) Or, remove/disconnect the power servo wire

from each ESC. This may be required anyway,

as some non-optoisolated ESCs could be

damaged if the red wires are connected

together.

c) Or, be sure to never connect your main pack to the current sensor without having the ESC main power

connector also plugged into the current sensor.

If one of these steps is not followed, your ESCs will receive power even when the ESC main power

connector is not plugged into the current sensor. This can cause at least two potential problems if you

arm the multirotor in this condition:

The propellers can spin even though the main pack is not connected to the ESCs!

With some ESCs, a brownout can occur in this condition that has been known to cause these ESCs to

reprogram their endpoints. This can lead to unpredictable results such as propellers spinning at

different speeds after arming, possibly creating an unsafe condition!

21

Page 22

USER GUIDE

3.5.7 Connecting Receiver and Servos/ESCs to the Vector

First, connect your ESC or servo wires to the Vector output ports without powering the Vector, to make sure

they reach the desired Vector mounting location. Then disconnect them before proceeding to the configuration

section.

Never connect ESCs or servos to the Vector servo outputs until you have verified the Vector airframe

type is correctly selected! If a fixed wing airframe type is selected with a multirotor, the propellers can

spin uncontrollably at high speed at power-up! Likewise, if a multrotor airframe type is selected with fixed

wing, the servos can be pushed beyond their endpoints and be destroyed!

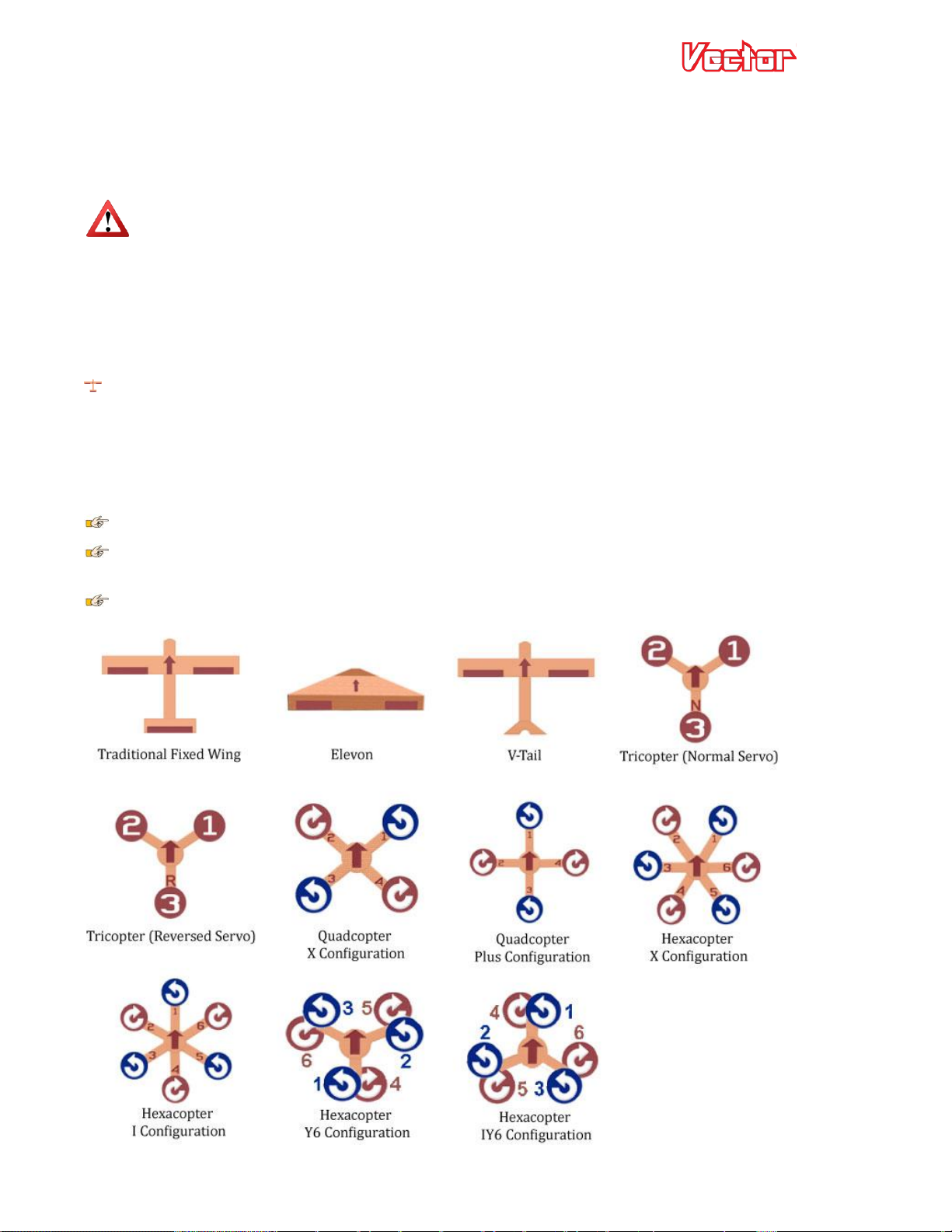

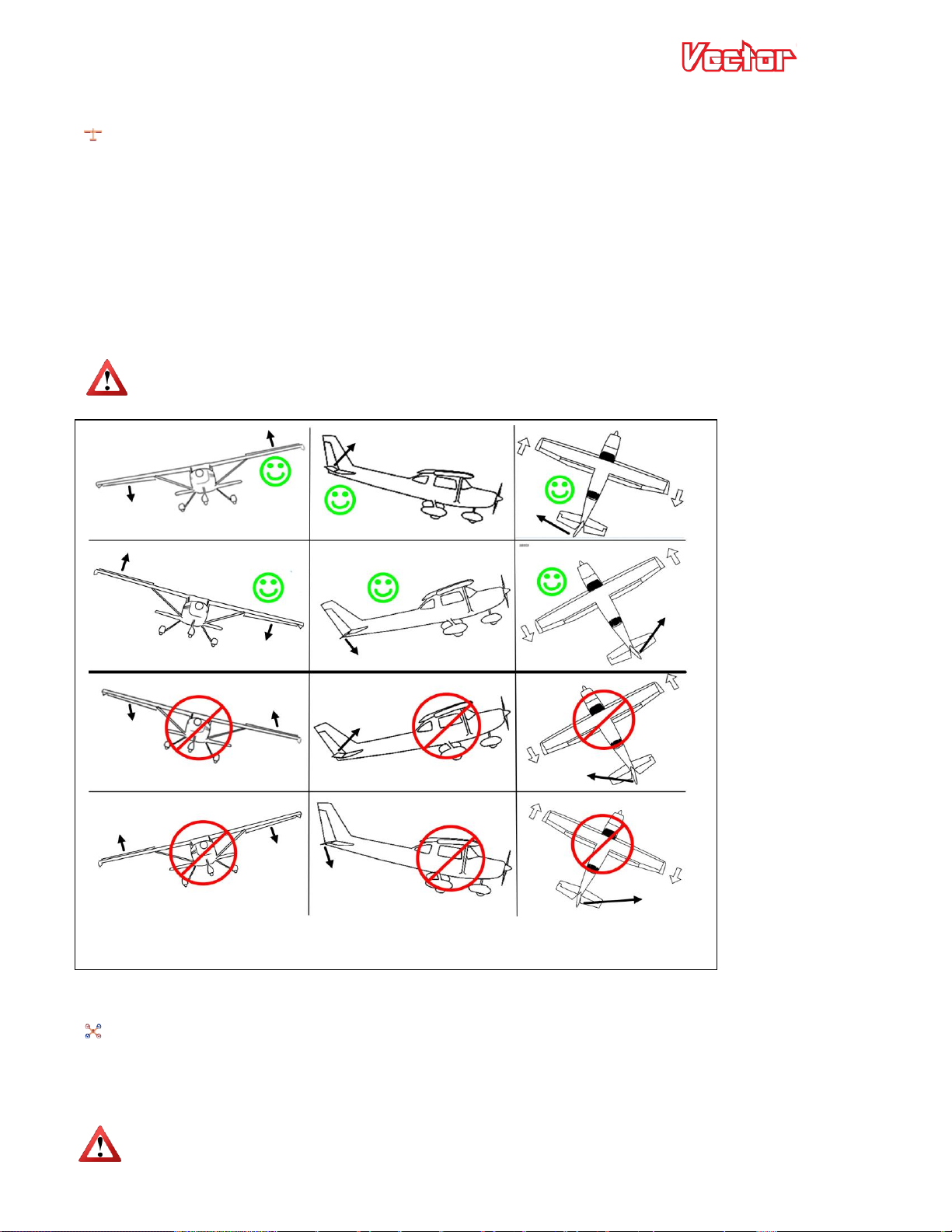

The figure below shows the supported airframe types. For each airframe, the arrow indicates the direction of

forward travel, which corresponds to the forward direction of the arrow on the Vector label when the Vector is

mounted correctly.

If you have dedicated flaps, they do not connect to the Vector. Connect the flaps directly to your receiver

channel that is controlled by the desired flap switch.

For the multirotor airframe types, the numbers in the figure correspond to the motor numbers on the Vector

servo connector label (1 = M1, etc.). For quadcopters and hexacopters the curved arrows indicate the correct

motor rotation.

For tricopters, the motor rotation directions are arbitrary. Also, the yaw servo MUST be digital!

Tricopter rudder control of the yaw servo is initially disabled when the throttle is at its off position. In

order to test yaw, you will need to increase the throttle stick slightly with the system disarmed.

For Hexacopter Y6 and IY6, the blue motors in the figures below are ON TOP.

22

Page 23

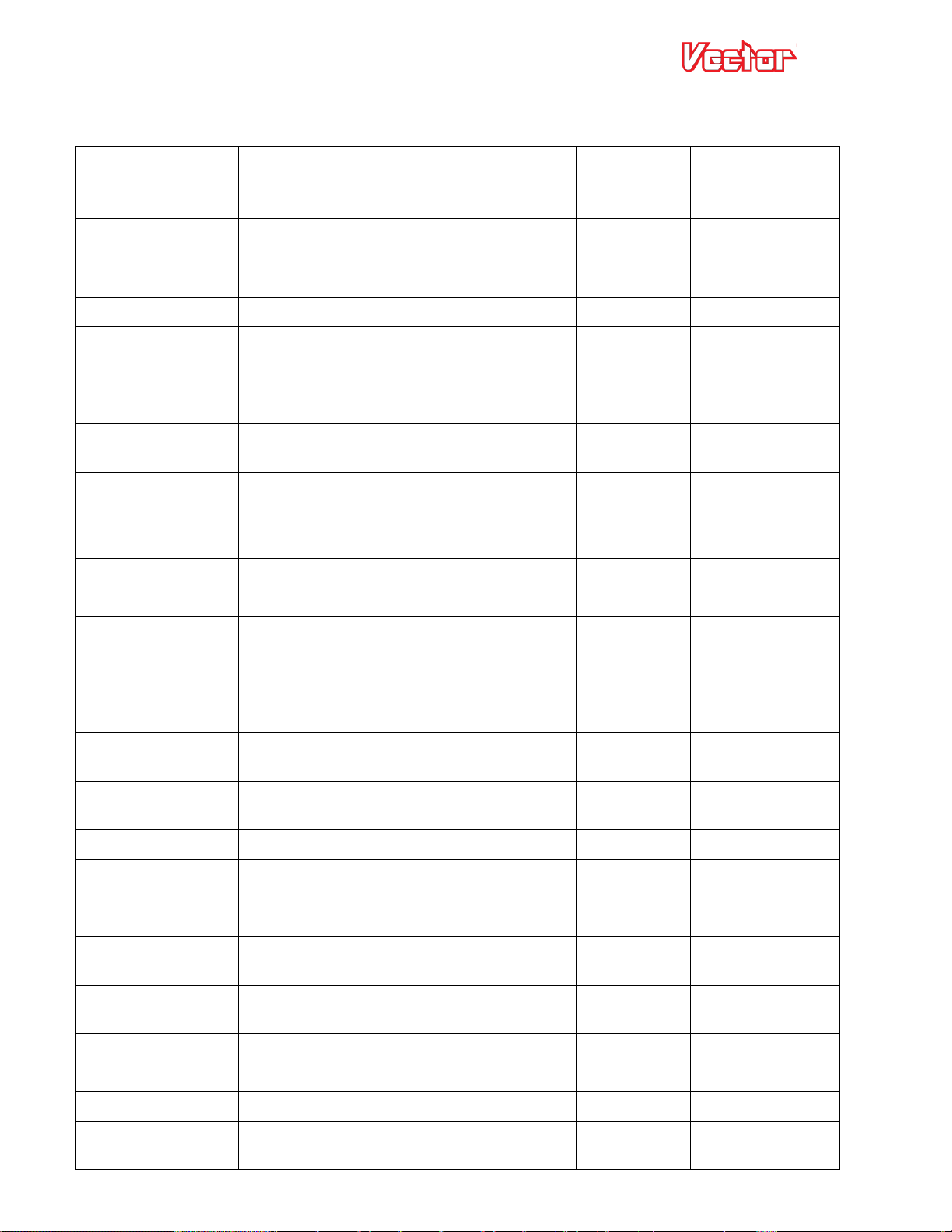

The chart below shows typical receiver and servo/ESC connections for these airframe types.

Airframe

Vector

Airframe Type

Receiver Output*

Vector Rx

Harness*

Vector Output

Servo/ESC

Connection at

Model

Traditional Fixed

Traditional

Fixed

Rudder

Rud

Rudder/M1

Rudder Servo

Aileron

Ail

Aileron/M2

Aileron Servo

Elevator

Elv

Elevator/M3

Elevator Servo

Throttle

Thr

Throttle/M4

Motor ESC or Throt

Servo

2/3 position

Mode Switch

Mod

N/A

N/A

Gain Knob or

Submode switch

Aux

N/A

N/A

Fixed Wing with 2nd

Aileron, Flaperon,

Elevator, or Rudder

(with Tx Mixing)

Traditional

Fixed

Rudder

Rud Rudder/M1

Rudder Servo

Aileron

Ail

Aileron/M2

Aileron Servo

Elevator

Elv

Elevator/M3

Elevator Servo

Throttle

Thr

Throttle/M4

Motor ESC or Throt

Servo

2nd Aileron,

Elevator, Rudder

or Flaperon

Aux

Aux1/M5 (or

N/A)

2nd Aileron,

Elevator, Rudder or

Flaperon

2/3 position

Mode Switch

Mod

N/A

N/A

Elevon or V-Tail

without Ailerons

Elevon

Rudder (if used)

Rud

Rudder/M1

Rudder Servo

Aileron

Ail

Aileron/M2

Elevon Servo 1

Elevator

Elv

Elevator/M3

Elevon Servo 2

Throttle

Thr

Throttle/M4

ESC or Throttle

Servo

2/3 position

Mode Switch

Mod

N/A

N/A

Gain Knob or

Submode switch

Aux

N/A

N/A

V-Tail with Ailerons

V-Tail

Rudder

Rud

Rudder/M1

V-Tail Servo 2

Aileron

Ail

Aileron/M2

Aileron Servo

Elevator

Elv

Elevator/M3

V-Tail Servo 1

Throttle

Thr

Throttle/M4

Motor ESC or Throt

Servo

* The Receiver Output and Vector Rx Harness sections do not apply to SPPM or S.BUS™ receiver modes.

USER GUIDE

23

Page 24

USER GUIDE

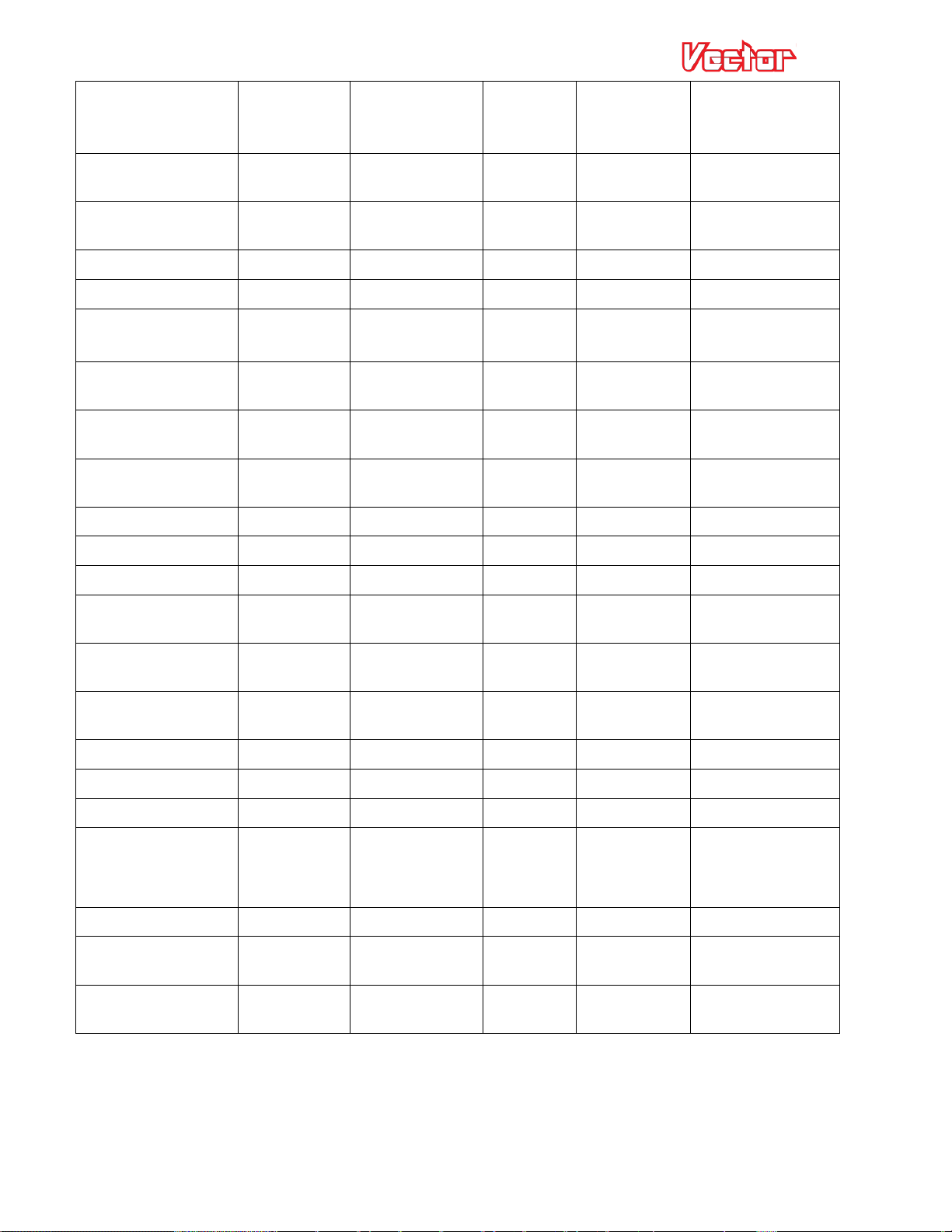

Airframe

Vector

Airframe Type

Receiver Output*

Vector Rx

Harness*

Vector Output

Servo/ESC

Connection at

Model

V-Tail with Ailerons

(cont.)

Gain Knob or

Submode switch

Aux

N/A

N/A

Tricopter

Tricopter

Norm or Rev

Rudder/yaw

Rud

Rudder/M1

Motor 1 ESC

Aileron/roll

Ail

Aileron/M2

Motor 2 ESC

Elevator/pitch

Elv

Elevator/M3

Motor 3 ESC

Throttle

Thr

Throttle/M4

Yaw Servo

(MUST be digital!)

2/3 position

Switch

Mod

N/A

N/A

Gain Knob, Kill or

Submode Switch

Aux

N/A

N/A

Quadcopter

Quadcopter

X or Plus

Rudder/yaw

Rud

Rudder/M1

Motor 1 ESC

Aileron/roll

Ail

Aileron/M2

Motor 2 ESC

Elevator/pitch

Elv

Elevator/M3

Motor 3 ESC

Throttle

Thr

Throttle/M4

Motor 4 ESC

2/3 position

Switch

Mod

N/A

N/A

Gain Knob, Kill or

Submode Switch

Aux

N/A

N/A

Hexacopter

Hexacopter

X or I

Rudder/yaw

Rud

Rudder/M1

Motor 1 ESC

Aileron/roll

Ail

Aileron/M2

Motor 2 ESC

Elevator/pitch

Elv

Elevator/M3

Motor 3 ESC

Throttle

Thr

Throttle/M4

Motor 4 ESC

Aux1/M5

Motor 5 ESC

Aux2/M6

Motor 6 ESC

2/3 position

Switch

Mod

N/A

N/A

Gain Knob, Kill or

Submode Switch

Aux

N/A

N/A

24

Page 25

USER GUIDE

3.5.8 Connecting you Receiver’s RSSI Output (if available)

Note: If you have a PPM capable receiver that outputs RSSI and/or link quality in the PPM stream, instead of

through a separate wire, skip to the next section.

If you wish to display the receiver’s signal strength (RSSI), and your receiver supports this feature, you will

need to connect the top (signal) pin of the “RSSI/5V Backup” connection of the Vector to your receiver’s RSSI

output. The Vector’s RSSI input is fully buffered with a high impedance op amp.

In general, only “LRS” and Spektrum™ receivers support RSSI externally. However, some clever people

have posted ways of retrieving the RSSI output from traditional receivers on the RC forums.

Make sure you range test your receiver after connecting the RSSI output to the Vector. Some early LRS

receivers could lose range when the RSSI output was utilized.

The Vector supports 3 types of RSSI via this connection, depending on your receiver type:

1. Analog RSSI output - this is the most common RSSI output

2. Pulse Width Modulated (PWM) output – EZUHF™ and perhaps other receivers use this method.

3. Spektrum Flightlog™ - The signal pin of the “data” port of your Spektrum™ receiver normally provides

Flightlog™ data, which the Vector can display.

Never connect a voltage higher than 3.3V to the RSSI input pin! No known receiver outputs an RSSI

greater than 3.3V.

For types 1 and 2 above, the minimum and maximum RSSI output of your receiver is learned during the

Receiver Analysis Wizard.

If you use an S.BUS™ receiver without an analog RSSI output, a very simple RSSI is provided

automatically. The OSD RSSI readout drops to 25% if the receiver indicates packet loss, and goes to 0% if the

recevier indicates failsafe.

3.5.9 Configuring SPPM Based RSSI and Link Quality

If you have an SPPM capable receiver that outputs RSSI and/or link quality in the SPPM stream, and you wish

to view RSSI information, the RSSI setup steps are as follows:

1) Make sure your receiver is configured for SPPM, and connected to the Vector as described elsewhere in this

manual.

2) Start the software, and run the Receiver Analysis wizard, which should configure the SPPM input to the

Vector.

3) Navigate to the RC Configuration tab, and in the Serial PPM/S-BUS section, select the PPM channel(s) used

for RSSI, and/or Link Quality. You’ll need to consult with your receiver manual to determine these

channels. Note that presumably these channels should change greatly when the transmitter is turned on

and off.

4) After you have selected the channel(s) to use, rerun the Receiver Analysis Wizard (you can skip the SPPM

setup part of the wizard) so that the Vector can learn the minimum and maximum RSSI and link quality

outputs.

25

Page 26

USER GUIDE

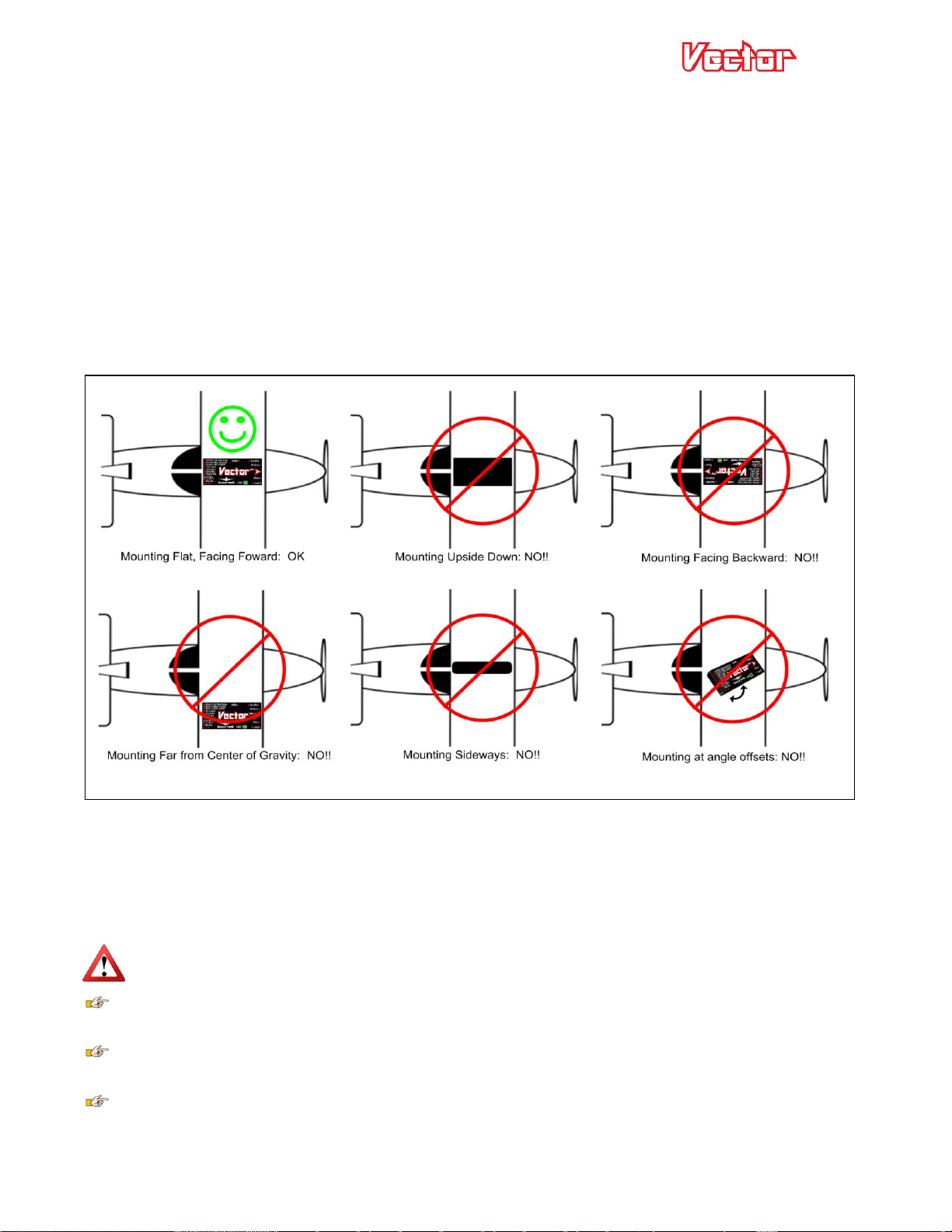

GOOD AND BAD WAYS TO MOUNT THE VECTOR

4 Mounting the Vector and Accessories

4.1 Mounting the Vector

4.1.1 Mounting Location and Orientation

Mount the Vector flat and level with the label facing toward the sky and the red arrow on the Vector case facing

toward the nose of your model (the direction of forward travel).

The Vector should be mounted as near to the model’s Center of Gravity (CG) as practical. Ideally, the Vector

will be mounted with the mark shown in section 3.1 (just behind the red arrow) directly above your model’s

CG. However, precise centering may not be critical.

4.1.2 Mounting Technique

The Vector should be firmly and securely mounted to your model, so it won’t come loose or vibrate. The best

way to mount it is to use double sided, closed cell (solid, gum like) foam tape. A great choice is Scotch/3M

indoor-outdoor tape, model 411-DC, but there are many good options.

If the Vector is not mounted correctly, or if it comes loose during flight, your model may become

uncontrollable and crash!

It is recommended to do a “test fit” of all your model’s wiring and components before permanently

mounting the Vector.

When removing the Vector from mounting tape, twist the Vector rather than trying to pull the Vector

up. It’s easier that way .

Try to mount the Vector and other components so that the USB connection is easily accessible. If this

is not possible, USB extender cables are available at many FPV shops.

26

Page 27

USER GUIDE

4.2 Mounting the GPS/MAG Sensor

4.2.1 GPS Signal Interference

RF noise from video transmitters, cameras, and other devices can interfere with GPS reception. It’s important

to mount the GPS/MAG as far away from these sources as practical.

Also, obstructions such as trees or buildings that block the Vector from having a clear, unobstructed view of the

sky can cause issues with GPS reception.

If the GPS loses signal during GPS flight modes, such as RTH or loiter, the Vector will exit these flight

modes.

GPS satellites are constantly moving around in the sky, and GPS signals are affected by changes in

weather, so GPS fix quality can vary greatly over time, even at the same location.

4.2.2 Magnetometer Interference

Power lines generate electromagnetic fields when current flows through them. These magnetic fields will

interfere with the compass function of the GPS if insufficient separation is observed. Unless you don’t plan to

use the compass (it’s required for multirotor GPS modes and optional for fixed wing GPS modes) you must

mount the GPS/MAG at least 8cm (3.5”) away in all directions from any high current carrying wires, such as

your battery wires, ESC wires, or motor wires. Additionally, magnets (such as motor magnets or canopy

magnets) can interfere with the compass, and the GPS/MAG should be mounted as far away from them as is

feasible.

If the compass is enabled, and there is electromagnetic interference, GPS flight modes such as RTH and

loiter will not work correctly, and the model may fly erratically when in these modes! Multirotor

models could “toilet bowl” and the model may fly the wrong direction in RTH!

4.2.3 GPS/MAG Mounting Orientation

The GPS must be mounted so that the top of the GPS (the label) normally faces

toward the sky.

If you are going to use the compass, the GPS/MAG must be mounted flat and level,

and facing forward. The GPS/MAG cannot be tilted or rotated relative to the

Vector. The arrow on the GPS/MAG must be pointing in the same direction as the

Vector arrow.

If the compass is enabled, and the GPS/MAG is not mounted in the correct orientation or detaches from

its mounting during flight, flight modes such as RTH and loiter will not work correctly, and the model

may fly away at high speed when in these modes! Multirotor models could “toilet bowl” and the model may

fly the wrong direction at high speed during RTH!

The GPS/MAG must be flat relative to the Vector. Mounting errors of even a few degrees in the pitch or

roll axes can introduce noticeable error in the compass heading, leading to toilet bowl behavior in multirotors

or inaccurate navigation in planes.

The Vector automatically computes the magnetic declination (compass error) at your location, so it is

normally not necessary to rotate the GPS/MAG to correct for compass error.

The GPS/MAG has an LED, which can be viewed from the back of the unit (see the arrow on the label).

When the LED is OFF (not blinking) the GPS/MAG has attained a 3D GPS Fix.

27

Page 28

USER GUIDE

4.2.4 The GPS Stand and Clip

The GPS Stand is designed for multirotors, where it lifts the GPS/MAG sufficiently above the

multirotor frame to avoid electromagnetic interference. However, it can be used for any

type of model. The stand must be mounted vertically, and the base can be mounted either

by placing it under 2 or more of the multirotor’s arm mounting bolts, or with closed cell,

double sided foam tape.

The stand also has a slot that can be used to neatly route the GPS cable.

Make sure that the screw that holds the mounting clip to the stand is tightened sufficiently

to keep the GPS from rotating easily, but don’t tighten it so tightly that the threads are stripped.

If the stand comes loose or rotates during flight and the compass is enabled, GPS flight modes such as

RTH and loiter will not work correctly, and the model may fly away at high speed when in these modes!

Consider using a small amount of glue or double sided foam tape on the top of the GPS stalk where it

meets the clip, to permanently set the direction the GPS/MAG is facing.

4.3 Mounting the Current Sensor/PSU

The Current Sensor/PSU can be mounted with double sided foam tape, or with other methods. Before

mounting the Current Sensor/PSU, make sure that your ESC/Motor connector, battery connector and video

harness will reach.

It is recommended that the Current Sensor/PSU be mounted so that cooling air can flow into the one of the

openings of the current sensor during flight.

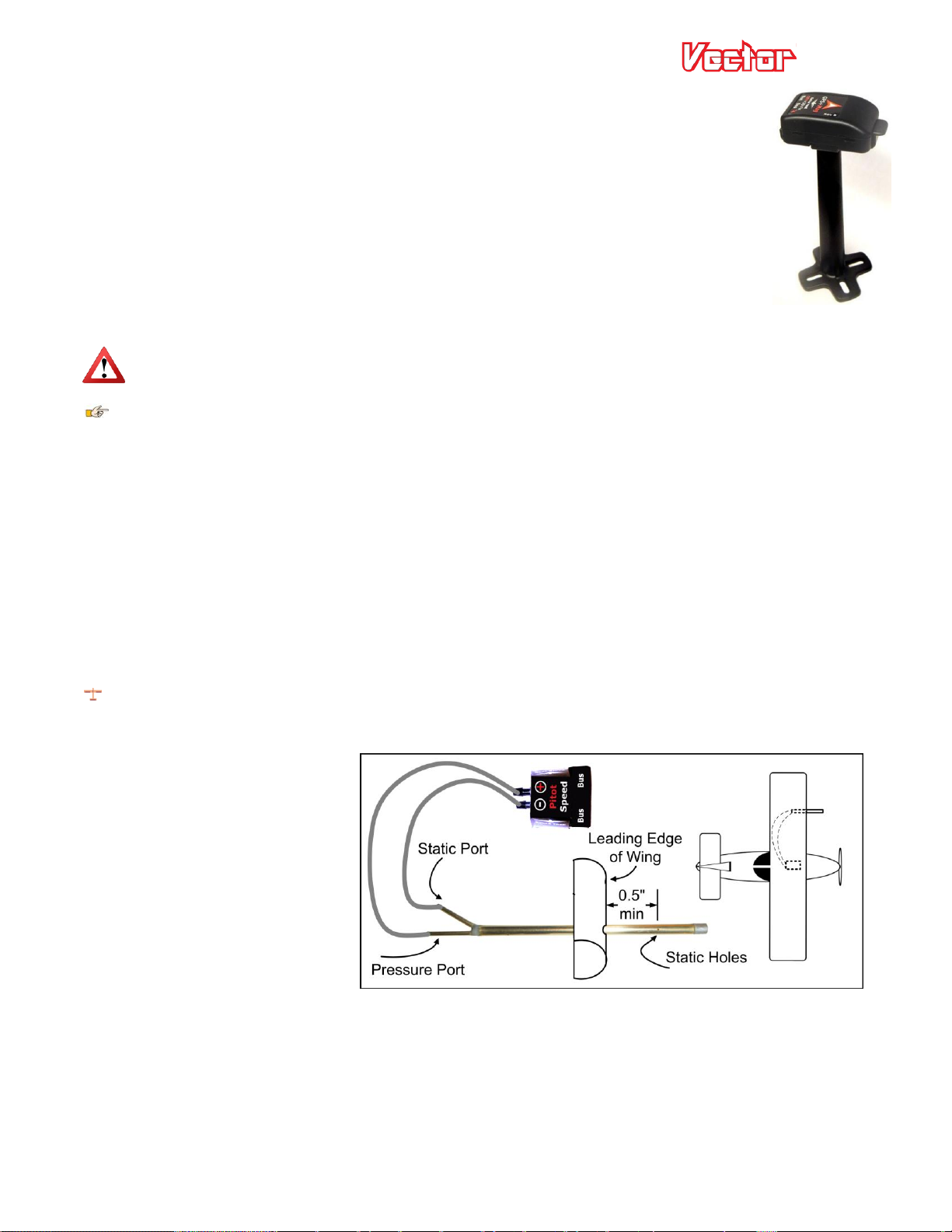

4.4 Mounting the Optional Pitot Tube

If you have the optional airspeed sensor, the pitot tube should be mounted as follows.

Using two lengths of the included small diameter silicon tube, the pressure and static connections of the pitot

tube connect to the “+” and “-”

ports of the MicroSensor,

respectively, as shown below.

It is best to mount the pitot tube in

your model first, then determine

where you will mount the sensor,

and then cut the two lengths of

silicon tube so they reach between

the two. Note that the sensor itself

can be mounted anywhere in the

model.

Follow these guidelines when

mounting the pitot tube:

1) The pickup end of the pitot tube (the silver colored tip) should be pointing toward the direction of the

model’s travel. While best results will be obtained if the pitot tube is perfectly aligned with the direction

of travel in both axes, the “Prandtl” design of the tube will compensate somewhat for higher angles of

attack.

28

Page 29

USER GUIDE

2) The static holes on the pitot tube (shown in the figure) should extend at least 1/2” (13mm) past the wing’s

leading edge or the nose cone, or past any other obstructions - the farther out, the better. This is to

ensure that the static holes and pitot pickup are in undisturbed air.

3) For prop planes, it’s important that the tube be placed so that it is not directly in the plane’s prop-wash,

which will result in erroneous readings. The best place to install the tube is on the leading edge of the wing

several inches out from the fuselage, as shown in the figure.

4) For jets, gliders, or “pusher” prop planes, the nose cone often provides a perfect mounting location.

After pitot tube installation, it is recommended that you glue or otherwise attach the silicon hose to the

airframe, to reduce the chance that hose vibration or movement which could cause erroneous readings.

4.5 Controlling the Vector

The Vector is controlled and optionally configured with the following radio switch

inputs:

4.5.1 The Mode Switch

The Mode switch (a 2 or 3 position switch on your radio that is mapped to the “Mod” input of the receiver

harness, or mapped to an SPPM or S.BUS™ channel) is the primary way that you communicate with the Vector

via your radio.

The mode switch serves two purposes:

1) The position of the switch determines the Vector’s present flight mode

2) Toggling the switch (rapid back and forth movement of the switch) invokes the Vector menu system, letting

you configure the Vector via your radio sticks, and performs other operations based on the number of

toggles:

One toggle: switches OSD screens to the next screen (if multiple screens are configured), and serves as

an “OK” switch during menus

Two toggles: initiates menu mode

Five Toggles: initiates the Vector leveling procedure.

Seven Toggles: starts the compass calibration procedure.

4.5.2 The Submode Switch

The Submode switch is an optional 2 or 3 position switch on your radio, which allows selection of additional

flight modes. This switch is useful if you need to utilize more than 3 flight modes, which is the limit when using

just the Mode switch.

The Submode function can be mapped to the “Aux” input of the receiver harness, or to an SPPM or S.BUS™

channel.

4.5.3 The Gain Knob

The gain knob is an optional control that can be used for adjusting stabilizer gains during flight.

The gain knob can be mapped to the “Aux” input of the receiver harness, or to an SPPM or S.BUS™

channel.

29

Page 30

USER GUIDE

4.5.4 The Kill Switch (for Multirotors Only)

The kill switch is an optional control for multirotors that can be used to instantly kill all motors. This

can be especially useful for initial flight testing.

A momentary (spring loaded) switch can help reduce the likelihood of inadvertent triggering.

The kill switch can be mapped to the “Aux” input of the receiver harness, or to an SPPM or S.BUS™ channel.

Note that the multirotor will rearm instantly when the kill switch is disengaged, until about 3 seconds

after it’s engaged (in case the kill was accidental). Once 3 seconds have elapsed with the Kill Switch set,

the multirotor is permanently disarmed until you rearm it.

During RTH (including RTH test modes) the Gain Knob and Kill Switch inputs are disabled, to prevent

inadvertant changes in these inputs due to loss of reliable Rx signal.

Make sure that your radio does not trigger the kill switch during failsafe! If it does, the multirotor will

shut off, and not rearm until RTH engages (if at all)!

5 Configuring the Vector

5.1 Configuration Overview

The Vector can be completely configured using either the onscreen (stick) menus, or the Vector Windows

Software (the software).At a high level, configuration consists of these steps:

Configuring your radio to work with the Vector

Teaching the Vector about your radio’s serial channel mapping, if you are using the SPPM or S.BUS™

receiver protocol

Selecting the airframe type (airframe type must be confirmed with Mode switch after rebooting – see

section 5.6)

Teaching the Vector about your receiver connections, radio stick directions and throws