Page 1

FlightDEK-D180

Installation Guide

This product is not approved for installation in type certificated aircraft

P/N 100600-000, Revision H

For use with firmware version 5.4

August, 2010

Copyright © 2003-2010 by Dynon Avionics, Inc.

Page 2

Page 3

Contact Information

Dynon Avionics, Inc.

19825 141

st

Place NE

Woodinville, WA 98072

Phone: (425) 402-0433 - 7:00 AM – 5:00 PM (Pacific Time) Monday - Friday

Fax: (425) 984-1751

Dynon Avionics offers online sales, extensive support, and continually-updated information on its products via its

Internet sites:

www.dynonavionics.com/support

docs.dynonavionics.com

– Current and archival documentation.

downloads.dynonavionics.com

support.dynonavionics.com

store.dynonavionics.com

wiki.dynonavionics.com

– Dynon’s secure online store for purchasing all Dynon products 24 hours a day.

– Dynon Avionics’ Documentation Wiki provides enhanced, extended,

–Dynon Avionics primary web site; including:

– Software downloads.

– Support resources.

continuously-updated online documentation contributed by Dynon employees and customers.

forum.dynonavionics.com

– Dynon Avionics’ Internet forum where Dynon customers can interact and

receive Dynon technical support outside of telephone support hours. A key feature of the forum is that it

allows the exchange of diagrams, photos, and other types of files.

newsletter.dynonavionics.com

blog.dynonavionics.com

– Dynon’s email newsletter.

– Dynon’s blog where you can find new and interesting Dynon-related content.

Copyright

2003-2010 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and

provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(www.dynonavionics.com

products.

) for current updates and supplemental information concerning the use and operation of this and other Dynon Avionics

Limited Warranty

Dynon Avionics warrants this product to be free from defects in materials and workmanship for three years from date of shipment. Dynon

Avionics will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge

to the customer for parts or labor. The customer is, however, responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, improper installation or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE, AND IN LIEU OF ALL OTHER WARRANTIES

EXPRES

SED OR IMPLIED, INCLUDING ANY LIABILITY ARISING UNDER WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH

MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL DYNON AVIONICS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMA

GES, WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN

THE PRODUCT. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Dynon Avionics retains the exclusive right to repair or replace the instrument or firmware or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

T

hese instruments are not intended for use in type certificated aircraft at this time. Dynon Avionics makes no claim as to the suitability of its

products in connection with FAR 91.205.

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for replacing the optional internal backup battery in

EFIS-based products per the installation guide, our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon Avionics unit is opened up, it will require calibration

and verification at our Woodinville, WA offices before it can be considered airworthy.

Page 4

Page 5

Table of Contents

Contact Information......................................................................................................................................................iii

Copyright......................................................................................................................................................................iii

Limited Warranty .........................................................................................................................................................iii

1. 1-1 Introduction

OEM Installations...................................................................................................................................................... 1-1

Warning ..................................................................................................................................................................... 1-1

About this Guide........................................................................................................................................................ 1-2

Menu Descriptions..................................................................................................................................................... 1-2

2. 2-1 Wiring Overview

Recommended Wiring Practices................................................................................................................................2-1

Power Requirements.................................................................................................................................................. 2-1

Grounding.................................................................................................................................................................. 2-2

+5V Excitation........................................................................................................................................................... 2-3

Thermocouple Harness Preparation........................................................................................................................... 2-3

Harness Mating.......................................................................................................................................................... 2-3

25-Pin Female EFIS Harness..................................................................................................................................... 2-4

37-Pin Female EMS Harness..................................................................................................................................... 2-7

25-Pin Male EMS Harness ........................................................................................................................................ 2-9

3. 3-1 Transducer Installation

Tools and Equipment Required ................................................................................................................................. 3-1

Exhaust Gas Temperature (EGT) Probes................................................................................................................... 3-2

Cylinder Head Temperature (CHT) Probes ............................................................................................................... 3-3

Tachometer................................................................................................................................................................ 3-4

Manifold Pressure Sensor.......................................................................................................................................... 3-5

Oil Pressure Sensor.................................................................................................................................................... 3-6

Oil Temperature Sensor............................................................................................................................................. 3-7

Fuel Pressure Sensor.................................................................................................................................................. 3-7

Fuel Flow Sensor....................................................................................................................................................... 3-9

Fuel Level Sensor .....................................................................................................................................................3-11

Ammeter Shunt.........................................................................................................................................................3-12

General Purpose Inputs.............................................................................................................................................3-13

Contacts ....................................................................................................................................................................3-18

General Purpose Thermocouple ...............................................................................................................................3-19

4. 4-1 Instrument Installation

Selecting a Remote Compass Module Location ........................................................................................................ 4-1

EDC-D10A Communication Cable ........................................................................................................................... 4-2

Power Inputs.............................................................................................................................................................. 4-3

Serial Communication Cables ................................................................................................................................... 4-4

SL30 and/or GPS connection..................................................................................................................................... 4-6

Altitude Encoder Wiring ........................................................................................................................................... 4-8

External EMS Warning Light...................................................................................................................................4-10

Audio Alert Outputs .................................................................................................................................................4-10

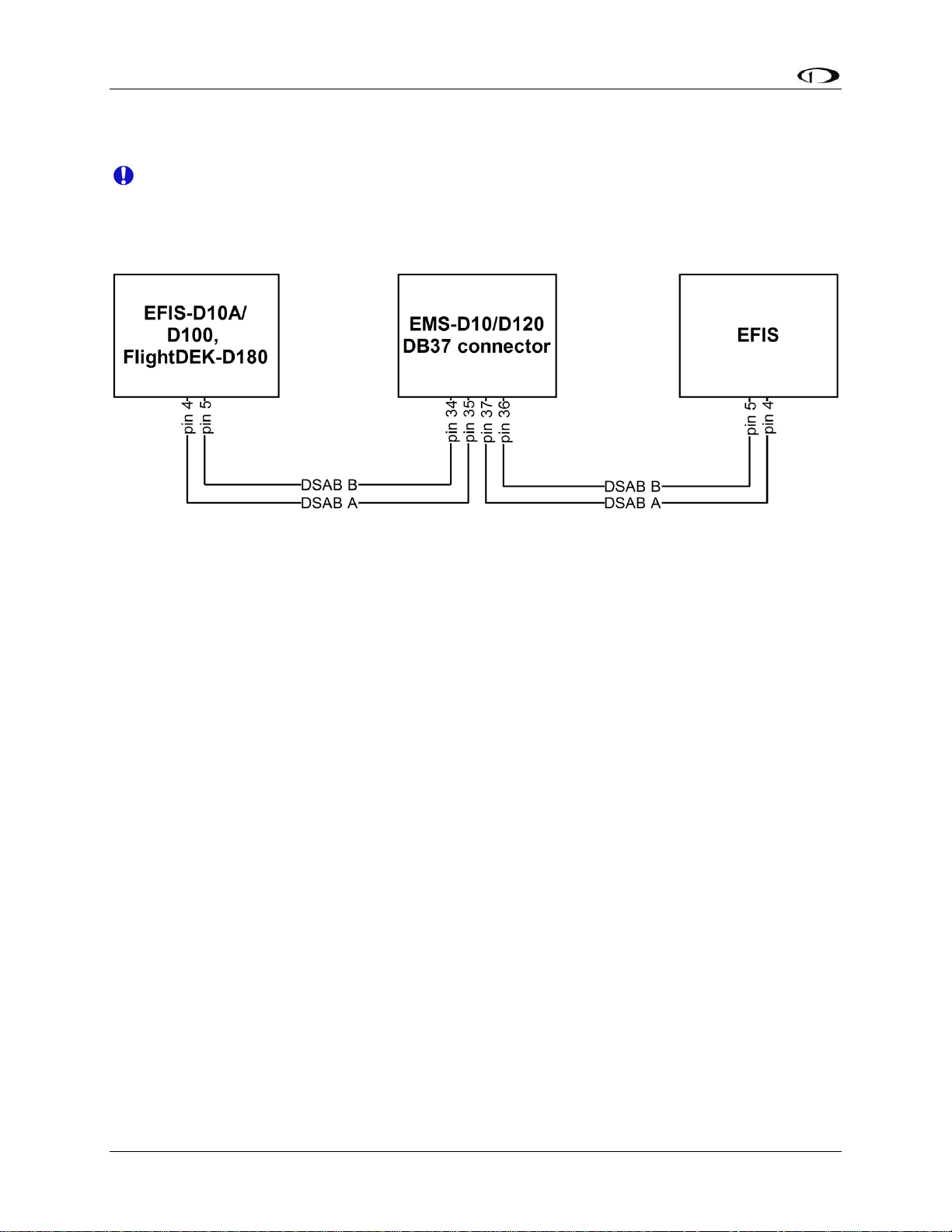

Dynon Smart Avionics Bus (DSAB) Wiring............................................................................................................4-11

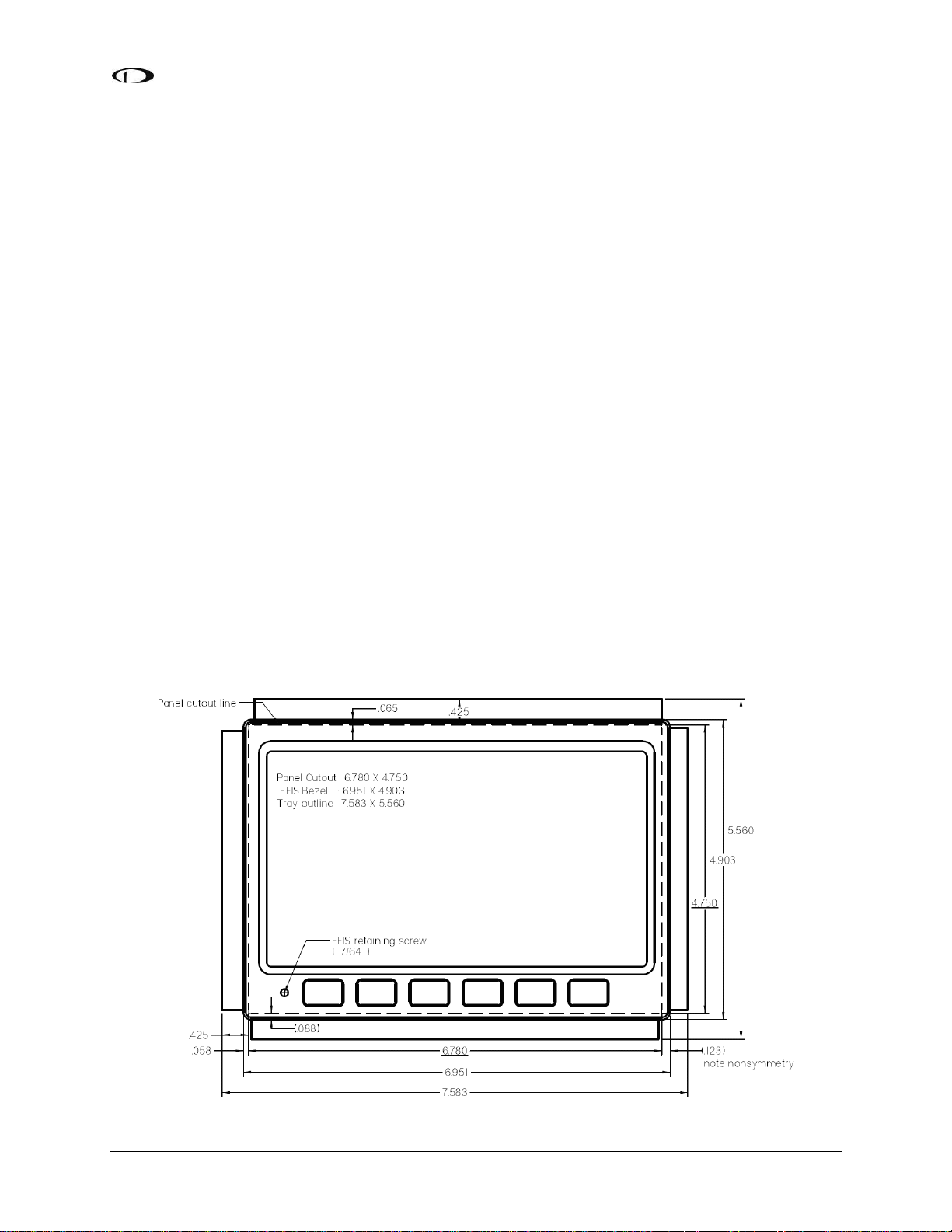

Panel Location and Mounting...................................................................................................................................4-13

Connecting Static & Pitot Lines ...............................................................................................................................4-14

5. 5-1 EFIS Calibration and Configuration

Ensuring Proper Installation ...................................................................................................................................... 5-1

Setting Zero Pitch (In flight)...................................................................................................................................... 5-1

FlightDEK-D180 Installation Guide v

Page 6

Table of Contents

Compass Heading Calibration ................................................................................................................................... 5-1

Configure Airspeed Color Thresholds....................................................................................................................... 5-4

6. 6-1 EMS Configuration

Full-Page Setup Menu Overview............................................................................................................................... 6-1

Alarm and Color Threshold Configuration................................................................................................................ 6-2

Global Parameters Setup ........................................................................................................................................... 6-3

Engine Type Configuration ....................................................................................................................................... 6-4

Fuel Level Calibration ............................................................................................................................................... 6-5

Trim Calibration ........................................................................................................................................................ 6-6

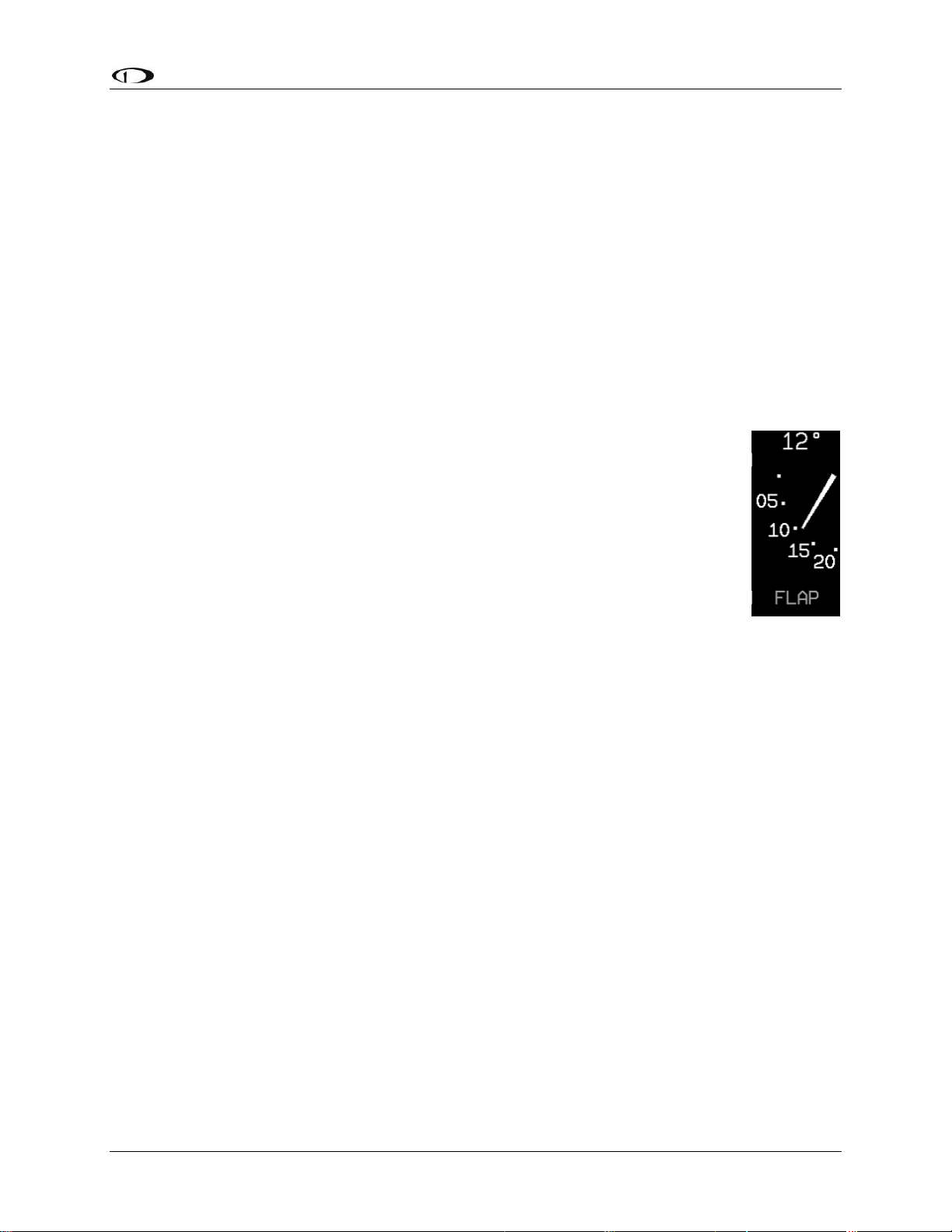

Flaps Calibration ....................................................................................................................................................... 6-7

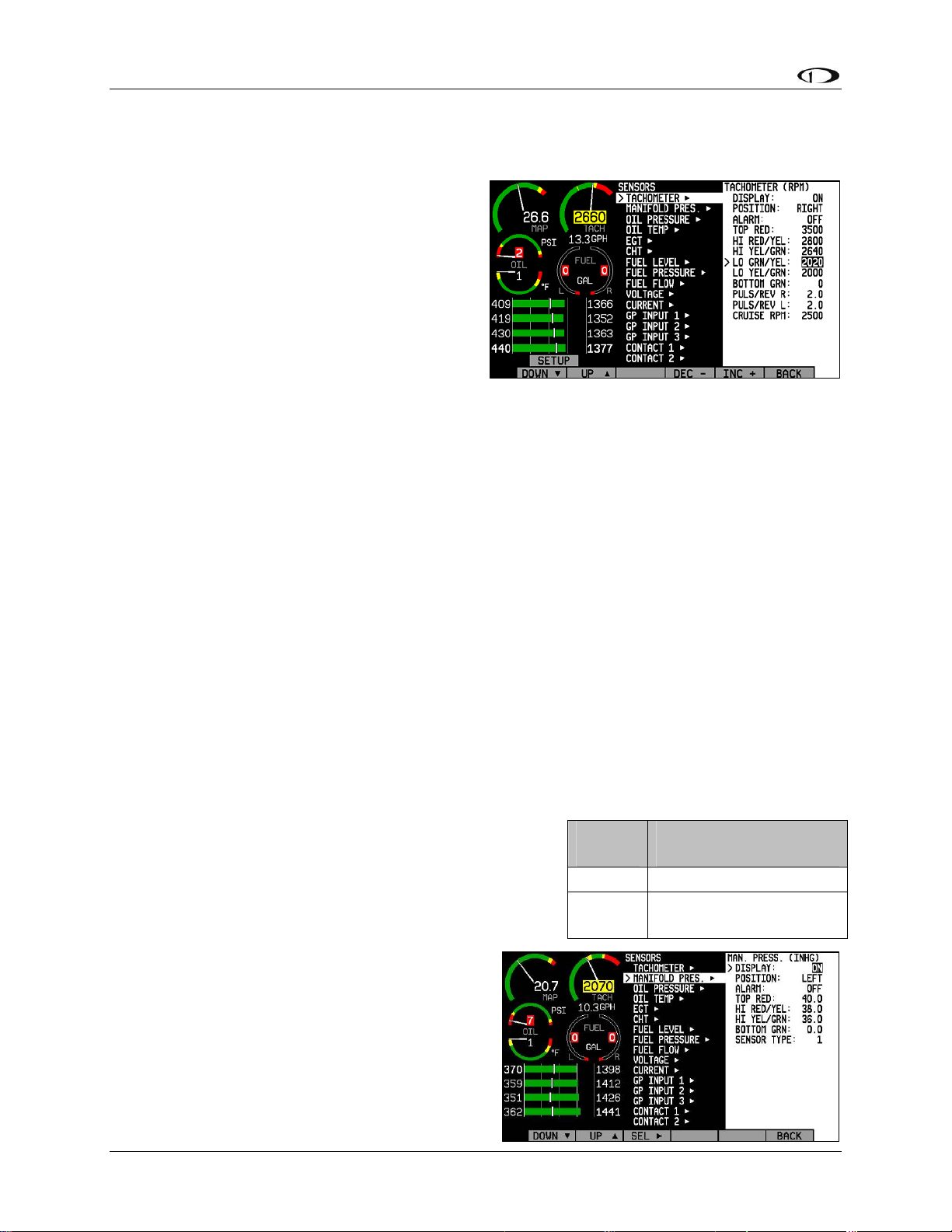

Tachometer................................................................................................................................................................ 6-8

Manifold Pressure...................................................................................................................................................... 6-8

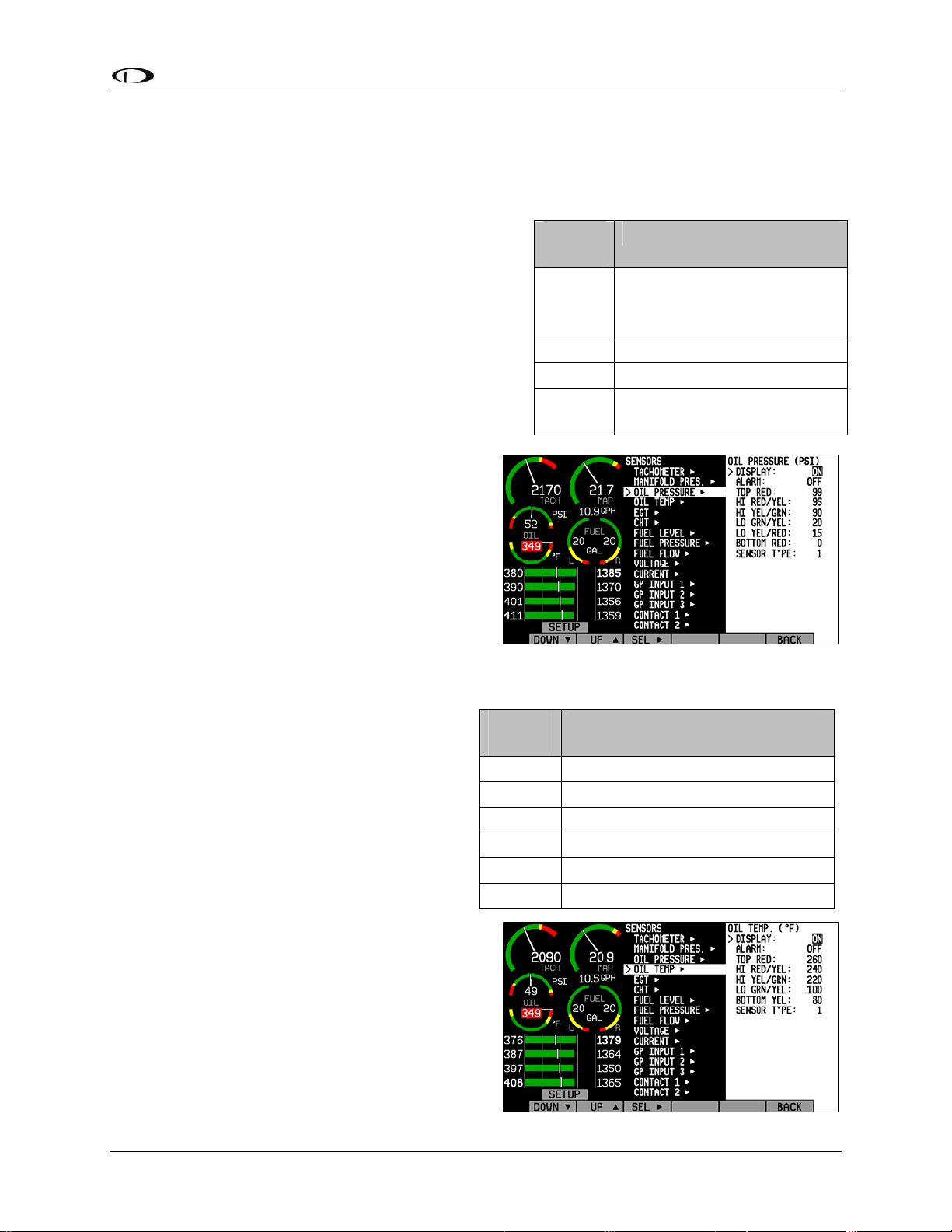

Oil Pressure ............................................................................................................................................................... 6-9

Oil Temperature......................................................................................................................................................... 6-9

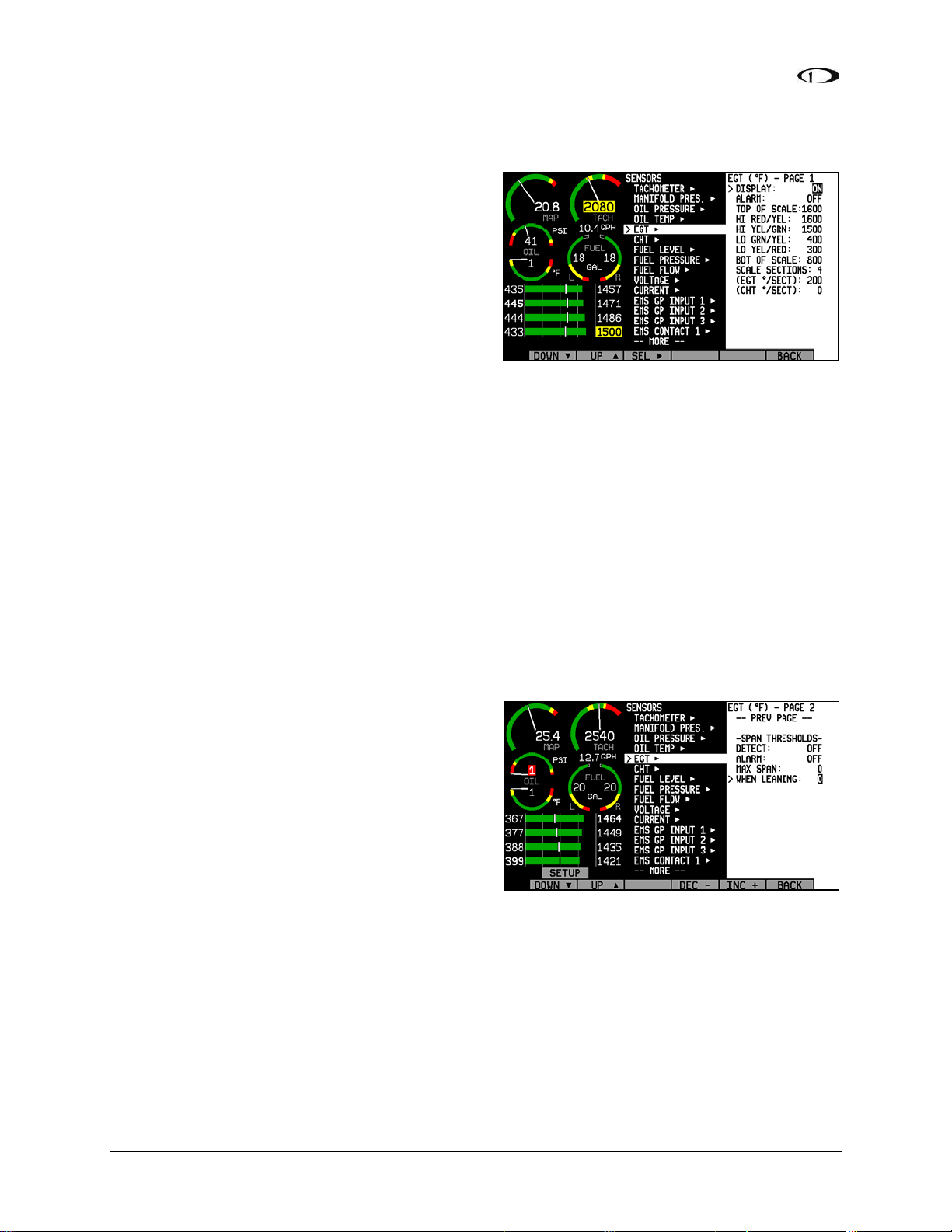

Exhaust Gas Temperature (EGT) .............................................................................................................................6-10

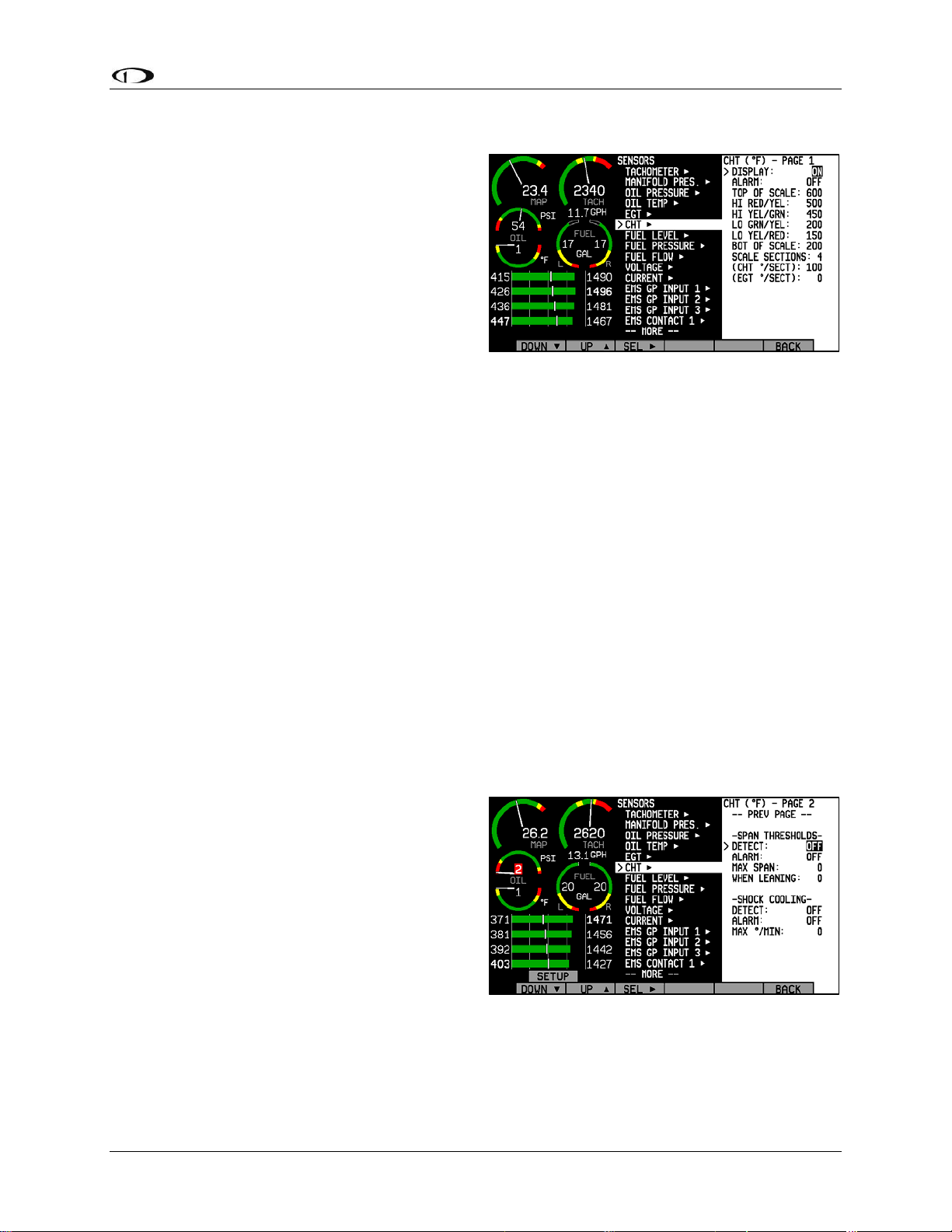

Cylinder Head Temperature (CHT)..........................................................................................................................6-11

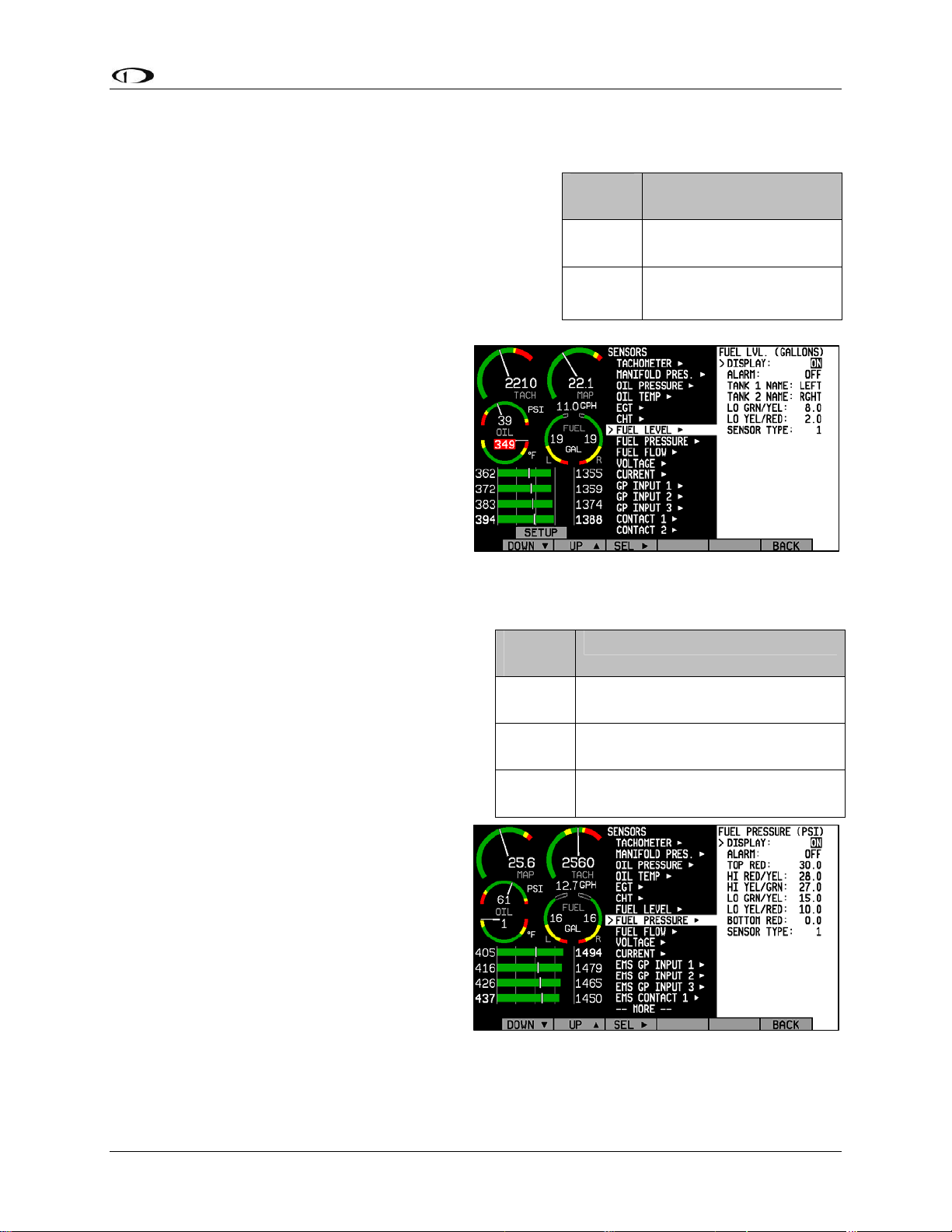

Fuel Level.................................................................................................................................................................6-13

Fuel Pressure ............................................................................................................................................................6-13

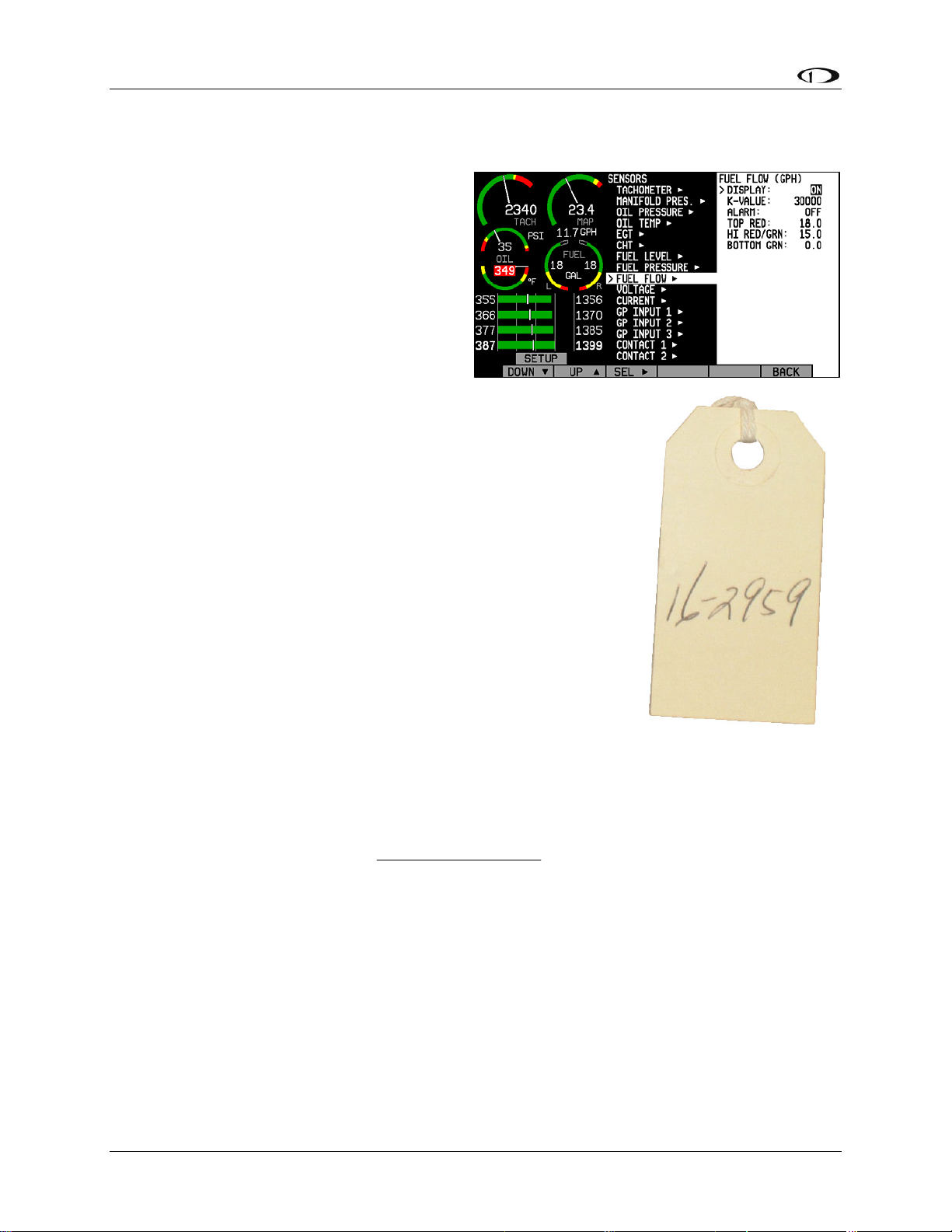

Fuel Flow..................................................................................................................................................................6-14

Voltage .....................................................................................................................................................................6-15

Current......................................................................................................................................................................6-15

General Purpose Inputs.............................................................................................................................................6-16

Contacts ....................................................................................................................................................................6-18

General Purpose Thermocouple ...............................................................................................................................6-19

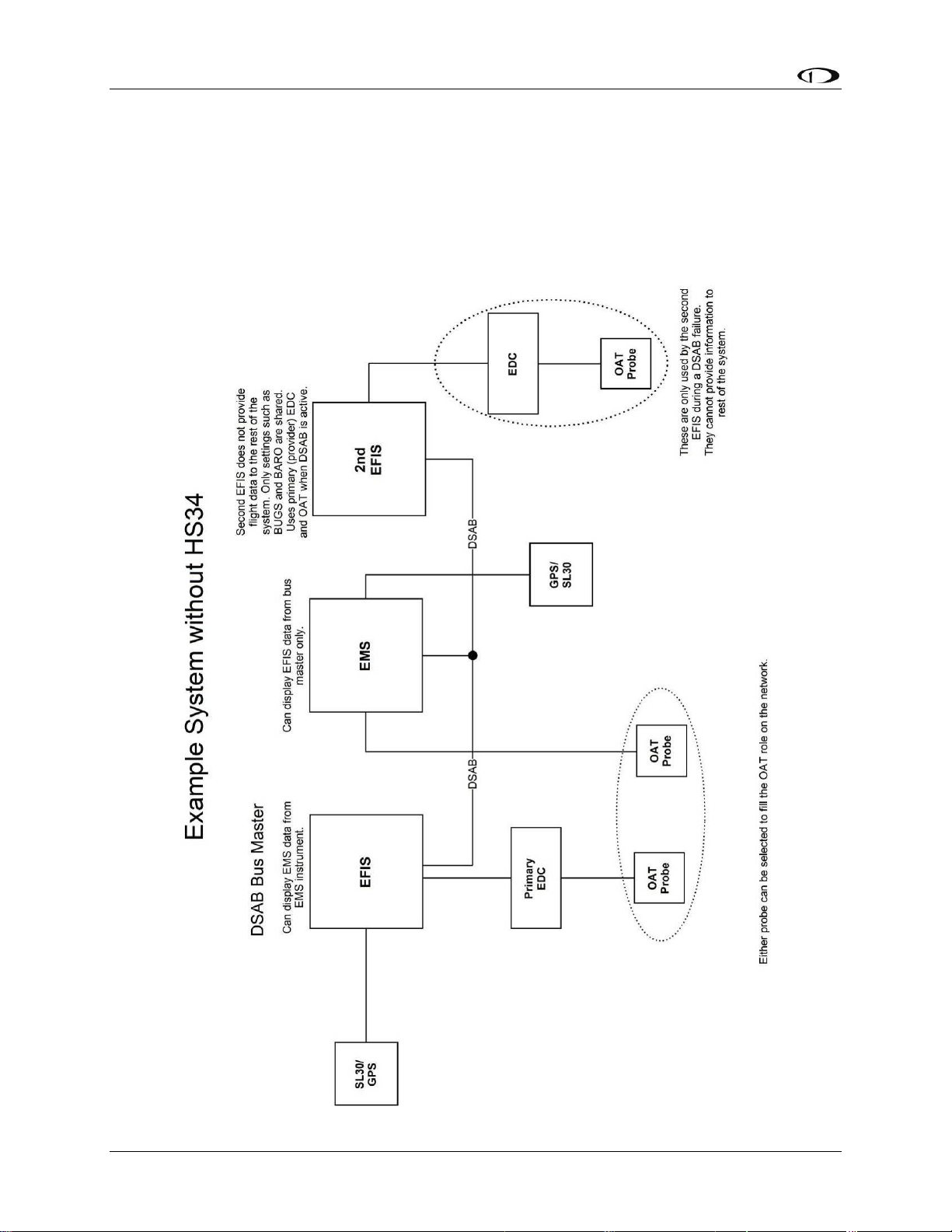

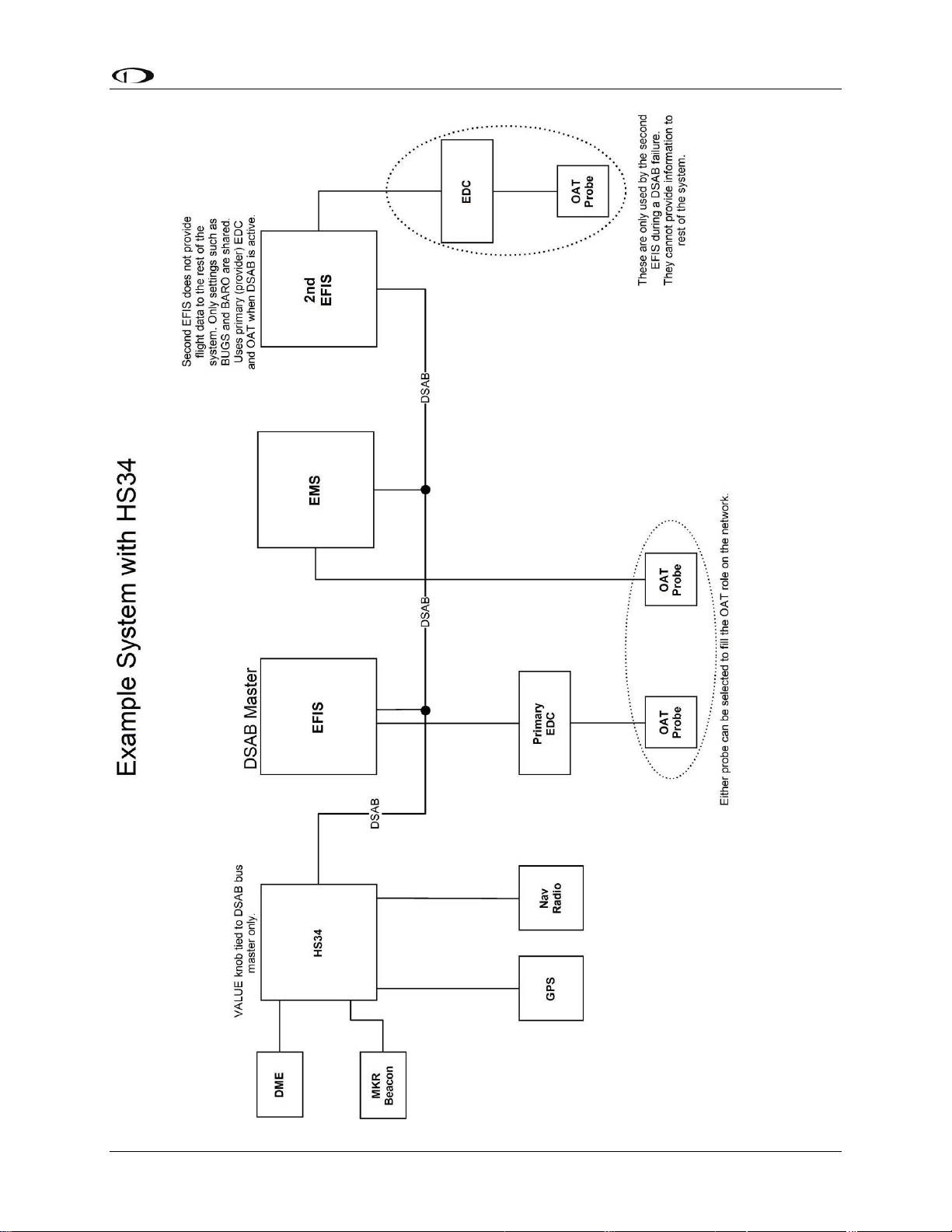

7. 7-1 DSAB Configuration

Network Concepts ..................................................................................................................................................... 7-1

Example Networks .................................................................................................................................................... 7-2

Initial Setup ............................................................................................................................................................... 7-4

Brightness Configuration........................................................................................................................................... 7-5

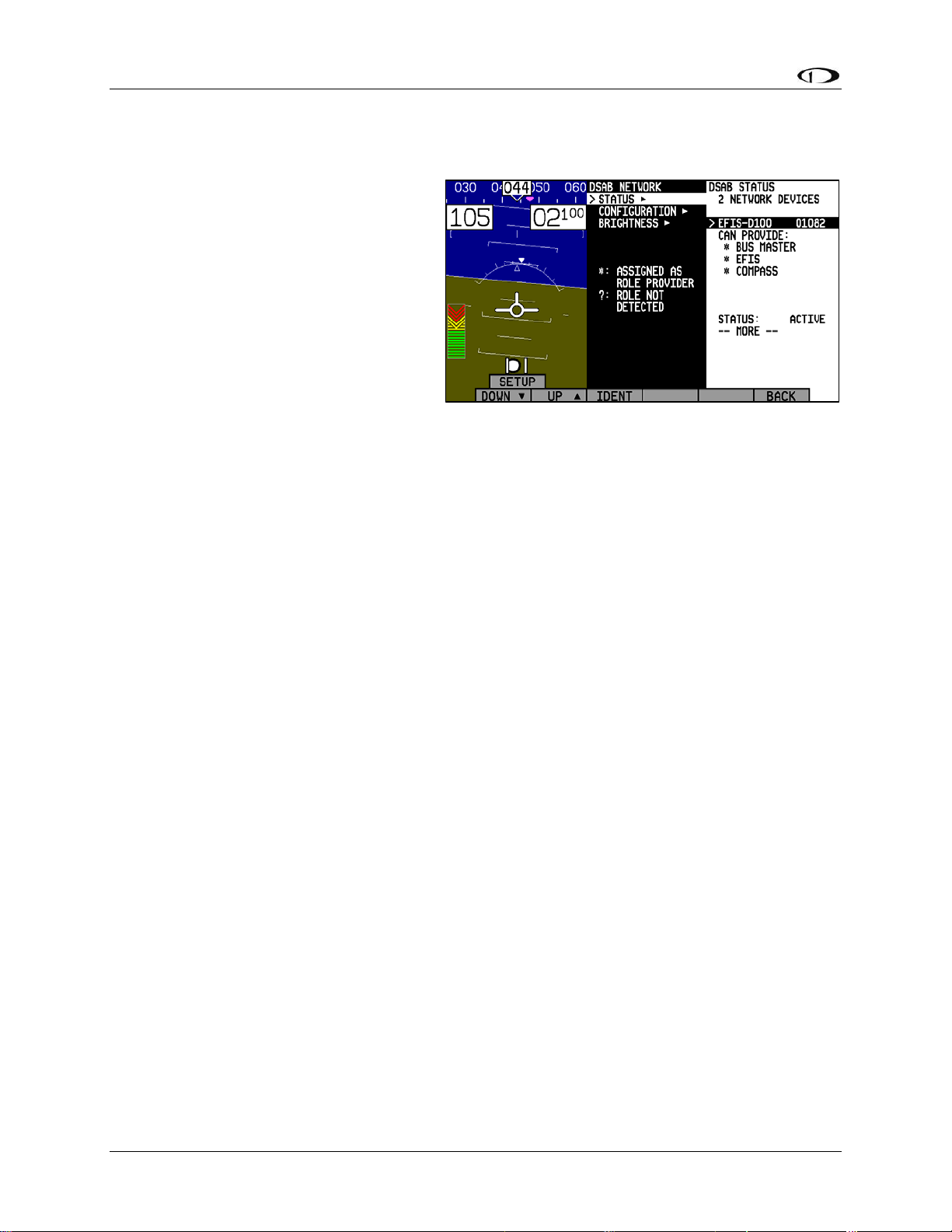

Network Status .......................................................................................................................................................... 7-6

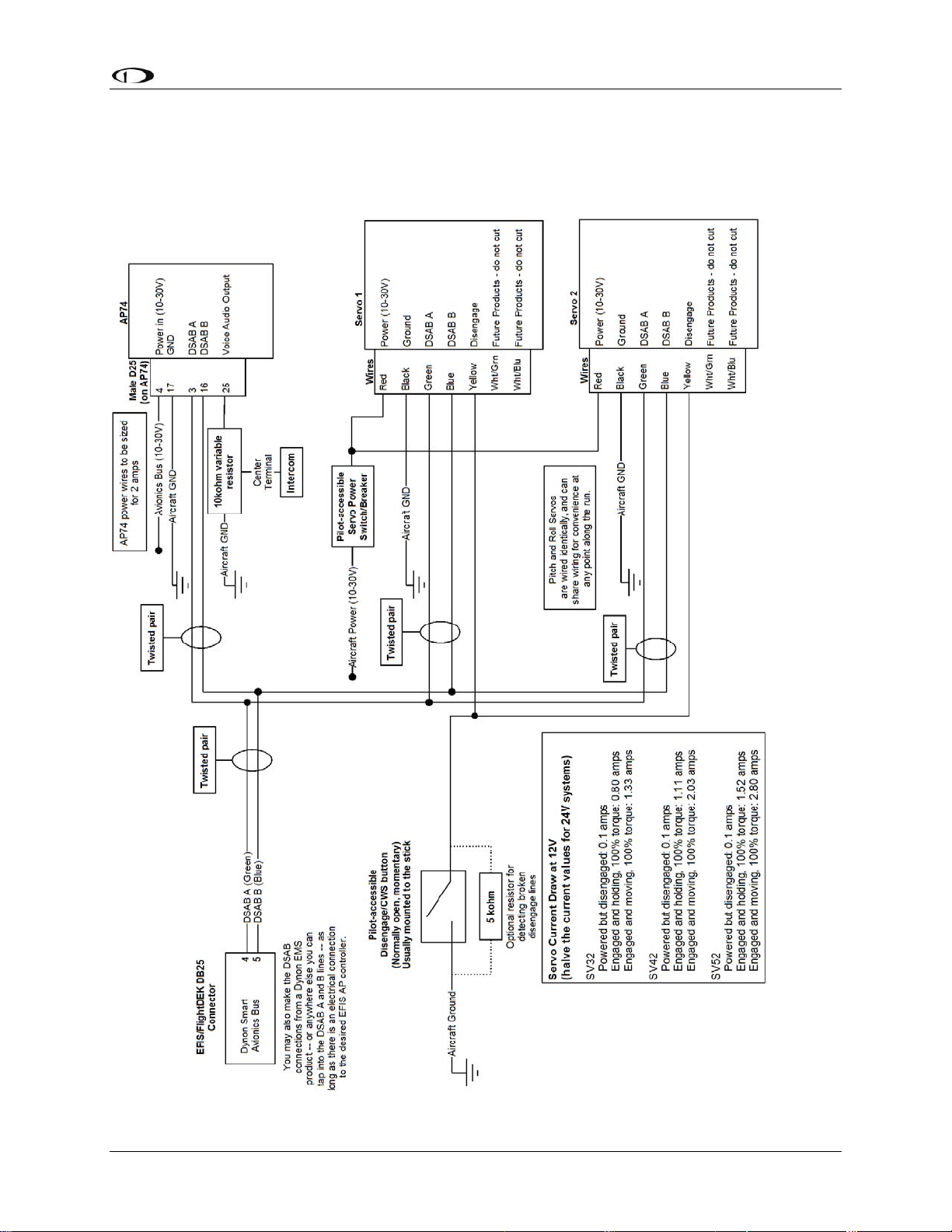

8. 8-1 Autopilot Installation and Configuration

Additional Information and Updates ......................................................................................................................... 8-1

DSAB Firmware Compatibility................................................................................................................................. 8-2

Compass Calibration Critical For Certain AP Modes................................................................................................ 8-2

Autopilot System Electrical Installation .................................................................................................................... 8-3

Servo Mechanical Installation ................................................................................................................................... 8-6

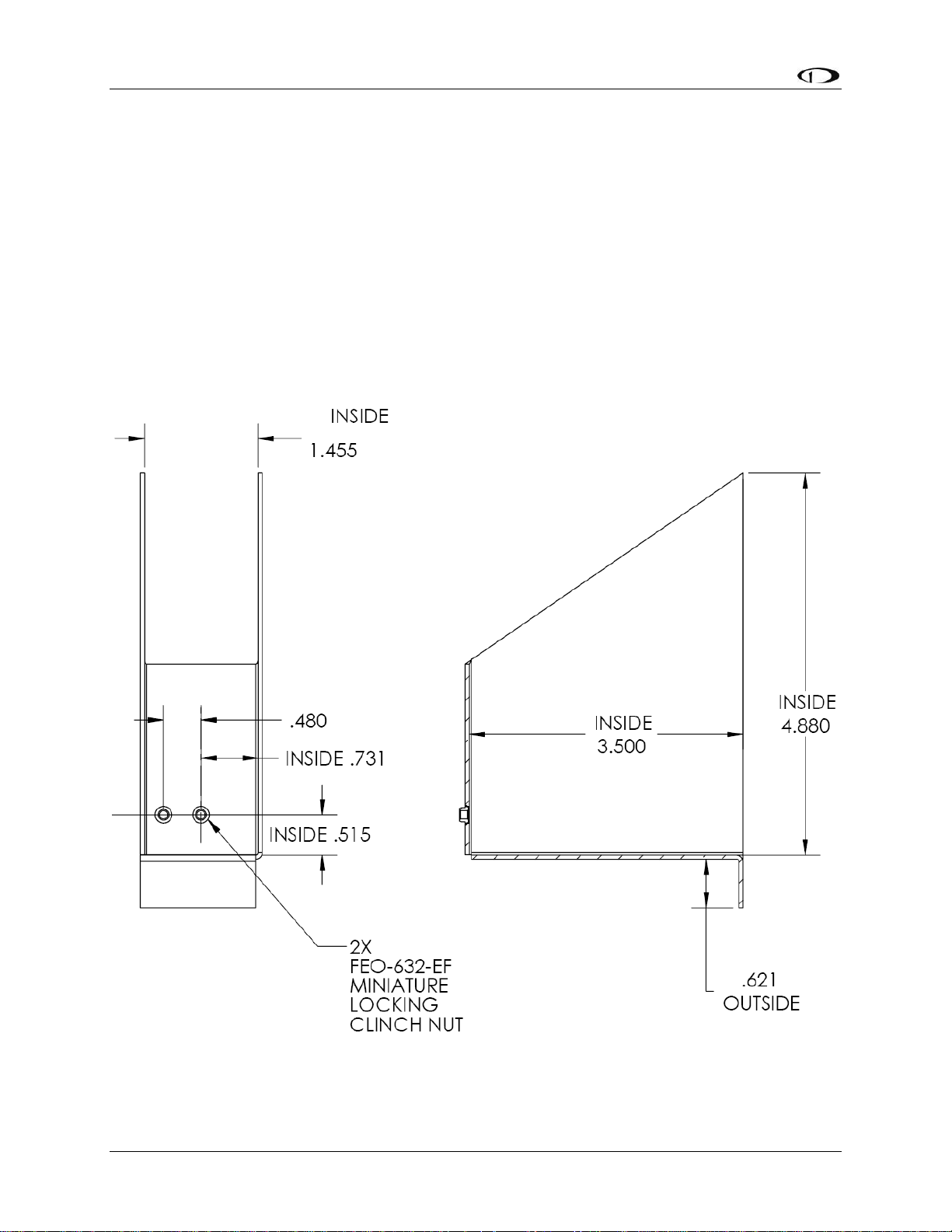

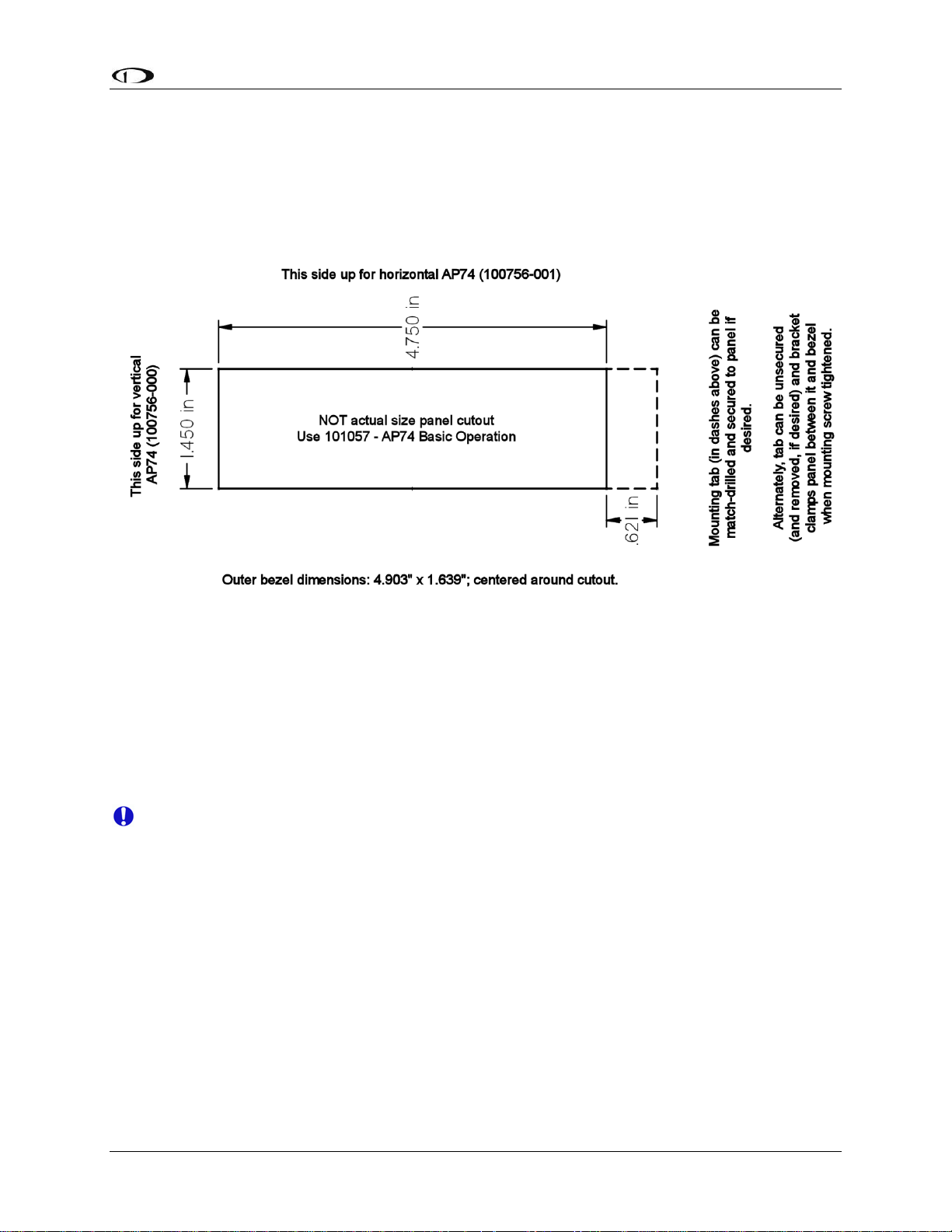

AP74 Mechanical Installation...................................................................................................................................8-11

Firmware Upgrades Required For AP Functionality ................................................................................................8-13

AP Servo Configuration ...........................................................................................................................................8-14

AP74 Configuration..................................................................................................................................................8-30

9. 9-1 Appendix

Appendix A: Ongoing Maintenance and Troubleshooting........................................................................................ 9-1

Appendix B: Dynon EFIS OAT Probe Installation and Usage.................................................................................. 9-7

Appendix C: HS34 Installation and Configuration...................................................................................................9-10

Appendix D: Dynon AOA/Pitot Installation and Calibration ...................................................................................9-24

Appendix E: Encoder Serial-to-Gray Code Converter Installation...........................................................................9-32

Appendix F: Capacitance-to-Voltage Converter Installation....................................................................................9-35

Appendix G: Replacing the FlightDEK-D180 battery pack .....................................................................................9-36

Appendix H: Weights...............................................................................................................................................9-36

Appendix I: FlightDEK-D180 Specifications...........................................................................................................9-38

vi FlightDEK-D180 Installation Guide

Page 7

1. INTRODUCTION

This manual provides information about the physical, electrical, and plumbing installation of the

FlightDEK-D180, EDC-D10A, optional AOA pitot probe, and all engine sensors purchased from

Dynon Avionics. Additionally, this guide deals with setting up the installation-dependant

firmware options. Because you may not have purchased all the components, you need only read

through the relevant sections of this guide. Information about the operation of this instrument

can be found in the FlightDEK-D180 Pilot’s User Guide.

The EFIS component of the FlightDEK-D180 uses solid-state sensor technology to give an

accurate and easy-to-understand display. To ensure accuracy in its readings, it is very important

that you install the instrument correctly and perform the specified calibration steps. This

installation guide helps you through that process.

OEM Installations

If your FlightDEK-D180 is installed by an OEM distributor, you may find that you are unable to

access some menus and settings. Some Dynon distributors customize various areas of the

FlightDEK-D180 firmware to maintain a consistent pilot experience and minimize integration

issues across a large number of installations. Currently, OEMs can customize access levels to the

following settings on Dynon systems: EMS GLOBAL setup menu, EMS SENSOR setup menu,

fuel calibration, trim calibration, flaps calibration, GPS/NAV setup menu, screen configurations,

data logging, and checklists/data panels. OEM distributors have the option of customizing some

or all of these areas. Please contact your aircraft’s manufacturer if you have any questions about

how your unit has been customized.

Warning

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for

replacing the optional internal backup battery in EFIS-based products per the installation guide,

our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon

Avionics unit is opened up, it will require calibration and verification at our Woodinville, WA

offices before it can be considered airworthy.

FlightDEK-D180 Installation Guide 1-1

Page 8

Introduction

About this Guide

In the electronic (.PDF) version of this manual, page and section references in the Table of

Contents and elsewhere act as hyperlinks taking you to the relevant location in the manual. The

latest version of this manual is available on the Dynon Avionics website at

docs.dynonavionics.com.

The following icons are used in this guide:

Any text following this icon describes functionality available only with the HS34 HSI

Expansion Module connected to your system.

Any text following this icon describes functionality available only with the AP74

Autopilot Interface Module connected to your system.

Any text following this icon describes functionality that is possible when multiple Dynon

Avionics products are networked together via the Dynon Smart Avionics Bus (DSAB).

Any text following this icon refers to a setting or situation which merits particularly close

attention.

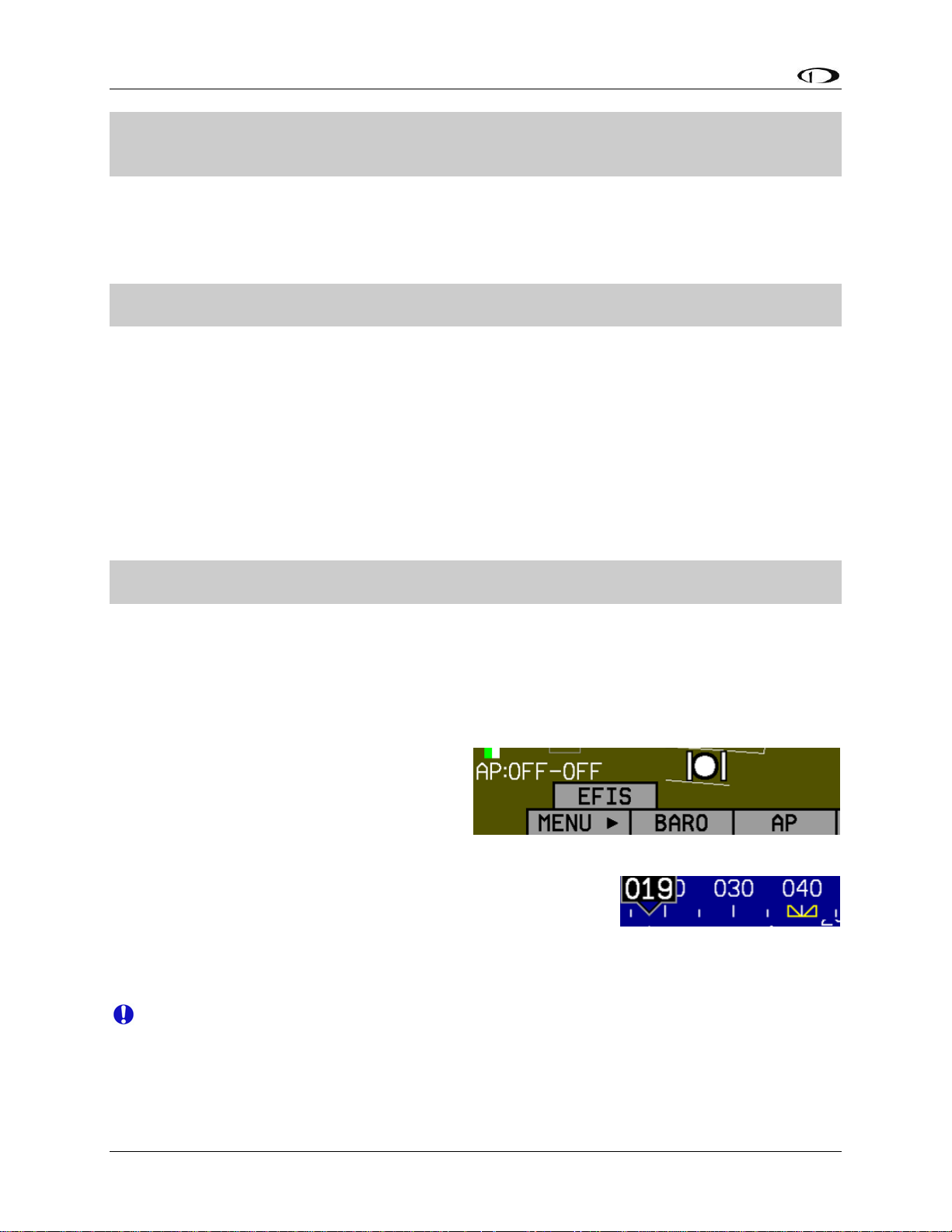

Menu Descriptions

Throughout this guide, the “>“ character is used to indicate entering a deeper level of the menu

system. For example, “EFIS > INFO > LEFT” indicates entering the EFIS menu, pressing

MORE, then pressing INFO, and then pressing LEFT to enter the left info item menu. Note that

the MORE button is not shown in the sequence, since pressing MORE reveals more options in

the same level of the menu system.

1-2 FlightDEK-D180 Installation Guide

Page 9

2. WIRING OVERVIEW

Please follow these instructions explicitly as improper wiring can result in permanent damage to

your instrument and/or the accompanying sensors.

All electrical power and EFIS-specific lines interface with the FlightDEK-D180 via the female

25-pin D-sub connector on the back of the instrument. All EMS-related sensor inputs enter the

FlightDEK-D180 via the male 37-pin and female 25-pin D-sub connectors on the back of the

instrument. Ensure that the unit powers on and that all indicators display expected values before

completing the final physical assembly.

Recommended Wiring Practices

For all electrical connections, use correct wiring techniques, taking care to properly

insulate any exposed wire. A short circuit between any of the wires may cause damage to

the FlightDEK-D180 and/or your aircraft. Make all connections to your harness before

plugging it into any of the components of the system. Do not make connections while

power is applied at any point in the system.

Dynon Avionics sells wiring harnesses for all connections to the FlightDEK-D180. The

harnesses are made up of 22 AWG wire and – with the exception of the thermocouple harnesses

– meet Mil Standard MIL-W-22759/16 (Tefzel insulation). If you have opted not to purchase

these harnesses, please refer to the provided wiring diagrams for construction information. We

recommend that all wire you use also meets Mil Standard MIL-W-22759/16; all wire supplied by

Dynon Avionics (with the exception of thermocouple wire, which uses FEP insulation) meets

this specification.

When using any pre-manufactured harness, verify that each pin has continuity with the expected

wire on the wiring diagram. This test can be easily done with a multimeter. When verifying

harnesses, use the wiring charts and diagrams in this guide as your ultimate authority on pin

function (for any harness) and wire color (for harnesses purchased from Dynon Avionics).

Route all wiring through the engine compartment such that there are no spots where it could

chafe or break. Use appropriate strain relief at all junctions between wires and connectors. We

recommend that you secure all wires at regular intervals along wiring runs to accommodate

vibration effects.

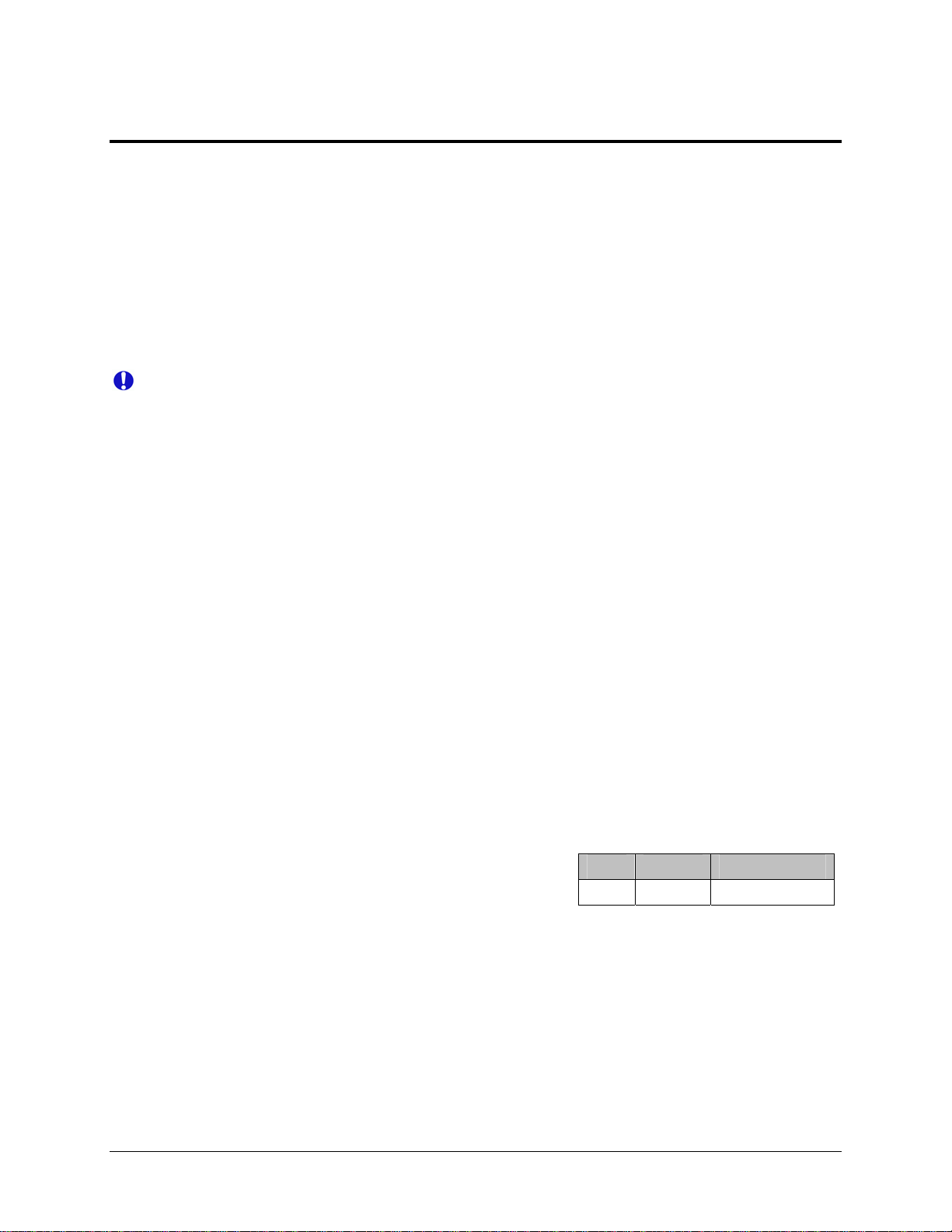

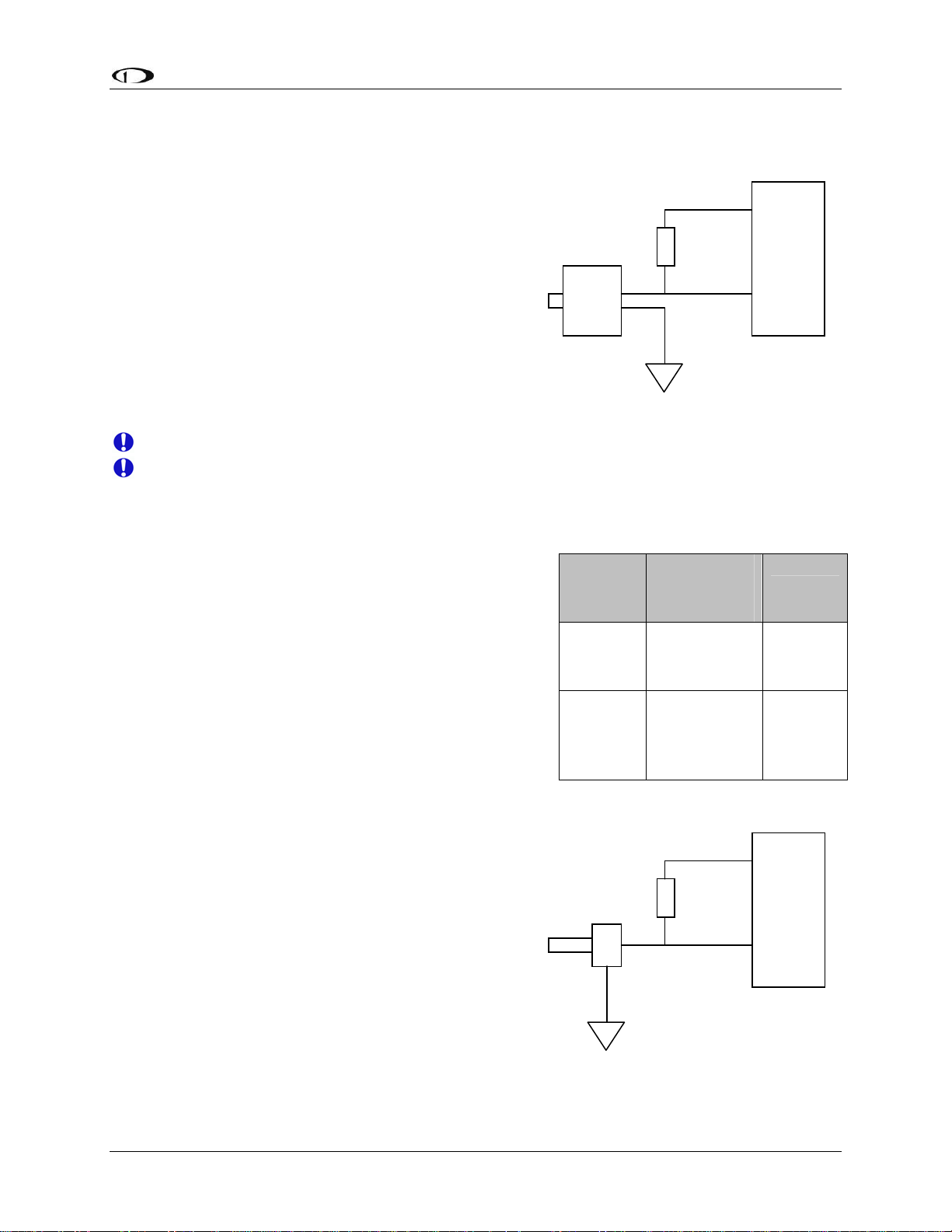

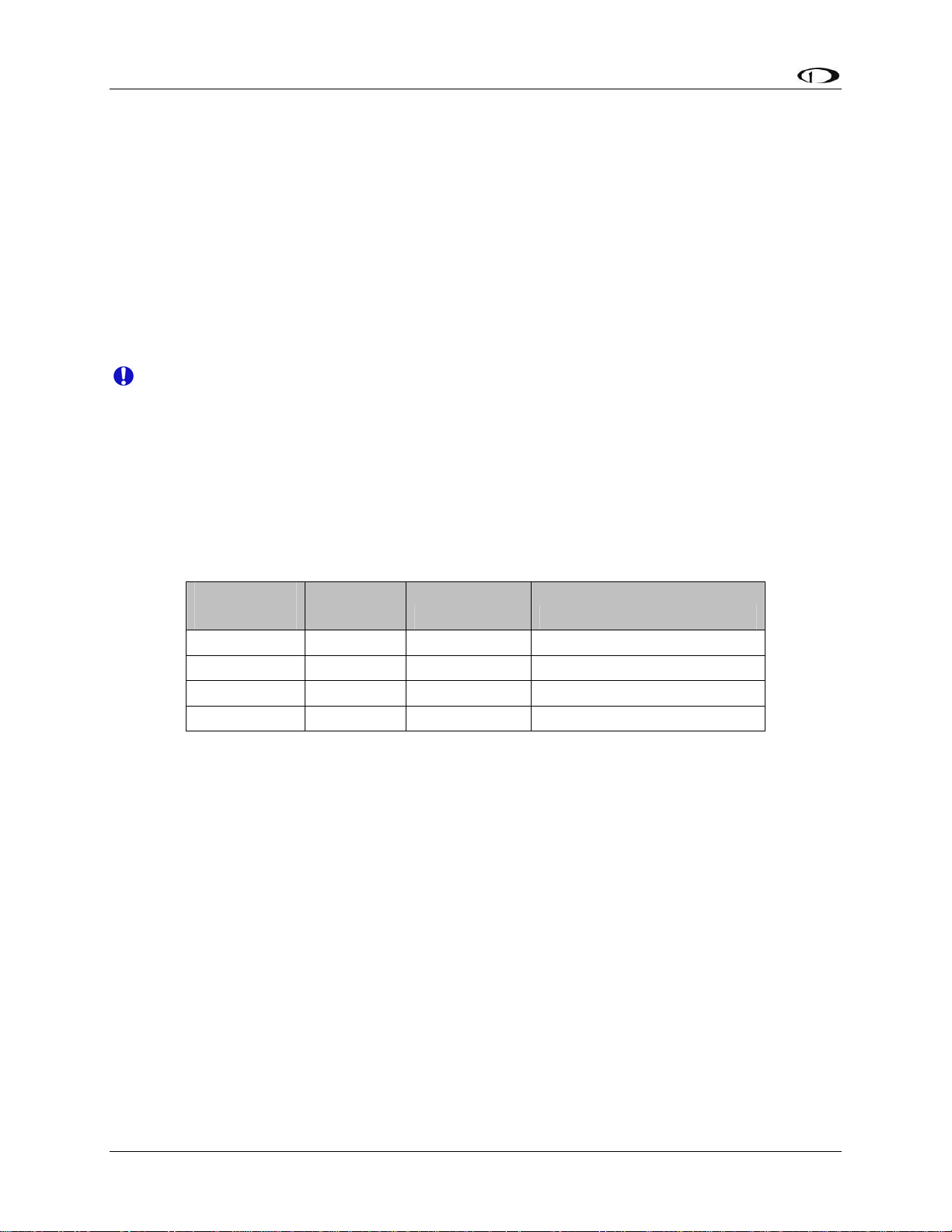

In the sections below, many connections have an

associated legend, as shown at right. All connections on

the EMS male 25-pin harness route to thermocouples and

are color-coded to correspond to the thermocouple

coloring. All connections on the EFIS female 25-pin harness are described in the 25-Pin Female

EFIS Harness section on page 2-4.

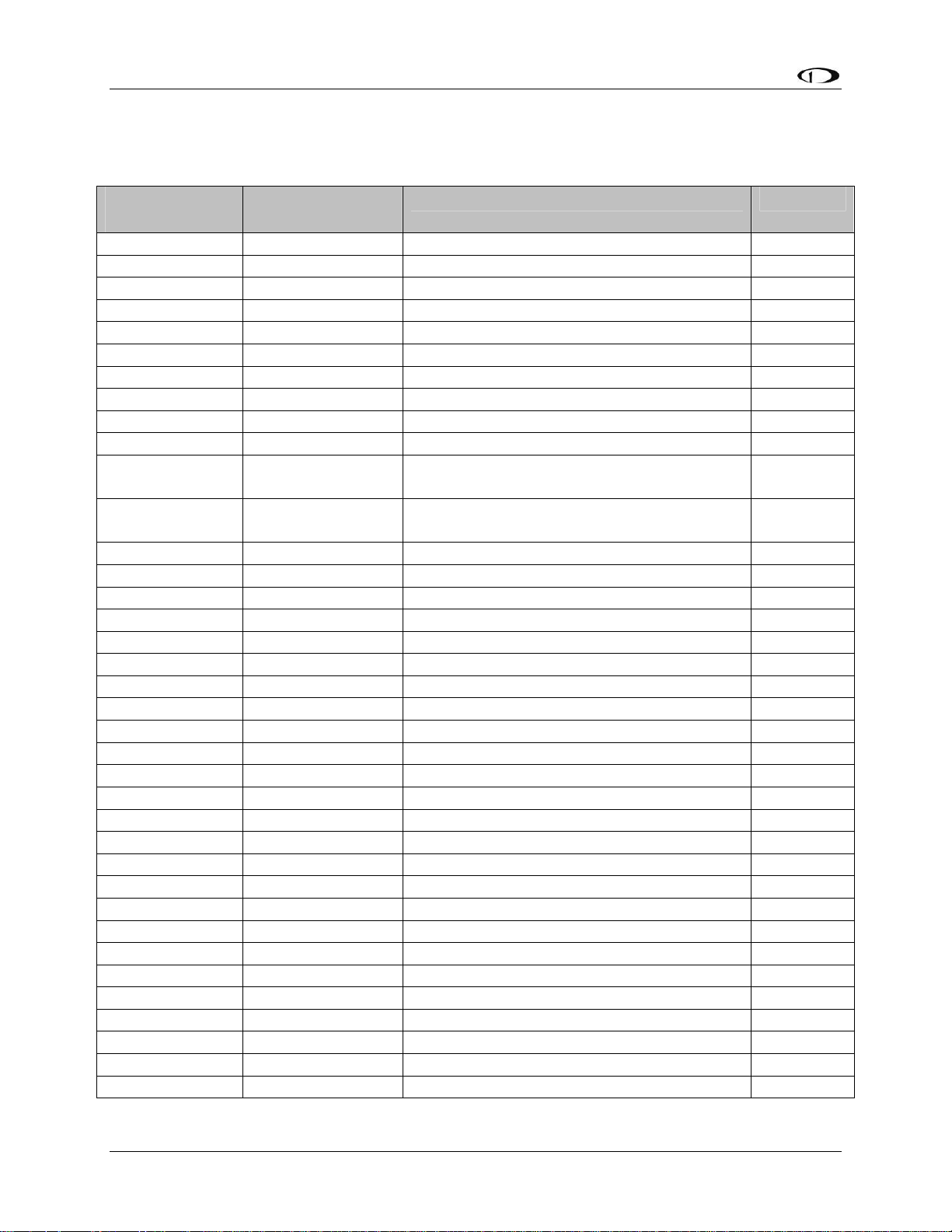

Pin Color Function

# Color function

Power Requirements

22 AWG wire is normally sufficient for the power supply and ground lines, but we recommend

that you consult a wire sizing chart and determine the size required for the wire routing in your

particular aircraft. Ensure that the power lines include a circuit breaker or an appropriately sized

FlightDEK-D180 Installation Guide 2-1

Page 10

Wiring Overview

fuse for the wire you select. Power is fed to the FlightDEK-D180 via pins in the female D-25

connector as shown on the 25-Pin Female EFIS Harness diagram on page 2-4.

The FlightDEK-D180 system-wide power requirement is 14 watts typical and 19 watts

maximum. On a 12-volt system, this translates to about 1.5 amps of maximum current draw. On

a 24-volt system, this translates to about 0.8 amps maximum current draw. Normally, a 3-amp

circuit breaker or fuse is sufficient.

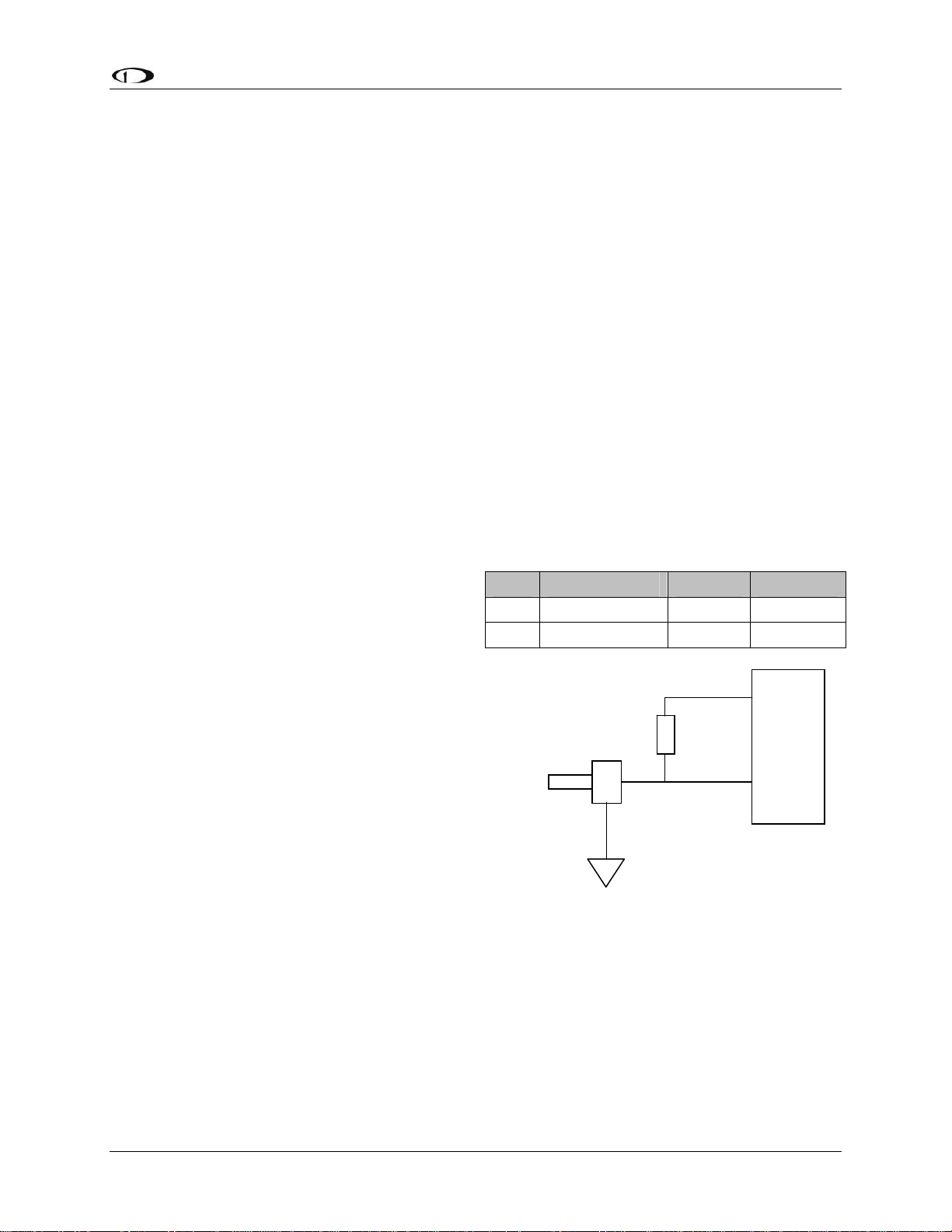

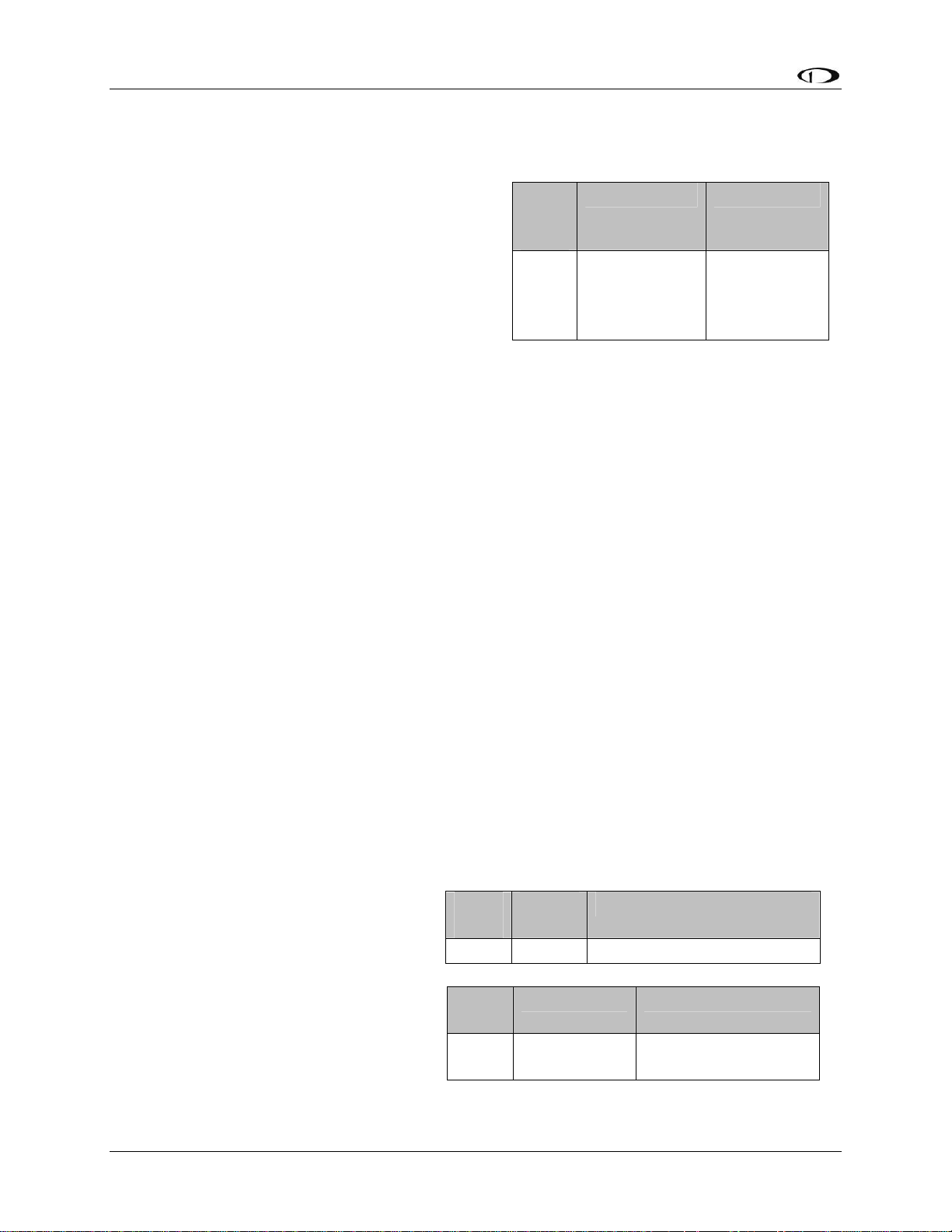

Grounding

Many of the engine sensors require a connection to a

shared electrical ground with the FlightDEK-D180. There

are many places on an aircraft where you could connect

these sensors. However, the ideal location to ground these

sensors is near the FlightDEK-D180 to minimize voltage

differences between the sensor and instrument grounds.

Some sensors (e.g., oil pressure and oil temperature)

connect to ground via their cases’ contact with the engine

or aircraft body. There must be a solid connection between

this “case ground” and the FlightDEK-D180 ground. The oil temperature sensor is very

susceptible to voltage differences between the engine case and the negative terminal of the

battery. Ensure that solid, thick electrical connections exist between the engine and battery

ground. Other sensors (e.g., fuel pressure) do not have a grounded case and have two leads

instead. One lead must be connected to ground, the other to the sensing input of the FlightDEKD180. The FlightDEK-D180 has 3 pins on the 37-pin harness which may be used for connecting

such sensors to ground. More than one sensor’s ground may be connected to any of these three

grounds using a splice.

The case of the FlightDEK-D180 is connected to its supply ground. If your panel is connected to

aircraft ground, the connection between the instrument’s case and the panel dramatically helps

minimize voltage differences between the instrument and sensor grounds. If your panel is not

metal, or is otherwise isolated from engine ground, connect a 14 AWG or larger wire to the

instrument case. The most convenient place to do this is at the back of the mounting tray.

Additionally, connect any unused EMS ground leads to a convenient ground. Keep all ground

leads as short as possible.

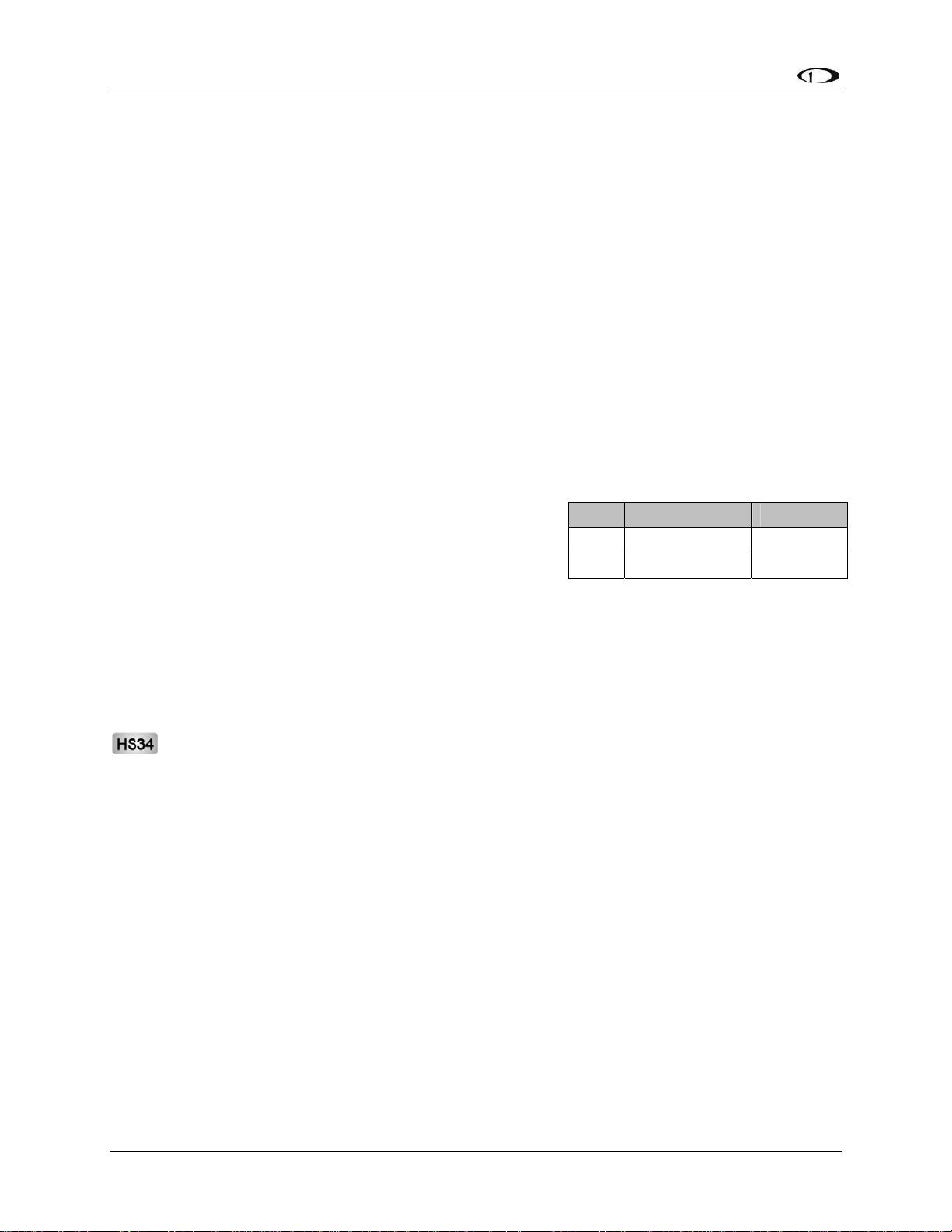

EMS

DB37

Pin

5 Black Ground

16 Black Ground

17 Black Ground

Color Function

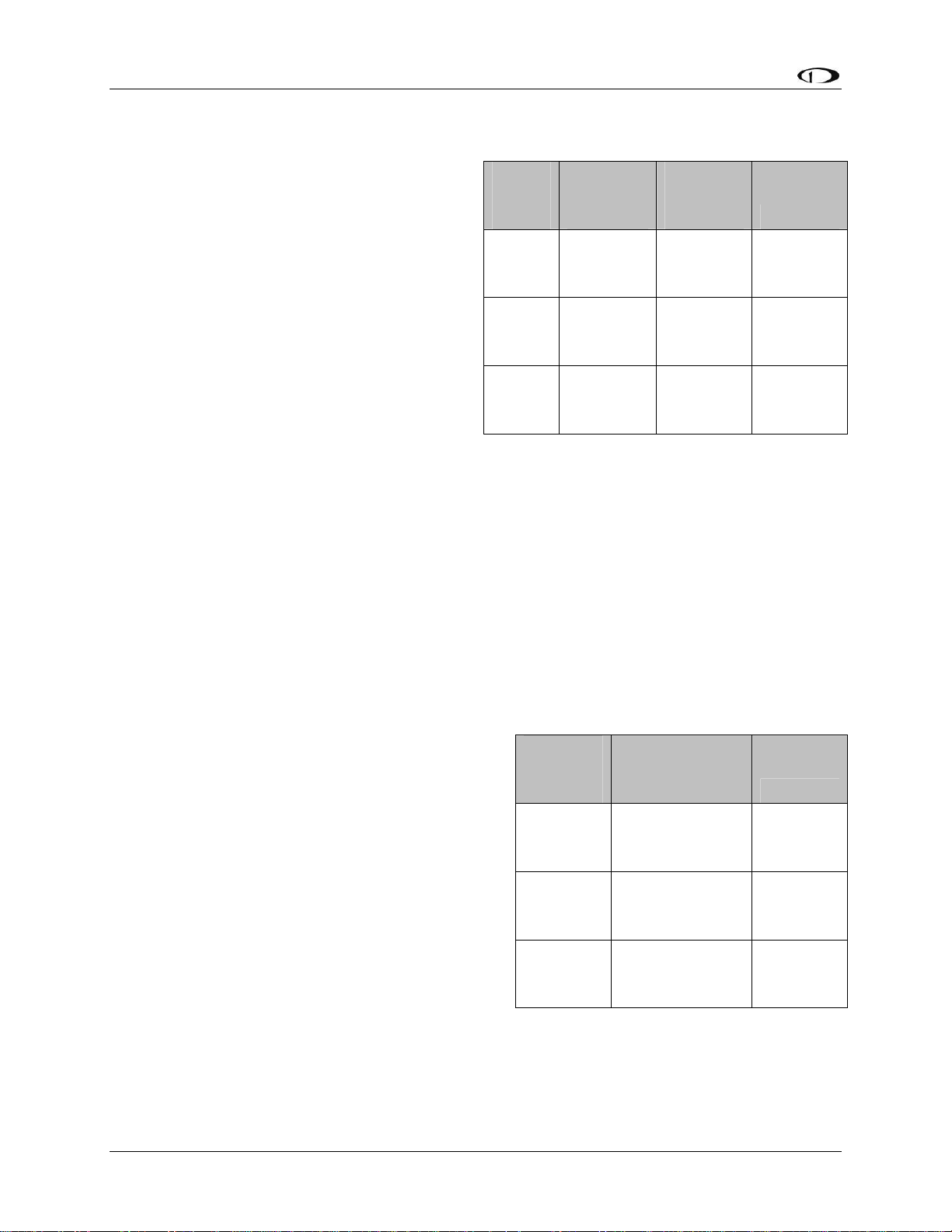

Because of the current drawn by the FlightDEK-D180, even very small resistances between

battery ground and instrument ground can cause voltage differences which adversely affect

engine sensor readings. An easy way to test the quality of the instrument’s ground is to measure

voltage between the ground pin at the FlightDEK-D180 and the ground lead at your aircraft’s

battery. With the FlightDEK-D180 powered on, connect one lead of your voltmeter to a free

ground lead coming from the FlightDEK-D180. Connect the other lead of your voltmeter to the

ground terminal of your battery. The voltage between these two points should measure very

close to 0 mV (within 5 mV). If it does not, you must improve the ground connection between

the ground of your battery and that of your avionics bus.

2-2 FlightDEK-D180 Installation Guide

Page 11

Wiring Overview

+5V Excitation

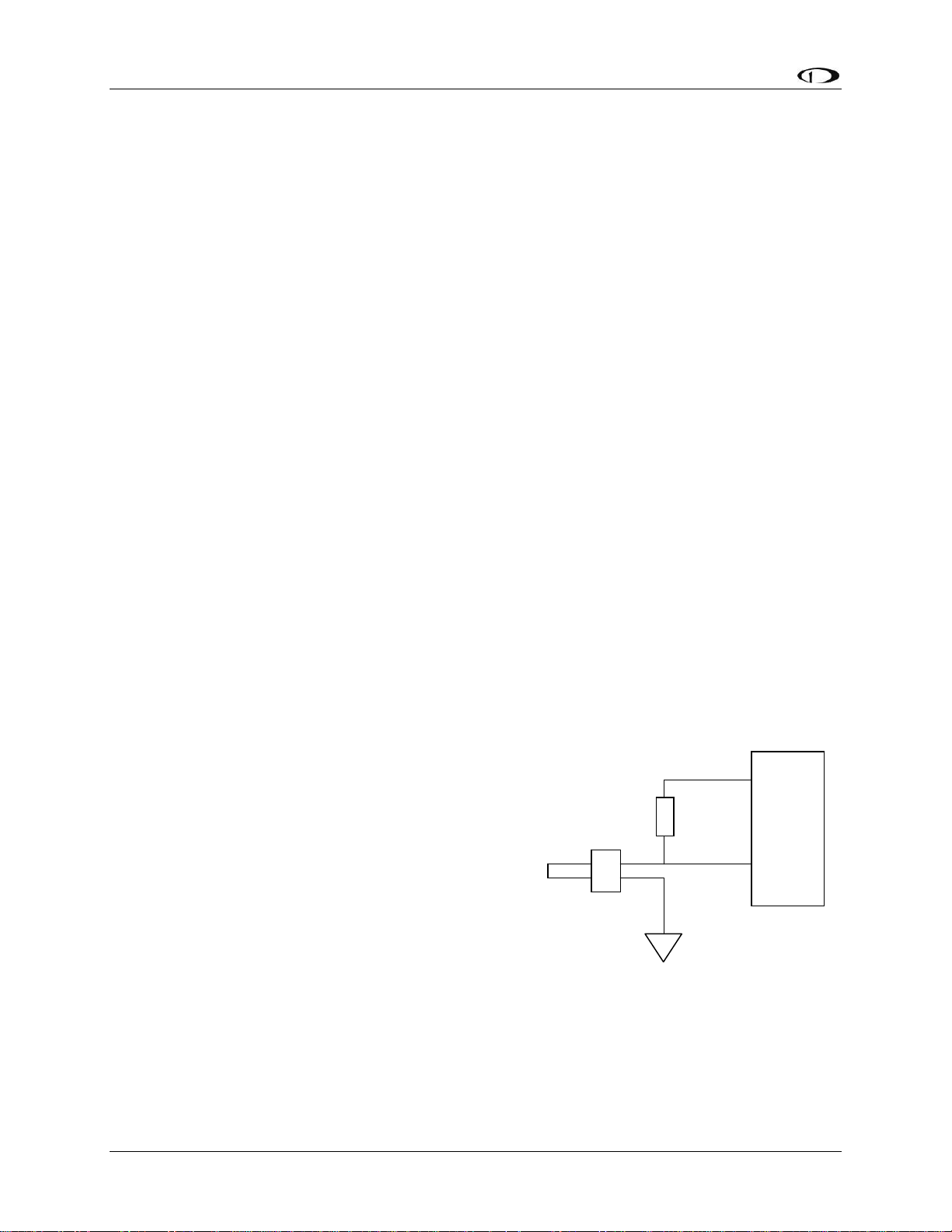

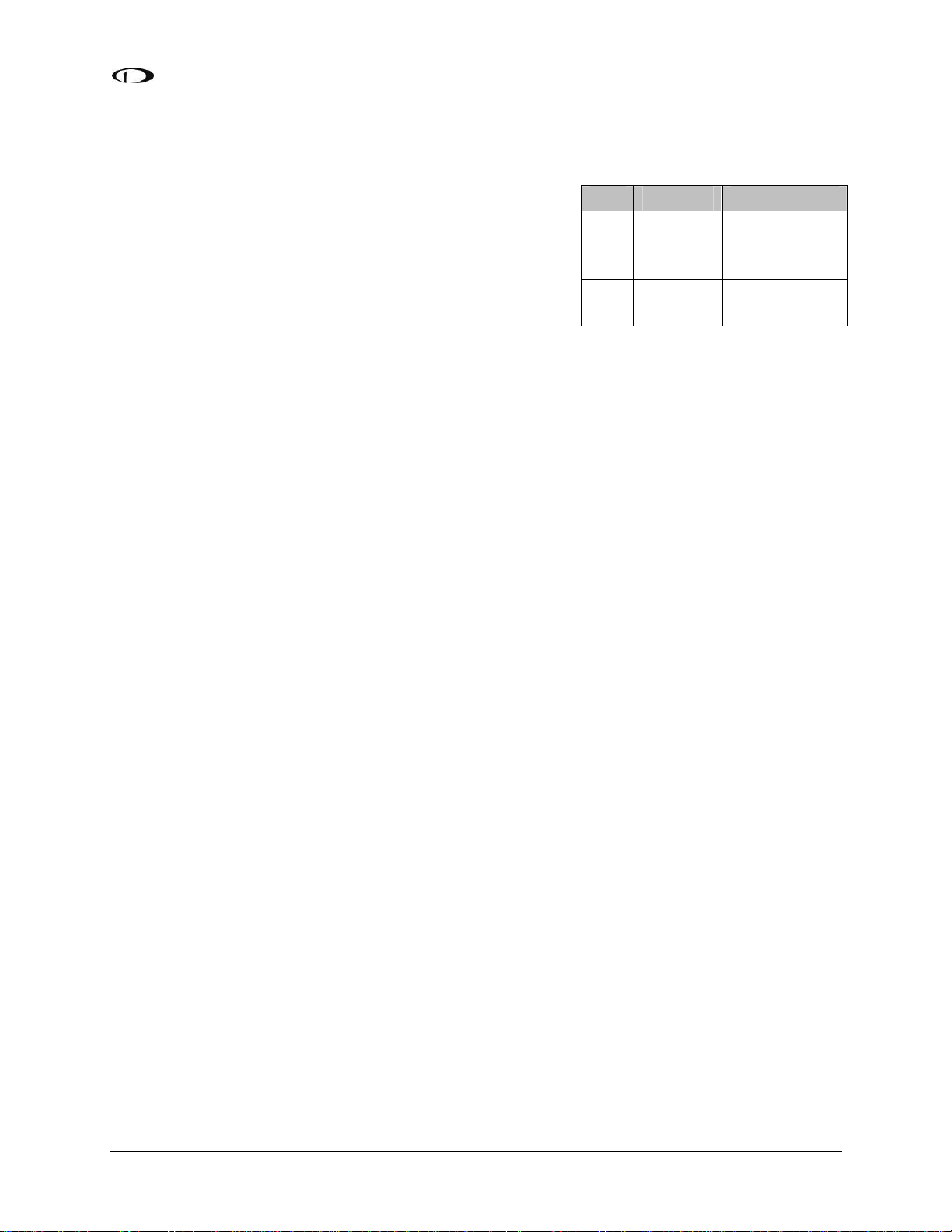

Some of the sensors require either a direct connection, or

connection via a resistor, to the +5V excitation circuit. We

recommend that you allow for more than one splice into

this line.

EMS

DB37

Pin

18 White/red

Color Function

+5V

excitation

Thermocouple Harness Preparation

Refer to the 25-Pin Male EMS Harness section on page 2-9 during this procedure. Strip 1” of

brown outer insulation off each thermocouple wire pair on the supplied 25-pin thermocouple

harness. Strip ¼” of insulation from each of the thermocouple wires inside. Crimp the supplied

male Fastons onto each wire on the thermocouple harness. These will later be inserted into the

female Fastons on each thermocouple.

Do not connect the Fastons on the harness with those on the thermocouples until you have routed

the wires and mounted the thermocouples at the desired location.

The thermocouple wires can be cut to a desired length if your application requires. If you need to

extend the length of the thermocouple, you must use the correct type (J or K) thermocouple wire

to accomplish this. It is acceptable to use non-thermocouple fasteners to join two pieces of

thermocouple pair wire, provided the junction does not extend very far or have large temperature

differences across it. Please contact Dynon Avionics to order extension wire.

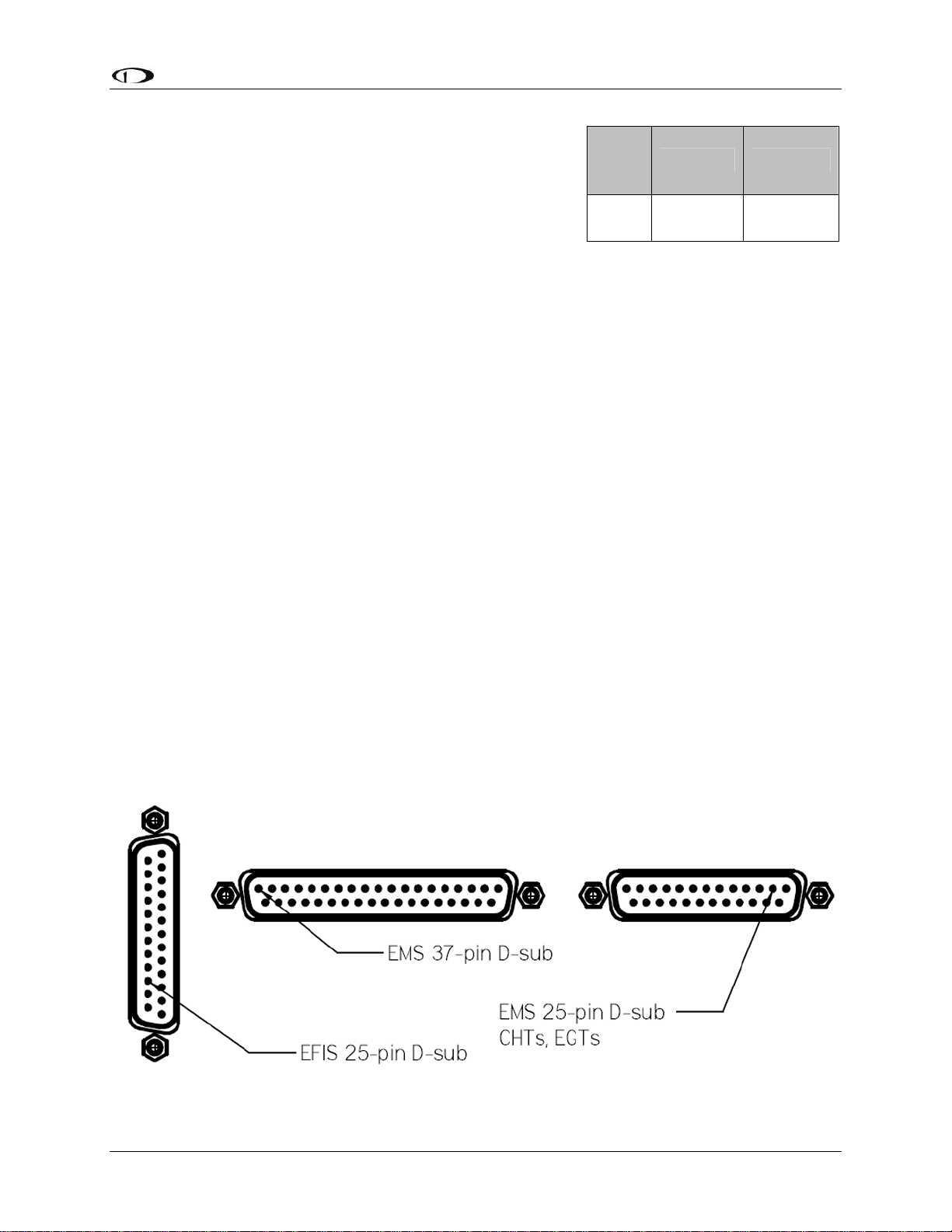

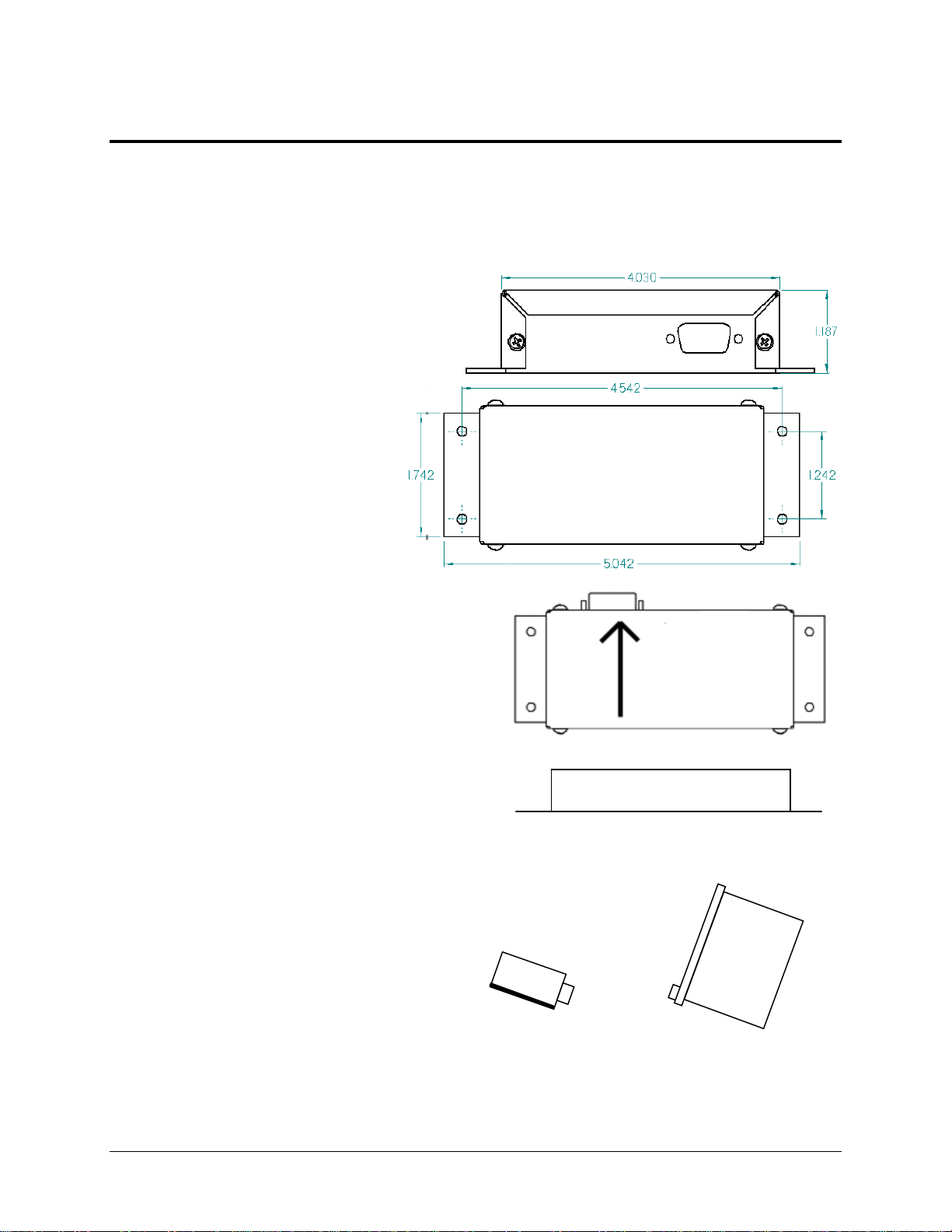

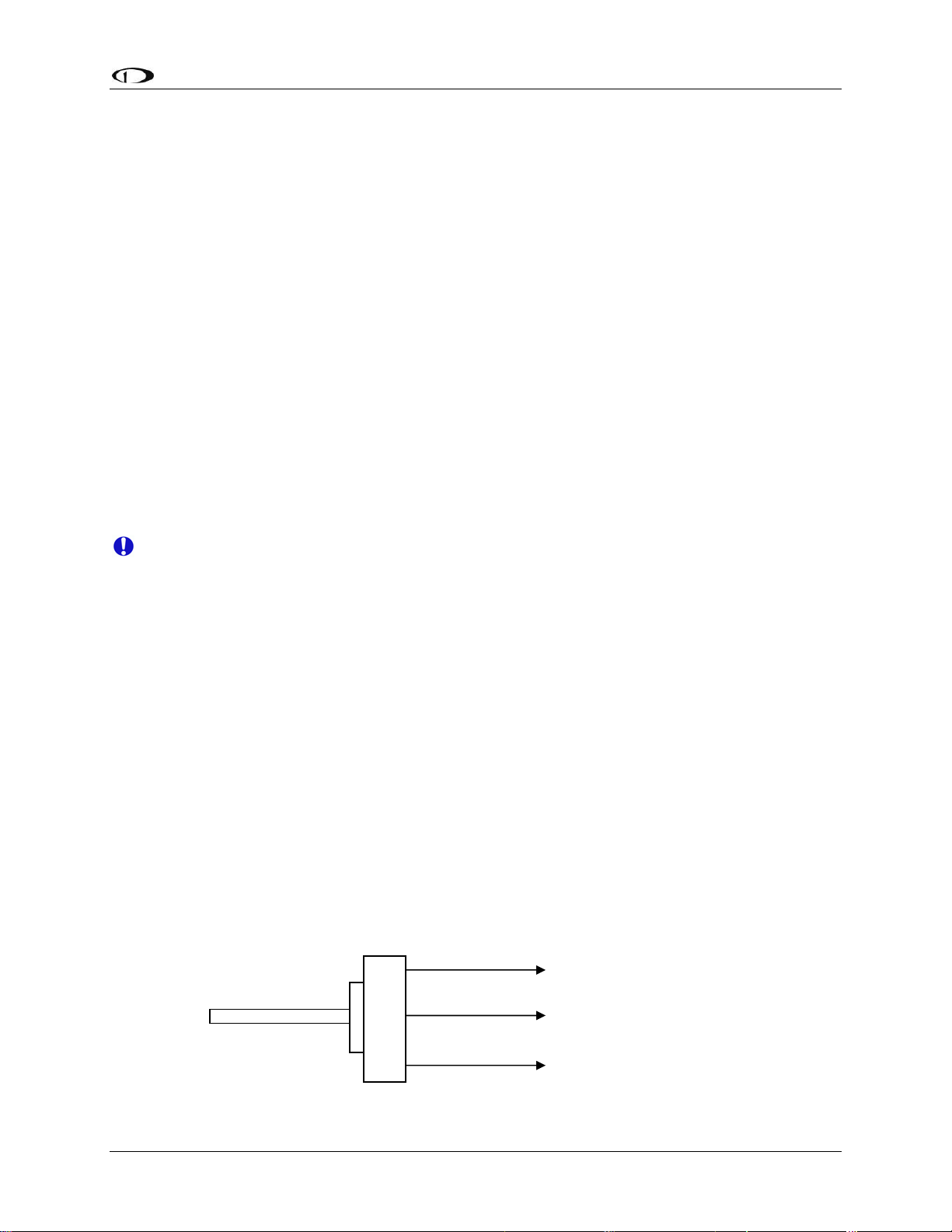

Harness Mating

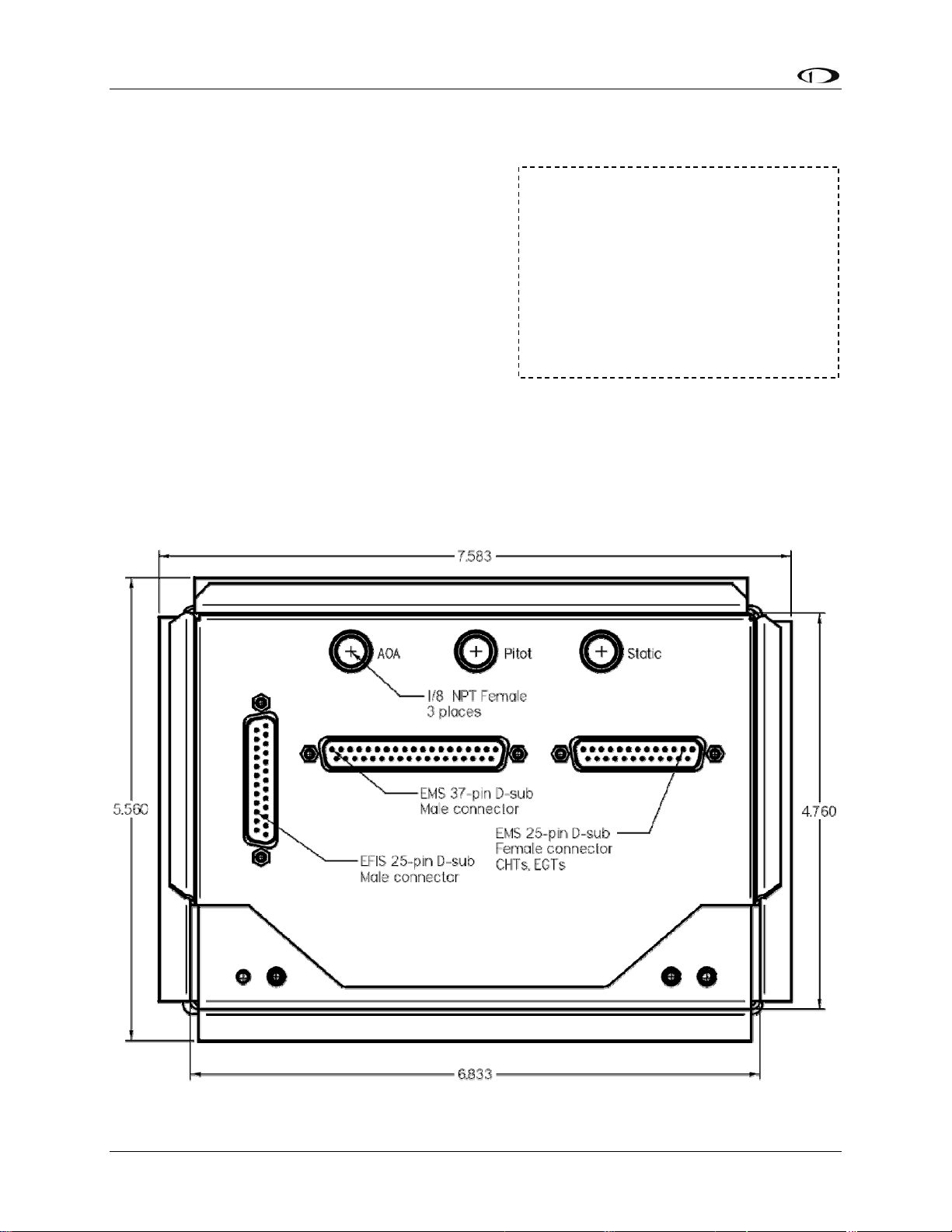

The following diagram shows the 3 electrical connectors on the back of the FlightDEK-D180.

The two horizontal connectors are used for the EMS portion of the product; the vertical

connector is used for the EFIS portion. The main EMS harness (for all connections except EGT

& CHT thermocouples) should terminate in a 37-pin female D-sub connector. The EGT/CHT

thermocouple harness should terminate in a 25-pin male D-sub connector. The EFIS harness

(also used to provide power to the instrument) should terminate in a 25-pin female D-sub

connector. The following pages provide wiring diagrams and details for each of these harnesses.

FlightDEK-D180 Installation Guide 2-3

Page 12

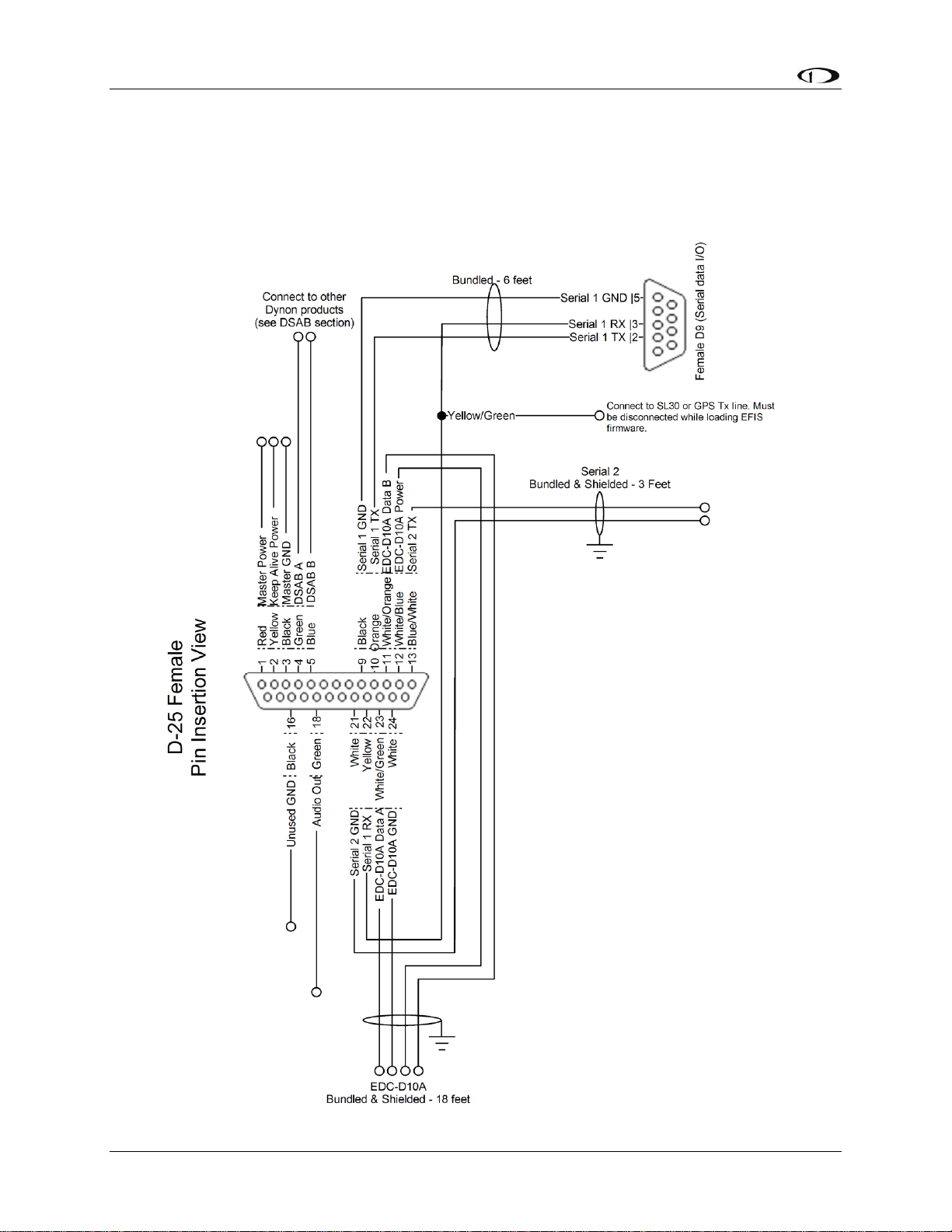

25-Pin Female EFIS Harness

Below is the wiring diagram of the EFIS 25-pin female harness. If you purchased your harness

from Dynon Avionics, it is color coded according to the chart on the following page. Unless

noted otherwise, all wires are 3 feet long on the Dynon-provided harness.

2-4 FlightDEK-D180 Installation Guide

Page 13

The pin assignments for the female 25-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

Female

DB25

Pin#

1 Red Master Power (10-30 volts) Page 4-2

2 Yellow Keep Alive Power (10-30 volts, always on) Page 4-2

3 Black Master Ground Page 4-2

4 Green DSAB-A Page 4-11

5 Blue DSAB-B Page 4-11

6 N/A No Connect

7 N/A No Connect

8 N/A No Connect

9 Black (bundled) PC Serial Ground – EFIS logging only Page 4-5

10 Orange (bundled)

11

12

13

14 N/A No Connect

15 N/A External Backup Power Page 4-2

16 Black Ground

17 N/A No Connect

18 Green Audio Alert Out Page 4-10

19 N/A No Connect

20 N/A No Connect

21

22 Yellow (Bundled)

23

24 White EDC-D10A GND Page 4-2

25 N/A No Connect

Dynon Harness

Wire Color

White/Orange (Red

on some harnesses)

White/Blue (Black

on some harnesses)

Blue/White (black

on some harnesses)

White (Bundled in

Encoder cable)

White/Green (Green

on some harnesses)

Function Details

FlightDEK-D180 Transmit / PC Serial

Receive (RS-232) – EFIS logging only

EDC-D10A Data B

EDC-D10A Power (12V)

Serial Encoder Transmit (RS-232)

Serial Encoder Ground

FlightDEK-D180 Receive / PC Serial

Transmit (RS-232) – EFIS logging

EDC-D10A Data A

Page 4-4

Page 4-2

Page 4-2

Page 9-32

Page 9-32

Page 4-5

Page 4-2

FlightDEK-D180 Installation Guide 2-5

Page 14

Wiring Overview

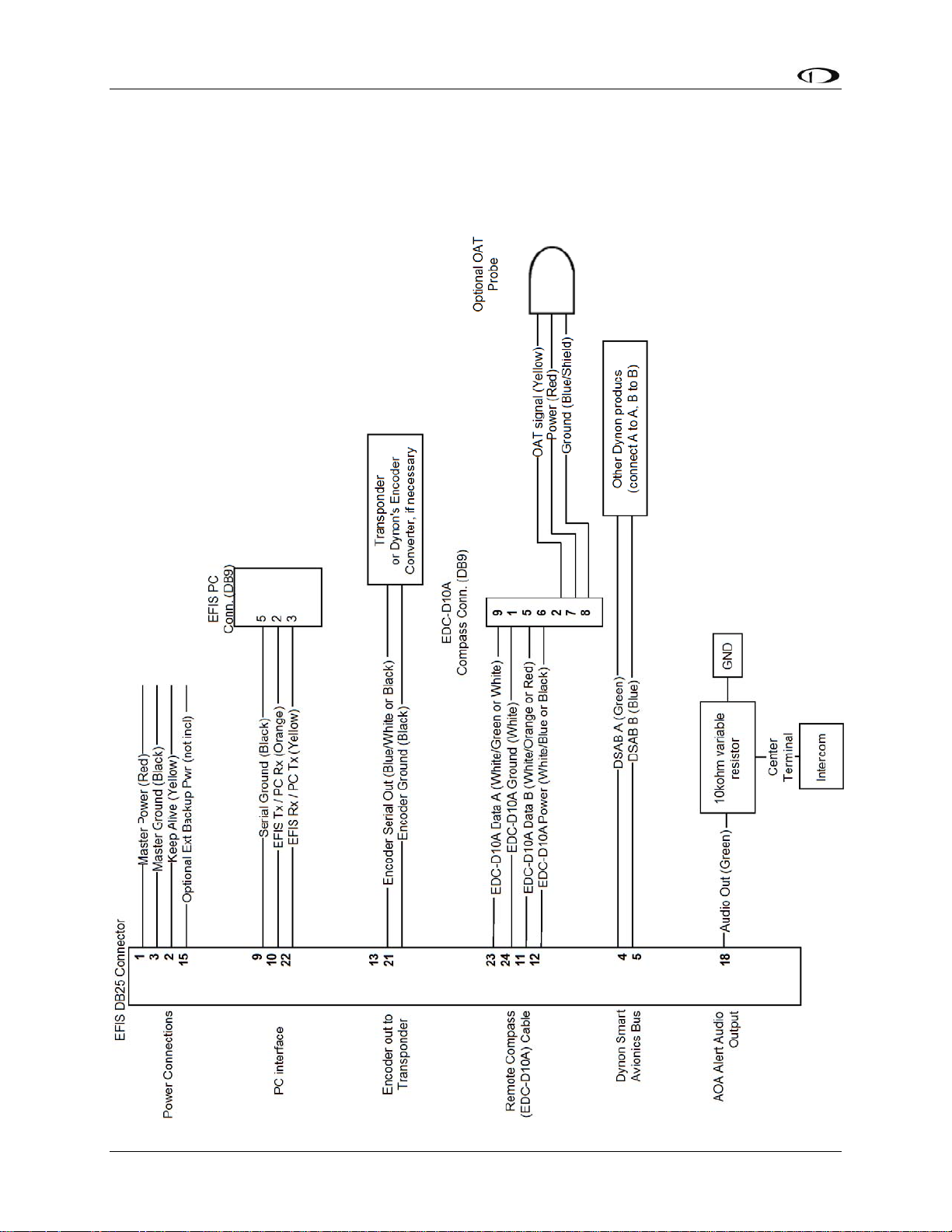

WIRING SYSTEM OVERVIEW

The following block diagram depicts the basic layout of the EFIS DB25 electrical connections

and is for reference only. Read the specific instructions for each connection prior to installation.

The colors shown refer to the Dynon-supplied EFIS harness.

2-6 FlightDEK-D180 Installation Guide

Page 15

Wiring Overview

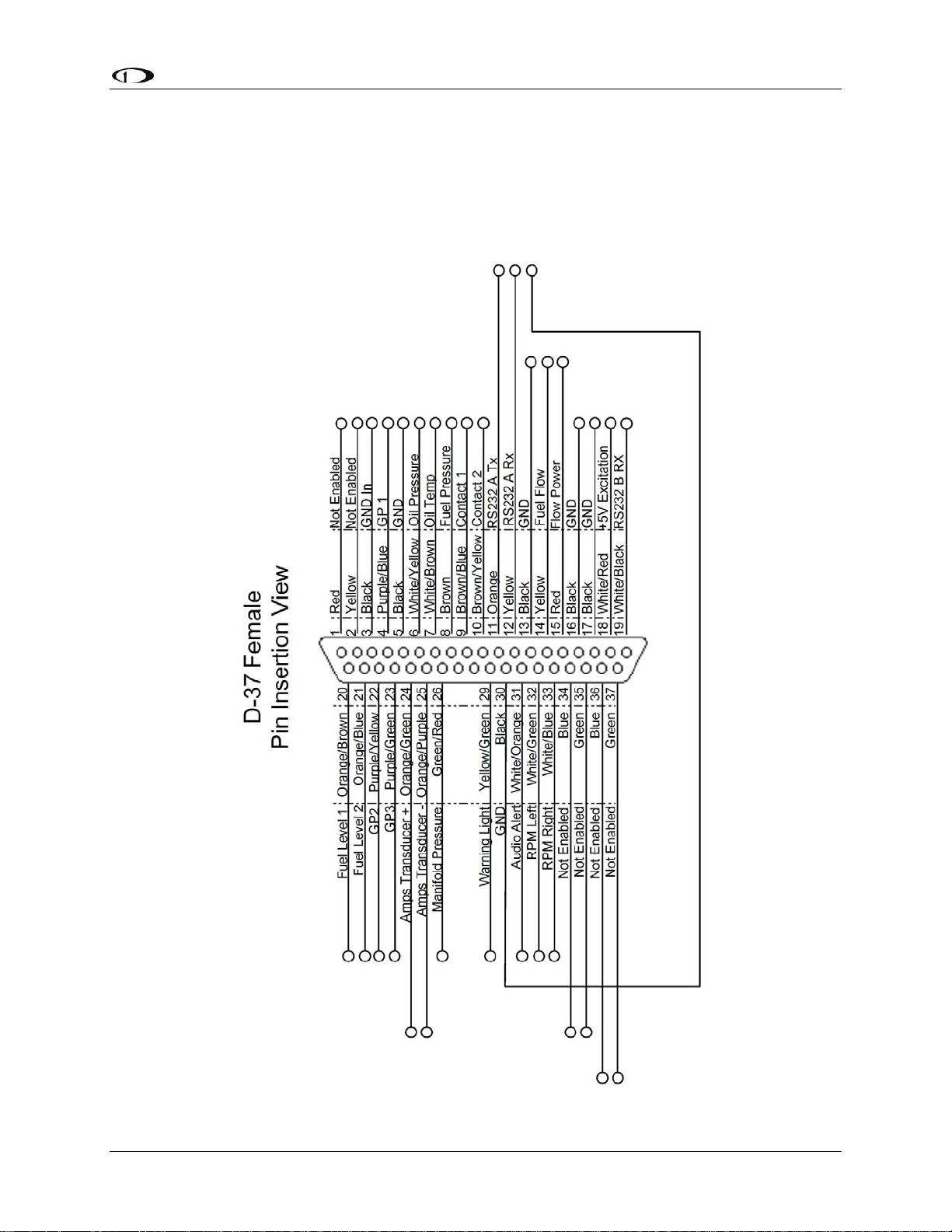

37-Pin Female EMS Harness

Below is the wiring diagram of the EMS 37-pin female harness. If you purchased your harness

from Dynon Avionics, pins 1, 2, 34, 35, 36, and 37 have wires inserted, but are not used. You

may clip the wires or remove the pins as needed. Refer to the following page for detailed pin out

descriptions.

FlightDEK-D180 Installation Guide 2-7

Page 16

Wiring Overview

The pin assignments for the female 37-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

DB37 harness

Pin#

1 Red

2 Yellow

3 Black Ground Page 2-2

4 Purple/blue GP 1 (general purpose resistive) Page 3-13

5 Black Ground Page 2-2

6 White/yellow Oil pressure Page 3-6

7 White/brown Oil temperature Page 3-7

8 Brown Fuel pressure Page 3-7

9 Brown/blue Contact 1 Page 3-18

10 Brown/yellow Contact 2 Page 3-18

11

12

13 Black Ground (Fuel Flow) Page 3-9

14 Yellow Fuel flow input Page 3-9

15 Red Fuel flow power (12V) Page 3-9

16 Black Ground Page 2-2

17 Black Ground Page 2-2

18 White/red 5V excitation circuit Page 2-3

19 White/black Auxiliary Serial Receive (RS-232) Page 4-6

20 Orange/brown Fuel level 1 Page 3-11

21 Orange/blue Fuel level 2 Page 3-11

22 Purple/yellow GP 2 (General Purpose Resistive) Page 3-13

23 Purple/green GP 3 (General Purpose Resistive) Page 3-13

24 Orange/green Amps High Page 3-12

25 Orange/purple Amps Low Page 3-12

26 Green/red Manifold pressure Page 3-5

27

28

29 Yellow/green External warning light Page 4-10

30 Black PC Serial ground – EMS logging only Page 4-5

31 White/orange Intercom audio alert Page 4-10

32 White/green RPM left Page 3-4

33 White/blue RPM right Page 3-4

34 Blue

35 Green

36 Blue

37 Green

Dynon Harness

Wire color

Orange FlightDEK-D180 Transmit / PC Serial

Receive (RS-232) – EMS logging only

Yellow FlightDEK-D180 Receive / PC Serial

Transmit (RS-232) – EMS logging only

Not supplied

Not supplied

General purpose thermocouple (J or K-type) Page 3-19

General purpose thermocouple (J or K-type) Page 3-19

Function Details

Do not connect

Do not connect

Do not connect

Do not connect

Do not connect

Do not connect

Page 4-5

Page 4-5

2-8 FlightDEK-D180 Installation Guide

Page 17

Wiring Overview

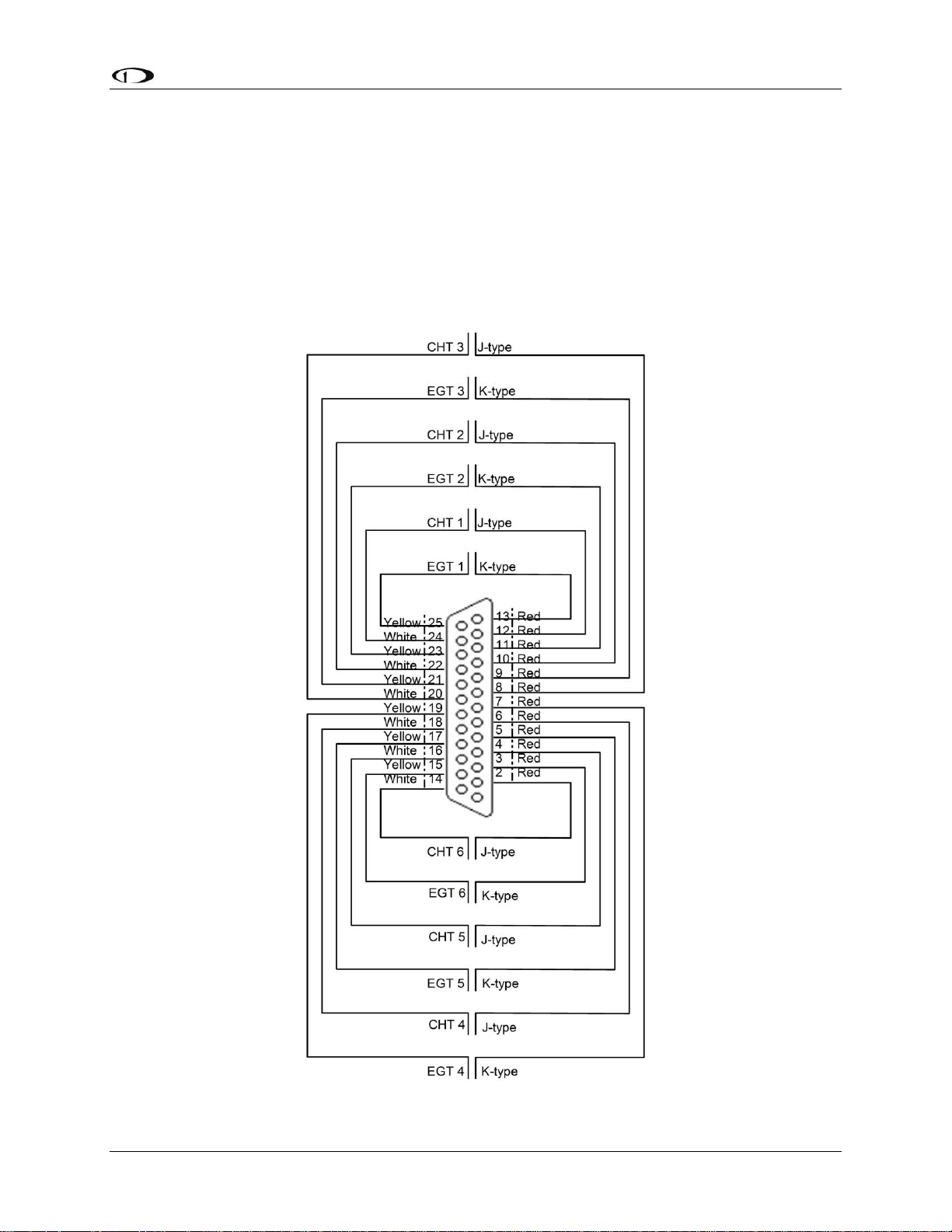

25-Pin Male EMS Harness

Below is the EMS 25-pin harness wiring diagram. The 4-cylinder harness only has EGTs 1

through 4 and CHTs 1 through 4 wired. The Rotax harness only has EGTs 1 and 2 wired, as the

EMS measures the Rotax-supplied resistive CHTs through its GP inputs. On the supplied

harness, each pair of wires is encased in brown insulation and labeled with corresponding

cylinder number. Inside the outer insulations, each wire in the pair has the color listed on the

diagram below. If you are making your own harness, utilize J & K type thermocouple wire as

indicated in the diagram.

FlightDEK-D180 Installation Guide 2-9

Page 18

Page 19

3. TRANSDUCER INSTALLATION

This section explains the steps required to install and connect all transducers supplied by Dynon

Avionics. Additionally, connection instructions are given for some transducers that Dynon

Avionics does not sell, like the tachometer, fuel level, flaps, trim, and contacts.

Tools and Equipment Required

The following list contains commonly used tools and equipment; however some of the tools or

equipment listed below may not apply to your installation.

Wire strippers

22 AWG wire (if harness not purchased or extending harness beyond 6 feet)

D-sub pin crimper

Faston/ring terminal crimp tool

o Available from www.bandcspecialty.com – (316) 283-8000 – part number RCT-1

Weather Pack crimp tool (common slip joint pliers will also work)

o Available from www.whiteproducts.com/tools.shtml

#2 Phillips screwdriver

Flathead screwdriver

¼” ID tubes, any necessary adapters, and clamps for routing manifold pressure to the

sensor.

Drill and 1/8” bit

FlightDEK-D180 Installation Guide 3-1

Page 20

Transducer Installation

Exhaust Gas Temperature (EGT) Probes

Correct placement of EGT probes on the exhaust manifold is critical to obtaining accurate

readings. Placement differs between engine types, and even specific models. Consult your

specific engine’s manual for proper EGT locations.

ROTAX ENGINES

For Rotax 912 engines, only two of the four cylinders are typically monitored for EGT. Unlike

the CHT probes which are mounted on diagonal cylinders, the EGT probes should be mounted

on the two rear cylinders’ exhaust manifolds. It is critical that the EGT probes be mounted to

parallel cylinders’ exhaust manifolds for proper temperature comparison.

ALL ENGINES

Once you have determined the appropriate EGT locations for your engine, drill 1/8” diameter

holes at the specified positions in the exhaust manifold. Usually, this spot is 2 to 8 inches from

the cylinder. This spot should be on a straight portion of the exhaust manifold, as this provides a

better fit for the hose clamps. For best results, mount all probes the same distance from each

cylinder.

1. Make sure the hole is placed to ensure that the probe does not interfere with the cowl or

spark plug. Also, when making holes, keep in mind that the probe could inhibit the ability

to perform routine maintenance if placed incorrectly.

2. Place probe in exhaust manifold, and secure it by tightening the clamp with a flathead

screwdriver. Make sure the clamp is tight and provides a secure fit, but do not over-tighten

such that visible stress is put on the pipe.

Now, plug each thermocouple wire into its corresponding wire on the thermocouple harness.

Ensure that you match the wire color pairs on the harness to those on the thermocouple. All

thermocouple harnesses supplied by Dynon have each function (e.g., CHT1, EGT1) labeled on

each thermocouple pair.

A loose probe could allow exhaust to leak. This can lead to carbon monoxide poisoning

in the cabin and/or a potential fire. Have a knowledgeable mechanic inspect the

installation.

The probe can come lose during flight, and could potentially come in contact with

rotating engine parts or the propeller. We suggest a safety wire to keep the probe in place.

3-2 FlightDEK-D180 Installation Guide

Page 21

Transducer Installation

Cylinder Head Temperature (CHT) Probes

Dynon Avionics sells and supports a variety of CHT probes. All thermocouple harnesses

supplied by Dynon have each function (e.g., CHT1, EGT1) labeled on each thermocouple pair.

LYCOMING/CONTINENTAL

Dynon Avionics sells bayonet style CHT probes (used in Lycoming and Continental engines).

With each probe we sell, a bayonet adapter is included. Your specific engine manual should

describe where to mount these bayonet adapters, but normally, there is a threaded hole (CHT

well) near the bottom of the cylinder close to the lower spark plug. Screw the bayonet adapter

into this hole. Screw the locking collar up or down the spring surrounding the probe such that the

tip of the probe is pressed against the bottom of the CHT well when the collar is attached to the

adapter. Insert the CHT probe into the well and lock the collar to the adapter. Now, plug each

thermocouple wire into its corresponding wire on the thermocouple harness. Ensure that you

match the wire color pairs on the harness to those on the thermocouples.

ROTAX

Rotax 912 engines use 2 resistive CHT probes that are included with the engine. These probes

are preinstalled, but you need to route the connections from them to the FlightDEK-D180. See

the CHT General Purpose Installation section on page 3-15 for information on making the

physical connection to the sensor.

JABIRU

Jabiru engines require a 12mm ring-terminal CHT probe for each cylinder. First, slide the

compression washer off the spark plug. Slide the 12mm ring-terminal probe onto the plug. Now,

slide the spark plug compression washer back onto the spark plug. Reinstall the spark plug into

the spark plug hole. Please refer to the documentation that came with your engine for more

information. Now, plug each thermocouple wire into its corresponding wire on the thermocouple

harness. Ensure that you match the wire color pairs on the harness to those on the thermocouples.

FlightDEK-D180 Installation Guide 3-3

Page 22

Transducer Installation

Tachometer

Dynon Avionics does not sell a tachometer transducer.

Depending upon existing equipment and engine type,

you have a few options for connecting the tachometer

inputs on the FlightDEK-D180. See the relevant

subsections below for your particular method. You may

connect different types of signals to the two different RPM inputs (e.g., p-lead to RPM Left and a

12V transducer to RPM Right). Once you have connected the tachometer inputs according to

your engine and transducer type, you must set the appropriate pulses/revolution as described on

page 6-8.

TACHOMETER TRANSDUCER

If you have a standard tachometer transducer (usually with a 12V output), you may simply

connect its output to the RPM Left input on the FlightDEK-D180. Ensure that you follow all

recommendations given in the manual for your individual tachometer transducer.

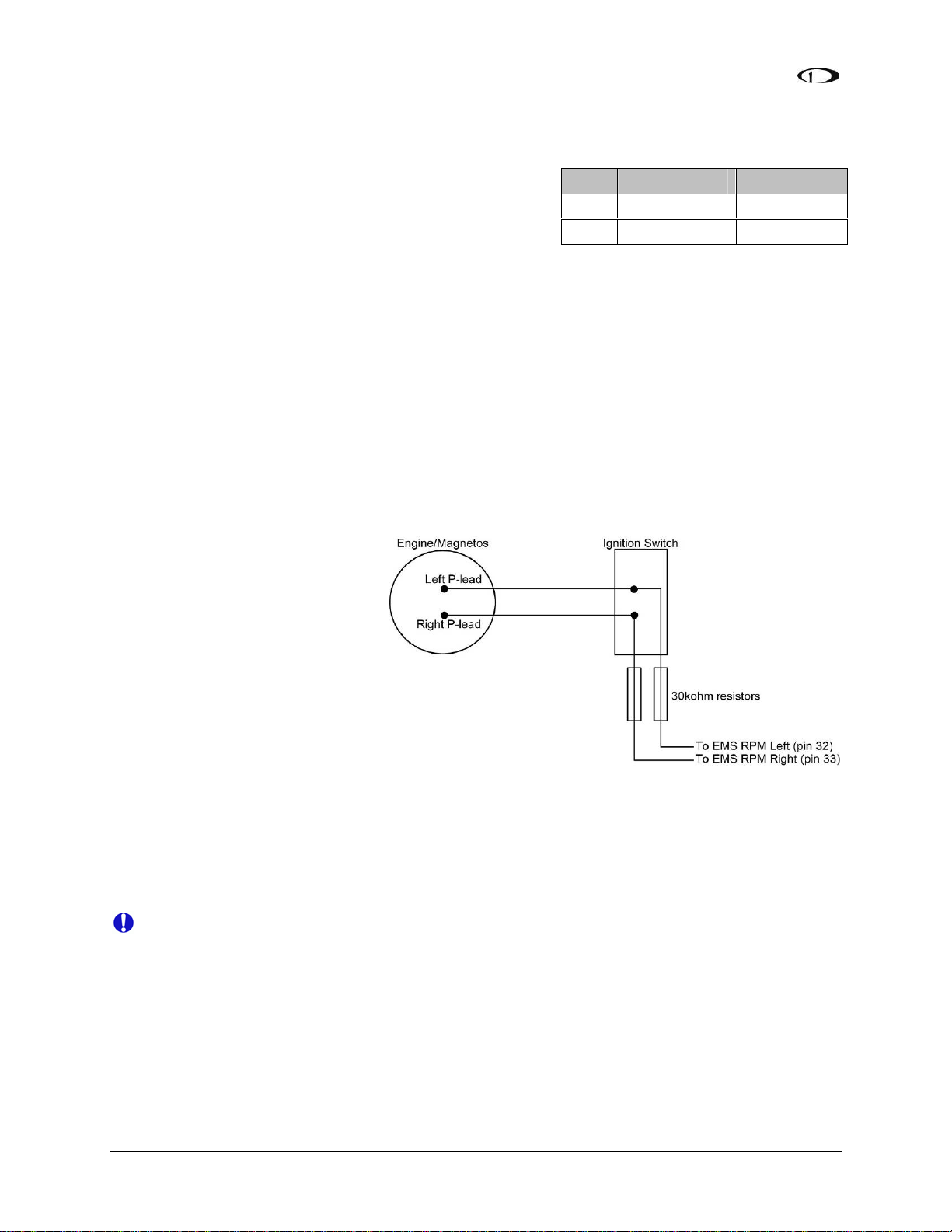

P-LEAD PICKOFF (LYCOMING AND CONTINENTAL)

If you do not have a standard

tachometer pickoff, you must

follow the instructions below. The

magneto P-lead has high voltages

which can very easily damage the

FlightDEK-D180 if not dealt with

properly.

Pin Color Function

32 White/green RPM Left

33 White/blue RPM Right

Use the two included 30kΩ

resistors (color bands: orange,

black, brown, red, brown; connect

in either direction) to attach left

and right P-leads to the RPM Left

and RPM Right inputs on the FlightDEK-D180. Connect them as shown in the following

diagram. It is important to connect each resistor as close as possible to the spot where you tap

into the P-lead. This minimizes the length of cable carrying high voltage spikes. 6 cylinder

Lycoming engines sometimes need more inline resistance to prevent false readings by the

FlightDEK-D180.

If, after setting the PULS/REV R and L values as described on page 6-8, you see higher

than expected RPM or unstable values, you may need to increase the series resistance to

as high as 150kΩ.

TRIGGER COIL (ROTAX)

The Rotax 912 engines have a 5th trigger coil for the purposes of electrically monitoring rev

counts. This trigger coil outputs to a two-wire harness. Connect either of the two wires to

ground; connect the other to one of the included 30kΩ resistors (color bands: orange, black,

3-4 FlightDEK-D180 Installation Guide

Page 23

Transducer Installation

y

brown, red, brown; connect in either direction). Connect the other end of the resistor to the RPM

Left input on the FlightDEK-D180.

ALTERNATOR WIRE (JABIRU)

The most common tachometer pickoff location for Jabiru 2200 and 3300 engines is one of the

alternator wires. Splice a wire off one of the two white alternator wires, connect it through a 1amp fuse to the RPM Left input on the FlightDEK-D180.

DIGITAL IGNITION AND OTHER PICKOFFS

The FlightDEK-D180 can read frequency-based RPM signals, provided the peak voltage is at

least 10 volts above ground. If the peak voltage exceeds 50 volts, use the included 30kΩ resistors

as described in the P-lead Pickoff section above. Like the other methods above, you must know

the number of pulses per revolution for your RPM transducer.

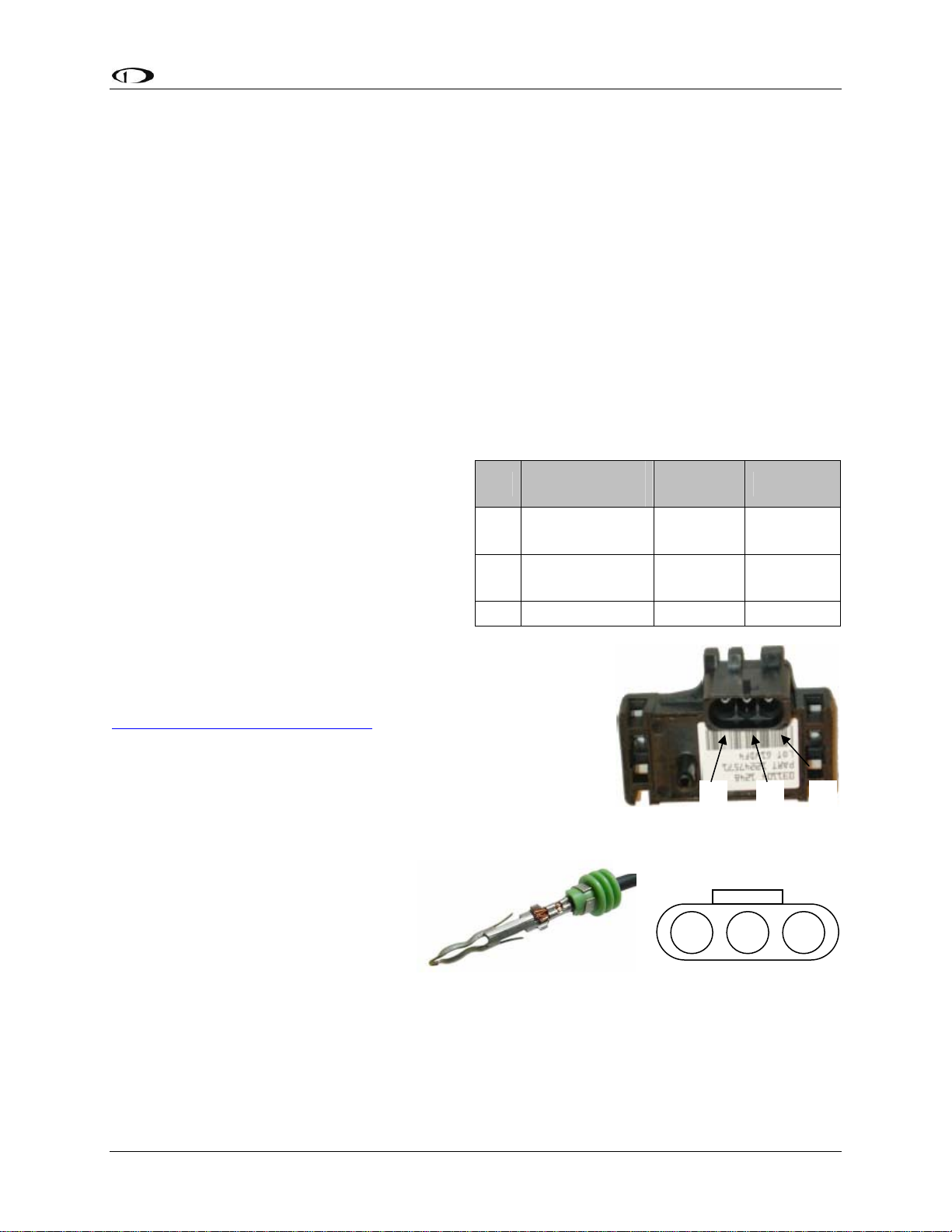

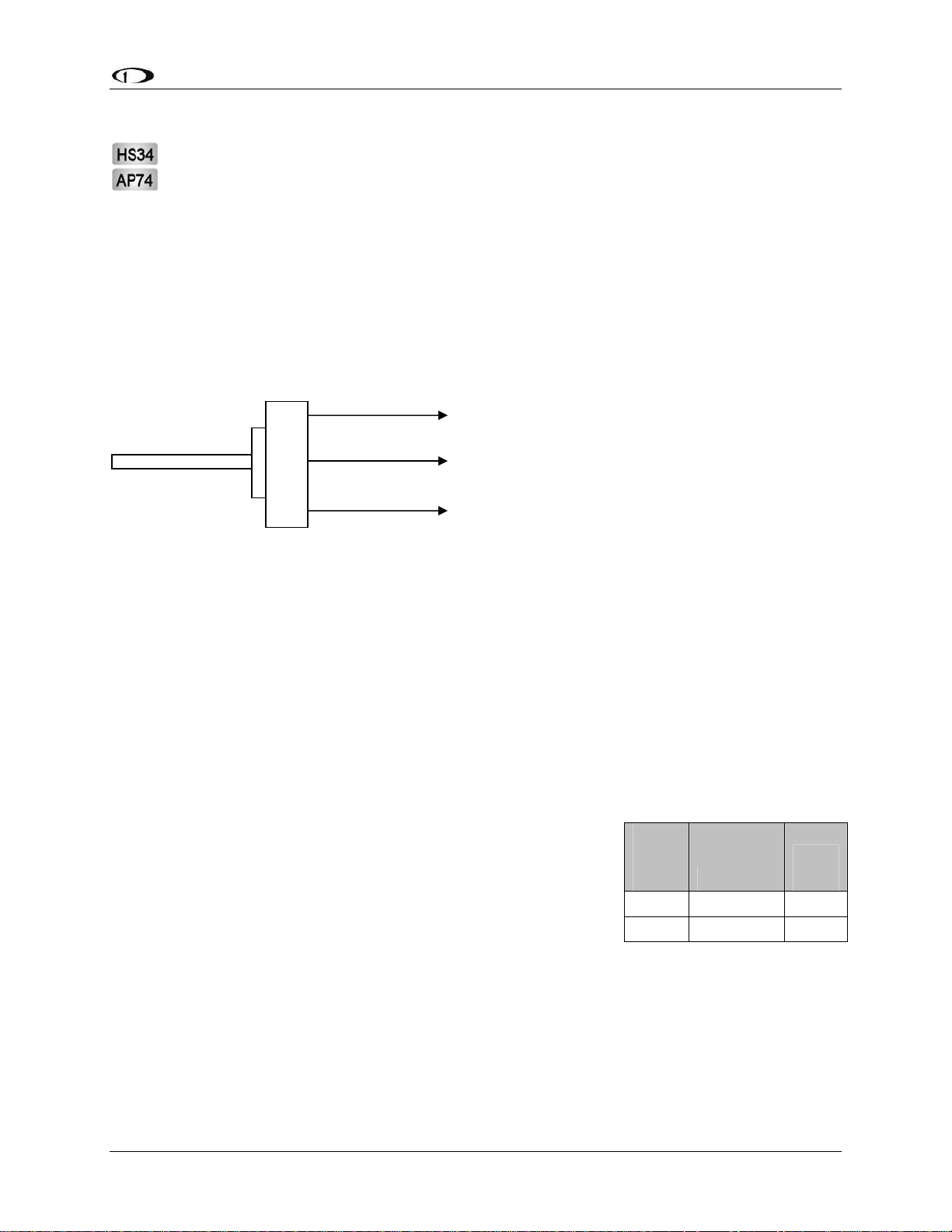

Manifold Pressure Sensor

The manifold pressure sensor is an integral

Pin

assembly consisting of three pins, a rubber

seal, and a connector housing. Strip 3/16”

18 C White/red

insulation off the ends of the three wires

listed at right. Slide the three rubber seals

26 B Green/red

onto the three wires and the pins onto the

ends of the wires. Crimp the 3 provided pins

17 A Black Ground

onto the ends of the wires, ensuring that the

long tabs that cradle the rubber seal wrap

around the seal (see picture at right for example). For more

details on preparing and crimping the Weather Pack pins, see

www.whiteproducts.net/faqs.shtml.

Weather

Pack Pin#

Color Function

+5V

excitation

Manifold

pressure

Note that you will need access to the +5V excitation circuit for

other sensor installations, so make allowances for breaking out

the connection to other areas. Route the three wires to the

C

B A

location where you would like to mount the manifold pressure

sensor.

Figure 1 Connection diagram for

sensor with all black wires only

Plug the crimped pins into the

provided Weatherpack connector.

Now, mount the manifold pressure

sensor in a secure fashion using the

C

B A

mounting holes on either side of the

sensor.

The pressure port on the manifold

pressure sensor requires 1/4” inner

Figure 3: Detail view of properl

crimped pin.

Figure 2: Pin insertion

(rear) view of supplied

connector.

diameter tubing for a secure fit. You may need to use adapters to

convert down to smaller inner diameter tubing for your specific engine. We recommend that you

use pipe clamps at every transition point, including at the sensor itself.

FlightDEK-D180 Installation Guide 3-5

Page 24

Transducer Installation

If you notice fluctuations on the manifold pressure reading on the FlightDEK-D180, you may

need to install a restrictor with a small hole inline between the sensor and the head where the

manifold pressure line is split off.

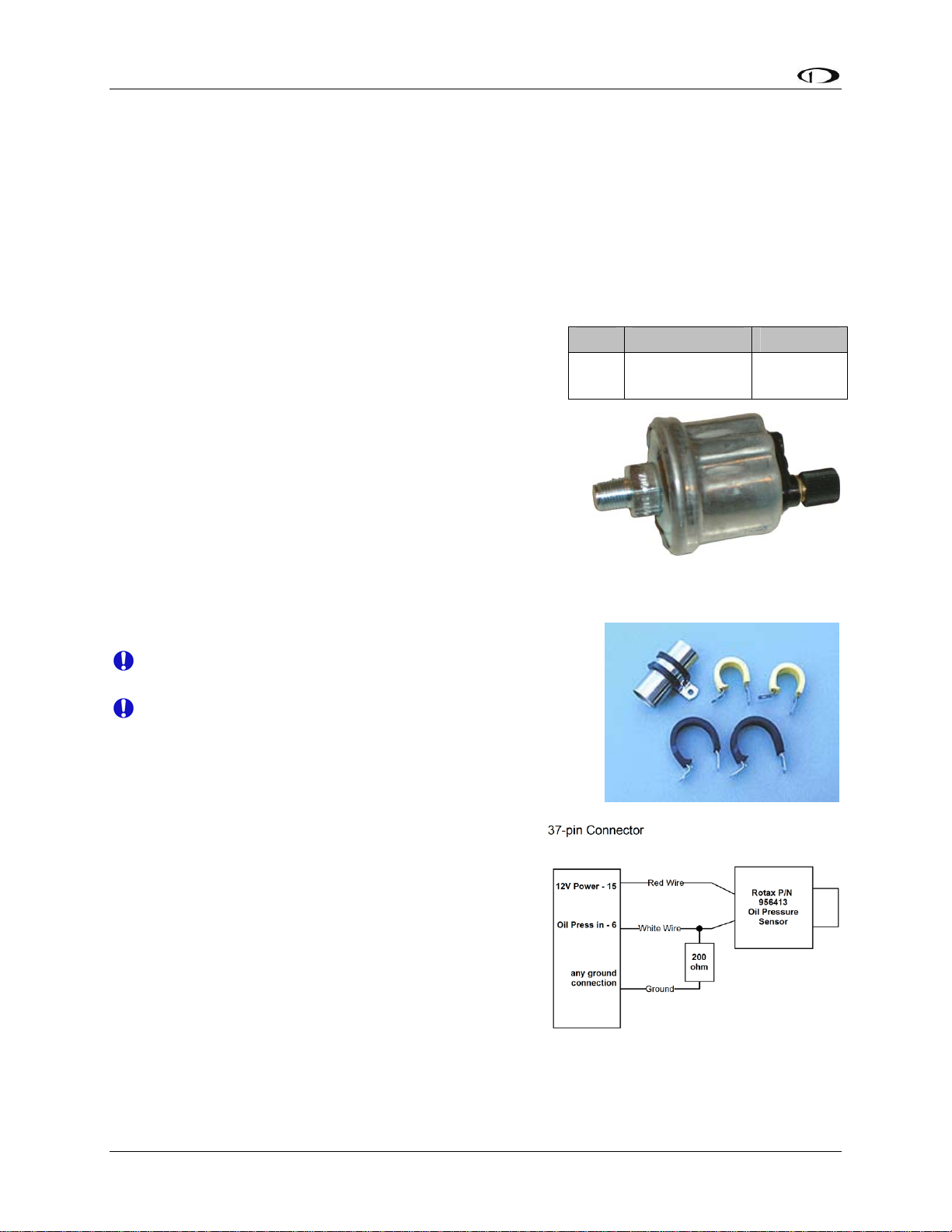

Oil Pressure Sensor

The FlightDEK-D180 supports several oil pressure sensor installations. The Dynon-supplied

sensor and the Rotax and Jabiru pre-installed sensors are the most common.

DYNON-SUPPLIED OIL PRESSURE SENSOR

First, mount the oil pressure sensor to a fixed location

using an Adel clamp (see picture at lower right) or other

secure method. The oil pressure sensor must not be

installed directly to the engine due to potential vibration

problems. Dynon Avionics’ sensor is supplied with a

1/8” NPT pipe thread fitting. An adapter might be necessary

for some engines. Please see the manual supplied by the

engine’s manufacturer. You must use appropriate pipe fitting

adapters and ensure that the case of the sender has a

connection to ground. This is critical for functionality.

Crimp a standard #8 ring terminal onto the white/yellow wire

from pin 6. Unscrew the stud cap from the threaded stud.

Place the ring terminal on the stud and secure the cap down

sandwiching the ring terminal.

Due to vibration issues, never connect the sensor

directly to the engine.

If you use Teflon tape or other seal, ensure the sensor

casing still maintains a good connection to ground.

JABIRU AND ROTAX OIL PRESSURE

Pin Color Function

6 White/yellow

1/8-27 NPT

0-150 PSI

Oil

pressure

If you are installing on a Jabiru or Rotax engine, your engine

comes with a pre-installed oil pressure sensor.

Prior to mid-2008, Rotax provided an oil pressure

sensor with 2 tabs for electrical connection. In mid2008, Rotax switched to a new type of oil pressure

sensor (Rotax P/N 956413) with an integrated 2-wire

cable. Connect this newer sensor according to the

wiring diagram at right. Connect the red wire of the

new sensor to EMS DB37 Pin 15 (12V). Connect the

white wire of the new sensor to EMS DB37 Pin 6.

Then, connect one end of a 200Ω resistor to pin 6,

and the other end to ground. The Jabiru and both types of Rotax oil pressure sensors are

compatible with the FlightDEK-D180. Select the correct sensor type as described in the Oil

Pressure Configuration section on page 6-9.

3-6 FlightDEK-D180 Installation Guide

Use an Adel clamp similar to the

above to secure the pressure sensor

Page 25

Transducer Installation

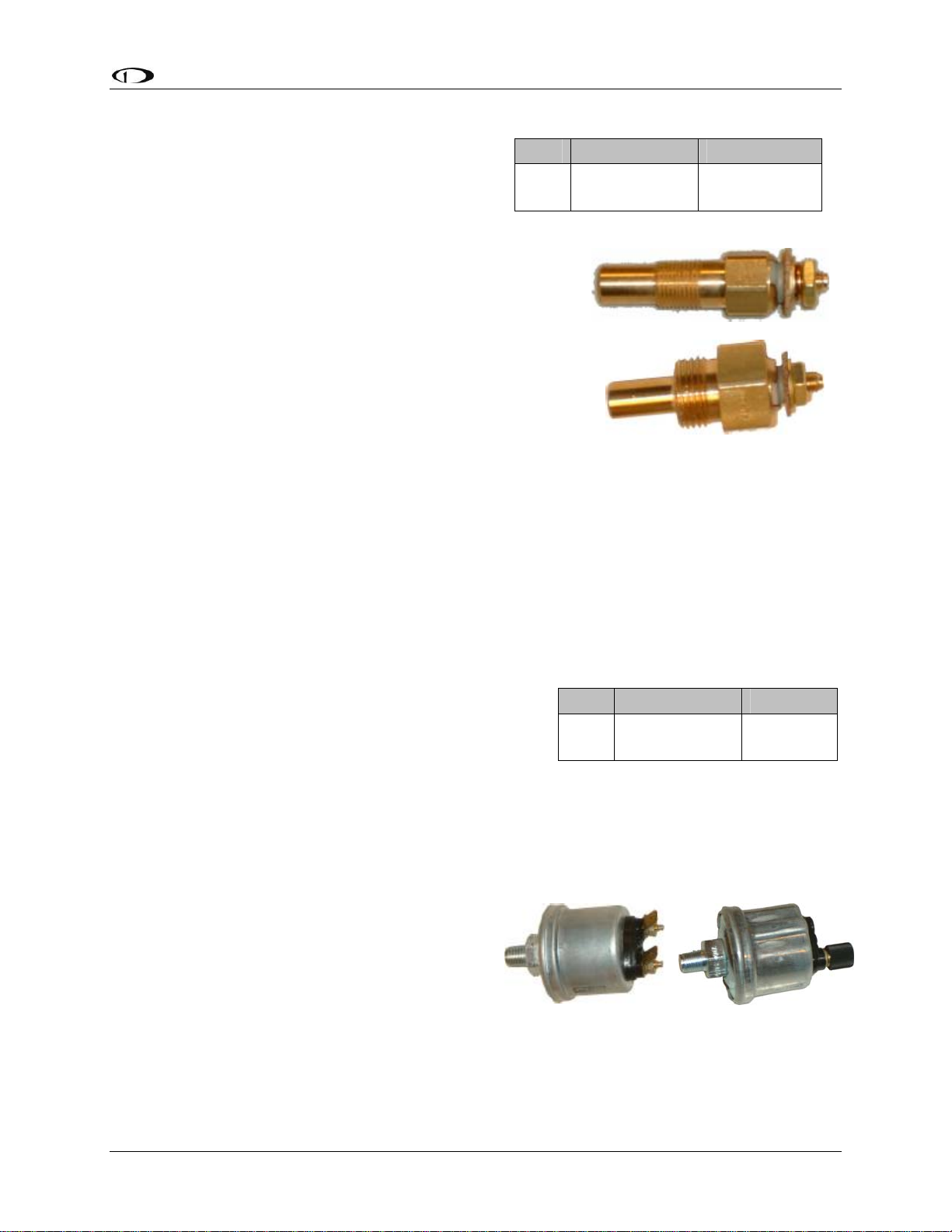

Oil Temperature Sensor

The oil temperature sensor needs to be installed

according to the directions of the engine

manufacturer. Dynon Avionics sells oil

temperature sensors with both 5/8-18 UNF

(Dynon P/N 100409-001) and 1/8-27 NPT

(Dynon P/N 100409-000) threads. Ensure that you have the

right sensor for your engine. Using a crush washer (not

provided) between the sensor and the engine case, tighten the

sensor according to your engine manufacturer’s

recommendations.

Route the wire from pin 7 on the 37-pin harness to where the

oil temperature sensor is mounted. When routing the wires,

make sure that they are secured, so they will not shift position

due to vibration. Strip ¼” of insulation off the end of the w

Crimp a #10 ring terminal onto the end of the wire, ensuri

that a good connection is made between the wire and the connector. Unscrew the nut from the

stud on the oil temperature sensor. Slip the ring terminal onto the stud and secure the nut over i

Pin Color Function

7 White/brown

1/8-27 NPT

ire.

5/8-18 UNF

Oil

Temperature

ng

t.

As mentione

susceptible to voltage differences between the en

d in the Grounding section on page 2-2, the oil temperature sensor is very

gine case and the negative terminal of the

battery. Ensure that solid, thick, and short electrical connections exist between the engine an

battery ground.

Fuel Pressure Sensor

First, mount the fuel pressure se

using an Adel clamp or other secure method. The fuel

pressure sensor must not be installed directly to the

engine due to potential vibration problems. Next,

connect the fuel sensor to the engine using approp

hoses and fittings. Its pressure port has a 1/8-27 NPT pi

to connect to the pressure port on your engine. Locate the correct fuel pressure port for your

engine. This port must have a pressure fitting with a restrictor hole in it. This restrictor hole

ensures that, in the event of a sensor failure, fuel leakage rate is minimized, allowing time fo

emergency landing.

Carbureted engines

: Use the 0-30 PSI sensor

(Dynon P/N 100411-000). Crimp a standard ¼”

female Faston onto one of the ground wires (see

the Grounding section on page 2-2) coming from

the 37-pin harness. Crimp another ¼” fe

Faston onto the brown wire from pin 8. Push t

two Fastons onto the two terminals on the fuel

pressure sensor. Polarity is not important. If you

nsor to a fixed location

riate

male

he

Pin Color Function

8 Brown

Fuel

Pressure

pe thread fitting; you may need adapters

1/8-27 NPT

0-30 PSI

1/8-27 NPT

0-80 PSI

d

r an

FlightDEK-D180 Installation Guide 3-7

Page 26

Transducer Installation

are converting from a GRT EIS system, you must disconnect the external resistor pull-up from

the fuel pressure output. This will make the sensor output equivalent to the sensor supplied by

Dynon Avionics.

Injected engines: Use the 0-80 PSI sensor (Dynon P/N 100411-001). Crimp a standard #8 ring

terminal onto the brown wire from pin 8. Unscrew the stud cap from the threaded stud. P

ring terminal on the stud and secure the cap down sandwiching the ring terminal. If the

connection between the sensor and your engine is non-metallic, you must connect the sensor c

to ground through other means. The best way to accomplish this is b

connected ring terminal between the sensor and the mating fitting.

y sandwiching a ground-

lace the

ase

Due to vibration issues, never connect the sensor directly to engine.

If you use Teflon tape or other seal, ensure the sensor casing still maintains a good

connection to ground.

3-8 FlightDEK-D180 Installation Guide

Page 27

Transducer Installation

Fuel Flow Sensor

Dynon Avionics supplies two different fuel flow

transducers:

Floscan 201B (Dynon P/N 100403-001)

Electronics International FT-60 (Dynon P/N 100403-

003)

GENERAL PLACEMENT RECOMMENDATIONS

When placing either sensor, ensure that the three wire leads

are pointed straight up. A filter should be placed upstream from the sensor to screen out debris.

Placement of the fuel flow sender relative to other items in the fuel system like fuel pumps is left

to the builder. The manufacturer of the fuel flow sender does not make strong recommendations

on this point. It is not uncommon, though, to place the sender downstream of any auxiliary

electric boost pumps but upstream of the engine driven fuel pump. For best measuring

performance, the fuel should travel uphill by one to two inches after leaving the fuel flow sender.

Pin Color Function

13 Black Ground

Yellow (or

14

15 Red

white)

Fuel flow

input

Fuel flow

power

(14V)

Due to vibration issues, never connect the sensor directly to engine.

Do NOT use Teflon tape when screwing in any of the fittings.

FLOSCAN TRANSDUCER INSTALLATION

The FloScan fuel flow transducer has ¼” female NPT threads

at both the inlet and outlet. Only use ¼” NPT fittings to match.

When installing, do not screw fittings more than two full turns

past hand tightened. The torque should not exceed 180 inchlbs.

¼” NPT Female

Make note of the numbers on the tag attached to the fuel

flow sensor. You will need it in the Fuel Flow Configuration

section on page 6-14.

EI “RED CUBE” INSTALLATION

The Electronics International “Red Cube” FT-60 flow transducer has ¼” female NPT ports. Do

not exceed a torque of 300 inch-lbs when installing fittings into the transducer. The fuel line on

the outlet port should not drop down after exiting the transducer. This configuration can trap

bubbles in the transducer, causing jumpy readings.

The inlet port, outlet port, and flow direction are marked on the top of the FT-60.

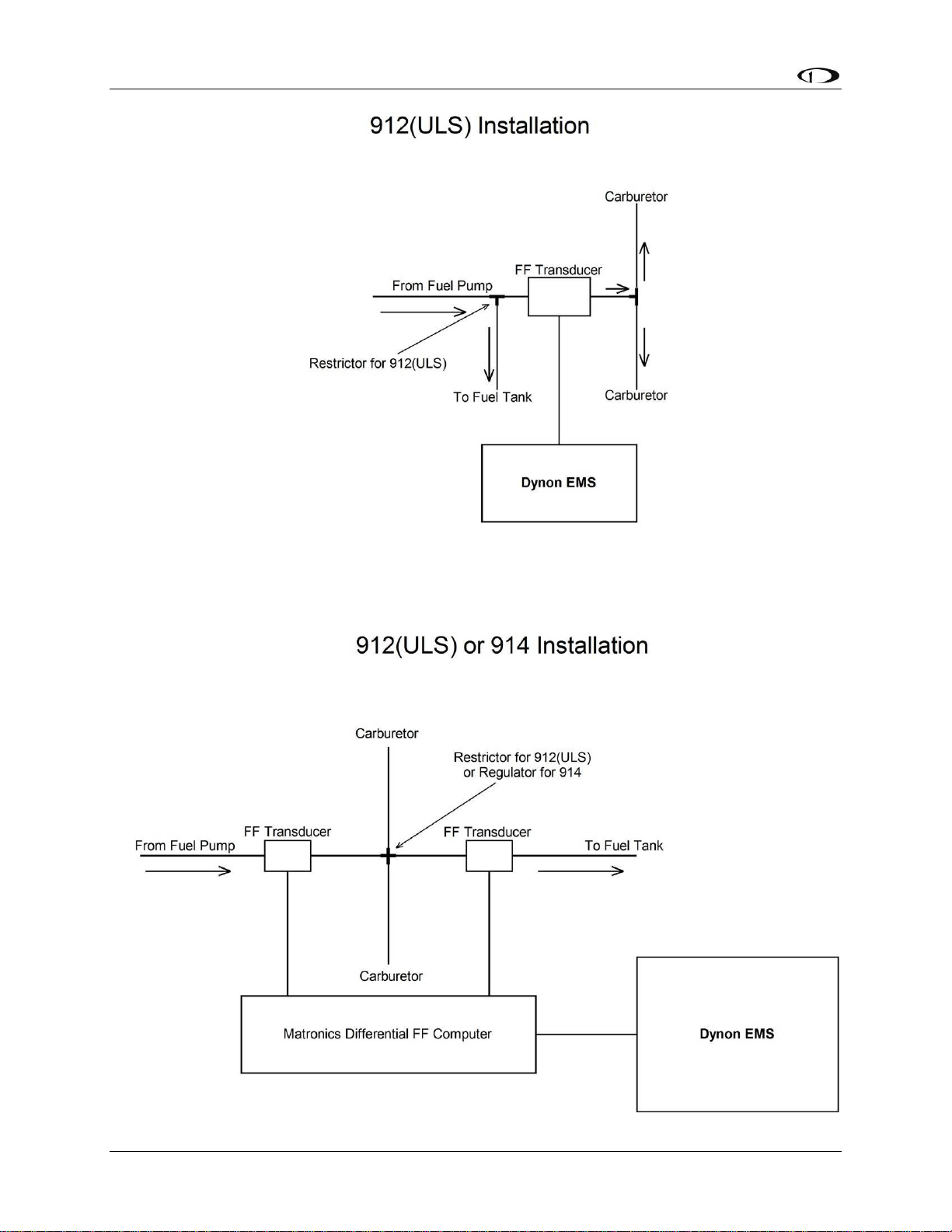

ROTAX PLACEMENT RECOMMENDATIONS

If installing on a Rotax 912, review the following page for recommendations specific to these

engines.

FlightDEK-D180 Installation Guide 3-9

Page 28

Transducer Installation

3-10 FlightDEK-D180 Installation Guide

Page 29

Transducer Installation

Fuel Level Sensor

Dynon Avionics does not sell fuel level sensors.

The FlightDEK-D180 supports both resistive type

sensors as well as capacitive sensors which output a

voltage (e.g., Princeton). If you have a capacitive

sensor which does not output a voltage on its own,

you may be able to use Dynon’s Capacitance-toVoltage Converter. Read the relevant section below

for the type that you are installing.

Once you have installed your fuel level sensors, you

will need to calibrate each of them, as described in

Fuel Level Calibration on page 6-5.

RESISTIVE FUEL LEVEL SENSOR

Pin Color Function

Fuel level 1

20 Orange/brown

(resist or

cap)

Fuel level 2

21 Orange/blue

(resist or

cap)

See General Purpose Inputs section

4 Purple/blue GP 1

22 Purple/yellow GP 2

23 Purple/green GP 3

You may connect up to four resistive fuel level sensors to the FlightDEK-D180. Simply connect

the output of the sensor you would like to be Fuel Level 1 (left tank) to pin 20 and the sensor you

would like to be Fuel Level 2 (right tank) to pin 21. You may also connect third and fourth fuel

level transducers to the general-purpose inputs of your choice. See the General Purpose Inputs

section on page 3-13 for more information.

CAPACITIVE FUEL LEVEL SENSOR

Capacitive fuel level sensors are only supported on the Fuel Level 1 and Fuel Level 2 inputs.

Additionally, your capacitive sensor needs to output a variable voltage within the ranges of 05Vdc. First, supply the sensor with power according to the manufacturer’s instructions. If the

sensor manufacturer requires a sensor calibration, perform that calibration first. Connect the

sensor’s output to pin 20 or 21, depending on whether you want the tank to display as left (Fuel

Level 1) or right (Fuel Level 2) tank. Do not connect capacitive fuel level sensors to any of the

general-purpose inputs. Be sure to configure the firmware to recognize the capacitive fuel level

sensor on the fuel level input(s) you’ve chosen as described in the Fuel Level Configuration

section on page 6-13.

If you are installing Dynon’s Capacitance-to-Voltage Converter (most commonly used with the

capacitive plates in some RVs), please read Capacitance-to-Voltage Converter Installation on

page 9-35.

FlightDEK-D180 Installation Guide 3-11

Page 30

Transducer Installation

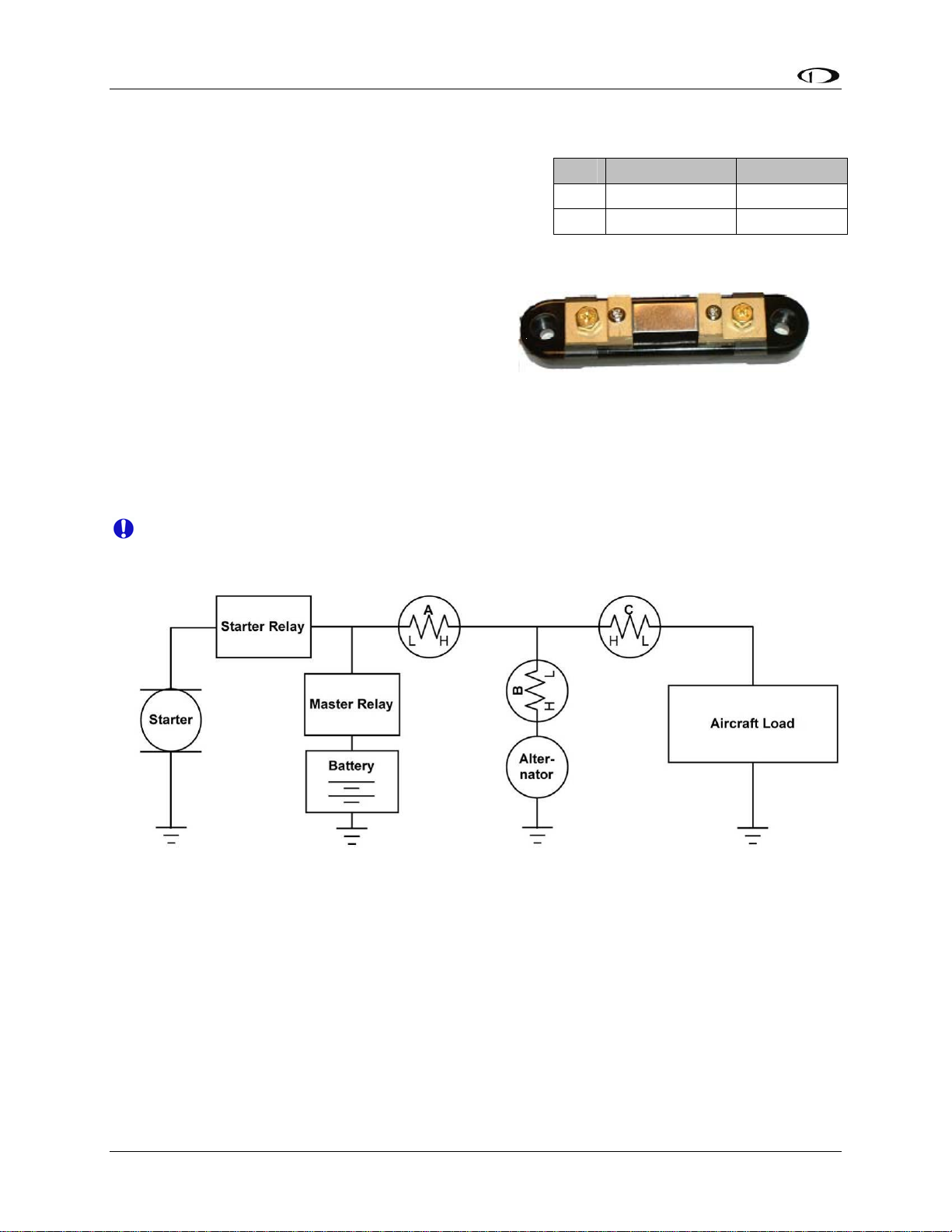

Ammeter Shunt

The ammeter shunt should be mounted so that the metal

part of the shunt cannot touch any part of the aircraft.

The ammeter shunt can be installed in your electrical

system in one of three locations as shown in the

(simplified) electrical diagram below.

Position A: Ammeter indicates current flow into

or out of your battery. In this position, it will

show both positive and negative currents. (-60A

to 60A)

Position B: Ammeter indicates only the positive currents flowing from the alternator to both

the battery and aircraft loads. (0A-60A)

Position C: Ammeter indicates the current flowing only into the aircraft loads. (0A-60A)

Note that the ammeter shunt is not designed for the high current required by the starter and must

not be installed in the electrical path between the battery and starter.

Pin Color Function

24 Orange/green amps high

25 Orange/purple amps low

Electrically, the shunt should be placed so that it does not receive power when the master

switch is off. If it does receive power in this case, it is possible for your aircraft battery to

slowly discharge over a few weeks or months.

Use two ¼” ring terminals sized appropriately for the high-current wire gauge you will be

routing to and from the ammeter shunt. Cut the wire where you would like to install the ammeter

shunt. Strip the wire and crimp on the ring terminals. Using a Phillips screwdriver, remove the

two large screws (one on either end of the shunt), slip the ring terminals on, and screw them back

into the base.

We highly recommend that you fuse both the connections between the shunt and the FlightDEKD180. There are two methods for accomplishing this. You may simply connect two 1 amp fuses

in-line between the shunt and the FlightDEK-D180. Or, you may use butt splices to connect 1” to

2” sections of 26 AWG wire between the shunt and each of the Amps leads connecting to the

3-12 FlightDEK-D180 Installation Guide

Page 31

Transducer Installation

FlightDEK-D180. These fusible links are a simple and cost-effective way to protect against

short-circuits.

Next, crimp the two supplied #8 ring terminals onto the wires using the fusing method chosen

above. Connect the other ends of the fuses to the Amps High and Amps Low leads (pins 24 and

25) on the 37 pin harness. Unscrew the two smaller screws on the ammeter shunt. Slide the ring

terminals onto them and screw them back into the base. Connect the “Amps High” lead to the

side of the shunt marked by “H” in the diagram above; connect the “Amps Low” lead to the side

marked by “L”.

If you find that the current reading on the FlightDEK-D180 is the opposite polarity of what you

want, swap the two signal inputs (Amps High and Amps Low) to obtain the desired result.

It is extremely important that you secure all loose wires and ensure that exposed

terminals cannot touch or short out to other objects in the plane. All metal on the shunt is

at the same voltage as – and carries the same risks as – the positive terminal on the

battery. Improperly installing the ammeter shunt can result in high current flow, electrical

system failure, or fire.

If you are using GRT’s Hall effect amps transducer (P/N CS-01), route its output to pin 24, the

Amps High input, on the 37-pin EMS connector.

General Purpose Inputs

Dynon Avionics supports many sensors for which the

FlightDEK-D180 does not have dedicated inputs. The

instrument has 3 GP (general-purpose) inputs which

can be used for a variety of sources.

OUTSIDE AIR TEMPERATURE SENSOR

Note that this section only applies to the OAT with 2

wires (both colored black/white), for

connection to the EMS DB37 connector. If

you have the 3-wire OAT, see Dynon EFIS

OAT Probe Installation and Usage on page 9-

7. Alternatively, you may still use the 3-wire

OAT on the EMS DB37 connector by ignoring

the red wire and connecting the yellow and

blue wires (irrespective of polarity)

same way as the black/white wires described

here.

Mount Location

It is important that the OAT probe be mounted somewhere on the skin of the aircraft where it

will not be affected by heat sources (sun, engine, aircraft interior, etc). The ideal location would

receive no heat from the aircraft engine or any other source in the aircraft body. While this may

be impractical, it is a good idea to mount the probe as far away from heat sources as possible. On

in the

Pin

Desired

GP

input #

Ground

pin

Pin Color Function

4 Purple/blue GP 1

22 Purple/yellow GP 2

23 Purple/green GP 3

EMS

harness

Color

See chart

above

Black

OAT

sensor

color Function

Black/

White

Black/

White

GP

ground

FlightDEK-D180 Installation Guide 3-13

Page 32

Transducer Installation

the RV series, common locations include the wingtip and under the horizontal stabilizer. Avoid

these three locations:

Engine exhaust paths

The engine itself

Where the sensor will have direct sunlight

Where the backside is exposed to a heated cabin

Mounting Instructions

After the mounting location has been determined, drill a 3/8” hole in the skin at the desired

location. Uncoil the cable attached to the OAT probe. Remove the nylon nut from the cable.

From outside the skin of the aircraft, insert the cable first and then the threaded end of the OAT

probe. From within the skin of the aircraft, gently pull the cable until the threaded end of the

OAT probe pokes through the hole. Thread the nylon nut down the cable and up to the threaded

end of the OAT probe. Spread some Loctite around the threads of the OAT probe. Twist the nut

onto the threads of the OAT probe and tighten.

Wiring Instructions.

Once you have physically mounted the OAT probe, route its attached cable to the FlightDEKD180. Connect one of the black/white wires to ground, either at a supplied connection on the 37pin harness or at another convenient location. If using the EFIS 3-wire OAT simply route either

the yellow or blue wire to ground.

Connect the other black/white wire on the OAT probe to the desired GP input on the FlightDEKD180 main harness. Again, if using the EFIS 3-wire OAT simply route either the yellow or blue

wire (whichever did not get routed to ground) to the desired GP input. When routing wires for

this sensor, try to keep wires away from radios, ignition, or other electronics.

CARBURETOR TEMPERATURE SENSOR

Install the carburetor temperature sensor in the venturi

area at the point where ice first begins to form. This is

located after the main nozzle, before the throttle valve.

You must remove the plug in the carburetor housing

1kΩ

+5V

ex

citation

below the throttle valve. On 4-cylinder engines which

use the Marvel Schebler MA-3 carburetors, this plug is

GP in

located on the forward side. On 6-cylinder engines

using the MA-4 carburetor, the plug is located on the

rear. If your carburetor is not drilled and tapped for the

plug, you must remove the carburetor from the engine

and drill out the lead plug in the appropriate spot. Tap

the hole with a ¼-28 tap. Remove all chips and burrs

before reinstalling.

Connection for all black wire sensor

(P/N 100413) only. No resistor needed

for black/white wire sensor (P/N

Route either of the two wires to an electrical ground.

100468).

Route the other wire to the general-purpose input of

your choice. If you received a temperature sensor with all black wires (Dynon P/N 100413), you

3-14 FlightDEK-D180 Installation Guide

Page 33

Transducer Installation

should find a 1kΩ resistor (color bands: brown, black, black, brown, brown; connect in either

direction) in the package. Connect one end of this resistor to the +5V Excitation Circuit (pin 18)

and the other end to the GP input you’ve connected the sensor to. If you received a sensor with

black/white wires (Dynon P/N 100468), there will be no resistor in the package and you do not

need to make any additional connections.

Be sure to configure the FlightDEK-D180 to recognize the carburetor temperature sensor on the

general-purpose input you’ve chosen as described in the General Purpose Inputs section on page

6-16.

FUEL LEVEL (RESISTIVE) SENSORS

You may connect up to two resistive fuel level sensors to the GP inputs. Generally, this should

only be done if the plane has more than two tanks and the dedicated fuel level inputs are already

used. Connect the output of the fuel level sensor to the desired GP input. Also, connect this same

node to a 200Ω resistor (color bands: Red, black, black, black, brown; connect in either

direction); the other end of which should be attached to the +5V Excitation Circuit. (Resistor

values between 150Ω and 300Ω can be used if 200Ω is not readily available.)

Be sure to configure the firmware to recognize the fuel level sensor on the general-purpose

input(s) you’ve chosen as described in the General Purpose Inputs section on page 6-16.

ROTAX CHT SENSORS

Crimp bare ¼” female Faston terminals

(6.3x0.8 according to DIN 46247) onto the

ends of the wires connected to GP 1 (pin 4)

and GP 2 (pin 22) on the FlightDEK-D180.

Pin Color Sensor Function

4 Purple/blue CHT L GP 1

22 Purple/yellow CHT R GP 2

Locate the left-side CHT sensor screwed into

the bottom side cylinder head 2; slide the Faston

connected to GP1 input onto it. Locate the left-side

CHT sensor screwed into the bottom side cylinder head

1.21kΩ

+5V

citation

ex

3; slide the Faston connected to GP2 input onto it.

You will find two 1.21kΩ resistors (color bands: brown,

GP in

red, brown, brown, brown; connect in either direction)

in the accessories package (Dynon P/N 100446-000)

included with the FlightDEK-D180. Connect either end

Case

grounded

of one of the resistors to the +5V Excitation Circuit (pin

18) and the other end to the wire connecting the left

CHT sensor to pin 4. Repeat this with the right CHT sensor.

Be sure to configure the FlightDEK-D180 to recognize the Rotax CHT sensors on the 2 generalpurpose inputs as described in the General Purpose Inputs section on page 6-17.

FlightDEK-D180 Installation Guide 3-15

Page 34

Transducer Installation

TRIM AND FLAPS POSITION POTENTIOMETERS

Dynon Avionics does not sell trim or flaps

position sensors. These are normally included

with, or added on to, their respective servos.

Most flap and trim sensors are potentiometers

(variable resistors) which require power and

ground inputs, and supply an output that is a

function of position. These potentiometers

come in a variety of resistance ranges, but are

typically 1kΩ, 5kΩ, 10kΩ, and 20kΩ. All of

these values will work properly with the

FlightDEK-D180, as there is a calibration

required, as described on page 6-6. Connect

the 5V Excitation line from the FlightDEK-

DB37

EMS

Pin

Desired

GP

input #

EMS

harness

Color

See chart

on page 3-

13

Position

Pot

Function Function

Position

out

(voltage)

18 White/Red +5V in

Ground

pin

Black

Ground in

(common

to EMS)

GP

Position

sensor

power

ground

D180 37-pin EMS connector to the +5V input

on your trim/flap position sensor. Connect the

ground input on the sensor to a ground common to the FlightDEK-D180. Connect the output of

the sensor to the desired GP input. You may connect up to three trim/flap sensors. For physical

installation, refer to the instructions that came with your position sensor.

If you are using the output from a Ray Allen servo or sensor, connect its white/orange wire to the

Dynon 5V excitation line (pin 18), its white/blue wire to ground, and its white/green wire to your

GP input of choice.

Be sure to configure the FlightDEK-D180 to recognize the various sensors on the generalpurpose inputs as described in the General Purpose Inputs section on page 6-17. Additionally,

you will need to calibrate each flap/trim sensor as described on page 6-6.

COOLANT PRESSURE SENSOR

You will find two 1kΩ resistors (color bands:

brown, black, black, brown, brown; connect in

either direction) in the accessories package (Dynon

P/N 100446-000) included with the FlightDEKD180. You will be using one of these resistors for

proper installation of this sensor.

The Dynon-supplied coolant pressure sensor is a 030 psi sensor (Dynon P/N 100411-000). First,

mount the pressure sensor to a fixed location using

an Adel clamp or other secure method. The

pressure sensor must not be installed directly to the

engine due to potential vibration problems. Next,

EMS

DB37

Pin

Desired

GP input

#

EMS harness

Color

See chart on

page 3-13

18 White/Red

Ground

pin

Black

Function

GP

5V supply

to 1kΩ

resistor

Ground in

(common

to EMS)

connect the sensor to the coolant line using

appropriate hoses and fittings. Its pressure port has

a 1/8-27 NPT pipe thread fitting; you may need adapters to connect to the pressure port on your

engine. Locate (or drill and tap) the pressure port along the coolant line. This port must have a

3-16 FlightDEK-D180 Installation Guide

Page 35

Transducer Installation

pressure fitting with a restrictor hole in it. This restrictor hole ensures that, in the event of a

sensor failure, coolant leakage rate is minimized, allowing time for an emergency landing.

Crimp a standard ¼” female Faston onto one of the

ground wires (see the Grounding section on page 2-2)

ing from the 37-pin harness. Crimp another ¼”

com

female Faston onto both the wire that corresponds to the

1kΩ

+5V

excitation

desired GP input and a 1kΩ resistor (color bands:

brown, black, black, brown, brown; connect in either

direction), or splice the resistor into the GP input line

GP in

elsewhere on the run. Push the two Fastons onto the two

terminals on the fuel pressure sensor. Polarity is not

important. Connect the other side of the 1kΩ resistor

(color bands: brown, black, black, brown, brown;

connect in either direction) to the 5V Excitation Circuit, pin 18, as shown in the diagram.

Due to vibration issues, never connect the pressure sensor directly to engine.

If you use Teflon tape or other seal, ensure the sensor casing still maintains a good

connection to ground.

COOLANT TEMPERATURE SENSOR

You will find two 1kΩ resistors (color bands: brown,

black, black, brown, brown; connect in either direction)

in the accessories package (Dynon P/N 100446-000)

included with the FlightDEK-D180. You will be using

one of these resistors for proper installation of your

coolant temperature sensor.

The coolant temperature sensor needs to be installed

according to the directions of your engine’s

manufacturer. Dynon Avionics sells temperature sensors

with both 5/8-18 UNF (Dynon P/N 100409-001) and 1/8-

EMS

DB37

Pin#

Desired

GP input

#

EMS

harness

Color

See chart on

page 3-13

18 White/Red

Functio

n

GP

5V

supply

to 1kΩ

resistor

27 NPT (Dynon P/N 100409-000) threads; these are the

same as those used by the oil temperature inputs. If

neither of these threads matches those in your coolant

line, you will need to use adapters or drill/tap your own.

Using a crush washer between the sensor and the mating