Dwyer DM-2000 User Manual

Bulletin E-43-DM

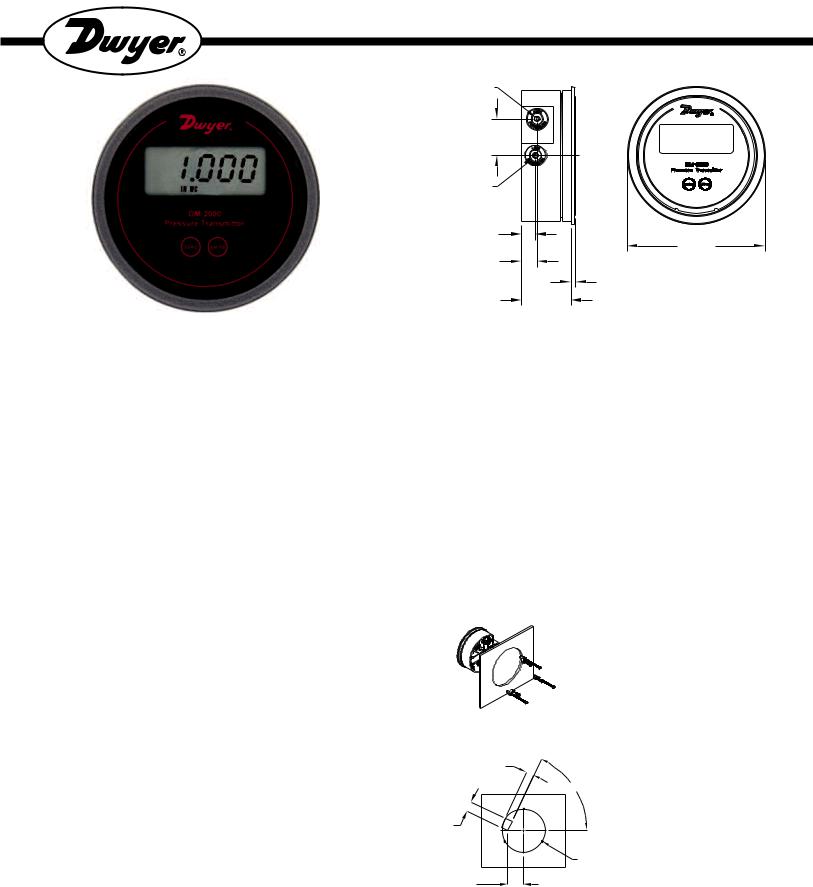

Series DM-2000 Differential Pressure Transmitter

Specifications – Installation and Operating Instructions

The Dwyer Series DM-2000 Differential Pressure Transmitter senses the pressure of air and compatible gases and sends a standard 4-20 mA output signal. The DM-2000 housing is specifically designed to mount in the same diameter cutout as a standard Magnehelic® differential gage. A wide range of models are available factory calibrated to specific ranges.

Pressure connections are inherent to the glass filled plastic molded housing making installation quick and easy. Digital push-button zero simplifies calibration over typical turn-potentiometers. Single push button allows field selection of 5 engineering units (LCD models only). An optional 3.5 digit LCD shows process and engineering.

Accessories

Mounting Lugs

6-20 x 2˝ Screws - 3

6-19 x 1/2˝ Screws - 3

INSTALLATION 1. Location

Select a clean, dry mounting location free from excess vibration where the temperature will remain between 20 and 120˚F (-6.7 and 48.9˚C). Distance from the receiver is limited only by total loop resistance. See Electrical Connections on next page. The tubing supplying pressure to the instrument can be practically any length required, but long lengths will increase response time slightly.

2. Position

A vertical position required. That is the position in which all standard models are spanned and zeroed at the factory.

Pressure Connections

Two integral tubing connections are provided on the side of the gage. They are sized to fit 1/8˝ (3.12 mm) I.D. tubing. Be sure the pressure rating of the tubing exceeds that of the operating ranges.

Note: The tubing connections on the back of the gage are not to be used as process connections.

3. Mounting

Panel - Provide a 4-9/16˝ diameter opening in panel. Insert gage and secure in place with provided screws and adapters.

Surface - Provide three 3/16˝ diameter holes in panel on a 4-1/8˝ diameter bolt circle. Cut opening for terminal block as shown in diagram to right.

HIGH PRESSURE PORT |

|

1-1/4 |

|

[31.75] |

|

LOW PRESSURE PORT |

|

7/16 |

|

[11.11] |

ø4-3/4 |

17/32 |

[120.65] |

|

|

[13.50] |

|

|

5/32 |

|

[3.97] |

|

1-11/16 |

|

[42.86] |

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Accuracy: ±1% F.S. at 70°F. Stability: ±1% F.S./yr.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C). Pressure Limits: 10 psig (0.69 bar).

Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

Power Requirements: 10-35 VDC (2 wire). Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Digital push-button zero and span. Loop Resistance: DC: 0-1250 ohms maximum.

Current Consumption: DC: 38 mA maximum.

Electrical Connections: Screw-type terminal block.

Process Connections: 1/8˝ I.D. tubing. Mounting Orientation: Vertical.

Weight: 4.8 oz (136 g).

Agency Approvals: CE.

Panel

Surface

11/16

(17.46)

65.000°

1

(25.40)

(3) HOLES FOR #6 SCREW EQUALLY SPACED ON 4-1/8 (104.78) B.C.

1-1/2

(38.10)

DWYER INSTRUMENTS, INC. |

|

Phone: 219/879-8000 |

www.dwyer-inst.com |

|

|||

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. |

|

Fax: 219/872-9057 |

e-mail: lit@dwyer-inst.com |

|

|

|

|

Loading...

Loading...