Dwyer DCT1000 User Manual

Bulletin E-97

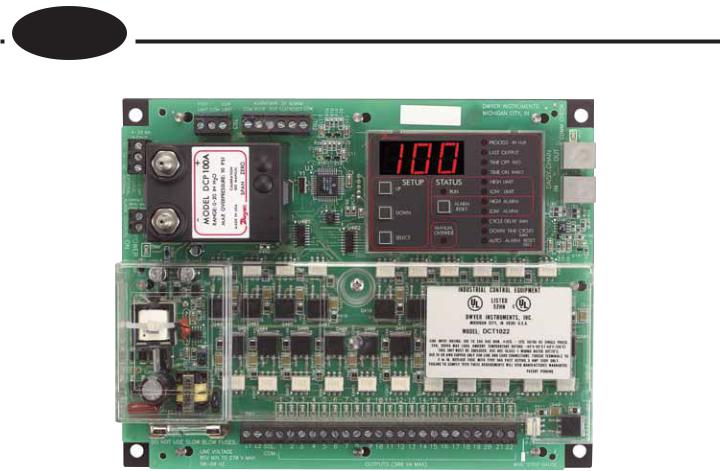

Series DCT1000 Dust Collector Timer Controller

Specifications – Installation and Operating Instructions

Thank you for purchasing the DCT1000 Dust Collector Timer Controller. You have selected a state of the art dust collector timer control that will provide years of dependable operation and service.

The DCT1000 Dust Collector Timer Controller was designed to be used with pulse-jet type dust collectors for on-demand or continuous cleaning applications.

Continuous cleaning applications do not require external inputs and can be used for time based “on-demand” cleaning through use of the cycle delay feature.

For on-demand applications, the plug-in pressure modules (DCP100A/200A) can be used to take full advantage of all the features the DCT1000 offers, or an external pressure switch (such as the Dwyer Photohelic®) can be used for High/Low limit control.

As with traditional Dwyer products, the Dwyer DCT1000 was designed so that it is easy to use, thus allowing for a quick and easy start up for your dust control applications. The contents inside this installation and operating manual will guide you through the features of the DCT1000 and how they can be applied to get the most out of your dust control requirements.

SPECIFICATIONS

DCT1000 Timer Controller:

Output Channels: 6, 10, & 22 channels. Expandable to 255 channels using DCT1122 & DCT1110 channel expander boards.

Power Requirements: 85 to 270 VAC, 50 or 60 Hz.

Solenoid Supply: 3A maximum per channel.

Fuse: 3A @ 250 VAC. Low voltage control circuitry is isolated from the line voltage for system safety.

Temperature Limits: -40 to 140°F (-40 to 60°C).

Storage Temperature Limits: -40 to 176°F (-40 to 80°C).

On Time: 10 msec to 600 msec, 10 msec steps.

On Time Accuracy: ±10 msec.

Off Time: 1 second to 255 seconds, 1 second steps.

Off Time Accuracy: ±1% of the value or ±50 msec, whichever is

greater.

Weight: 1 lb 3.0 oz (538.6 g).

Agency Approvals: UL, cUL.

DWYER INSTRUMENTS, INC. |

|

Phone: 219/879-8000 |

www.dwyer-inst.com |

|

|||

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. |

|

Fax: 219/872-9057 |

e-mail: info@dwyer-inst.com |

|

|

|

|

|

|

|

|

|

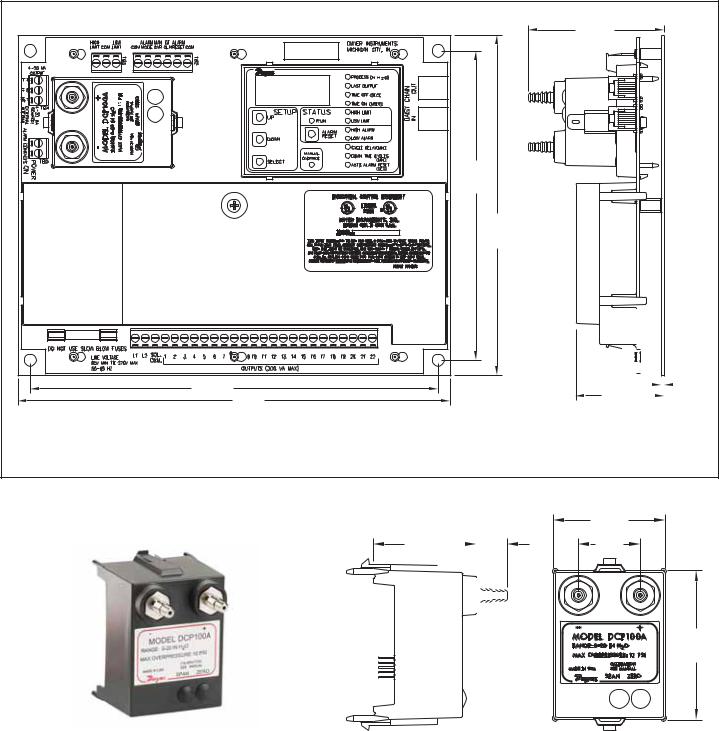

6-1/4 |

|

[158.75] |

|

6-7/8 |

|

[174.62] |

8-1/4 |

|

[209.55] |

8-3/4 |

|

[222.25] |

Figure 1 – Dimensional Specifications for the DCT1000 (shown with optional module DCP100A)

2-3/4 |

[69.85] |

|

|

|

|

|

|

|

|

|

|

|

1/16 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

1-13/16 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

[1.59] |

|||

|

|

|||||||||||

|

|

|

|

|

|

|||||||

[46.04] |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

1-11/16 |

|

|

|

1/2 |

|

|||||

|

||||||||||

[42.86] |

|

|

|

|

[12.70] |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-13/16 [46.04]

1 |

[25.40] |

2-7/16 [61.91]

The DCP100A or DCP200A pressure modules are designed exclusively for use with the Dwyer DCT1000 Dust Collector Timer Controller boards for on-demand cleaning requirements. These series of modules are available in 10˝ w.c. [2.49 kPa] or 20˝ w.c. [4.98 kPa] ranges, which allow for differential process pressure measurement as indicated on the display of the master controller. An isolated 4-20 mA readout channel is provided for remote pressure display. The 4-20 mA output may be wired either for use with an external power supply and indicator or using the isolated onboard 24 volt power supply to power the loop.

SPECIFICATIONS

Pressure Ranges: 10˝ w.c. or 20˝ w.c. Temperature Limits: -40 to 140°F (-40 to 60°C). Pressure Limit: 10 psi (68.95 kPa).

Pressure Limit (differential): 10 psi (68.95 kPa).

Accuracy: ±1.5% F.S. @ 73°F (22.8°C).

Output Signal: 4-20 mA.

Alarm Contacts: 1.5A inductive load, 3A resistive load @ 30 VAC or 40 VDC.

Process Connections: Two barbed connections for use with 1/8˝ (3.18 mm) or 3/16˝ (4.76 mm) I.D. tubing.

Weight: 5.5 oz (155.9 g).

2

Table of Contents |

Page No. |

Figure 1 Dimensional Specifications . . . . . . . . |

. . . . . . . .2 |

1.0 Installing the DCT1000 . . . . . . . . . . . . . . . .3

1.1 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .3 1.2 DCT1000 Terminal Connections . . . . . . . . . . . . . . . . . .3 1.2.1 External Pressure Connection . . . . . . . . . . . . . . . . . . . .3 1.2.2 Manual Override Switch Connection . . . . . . . . . . . . . . .4 1.2.3 Down Time Clean Connection . . . . . . . . . . . . . . . . . . . .4 1.2.4 Connecting Multiple Timer Boards . . . . . . . . . . . . . . . . .4 1.2.5 Continuous Cycle Mode . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 2 Wiring Connections . . . . . . . . . . . . . . . . . . . . .4 1.3 DCP Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Figure 3 DCP Installation . . . . . . . . . . . . . . . . . . . . . . . .5 1.3.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.2 Connecting DCP to Master Controller . . . . . . . . . . . . . .5 1.3.3 Pressure Model Locking Pins . . . . . . . . . . . . . . . . . . . . .5 1.3.4 DCP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 1.3.5 DCP Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 1.4 Alarm Mode Switch Connection . . . . . . . . . . . . . . . . . .5 1.4.1 Alarm Reset Switch Connection . . . . . . . . . . . . . . . . . .5 1.4.2 Connecting the 4-20 mA Loop . . . . . . . . . . . . . . . . . . .5 1.4.3 Connecting the Alarm Relay . . . . . . . . . . . . . . . . . . . . . .6 1.5 Three Position Selection Switch Wiring . . . . . . . . . . . . .6

2.0Programming the DCT1000 Master

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Last Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2 Time Off Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Time On Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 High Limit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.5 Low Limit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.6 High Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.7 Low Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.8 Cycle Delay Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.9 Down Time Cycles Setup . . . . . . . . . . . . . . . . . . . . . . .7

2.10 Auto Alarm Reset Setup . . . . . . . . . . . . . . . . . . . . . . . .7

3.0Maintenance Support and Diagnostics . .7

3.1 Restoring Factory Defaults . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Active Channel Indicator . . . . . . . . . . . . . . . . . . . . . . . .7

3.4 Comm Check Indicator . . . . . . . . . . . . . . . . . . . . . . . . .7

3.5 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.0 Glossary of Terms . . . . . . . . . . . . . . . . . . . .8

Customer Service Phone Number . . . . . . . . . . . . . . .. . 8

1.0 Installing the DCT1000

Warning: Always install and service this device with the power off and a lockout installed if required. Line voltages will be exposed at the power/output connector and at the fuse. For this reason, we have installed a

plastic guard to protect the user from accidentally contacting line voltages.

Please note that the power guard serves as a safety feature and should not be removed under any circumstances.

For ease of installation and maintenance, the connectors and fuse have been left unprotected. The open frame design of the DCT1000 will require an enclosure that meets appropriate safety and local code requirements. For optimal performance, the enclosure should also protect the controller from dirt, water and direct sunlight. There are no special orientation requirements, and the controller mounts easily using the mounting holes on the factory installed base plate.

Caution: Do not run control wires, communication cables, or other class 2 wiring in the same conduit as power leads. The system may malfunction if class 2 wiring is run

together with power conductors.

1.1 Power Requirements

The controller has a “universal” power supply that will allow operation on 120 VAC to 240 VAC power lines. The input voltage must be between 85 VAC and 270VAC either 50 or 60 Hz. No circuit changes are required when switching between these voltages. The solenoid loads, however, must be sized to accommodate the line voltage selected.

1.2 DCT1000 Terminal Connections

The line and solenoid connections are located at the lower edge of the board below the plastic guard. The terminal block is a “Euro” style connector system that clamps the wire within the connector body. The connector will accept wire sizes from 14 to 22 AWG. The wire should be stripped to no more than 0.25 inches to avoid shorts or expose line voltages creating a potential safety hazard. To assist you in determining the proper wire gauge required, a strip gauge is provided at the lower right corner of the board. The connector system used on the DCT1000 is specified for single connection but you can piggyback to a single lug provided that local codes allow for this and good workmanship practices are followed. To power up the master controller and the channel expander, connect line power to L1 and L2 (see Dimensional Specifications, Figure 1). Connect the solenoids between the selected output and the solenoid common. Solenoid common and L2 are internally connected. Switches connected to the control inputs at the top of the board must be isolated contacts connected only to the relevant terminal and to the common terminals. The following subparagraphs describe the external switch connections. Refer to figure 2 for switch connection illustration.

1.2.1 External Pressure Connection

The controller may be used with an external pressure limit switch or sensor to provide demand-cleaning operation. The high limit and low limit inputs may be used for this purpose. A simple on-off system can be established with a single pressure switch connected to the high limit input. Better control can be achieved with a high and low limit switch/gage such as the Dwyer Photohelic®. In this ondemand mode, time on, time off, and cycle delay may be programmed to define the cleaning cycle. A three pin terminal block (TB3) provides connection for external high and low limit switches (see Figure 2 on the next page). These switches must be isolated contacts. The common line must not be connected to equipment ground or protective ground, since these may introduce electrical noise and cause improper operation or possible damage to the control board. The operation of these inputs are summarized as follows (see next page):

|

Current |

Low Limit |

High Limit |

Next |

|

Operation |

Switch |

Switch |

Operation |

|

Hold |

Open |

Open |

Hold |

|

Hold or Run |

X |

Closed |

Run |

|

Hold |

Ø |

Open |

Hold |

|

Hold |

Closed |

Ø |

Run |

|

Run |

Closed |

≠ |

Run |

|

Hold |

Closed |

Ø |

Run |

|

Run |

≠ |

Open |

Hold |

Ø Transition from open to closed ≠ Transition closed to open

X Either open or closed

Note: If a DCP100A or DCP200A pressure module is installed in the master controller, the switching functions are ignored.

3

Loading...

Loading...