Dwyer 3000MR User Manual

Bulletin E-70

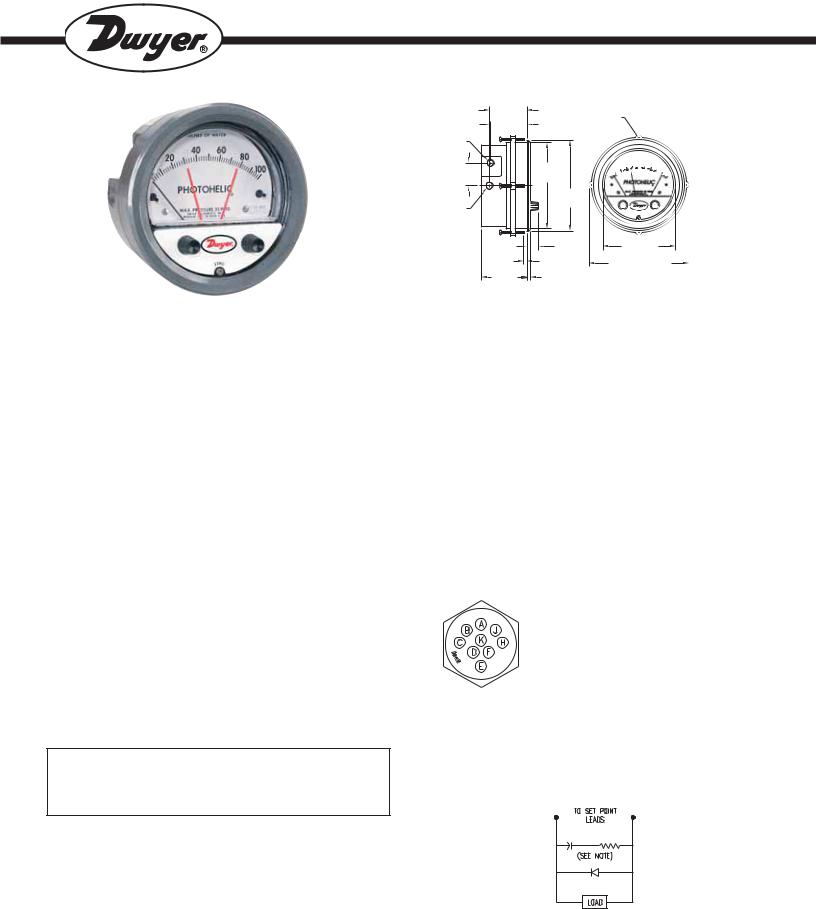

Series 3000MR Photohelic® Differential Pressure Switch/Gage

Specifications — Installation and Operating Instructions

1/8 FEMALE NPT HIGH |

2-1/61 |

(4) 6-32 HOLES |

|

|

PRESSURE CONNECTION |

[52.39] |

EQUALLY SPACED ON A |

|

|

|

2 |

5-1/8 [130.18] B.C. |

|

|

1/8 FEMALE NPT HIGH |

[50.80] |

|

|

|

|

|

|

|

|

PRESSURE CONNECTION |

|

|

|

|

|

|

|

INCHES OF WATER |

|

|

|

Ø4-47/64 |

.4O |

.60 |

1-1/4 |

|

.2O |

.80 |

|

|

[120.25] |

O |

1.0 |

|

[31.75] |

|

|||

|

|

|

||

|

|

|

|

|

|

|

Ø5 |

|

|

1/8 FEMALE NPT LOW |

|

[127.00] |

|

|

|

|

|

|

|

PRESSURE CONNECTION |

|

|

|

|

|

|

5/8 |

Ø4 [101.60] |

|

|

|

[15.88] |

||

|

|

FACE |

||

|

|

5/8 [15.88] |

||

|

|

5-1/2 [139.70] O.D. |

||

|

|

PANEL MAX |

||

|

2-1/2 |

MOUNTING RING |

||

|

3/16 |

|||

|

[63.50] |

|

|

|

|

[4.76] |

|

|

|

|

|

|

|

|

Using solid state technology, the Series 3000MR Photohelic® switch/gage combines the functions of a precise, highly repeatable differential pressure switch with a large easy-to-read analog pressure gage employing the durable, time-proven Magnehelic® gage design. Switch setting is easy to adjust with large external knobs on the gage face. Gage reading is unaffected by switch operation — will indicate accurately even if power is interrupted. Solid state design now results in greatly reduced size and weight. Units can be flush mounted in 413⁄16˝ (122 mm) hole or surface mounted with hardware supplied. 3000MR models employ versatile electromechanical relays with gold over silver contacts — ideal for dry circuits. All models provide both low and high limit control and include 18-inch (45 cm) cable assemblies for electrical connections.

Gage accuracy is ±2% of full scale and switch repeatability is ±1%. Switch deadband is one pointer width — less than 1% of full scale. Compatible with air and other non-combustible, noncorrosive gases, they can be used in systems with pressures to 25 psig (1.725 bar). Optional construction is available for use to either 35 psig (2.42 bar) or 80 psig (5.51 bar).

Accessories

Mounting ring, snap ring |

(4) |

6-32 x 11⁄4˝ RH machine screws |

|

18˝ (45 cm) cable assembly |

(panel mounting) |

||

(2) |

3⁄16˝ tubing to 1⁄8˝ NPT adapters |

(3) |

6-32 x 5⁄16˝ RH machine screws |

(2) |

1⁄8˝ NPT pipe plugs |

(surface mounting) |

|

ELECTRICAL CONNECTIONS

CAUTION: Do not exceed specified electrical ratings. Permanent damage not covered by warranty will result. This unit is not designed for AC line voltage operation.

Electrical connections are made by means of the cable assembly supplied which has a multi-pin female plug installed on one end which mates with the male connector on the rear of the gage. Wire leads on the opposite end of the assembly are connected in accordance with the drawing and chart to the right.

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Accuracy: ±2% of full scale (3000-0 ±3% of full scale).

Pressure Limit: -20˝ Hg. to 25 psig (-0.677 bar to 1.72 bar). MP option; 35 psig (2.41 bar), HP option; 80 psig (5.52 bar).

Temperature Limits: 20 to 120°F. (-6.67 to 48.9°C).

Process Connections: 1/8 female NPT (duplicated side and back). Size: 4˝ (101.6 mm) dial face, 5˝ (127mm) O.D. x 3-1/8˝ (79.38 mm). Weight: 1.8 Ib., (816 g).

SWITCH SPECIFICATIONS 3000MR

Switch Type: Each setpoint has 1 Form C relay (SPDT).

Relay Contacts: (resistive load) 1 Form C rated 1.0 amp @ 30 VDC, 0.3 amp @ 110 VDC or 0.5 amp @ 125 VAC. Gold over clad silver - suitable for dry circuits.

Electrical Connections: 18˝ (46 cm) cable assembly with 8 conductors. Optional lengths to 100´ (30.5 m).

Power Requirements: 24 VDC, regulated ± 10%.

Mounting Orientation: Diaphragm in vertical position. Consult factory for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

Power |

|

LETTER |

COLOR |

|

+ |

A |

Red |

||

Supply |

- |

E |

Black |

|

Low |

COM |

C |

Brown |

|

NC |

B |

Violet |

||

Set Point |

||||

NO |

D |

Blue |

||

|

||||

High |

COM |

H |

Green |

|

NC |

J |

White |

||

Set Point |

||||

NO |

F |

Orange |

||

|

Note: An R/C (resistor/capicitator) snubber is required when switching inductive loads such as a solenoid or contactor. specify Dwyer Instruments, Inc. part number A-600. For DC circuits, also include a 1N4005 diode.

DWYER INSTRUMENTS, INC. |

|

Phone: 219/879-8000 |

www.dwyer-inst.com |

|

|||

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. |

|

Fax: 219/872-9057 |

e-mail: info@dwyer-inst.com |

|

|

|

|

|

|

|

|

Loading...

Loading...