Page 1

Warranty

• DuraTrax will warranty this kit for 90 da ys after the purchase date from def ects in materials or workmanship.DuraTrax will either repair

or replace, at no charge, the incorrectly made part.

• Make sure you save the receipt or invoice you were given when you purchased your model. It is your proof of purchase and we must

see it before we can honor the warranty.

• To return your Mini Quake SE for repairs covered under warranty you should send your model to:

Hobby Services

3002 N. Apollo Drive Suite 1

Champaign, Illinois 61822

Attn: Service Department

Phone: (217) 398-0007 9:00 am-5:00 pm Central Time M-F

E-mail:

hobbyservices@hobbico.com

If the buyer is not prepared to accept the liability associated with the use of this product,the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

© Copyright 2005

DTXZ1111 For Kit DTXC0011

ASSEMBLY AND OPERATION MANUAL

Length: 9.5" [240mm]

Width: 7.4" [185mm]

Height: 4.7" [120mm]

Ground Clearance: 1.25" [32mm]

Weight: 25 oz [725g] approx.running

weight with battery/motor/ESC

™

Technical Support Information

For technical assistance, contact:

DuraTrax Product Support

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

(217) 398-8970, Ext. 5

carsupport@duratrax.com

®

Page 2

INTRODUCTION................................................................2

IMPORTANT SAFETY PRECAUTIONS............................2

HELPFUL HINTS...............................................................2

STRESS TECH P ARTS......................................................2

REPAIR SERVICE .............................................................2

SPECIFICATION AND DESCRIPTION CHANGES ..........3

FINISHING THE MINI QUAKE SE.....................................3

ASSEMBLY GUIDE ...........................................................5

MAINTENANCE TIPS........................................................6

TUNING..............................................................................6

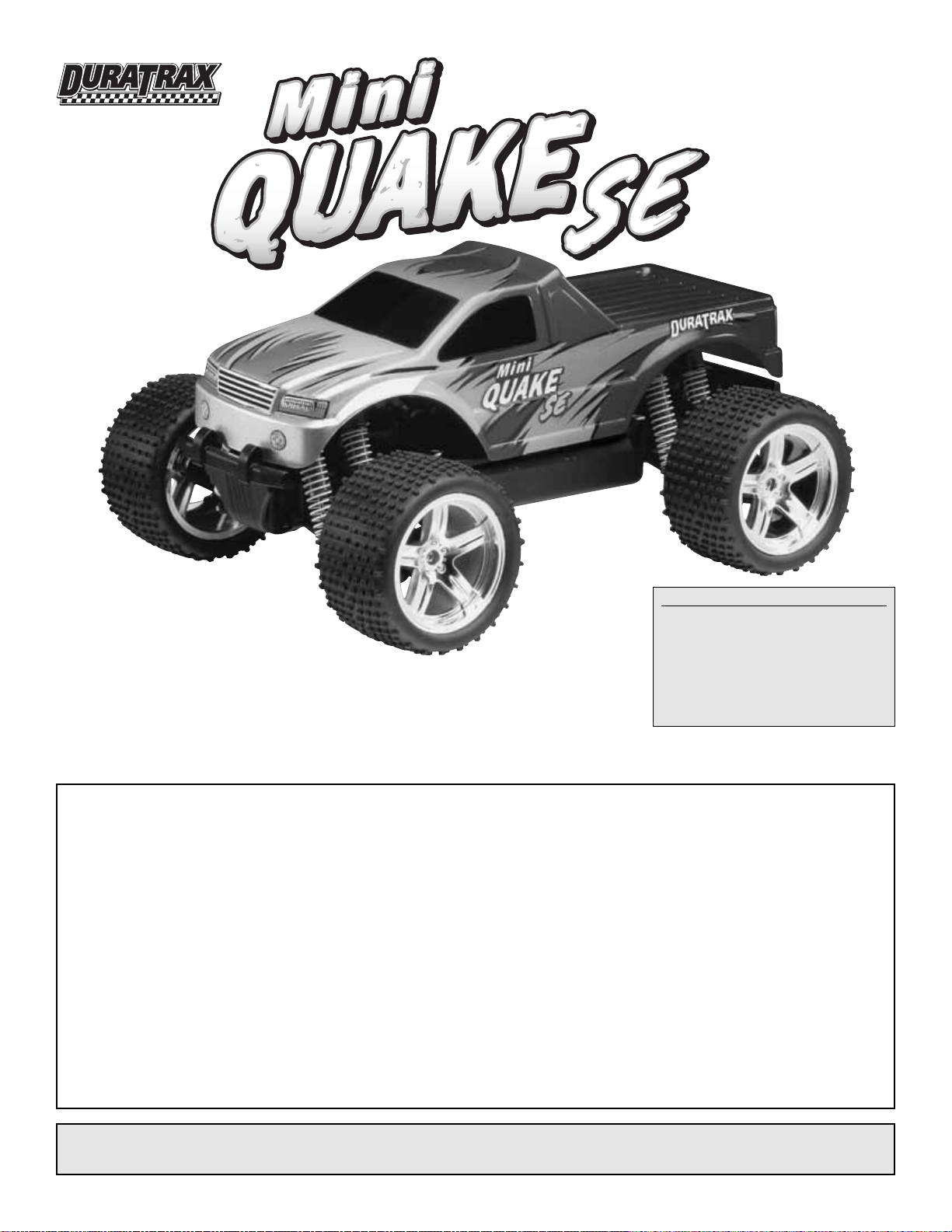

Thank you for purchasing the DuraTrax Mini Quake SE.This

manual contains the instructions you need to build, operate

and maintain your new electric R/C vehicle. Read over this

manual thoroughly before building or operating the Mini

Quake SE.

When the safety precautions are follo wed, the Mini Quak e SE

will provide years of enjoyment.Use care and good sense at

all times when operating this radio controlled vehicle.Failure

to use this vehicle in a safe, sensible manner can result in

injury or damage to proper ty. You and you alone must insure

that the instructions are carefully followed and all safety

precautions are obeyed.

• Do not operate the Mini Quak e SE near people.Spectators

should be behind the driver or at a safe distance aw a y from

the vehicle.

• Make sure to read the instructions before charging

the battery.

• Do not leave the charger unattended during charging. If

the battery or charger become hot at any time,

disconnect the battery from the charger immediately!

Failure to do so may cause permanent damage to the

charger and battery and may cause bodily harm.

• Do not cover the charger during charging. This may

cause the charger to overheat.

• Do not allow the electronic speed control (ESC) or radio

equipment to come into contact with moisture. Water

can cause the electronics to short out and cause

permanent damage.

• Always turn on the transmitter before turning on the

electronic speed control.

• Before turning on your radio, check to make sure that

no one else is running on the same frequency as your

Mini Quake SE.

• Avoid working over a deep pile carpet. If you drop a small

part or screw, it will be difficult to find.

• Place a mat or towel o ver y our work surface.This will prevent

parts from rolling off and will protect the work surface.

• Test fit all parts before attaching them permanently.

We have engineered the Mini Quake SE to take the rough

and tumble abuse that makes R/C fun.We are so confident

of the quality and durability of the Stress-Tech plastic par ts

that we will replace any Stress-Tech plastic par t you break

during the first 12 months you own the vehicle.Just send in

the part to us and we will send you a FREE replacement.

Please see the Mini Quake SE parts list for the items

covered under the Stress-Tech guarantee.

To receive your free replacement part, please send the

following to the Hobby Ser vices address listed on the front

cover of this manual.

❏ 1.The broken part must be included.

❏ 2.The part number and description of the broken part.

❏ 3. Copy of your dated invoice or purchase receipt.

❏ 4.Your name, phone number and shipping address.

Repair service is available anytime.

• After the 90 day warranty, you can still have your Mini

Quake SE repaired for a small charge by the experts at

DuraTrax’s authorized repair facility, Hobby Services, at

the address listed on the front cover of this manual.

• To speed up the repair process, please follow the

instruction listed below.

❏ 1. Under most circumstances return the ENTIRE vehicle.

The exception would be sending in a Stress-Tech par t. See

the instruction under the Stress-Tech Guarantee.

❏ 2. Make sure the transmitter is turned off and all of the

batteries are removed.

❏ 3. Send written instructions which include: a list of all

items returned, a THOROUGH explanation of the problem,

the service needed and your phone number during the day.

If you expect the repair to be covered under warranty, be

sure to include a proof of date of purchase (your store

receipt or purchase invoice).

❏ 4. Also be sure to include your full return address.

REPAIR SERVICE

STRESS-TECH™PARTS GUARANTEE

HELPFUL HINTS

SAFETY PRECAUTIONS

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

All pictures, descriptions and specifications found in this

instruction manual are subject to change without notice.

DuraTrax maintains no responsibility for inadvertent errors

in this manual.

❏ 6-Cell Mini Quake Battery (DTXC2196)

❏ Charger (DTXC4005)

❏ Radio system with one servo (FUTJ13**)

❏ Electronic Speed Control (DTXM1260)

❏ 380-Size Motor (DTXC3307)

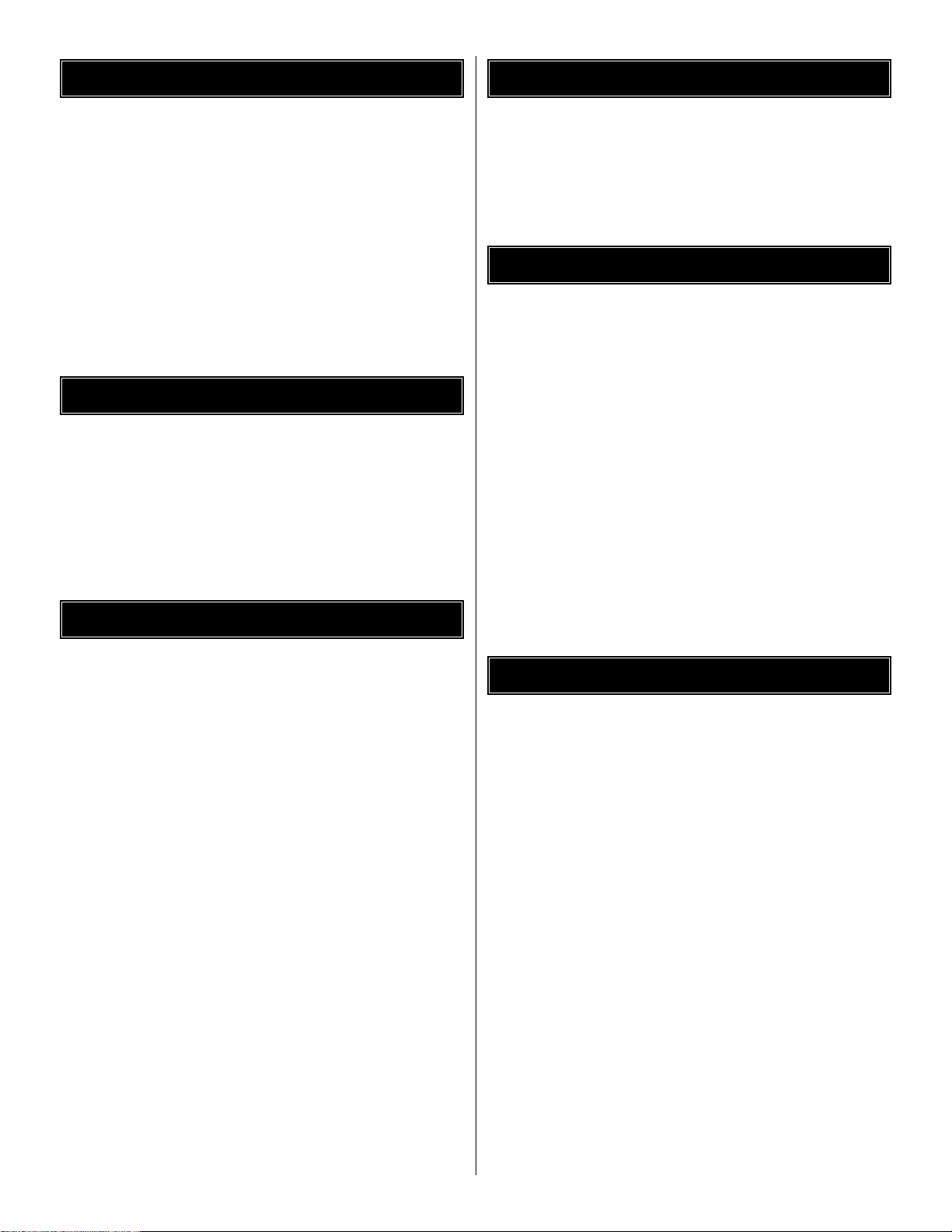

❏ 1. Using (2) 2.6x6mm (H) screws, secure your motor (not

included) onto the Mini Quake SE’s motor mount (5).

❏ 2. Install the included 16 tooth pinion (40) onto the motor

shaft and secure it to the motor shaft with a 3mm set screw (P).

❏ 3. Install the motor assembly onto the chassis (1).Secure

the motor mount (5) to the chassis using (2) 2.6x6mm (M)

screws. Before tightening the 2.6x6 screws, make sure the

gear mesh between the motor pinion (40) and the spur gear

(39) is set correctly.With a properly set gear mesh, you can

hold the pinion and still be able to slightly rock the spur gear

teeth back and forth in the pinion gear.Be careful not to set

the gear mesh too loose. It will cause the spur gear to strip.

Setting the gear mesh too tight will cause binding and could

damage your motor and speed control.

❏ 4. Once the gear mesh is properly set, tighten the

2.6x6mm (M) screws to secure the motor assembly in place.

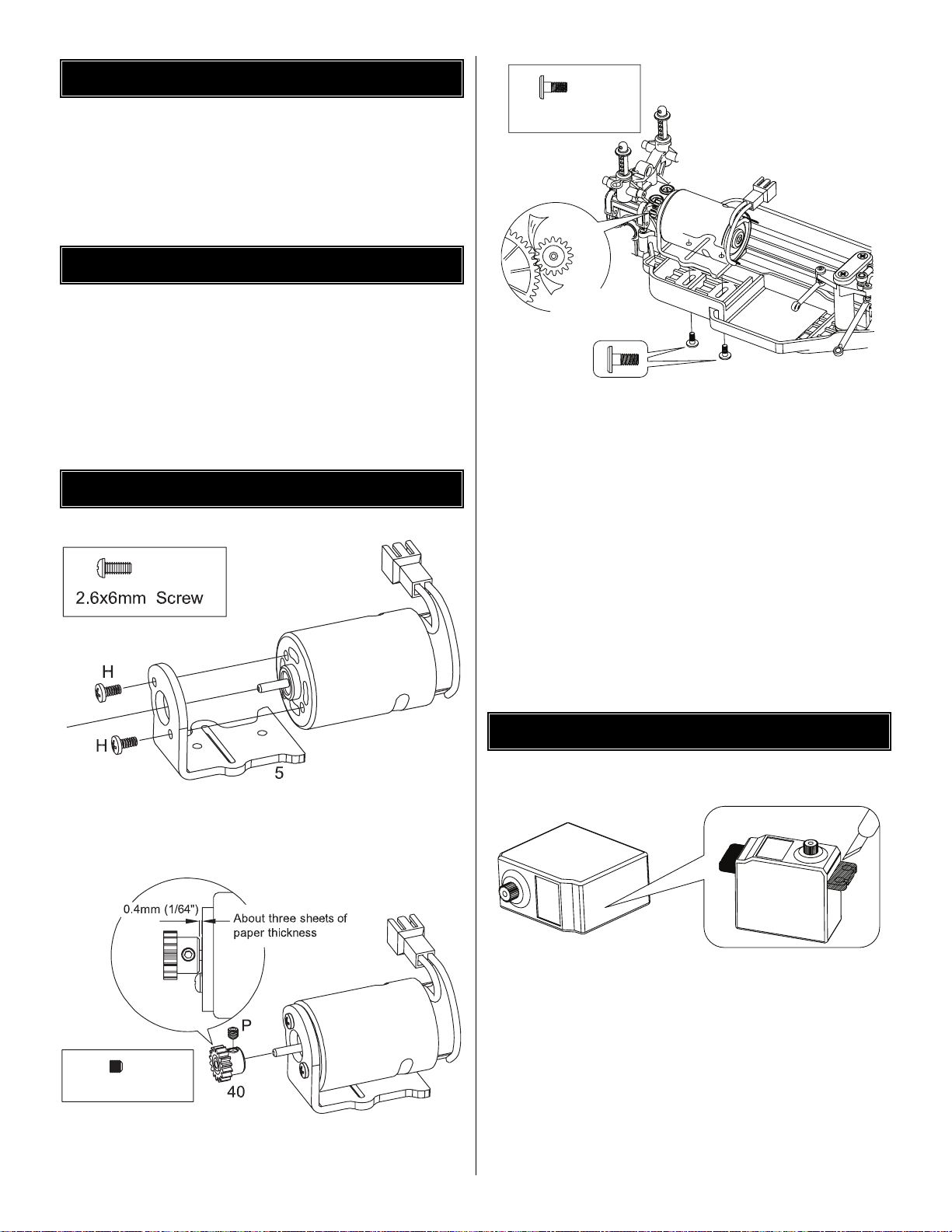

❏ 1. For standard size servos, you will need to trim the

mounting tabs off the sides of the servo. TIP: Use Lexan

®

scissors to trim the mounting tabs from the servo. Carefully,

use a sharp hobby knife blade to clean up the remaining

portion of the mounting tab.

❏ 2. Locate the correct ser vo horn (30). There are multiple

servo horns included with the Mini Quake SE to fit different

brands of servos. NOTE: The correct servo horn should

slide on, without forcing it, onto the servo output shaft.

SERVO INSTALLATION

MOTOR INSTALLATION

ITEMS REQUIRED FOR COMPLETION

SPECIFICATION & DESCRIPTION CHANGES

3

x2 (H)

x2 (M)

2.6x6mm Screw

TIP: Sqeeze a piece

of paper to help set

the proper mesh.

With the proper mesh, you

should just be able to move

the gears independently. Too

tight will cause drag, too loose

and the gears will strip.

M

x1 (P)

3mm Set Screw

Trim off the tabs.

Standard

Servo

Page 4

❏ 3. Install a 3.8mm ball (D) into the lower hole of the servo

horn (30) as shown in the drawing.

❏ 4.Center the trim of the servo.Y ou will need to hook up the

servo, receiver, speed control, and charged battery for this.

Center the trims on the transmitter.Then tur n the transmitter

on followed by the speed control. See your radio instructions

for location of the steering servo trim.

❏ 5. Make sure the servo is positioned properly (note the

output shaft orientation in the drawing) and install the servo

horn (30) onto the servo as shown. Secure the servo horn

(30) to the servo using the screw included with the servo.

❏ 6. Install the piece of

included double-sided tape

(S) onto the bottom of the

servo. TIP: Thoroughly clean

the bottom of the servo with

rubbing alcohol.This wiil help

ensure a good bond between

the servo and the doublesided tape.

❏ 7. Test fit the servo into the chassis so you know where it

needs to be mounted. Hold the servo in place and rotate the

steering back and forth.Make sure the linkage does not bind.

❏ 8. Remove the remaining protective backing from the

double-sided tape and install the servo into the chassis.TIP:

Thoroughly clean the chassis with rubbing alcohol. This wil

help ensure a good bond between the chassis and the

double-sided tape.

❏ 9. Attach the steering linkage connecting rod (31) to the

3.8mm ball (D) that was installed into the servo horn.

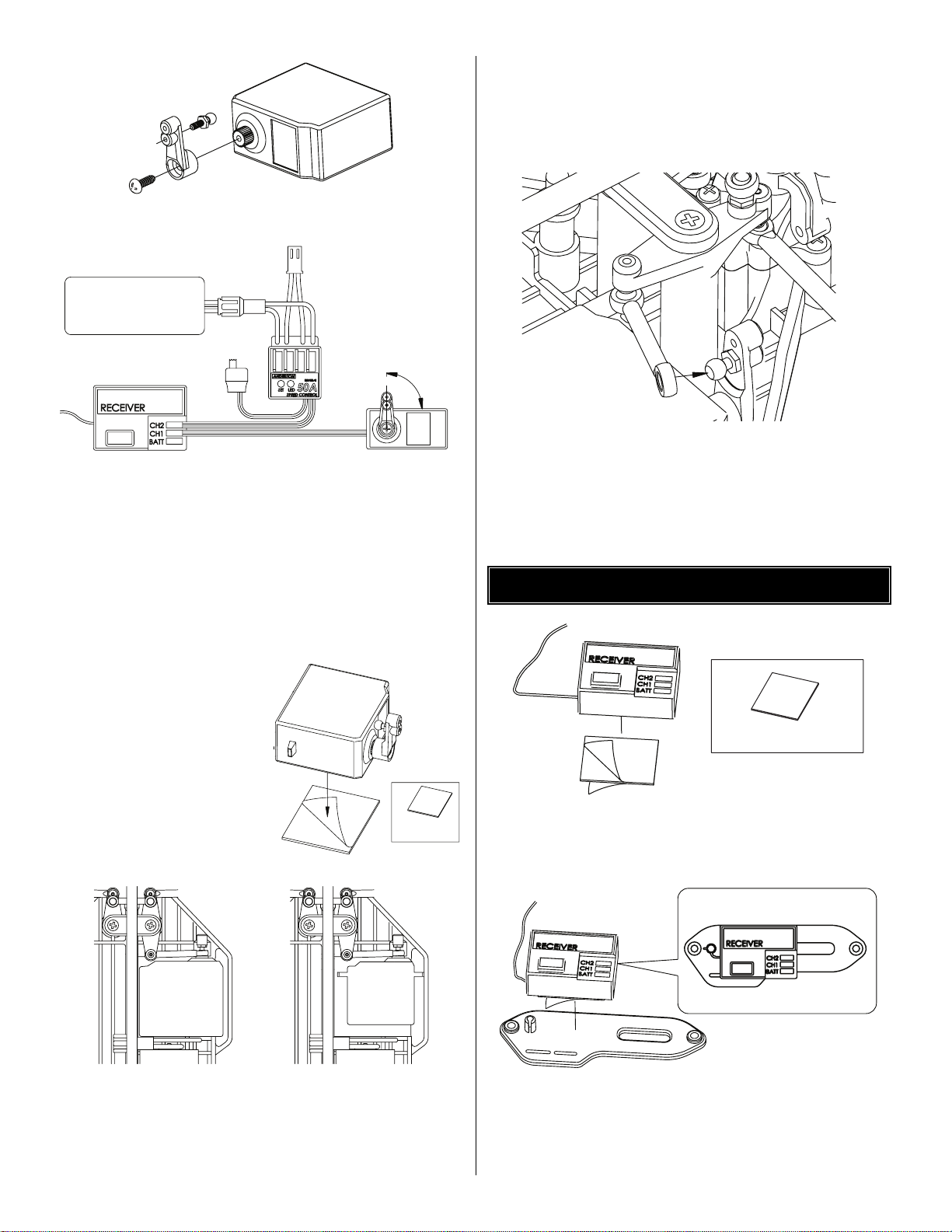

❏ 1. Install a piece of double-sided tape (S) onto the bottom

of your receiver. TIP: Thoroughly clean the receiver with

rubbing alcohol.

❏ 2. Install the receiver onto the wide portion of the battery

strap (42) as shown in the drawing.Make sure the receiver

is positioned so that the receiver antenna is pointing toward

the antenna mount. TIP: Thoroughly clean the receiver with

rubbing alcohol.

RECEIVER INSTALLATION

31

Standard servo

Micro servo

Typical steering

servo installation.

ON

7.2V BATTERY

90 deg

Center your servo with

your transmitter trims

before installing the servo

D

4

30

S

S

Double-Sided

Tape

S

Double-Sided Tape

S

42

Page 5

❏ 3.Run the receiver antenna wire through your fingers sever al

times to straighten it and then install it into the antenna tube

(43). A small amount of soapy water may also be used to help

get the antenna through the tube.

❏ 4. Leave a small amount of slack between the receiver

and the antenna mount and install the antenna tube (43)

into the antenna mount molded on the battery strap (42).

❏ 5. Secure the antenna to the antenna tube (43) using the

antenna cover (66).

❏ 1. Install a piece of double-sided tape (S) onto the bottom

of your speed control.

❏ 2. Remove the protective backing from the double-sided

tape and install the speed control onto the top of the servo

as shown in the drawing.

❏ 3. Make sure the wires are not too close to the drive shaft

(17).They could get caught in the shaft and become damaged.

❏ 4. Refer to the instructions that came with your speed

control for proper setup.

❏ 1. Remove the body clips from the battery holder and

insert the charged 6-cell batter y pack into the chassis.

❏ 2. Re-install the battery clips onto the batter y holder.

❏ 3.T urn the transmitter on, then the receiver.NOTE:Always

turn your transmitter on first. Gently pull back on the throttle

trigger.The Mini Quake SE should slowly move forward. If the

Mini Quake SE goes in reverse, move the throttle reversing

switch on the transmitter to the opposite position. After doing

this, the throttle trim may need to be adjusted to find the

throttle’s neutral point.See radio instructions.

❏ 4. Now, check that the steering reversing switch is set

properly.With the transmitter wheel facing you and the truck

facing away from you, turn the transmitter steering wheel to

the right. The wheels of the truck should turn so that when

the truck moves it will turn to the right. If it tur ns to the left,

the steering servo reversing switch needs to be moved to

the opposite position. After reversing the steering, the

steering trim on the transmitter may need to be adjusted to

center the steering of the truck.

FINISHING THE MINI QUAKE SE

23mm

23mm

Double Sided Tape

MOTOR

BATTERY

CH2

Speed Control

SPEED CONTROL INSTALLATION

Antenna Tube

IMPORTANT: Never cut the receiver antenna!

Doing so will severely reduce your range.

43

43

5

66

66

Antenna Cover

Page 6

The Mini Quake SE body comes clear. Below are a few tips

to follow when painting your Mini Quake SE body.

CAUTION:

• Always paint in a well-ventilated area.

• Never paint near an open flame.

❏ 1. Wash the inside of the body out with dish soap and

water.Make sure the body is thoroughly rinsed out.

❏ 2. Install the included window masks into the inside of the

body. Make sure the edges are well sealed to the body

to prevent leaks.

❏ 3. Use a quality masking tape or Hobbico

®

Liquid Mask to

mask the inside of the body off.

❏ 4.If using masking tape, make sure it is properly

sealed down.

❏ 5. If using Hobbico Liquid Mask, make sure to use

multiple coats.Make sure not to put the liquid mask on

too thick or too thin. 2-3 medium coats work best.

❏ 6. Use a new hobby b lade when cutting the masking tape

or liquid mask.

❏ 7. Paint the inside of the body using a quality Lexan

compatible paint. Spray dark colors first and always

back light colors with white or silver.

❏8.Decal the body as desired and install it onto the chassis,

securing it in place with the four included body clips.

For additional painting tips, please visit the f ollowing websites:

www.rccaraction.com/articles/htshake_1.asp

www.rctech.net/articles/painting_hauntedmyst.shtml

www.rcxotic.com/pkg-how/000002/index.shtml

BEFORE EACH RUN

• Make sure the batteries in the transmitter are charged.

• Mak e sure there are no loose or damaged parts on the kit.

• Check the drive train for binding that could cause

possible damage to the kit or the electronics.

• Check that the ESC and receiver are properly secured to

the chassis.

• Check to make sure all wires are properly secured.

AFTER EACH RUN

• Clean any large globs of dir t, carpet fuzz or any other

debris from the chassis.

• Disconnect and remov e the battery from the Mini Quake SE.

• Check for any broken or damaged parts. This way parts

may be replaced before the next run.

AFTER EVERY 10 RUNS

• Check to make sure the bearings are free of debris.

• Check for a smooth gear mesh.

• Check the tires to make sure they are still properly glued

to the wheels.

RIDE HEIGHT ADJUSTMENT

The ride height of the Mini Quake SE is easily adjusted by

using the included pre-load spacers (67). To increase the

ride height of the Mini Quake SE, install a pre-load spacer

onto each of the shock bodies between the spring and the

shock cap.The more pre-load clips you install, the more ride

height you will achieve. Make sure you install the same

amount of pre-load clips to each of the shocks.To lower the

ride height of the Mini Quake SE, remove the desired

amount of pre-load spacers from the shocks. TIP: Rough,

rocky surfaces require higher ride height; flat, smooth

surfaces allow a lower ride height.

PINIONS

The Mini Quake SE comes stock with the 16 tooth pinion.To

obtain higher top speeds you can install a larger pinion gear

onto the motor.This will, howe ver, decrease your acceleration

and run time. TIP: Smaller pinion equals more torque, less

top speed. Larger pinion equals more top speed, less torque.

SPURS

DuraTrax offers two different spur gear options for the Mini

Quake (a 45-tooth spur gear is included with the Mini Quake

SE): 40-Tooth (DTXC7409) and 49-Tooth (DTXC7432). The

40-tooth will give increased top speed, but decrease torque,

the 49-tooth will increase torque but decrease top speed.

SHOCK MOUNT LOCATION

There are three different lower shock mounting positions on

the Mini Quake SE. For jumping and climbing, the best

location is the inner most hole of suspension arm. This

makes the truck’s suspension feel softer. For racing and

surfaces with more traction, the best location is the outer

most hole.This location gives the truck’s suspension a stiff er

feel and allows less chassis roll in the corners.The middle

is a good all around location. Tip: Make sure the front

shocks are all in the same location and make sure all of the

rear shocks are all in the same location.They do not have to

be in the same location from front to rear.

SHOCK OIL

The Mini Quake SE comes stock with 25 weight oil in the

shocks.The handling of the tr uck can be tuned by changing

the shock oil to either heavier (bigger number) or lighter

(lower number .) By putting hea vier oil in the shocks , the truck

will have less chassis roll and become less responsive.

Putting lighter oil in the shocks will cause the truck to be

more responsive and hav e more chassis roll.For smooth, flat

surfaces, a thicker oil would be best. For surfaces that are

rough or have jumps, a lighter oil would be best.

SHOCK SPRINGS

DuraTrax offers three different shock springs: Soft (gray),

Medium/Stock (white) and Heavy (yellow). For rutted tracks

with small jumps, a soft spring should be used. For tracks

with large jumps, a heavy spring should be used to help

prevent chassis slap.

TUNING

RUNNING AND MAINTENANCE TIPS

P AINTING THE BOD Y

6

Page 7

❏1. Install a 6x10 bearing (61) onto the diff outdrive 1 (44).

❏2. Install diff outdrive 1 (44) into diff plate holder 1 (45).

❏3. Install a diff plate (46) onto the diff plate holder 1 (45).

❏4. Install a 4x7mm bearing (49) onto the diff plate holder

1 (45).Then install the differential main gear (47).

❏ 5. Apply grease to each of the 12 differential balls (48) and

install them into the differential main gear (47).

❏6. Install a second 4x7mm bear ing (49) onto the diff plate

holder (45).

❏7. Install the other differential plate (46) onto the

differential plate holder 2 (69).

❏8. Install a differential thrust plate (71) onto the differential

bolt (73).

❏9. Place a generous amount of diff grease (not included)

onto the differential thrust plates (71). Then install six

differential balls (48) onto the diff thrust plate (71).

❏10. Next install the second differential thrust plate (71)

onto the differential bolt (73).

❏11. Install a rubber spacer (70) onto the differential bolt

(73) and slide it up against the differential plate (71).

❏ 12. Apply threadlocking compound on the diff bolt (73)

threads and install the diff bolt into the diff plate holder (69).

❏ 13. Carefully install the diff outdr ive inner side 2 (75) onto

the diff plate holder side 2.Note:This will hold the thrust

balls in place when you tighten the differential bolt.

❏ 14. Install a 6x10mm bearing (61) onto the diff outdrive

outer side 2 (75). Then install the diff outdrive outer (75)

into the diff outdrive inner (74).Secure the pieces together

by installing a 5mm E-clip (C).

Using a 1.5mm hex wrench, gently tighten the differential bolt

(73). Tighten the bolt until it becomes snug.Then back it off

1/16 of a turn. Note: Do not over tighten the bolt. It could

damage the differential balls and differential plates.The

differential bolt may need to be tightened after the first

couple of runs.This is due to the par ts wearing in.

You can use the adjustable ball diffs to tune your truck’s

handling. Tightening the ball diff will increase forward

traction, but decrease cornering. TIP: Be sure not to

overtighten or loosen the ball diff.Ov ertightening will put flat

spots on the balls, causing excess drag. Too loose of a

setting will make the differential slip and overheat.

BALL DIFFERENTIAL TUNING

BALL DIFFERENTIAL ASSEMBLY

7

ASSEMBLY GUIDE

Page 8

8

Apply ball diff grease

Using a 1.5mm hex wrench, gently tighten the differential bolt (73) until it

becomes snug.Then back it off 1/16 of a turn.

Note: Do not overtighten the bolt. It could damage the differential balls and

differential plates. The differential bolt may need to be tightened after the

first couple of runs.This is due to parts wearing in.

Page 9

9

Page 10

10

3.8mm Ball Stud

3.8mm Ball Stud

4x7mm Bushing

Page 11

11

Page 12

12

Tip: Squeeze a piece

of paper to help set

the proper mesh.

Page 13

131415

Page 14

Page 15

Page 16

163517

Page 17

SET

LED

Apply CA glue to the inside

of both the rim and the tire.

Page 18

18

S

Double Sided

Tape

Page 19

19

Page 20

OTHER ITEMS AVAILABLE FROM DURATRAX

DTXC2377

Kwik Trak Racing Cones

DTXQ0100

Metric Phillips Head Screw Set

DTXR0140 Screwdriver Set

DTXC2375

Kwik Ramp Portable Jump

Pit Tech Mini Car Stand

DTXC2361 Blue

DTXC2362 Orange

DTXC2363 Purple

DTXC2364 Green

DTXR0183 Ultimate Drivers

Phillips Screwdriver

DTXR0292 Ultimate Drivers

Metric Hex Drivers

DTXP2040 Vinyl W ork Mat

DTXC2459

Power Shot Motor Cleaner

DTXP2015

Transmitter Bag

DTXC8279

Motor Heatsink Blue

DTXC6997

Graphite Chassis

Loading...

Loading...