Duke SPE-VC-1 User Manual

SUGGESTED SPECIFICATIONS FOR CONTROL CABINET

MODEL SPE-VC-1__

Control Cabinet to be SOUTHERN ENGINEERING SYSTEMS by Duke Mfg Co., model SPE-VC-1__,

UL Listed, water wash control cabinet.

Cabinet constructed of 18 gauge stainless steel, consisting of two individual compartments. Polish stainless

steel to a #3 finish.

The Electrical Compartment houses all necessary controls for system operation including fan controls,

relays, P.C. board, fuses and terminal blocks designed to operate exhaust and make-up air blowers in

coordination with ventilator damper and ventilator wash cycle functions.

The Plumbing Compartment shall incorporate wash solenoid valve(s), water shut-off valve, line strainer,

detergent level sensor, detergent pump and tank, temperature/pressure gauge and shock arrestor. All

plumbing components are accessible behind a hinged access door.

NOTE: A remote detergent assembly is available for larger hood installations with significant detergent

demands.

A Vacuum Breaker-detergent injection assembly and Remote Fire Switch are furnished loose for field

installation by others..

The standard cabinet can accommodate Optional Features such as: Sequential washing and ventilator light

switch.

Applicable field trades to supply and connect rough-ins and field connections required to control cabinet,

ventilator and mechanical roof-top equipment.

Cabinet shall be UL listed. Equipment built in an ISO 9001:2000 approved manufacturing facility.

2305 N. Broadway

St. Louis, MO 63012

Ph 314-231-1130

Fax 314-231-5074

www.dukemfg.com

BY

"Your Solutions Partner"

4/07

Optional Accessories

Light switch

Sequence Washing - Qty. ___ ( Max. 4 )

Reduced Pressure Backflow Preventer

Stainless Steel Perimeter Angle Trim ( Furn. Loose )

Design Option (Pick One)

VC-1C S/S Conventional Control Module with push button controls

VC-1M S/S Mode Commander Control Module with programmable Microprocessor

Shipping Wt. 150 lbs. (Per Section)

COMMENTS/NOTES __________________________________________________________________

E2

E3

H.W. OUTLET. INSUL. LINE FROM

DETERGENT ASSEMBLY TO

VENTILATOR (BY PLUMBER)

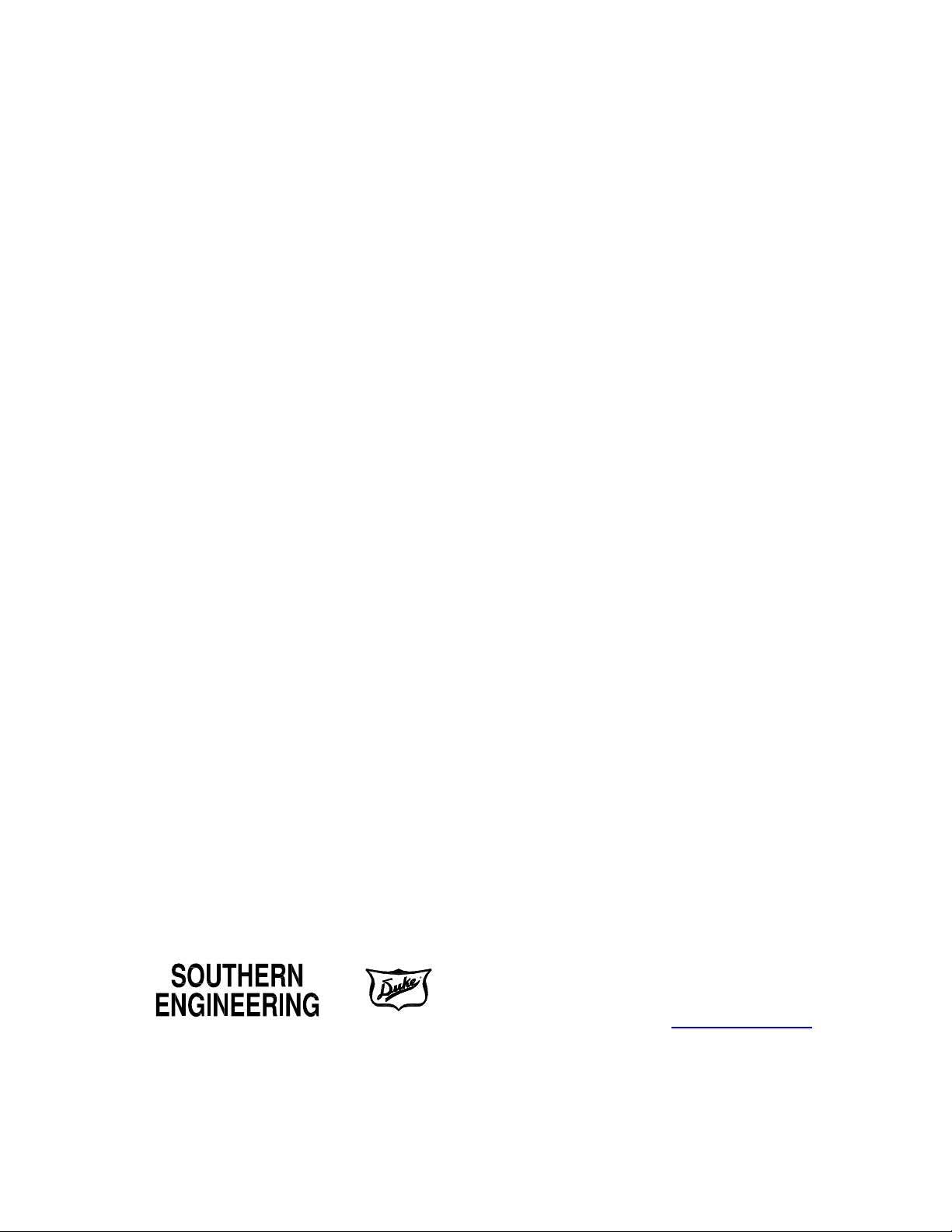

#VC-1C OR #VC-1M SINGLE WASH

WALL CUT-OUT TO BE 2'-6 1/2"w X 2'-0 1/2"h X 7"d

E1

7"

P3

P2

VACUUM BREAKER -DETERGENT

INLET ASSEMBLY FURN. LOOSE

1/4" COPPER DET. LINE

FROM CABINET TO INLET

ASSEMBLY (BYPLUMBER)

2'-6"

O.A. SIZE TO BE 2'-6"w X 2' -0"h X 7"d

P1

P1

*VACUUM BREAKER MUST BE

INSTALLED (BY PLUMBER) AT

LEAST 6" ABOVE ANY PIPING

BETWEEN VACUUM BREAKER

AND VENTILATOR.

2'-0"

H.W. SUPPLY (BY PLUMBER)

DRAIN EXTENDED TO FUNNEL

4'-0" A.F.F.

FLOOR DRAIN (BY PLUMBER)

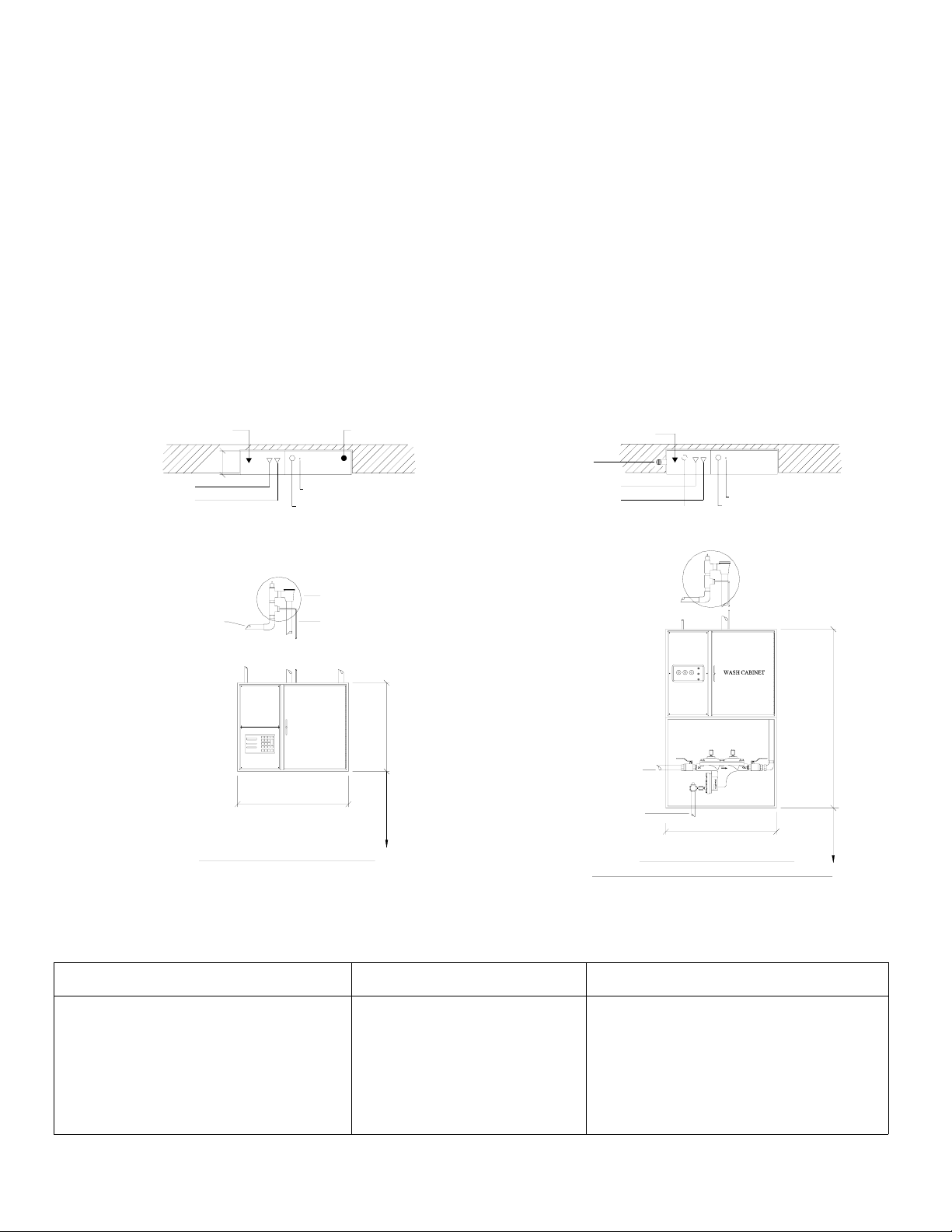

WITH REDUCED PRESSURE BACKFLOW PREVENTER

E1

E2

E3

WALL CUT-OUT TO BE 2'-6 1/2"w X 2'-0 1/2"h X 7"d

P6

(BELOW)

#VC-1C OR #VC-1M SINGLE WASH

O.A. SIZE 2'-6"w X 4'-0"h X 7"d

2'-6"

P3

P2

4'-0"

3'-6" A.F.F.

ELECTRICAL

E1 - 1/2" CONDUIT CONTAINING

120V. ELECTRIC SUPPLY

(AVAILABLE 24 HOURS)

E2 - 1/2" CONDUIT CONTAINING

TWO (2) WIRES (16V.) TO VNT'L. T-STATS

E3 - 1/2" CONDUIT CONTAINING

A. TWO (2) WIRES TO VNT'L. J-BOX

B. TWO (2) WIRES TO REMOTE FIRE SWITCH

C. TWO (2) WIRES TO MAGNETIC STARTER OF EXH. FAN

PLUMBING

P1 - HOT WATER INLET

P2 - HOT WATER OUTLET

P3 - 1/4" COPPER DETERGENT OUTLET

P4 - 1-1/2" OPEN DRAIN

INSTALLATION NOTES

1 - 110° TO 160° HOT WATER REQUIRED

2 - 40 P.S.I. FLOW PRESSURE REQUIRED

(ALLOWABLE RANGE = 26 to 60 P.S.I.)

3 - HOT WATER INLET SIZE BASED ON VENTILATOR

LENGTH: 3'-0" to 15'-0" = 3/4", 15'-6" to

30'-0" = 1", 30'-6" to 50'-0" = 1-1/4",

50'-6" to 100'-0" = 1-1/2"

4 - DETERGENT CONSUMPTION APPROXIMATELY

1-G.P.M. PER LINEAL FOOT OF VENTILATOR

FOR A 5-MINUTE WASH CYCLE

Loading...

Loading...