Duke DSO 500 Service Manual

SPEED OVEN

MODEL

DSO 500

Service Manual

Please read this manual completely before attempting to

install, operate or service this equipment

This manual is Copyright ©2011 Duke Manufacturing Company. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Company.

Duke Manufacturing Company

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 168465B

Service Manual for Speed Oven Model DSO 500

2

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with the door open.

(b) Make the following safety checks on all ovens to be serviced before activating the magnetron

or other microwave source, and make repairs as necessary.

(1) interlock operation

(2) proper door closing

(3) seal and sealing surfaces (arcing, wear, and other damage)

(4) damage to or loosening of hinges and latches

(5) evidence of dropping or abuse

(c) Before turning on microwave power for any service test or inspection within the microwave

generating compartments, check the magnetron, wave guide or transmission line, and cavity

for proper alignment, integrity, and connections.

(d) Any defective or misadjusted components in the interlock monitor, door seal, and microwave

generation and transmission systems shall be repaired, replaced, or adjusted by procedures

described in this manual before the oven is released to the owner.

(e) A microwave leakage check to verify compliance with the Federal Performance Standard should

be performed on each oven prior to release to the owner.

CAUTION: When servicing the unit, be sure no electrical wires contact a sharp edge.

Check all wiring for possible cuts and/or abrasions, which can occur during servicing.

3

Service Manual for Speed Oven Model DSO 500

TABLE OF CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................3

INTRODUCTION .................................................................................................................................6

MAIN FEATURES ..........................................................................................................................7

INSTALLATION ...................................................................................................................................8

UNPACKING OVEN ......................................................................................................................8

RADIO INTERFERENCE ..............................................................................................................8

OVEN PLACEMENT......................................................................................................................8

ELECTRICAL INFORMATION .......................................................................................................8

EARTHING INSTRUCTIONS ........................................................................................................9

EXTERNAL EQUIPOTENTIAL ......................................................................................................9

SPECIFICATIONS .............................................................................................................................10

INPUT POWER ...........................................................................................................................10

OUTPUT POWER .......................................................................................................................10

DIMENSIONS ..............................................................................................................................10

WEIGHT ......................................................................................................................................10

RECOMMENDED CLEARANCES ..............................................................................................10

INTERNAL COOKING CAVITY DIMENSIONS............................................................................10

PREVENTIVE MAINTENANCE .........................................................................................................11

CLEANING ..................................................................................................................................11

SERVICING PROCEDURES ............................................................................................................12

GENERAL ....................................................................................................................................12

COMPONENT OVERVIEW ...............................................................................................................13

STIRRER MOTOR AND GEARBOX ...........................................................................................13

HIGH VOLTAGE TRANSFORMERS ...........................................................................................15

HIGH VOLTAGE RECTIFIERS ....................................................................................................17

HIGH VOLTAGE CAPACITORS ..................................................................................................19

MAGNETRONS ...........................................................................................................................21

MAGNETRON THERMAL SWITCHES .......................................................................................23

SOLID STATE RELAYS ...............................................................................................................25

MECHANICAL RELAYS AND INTERLOCK SWITCHES ............................................................27

HEATERS AND THERMAL CUTOUTS .......................................................................................29

LINE FUSES ................................................................................................................................31

JET PLATES ................................................................................................................................33

CABINET COOLING FANS .........................................................................................................35

4

TABLE OF CONTENTS

MAGNETRON COOLING FANS .................................................................................................37

CABINET THERMAL SWITCH ....................................................................................................39

KEYPAD/CONTROL BOARD ......................................................................................................41

INVERTERS ................................................................................................................................43

SYSTEM TESTING ...........................................................................................................................45

POWER OUTPUT MEASUREMENT ..........................................................................................45

MICROWAVE LEAKAGE TEST ...................................................................................................45

COMPONENT TESTING ...................................................................................................................47

POWER TRANSFORMER TEST ................................................................................................47

DISCHARGING THE HIGH VOLTAGE SYSTEM ON THE DUKE SPEED OVEN. .....................48

HIGH VOLTAGE CAPACITOR TEST ..........................................................................................49

HIGH VOLTAGE RECTIFIER TEST ............................................................................................50

MECHANICAL RELAYS AND INTERLOCK SWITCHES ............................................................51

REPAIR PROCEDURES ...................................................................................................................53

RELAY AND SWITCH REPLACEMENT ......................................................................................53

LINE FUSE REPLACEMENT ......................................................................................................54

INVERTER REPLACEMENT .......................................................................................................55

BLOWER MOTOR REPLACEMENT ...........................................................................................56

ELECTRICAL PANEL REPLACEMENT ......................................................................................58

MAGNETRON REPLACEMENT .................................................................................................59

STIRRER MOTOR REPLACEMENT ...........................................................................................60

HEATER ELEMENT REPLACEMENT ........................................................................................61

CABINET THERMAL SWITCH REPLACEMENT ........................................................................62

HIGH VOLTAGE TRANSFORMER REPLACEMENT..................................................................63

FRONT THERMAL COOLING FAN REPLACEMENT .................................................................64

INTAKE AND EXHAUST FANS REPLACEMENT .......................................................................65

ADJUSTMENTS ..........................................................................................................................66

TROUBLESHOOTING ......................................................................................................................67

SCHEMATIC DIAGRAM ....................................................................................................................71

SPARE PARTS LIST .........................................................................................................................72

APPENDIX A INVERTER PROGRAMMING .....................................................................................73

PROGRAMMING PROCEDURE .................................................................................................73

INVERTER SETTINGS................................................................................................................74

5

Service Manual for Speed Oven Model DSO 500

INTRODUCTION

7

512 10

1012 63 4

4

8 911

Figure 1

6

EQUIPMENT OVERVIEW

MAIN FEATURES

The main features of the Model DSO 500 Speed

Oven are identied in Figure 1 and described

below.

1. ON/OFF SWITCH

Turning ON the power switch will operate the

blower fans, stirrer motor and cooling system. It

will also activate the control panel and heat up

the oven to the temperature setting, which will

display “Oven Ready.

NOTE: When the Power Switch is turned “OFF”,

the rear mounted Cooling Fans will be

running until the unit has cooled down or

the power cord removed.

2. CONTROL PANEL

This is the electronic control board that is

programmable for different menus, temperature

setting, variable fan speed, Microwave Power

Connection only, Microwave and Convection

Combination, etc. This also has some service

diagnostics.

3. DRAIN PAN

This serves as the collector of any liquid from the

Oven cavity during cooking or cleaning.

4. OVEN CAVITY

The oven cavity is constructed from stainless

steel and must be kept clean. (See CARE and

CLEANING instructions in the OPERATOR’S

MANUAL). The top cavity has a thin jet plate and

the bottom cavity has the wire rack and bottom

jet plate. A drain plug is also provided for ease

of cleaning.

5. CONVECTION FAN

The unit has two blower systems (Top and

Bottom) for distributing the patented impingement

air system. Both blower systems can be operated independently over the entire speed range

for more precise control of cooking, browning,

etc. The perforated rear panel and the bottom

jet plates must be kept clean and free of debris.

(See CARE and CLEANING instructions in the

OPERATOR’S MANUAL).

6. DOOR AND HEAT SHIELD

The door is pulled downwards and towards you

to open. The door is designed with interlocks for

microwave safety. The door should NOT be used

to support heavy dishes. It must be kept clean.

The door includes a heat shield attached to the

front.(See CARE and CLEANING instructions in

the OPERATOR’S MANUAL).

7. DOOR SEAL

These ensure a seal around the door cavity. They

should be kept clean and checked regularly for

signs of damage.

8. REMOVABLE BOTTOM JET PLATE

The bottom jet plate directs the air from the

bottom of the oven to the underside of the

product.

9. DRAIN OUTLET AND PLUG

Remove drain plug when cleaning. (See CARE

and CLEANING instructions in the OPERATOR’S

MANUAL). Make sure it is replaced into position

before replacing bottom jet plate.

10. AIR OUTLETS

These air outlets and louvers on the left side,

right side and rear panels are part of the cooling

system of the electrical components. They must

be kept free from obstruction. It will not allow

microwave energy to escape into the environment. See clearance allowances specied in the

INSTALLATION Section of this manual.

11. EXHAUST VENT

The exhaust vent is at the rear of the oven. This

enables steam to escape and prevents build up of

condensation. It will not allow microwave energy

to escape into the environment.

12. COOLING FANS

Cooling Fans above the power cord are mounted to bring in cool air from the room into the

machinery compartment. The single fan below

the exhaust vent is directed to blow out the air

from the machinery compartment.

7

Service Manual for Speed Oven Model DSO 500

INSTALLATION

UNPACKING OVEN

• Inspect oven for damage such as dents

in door or inside oven cavity.

• Report any dents or breakage to source

of purchase immediately. Do not attempt

to use oven if damaged.

• Remove all materials from oven interior.

• If oven has been stored in extremely cold

area, wait a few hours before connecting

power.

RADIO INTERFERENCE

Microwave operation may cause interference

to radio, television, or similar oven. Reduce or

eliminate interference by doing the following:

• Clean door and sealing surfaces of oven

according to instructions in Care and

Cleaning instruction in the OPERATORS

MANUAL

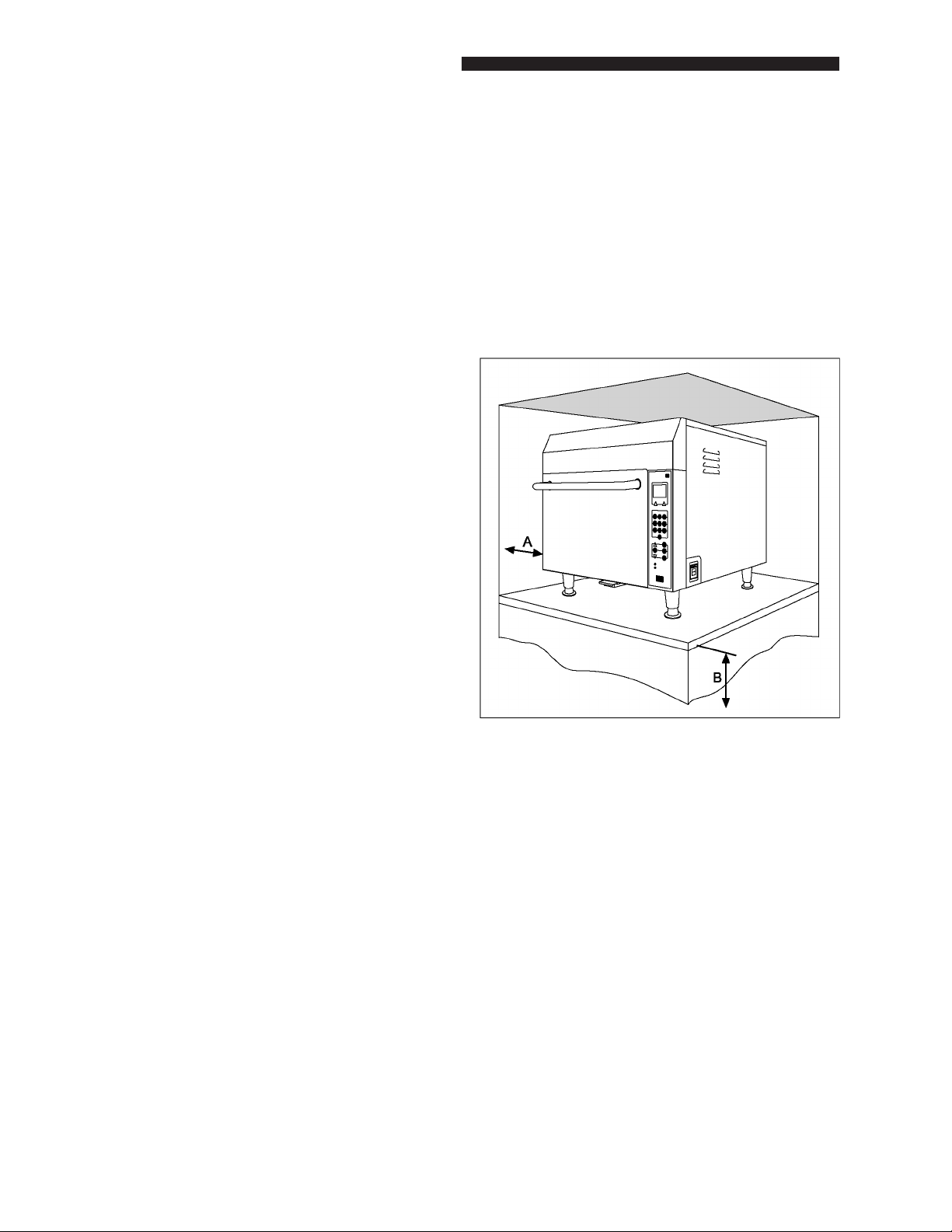

A. Allow at least 3” (7.62 cm) of clearance

around the sides of oven. Proper airow

around the oven cools electrical components. With restricted airow, the oven

may not operate properly and the life of

electrical parts is reduced.

B. Install oven so oven bottom is at least 3

feet (91.5 cm) above oor.

• Place radio, television, etc. as far as possible from oven

• Use a properly installed antenna on radio,

television, etc. to obtain stronger signal

reception

OVEN PLACEMENT

• Do not install oven next to or above source

of heat, such as pizza oven or deep fat

fryer. This could cause microwave oven

to operate improperly and could shorten

life of electrical parts

• Install oven on level countertop surface

• If provided, place warning label in a

conspicuous place close to microwave

oven

• Outlet should be located so that plug is

accessible when oven is in place

• Provide clearance as shown in Figure 2

and described in the following paragraphs

“A” and “B”

Figure 2. Oven Clearance Dimensions

ELECTRICAL INFORMATION

The switching operation of this microwave oven

can cause voltage uctuations on the supply

line. The operation of this oven under unfavorable voltage supply conditions can have adverse

effects. This device is intended for the connection to a power supply system with maximum

permissible system impedance Zmax of 1.1 Ohm

at the interface point of the user’s supply. The

user has to ensure that this device is connected

only to a power supply system, which fullls the

requirement above, If necessary, the user can ask

the public power supply company for the system

impedance at the interface point. The circuit

breakers used in this oven are Type C.

8

EQUIPMENT OVERVIEW

WARNING

TO AVOID RISK OF ELECTRICAL SHOCK OR

DEATH, THIS OVEN MUST BE GROUNDED

AND PLUG MUST NOT BE ALTERED.

WARNING

IMPROPER USE OF THE GROUNDING CAN

RESULT IN RISK OF ELECTRICAL SHOCK.”

CONSULT A QUALIFIED ELECTRICIAN

OR SERVICEMAN. IF THE GROUNDING

INSTRUCTIONS ARE NOT COMPLETELY

UNDERSTOOD, OR IF DOUBT EXISTS AS

TO WHETHER THE APPLIANCE IS PROPERLY GROUNDED, AND “DO NOT USE AN

EXTENSION CORD. IF THE POWER SUPPLY

CORD IS TOO SHORT, HAVE A QUALIFIED

ELECTRICIAN OR SERVICEMAN INSTALL

AN OUTLET NEAR THE APPLIANCE.

If the product power cord is too short, have a

qualied electrician install a three-slot receptacle.

This oven should be plugged into a separate

circuit with the electrical rating as provided in

product specifications (available on Duke’s

Wavelink website).

EXTERNAL EQUIPOTENTIAL

Earthing Terminal (export only)

Equipment has secondary earthing terminal.

Terminal provides external earthing connection used in addition to earthing prong on plug.

Located on outside of oven back, terminal is

marked with this symbol.

WARNING

EARTHING INSTRUCTIONS

WARNING

OVEN MUST BE GROUNDED.

Grounding reduces risk of electric shock by

providing an escape wire for the electric current if

an electrical short occurs. This oven is equipped

with a cord having a grounding wire with a

grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded.

Consult a qualied electrician or service provider if grounding instructions are not completely

understood, or if doubt exists as to whether the

oven is properly grounded.

CAUTION: Do not use an extension cord.

DO NOT R EMOVE EARTHING PRONG

WHEN INSTALLING EARTHED APPLIANCE

IN A LOCATION THAT DOES NOT HAVE

THREE WIRE EARTHING RECEPTACLE,

UNDER NO C ONDITION IS EARTHING

PRONG TO BE CUT OFF OR REMOVED. IT IS

THE PERSONAL RESPONSIBILITY OF THE

EQUIPMENT OWNER TO CONTACT A QUALIFIED ELECTRICIAN AND HAVE PROPERLY

EARTHED THREE PRONG WALL RECEPTACLE INSTALLED IN ACCORDANCE WITH

APPROPRIATE ELECTRICAL CODES.

Wire Color Code

The standard accepted color coding for earthing

wires is Green or green with a yellow strip.

WARNING

EARTHING LEADS ARE NOT INTENDED TO

CARRY CURRENT IN NORMAL OPERATION.

The service technician must replace all earths

prior to completion of the service call. Under no

condition should earth wire be left off causing

a potential hazard to service technicians and

consumer.

9

Service Manual for Speed Oven Model DSO 500

SPECIFICATIONS

Table 2 lists the specications for the Model DSO 500 Speed Oven.

Table 2. Specications

MODEL NO. DSO 500

INPUT POWER

Operating Voltage 208 – 240 VAC, 60 Hz

Current 29 Amps

Phase Single

Circuit Breaker 30A, Type C or D

OUTPUT POWER

Microwave 1600 Watts

Heaters 5400 Watts

DIMENSIONS

Height 26 in. (with 4 in. legs)

Width 25 7/8 in.

Depth 31 in. (incl. door handle)

WEIGHT

Unpacked Approximately 250 lbs.

Packed 360 lbs.

RECOMMENDED CLEARANCES

Height None required

Width 3 inches on each side

Depth None required

INTERNAL COOKING CAVITY DIMENSIONS

Height 8 in.

Width 16 in.

Depth 14-1/2 in.

10

PREVENTIVE MAINTENANCE

EQUIPMENT OVERVIEW

CLEANING

Stainless Steel Care and Cleaning

To prevent discoloration or rust on stainless steel

several important steps need to be taken. First,

we need to understand the properties of stainless steel. Stainless steel contains 70-80% iron

which will rust. It also contains 12-20% chromium

which forms an invisible passive lm over the

steels surface which acts as a shield against

corrosion. As long as the protective layer is

intact, the metal will not corrode. If the lm is

broken or contaminated, outside elements can

begin to breakdown the steel and begin to form

rust or discoloration.

Proper cleaning of stainless steel requires soft

cloths or plastic scouring pads.

CAUTION: Never use steel pads, wire brushes

or scrapers.

Early signs of stainless steel breakdown can

consist of small pits and cracks. If this has

begun, clean thoroughly and start to apply stainless steel cleaners in attempt to restore the

passivity of the steel.

WARNING

THE POWER MUST BE TURNED OFF AND

POWER CORD DISCONNECTED WHENEVER PERFORMING MAINTENANCE OR

REPAIR FUNCTIONS.

Gasket Maintenance

Gaskets require regular cleaning. Gasket cleaning can be done with the use of warm soapy

water. Also, never use sharp tools or knives to

scrape or clean the gasket which could possibly

damager the gasket.

Cleaning solutions need to be alkaline based or

non-chloride cleaners. Any cleaner containing

chlorides will damage the protective lm of the

stainless steel. Chlorides are also commonly

found in hard water, salts and household and

industrial cleaners. If cleaners containing chlorides are used, be sure to rinse repeatedly and

dry thoroughly upon completion.

Routine cleaning of stainless steel can be done

with soap and water. Extreme stains or grease

should be cleaned with a non-abrasive cleaner

and plastic scrub pad. It is always good to rub

with the grain of the steel. There are also stainless steel cleaners available which can restore

and preserve the nish of the steels protective

layer.

11

Service Manual for Speed Oven Model DSO 500

SERVICING PROCEDURES

GENERAL

The service section of this manual includes a

section called component overview. Information

on each component is a separate page. This

overview is not intended to provide detailed

information. Its purpose is to provide a general

understanding of what the component does and

how it is tested and replaced. When a procedure

is to be performed, refer to the detailed REPAIR

PROCEDURES. The information in this overview

includes the following:

• A general description of the function of

the component in the oven operation

• Location and Access information

• Safety Issues

• Tools Required

• Operational Testing

• Test Procedure

• Replacement Procedure

NOTE: Remember this overview is only intended

to provide a brief discussion on each component. Details for testing, adjusting and

replacement are provided separately in

the TESTING and REPAIR section of this

manual and should be referred to when

performing any procedure.

In addition to the Overview section this chapter

includes the following:

• Power Output Measurement

• Microwave Leakage Test

• Component Detailed Testing

• Detai l ed Re p air an d Re p l acement

Procedures

• Adjustment Procedures

• Troubleshooting Procedures

Additional chapters provide the Schematic Diagram and the Spare Parts list.

12

COMPONENT OVERVIEW

COMPONENT OVERVIEW

STIRRER MOTOR AND GEARBOX

The stirrer motor and gearbox, Figure 3, is

located near the front of the oven upper chamber above the upper jetplate. The stirrer motor

rotates the stirrer blade at 20 rpm. The rotating

stirrer blade evenly distributes the microwave

eld and the upper hot airow into the cook

chamber to ensure uniformity. Should the stirrer

blade cease to rotate during cooking, severe nonuniformity of cooking will be observed. Localized

burning of the food may occur and in the case of

cooking frozen food, very cold uncooked areas

may be detected.

Location and access

The stirrer motor is centrally located above the

top of the cook chamber. The top and side panels

will need to be removed.

Surface Components

Safety issues

• Electrical supply of 208/240 VAC to stirrer

motor which becomes live when power

cord is live

• Proximity to High Voltage system (5

kVDC) which can remain live, even after

power down

• Upper end of motor shaft rotates rapidly

with small exposed cooling fan

Tools required

• Flat blade screwdriver to remove top and

side panels

• 11/32 inch nut driver to remove nuts se-

curing motor and gearbox to top of oven

• Voltmeter

• Flash light

Operational testing

The stirrer motor is powered from the 208/240

VAC mains supply and is not controlled from

the main on/off switch on the right hand side.

The door safety interlocks interrupt this supply

when the door is opened, so that the stirrer blade

is stationary whenever the door is opened. The

interlock function should be checked by opening and closing the cook door and observing the

rotation of the stirrer motor fan. The rotation of

the stirrer blade can be checked by removing

the upper jet plate or observing the position

of the stirrer blade through the air holes in the

upper jet plate with a ashlight.

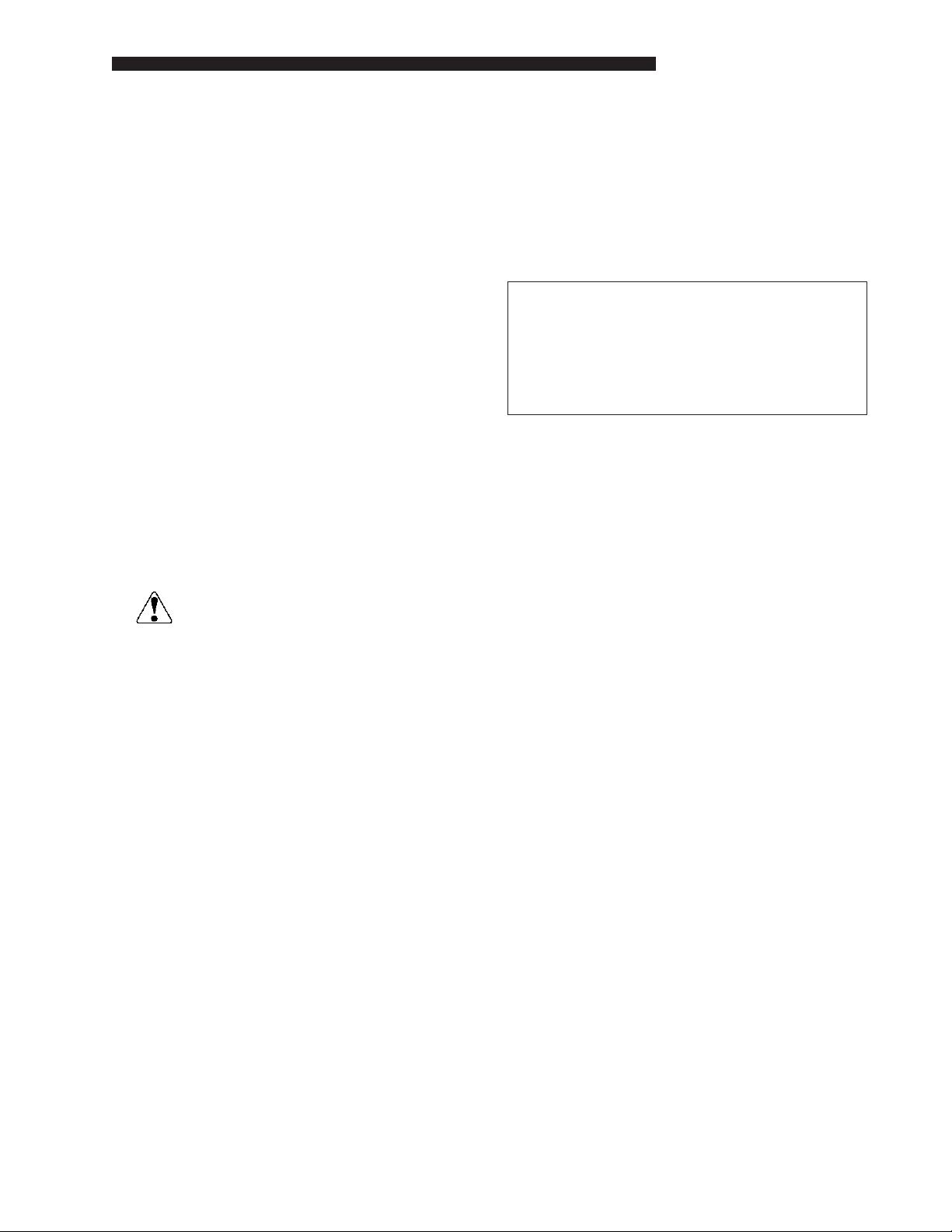

Figure 3. High Voltage and Inside Top

13

Service Manual for Speed Oven Model DSO 500

Test procedure

Check 208/240 VAC is present on the motor

power connections, wires 47 and 49, as above.

If power is not present, check incoming line voltage, line fuses, mechanical relays K6, K8 and

primary and secondary door switches.

If power is present at all times, the door interlock

safety system has failed. Check the mechanical

relays K6, K8 and primary and secondary door

switches.

STIRRER MOTOR AND GEARBOX - NOTES

Replacement

After removing the side and top panels and

disconnecting the power cord, the stirrer motor

power leads can be disconnected. There are

four 11/32 inch nuts securing the stirrer motor

and gearbox. Upon retting, align the dnveshaft

of the gearbox with the head of the coupling to

the stirrer blade.

14

COMPONENT OVERVIEW

HIGH VOLTAGE TRANSFORMERS

The transformers, Figure 4, step up the input line

voltage to 2.5 kV. This voltage is rectied by the

high voltage diodes and the high voltage capacitors for operation of the magnetrons.

Location and Access

The transformers are centrally located above

the top of the cook chamber. The top and side

panels will need to be removed.

Safety Issues

WARNING

THE HIGH VOLTAGE CAPACITORS RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

• Electrical supply of 208/240 VAC to trans-

formers when POWER switch is in ON

position and oven doors are closed

Tools Required.

• Flat blade screwdriver to remove top and

side panels

• 3/8 inch nut driver to remove nuts secur-

ing transformers to top of oven

• Voltmeter

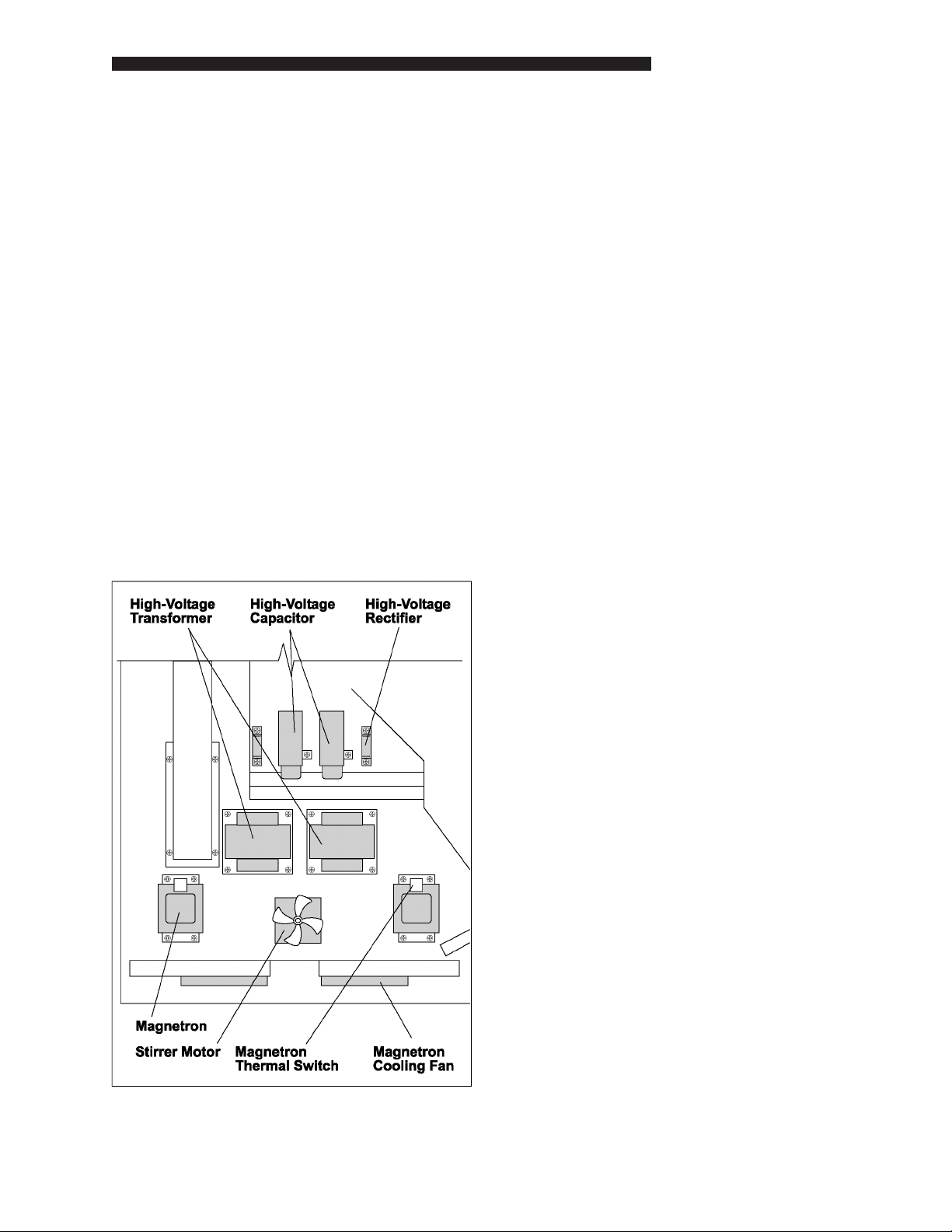

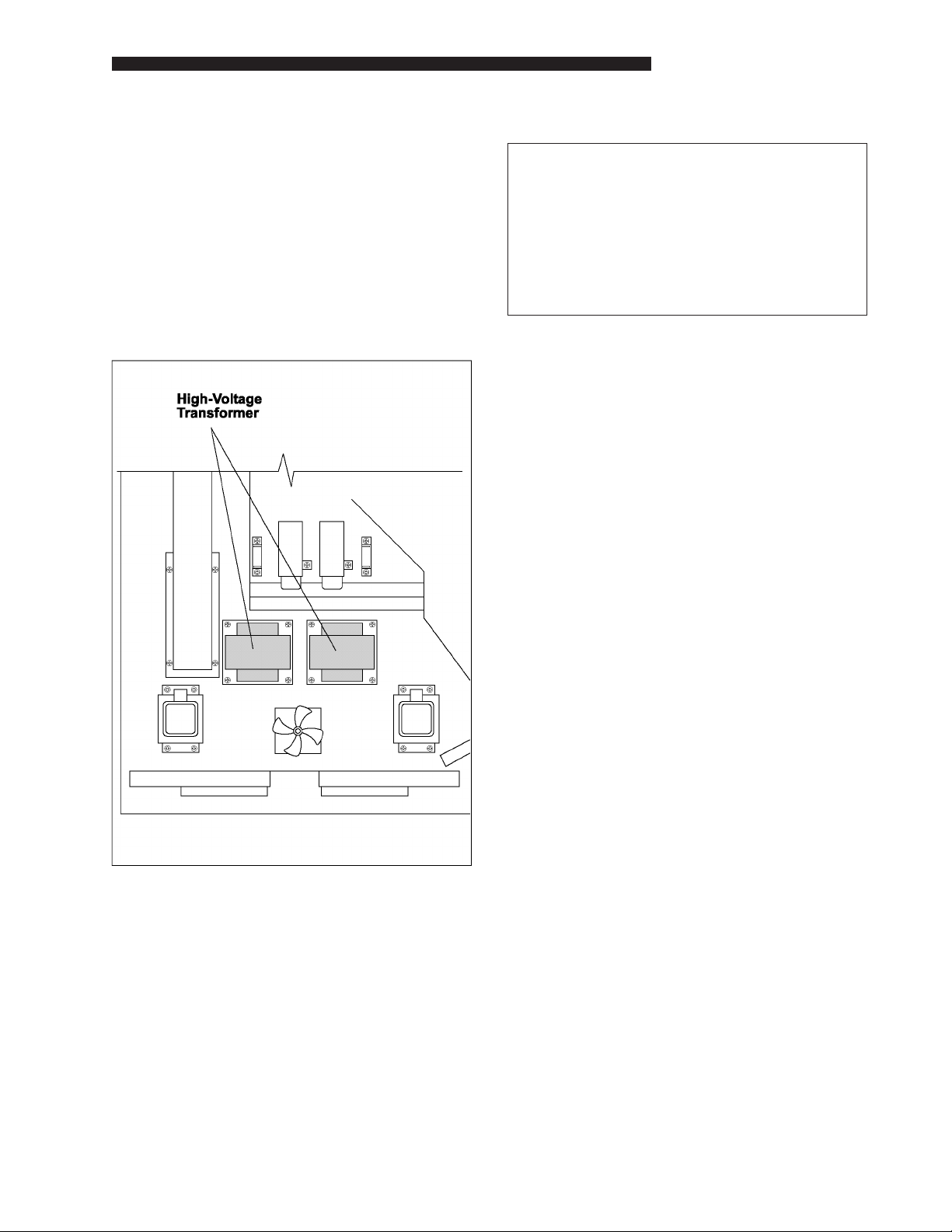

Figure 4. High Voltage Transformers

Operational Testing.

The transformers are powered from the 208/240

VAC mains supply through solid state relays K4

and K5 and mechanical relay K6 and K8. Relays K6 and K8 are controlled by the door safety

interlock requiring the oven door to be closed

to provide primary voltage to the transformers.

The door safety interlocks interrupt this supply

when the door is opened. Operation of relays K4

and K5 required the POWER switch to be in the

ON position to provide operating voltage to the

control board. The interlock function can be

checked by opening and closing the oven door

and observing the rotation of the blade on top of

the stirrer motor.

15

Service Manual for Speed Oven Model DSO 500

Test Procedure

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING. REFER TO DETAILED PROCEDURE IN THE

COMPONENT TESTING SECTION BEFORE

TESTING.

NOTE: Dangerous voltages can be present at

this component. Refer to detailed test

procedure for testing this component.

Check 208/240 VAC is present on the transformer primaries, wires 26 and 45 for mag #1

transformers and wires 27 and 48 for mag #2

transformer.

If power is not present, check incoming line voltage, line fuses, mechanical relays K6, K8 and

primary and secondary door switches.

Replacement

WARNING

THE HIGH VOLTAGE CAPACITOR RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

After removing the side and top panels and

disconnecting the power cord, the transformer

primary and secondary leads can be disconnected. There are four 3/8 inch nuts securing the

transformers.

If power is present at all times, the door interlock

safety system has failed. Check the mechanical

relays K6, K8 and primary and secondary door

switches and POWER ON/OFF switch.

HIGH VOLTAGE TRANSFORMERS - NOTES

16

COMPONENT OVERVIEW

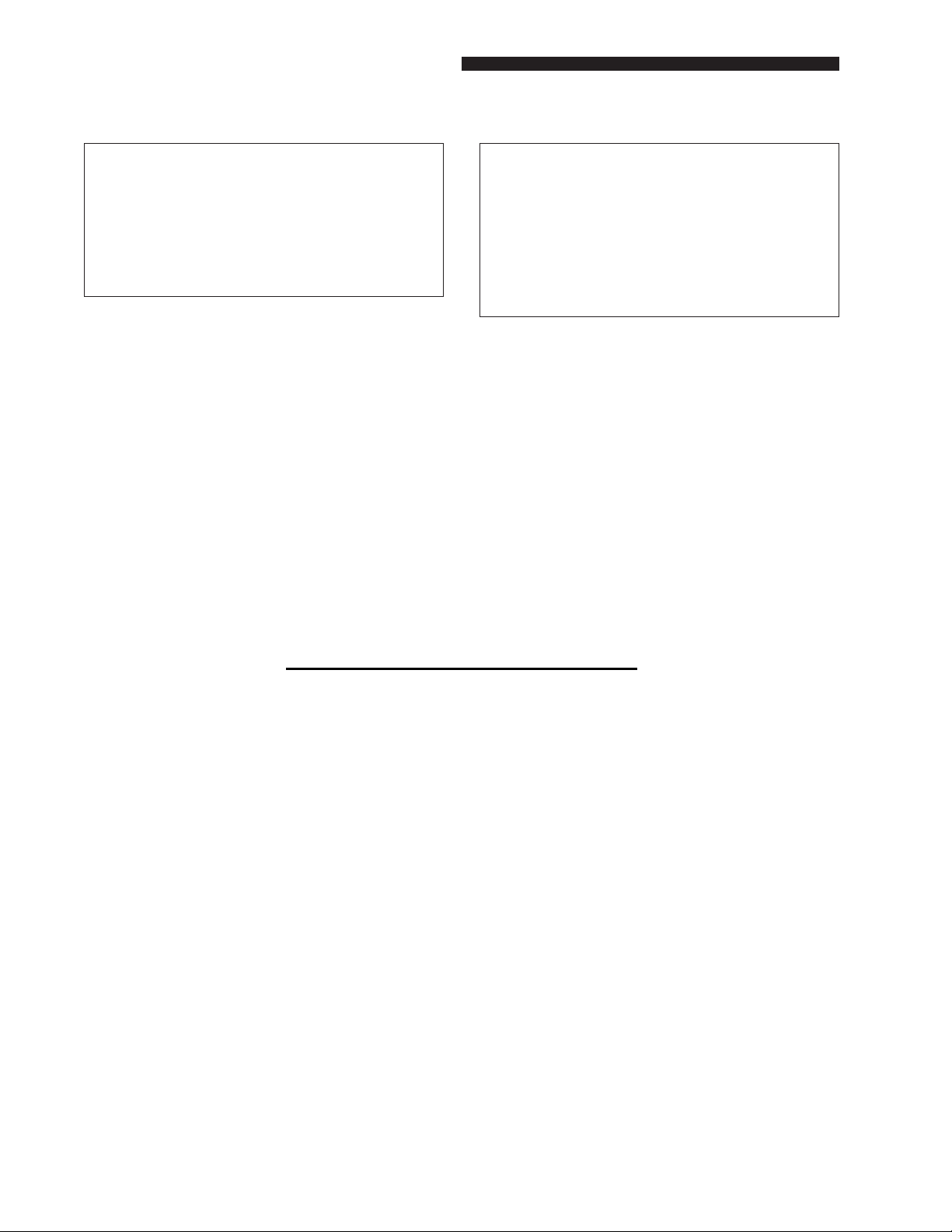

HIGH VOLTAGE RECTIFIERS

The high voltage diodes, Figure 5, rectify the

incoming 2.5 kV voltage and doubles it providing

5kVDC for magnetron operation.

Location and Access

The diodes are located above the top of the cook

chamber at the rear of the oven. The top and side

panels will need to be removed.

Safety Issues

WARNING

THE HIGH VOLTAGE CAPACITOR RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

• Electrical supply of 208/240 VAC to trans-

formers when POWER switch is in ON

position and oven doors are closed

Tools Required

• Flat blade screwdriver to remove top and

side panels

• Phillips #2 screwdriver to remove screws

securing diodes to top of oven

• Ohmmeter to check diodes

Figure 5. High Voltage Rectiers

Operational Testing

The transformers connected to the diodes are

powered from the 208/240 VAC mains supply through solid state relays K4 and K5 and

mechanical relay K6 and K8. Relays K6 and

K8 are controlled by the door safety interlock

requiring the oven door to be closed to provide

primary voltage to the transformers. The door

safety interlocks interrupt this supply when the

door is opened. Operation of relays K4 and K5

require the POWER switch to be in the ON position to provide operating voltage to the control

board. The interlock function can be checked by

opening and closing the oven door and observing the rotation of the blade on top of the stirrer

motor.

17

Service Manual for Speed Oven Model DSO 500

Test Procedure

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING. REFER TO DETAILED PROCEDURE IN THE

COMPONENT TESTING SECTION BEFORE

TESTING.

NOTE: Dangerous voltages can be present at

this component. Refer to detailed test

procedure for testing this component.

Disconnect the wires to the diodes. Use an ohmmeter to check diodes. Diodes should conduct

in one direction showing low resistance and not

conduct in the reverse direction, thus indicating

a very high resistance. High or low resistance in

both directions indicates a defective diode.

HIGH VOLTAGE RECTIFIERS - NOTES

Replacement

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING THE

TRANSFORMERS

After removing the side and top panels and

disconnecting the power cord, the diode leads

can be disconnected. There are two screws

securing each diode.

18

COMPONENT OVERVIEW

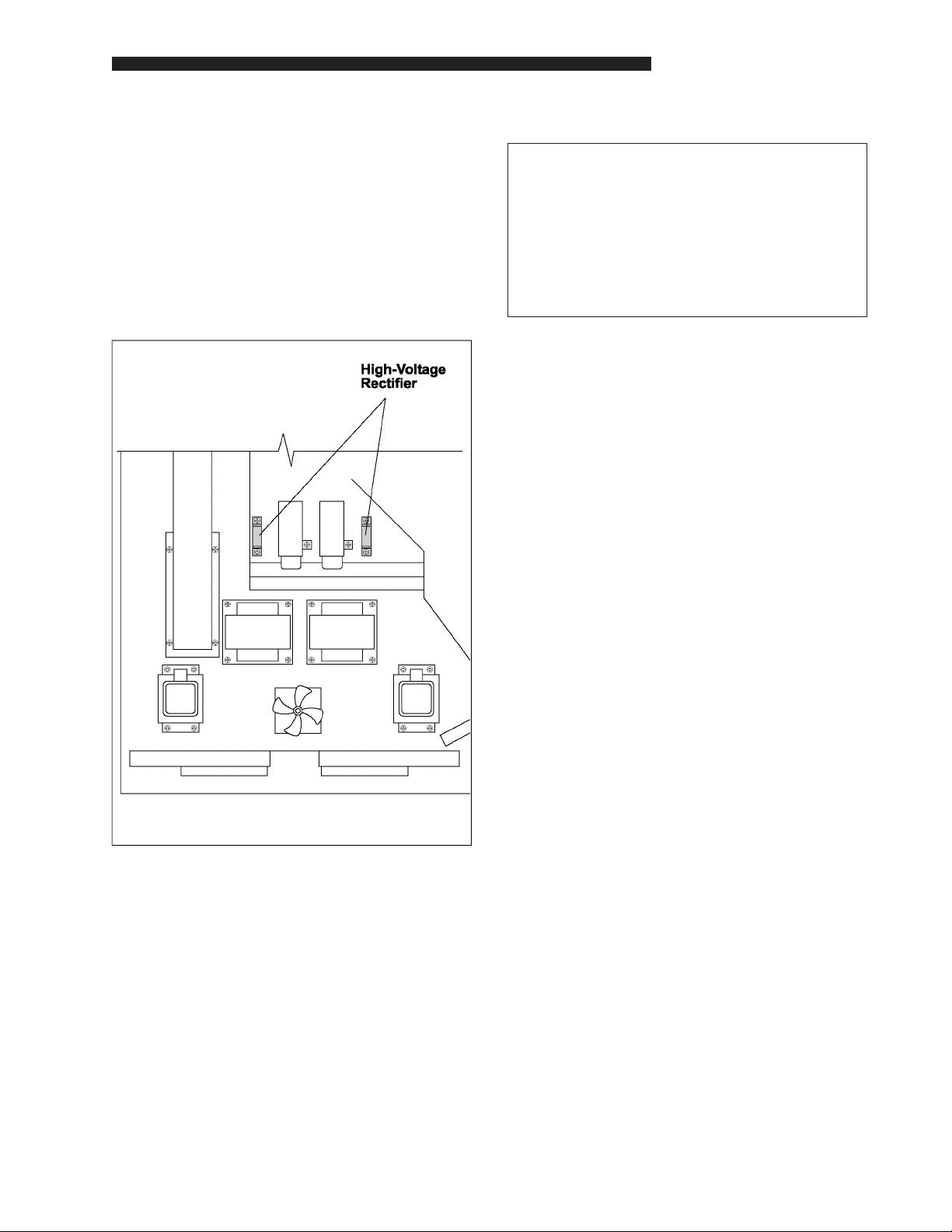

HIGH VOLTAGE CAPACITORS

The high voltage capacitors, Figure 6, store the

rectied high voltage (2.5 kVDC) for operation of

the magnetrons.

Location and Access.

The capacitors are located above the top of the

cook chamber at the rear of the oven. The top

and side panels will need to be removed.

Safety Issues

WARNING

THE HIGH VOLTAGE CAPACITOR RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

• Electrical supply of 208/240 VAC to trans-

formers when POWER switch is in ON

position and oven doors are closed

• Capacitors charge to the 2.5 kVDC level

when the high voltage circuit is properly

operating

Tools Required

• Flat blade screwdriver to remove top and

side panels

Figure 6. High Voltage Capacitors

• 5/16 inch nut driver to remove nuts secur-

ing diodes to top of oven

• Ohmmeter to check capacitors

Operational Testing

The capacitors charge whenever the transformer

is operating. The transformers connected to the

diodes for charging the capacitors are powered

from the 208/240 VAC mains supply through solid

state relays K4 and K5 and mechanical relay K6

and K8. Relays K6 and K8 are controlled by the

door safety interlock requiring the oven door to

be closed to provide primary voltage to the transformers. The door safety interlocks interrupt this

supply when the door is opened. Operation of

relays K4 and K5 require the POWER switch to

be in the ON position to provide operating voltage to the control board. The interlock function

can be checked by opening and closing the oven

door and observing the rotation of the fan on top

of the stirrer motor.

19

Service Manual for Speed Oven Model DSO 500

Test Procedure

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING. REFER TO DETAILED PROCEDURE IN THE

COMPONENT TESTING SECTION BEFORE

TESTING.

NOTE: Dangerous voltages can be present at

this component. Refer to detailed test

procedure for testing this component.

HIGH VOLTAGE CAPACITORS - NOTES

Replacement

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE REPLACEMENT.

Capacitor must be discharged before removal.

After discharging, disconnect leads. There are

two nuts securing the capacitor bracket.

20

COMPONENT OVERVIEW

MAGNETRONS

The magnetron filament voltage of 4.5 VAC

is supplied from the high voltage transformer

lament winding. The operating voltage of 5000

VDC is provided by the rectied output from the

transformer high voltage winding.

Location and Access

The magnetrons, Figure 7, are located above the

top of the cook chamber at the left and right side

of the oven. The top and side panels will need

to be removed.

Safety Issues

WARNING

THE HIGH VOLTAGE CAPACITOR RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

• Electrical supply of 208/240 VAC to trans-

formers when POWER switch is in ON

position and oven doors are closed

• Capacitors charge to the 2.5 kVDC level

when the high voltage circuit is properly

operating

• The 4.5 VAC magnetron lament supply

is at 2500 V relative to the chassis

Tools required

Figure 7. Magnetrons

• Flat blade screwdriver to remove top and

side panels

• 3/8 inch nut driver to remove nuts secur-

ing the magnetrons to top of oven

Operational Testing.

The magnetrons receive lament and high voltage from the high voltage transformers. The

transformers connected to the diodes for charging the capacitors are powered from the 208/240

VAC mains supply through solid state relays K4

and K5 and mechanical relay K6 and K8. Relays K6 and K8 are controlled by the door safety

interlock requiring the oven door to be closed to

provide primary voltage to the transformers. The

door safety interlocks interrupt this supply when

the door is opened. Operation of relays K4 and

K5 require the POWER switch to be in the ON

position to provide operating voltage to the control board. The interlock function can be checked

by opening and closing the oven door and

observing the rotation of the blade on top of the

stirrer motor.

21

Service Manual for Speed Oven Model DSO 500

Test Procedure

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING. REFER TO DETAILED PROCEDURE IN THE

COMPONENT TESTING SECTION BEFORE

TESTING.

NOTE: Dangerous voltages can be present at

this component. Refer to detailed test

procedure for testing this component.

MAGNETRONS - NOTES

Replacement

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISC H ARGED BEFORE M AGNETRON

REPLACEMENT.

Remove cooling duct. (Right side magnetron

only). Label and disconnect wires from transformer to magnetron lament. Disconnect wires

to thermostat. Remove nuts attaching magnetron

to top surface. When installing the new magnetron, be sure metal mesh gasket is properly

positioned around the magnetron dipole antenna

and that thermostat is installed on magnetron.

Secure magnetron to top surface with nuts.

Reconnect wires to lament and thermostat.

22

COMPONENT OVERVIEW

MAGNETRON THERMAL

SWITCHES

The magnetron thermal switches, Figure 8, are

used to monitor the magnetron temperature and

open the high voltage supply when the temperature exceeds 150°C.

Location and Access

The magnetrons thermostats are located on the

side of each magnetron. The top and side panels

will need to be removed.

Safety Issues

WARNING

THE HIGH VOLTAGE CAPACITOR RETAINS

THE 2.5 kVDC CHARGE EVEN AFTER THE

OVEN IS DISCONNECTED. THIS CAPACITOR MUST BE DISCHARGED BEFORE

WORKING ON ANY COMPONENTS IN THE

HIGH VOLTAGE AREA.

• Electrical supply of 208/240 VAC to trans-

formers when POWER switch is in ON

position and oven doors are closed

• Capacitors charge to the 2.5 kVDC level

when the high voltage circuit is properly

operating

Tools required

• Flat blade screwdriver to remove top and

side panels

Figure 8. Magnetron Thermal Switches

• 3/8 inch nut driver to remove nuts secur-

ing the magnetrons to top of oven

Operational Testing

The thermostats are connected in the high voltage transformer primary circuit and are normally

closed connecting primary voltage on wires 26

and 27 to the high voltage transformer. If magnetron is not operating check continuity across

thermostat terminals.

23

Service Manual for Speed Oven Model DSO 500

Test Procedure

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISCHARGED BEFORE SERVICING. REFER TO DETAILED PROCEDURE IN THE

COMPONENT TESTING SECTION BEFORE

TESTING.

NOTE: Dangerous voltages can be present at

this component. Refer to detailed test

procedure for testing this component.

NOTE: Disconnect wires to thermostat and check

continuity across thermostat terminals.

Continuity should be indicated when

thermostat is at normal ambient temperature.

MAGNETRON THERMAL SWITCHES - NOTES

Replacement

WARNING

HIGH VOLTAGE CAPACITOR MUST BE

DISC H ARGED BEFORE M AGNETRON

THERMOSTAT REPLACEMENT.

Label and disconnect wires to thermostat. Remove screw securing thermostat to magnetron

and remove thermostat. When installing a new

thermostat, secure with screw. Connect wires to

thermostat.

24

Loading...

Loading...