Duke BENCHMARK Installation Manual

"Your Solutions Partner”

OPERATION / MAINTENANCE MANUAL

VENTILATOR SERIES

"HVX" AND "HV-96"

"DESIGN 96"

"BENCHMARK"

Southern Engineering Div./Duke Mfg.

2305 N. Broadway St. Louis, MO 63102

314-231-1130 314-231-5074 (Fax)

0058613B

TABLE OF CONTENTS

"HVX", HV-96", "DHL", AND "DESIGN 96" CANOPIES

PAGE

GENERAL EQUIPMENT DESCRIPTION 3

1. "HVX" CARTRIDGE CANOPIES

2. "HV-96" HI-VELOOTY CANOPIES

3. "DESIGN 96" FILTER TYPE CANOPIES

4. "BENCHMARK" CANOPIES

5. "DESIGN OPTIONS" ( BOX, FM, IM )

INSTALLATION/OPERATION INSTRUCTIONS 4

MAINTENANCE

1. SCHEDULED MAINTENANCE 4-5

(CLEANING PROCEDURE)

A. "HVX" CARTRIDGE CANOPIES 6

B. "HV-96" HI-VELOCITY CANOPIES 7-8

C. "DESIGN 96" AND "BENCHMARK" CANOPIES 9

2. CORRECTIVE MAINTENANCE 10

3. 3. FUSIBLE LINK REPLACEMENT 11

TROUBLESHOOTING GUIDE 12

PARTS LIST 13

EXHAUST DUCT COLLAR INSTALLATION 14

SERVICE AND ORDERING INFORMATION 15

2 of 18

GENERAL EQUIPMENT DESCRIPTION

Southern Engineering ventilators are quality filter and high velocity cartridge hoods designed and constructed for

commercial kitchen application requiring removal of grease from the exhausted air stream prior to discharge into

me atmosphere. The filters and cartridges are designed to use sets of stainless steel baffles to remove grease and

other contaminants by centrifugal force. Collected grease and other contaminants drain from the condensing

surfaces by gravity into troughs and removable grease collection containers for easy cleaning. These elements are

more efficient, safer, and easier to use than wire mesh type filters. Each ventilator is constructed of all welded, 18

gauge, stainless steel for long life, strength, and durability, and is approved or in compliance with Underwriters

Laboratories, Inc. (U.L.), the National Sanitation Foundation (N.S.F.), and the National Fire Protection

Association (N.F.PA.). Proper ordering, application, and installation is subject to local building and public safety

code provisions. Be sure to review all requirements and secure necessary permits prior to installation.

Southern Engineering makes several styles of ventilators that are available in a wide selection of models. Each

may be provided with or without integral make-up air, lighting, fire dampers, and rooftop controls; each may be

fabricated as wall, single island, or dual island configurations. "Design 96", 'DHL", and "HV-96" ventilators

feature U.L. classified grease extracting filters constructed in accordance with N.F.P.A. Bulletin 96. "HVX"

cartridge ventilators use an engineered baffle system that is sectionalized into cleanable units.

A detailed explanation of each ventilator follows:

"HVX” CARTRIDGE CANOPIES

Southern Engineering high-velocity cartridge style canopies are designed for grease extraction

efficiency in moderate to heavy grease load applications. Stainless steel, self-draining cartridge inserts

are installed horizontally for the full length of the stainless steel housing. The housing forms a high

velocity slot resulting in 95 percent extraction efficiency when installed and balanced properly. The

cartridge inserts can be lifted out, using a tool provided by Southern Engineering; the grease collection

containers are also removable for easy accessibility and cleaning.

"HV-96" HIGH-VELOCITY CANOPIES

Southern Engineering high-velocity baffle filter type canopies are designed for grease extraction efficiency in

moderate to heavy grease load applications. Stainless steel U.L. classified filters are installed vertically the full

length of the stainless housing. The housing incorporates stainless steel front baffles forming a high velocity slot.

These front baffles lift out easily by the handles provided, to expose the fibers, which also lift out for easy

cleaning; the grease collection containers are also removable for easy accessibility and cleaning.

"DESIGNS 96" CANOPIES

Southern Engineering 96 candies are designed to force grease-laden air to pass through U-channels in

the U.L. classified stainless steel filters. The grease particles and contaminants are trapped on the filter

surface as the air passes through the filter. The grease particles drain into a trough and then into

stainless steel grease collection containers by force of gravity. The filters and grease collection

containers are removable for easy cleaning.

"BENCHMARK CANOPIES"

Southern Engineering Benchmark canopies are designed to force grease-laden air to pass through Uchannels in the U.L. classified stainless steel filters. The grease particles and contaminants are trapped

on the filter surface as the air passes through the filter. The grease particles drain into a trough and then

into stainless steel grease collection containers by force of gravity. The filters and grease collection

containers are removable for easy cleaning.

"B" (BOX STYLE)

Southern Engineering exhaust plenum detailed above supplied in a box configuration without the use of

supply air. This unit may be supplied with or without an exhaust (fire) damper.

"FM" (FRONT GRILL MAKE-UP)

Southern Engineering exhaust plenum supplied with a front grill make-up air delivery system. Supply air

volumes as high as 85% of exhaust may be selected with this unit. Each ventilator will be fitted with a

Design 96 supply air damper and optional exhaust (fire) damper.

3 of 18

"IM” (INTERNAL MAKE-UP)

Southern Engineering exhaust plenum supplied with an internal make-up air chamber. In regular duty

operations, make-up air may be delivered at 75%. Make-up air may be delivered at 55% on all heavyduty applications using 400 CFM/FT exhaust. Benchmark canopies with internal makeup air at 40% may

be used on solid fuel devices at 450 CFM/FT. Each canopy will be supplied with a Design 96 supply

damper and optional exhaust (fire) damper.

INSTALLATION / OPERATION INSTRUCTIONS

1. Units shall be installed by qualified personnel in accordance with NFPA and all local and municipal codes. It

is the responsibility of the dealer / installer to verify and follow all such codes before installing the equipment.

2. Wiring diagrams are provided with equipment as supplied when necessary. However, unless the rooftop

package and controls are supplied by Southern Engineering there will not be any wiring diagram.

3. Exhaust and supply air flow rates shall be in accordance with NFPA-96 and U.L. requirements.

4. Exhaust and supply (if provided) air flow rates were established under controlled laboratory conditions, and

greater and / or lesser supply air may be required for complete vapor and smoke removal in specific

installations.

MAINTENANCE

SCHEDULED MAINTENANCE (CLEANING)

Proper care of the previously mentioned ventilator assemblies is essential to prevent down time and unsightly

appearance of the canopy.

The following is a maintenance procedure that should be adhered to in order to maintain a positive appearance and

an efficient operating condition for the ventilator assemblies.

DAILY CLEANING PROCEDURE:

At the end of the day's shift and after the equipment has been cooled sufficiently, the exterior surfaces of the

stainless steel canopy should be wiped clean of all grease and dirt particles. This can be accomplished through

the use of a mild detergent and water.

NOTE: Always use non-abrasive detergents and wipe in the direction of the grain or polish. Failure to do

so may result in scratches or blemishes on the exterior surface of the stainless finish.

If mild soap and detergent rails to adequately remove the grease on the ventilator exterior, a chemical compound

such as "Sheila Shine" may be used for this purpose. Following the use of "Sheila Shine" or any chemical

cleaner on stainless steel, it is important to wipe the chemical completely from the surface. This will avoid

pitting or scarring of the metal.

BI-WEEKLY CLEANING PROCEDURE:

Twice a week the filters or cartridges should be removed from the ventilator assembly for cleaning purposes.

These items can be put into the dishwasher, cleaned, and reinstalled with little effort. If a dishwasher is not

available, a car wash or high-pressure sprayer may be substituted. Use the following procedure to remove these

items.

1. HVX: The cartridges can be lifted from the assembly with the use of the stainless steel tool supplied with

the ventilator canopy. This tool will be located in a bracket installed on the inside of the canopy. Using this

tool, insert the flat end of the tool into the slot at the top of each cartridge and lift the cartridge from the

ventilator.

2. HV-96: To remove the filters from the HV-96 assembly, it is necessary to first remove the "HV" panels

located on the clips above the cooking surface. Using a ladder, firmly grasp the two handles on each "HV

baffle and lift the baffles from their retaining clips.

NOTE: Use extreme care when lifting these baffles as dropping them may cause damage to the

cooking equipment below. Once the "HV baffles have been removed, lift the stainless steel filters out

of the filter rack with the handles located on each side of me filter. Place these filters in the dishwasher

or clean with a high-pressure sprayer and then reverse the above procedure to reinstall them.

4 of 18

3. DESIGN 96 AND BENCHMARK: To clean filters follow the same procedure used for the HV-96 with the

exception of the HV baffle, which is not used on these canopies. Filters are readily accessible in this

ventilator system and may be lifted out by the handles located on each filter. Place these filters in the

dishwasher or clean with a high-pressure sprayer and then reverse the above procedure to reinstall them.

WEEKLY CLEANING PROCEDURE:

Each week it is important to remove the glass globes or lens covers located on the interior canopy surface and

clean them thoroughly. These globes or lens covers become coated with grease during a normal cooking operation

and this diminishes their light efficiency.

To remove the globes, simply unscrew them and wash with warm soapy water using a mild detergent

WARNING: These globes are coated with a shatterproof plastic coating. Do not remove this coating. It is designed

to protect the operators and food product in the event of bulb or globe shatter.

When removing fluorescent light covers, care should be taken not to drop or hit the fluorescent tubes. These covers

are held in place by screws or clips located along the edge of the lens. Simply unscrew and remove as needed.

QUARTERLY CLEANING PROCEDURE:

Every three months, it is a good idea to remove the filters, cartridges, and HV panels to check for grease

accumulation and build up on the canopy interior surface. Depending upon the cooking load, the cleaning time for

ducting and canopies will vary from quarterly to annually. An inspection of the interior of the canopy and

ductwork at the duct collar every three months will ensure the hood and ducting can be maintained as necessary.

If a substantial amount of grease is present on the interior of the canopy surface or in the adjoining ductwork, it

will be necessary to call a maintenance or duct cleaning company to come in and clean the exhaust fan, ductwork,

and the interior ventilator surfaces. This procedure should be done as often as necessary to maintain a clean

system.

ANNUAL CLEANING PROCEDURE:

Once a year it is a good idea to have an air balance performed by a qualified service company to ensure

the ventilator system is operating properly and efficiently. This is also a good time to have them check

drive belts and pulleys to insure that belts are properly tensioned and pulleys are aligned and secure.

Indications of an inefficient system are smoke not being captured, cold drafts at doorways when doors are open,

along with high velocity air currents at the doors. If this is noted, it may indicate an improperly balanced ventilator

system.

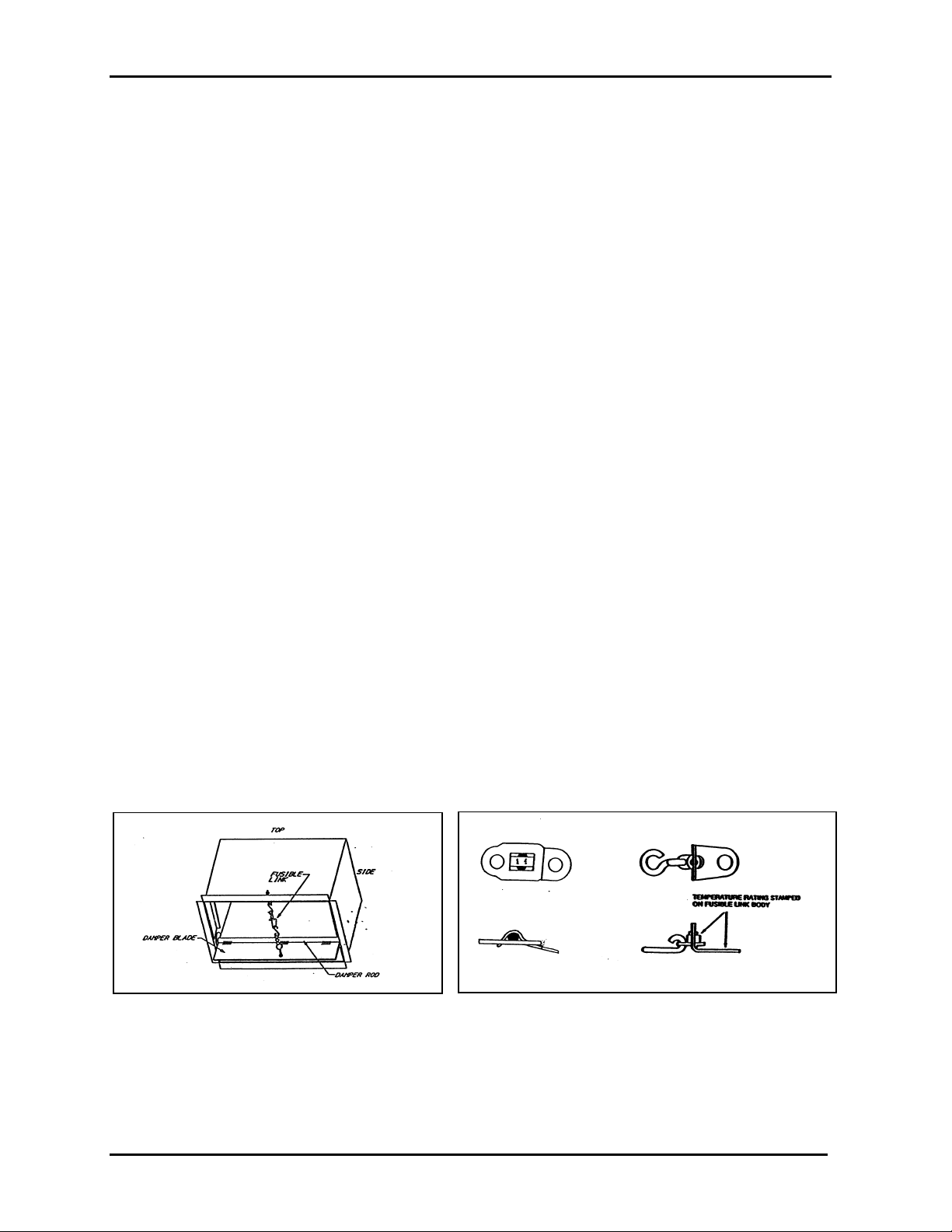

On an annual basis, the fusible links located in the U.L. exhaust dust collars and supply collars (if required) should

be checked by a certified file suppression service company to ensure they have not weakened due to heat and may

melt, tripping the fire extinguishing system unnecessarily. At this time, the complete chemical fire extinguishing

system can be re-certified.

Fire Damper Assy for Make-Up Air Collar Fire Links for Duct Collar

5 of 18

Loading...

Loading...