Duke 613Q-G4 User Manual

153810Q

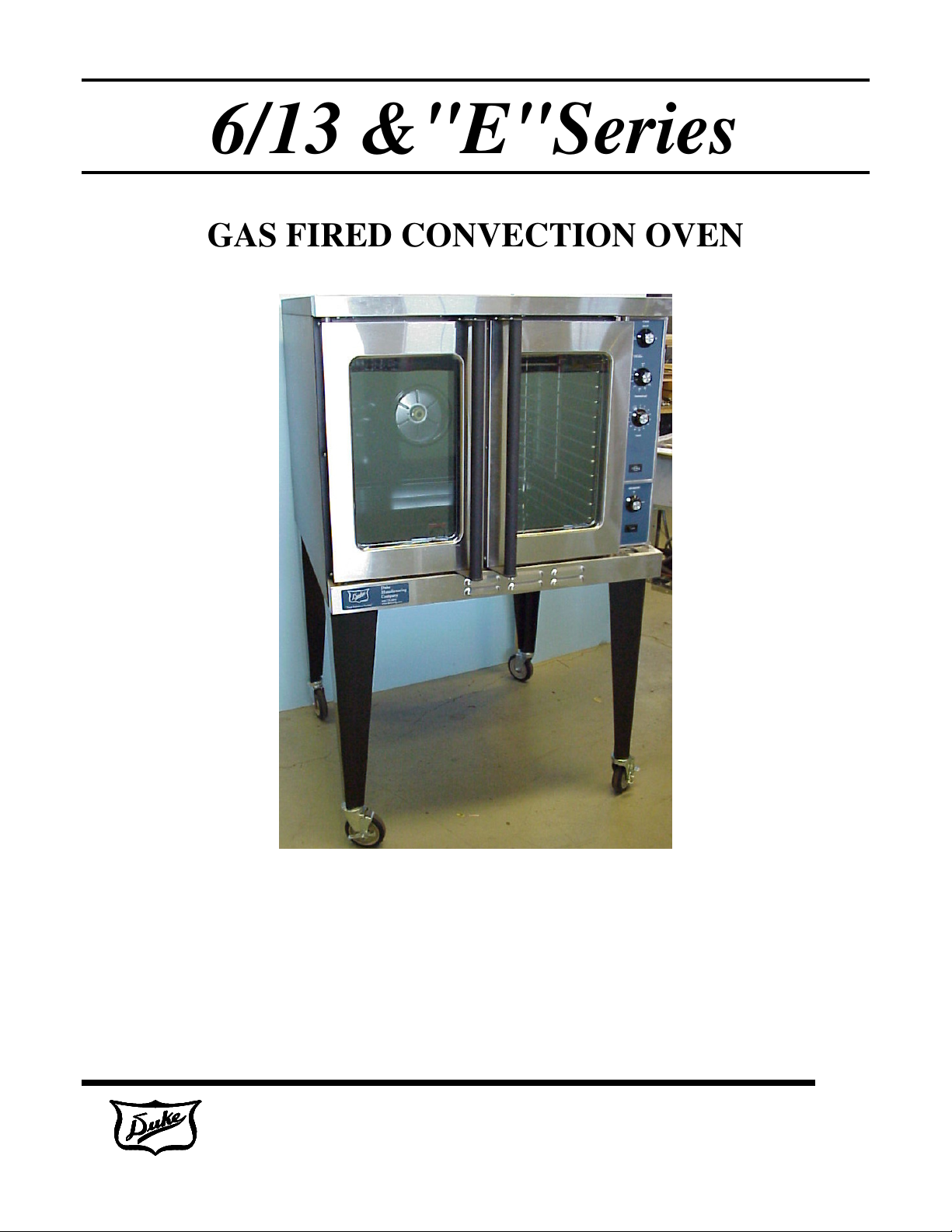

6/13 &"E"Series

GAS FIRED CONVECTION OVEN

Installation, Operation, Parts

& Maintenance Manual

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

6/13 & "E" Series Gas Specifications 3

Installation Instructions

A. Qualified Personnel

B. Delivery & Inspection 4

C. Location of Oven 4

D. Gas Piping 5

E. Electrical Connections 6

F Ventilation 6

G. Gas Oven Assembly 6-7

H. Adjustments Associated with Installation 7

I. Double Stack Ovens 8

Operating Instructions 9

A. Oven Controls

B. General Guidelines for Operation 13

C. Suggested Times & Temperatures 14

D. Cleaning the Oven 15

INDEX

PAGE

4

10 - 12

Maintenance Instructions

A. Adjustments 16

B. Door Adjustment 15

C. Door Switch Adjustment 15 - 16

D. Thermostat Calibration 16

E. Gas Pressure Regulation & Adjustment 17

F. Venting System 17

Repair Parts List 18

Door Assembly 19

“V” Controller Assembly 20

“XX Controller Assembly 21

Wiring Diagram 22

Please supply the ID Number and the Serial Number when ordering replacement parts or

requesting service. We recommend service by Duke Authorized Service Agencies during and

after the warranty period.

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

2 of 22

GAS PRESSURE AT

OVEN INPUT STANDARD DEPTH

BURNER ORIFICE SIZE

Instructions to be followed in the event the user smells gas. This information shall

POST IN A PROMINENT LOCATION:

be obtained by consulting the local gas supplier.

Specifications

HEATING VALUE

SPECIFIC GRAVITY

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

“E” & 6/13 SERIES GAS CONVECTION OVEN

NATURAL GAS

1000 BTU

0.63

37.3 MJ/m3

0.63

PROPANE GAS

2550 BTU

1.53

95.0 MJ/m3

1.53

MANIFOLD

PER BURNER

PER OVEN

3.5" W.C 0.87 kPa 10" W.C. 2.49 kPa

20,000 BTU/HR

40,000 BTU/HR

OVEN INPUT DEEP DEPTH

PER BURNER

PER OVEN

STANDARD DEPTH

DEEP DEPTH

23,000 BTU/HR

46,000 BTU/HR

#44

#43 2.26mm #54 1.40mm

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

5.9 kW

11.8 kW

6.8 kW

13.5 kW

2.18mm

www.dukemfg.com

20,000 BTU/HR

40,000 BTU/HR

23,000 BTU/HR

46,000 BTU/HR

#55

5.9 kW

11.8 kW

6.8 kW

13.5 kW

1.32mm

3 of 22

must be maintained between the oven and any

INSTALLATION INSTRUCTIONS:

A. Qualified Personnel

These installation instructions are for the use of qualified

installation and service personnel only. Installation or

service by other than qualified personnel may result in

damage to the oven and/or injury to the operator.

Qualified installation personnel are those individuals,

firms, companies or corporations which either in person

or through an agent is engaged in and responsible for:

• The installation or replacement of gas piping or the

connection, installation, repair or servicing of

equipment, who are experienced in such work,

familiar with all precautions required, and have

complied with all requirements of state and local

authorities having jurisdiction. See: National Fuel

Gas Code NFPA 54 (ANSI Z223.1).

• The installation of electrical wiring from the electric

meter, main control box or service outlet to the

electrical appliance. Qualified installation personnel

must be familiar with all precautions required and

have complied with all requirements of state and

local authorities having jurisdiction. See: National

Electrical Code, ANSI/NFPA70.

The installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1 as applicable, including:

•

The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of ½ psi (3.5 kPa).

•

The appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than ½ psi (3.5 kPa).

For an oven equipped with casters, the installation shall

be made with a connector that complies with the Standard

for Connectors for Movable Gas Appliances, ANSI

Z21.69/CSA 6.16 and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices

for Use with Gas Fuel, ANSI Z21.4/CSA 6.9. When

installing the oven with casters and quick-disconnect

hose, adequate means must be provided to limit the

movement of the oven without depending on the

connector and the quick disconnett device or its

associated piping to limit the oven movement. Restraining

means may be attached to the vertical portion of the base

frame in the rear of the oven.

B. Delivery and Inspection

Duke Manufacturing Co. does everything within its power

to insure you received your oven in good condition. They

are strapped down on heavy wooden skids and surrounded

by heavy "tri-wall" cartons to prevent shipping damage.

They have all been carefully inspected before they were

packaged and consigned to the carrier.

Upon delivery of your Duke oven:

• Look over the shipping container, carefully noting

any exterior damage on the delivery receipt, which

must also be signed by the driver/ delivery person.

• Uncrate and check for any damage, which was not

evident on the outside of the shipping container.

This is called concealed damage. The carrier must

be notified within fifteen (15) days of the delivery of

the oven and the carton, skid and all packaging

materials must be retained for inspection.

Duke Manufacturing Co. cannot assume liability for loss

or damage suffered in transit. The carrier assumes full

responsibility for delivery in good order when the

shipment was accepted. However, we are prepared to

assist you in filing your claim.

C. Location of the Oven

Proper planning and placement of the oven will give you

the best results in terms of long-term user convenience

and satisfactory performance. We urge you to give

adequate thought in the placement of your oven prior to

its arrival.

• The oven should be placed in an area that is free

from drafts and accessible for proper operation and

servicing.

• The area around the oven must be kept clear of

combustible materials. A minimum clearance of:

Combustible

RIGHT SIDE

LEFT SIDE

REAR

FLOOR

1" 0”

1" 0”

3" 3”

8" 8”

combustible or non-combustible surface.

NonCombustible

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

4 of 22

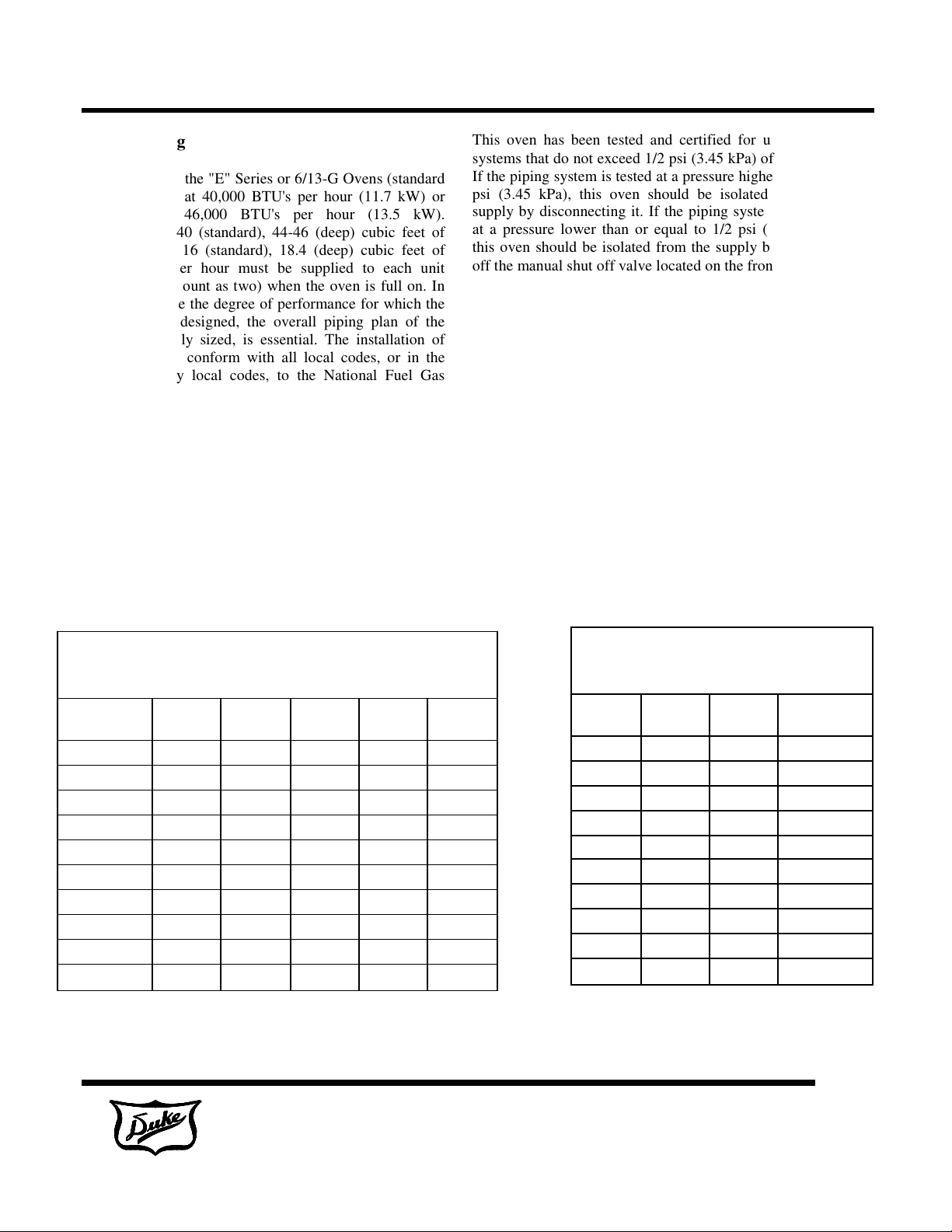

D. Gas Piping

Each section of the "E" Series or 6/13-G Ovens (standard

depth) is rated at 40,000 BTU's per hour (11.7 kW) or

(deep depth) 46,000 BTU's per hour (13.5 kW).

Therefore, 38-40 (standard), 44-46 (deep) cubic feet of

natural gas or 16 (standard), 18.4 (deep) cubic feet of

propane gas per hour must be supplied to each unit

(stacked units count as two) when the oven is full on. In

order to achieve the degree of performance for which the

unit has been designed, the overall piping plan of the

kitchen, properly sized, is essential. The installation of

this oven must conform with all local codes, or in the

absence of any local codes, to the National Fuel Gas

Code, NFPA 54 and ANSI Z 223.1.

Your local gas supplier should consult the National Fuel

Gas Code for proper sizing and installation of gas piping.

Generally, piping should be sized to provide a gas supply

sufficient to meet the maximum demand of all gas

appliances on a line without undue loss of pressure at the

outlet to the equipment. The total BTU requirements of

the equipment being served and the length of the piping

from the meter to the appliances are major considerations

in the proper design of the gas supply system.

This oven has been tested and certified for use on gas

systems that do not exceed 1/2 psi (3.45 kPa) of pressure.

If the piping system is tested at a pressure higher than 1/2

psi (3.45 kPa), this oven should be isolated from the

supply by disconnecting it. If the piping system is tested

at a pressure lower than or equal to 1/2 psi (3.45 kPa),

this oven should be isolated from the supply by shutting

off the manual shut off valve located on the front panel.

MAXIMUM CAPACITY OF IRON PIPE IN CUBIC FEET PER

HOUR (PRESSURE DROP OF 0.5" W.C.) NATURAL GAS

Length in Feet

10

20

30

40

50

60

70

80

90

100

1/2"

175

120

97

82

73

66

61

57

53

50

From National Fuel Gas Code

3/4"

360

250

200

170

151

138

125

118

110

103

1"

680

465

375

320

285

260

240

220

205

195

1.1/2"

2100

1460

1180

990

900

810

750

690

650

620

2"

3950

2750

2200

900

1680

1520

1400

1300

1220

1150

MAXIMUM CAPACITY OF PIPE IN

THOUSANDS OF BTU'S PER HOUR OF

UNDILUTED PROPANE GAS AT 11" W.C.

Length

in Feet

10

20

30

40

50

60

70

80

90

100

1/2"

275

189

152

129

114

103

96

86

83

78

From National Fuel Gas Code

3/4"

567

393

315

267

237

217

196

185

173

162

1"

1071

732

590

504

448

409

378

346

322

307

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

5 of 22

prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

prong receptacle. DO NOT cut or

Keep the oven are

a free and clear from combustibles.

E. Electrical Connections

Your oven is supplied for connection to a 115 volt, single

phase grounded circuit. The electric motor, oven lights,

indicator lights and control circuits are connected through a

seven-foot electric supply cord found at the rear of the

oven.

Before making any connections to these units, check the

rating plate to assure that the voltage and phase of the oven

is compatible with the electrical supply. When installing,

all ovens must be electrically grounded in accordance with

local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70 (in Canada -

CSA Std. C22.2). Wiring diagrams are located in the

control compartment area of the oven. Standard wiring

schematics are also provided with this manual.

WARNING:

This appliance is equipped with a three-

grounded threeotherwise remove the grounding prong from this plug.

F. Ventilation

Proper ventilation is very important for the proper function

of your oven. A good ventilation system will allow the

oven to function properly as well as remove unwanted

vapors and products of combustion. Not venting the ovens

properly can result in unsatisfactory baking results as well

as the possibility of damaging your oven. To keep your

warranty in force, a proper ventilation system must be

employed, either direct vented or under a canopy.

Venting to a Canopy Exhaust Hood

The best way to vent your oven is by placing it under a

properly designed mechanically driven exhaust hood. The

hood should be sized so the equipment that it is designed to

ventilate fits underneath with a minimum six (6) inch (152

mm) overhang on all sides not adjacent to a wall. The

distance from the floor to the lower edge of the canopy

should not exceed seven (7) feet (2.2 m).

The hood should have adequate capacity and provide a

sufficient supply of make- up air. Ventilation hoods come

in many sizes and capacities. Hood capacity is expressed in

cubic feet per minute (CFM). The total make-up and

exhaust air required for the canopy hood should be about

22 CFM per oven section. Information for the proper

construction and installation of ventilating hoods may be

obtained from the "Standard for the Installation of

Equipment for the Removal of Smoke and Grease-Laden

Vapors from Commercial Cooking Equipment, NFPA-96".

Direct Flue Venting

Occasionally it is not possible or practical to install a

powered canopy hood. In those cases the oven can be

vented directly by means of a direct flue method. Correctly

venting your oven is very important to insure proper

cooking results and preclude any premature failures in the

burner or burner compartment. The direct flue method

incorporates a drafthood that is mounted to the top of the

oven (or the upper oven section in a stacked unit). The flue

then rises from the drafthood vertically to a point 6-8 feet

above the roof or any close structure. The flue is then

capped with an approved vent cap to isolate the flue from

the external environmental conditions.

The direct flue method does not incorporate the ability to

replace air consumed by and vented from the oven. An

adequate supply of room make-up air must be provided if

your oven is to be vented by this method. The total

makeup air requirement for one oven section is

approximately 30 CFM.

Lighting Instructions:

• Turn Gas Shut Off to ON Position

• Turn Power Switch to COOK Position

• Set Thermostat to Desired Temperature

Shut Down Instructions:

• Turn Power Switch to OFF Position

• Wait 5 Minutes Before Relighting Oven

WARNING:

Note: This manual must be retained for future

reference.

G. Oven Assembly

Before assembling and installing the oven, please check to

make sure that all necessary parts are present. In addition

to the oven itself, there will also be legs, feet or casters, the

flue/vent guard or drafthood & drafthood collar assembly,

(for double sections, retaining clips, flue riser and/or

common manifold) and miscellaneous hardware. Please

check the interior of all oven sections for the parts needed

to assemble and install your oven(s).

Leg Attachment

• Once the oven has been removed from the carton, lay

it on its left side (the side without the controls), hold

the leg and align with the threaded holes in the front

comer of the bottom of the oven. Carefully start the

threads of the comer leg bolt (5/16"-18 X 1/2"),

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

Duke Manufacturing Co.

www.dukemfg.com

6 of 22

avoid cross threading.

• Align the leg plate holes in each leg with those in the

corners of the oven bottom and secure using two 5/

16"-18 x 1/2" bolts. Tighten all bolts firmly. Repeat

this procedure for all legs.

• Raise the oven up on its legs.

Level the oven by turning the adjustable feet in or out as

needed.

Caster Installation

• Casters are available as an option for both the single

and double oven sections.

• The installation of casters requires the removal of

the adjustable feet from the legs. This is done by

placing the bit of a large screwdriver against the lip

of the foot and rapping the screwdriver to drive the

foot out of the leg. The caster is then inserted fully

into the opening where the foot came out and the

locking nut tightened to expand the compression

sleeve of the caster.

NOTE: The casters with locking brakes are best

mounted on the front side of the oven for easier access.

NOTE: If you plan to use casters and flexible fuel gas

connectors, a fixed restraint of the proper length must

be incorporated to secure the oven to a non-movable

surface to eliminate strain on the connector. If the oven

is removed from its normal position, the restraint must

then be reattached when returned.

Installation of the Vent

• Ovens ordered for installation under a powered

canopy exhaust hood should have the flue guard in

place. This item can be installed by placing it over

the flue opening, making sure that it does not

obstruct the flue, and attaching it with the screws

provided.

• Ovens ordered for installation in a location other than

under a powered canopy exhaust hood are supplied

with a drafthood & drafthood collar. This device

mounts to the top of the upper oven section by

attaching the drafthood adapter to the flue opening

with the screws provided, the drafthood is then

mounted on top of the adapter. The flue pipe is

attached vertically to the drafthood.

H. Adjustments Associated with Installation

Each oven section and all its component parts have been

tested thoroughly and inspected before your oven was

shipped from the factory. However, it is sometimes

necessary to further test or adjust the oven once it has been

installed. Such adjustments are the responsibility of the

Dealer or Installer. These types of adjustments are not

considered defects, rather a normal and routine part of the

proper installation of the equipment.

These adjustments include but are not limited to:

• Adjustments and recalibration of the thermostat

• Adjustment to the doors.

• Burner or pilot adjustment.

• Adjustments to the gas pressure regulator.

• Leveling, and tightening of fasteners.

No installation should be considered complete without

proper inspection and, if necessary, any adjustments by

qualified service or installation personnel.

It is also important not to obstruct the natural flow of

combustion and ventilation air if the oven is to operate

properly. This oven should not be installed on a curb base

or sealed to the wall. Either condition can restrict the flow

of air to the combustion compartment or prevent proper

ventilation of the blower motor. The blower motor has a

thermal protection device that will trip because of

excessive ambient temperature at the back of the oven.

This condition should be corrected immediately to avoid

damaging the oven permanently.

Before making any connections to the oven, check the

ratings plate to be sure the oven specifications concur with

the type of gas and voltage to be supplied to the oven.

The rating plate is located behind the lowered lower front

panel. To access, loosen the four screws below the doors,

and pull panel outward.

The plate bearing the oven's serial number is attached to

the underside of the upper ledge above the control panel.

I. Double Sections

• Secure the short legs to the bottom of the lower

section as described in previous section.

• Casters are installed by the method described for

single section ovens. Previous section.

• Place upper section on top of lower section and align

all edges of the ovens.

• Locate securing clips and align with holes on rear

frames of oven section, install three screws each as

provided and tighten.

• At the rear of the oven, install the flue connector by

sliding it up through the flue vent opening in the top

of the oven and over the upper flue vent. Push it

flush with the back of the oven then slide it down

over the lower flue vent. Attach with screws

provided.

• Install flue guard or drafthood adapter, drafthood and

drafthood collar to upper section.

See drawing on next page.

Duke Manufacturing Co.

2305 N. Broadway • St. Louis, Missouri

800-735-3853 • 314-231-1130 • Fax 314-231-5074

www.dukemfg.com

7 of 22

Loading...

Loading...